Barium slag processing system and method

A technology of treatment system and treatment method, applied in barium slag treatment system and treatment field, can solve the problems of low utilization rate of barium slag, small processing capacity, complicated production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

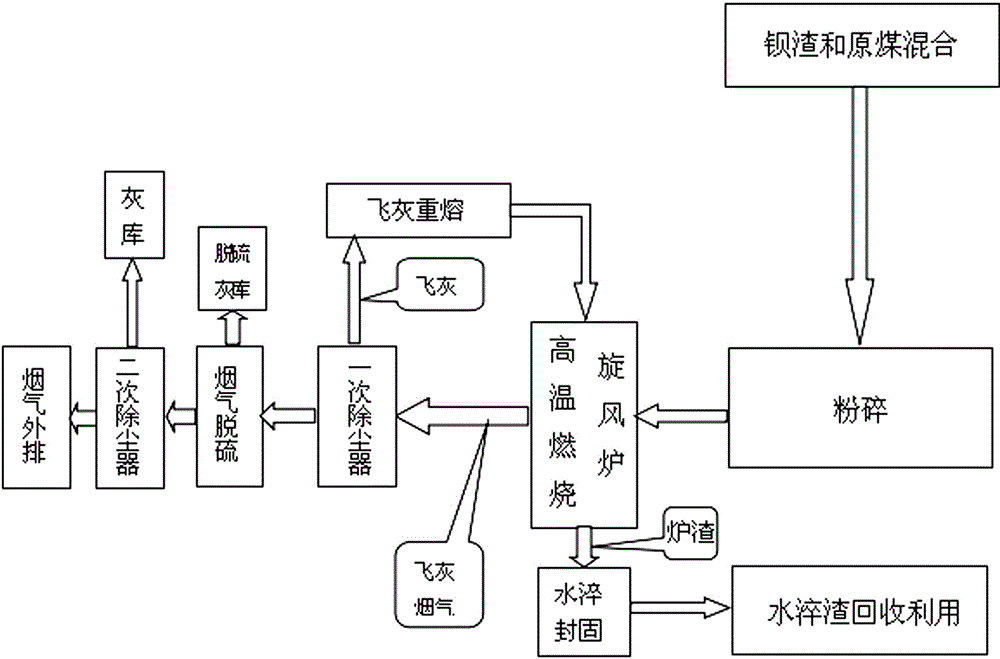

[0025] Embodiment 1: A barium slag processing system, including a crusher, a cyclone furnace, a primary dust collector, a secondary dust collector, desulfurization equipment and a water quenching water tank, wherein the cyclone furnace is WGZ260 / 9.8-1 type cyclone furnace , the primary dust collector is a double-chamber four-field electrostatic precipitator; the secondary dust collector is a bag filter, and the desulfurization equipment is a semi-dry desulfurization equipment. The discharge port of the crusher is connected with the feed port of the cyclone furnace, and the slag discharge port of the cyclone furnace is connected with the water quenching water tank; the dust collection port of the primary dust collector is connected with the cyclone furnace. The smoke outlet of the furnace is connected; the primary dust collector also includes a fly ash outlet and a flue gas outlet, the fly ash outlet is connected with the feed port of the cyclone furnace, and the flue gas outlet...

Embodiment 2

[0026] Embodiment 2: a kind of method that uses the barium slag treatment system in embodiment 1 to carry out barium slag treatment, see figure 1 , including the following steps:

[0027] (1) Raw material crushing: Mix barium slag and raw coal at a weight ratio of 1:9, and crush the obtained mixture to a powder with a fineness of R90=16% using a crusher.

[0028] (2) High temperature combustion: the operating temperature is 160°C and the flow rate is 86888m 3 / h, hot air with a flow rate of 30-35m / s sends the mixed powder obtained in step (1) into the cyclone furnace for combustion at a temperature of 1600°C, and forms molten slag after full combustion.

[0029] The cyclone furnace used is WGZ260 / 9.8-1 type cyclone furnace (liquid slag discharge furnace). The rotary cylinder adopts segmental combustion. After the coal powder and barium slag enter the cyclone cylinder with the primary wind, they rotate and fall, and the secondary wind also flows along the furnace wall. It ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com