Evacuated collector tube device internally provided with rotors

A vacuum heat collection tube and rotor technology, applied in the field of solar energy applications, can solve the problems of fouling in the tube and low heat transfer efficiency of the vacuum heat collection tube, and achieve the effects of small flow resistance, enhanced convective heat transfer, and prevention of scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

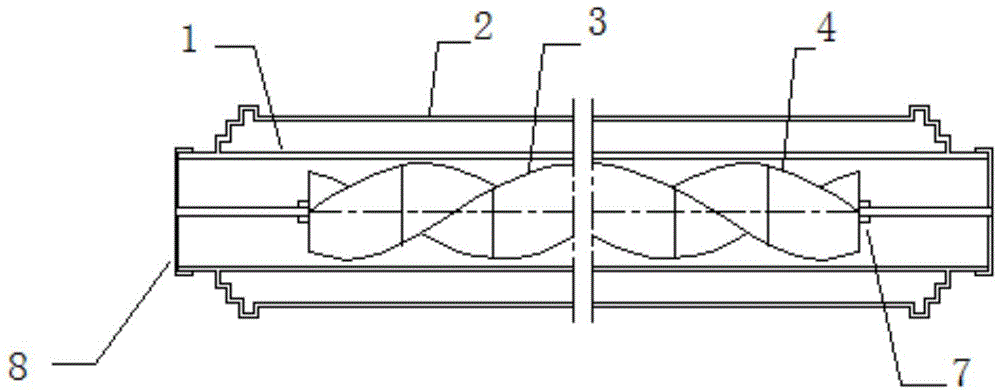

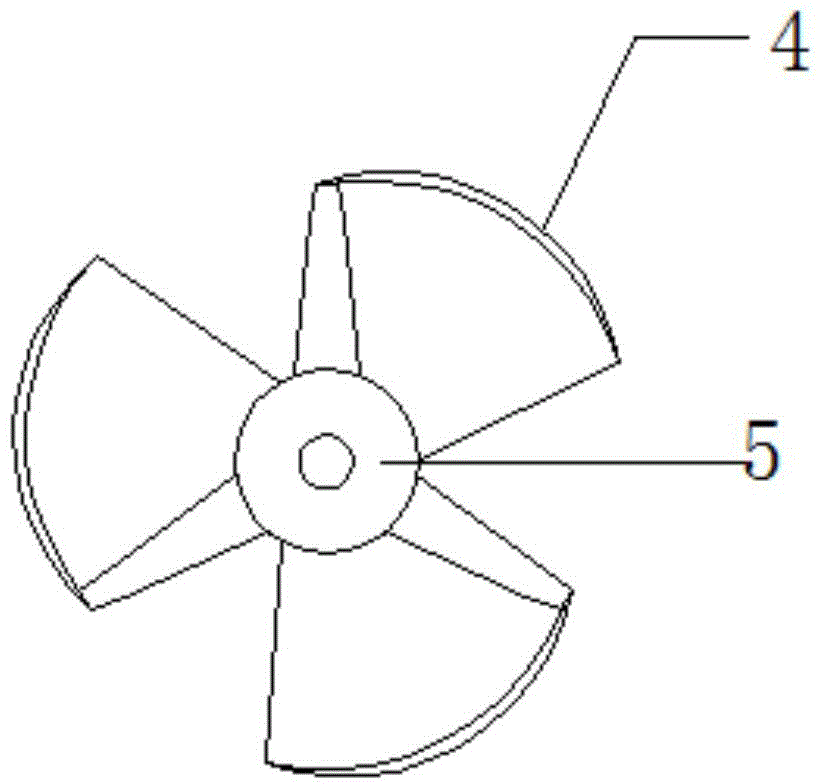

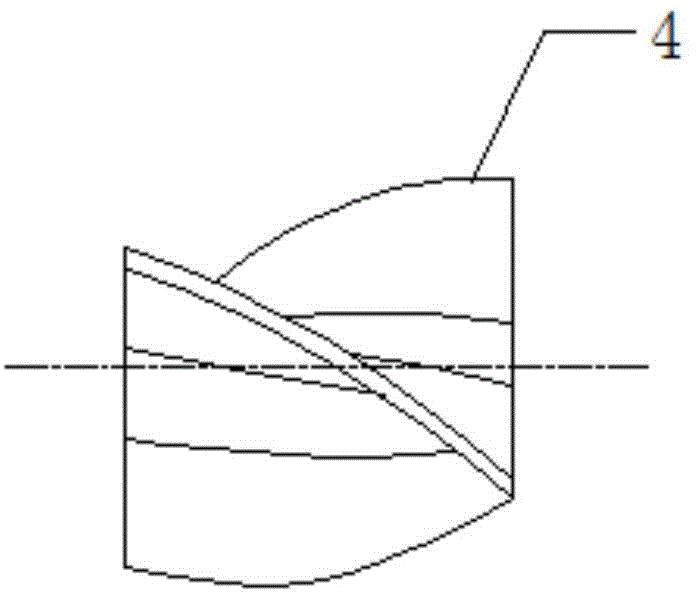

[0013] refer to Figure 1 to Figure 3 , a vacuum heat collecting tube device with an inner rotor in the present invention consists of a vacuum heat collecting tube inner tube (1), a vacuum heat collecting tube outer tube (2), a rotor (3), a rotating shaft (6), a fixing member (7), and a supporting member (8) Composition. The rotor (3) is fixed on the rotating shaft (6) through the fixing piece (7), and the rotating shaft (6) is fixed in the inner tube (1) of the vacuum heat collecting tube through the supporting piece (8). The pipe (1) is connected and fixed through the card slot. The heat transfer fluid impinges on the blade (4) to drive the blade (5) to rotate, forming a vortex in the tube to enhance heat transfer and prevent scale.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com