Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Promote grain growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

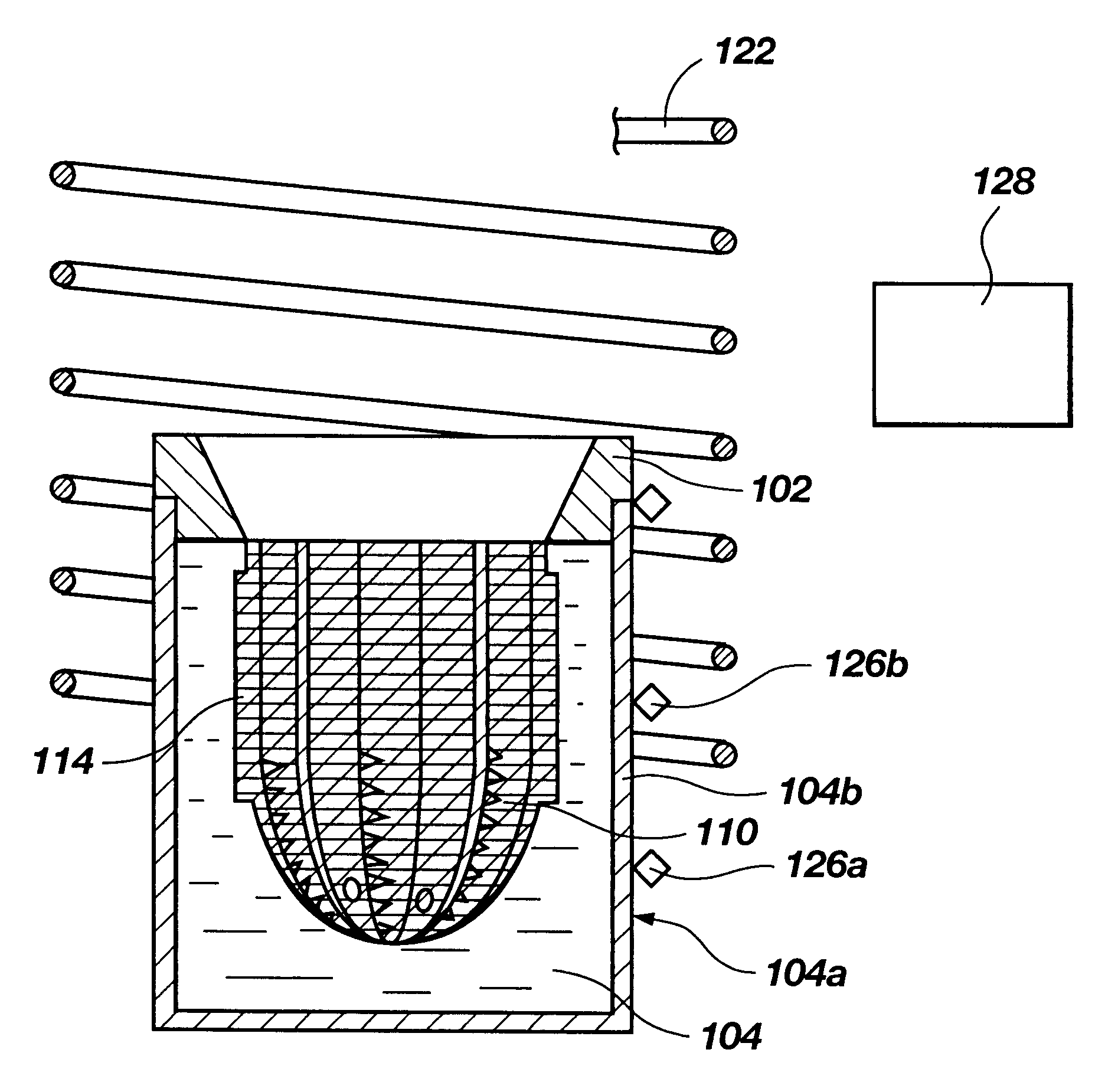

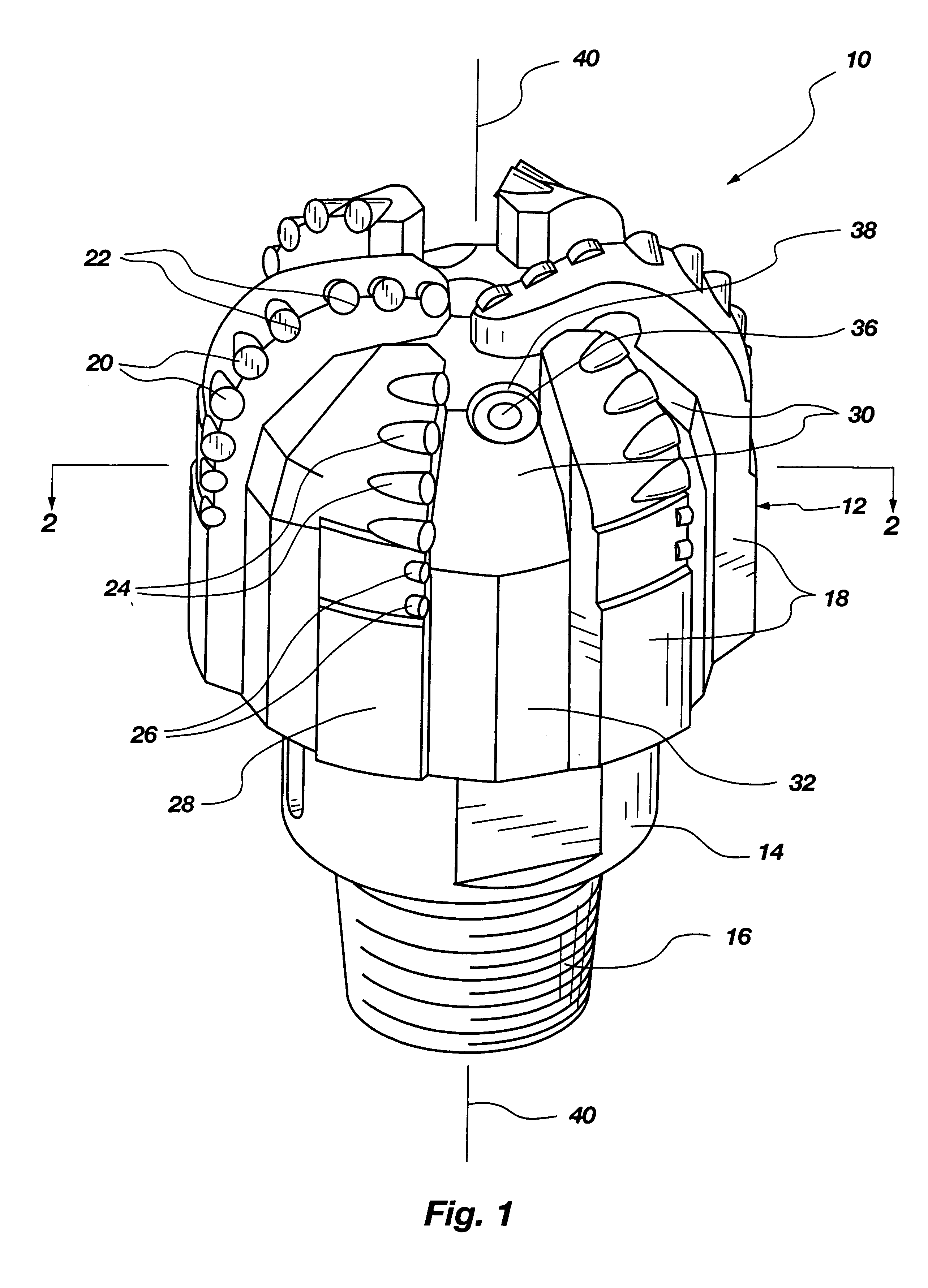

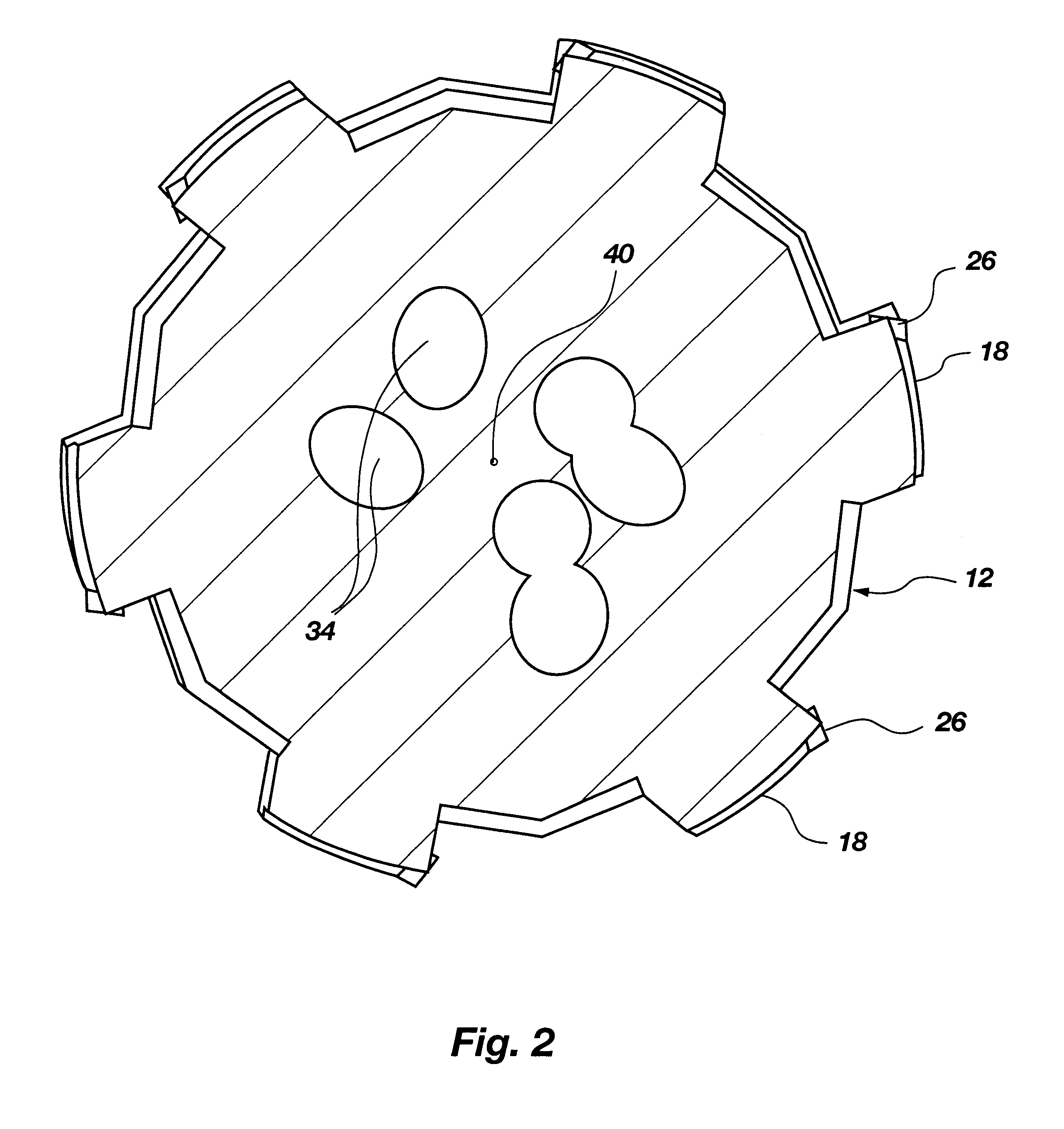

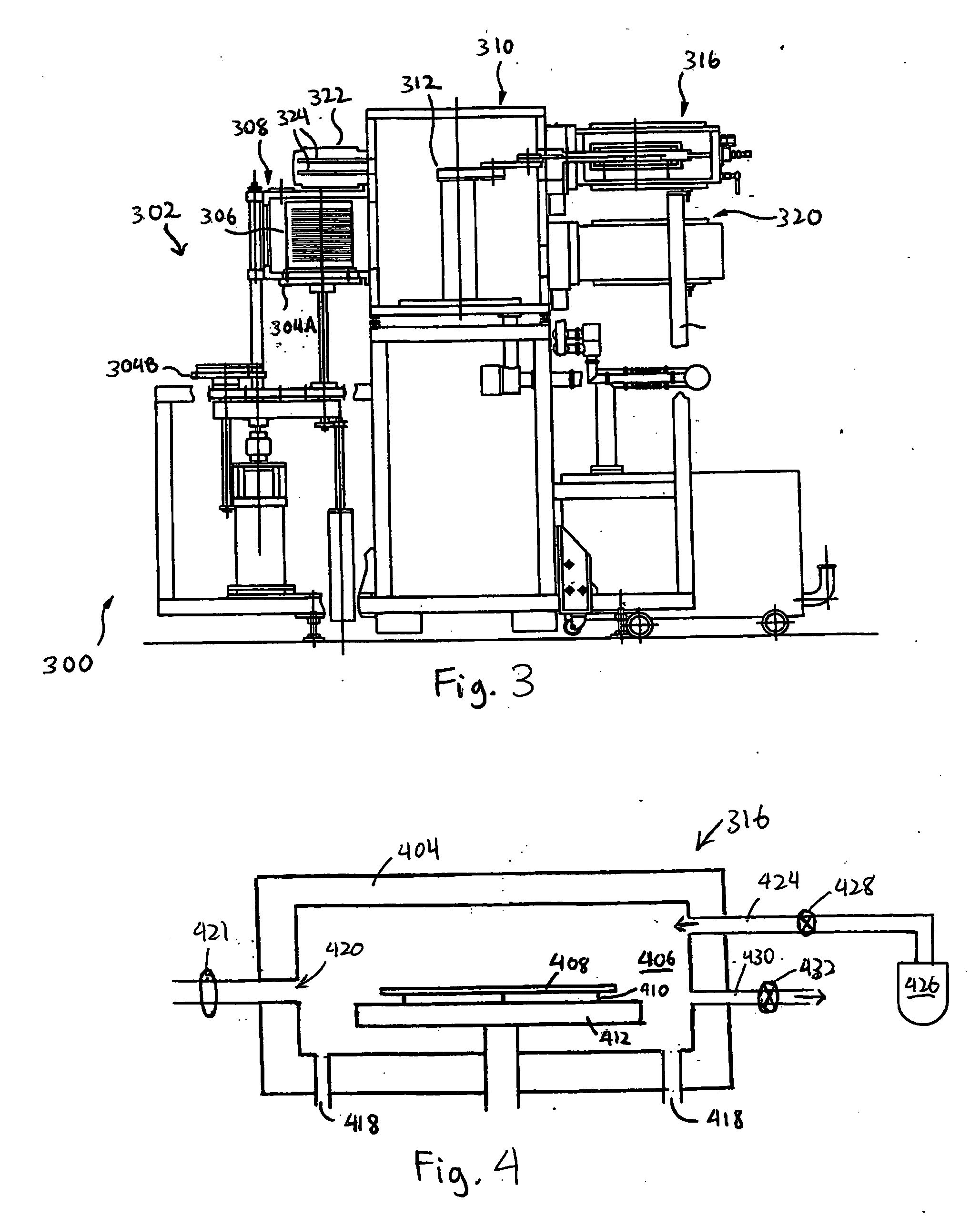

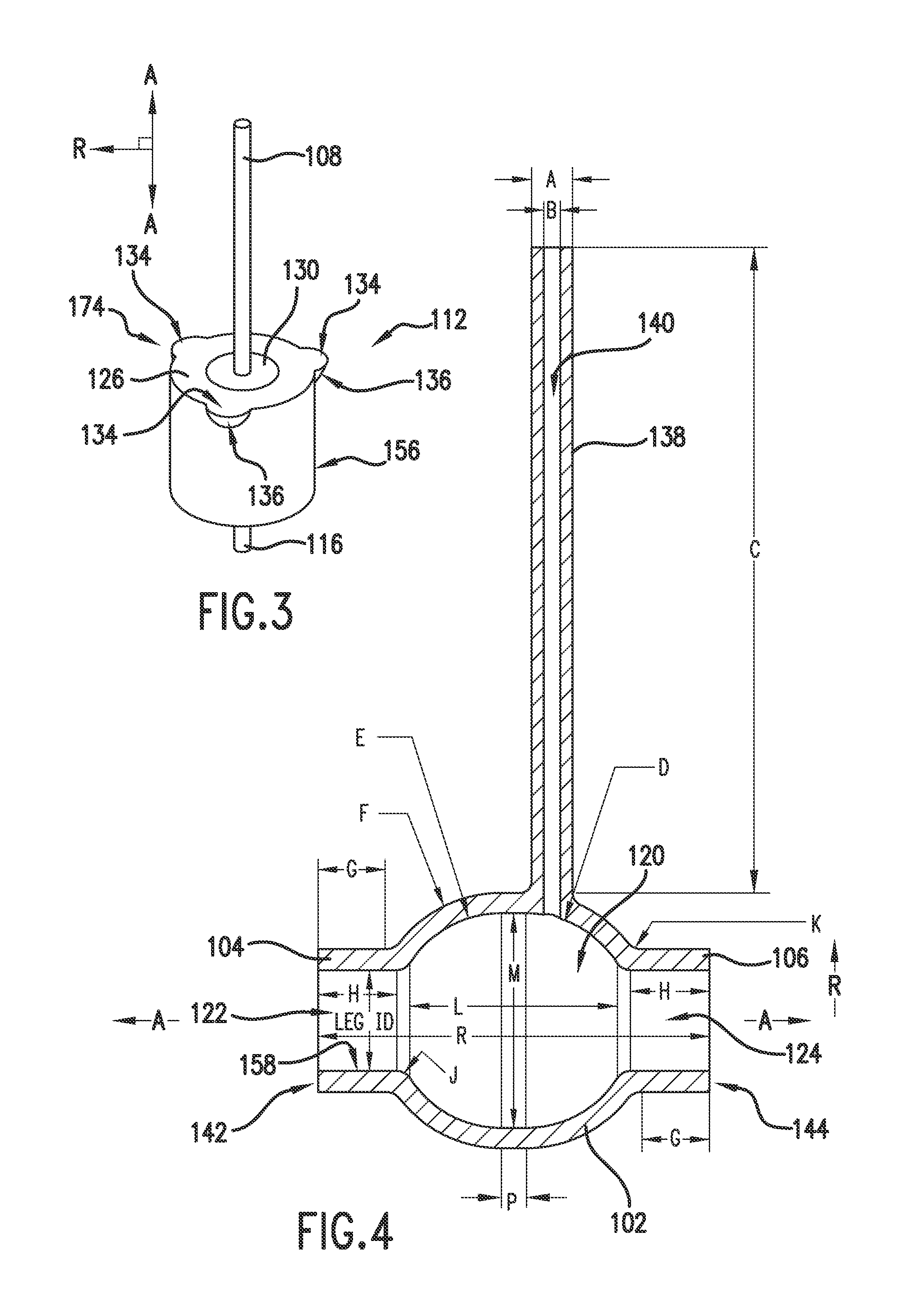

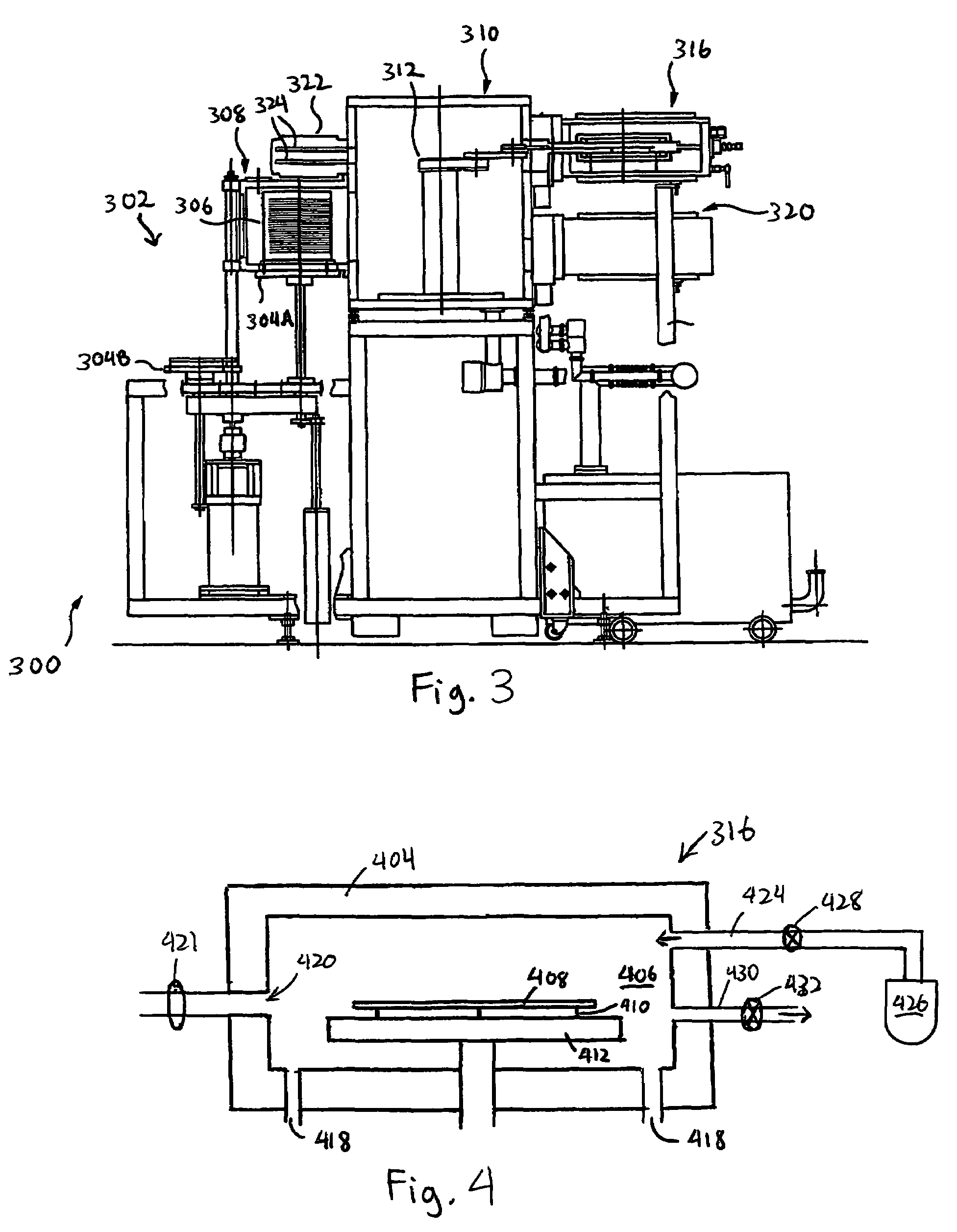

Methods of high temperature infiltration of drill bits and infiltrating binder

A method of manufacturing a bit body, other drilling-related component, or other article of manufacture, including fabricating a particulate-based matrix and infiltrating the particulate-based matrix with a binder that includes cobalt or iron. The binder may be a cobalt alloy or an iron alloy. The particulate-based matrix may be disposed within a non-graphite mold. The particulate-based matrix and binder are placed within an induction coil and an alternating current is applied to the induction coil in order to directly heat the binder, permitting the binder to infiltrate or otherwise bind the particles of the matrix together. The molten binder may then be directionally cooled by forming a cooling zone around an end portion of the bit body and increasing the size of the cooling zone relative to the bit body. The invention also includes a bit body, other drilling-related component, or other article of manufacture which includes a particulate-based matrix that is bound together with a binder that includes iron or cobalt.

Owner:BAKER HUGHES INC

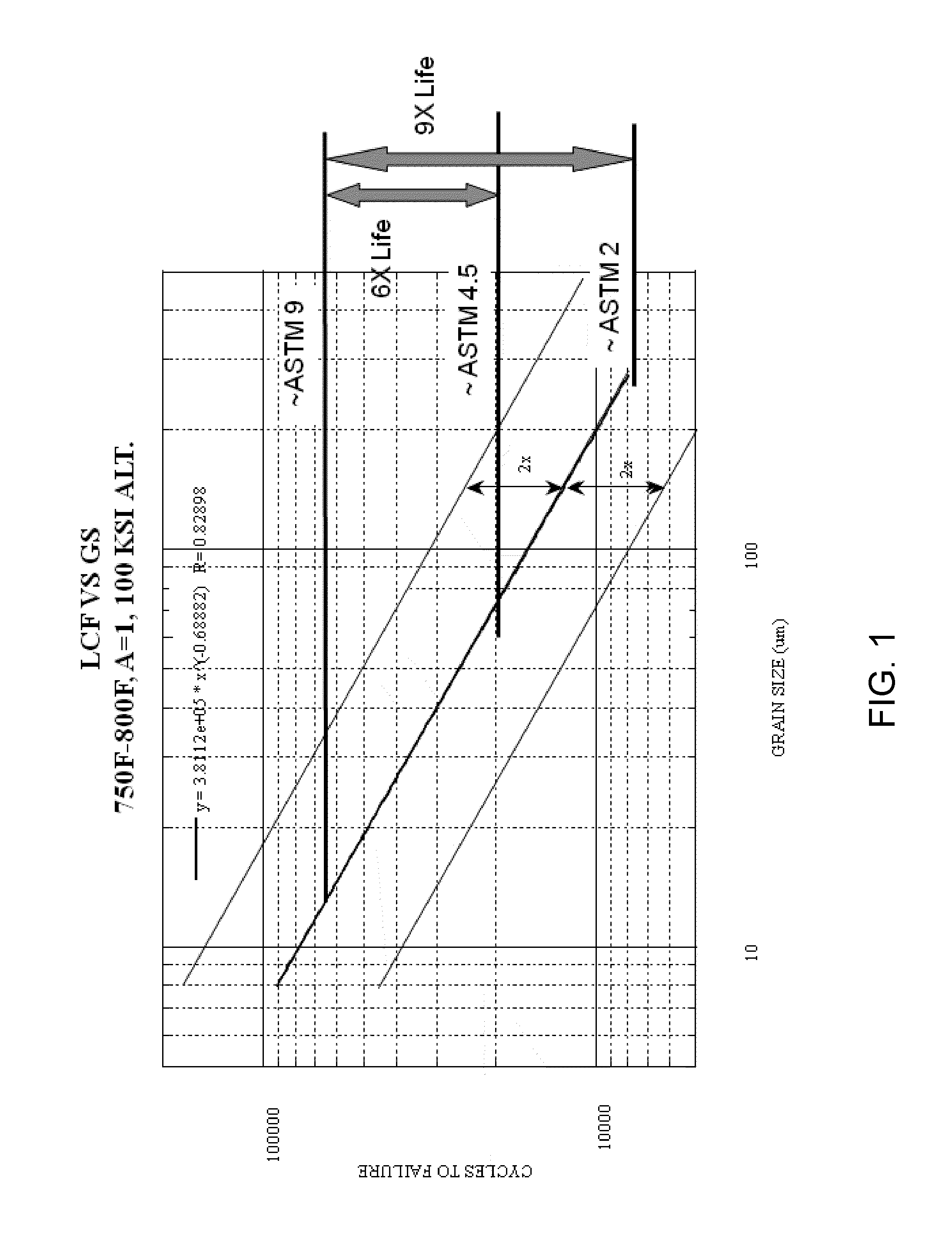

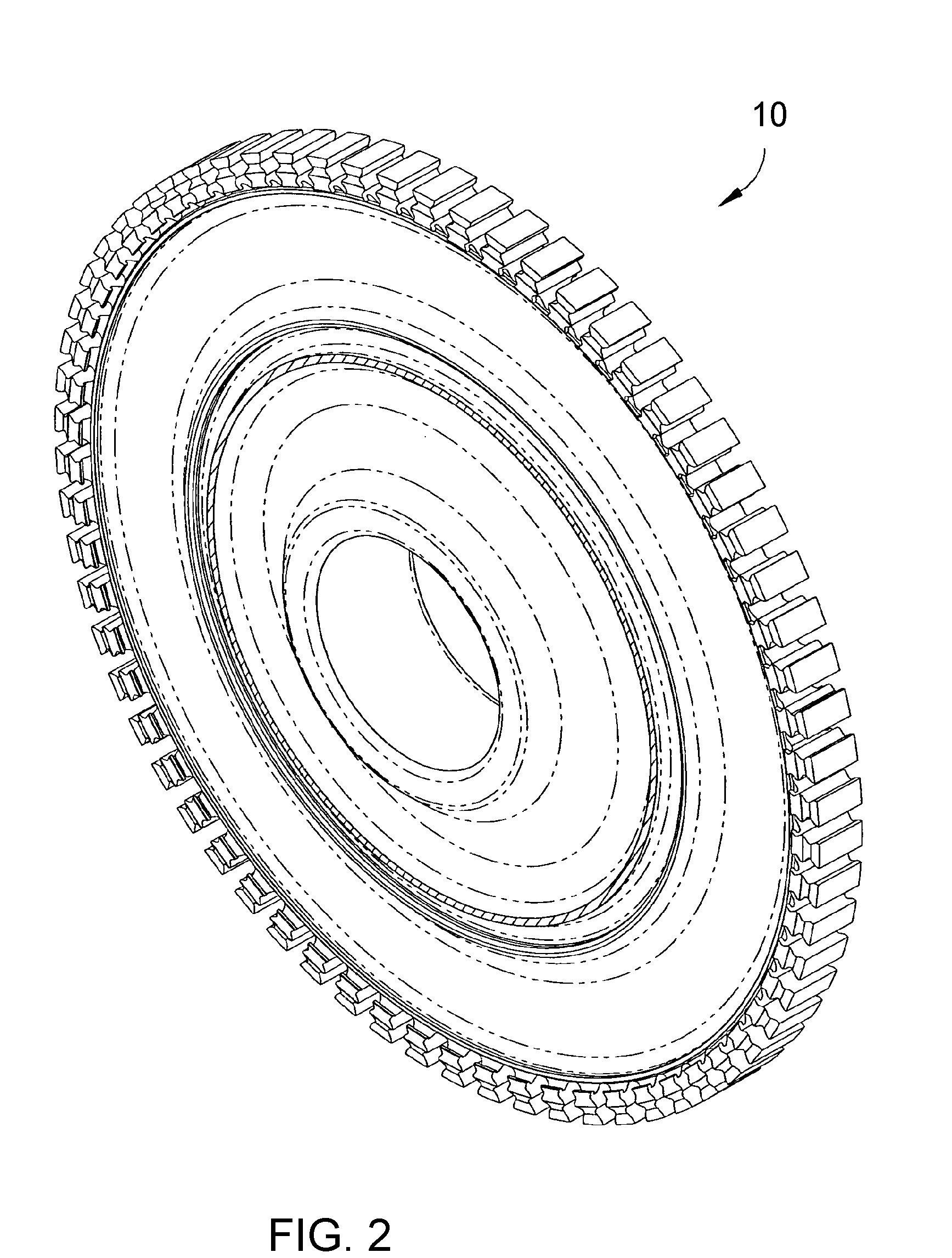

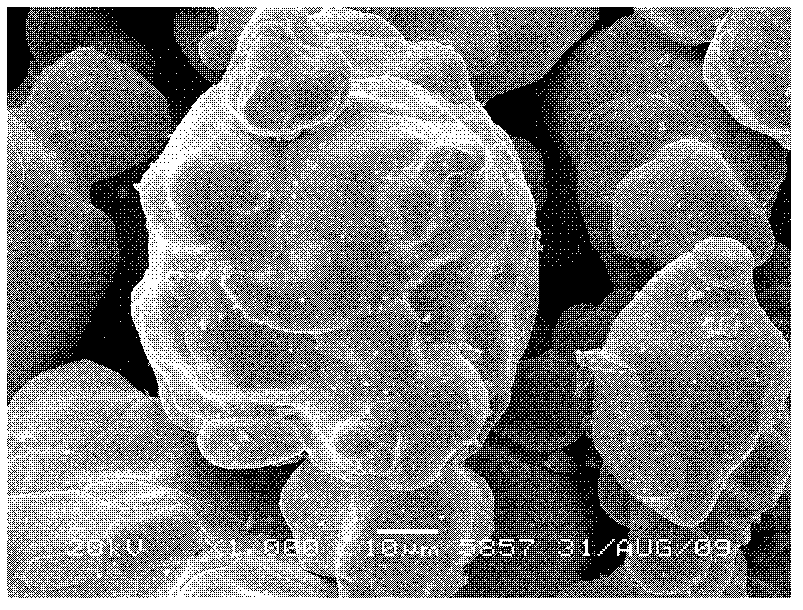

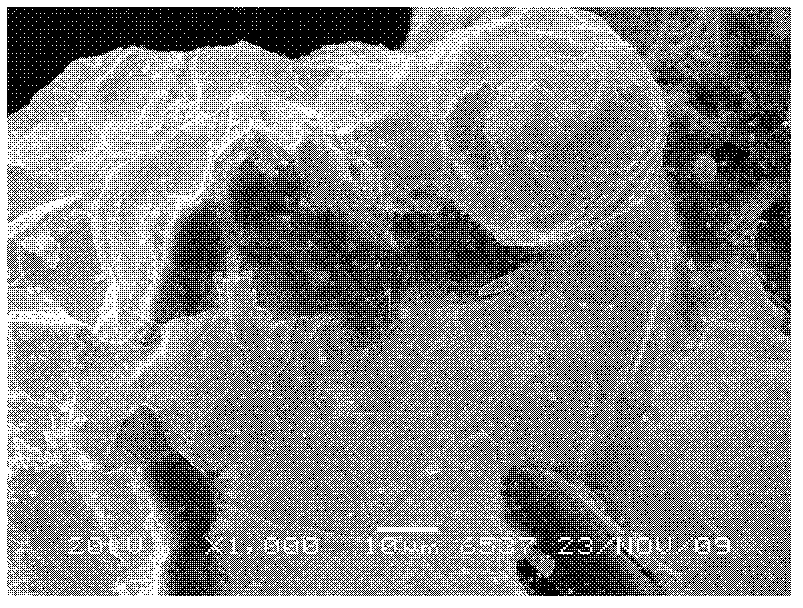

Method of controlling and refining final grain size in supersolvus heat treated nickel-base superalloys

InactiveUS20100329883A1Finer uniform grain sizeImproved low cycle fatigue behaviorPropellersEngine manufactureRheniumNiobium

A gamma prime precipitation-strengthened nickel-base superalloy and method of forging an article from the superalloy to promote a low cycle fatigue resistance and high temperature dwell behavior of the article. The superalloy has a composition of, by weight, 16.0-22.4% cobalt, 6.6-14.3% chromium, 2.6-4.8% aluminum, 2.4-4.6% titanium, 1.4-3.5% tantalum, 0.9-3.0% niobium, 1.9-4.0% tungsten, 1.9-3.9% molybdenum, 0.0-2.5% rhenium, greater than 0.05% carbon, at least 0.1% hafnium, 0.02-0.10% boron, 0.03-0.10% zirconium, the balance nickel and incidental impurities. A billet is formed of the superalloy and worked at a temperature below the gamma prime solvus temperature of the superalloy so as to form a worked article, which is then heat treated above the gamma prime solvus temperature of the superalloy to uniformly coarsen the grains of the article, after which the article is cooled to reprecipitate gamma prime. The article has an average grain size of not coarser than ASTM 7 and is substantially free of critical grain growth.

Owner:GENERAL ELECTRIC CO

Extra coarse grain WC-Co hard alloy and preparation process thereof

ActiveCN102534344APromote grain growthIncrease the carbon content of tungsten carbideCemented carbideGrain distribution

The invention relates to an extra coarse grain WC-Co hard alloy. The hard alloy comprises 5 to 15 weight percent of Co and the balance of WC, wherein the average grain size of the WC is 6 to 10mu m. A preparation process for the hard alloy comprises the following steps of: pre-ball-milling coarse and fine tungsten carbide to prepare mixed tungsten carbide powder, preparing mixed tungsten carbide powder-cobalt-former mixed powder, pressing, and sintering, wherein the sintering step is divided into a former removing part and a high-temperature sintering part. The average grain size of a metallographic structure of the WC-Co hard alloy prepared by the process is 6mu m or more than 6mu m, the process method is simple and convenient to operate, the prepared hard alloy has a large average grainsize, a narrow grain distribution range, a low thermal expansion coefficient and high heat conductivity, high-temperature wear resistance, transverse rupture strength and rupture toughness, and is suitable for a mining tool and an excavating tool, and the thermal fatigue crack resistance of the alloy is effectively improved.

Owner:HUNAN BOYUN DONGFANG POWDER METALLURGY

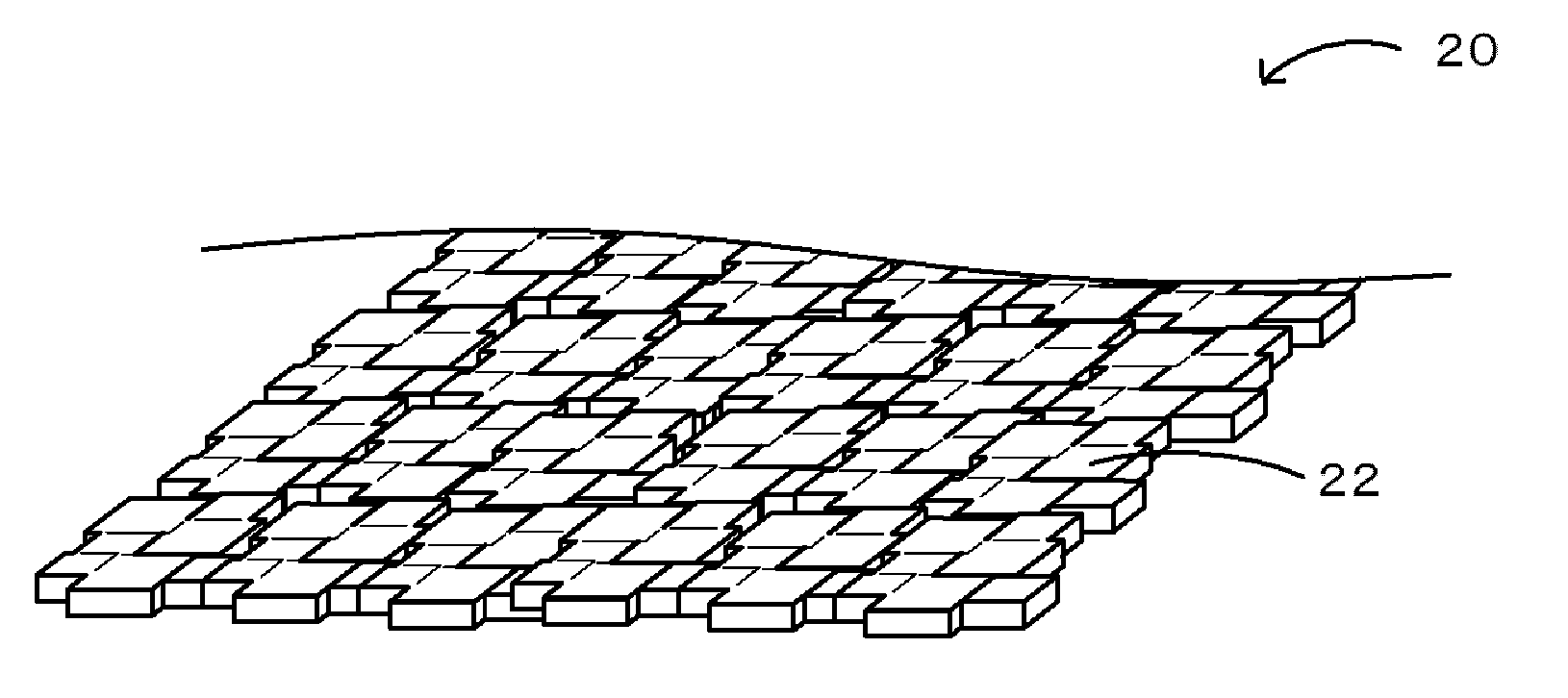

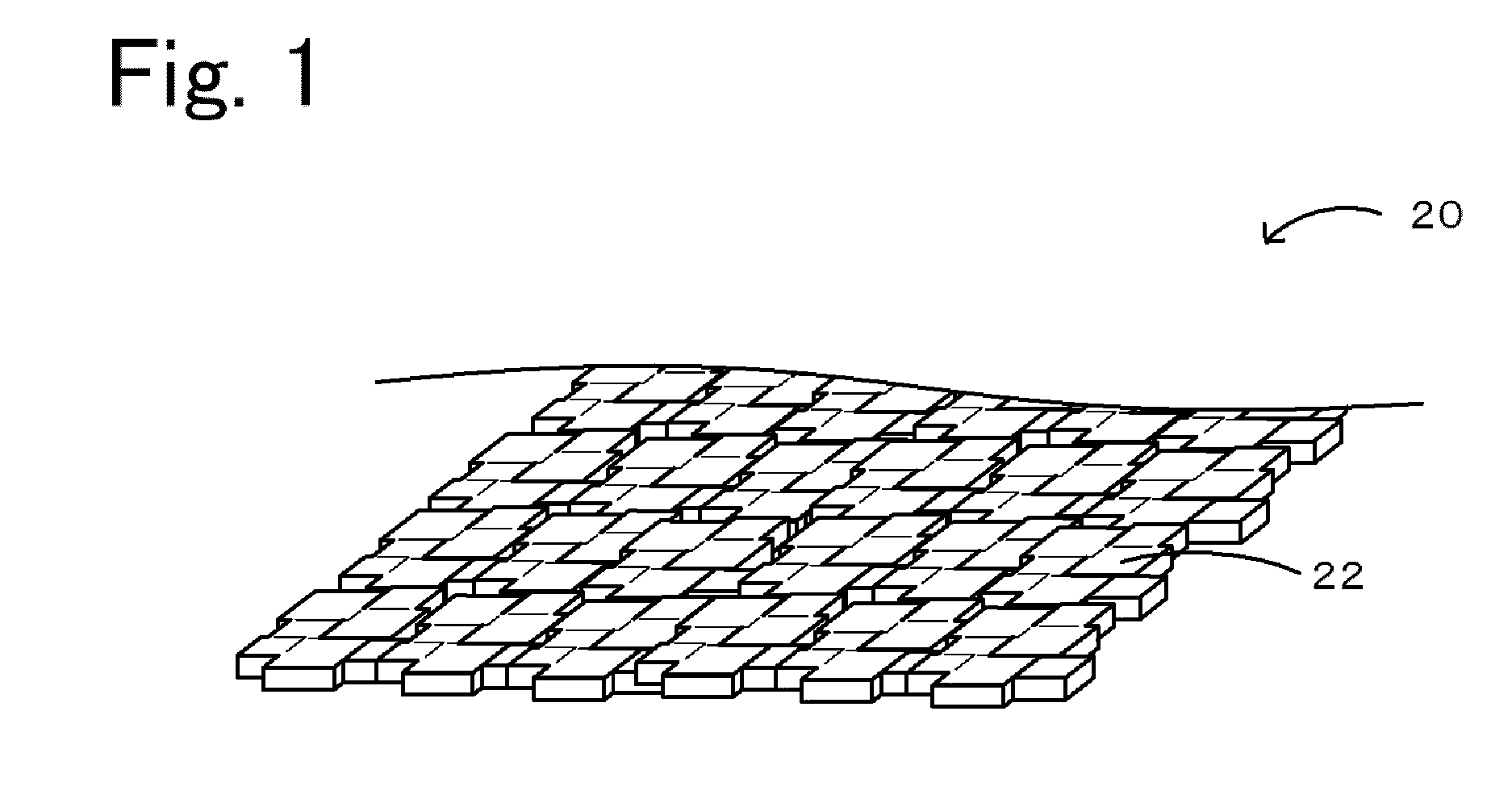

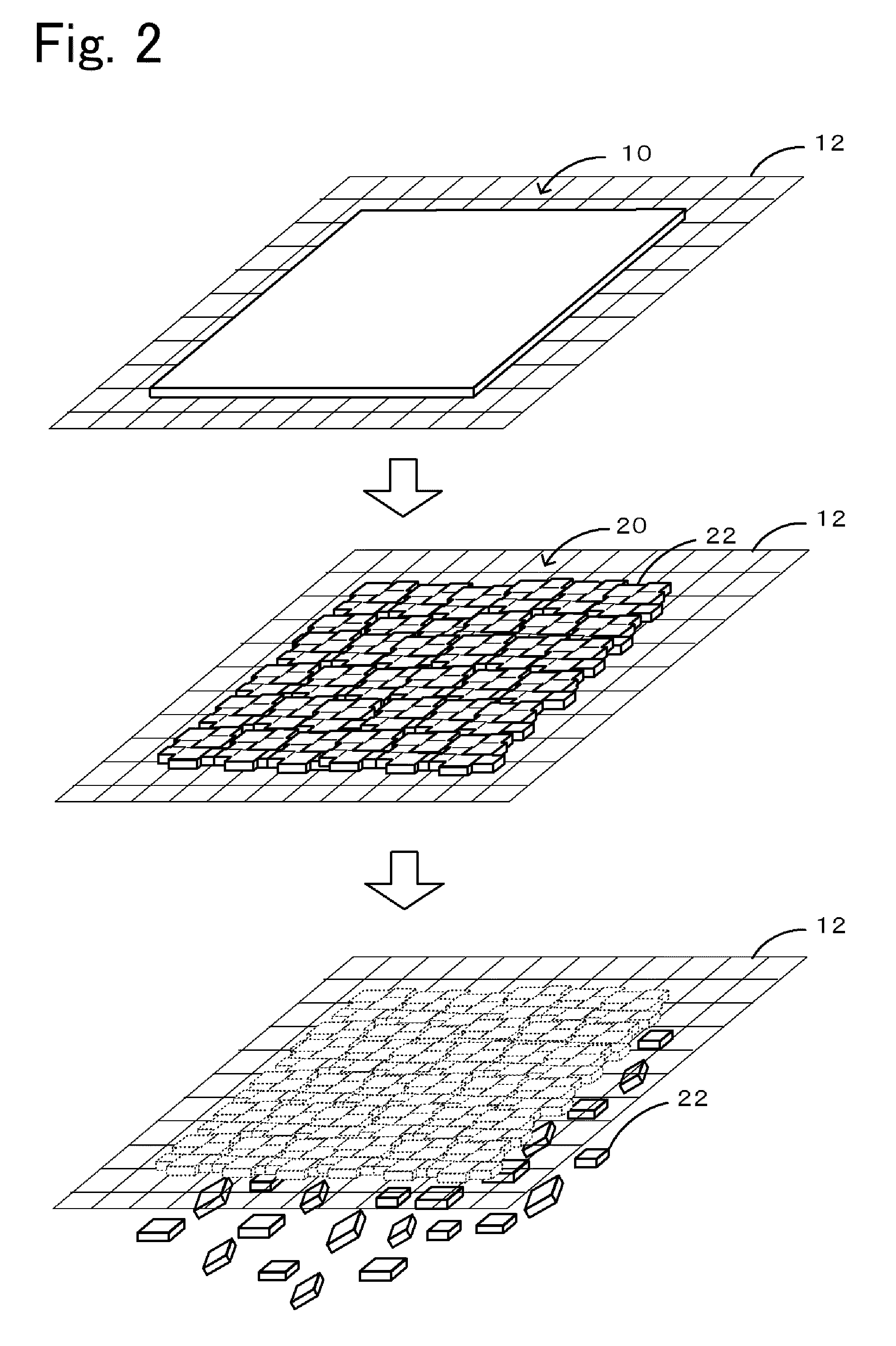

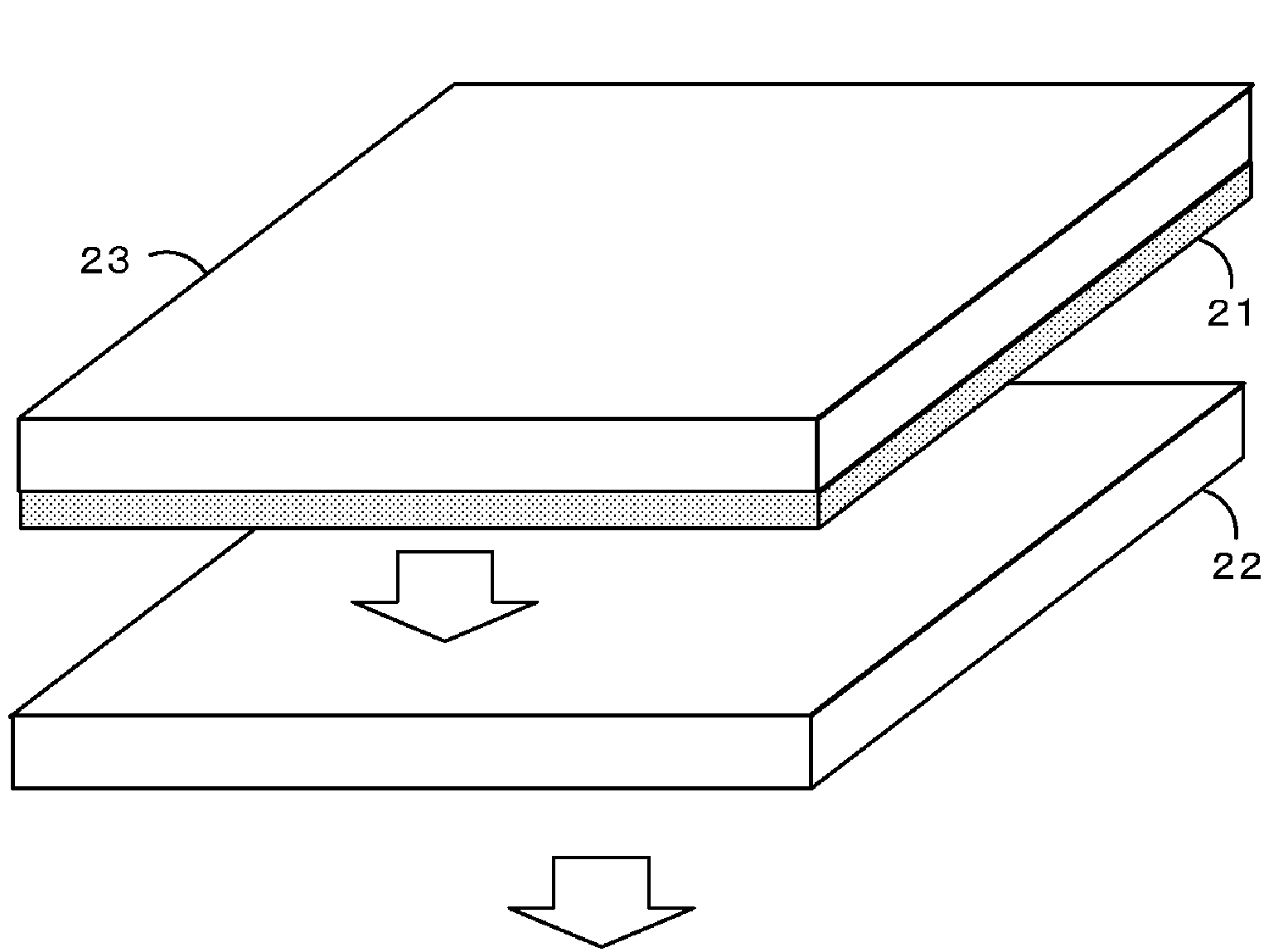

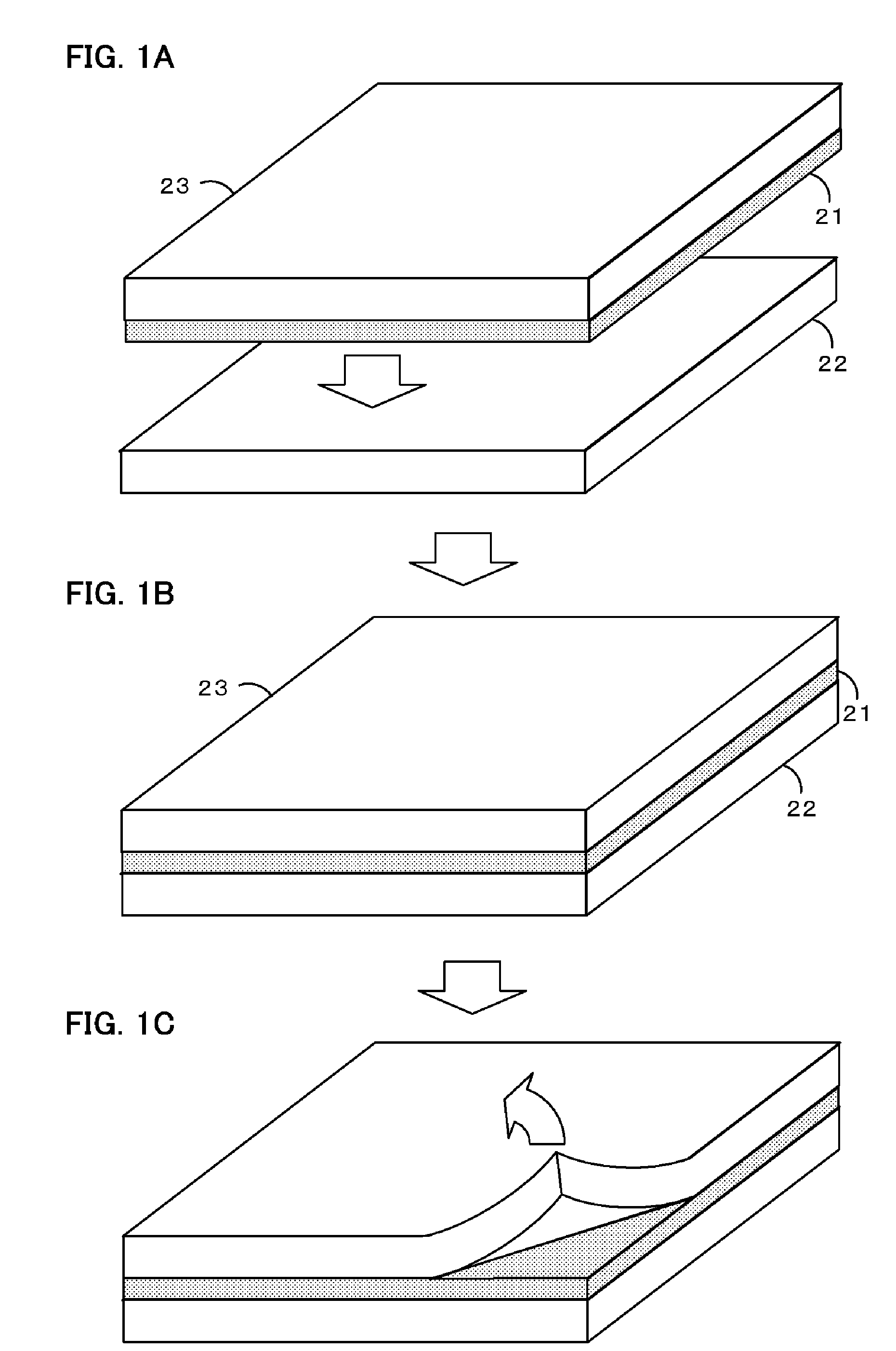

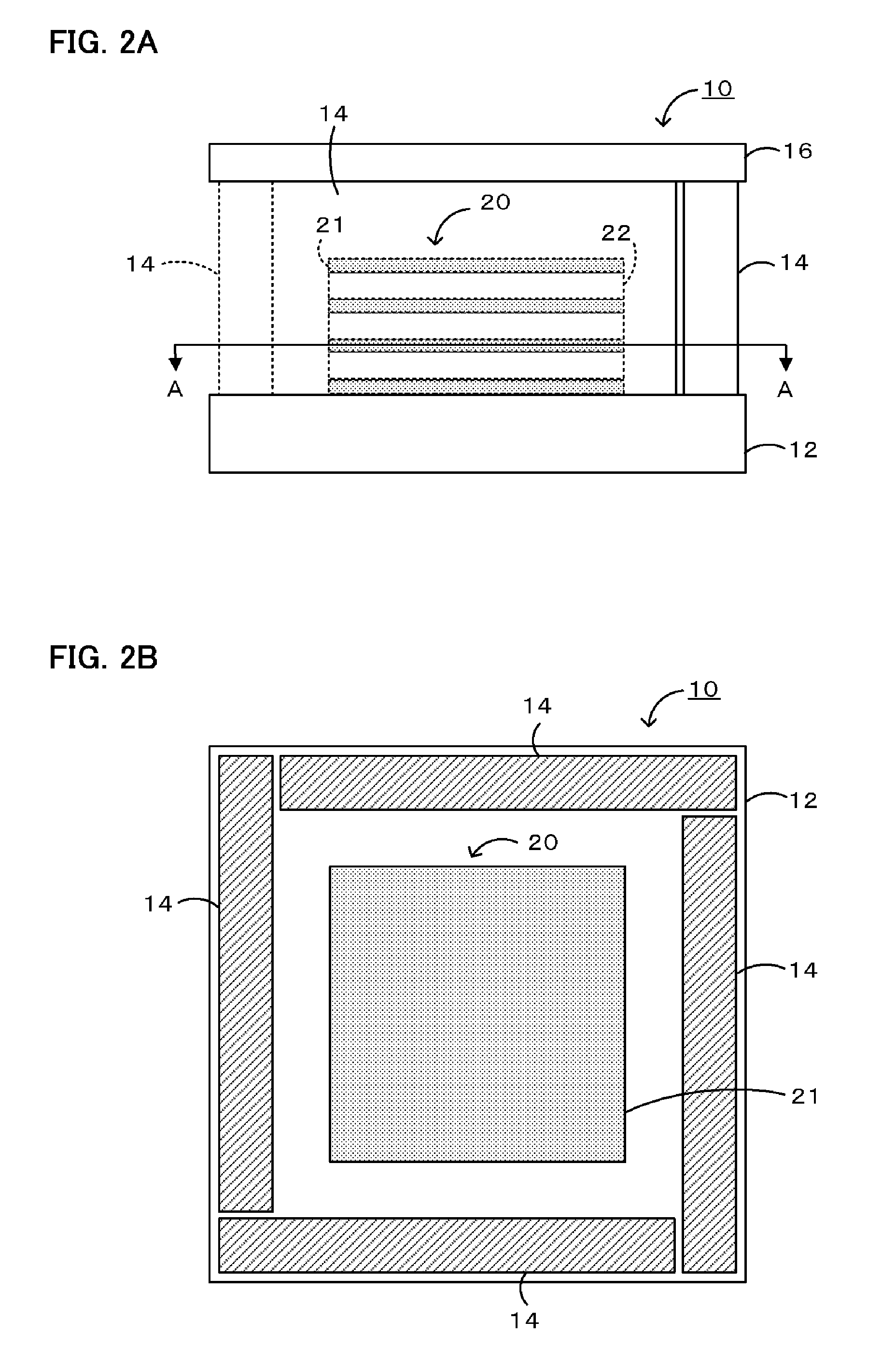

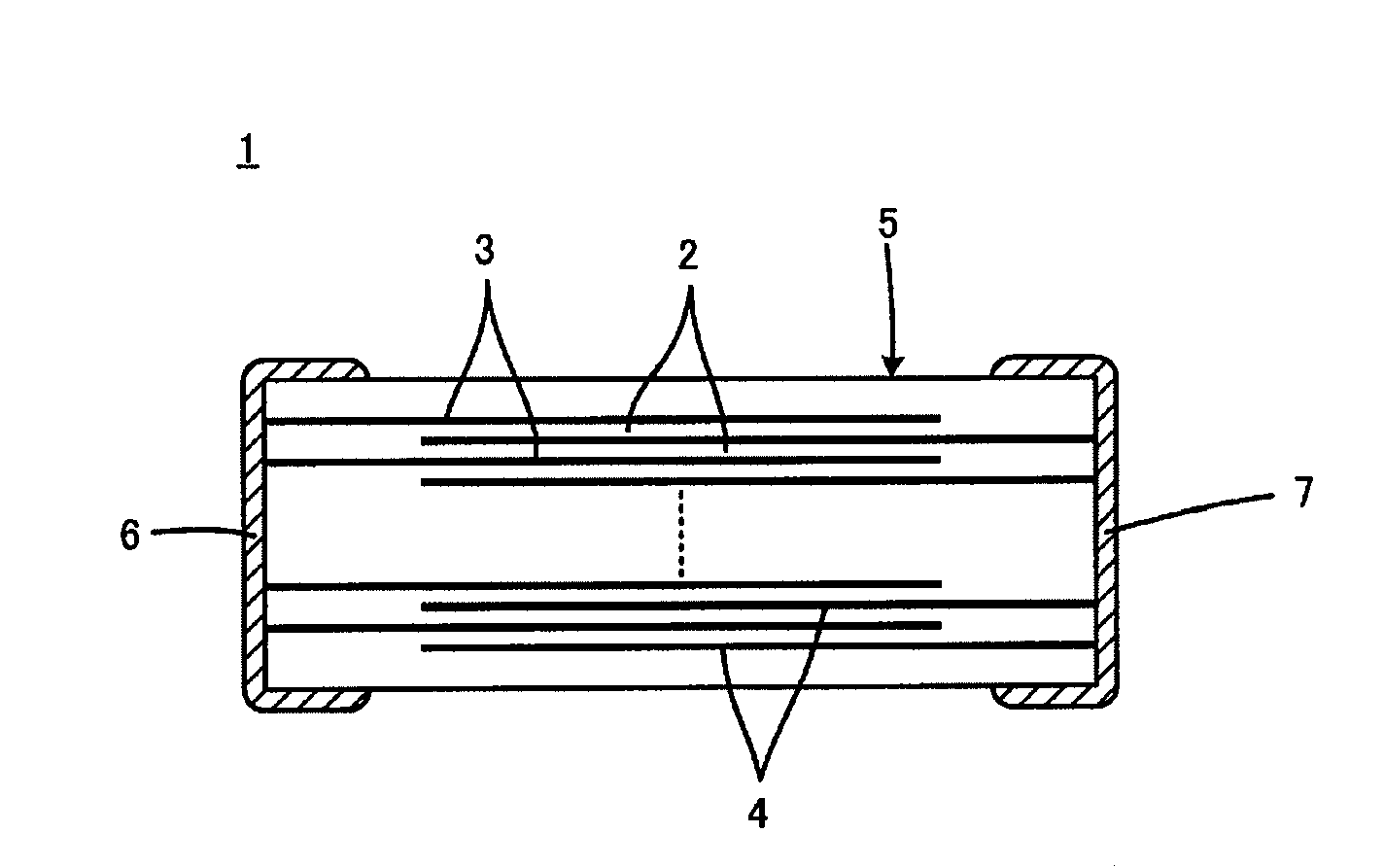

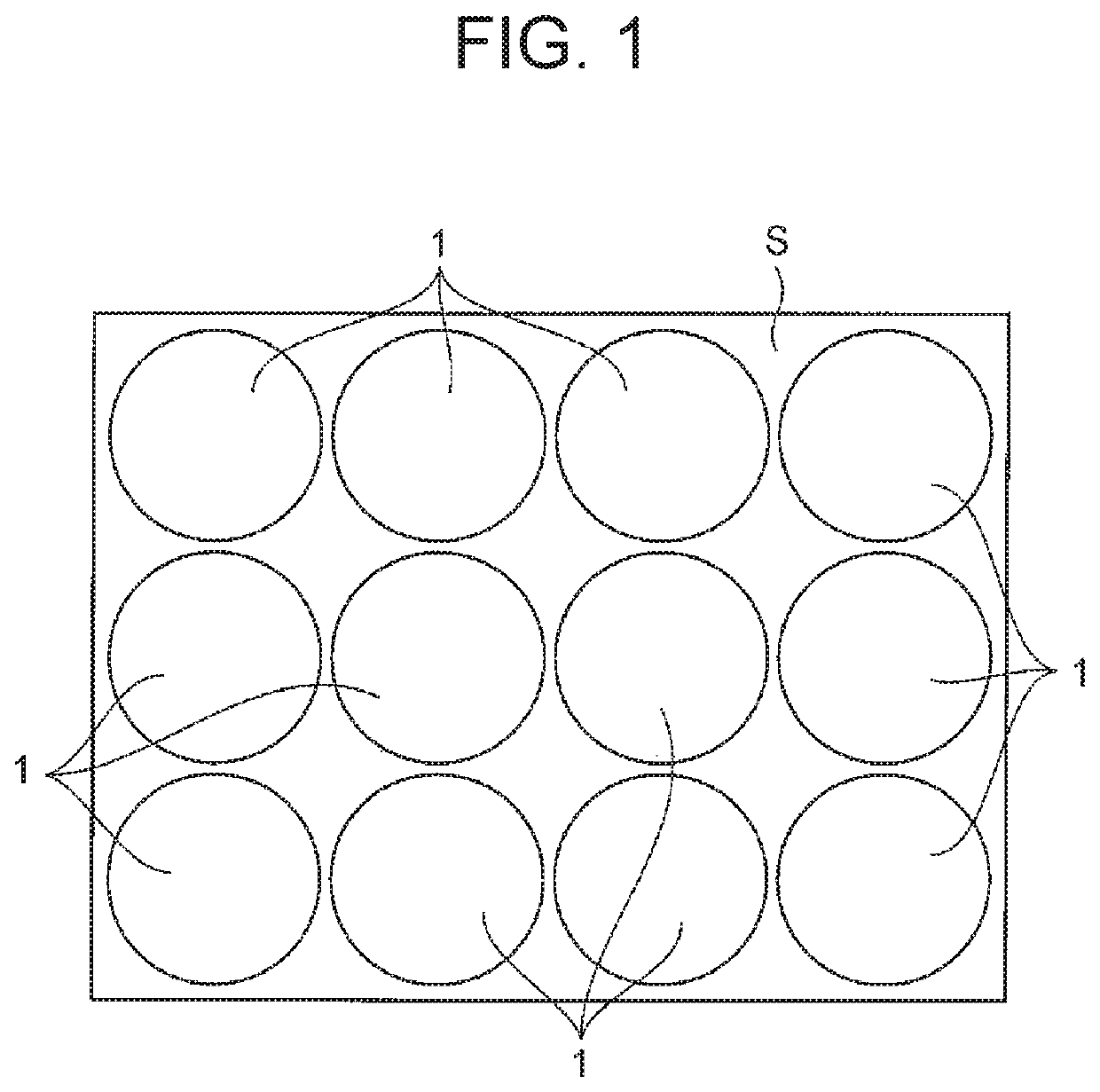

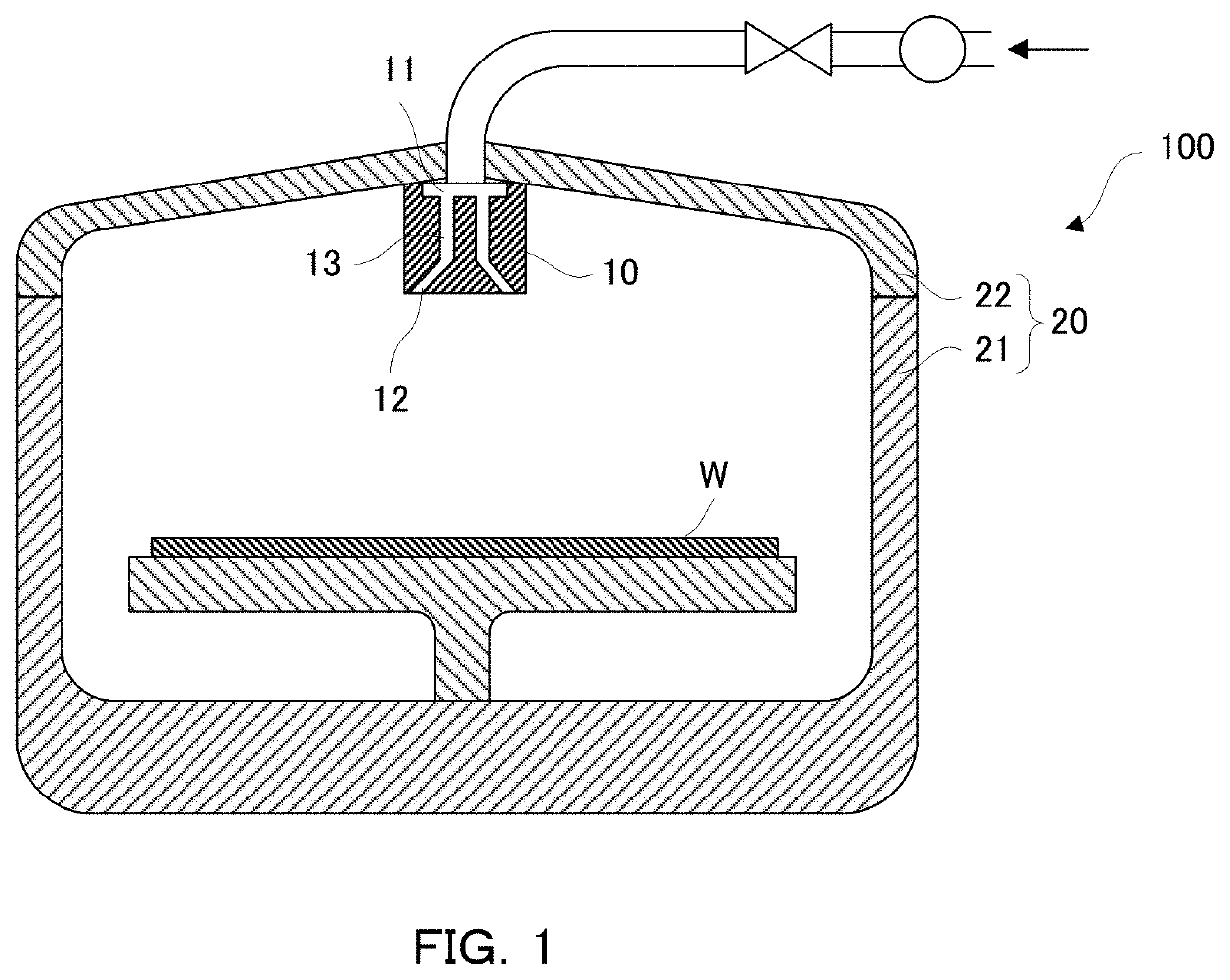

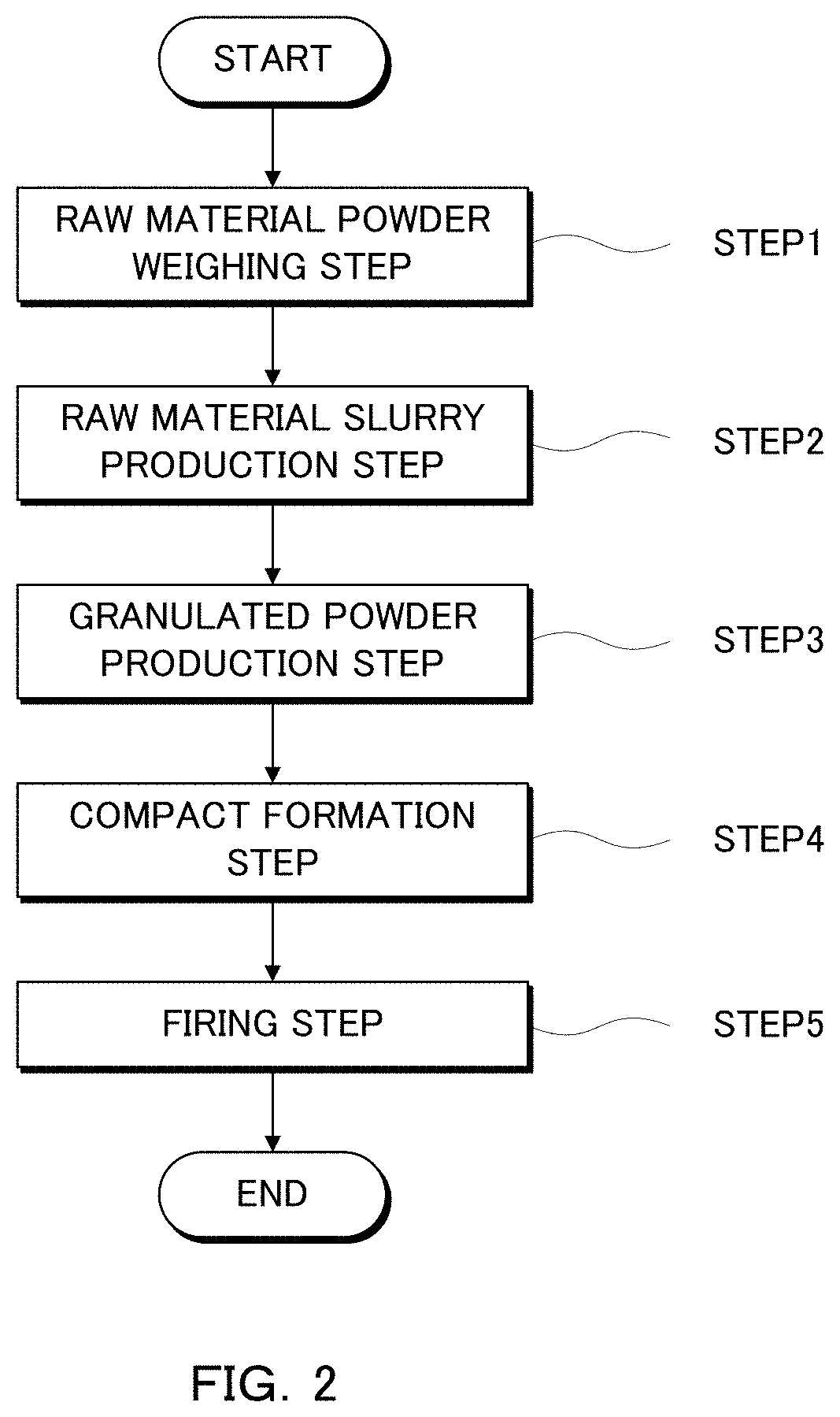

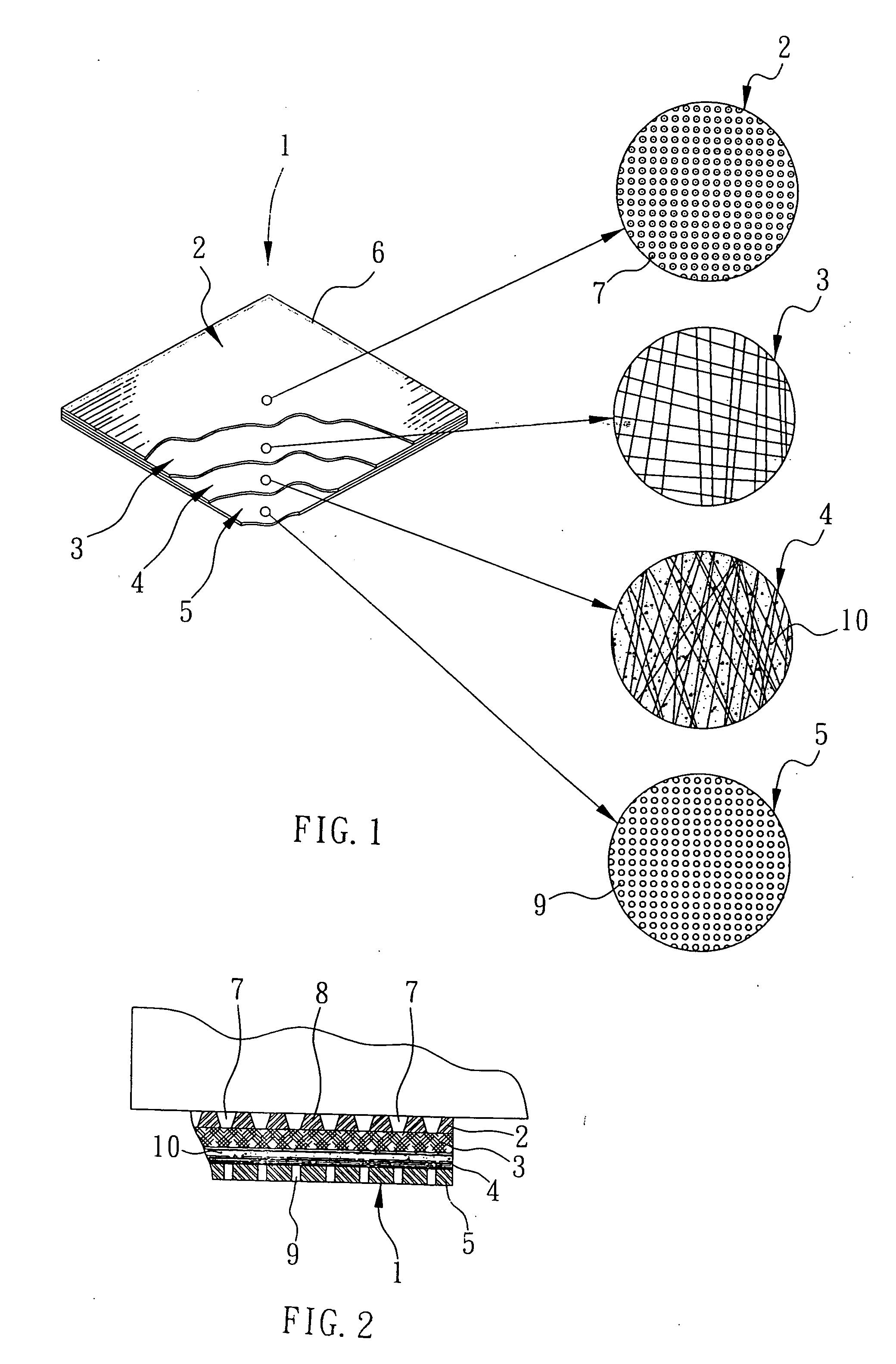

Ceramic sheet and method for producing the same

InactiveUS20100119800A1Reduce energy consumptionHigh densityPiezoelectric/electrostrictive device manufacture/assemblySynthetic resin layered productsInorganic particleInorganic particles

A ceramic sheet 20 is produced by a method in which inorganic particles including, as a main component, an oxide represented by general formula ABO3 and containing a volatile component are mixed such that the A / B ratio is 1.05 or more, the inorganic particles are formed into a self-supported planar shaped body with a thickness of 30 μm or less, and the shaped body is fired, without an inactive layer or with an inactive layer which does not substantially react with the shaped body and is disposed adjacent to the shaped body, at a temperature-rising rate of 30° C. / min or more in a temperature range which is equal to or higher than a temperature at which the volatile component is volatilized.

Owner:NGK INSULATORS LTD

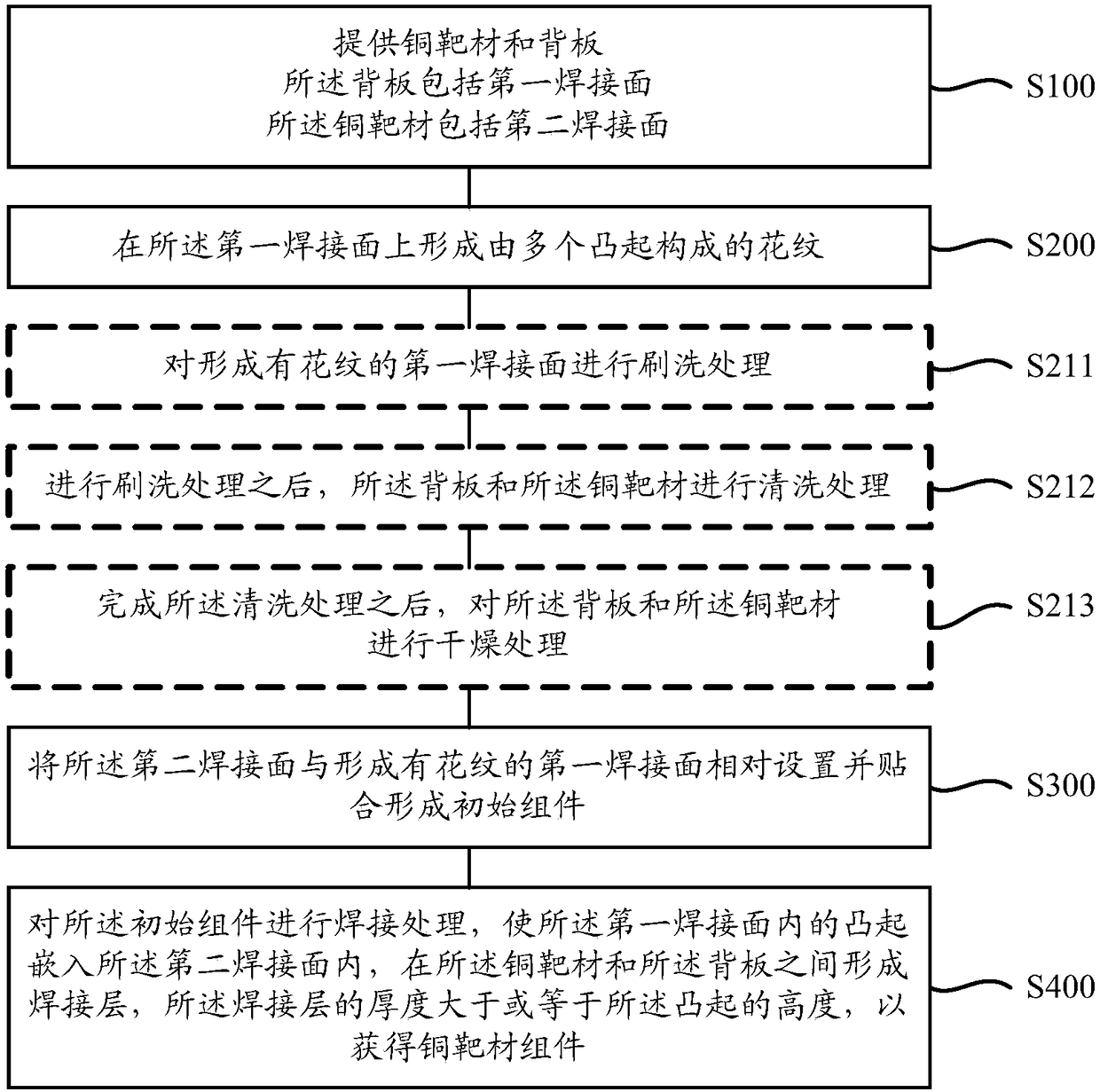

Copper target assembly and manufacturing method thereof

The invention provides a copper target assembly and a manufacturing method of the copper target assembly. The manufacturing method comprises the steps that a back plate and a copper target are provided, wherein the back plate comprises a first welding face, and the copper target comprises a second welding face; a pattern composed of multiple protrusions is formed on the first welding face; the second welding face and the first welding face provided with the pattern are oppositely arranged and attached to each other to form an initial assembly; welding treatment is conducted on the initial assembly, the protrusions of the first welding face are embedded into the second welding face, a welded layer is formed between the copper target and the back plate, the thickness of the welded layer is larger than or equal to the height of each protrusion, and then the copper target assembly is obtained. By the adoption of the copper target assembly and the manufacturing method of the copper target assembly, the possibility that a gap appears in the welded layer is effectively reduced, so that the quality and performance of the formed copper target assembly can be effectively improved, and the yield and performance of a manufactured semiconductor chip are improved beneficially.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

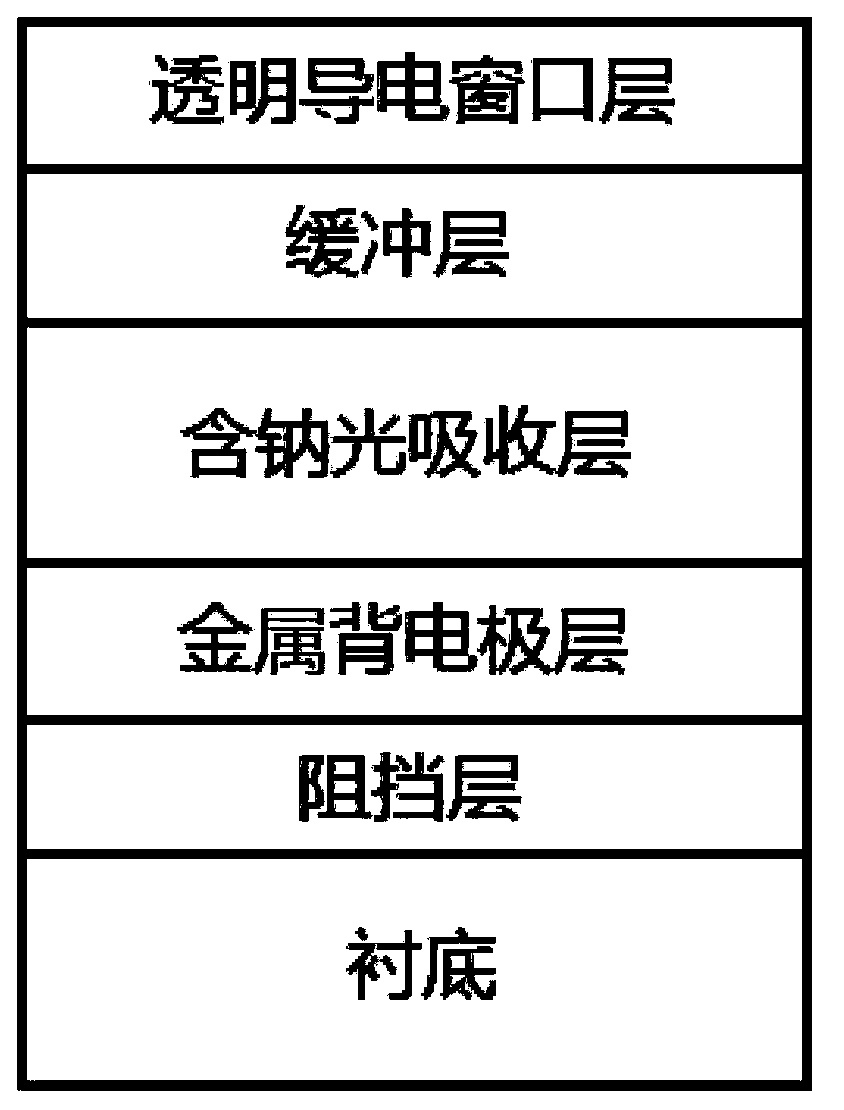

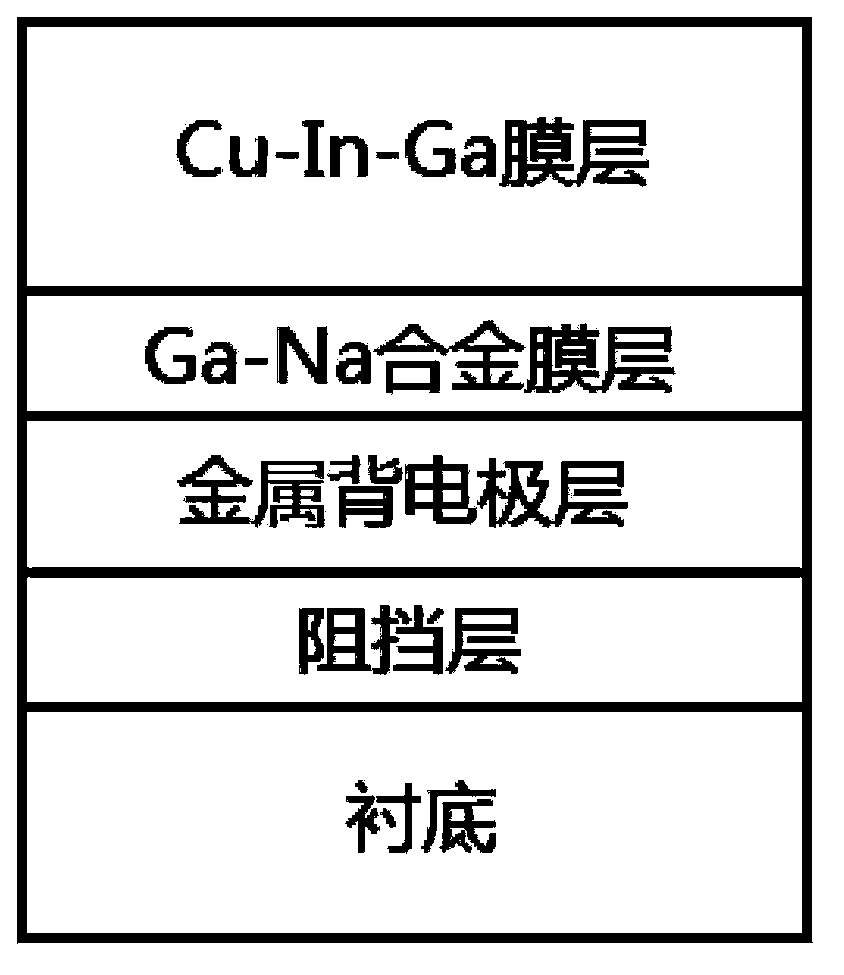

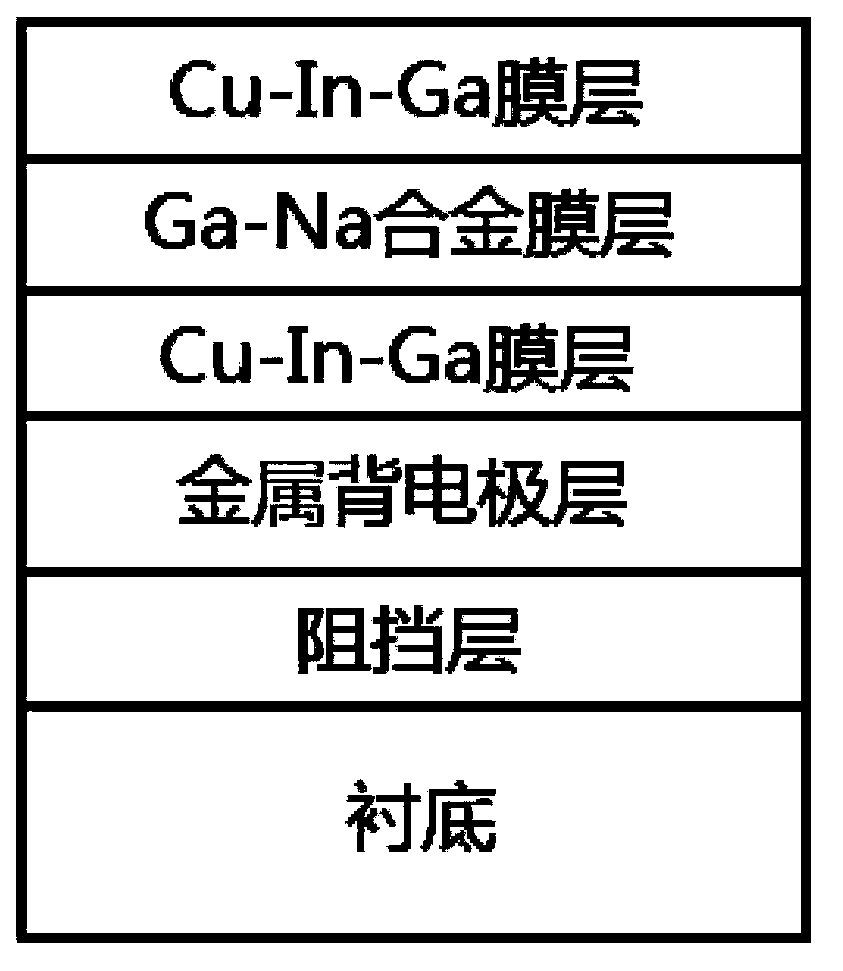

Sodium doping method for CIGS-based thin film photovoltaic material

ActiveCN103915516AAvoid poisoningPrecise control of sodium doping amountFinal product manufacturePhotovoltaic energy generationSodium dopingIndium

The invention discloses a sodium doping method for a CIGS-based thin film photovoltaic material. According to the method, a substrate, a barrier layer covering the surface of the substrate, a metal back electrode layer covering the barrier layer, a light absorption layer covering the metal back electrode layer, a buffering layer covering the light absorption layer and a transparent conductive window layer covering the buffering layer are included. Sodium doping is carried out on light absorption through the method of depositing Ga-Na alloy materials, heat treatment is carried out on the light absorption layer, and therefore the light absorption layer material containing sodium with the atomic ratio between copper and the sum of indium and gallium is 0.84-0.99 can be formed.

Owner:厦门神科太阳能有限公司

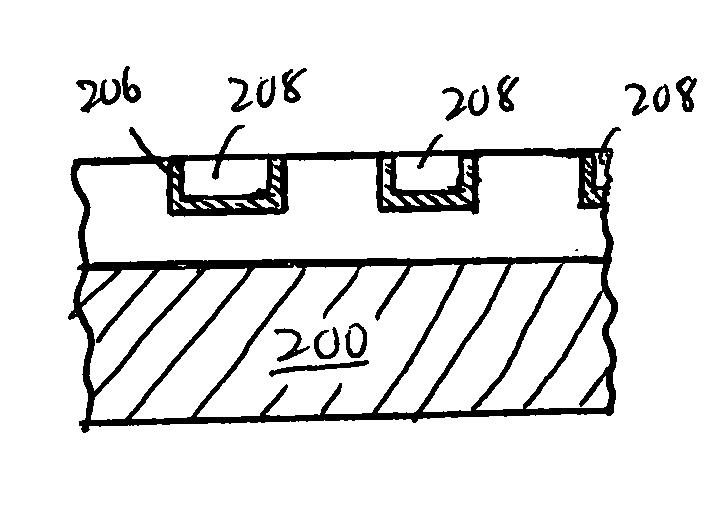

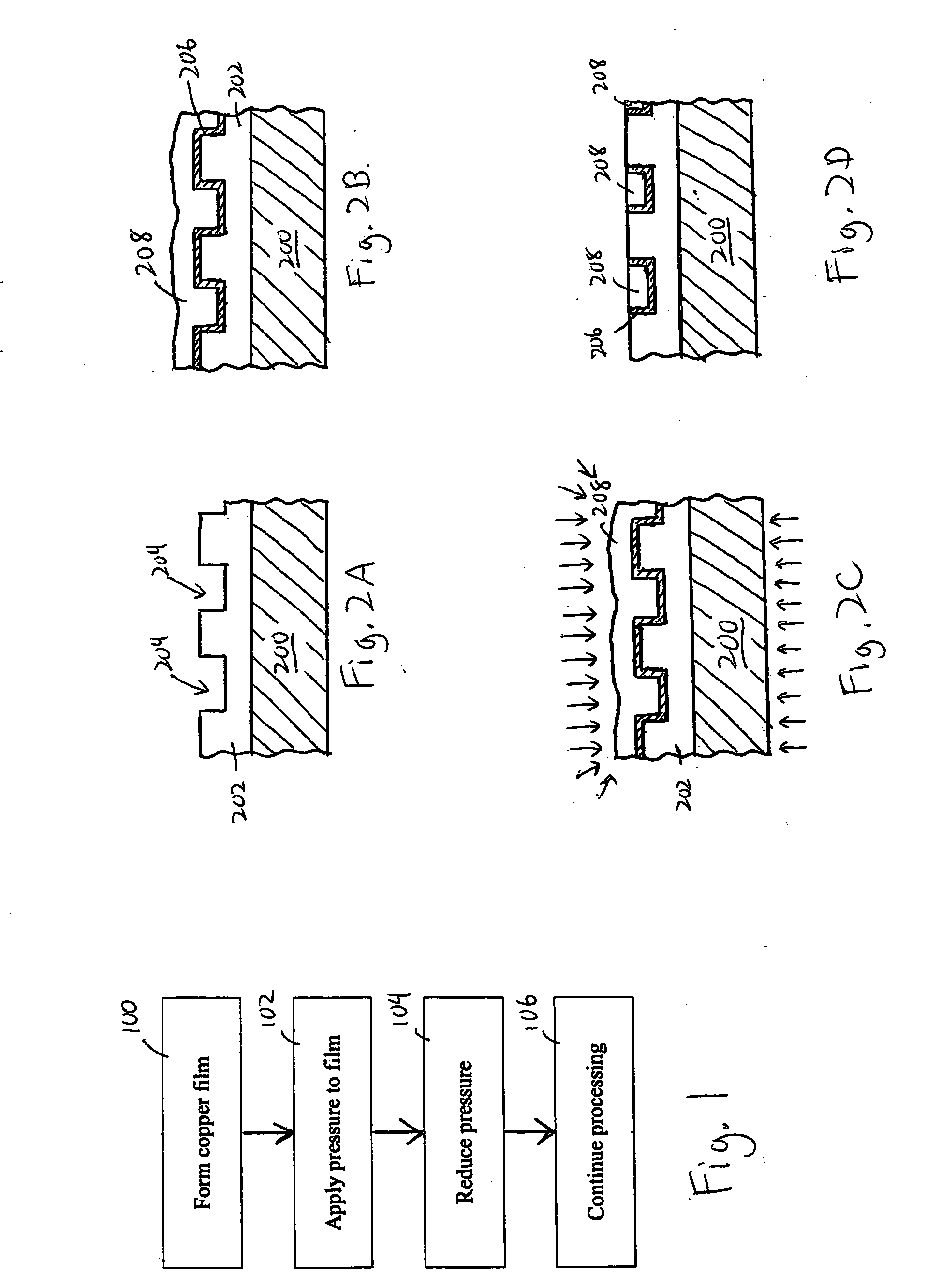

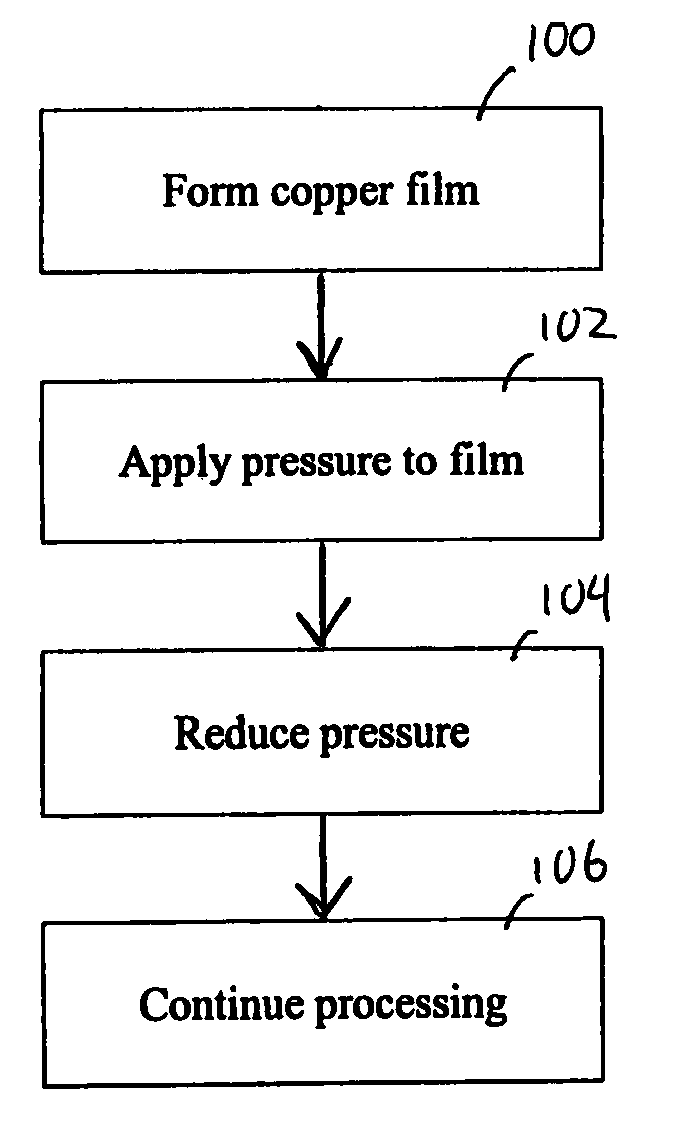

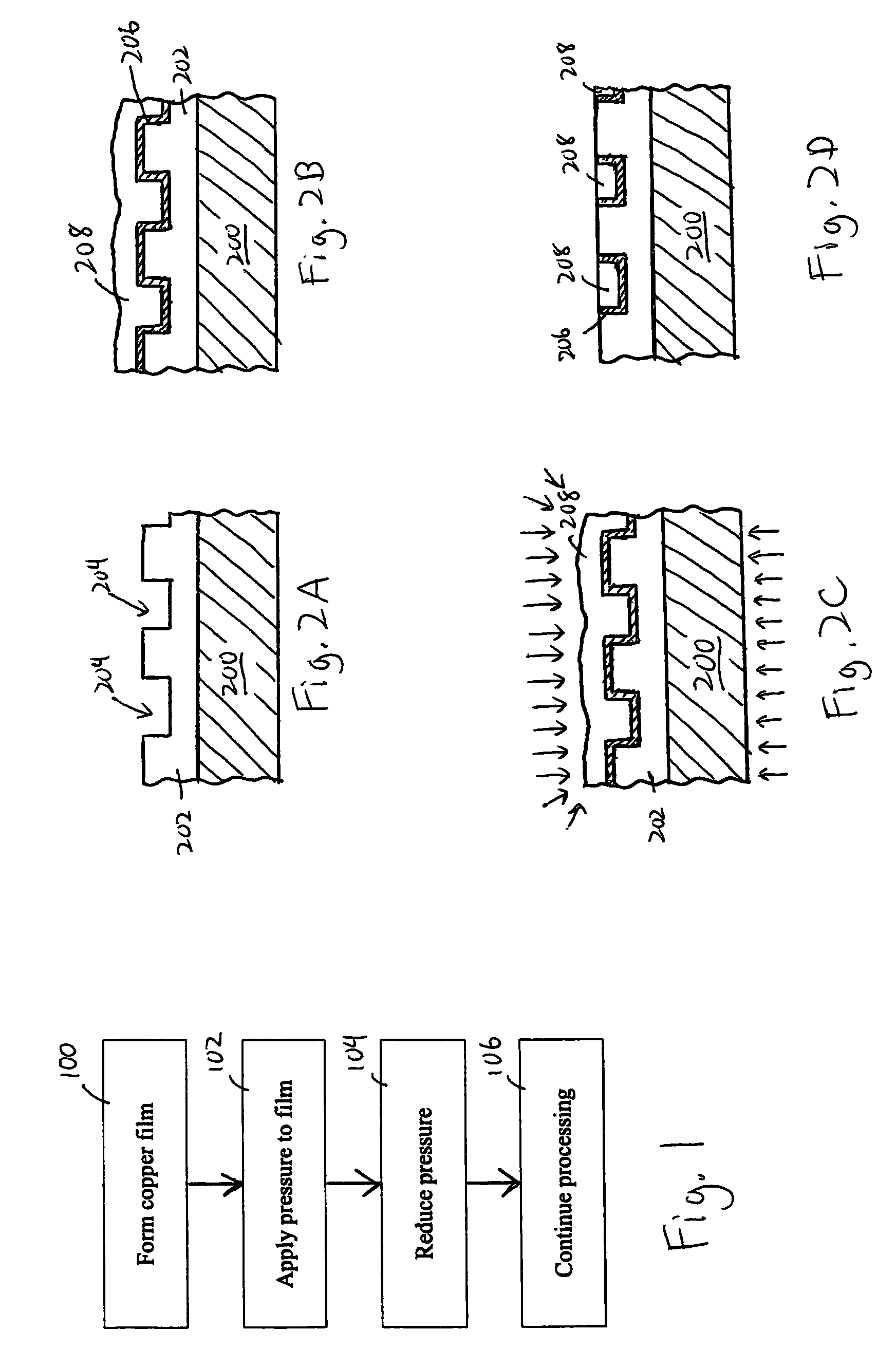

High pressure treatment for improved grain growth and void reduction

InactiveUS20060183326A1Fine grainEliminate microporositySemiconductor/solid-state device manufacturingDielectricRoom temperature

A copper film is annealed at high pressure to enhance grain growth and remove voids. Other films, such as dielectrics, may also be suitable. High pressure can be used in conjunction with temperatures lower than room temperature for annealing or higher temperatures may be used to further enhance grain growth.

Owner:WAFERMASTERS

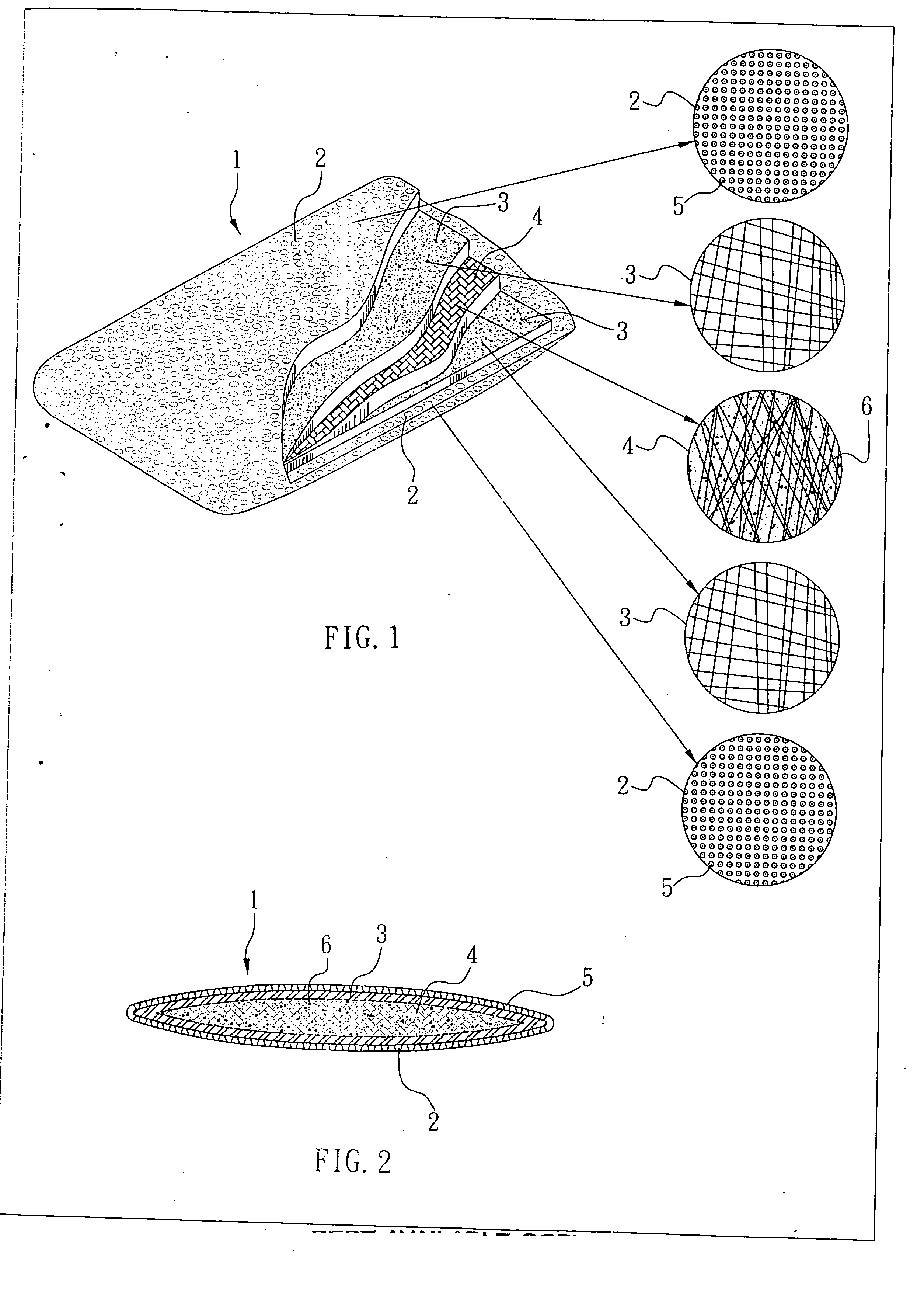

Three dimensional slow release agent absorbent dressing

InactiveUS20070178145A1Promote grain growthSuitable for useSynthetic resin layered productsAbsorbent padsFiberSecondary Infections

A three-dimensional slow release agent absorbent dressing particularly suitable for use in sinus cavity or infective wounds comprises a wound-contacting layer surrounding outside of the dressing. The wound-contacting layer is a soft-film covered with tapered apertures and the bottom surface of said tapered apertures faces outside to contact a wound for discharging exudate from the wound in many directions and transmitting exudate via a diffusion guiding layer to absorbent articles. Said absorbent articles formed of high-molecular polymeric fibers are mixed with a certain concentration of water-soluble agents, such as antiseptic agents, enzymes and growth factor agents, in a suitable amount. After exudate is into absorbent articles, said polymeric fibers expand forming into the shape of gel to avoid exudate flowing backward to the wound, which is more effective in preventing the wound from secondary infection.

Owner:CHOU CHANG TSUNG +1

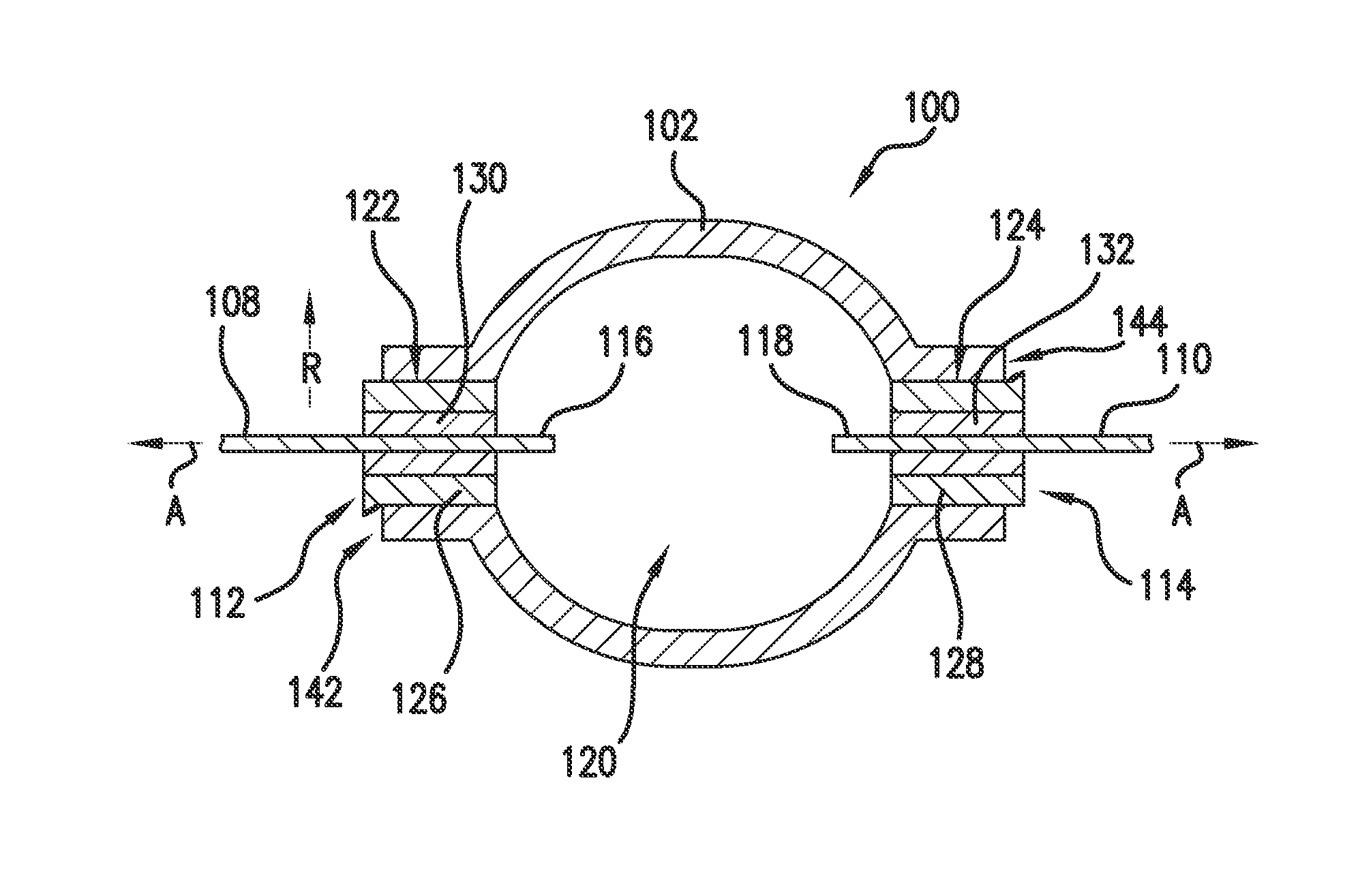

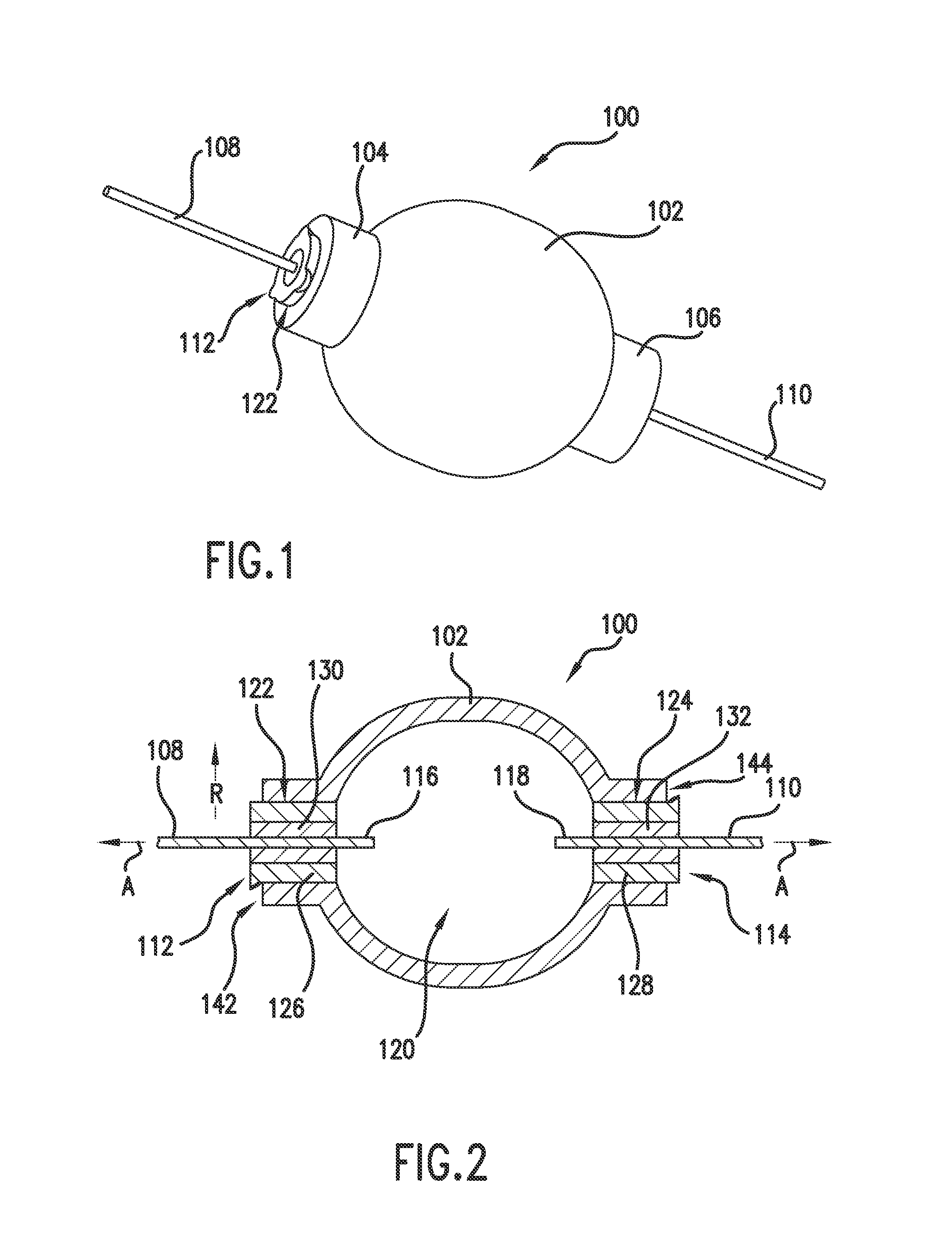

Voidless ceramic metal halide lamps

InactiveUS20140070695A1Improve light output and photometric performancePromote grain growthTube/lamp vessel fillingSolid cathode detailsPerformance improvementCermet

A voidless CMH lamp and a method of making such a lamp are provided. The CMH lamp includes a lamp body that receives at least one end plug. The end plug is constructed from a core of cermet material received within an outer layer of a ceramic material. An electrode is placed into the cermet material. The application of heat causes the cermet material to contract and eliminate voids between the lamp and cermet material. Co-sintering of the lamp, core, and outer layer provides a hermetic seal without necessarily using e.g., a sealing frit. Sintering of the ceramic material surrounding the cermet can be also used to improve light output and photometric performance of the lamp. The creation of one or more openings or recesses in the end plug can also provide performance improvements.

Owner:GENERAL ELECTRIC CO

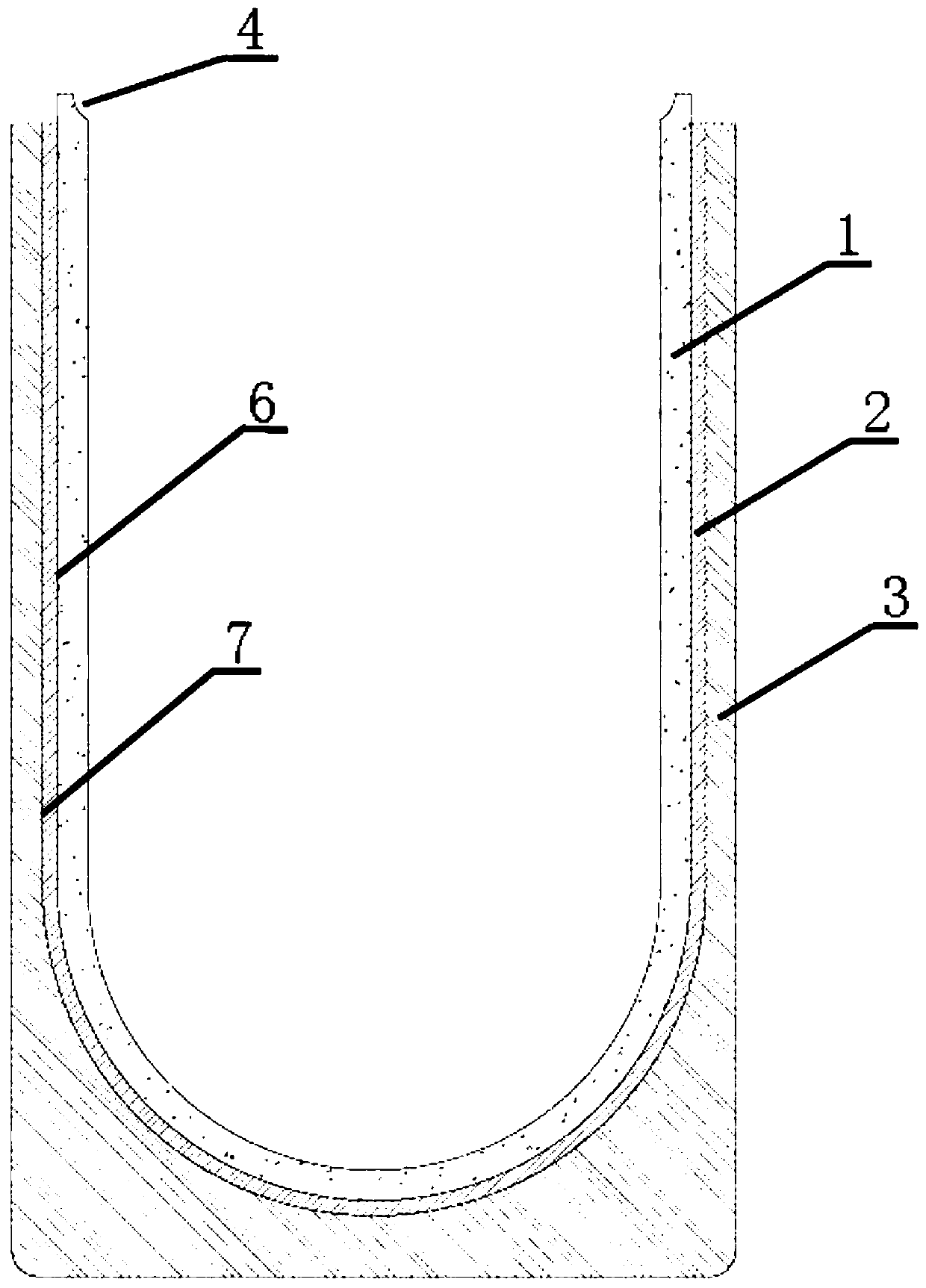

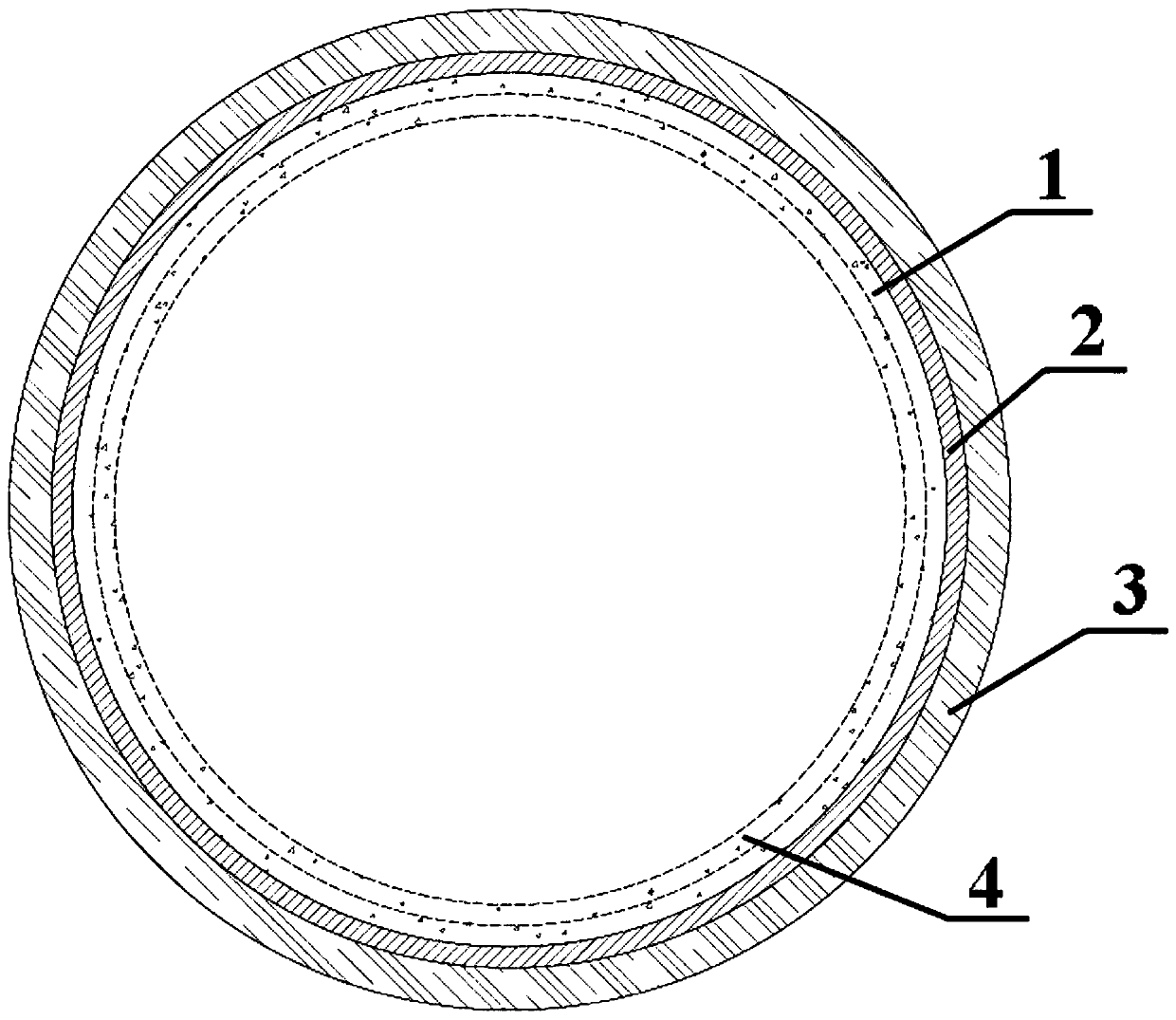

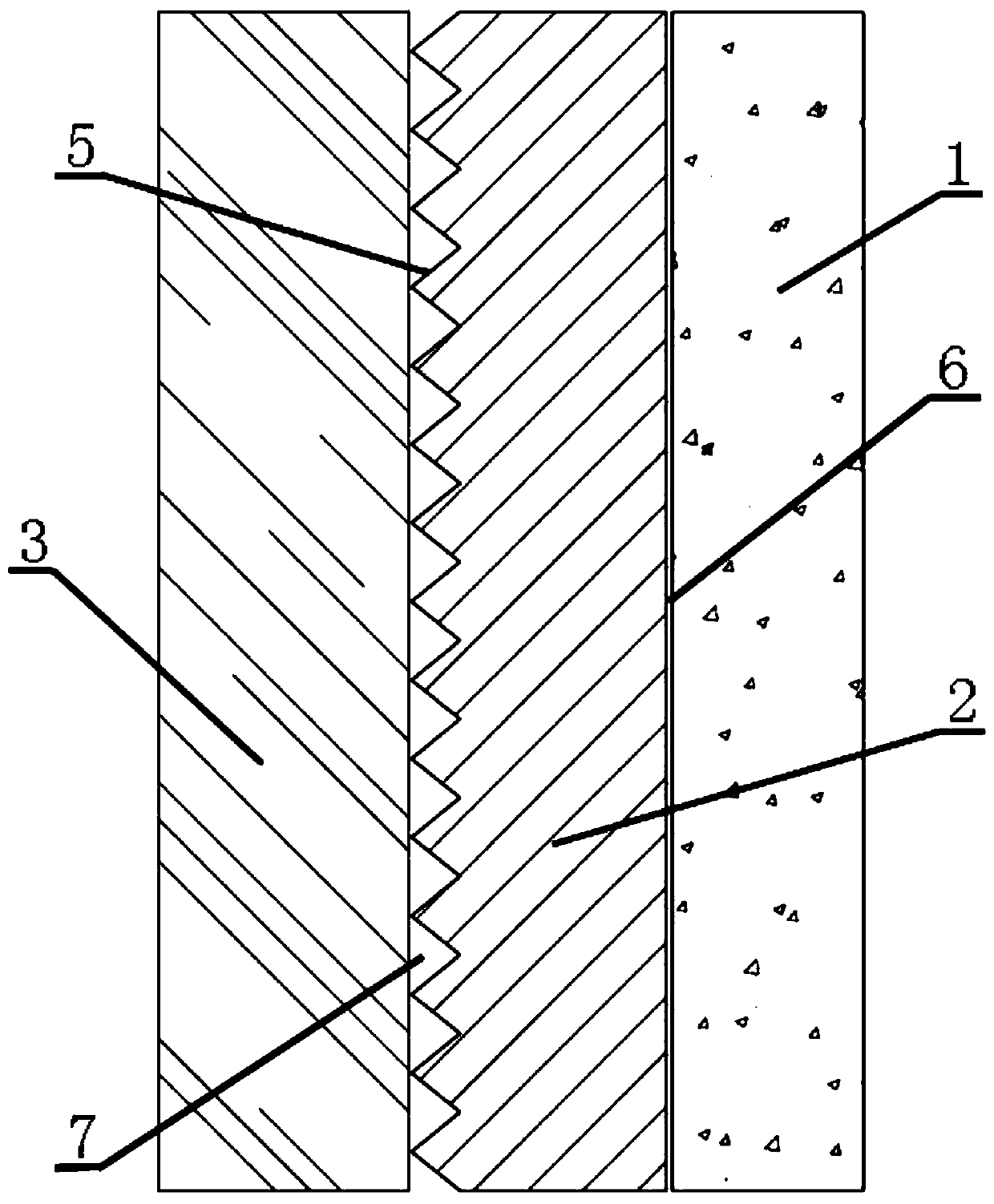

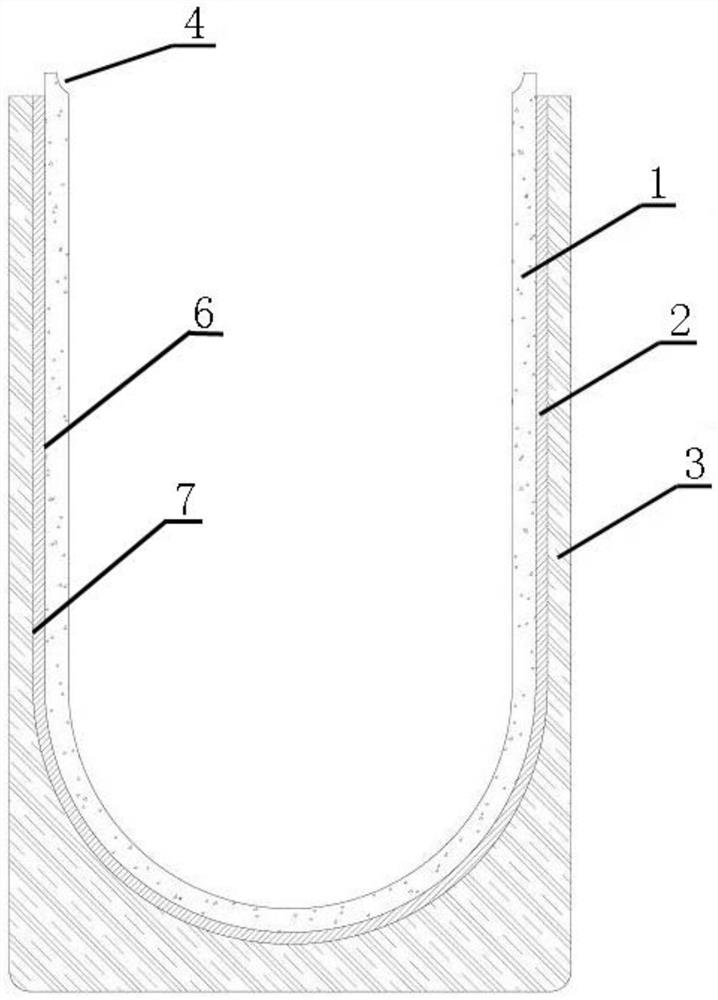

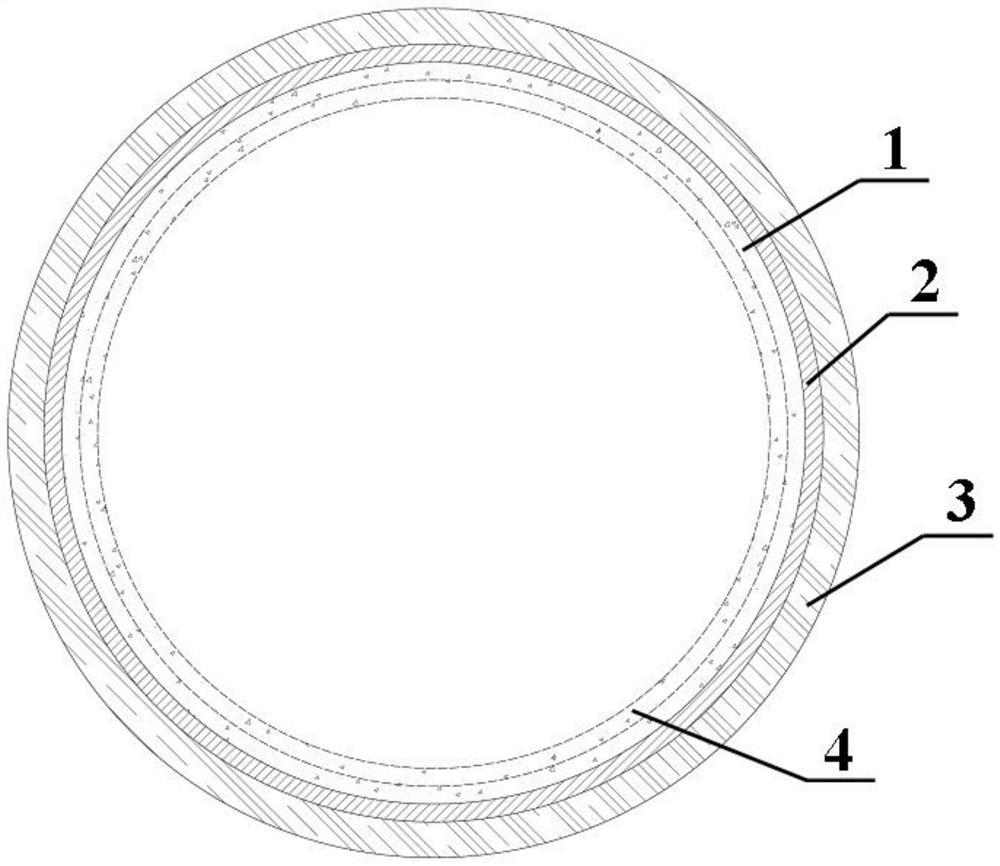

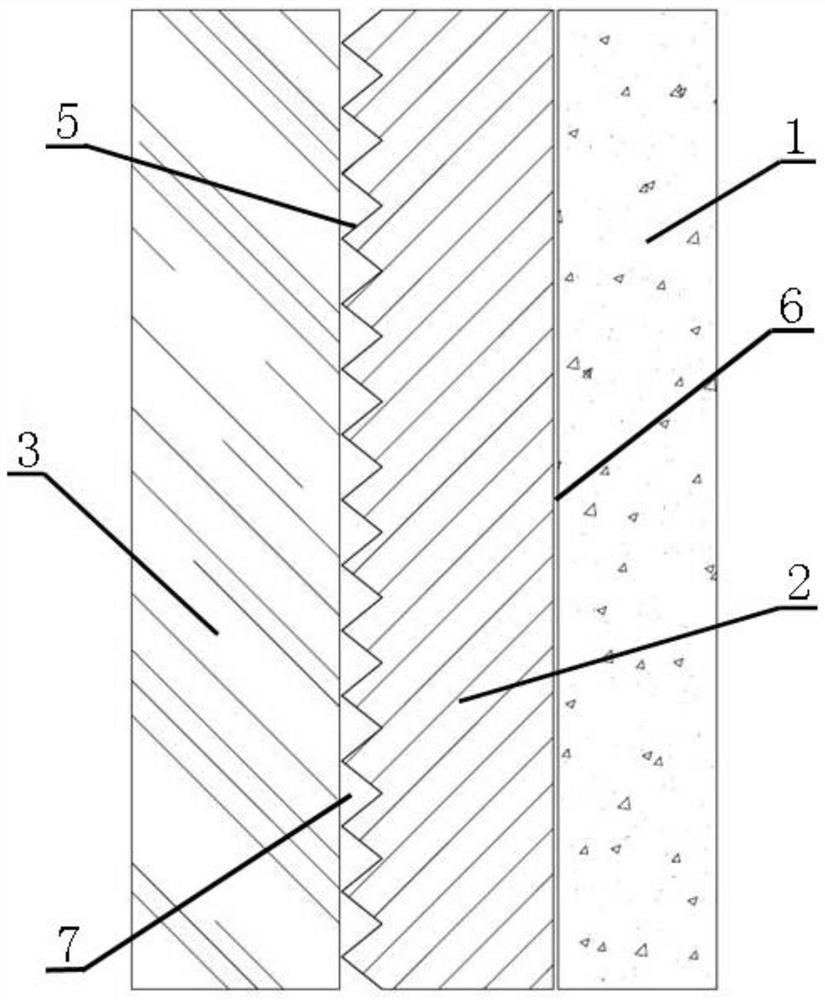

Composite multi-layer crucible for induction melting of bismuth aluminum alloy and preparation method thereof

ActiveCN109824370AImprove structural strengthChemically stableLayered productsCrucibleSmelting process

The invention discloses a composite multi-layer crucible for induction melting of a bismuth aluminum alloy and a preparation method thereof.The problem in the prior art thata crucible suitable for theinduction melting of the bismuth aluminum alloy does not exist is solved. The composite multi-layer crucible comprises an inner layer crucible, a middle layer crucible and an outer layer crucible which are fixedly connected from the inside to the outside; the inner layer crucible is prepared from 92.5-97.5 parts of cerium oxide, 1.0-2 parts of calcium oxide, 0.5-2.0 parts of bismuth oxide and 1.0-3.5 parts of silicon carbide; the middle layer crucible is made of graphite; the outer layer crucible is prepared from 90-95 parts of calcium oxide, 1-3 parts of magnesium oxide, 2-4 parts of ceriumoxide, 1-1.5 parts of zirconiaand 0.5-1.5 parts of clay. The composite multi-layer crucible has a high strength structure, can shield a considerable portion of an induced magnetic field, has stable chemical properties, and has no splashing phenomenon in the smelting process, the degree of oxygenation is low, some single-layer structures can be replaced and can be reused, and the service life is long.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

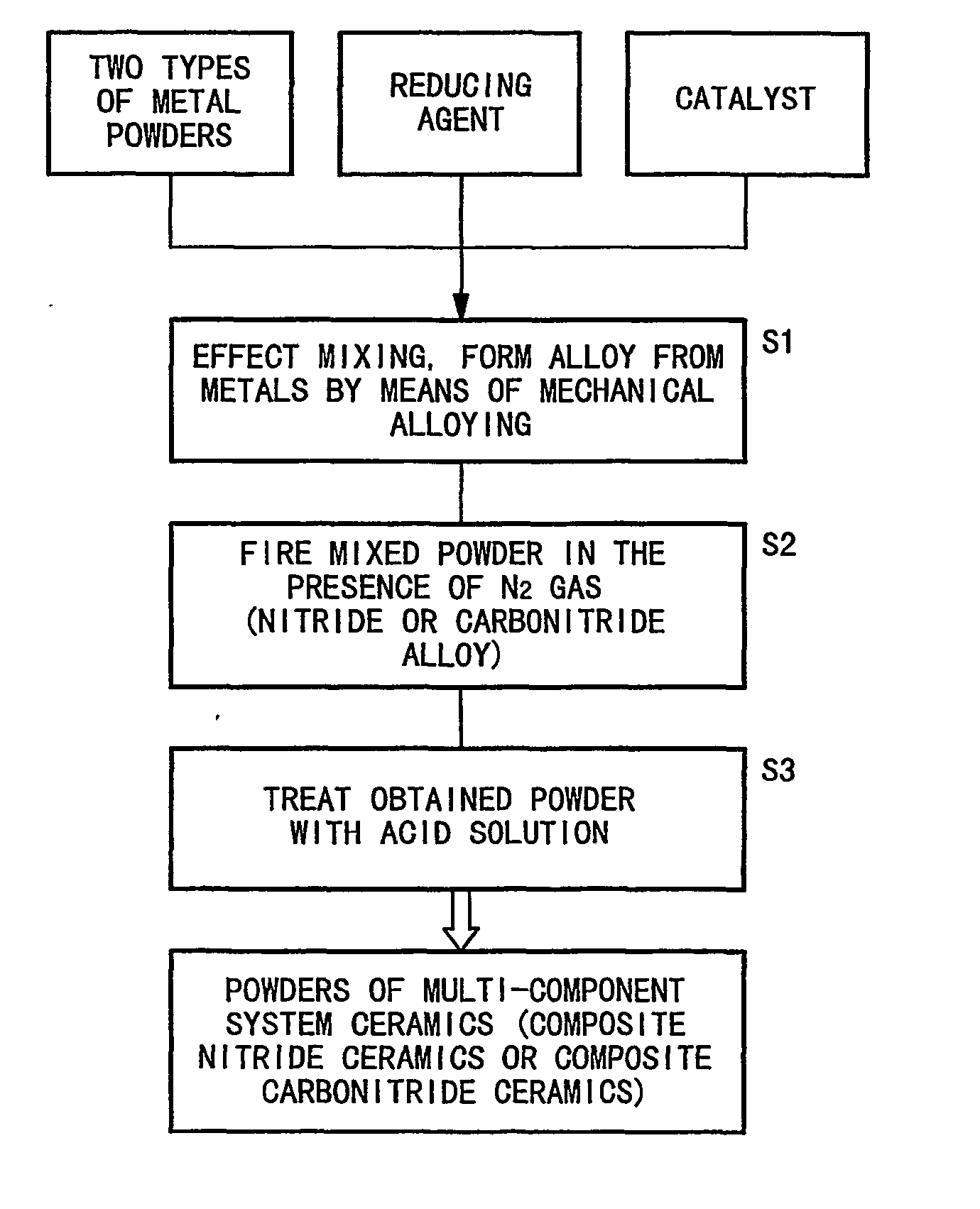

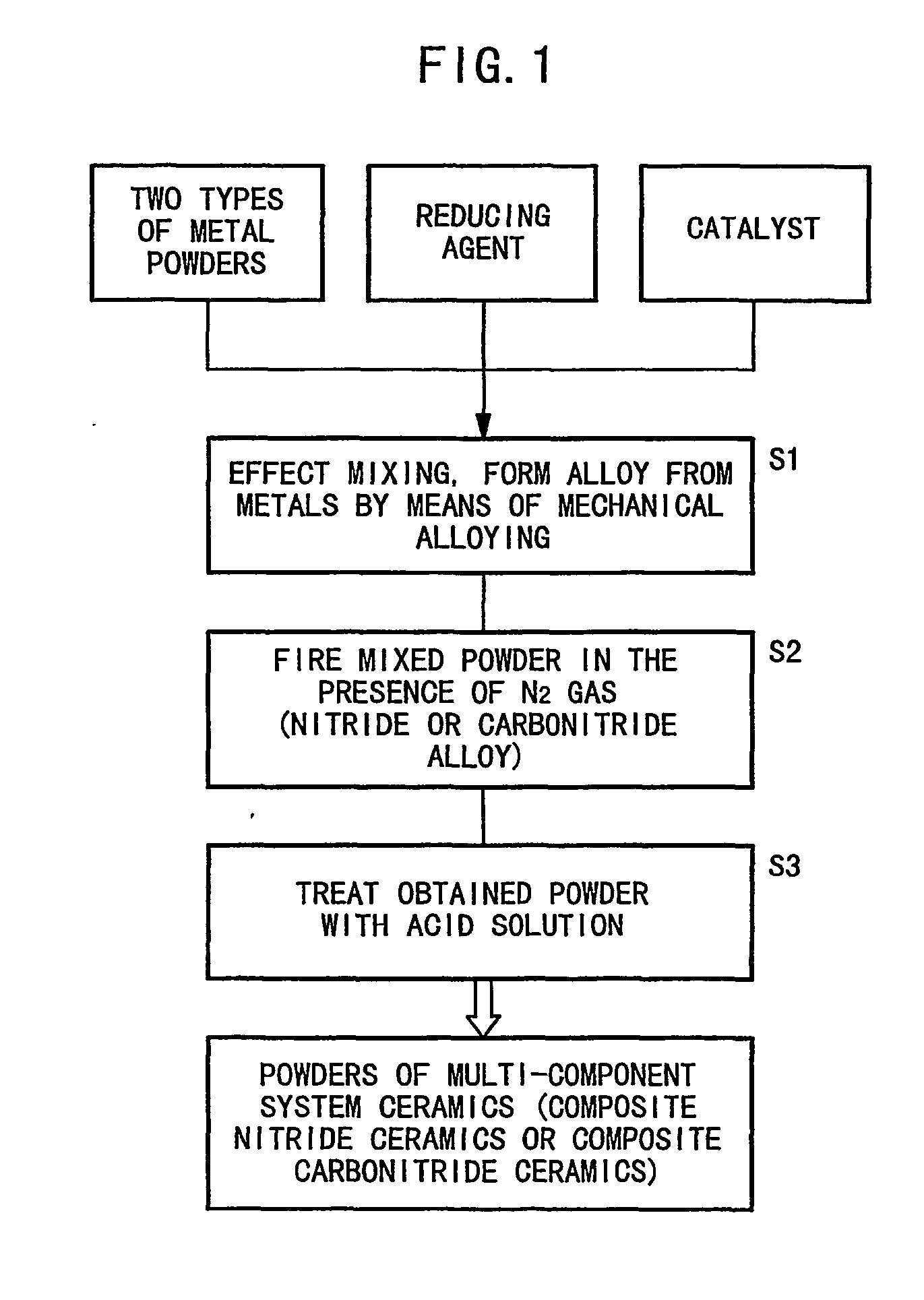

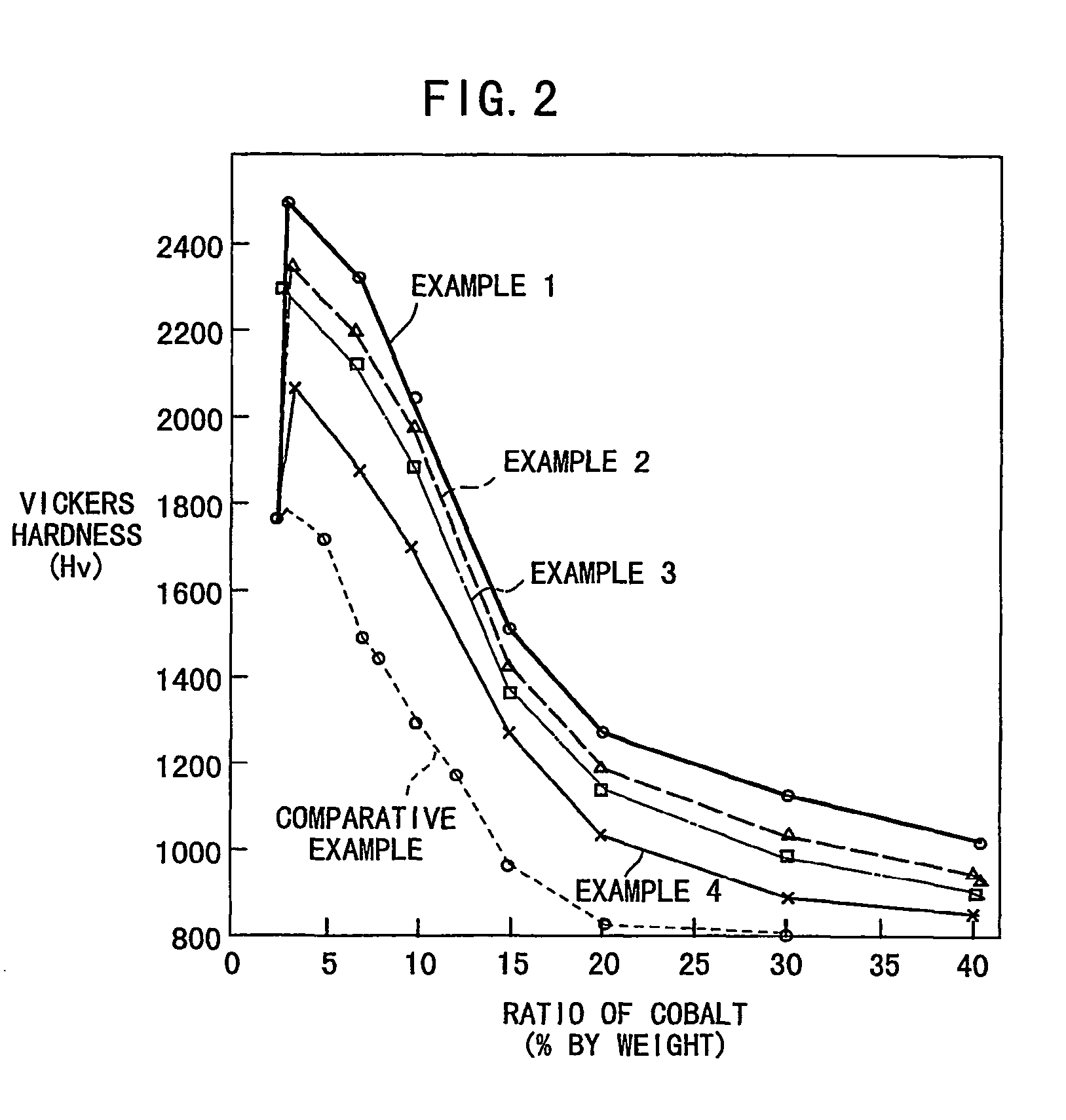

Composite material

A compact is obtained from a mixed powder of a multi-component system ceramics composed of constitutive elements of at least two metal elements selected from the group consisting of Ti, Al, V, Nb, Zr, Hf, Mo, Ta, Cr, and W, N, and optionally C; and Fe, Ni, Co, or an alloy composed of a constitutive element of at least one metal element of Fe, Ni, and Co. A composite material is prepared by sintering the compact.

Owner:HONDA MOTOR CO LTD

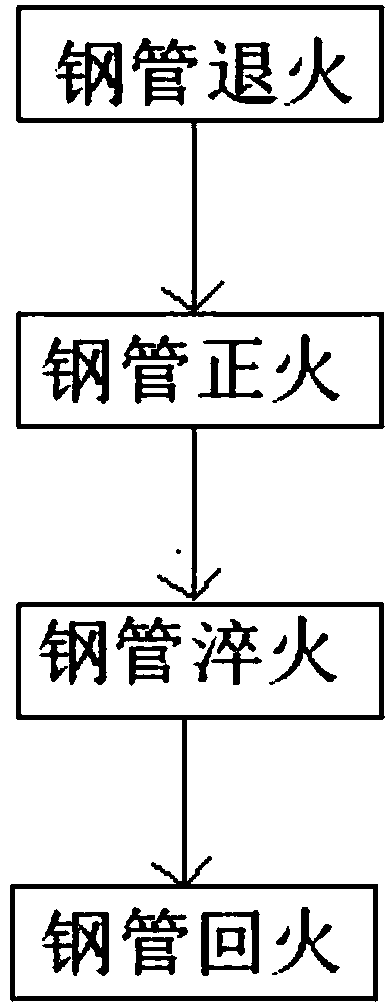

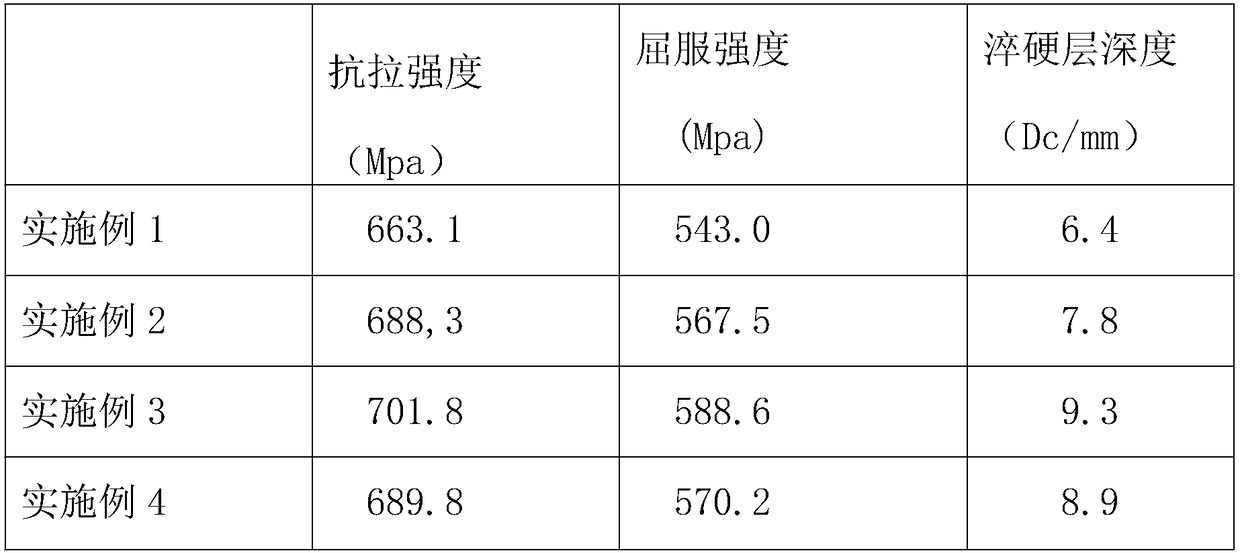

Heat treatment technology of steel-grade oil casing

InactiveCN108588354ARefine grain sizePromote grain growthFurnace typesQuenching agentsFree coolingLiquid nitrogen

The invention discloses a heat treatment technology of a steel-grade oil casing. The technology comprises the following steps of 1, annealing of a steel pipe, wherein the steel pipe is heated to 650-750 DEG C, subjected to heat preservation and cooled; 2, normalizing of the steel pipe, wherein the cooled steel pipe is heated to 750-850 DEG C, subjected to heat preservation and cooled; 3, quenchingof the steel pipe, wherein the cooled steel pipe is heated to 650-750 DEG C, subjected to heat preservation and then quickly cooled to obtain martensite; 4, tempering of the steel pipe, wherein the martensite steel pipe is heated to 650-750 DEG C, the tempering time is 1.5-2 h, and the steel pipe is subjected to heat preservation and then cooled. Two modes of oil cooling and natural cooling in air are adopted for cooling in the first step, the second step and the fourth step, and in the third step, the pipe is filled with liquid nitrogen, and a liquid nitrogen cooking mode is adopted. According to the heat treatment technology, the hardenability and mechanical properties of the steel pipe can be improved through heat treatment products, the bending protection effect is better, and the steel pipe is not easily broken.

Owner:LINZHOU FENGBAO PIPE

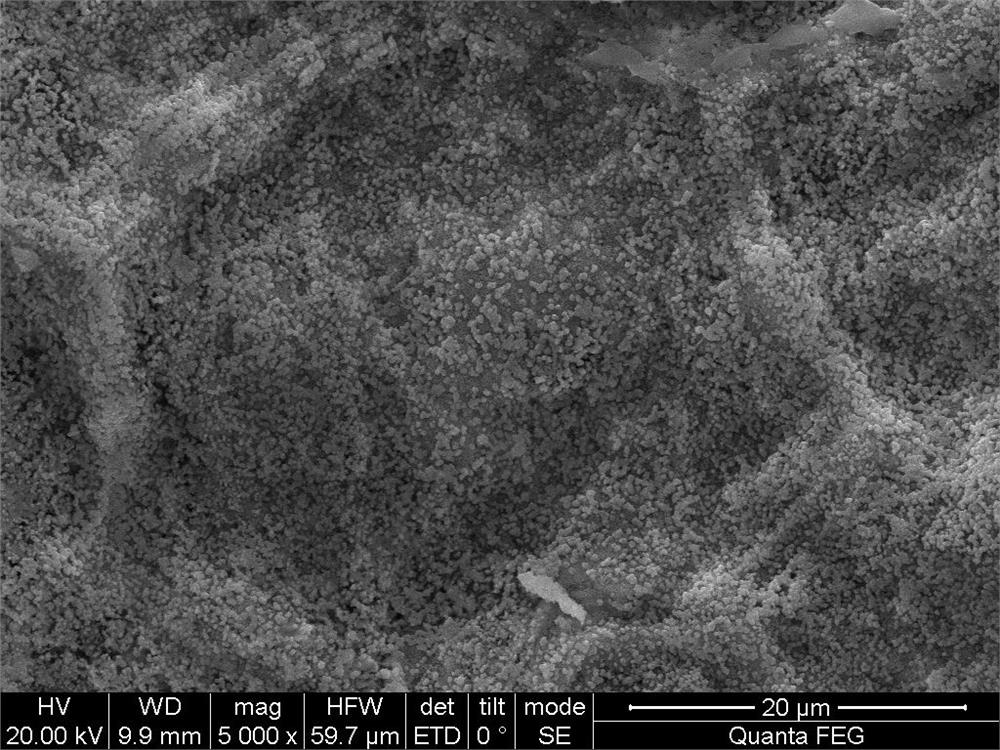

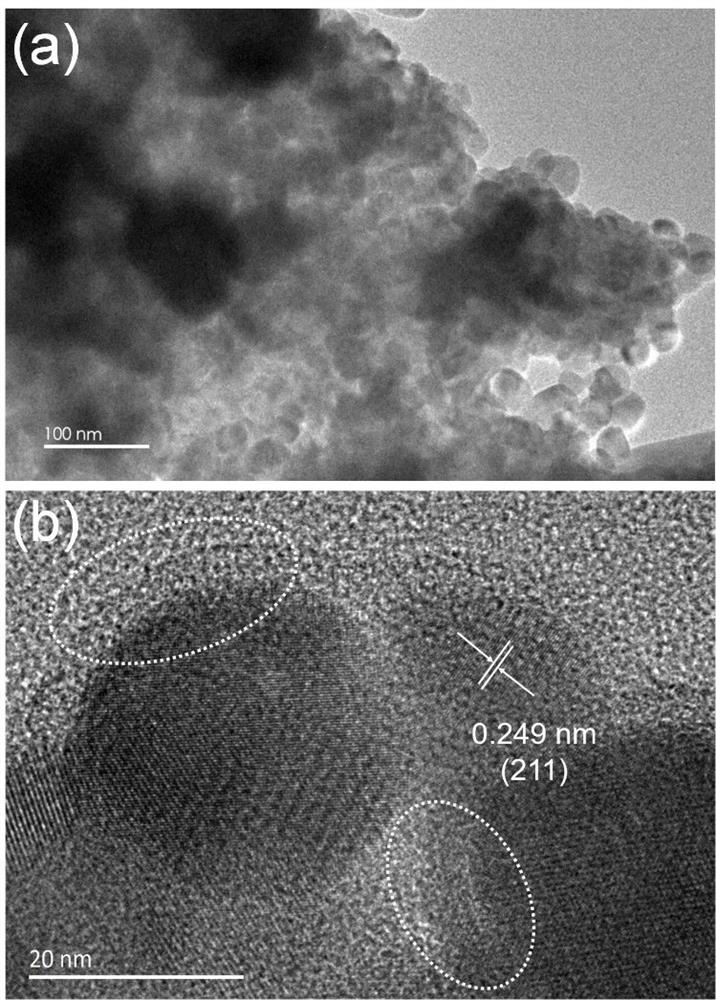

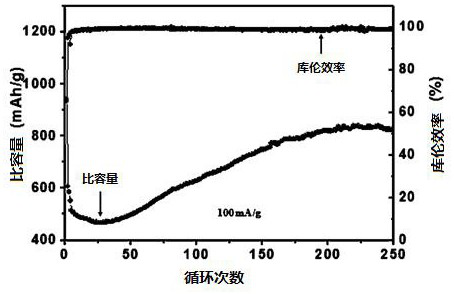

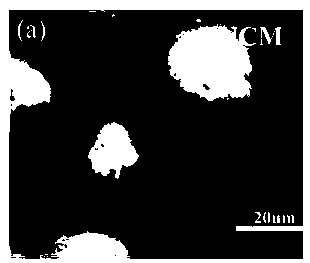

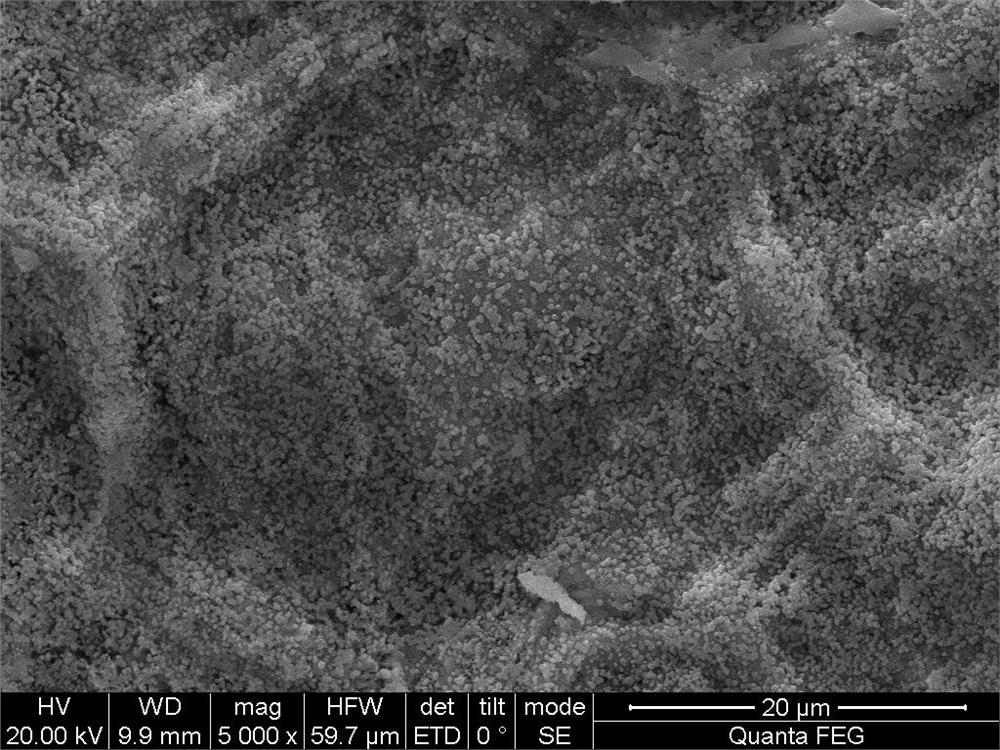

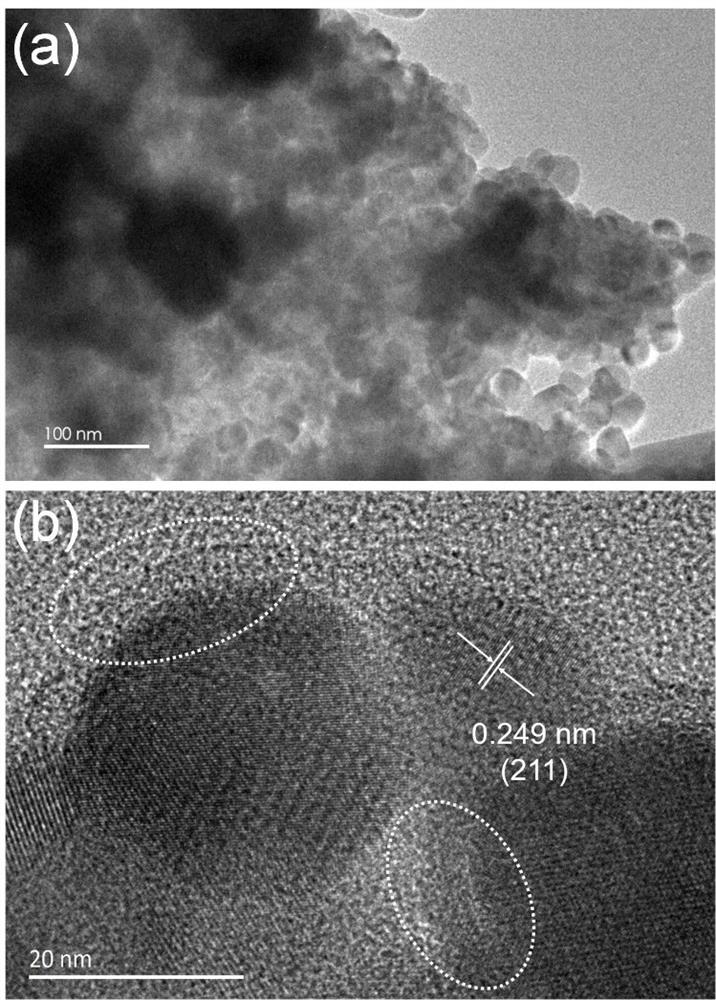

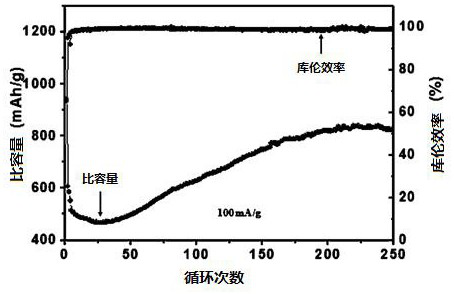

Carbon layer coated nano manganous-manganic oxide shell-core structure material and preparation method thereof

ActiveCN112382747APreserve biological formPromote growthMaterial nanotechnologySecondary cellsCarbon layerNanoshell

The invention relates to a carbon layer coated nano Mn3O4 shell-core structure material as well as a preparation method and application thereof. The nano Mn3O4@C material is synthesized by taking plant cell tissues as a structure-directing agent through dipping and step-by-step calcining. The synthesized material retains the biological form of a template, oxide nanoparticles and thin-layer biocharare formed in the step-by-step calcination process, retention of the biochar promotes Mn3O4 nano dispersion and grain growth, and the obtained material is uniform and free of obvious agglomeration. In the charging and discharging process of the battery, the biochar can effectively relieve structural collapse caused by lattice shrinkage in the lithium ion deintercalation process and provide support and protection for volume change, and in the circulation process, the carbon layer can limit nanoparticle aggregation and volume expansion and improve the performance of the battery. When the material is used as a lithium ion battery negative electrode material, after 250 cycles, the specific capacity is stabilized at 840 mAhg<-1>, and the cycle Coulombic efficiency is stabilized at 99%.

Owner:SUZHOU UNIV OF SCI & TECH

Method for producing crystallographically-oriented ceramic

InactiveUS20080295948A1Enhance crystallographic orientationSimple processPiezoelectric/electrostrictive device manufacture/assemblyCeramic layered productsCrystal planeInorganic materials

A method for producing a crystallographically-oriented ceramic includes the steps of forming a first sheet with a thickness of 10 μm or less containing a first inorganic material in which grain growth occurs at a first temperature or higher and a second sheet containing a second inorganic material in which grain growth occurs at a second temperature higher than the first temperature, laminating one or more each of the first and second sheets to form a laminated body, firing the laminated body at a temperature equal to or higher than the first temperature and lower than the second temperature to cause grain growth in the first inorganic material, and then firing the laminated body at a temperature equal to or higher than the second temperature to cause grain growth in the second inorganic material in the direction of a crystal plane of the first inorganic material.

Owner:NGK INSULATORS LTD

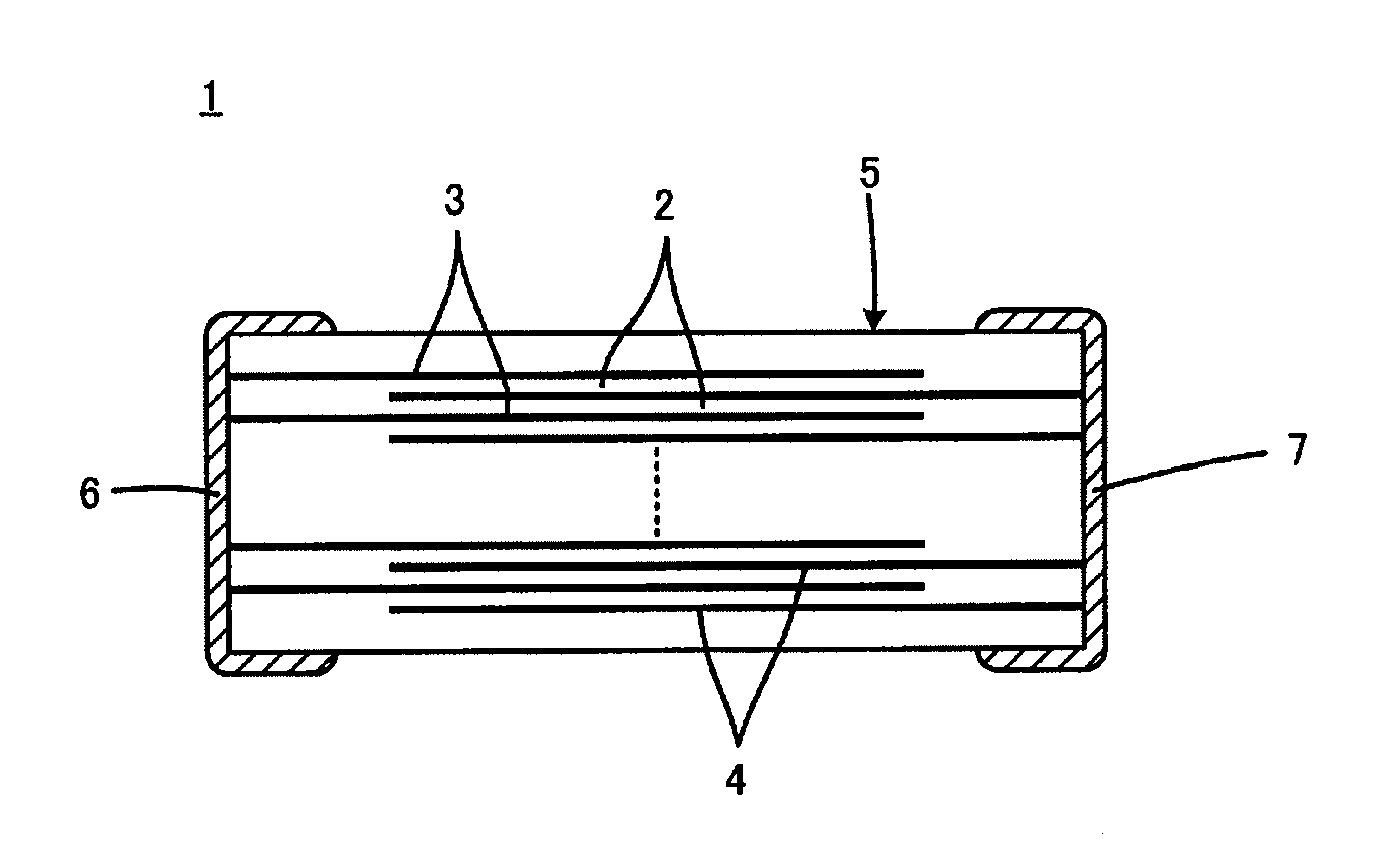

Dielectric ceramic and manufacturing method therefor and laminated ceramic capacitor

ActiveUS8358494B2Fine grainImprove reliabilityZirconium compoundsFixed capacitor dielectricBarium titanateCeramic capacitor

A laminated ceramic capacitor is provided which is excellent in reliability even when its dielectric ceramic layers thinned. For a dielectric ceramic in a laminated ceramic capacitor, a ceramic is used which includes a main component containing a barium titanate based composite oxide represented by the general formula: (Ba1-h-m-xCahSrmRex)k(Ti1-n-yZrnMy)O3, where Re is La or the like, M is Mg or the like, and the respective relationships of 0.05≦x≦0.50, 0.02≦y≦0.3, 0.85≦k≦1.05, 0≦h≦0.25, 0≦m≦0.50, and 0≦n≦0.40 are satisfied; and an accessory component as a sintering aid, wherein the average grain diameter of crystal grains in a sintered body is 0.6 μm or less.

Owner:MURATA MFG CO LTD

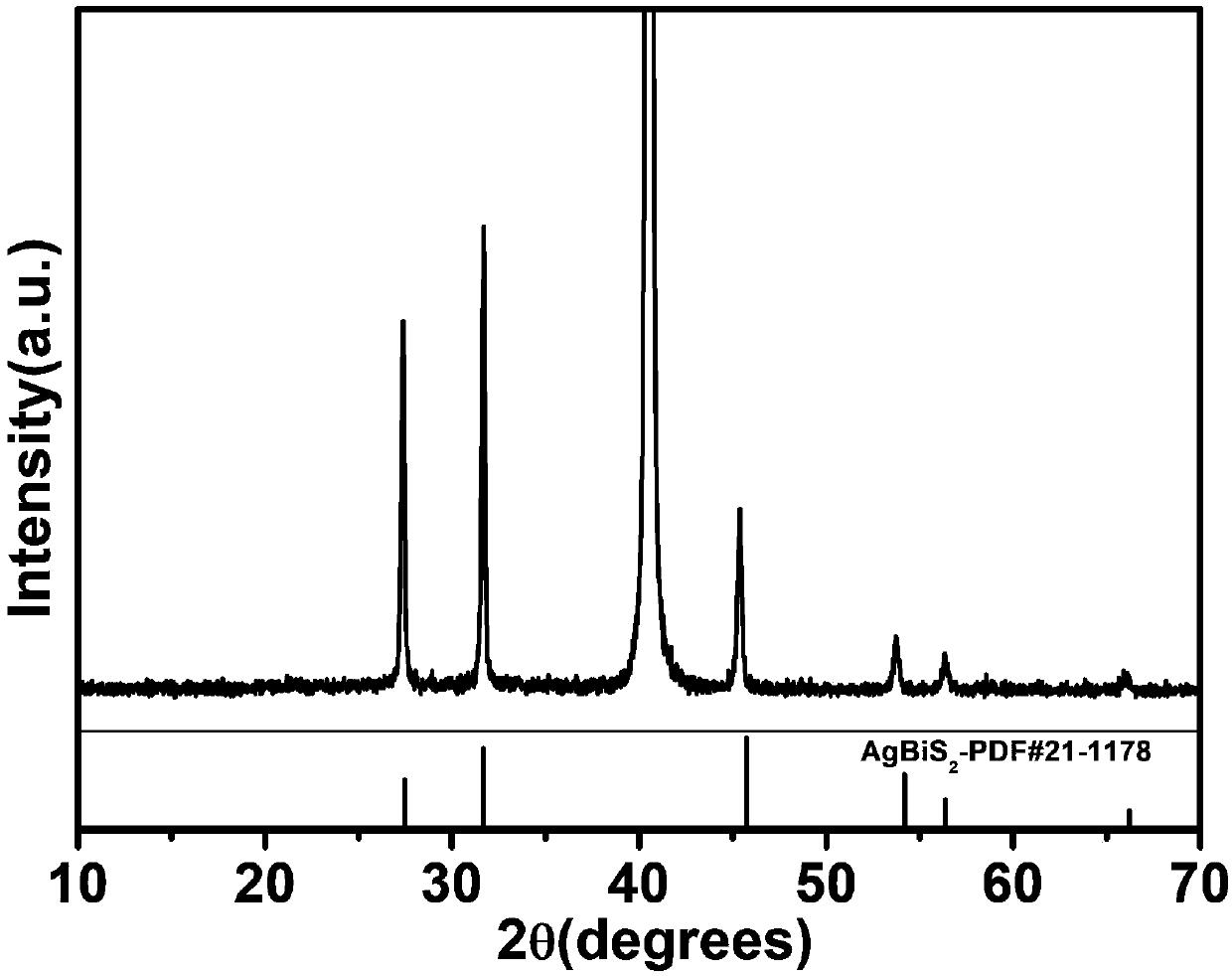

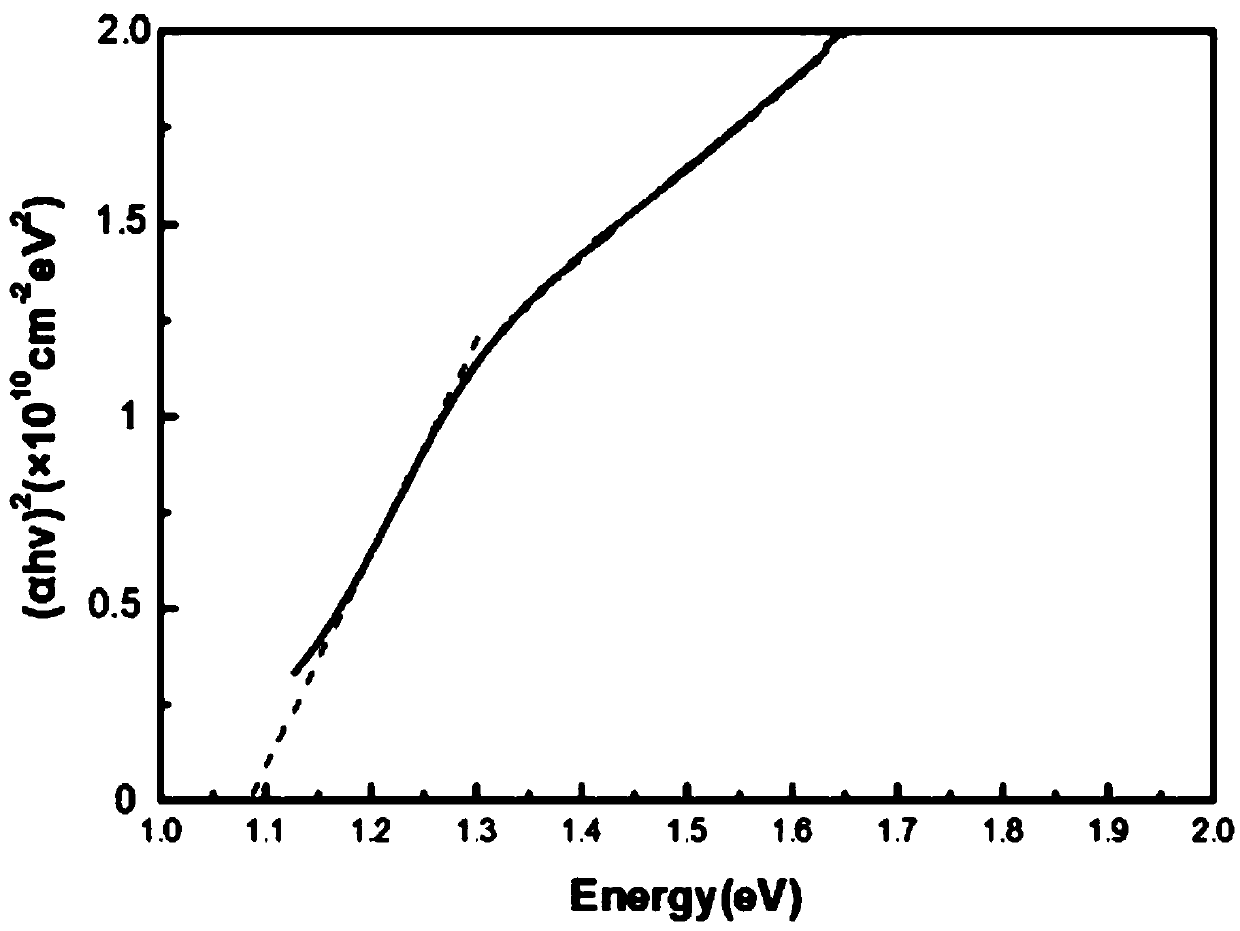

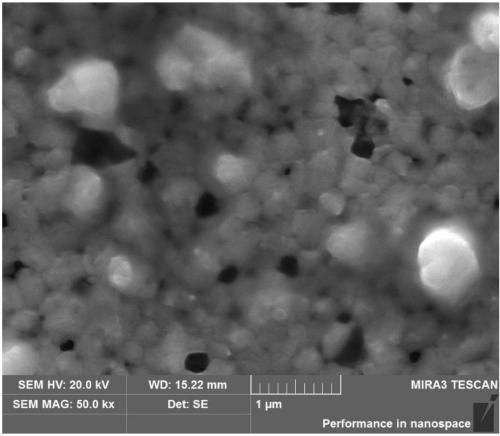

Method for preparing AgBiS2 semiconductor film

PendingCN109686817ADense growthGood lookingFinal product manufactureBismuth compoundsElectrical batteryThiourea

Owner:CENT SOUTH UNIV

Method for preparing forsterite refractory material through microwave heating

The invention relates to a method for preparing forsterite refractory material through microwave heating. The method includes: well mixing nickel-iron slag, magnesia powder and a binder, press-shaping to obtain a blank, putting the blank after being dried into a microwave reactor, and holding temperature of 1250-1340 DEG C for calcining for 10-60min to obtain a forsterite refractory material; according to formula composition, regulating and controlling a gradient temperature increase program of the microwave heating process to optimize phase transformation of the nickel-iron slag and grain growth process of the refractory material; combining with grain ratio of the nickel-iron slag and the magnesia powder, and accurately controlling porosity of the forsterite refractory material to finally obtain the forsterite refractory material which has high compressive strength and excellent thermal shock resistance. The method has the advantages of high sintering speed, low energy consumption, high production efficiency, high resource utilization rate, environment friendliness and excellent material performance and has good industrial application prospect.

Owner:CENT SOUTH UNIV

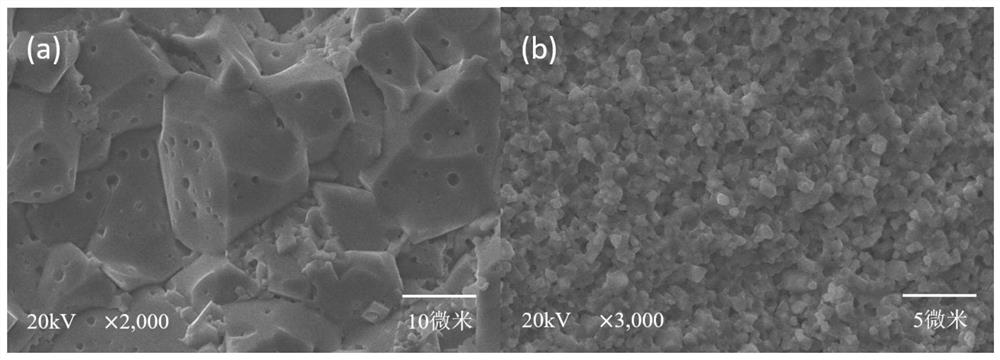

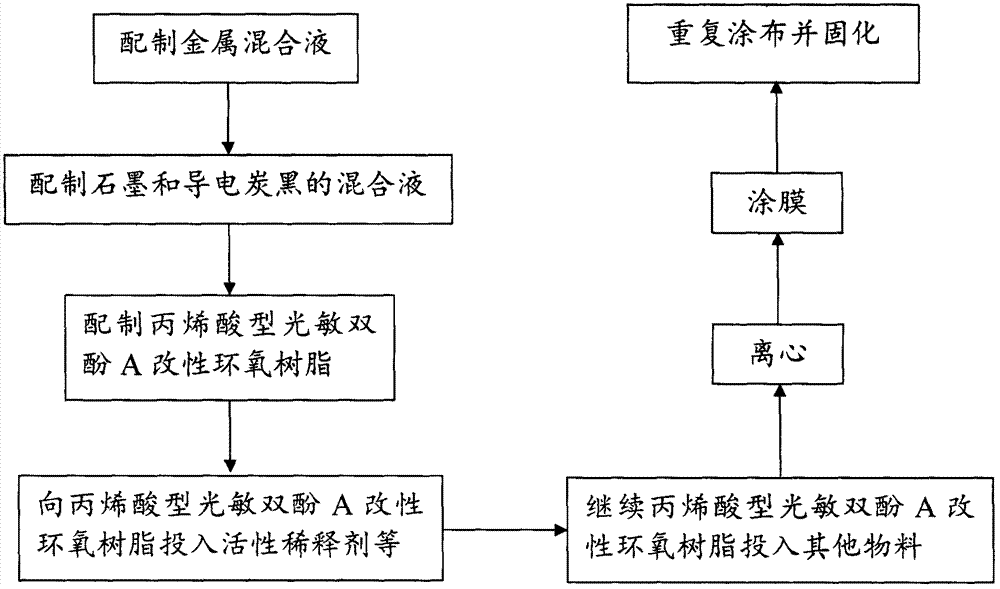

Method for non-vacuum preparation of nano thin film by taking metallic compound as precursor

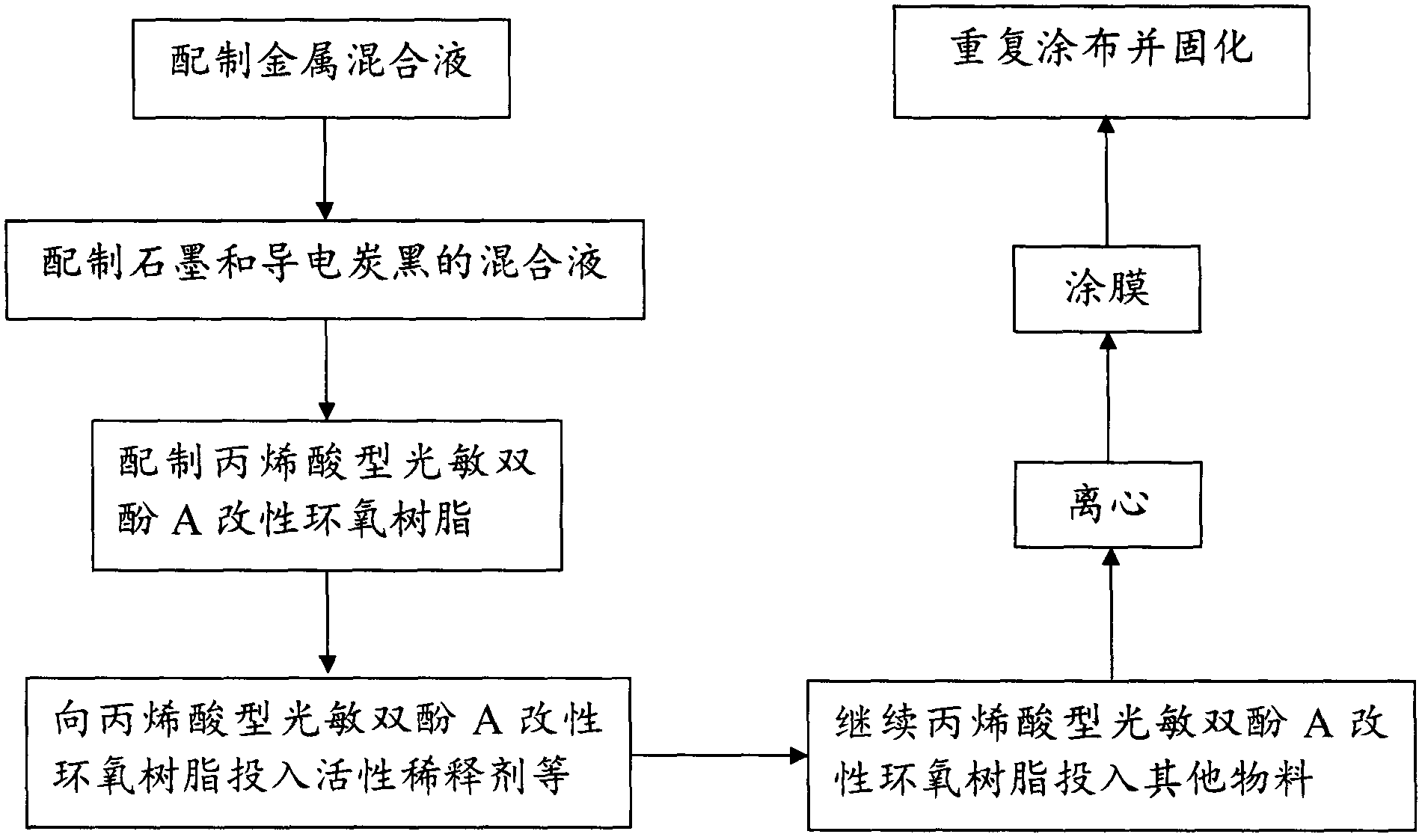

The invention discloses a method for non-vacuum preparation of a nano thin film by taking a metallic compound as a precursor. The method comprises the steps of S1. preparing a metallic nano mixing solution; S2. preparing a graphite and superconductive carbon black mixing solution; S3. preparing acrylic photosensitive bisphenol A modified epoxy resin; S4. adding a reactive diluent and the like to the acrylic photosensitive bisphenol A modified epoxy resin; S5. continuing adding other materials to the acrylic photosensitive bisphenol A modified epoxy resin; S6. centrifuging; S7. coating; and S8. recoating and curing. According to the preparation method of the metallic compound thin film, which is disclosed by the invention, a non-vacuum precursor 'ink' offset printing spraying method is adopted to spray the precursor on an elastic substrate to form a metallic absorbed layer thin film; by means of a spray conversion method, dosages of raw materials and additive are easily controlled, ingredients, thickness and uniformity of the film can be conveniently controlled, and full use of addition of the superconductive carbon black and graphite can be achieved; the prepared product is low in granularity, high in bulk crystallization density, and capable of effectively improving a forbidden gap.

Owner:上海先着点光电科技有限公司

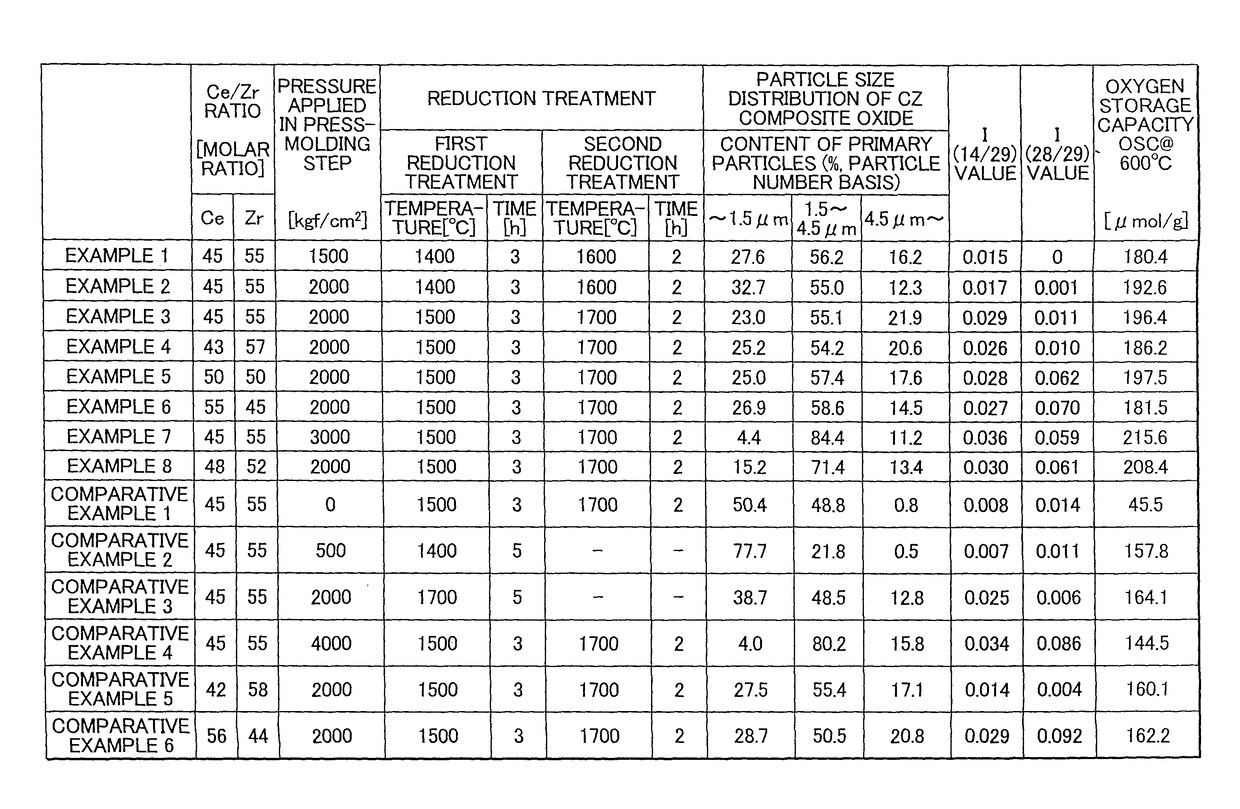

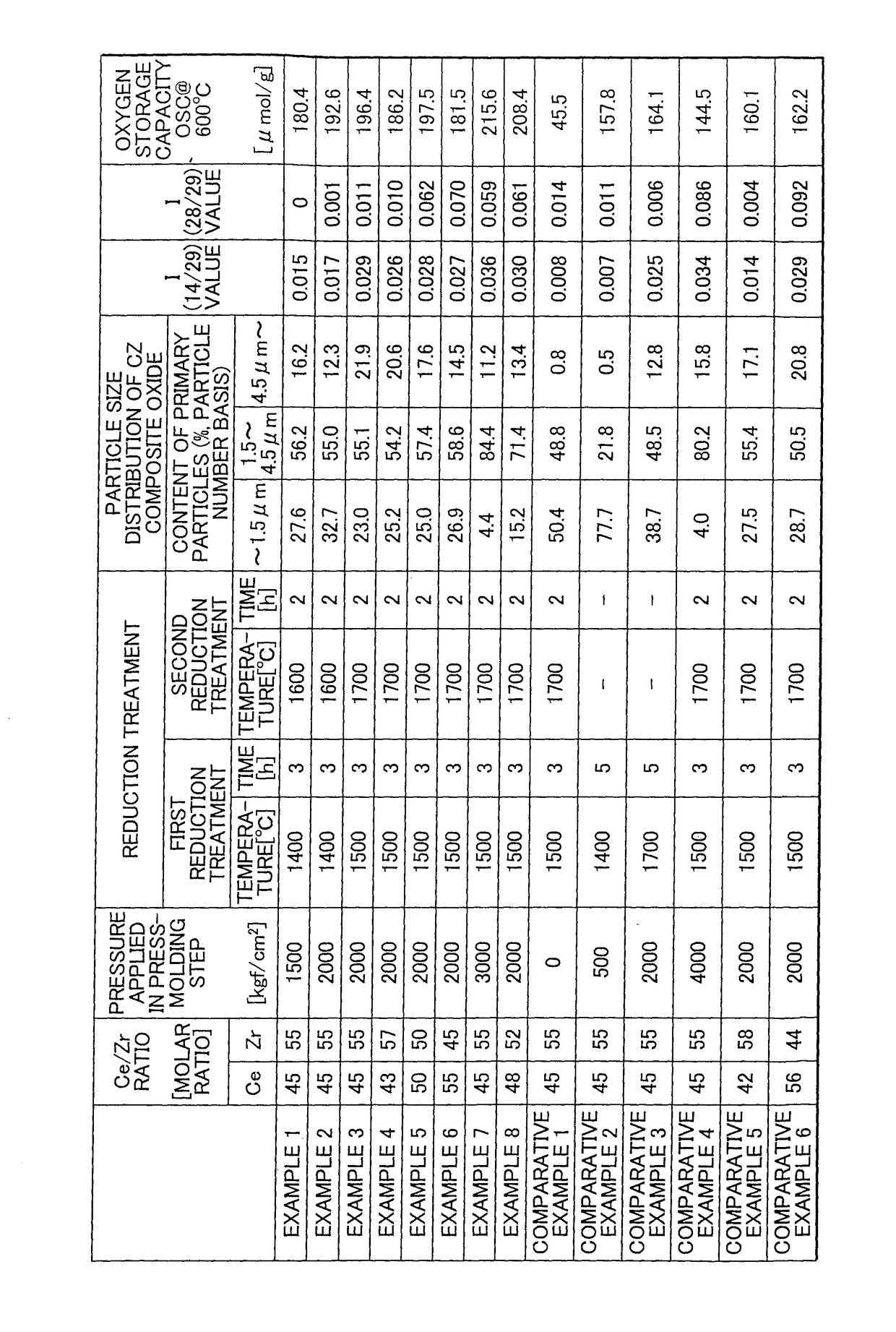

Ceria-zirconia-based composite oxide and method for producing same, and exhaust gas purification catalyst including ceria-zirconia-based composite oxide

ActiveUS10065179B2Reducing treatmentPromotes crystal growthZirconium compoundsDispersed particle separationCerium(IV) oxideComposite oxide

Owner:TOYOTA JIDOSHA KK +1

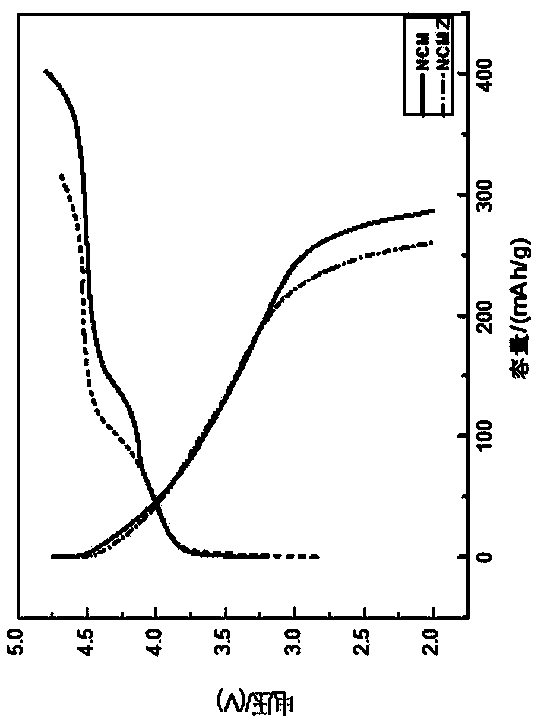

Quaternary lithium-rich manganese-based positive electrode material using Zn to replace Mn and preparation method of quaternary lithium-rich manganese-based positive electrode material

InactiveCN110943214AIncreased grain growthPromote grain growthCell electrodesSecondary cellsElectrical batteryPhysical chemistry

The invention discloses a quaternary lithium-rich manganese-based positive electrode material using Zn to replace Mn and a preparation method of the quaternary lithium-rich manganese-based positive electrode material, and belongs to the technical field of lithium ion battery positive electrode material production. A carbonate coprecipitation method is adopted, a metal salt solution and a precipitant solution are controlled to react in a base solution to prepare a precursor, and the precursor is calcined to obtain the positive electrode material with the structural formula of xLi2MnO3-(1-x) LiMO2. According to the method disclosed by the invention, the grade resonance is promoted, a more powerful support is provided for the material, and the stability of the material is improved, so that the performance of the positive electrode material is obviously improved, and the circularity is improved.

Owner:海安常州大学高新技术研发中心

Low-loss LiZnTiMn gyromagnetic ferrite material and preparation method thereof

PendingCN113845359AAchieve sinteringAchieve preparationInorganic material magnetismFerrite (magnet)Ceramic materials

The invention provides a low-loss LiZnTiMn gyromagnetic ferrite material and a preparation method thereof, and belongs to the technical field of magnetic materials. The gyromagnetic ferrite material comprises a main material and a composite sintering aid, the weight percentage of the main material is 99.0%-99.5%, and the weight percentage of the composite sintering aid is 0.5%-1.0%; the main material is Li < 0.42 > Zn < 0.27 > Ti < 0.11 > Mn < 0.1 > Fe < 2.1 > O < 4 >, the composite sintering aid is composed of Bi2O3 and Nb2O5, and the mass ratio of Bi2O3 to Nb2O5 is 5: (1-5). The low-temperature sintering of LiZnTiMn is realized by optimizing the sintering process and adding the composite sintering aid, the LiZnTiMn ferrite material with low loss is obtained, the coercive force of the material is reduced, and the performance of the material is optimized.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

The method of non-vacuum preparation of nanometer film with metal compound as precursor

The invention discloses a method for non-vacuum preparation of a nano thin film by taking a metallic compound as a precursor. The method comprises the steps of S1. preparing a metallic nano mixing solution; S2. preparing a graphite and superconductive carbon black mixing solution; S3. preparing acrylic photosensitive bisphenol A modified epoxy resin; S4. adding a reactive diluent and the like to the acrylic photosensitive bisphenol A modified epoxy resin; S5. continuing adding other materials to the acrylic photosensitive bisphenol A modified epoxy resin; S6. centrifuging; S7. coating; and S8. recoating and curing. According to the preparation method of the metallic compound thin film, which is disclosed by the invention, a non-vacuum precursor 'ink' offset printing spraying method is adopted to spray the precursor on an elastic substrate to form a metallic absorbed layer thin film; by means of a spray conversion method, dosages of raw materials and additive are easily controlled, ingredients, thickness and uniformity of the film can be conveniently controlled, and full use of addition of the superconductive carbon black and graphite can be achieved; the prepared product is low in granularity, high in bulk crystallization density, and capable of effectively improving a forbidden gap.

Owner:上海先着点光电科技有限公司

A kind of method for preparing forsterite type refractory material by microwave heating

The invention relates to a method for preparing forsterite refractory material through microwave heating. The method includes: well mixing nickel-iron slag, magnesia powder and a binder, press-shaping to obtain a blank, putting the blank after being dried into a microwave reactor, and holding temperature of 1250-1340 DEG C for calcining for 10-60min to obtain a forsterite refractory material; according to formula composition, regulating and controlling a gradient temperature increase program of the microwave heating process to optimize phase transformation of the nickel-iron slag and grain growth process of the refractory material; combining with grain ratio of the nickel-iron slag and the magnesia powder, and accurately controlling porosity of the forsterite refractory material to finally obtain the forsterite refractory material which has high compressive strength and excellent thermal shock resistance. The method has the advantages of high sintering speed, low energy consumption, high production efficiency, high resource utilization rate, environment friendliness and excellent material performance and has good industrial application prospect.

Owner:CENT SOUTH UNIV

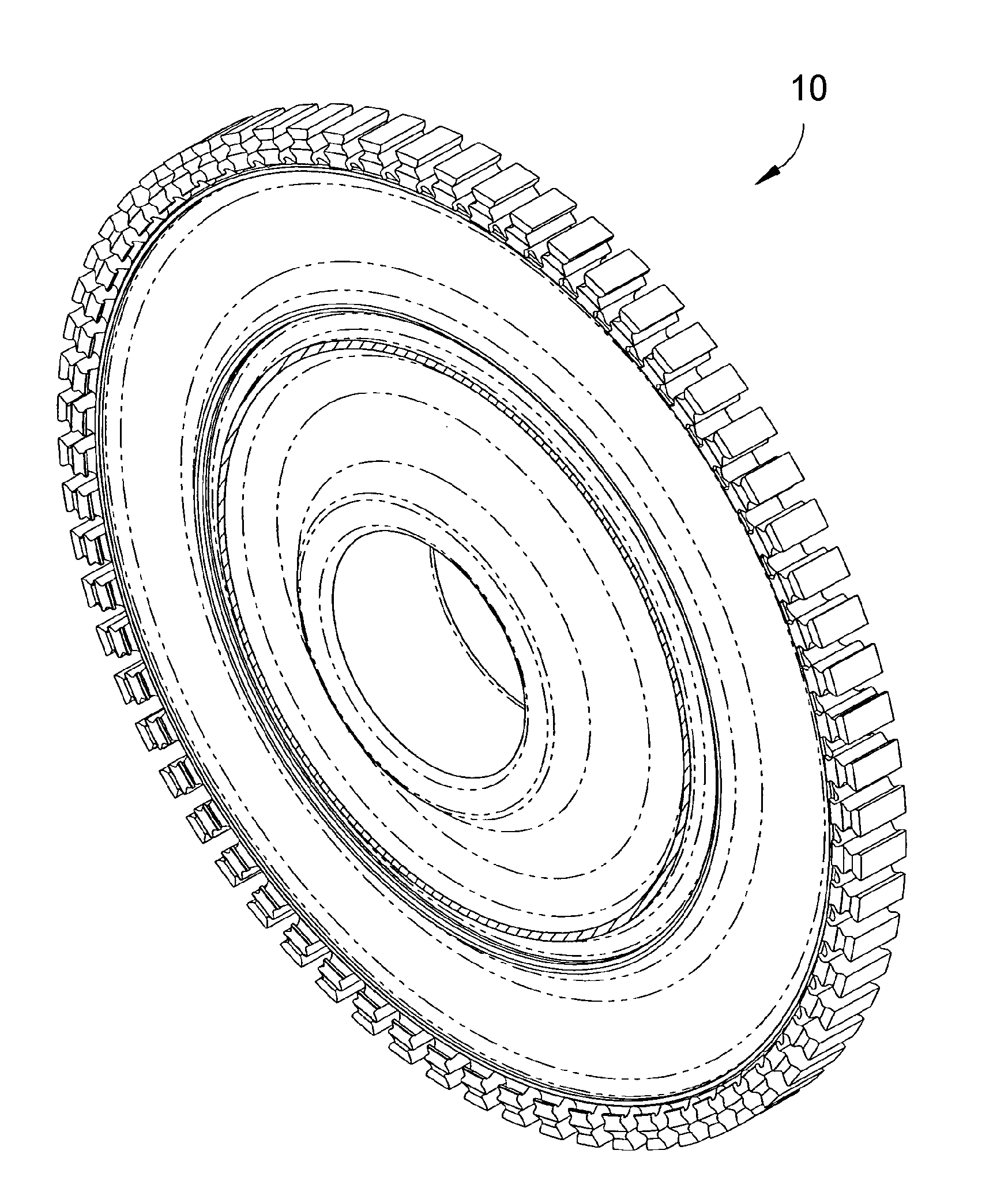

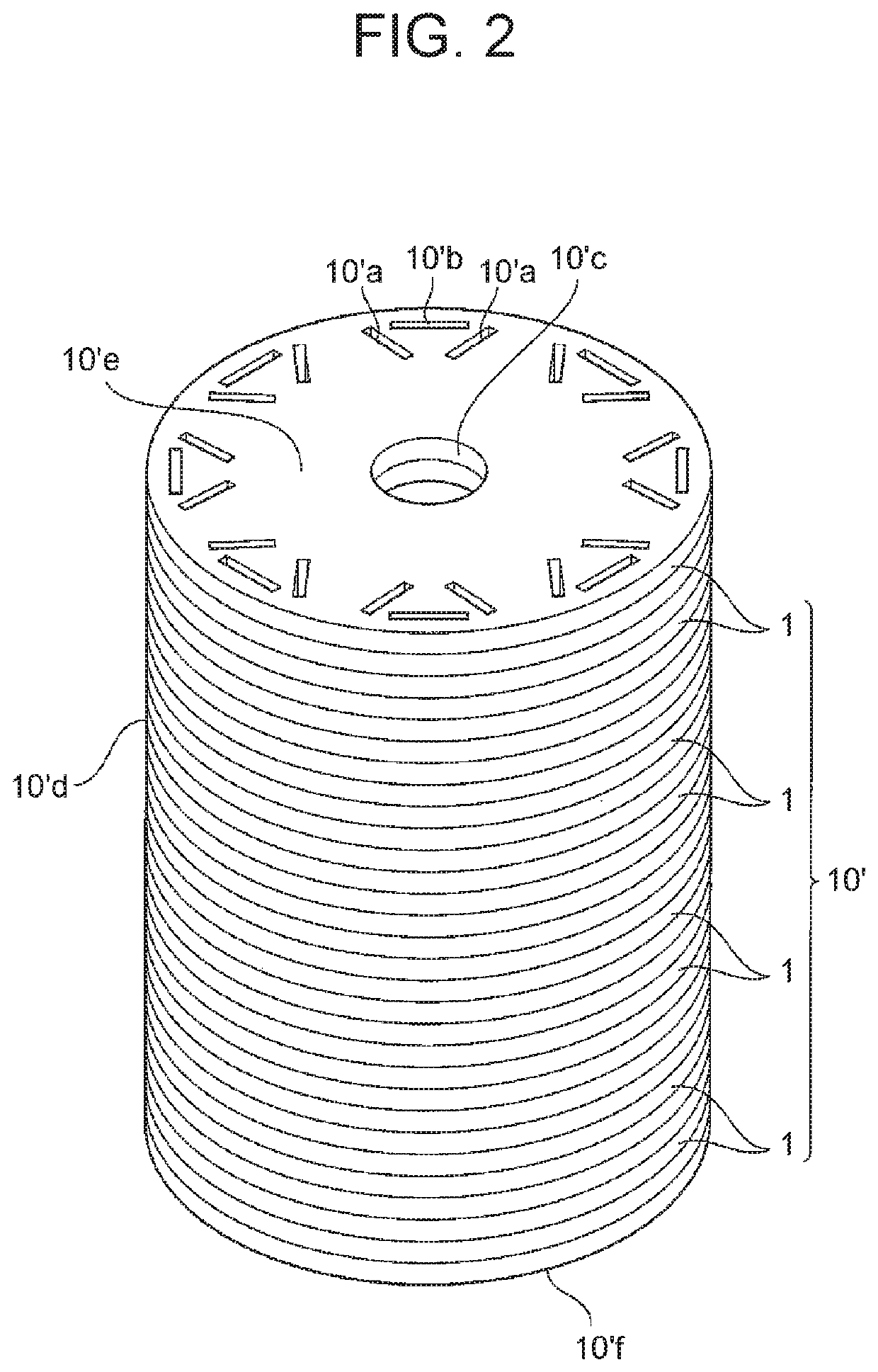

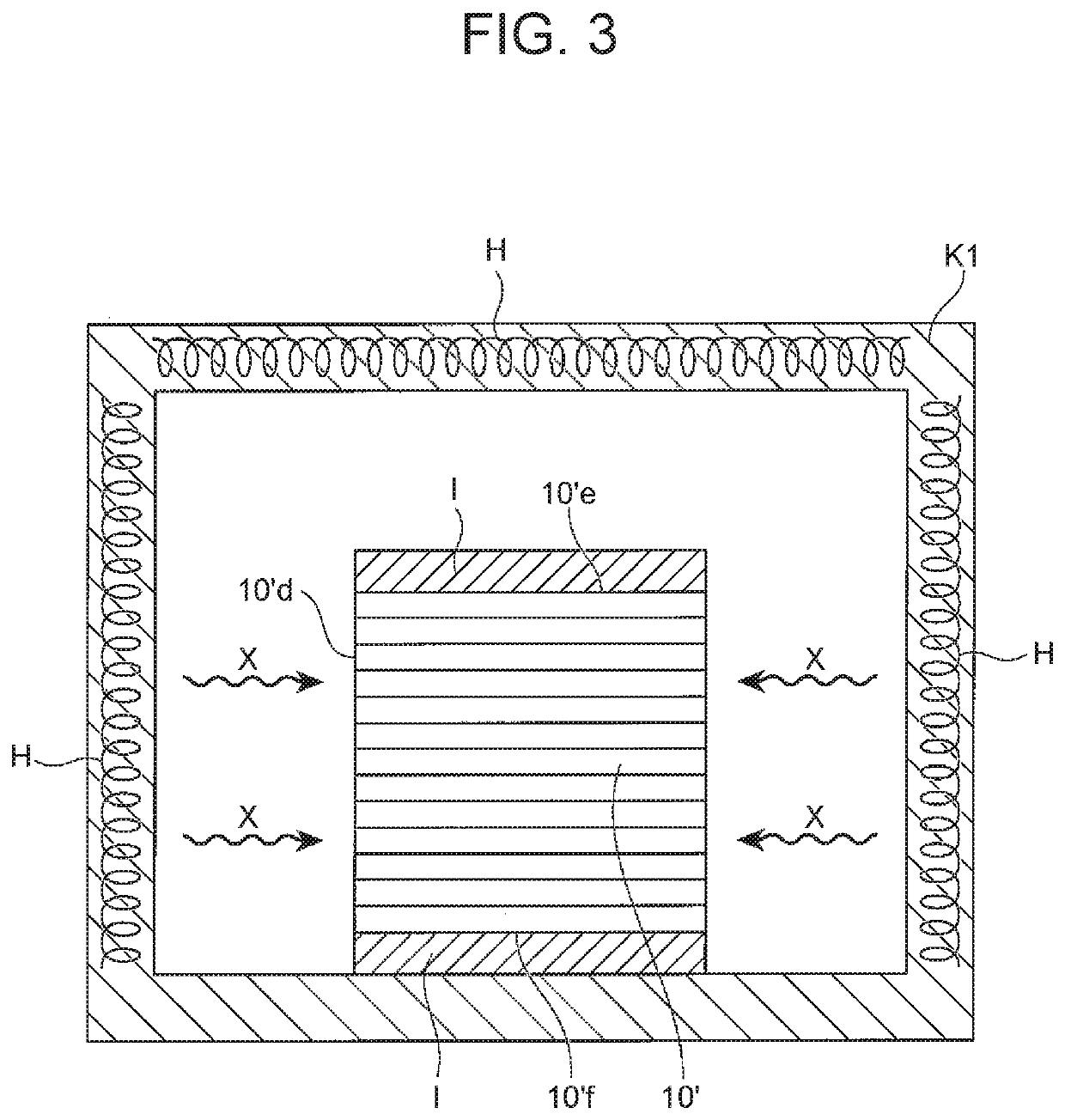

Manufacturing method for rotor core and manufacturing method for motor core

ActiveUS10554107B2Effectively reduce the iron loss in the rotor coreImprove featuresMagnetic circuit rotating partsElectric machinesElectric machineGrain growth

A manufacturing method for a rotor core included in a rotor of a motor punches an electromagnetic steel sheet includes punching a plurality of plates for rotor core from an electromagnetic steel sheet; producing a rotor-core precursor by stacking up the plates for rotor core; manufacturing a rotor core by annealing an outer circumferential region of the rotor-core precursor at a first predetermined temperature, and annealing an inner circumferential region of the rotor-core precursor at a second predetermined temperature; the first predetermined temperature being a temperature at which grain growth of crystals of the electromagnetic steel sheet is promoted; and the second predetermined temperature being a temperature at which grain growth of the crystals of the electromagnetic steel sheet is not promoted.

Owner:TOYOTA JIDOSHA KK

Carbon layer-coated nano-manganese tetraoxide shell-core structure material and preparation method thereof

ActiveCN112382747BPreserve biological formPromote growthMaterial nanotechnologyNegative electrodesCarbon layerElectrical battery

Owner:SUZHOU UNIV OF SCI & TECH

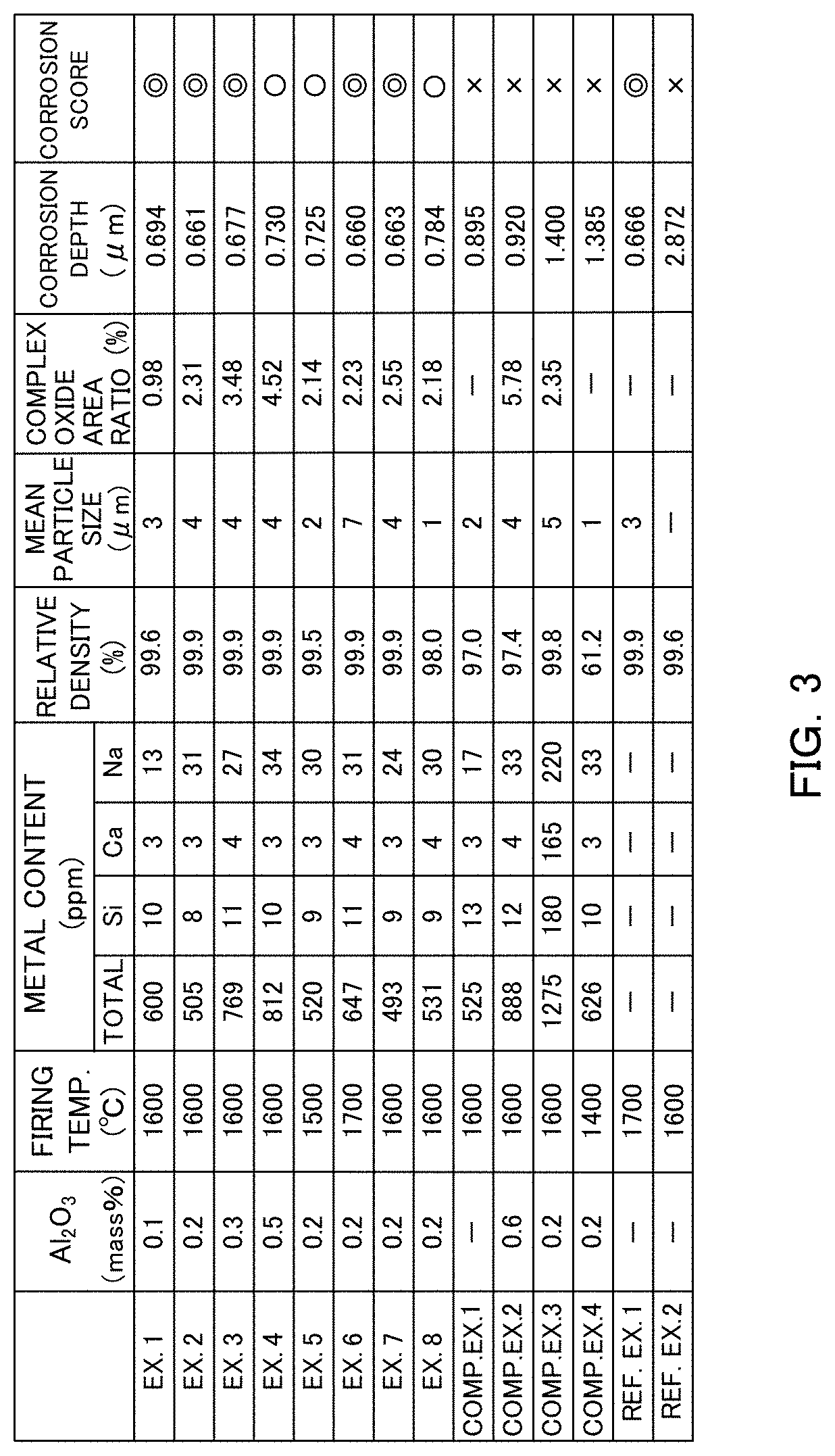

Yttrium oxide-based sintered body, production method therefor, and member for semiconductor production apparatus

An yttrium oxide-based sintered body includes yttrium oxide as a predominant component. The sintered body includes aluminum in an amount of 0.1 mass % to 0.5 mass % inclusive as reduced to aluminum oxide, has a metal content of 1,000 ppm or less, the metal excluding yttrium and aluminum, and has a relative density of 98% or higher. By virtue of the yttrium oxide-based sintered body, a plasma resistance comparable to that of a high-purity (99.9%) yttrium oxide sintered body can be achieved. Also, since the relative density is sufficiently high, plasma resistance can be enhanced. As a result, the yttrium oxide-based sintered body can be suitably used as a large-scale member by virtue of excellent mechanical strength.

Owner:NGK SPARK PLUG CO LTD

Slow release agent absorbent dressing

InactiveUS20070178146A1Promote grain growthPrevent backflowSynthetic resin layered productsAbsorbent padsFiberSecondary Infections

A slow release agent absorbent dressing particularly comprises a wound-contacting layer covered with tapered apertures. The bottom surface of said tapered apertures contacts a wound area to discharge exudate from the wound area and transmit exudate via a guiding layer to an absorbent layer. Said absorbent layer formed of high-molecular polymeric fibers is mixed with a certain concentration of water-soluble agents, such as antiseptic agents, enzymes and growth factor agents, in a suitable amount. After exudate is into the absorbent layer, said polymeric fibers expand forming into the shape of gel to avoid exudate flowing backward to the wound area. Also, a translucent evaporating layer having numerous micro pores for air venting is above the absorbent layer and the peripheral edges are joined together in the form of a sealed structure by heat-sealing to stop side escape of exudate, which is more effective in preventing the wound area from secondary infection.

Owner:CHOU CHANG TSUNG +1

A kind of preparation method of lithium ferrous phosphate and lithium ferrous oxide composite electrode material

ActiveCN103956462BImprove rate charge and discharge performanceImprove electronic conductivityHybrid capacitor electrodesCell electrodesMixed materialsLithium-ion battery

The invention relates to a preparation method of a lithium iron phosphate-ferrous lithium carbonate composite electrode material. The method comprises the following steps of mixing a carbon source, a lithium source, a phosphorus source and an iron source, drying the mixed material, sequentially roasting the mixed material at a low temperature and a high temperature under a non-oxidization gas environment, and naturally cooling the mixed material, mechanically grinding and sieving so as to obtain the lithium iron phosphate-ferrous lithium carbonate composite electrode material. The preparation method provided by the invention has the advantages that the technology is simple, the cost is low, the composite electrode material prepared by the preparation method provided by the invention has the advantages that the coated carbon content is small, the tap density is high, the specific surface area is 10-30m<2> / g, the specific capacity is high, great convenience is brought for formation of an electrode, the composite electrode material is used for a hybrid super capacitor, a lithium ion battery and the like.

Owner:ZHANGJIAGANG SMARTGRID FANGHUA ELECTRICAL ENERGY STORAGE RES INST +1

High pressure treatment for improved grain growth and void reduction

InactiveUS7344979B2Fine grainEliminate microporositySemiconductor/solid-state device manufacturingDielectricRoom temperature

A copper film is annealed at high pressure to enhance grain growth and remove voids. Other films, such as dielectrics, may also be suitable. High pressure can be used in conjunction with temperatures lower than room temperature for annealing or higher temperatures may be used to further enhance grain growth.

Owner:WAFERMASTERS

Composite multilayer crucible for beryllium aluminum alloy induction melting and preparation method thereof

ActiveCN109824370BImprove structural strengthChemically stableLayered productsMaterials scienceAluminium alloy

The invention discloses a composite multilayer crucible for beryllium-aluminum alloy induction melting and a preparation method thereof, which solves the problem in the prior art that there is no crucible suitable for beryllium-aluminum alloy induction melting. The composite multi-layer crucible of the present invention comprises an inner layer crucible, a middle layer crucible and an outer layer crucible which are fixedly connected sequentially from the inside to the outside; the inner layer crucible is composed of 92.5-97.5 parts of beryllium oxide, 1.0-2.0 parts of calcium oxide, and 0.5-2.0 parts of yttrium oxide. 2.0 parts, made of 1.0-3.5 parts of silicon carbide; the middle crucible is made of graphite; the outer crucible is made of 90-95 parts of calcium oxide, 1-3 parts of magnesium oxide, 2-4 parts of yttrium oxide, and 1-1.5 parts of zirconia , made from 0.5 to 1.5 parts of clay. The composite multilayer crucible structure of the invention has high structural strength and can shield a considerable part of the induced magnetic field. The chemical properties are stable, there is no splashing of the melt during the melting process, the degree of oxygenation is low, and some single-layer structures are replaceable and reusable, with long service life.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com