Low-free high-compatibility toluene diisocyanate trimer curing agent and preparation method thereof

A technology of toluene diisocyanate and ‐toluene diisocyanate, applied in the field of low-free high-compatibility toluene diisocyanate trimer curing agent and its preparation, can solve the problems of limited improvement of xylene tolerance, low free TDI content, high NCO value, etc. , achieve less side reactions, improve reaction selectivity and reduce viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

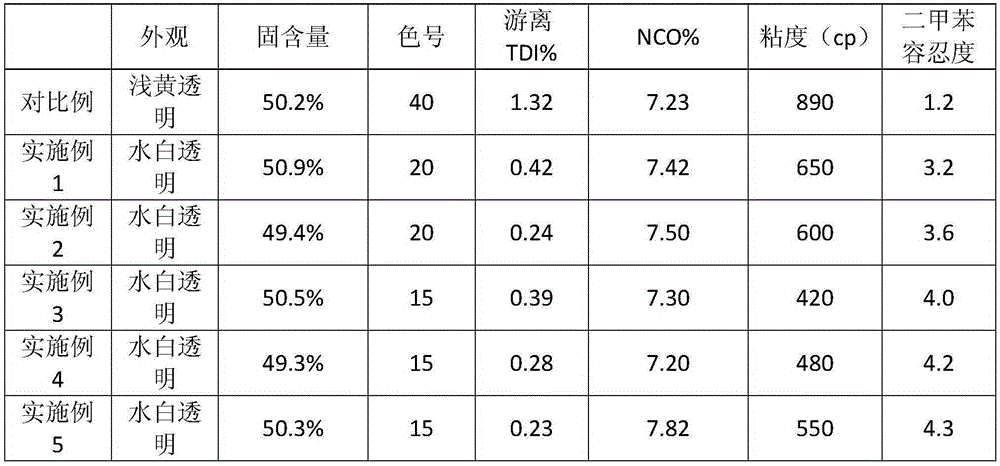

Examples

Embodiment 1

[0039] to a device with a stirrer, thermometer and 2 Add 100g TDI-80, 100g butyl acetate and 1gBHT (di-tert-butyl-p-cresol) to a protected 500mL four-neck flask, heat the water bath to 40°C, and then add 0.3g catalyst (2,4,6-tri(dimethyl Aminomethyl)phenol, referred to as DMP‐30), continued to stir and react at 40°C, and took samples every 0.5h to measure the NCO value. After 4 hours, the NCO value was 13.4wt%, and 0.15g DMP-30 was added for the second time to continue the incubation reaction. After 8 hours, the NCO value was 10.6wt%, and 0.15g DMP‐30 was added for the third time to continue the incubation reaction. After 12 hours, the NCO value was 9.5wt%, and 0.1g DMP-30 was added for the fourth time, and the temperature was raised to 70°C, and the reaction was stirred and kept warm. After 10h, the NCO value was 8.9wt%. Add 0.6g of polymerization inhibitor methyl p-toluenesulfonate, continue the heat preservation reaction for 0.5h, add 0.7g of isopropanol and 7g of butyl a...

Embodiment 2

[0041] to a device with a stirrer, thermometer and 2 Add 200g TDI‐80, 200g butyl acetate and 1g sodium hypophosphite into a protected 500mL four-neck flask, control the temperature of the water bath to 20°C, and then add 1.0g catalyst solution (2,2'‐bis[2,6‐bis( Dimethylaminomethyl)-4-hydroxyphenyl]propane, made into 25wt% DMF solution), continue to stir and react at 20°C, and take samples every 0.5h to measure the NCO value. After 6 hours, the NCO value was 12.2wt%, and 0.4g of catalyst solution was added for the second time, and the reaction was continued with heat preservation. After 8 hours, the NCO value was 10.3wt%, and 0.4g of the catalyst solution was added for the third time, and the reaction was continued at heat preservation. After 10 hours, the NCO value was 9.4 wt%, and 0.5 g of catalyst solution was added for the fourth time, heated to 60° C., stirred and kept warm for reaction. After 6 hours, the NCO value was 9.0wt%. Add 1g of polymerization inhibitor di-n-bu...

Embodiment 3

[0043] to a device with a stirrer, thermometer and 2 Add 300g TDI-80 and 300g butyl acetate and 2g antioxidant 1010 (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester) in the protected 1000mL four-necked flask, Control the temperature of the water bath to 35°C, then add 0.6g of catalyst (4‐methyl‐2,6‐bis(dimethylaminomethyl)phenol), continue to stir and react at 30°C, and take samples every 0.5h to measure the NCO value. After 6 hours, the NCO value was 12.5wt%, and 0.3g of catalyst was added for the second time, and the heat preservation reaction was continued. After 4 hours, the NCO value was 10.6wt%, and 0.4g of catalyst solution was added for the third time, and the heat preservation reaction was continued. After 15 hours, the NCO value was 9.4 wt%, and 0.4 g of catalyst solution was added for the fourth time, heated to 75° C., stirred and kept warm for reaction. After 3h, the NCO value was 9.1wt%. Add 1.5g of polymerization inhibitor methy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com