Manganese additive for casting aluminum magnesium alloy and preparation method of manganese additive

A technology of manganese additives and aluminum-magnesium alloys, which is applied in the field of additives for melting and casting of aluminum-magnesium alloys and its preparation, can solve problems such as slow melting speed, long melting time, and large energy consumption, and achieve fast melting speed, reduce microcracks, The effect of reducing dendrite segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Embodiment 1: A manganese additive for aluminum-magnesium alloy casting according to this embodiment is composed of 70-80 parts by mass of manganese powder and 20-30 parts of flux.

[0018] The flux described in this embodiment is a conventional manganese additive flux.

[0019] The magnesium-aluminum-aluminum-manganese additive in this embodiment can not only replace the aluminum-manganese intermediate alloy for melting 5-series magnesium-aluminum alloys, but also has a relatively simple manufacturing method, can be used at a lower melting temperature, reduces melting time, and improves yield. High efficiency, energy saving, convenient transportation and storage, etc.

[0020] Compared with existing products, the magnesium-aluminum-aluminum-manganese additive in this embodiment has the following advantages:

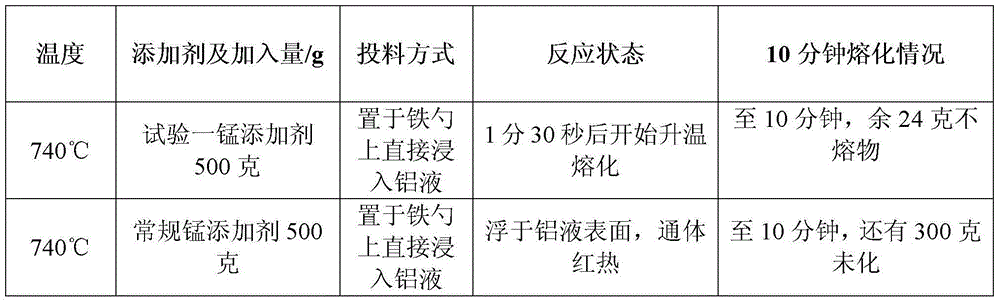

[0021] (1) The melting temperature is low, and it can be completely melted at 740°C, which can reduce burning loss, reduce bubble rate, reduce dendrite segregati...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass percentage of manganese in the manganese powder is not less than 99%. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass fraction of manganese in the manganese powder is 99.2%. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com