Self-heating continuous powdery biomass activated carbon preparation method and cyclone furnace thereof

A technology for powdered activated carbon and biomass, applied in chemical instruments and methods, educts, carbon compounds, etc., can solve the problem of low product performance, and achieve the effects of long residence time, convenient operation and sufficient reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

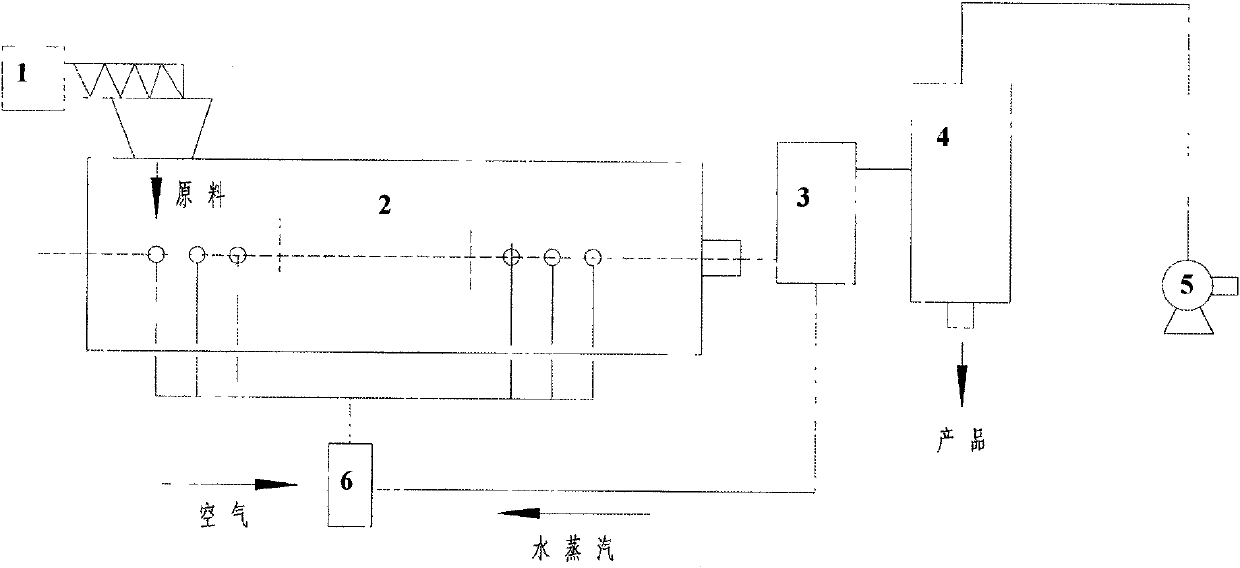

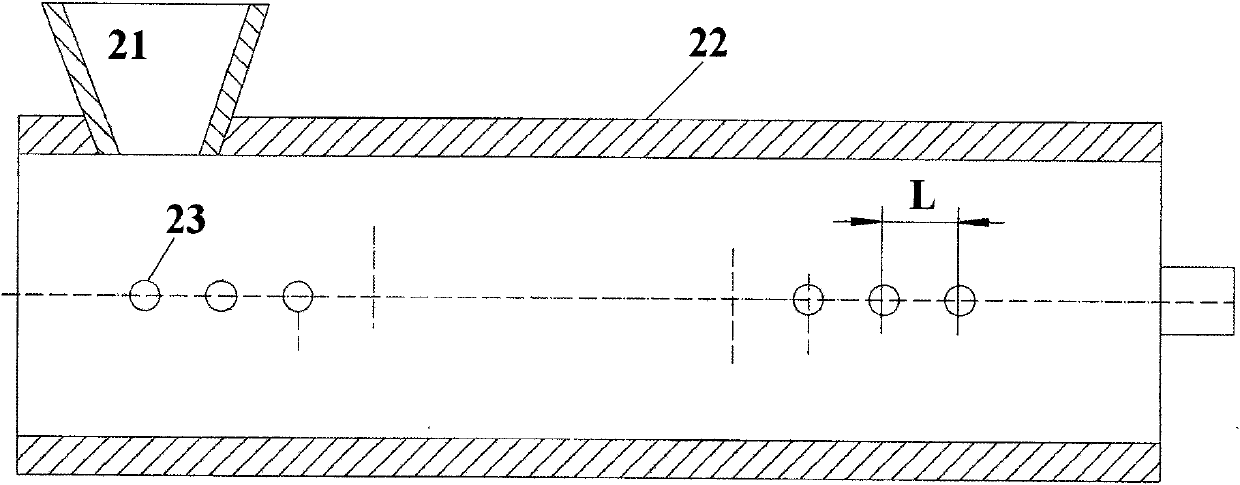

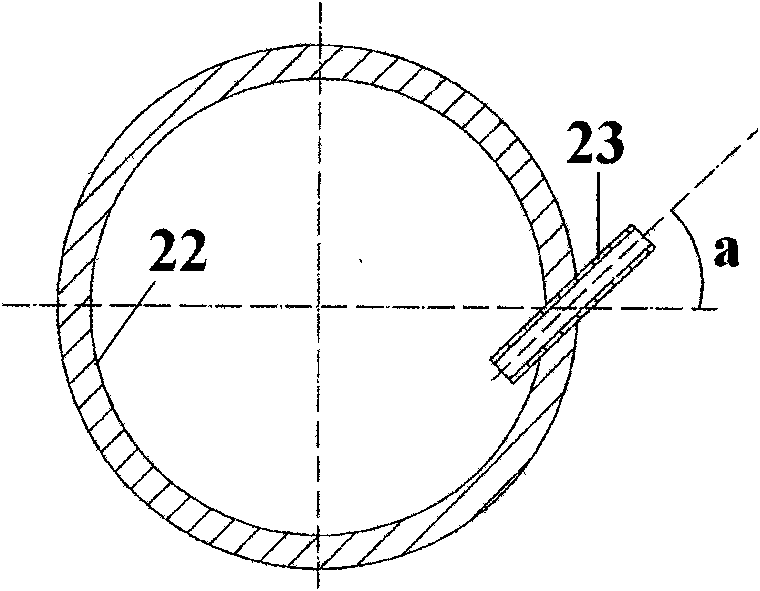

[0027] A self-heating method for continuously preparing biomass powdered activated carbon, wherein the biomass powdered carbonized material (wood chips or bamboo chips) with a moisture content of 8 to 20% wt is passed through a cyclone furnace by a screw feeder 1 The feed inlet 21 at the head is fed into the cyclone furnace 2 with a temperature of 900-1300°C, and the suction force of the induced draft fan 5 along the axial direction from the furnace head to the furnace tail and a row of intake pipes on the wall 22 of the cyclone furnace 23 Under the joint action of the activated mixed gas entering obliquely, the biomass powder carbonized material forms a whirlwind state in the furnace, and moves from the furnace head to the furnace tail in a rotating fluidized state, and activates with the entering activated mixed gas while moving The reaction produces gas gas and powdered activated carbon products mainly composed of carbon monoxide. The activation reaction can form the pore st...

Embodiment 2

[0032] A method for preparing biomass powdered activated carbon in a self-heating cyclone furnace is to form a mixed gas according to the ratio (weight ratio) of water vapor and air of 2:1, enter the cyclone furnace at 1300 ° C, and the mixed gas enters the cyclone The radial angle of the furnace is 30°, the moisture content of raw charcoal powder is 20wt%, the feeding speed is 250 kg per hour, and the induced air volume of the induced draft fan is 500M3 / h (standard state), obtain 40 kilograms of powdered activated carbon products per hour, product 0.15% methylene blue adsorption value is 20 milliliters, and A method caramel decolorization power is 80%.

Embodiment 3

[0034] A method for preparing biomass powdered activated carbon in a self-heating cyclone furnace is to form a mixed gas according to the ratio (weight ratio) of water vapor and air of 3:1, enter the cyclone furnace at 1000 ° C, and the mixed gas enters the cyclone The radial angle of the furnace is 80°, the moisture content of the raw bamboo charcoal powder is 8wt%, the feeding speed is 250 kg per hour, and the induced air volume of the induced draft fan is 500M 3 / h (standard state), obtain 45 kilograms of powdered activated carbon products per hour, product 0.15% methylene blue adsorption value is 18 milliliters, and A method caramel decolorization power is 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption value of methylene blue | aaaaa | aaaaa |

| Adsorption value of methylene blue | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com