Method of processing refuse burning fly ash through cyclone furnace high temperature melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

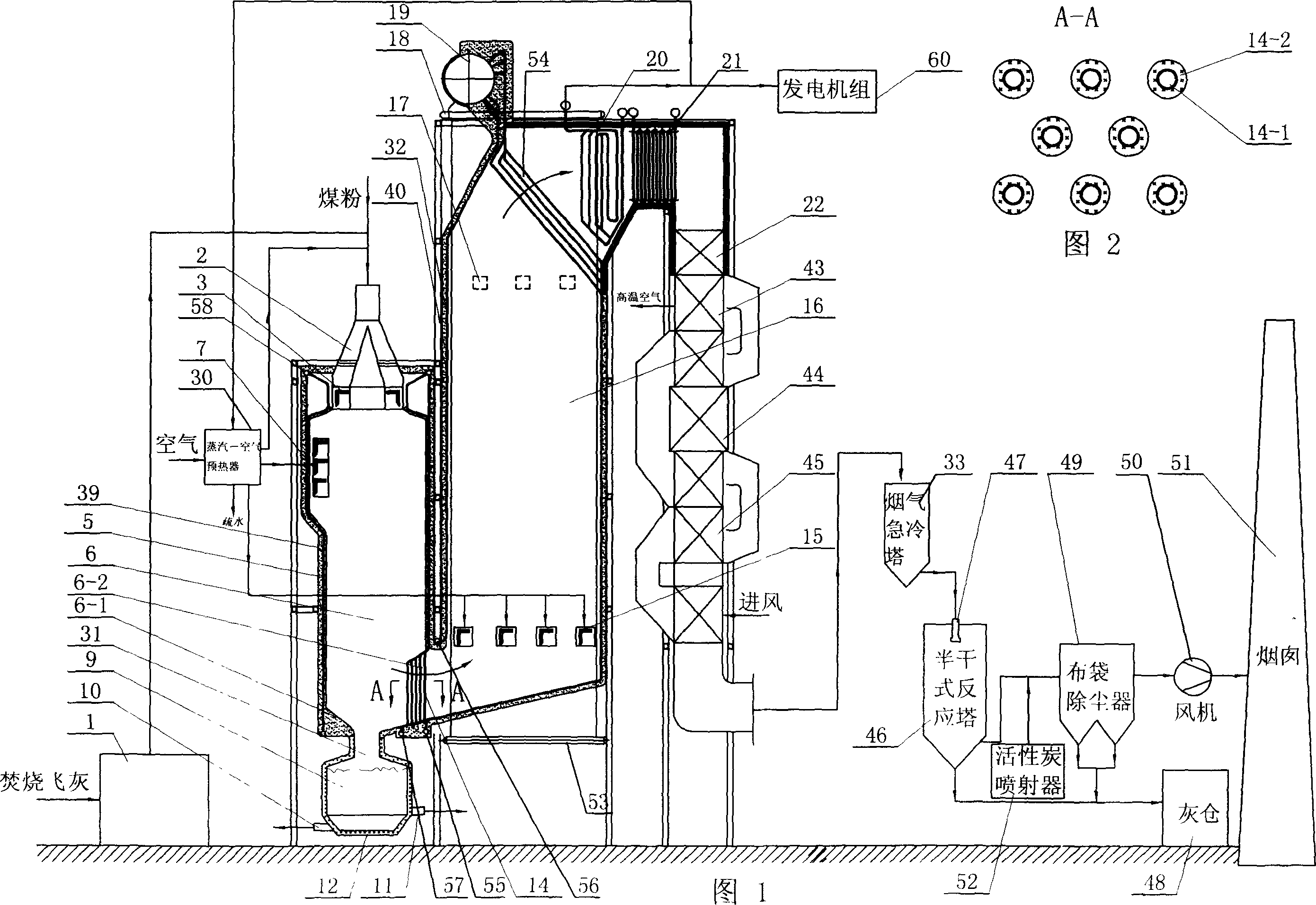

[0006] Specific Embodiment 1: The present embodiment will be specifically described below with reference to FIG. 1 and FIG. 2 . This embodiment is completed by the following steps: 1. Mix the fly ash and coal powder produced after garbage incineration in a ratio of 15-25:75-85 and send them into the cyclone furnace 6 for combustion until high-temperature melting; 2. Make the cyclone furnace 6 The internal combustion is in a reducing state, and the air excess coefficient is maintained at 0.8 to 0.9; 3. Most of the heavy metals in the molten fly ash (a small part of which is sublimated and taken away with the flue gas) sink to the molten slag at the bottom of the cyclone furnace 6 in a liquid state The bottom of the pool 9 is recovered after being discharged from the metal recovery outlet 10 at the bottom of the molten slag pool 9, and the molten ash floating on the liquid metal flows out of the molten slag pool from the molten slag recovery outlet 11, and is used as cement raw m...

specific Embodiment approach 2

[0007] Specific Embodiment 2: The present embodiment will be specifically described below with reference to FIG. 1 . The difference between this embodiment and the first embodiment is that the high-temperature flue gas after the secondary high-temperature combustion chamber 16 is discharged from the high-temperature economizer 22, and then enters the high-temperature air preheater 43, the low-temperature economizer 44, Low-temperature air preheater 45, the exhaust gas temperature is 160-180°C and then sent to the semi-dry reaction tower 46, the rotary sprayer 47 installed in the semi-dry reaction tower 46 sprays lime slurry to remove acid gas, and settles in the semi-dry reaction tower 46. The dust at the bottom of the type reaction tower 46 is sent into the ash bin 48, and the smoke and dust enter the bag filter 49, and before entering the bag filter 49, the dioxins that may be produced in the exhaust gas are sprayed through the activated carbon injector 52, and after passing ...

specific Embodiment approach 3

[0008] Specific embodiment three: this embodiment is completed by the following steps: 1. After the fly ash and coal powder produced after garbage incineration are mixed in a ratio of 15~25:75~85, they are sent into the cyclone furnace 6 and burned to high temperature melting; 2. 1. Keep the combustion in the cyclone furnace 6 in an oxidized state, and keep the air excess coefficient at 1.1 to 1.2; 3. The molten ash in the molten fly ash flows out of the slag pool from the slag recovery outlet 11, and is used as cement raw material after being quenched by water Or recycling of building materials. In this embodiment, liquid metal is not recovered, and the molten slag pool 9 only recovers the quenched glass body for recycling as cement raw material or building material. The present embodiment cancels the tertiary air spout.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com