Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Optimized annealing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

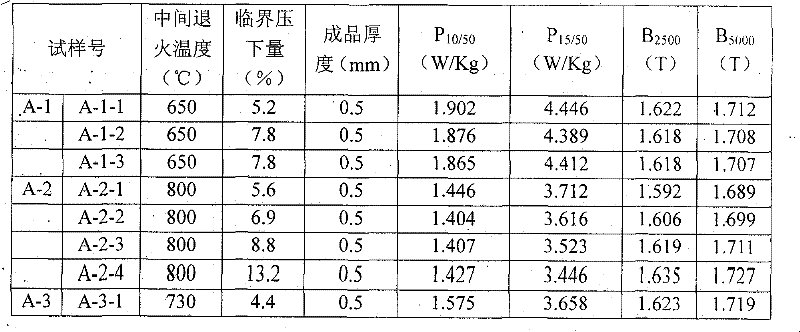

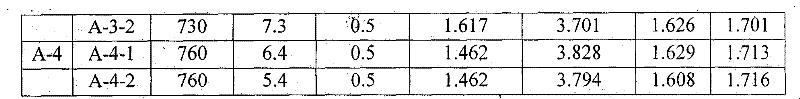

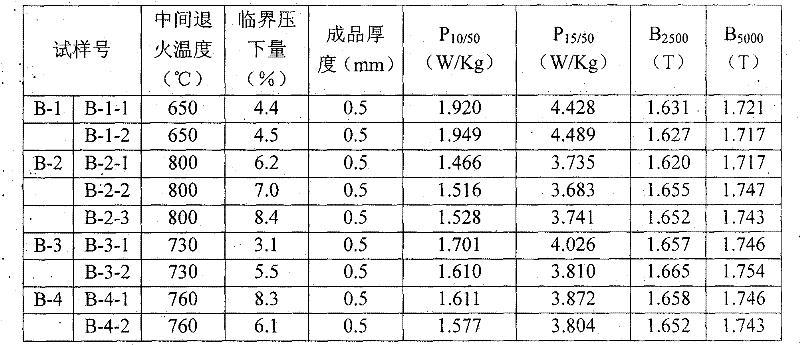

Preparation method of low carbon low silicon no-aluminum half-technique non oriented electrical steel

ActiveCN101306434AStrong magnetismLow costTemperature control deviceMetal rolling arrangementsRare-earth elementChemical composition

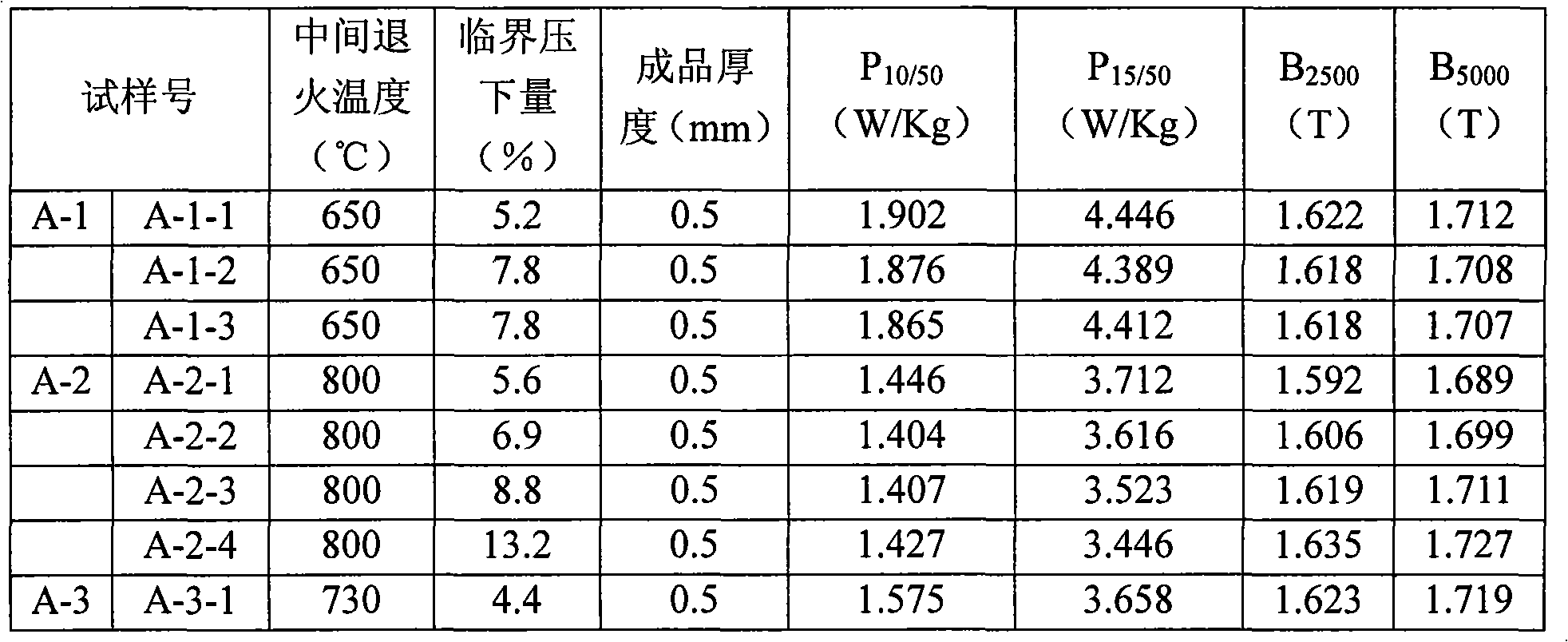

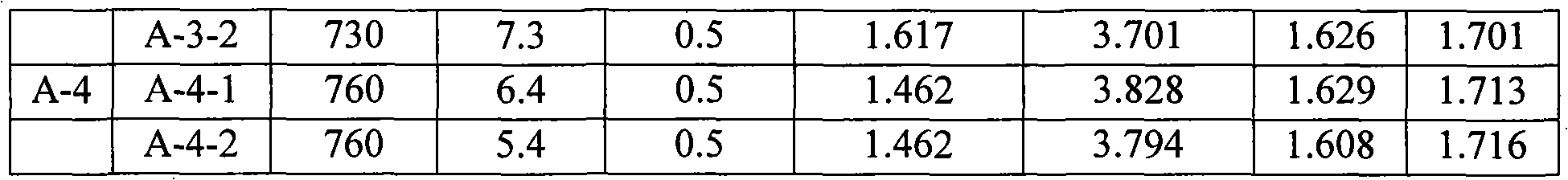

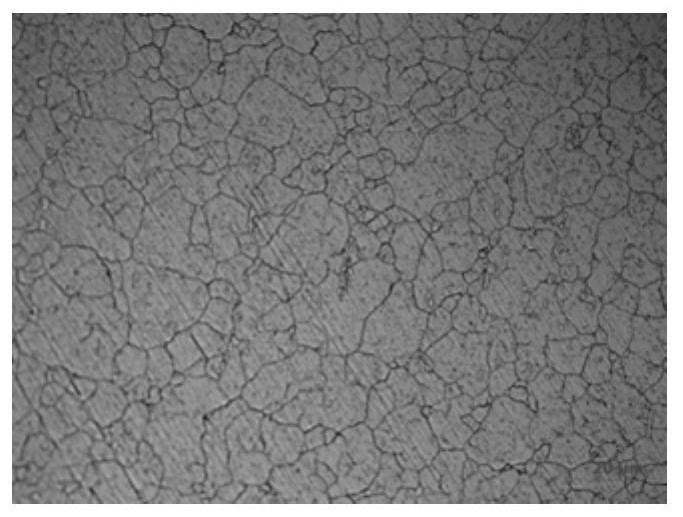

A method for preparing low-carbon low-silicon non-aluminum semi-process non-oriented electrical steel belongs to the technology field of the electrical steel with good magnetic performance. The preparation method includes the processing steps of meeting the requirements for the casting blank, such as the chemical components comprise less than or equal to 0.005% of C, 0.1%-1.0% of Si, less than or equal to 0.35% of Mn, less than or equal to 0.08% of P, less than or equal to 0.01% of S, less than or equal to 0.008% of N, less than or equal to 0.015% of O, inevitable impurities and Fe in balancing amount, according to the composition design for the hot rolling raw material; hot-charging and hot-rolling of the casting blank; acid-cleaning and cold-rolling of the steel plate after the hot-rolling; intermediate-annealing of the steel strip; cold-rolling of the critical deformation; relieving stress and annealing by users; and obtaining the semi-process non-oriented electrical steel with good magnetic performance. The method has the advantage that the final product has good magnetic performance: P15 / 50 is equal to 3.45-5.05 W / Kg, and B5000 is equal to 1.69-1.76 T. The casting blank contains no alloying elements such as Al, Sn, Sb, Cu, Cr, Ni, B, rare earth elements, etc., thus considerably reducing the production cost. The larger critical rolling reduction is adopted, the annealing technique is optimized, and the prepared finished products have better magnetic performance.

Owner:SHOUGANG CORPORATION

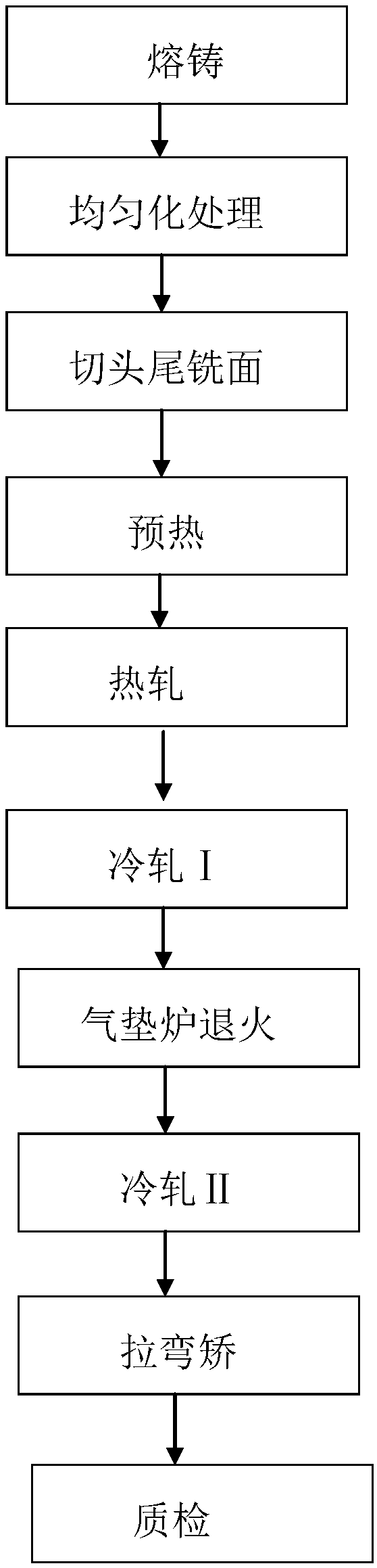

5182 aluminum alloy and technology method for preparing tank cover material strip through aluminum alloy

ActiveCN106834825AHigh strengthImprove performance uniformityTemperature control deviceRolling mill drivesUltimate tensile strengthImpurity

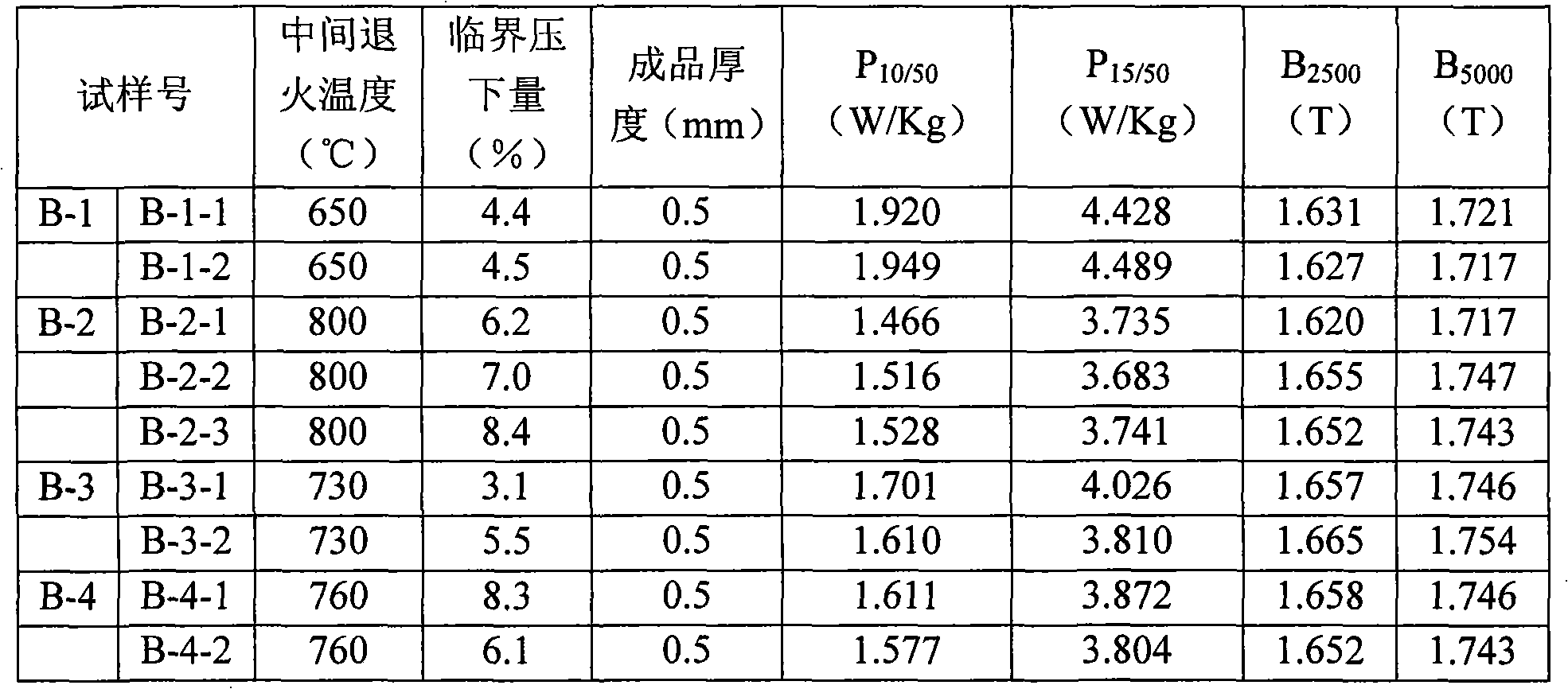

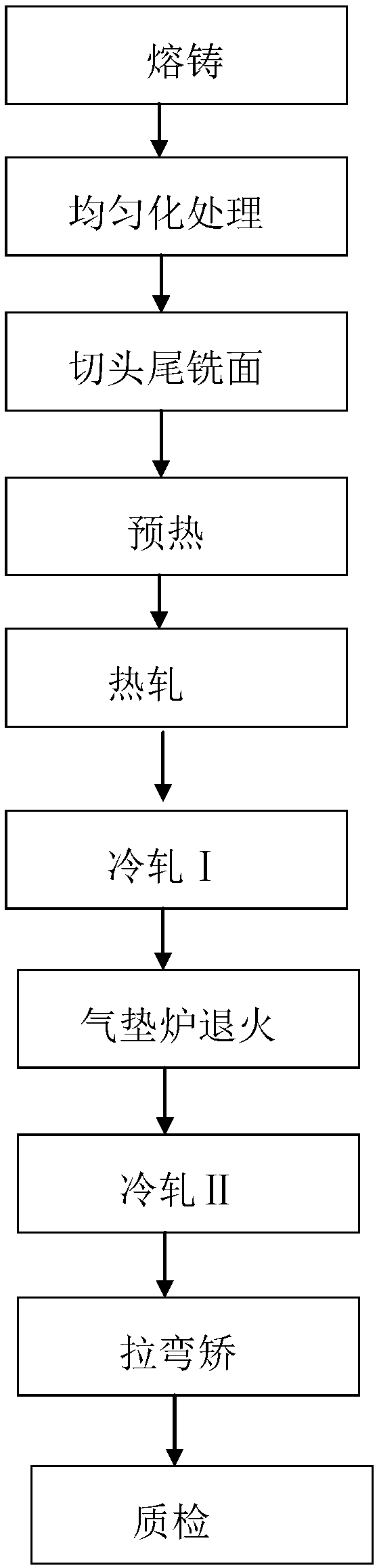

The invention discloses a 5182 aluminum alloy. The aluminum alloy is composed of Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, and remaining Al and some inevitable impurities. A preparing technology of a tank cover material strip through the 5182 aluminum alloy comprises the steps of firstly, taking of the 5182 aluminum alloy; secondly, hot rolling, cooling and obtaining a blank for cold rolling; thirdly, primary cold rolling, and obtaining a cold-rolled intermediate product, wherein the total deformation amount ranges from 66% to 78%; fourthly, air cushion furnace annealing; fifthly, secondary cold rolling, wherein the total deformation amount ranges from 71% to 76%; sixthly, stretch bending and correcting. According to the 5182 aluminum alloy and the preparing technology of the tank cover material strip through the 5182 aluminum alloy, through high alloying, the alloy strength is improved, meanwhile, the content of Fe and Si is reasonably controlled, and bank mark generation is restrained; continuous air cushion furnace annealing is adopted, through high-temperature short-time annealing, the grains are adjusted and controlled, uniformity of the strip performance is improved, and meanwhile the strip surface quality is ensured.

Owner:广西南南铝加工有限公司

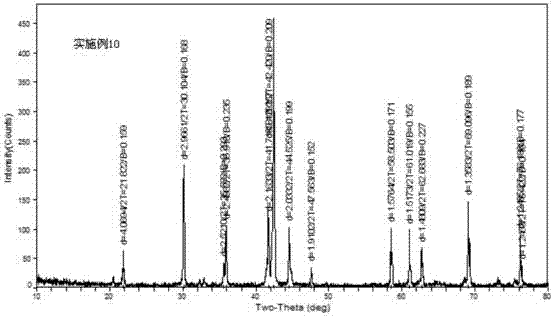

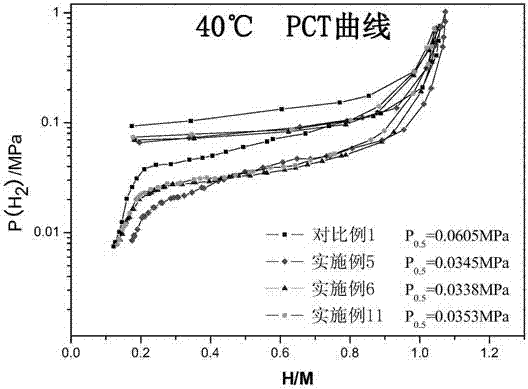

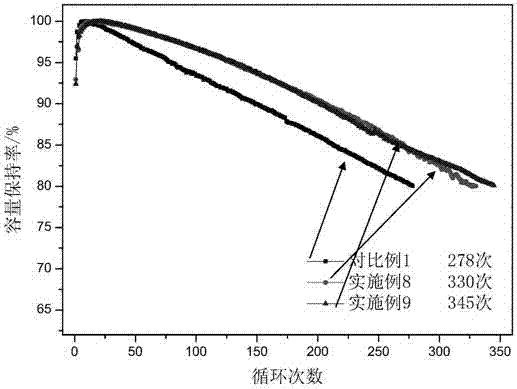

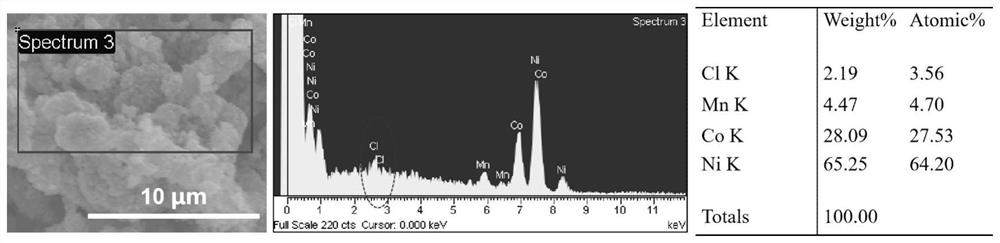

Rare earth-magnesium-nickel system heterogeneous hydrogen storage alloys used for nickel-hydrogen batteries and preparing method thereof

ActiveCN104195372AImprove discharge capacityImprove cycle lifeCell electrodesRare-earth elementSelf-discharge

The invention discloses rare earth-magnesium-nickel system heterogeneous hydrogen storage alloys used for nickel-hydrogen batteries and a preparing method thereof. The alloys are characterized in that: the general structure formula of the alloys is LnMgNi<x>Y<y>Z<z>, wherein the Ln is at least one element selected from rare earth elements; the Y is at least one element selected from a group comprising Co, Mn, Al, Cu, Nb, V, Fe, Zn, Ti, Cr, As, Ga, Mo, Sn, In, W, Si, B and P; the Z is at least one element selected from a group comprising Ag, Sr, Ge and Au; the a is less than 1 and not less than 0.5; the b is less than 0.5 and more than 0; the x is more than 2.5 and less than 4.5; the y is more than 0 and less than 2; the z is more than 0 and not more than 1; an AB5 phase accounts for 10-90%; an A2B7 phase accounts for 10-90%; and the ratio of other impurity phases is not more than 30%. B side elements are replaced by the Ag, the Sr, the Ge, the Au, and the like, alloy components and an annealing process are optimized, and the ratio of the AB5 phase to the A2B7 phase in the product is adjusted, thus increasing the discharge capacity of the hydrogen storage alloy, prolonging the cycle lifetime of the hydrogen storage alloy, and improving self-discharge and low-temperature properties.

Owner:SIHUI DABOWEN IND CO LTD +1

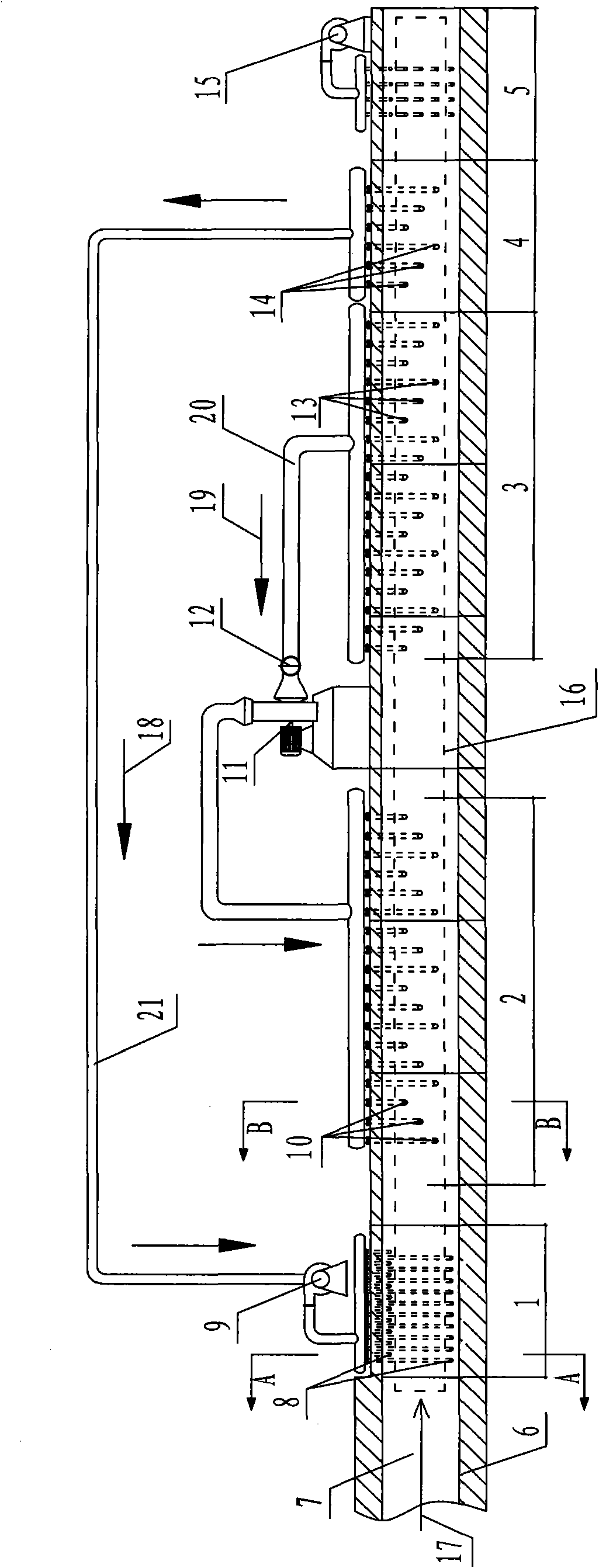

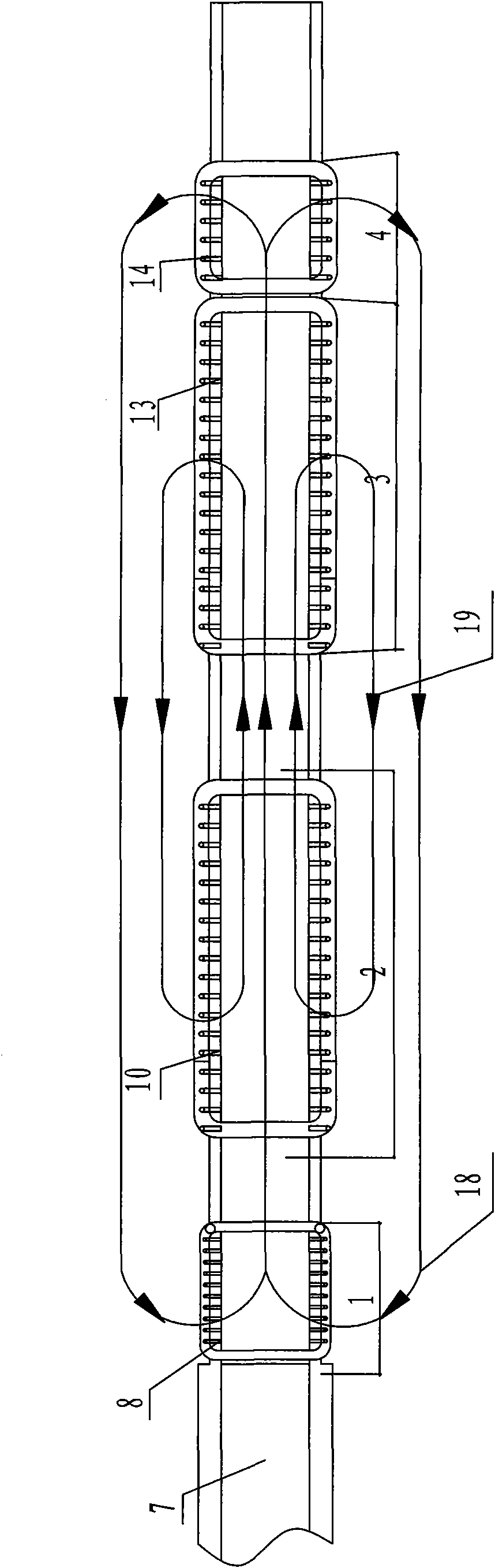

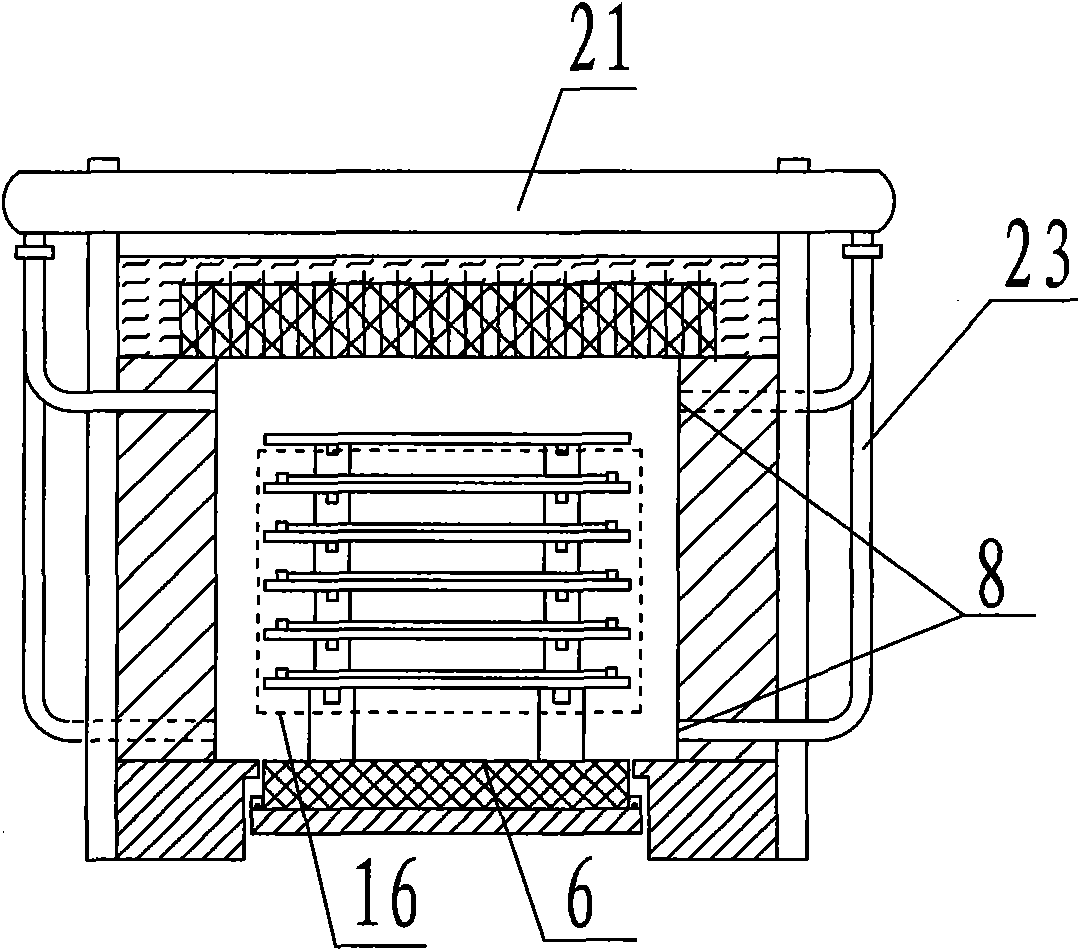

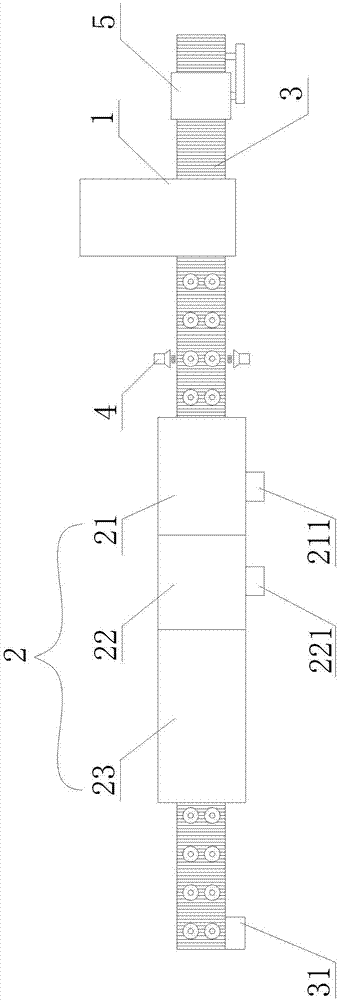

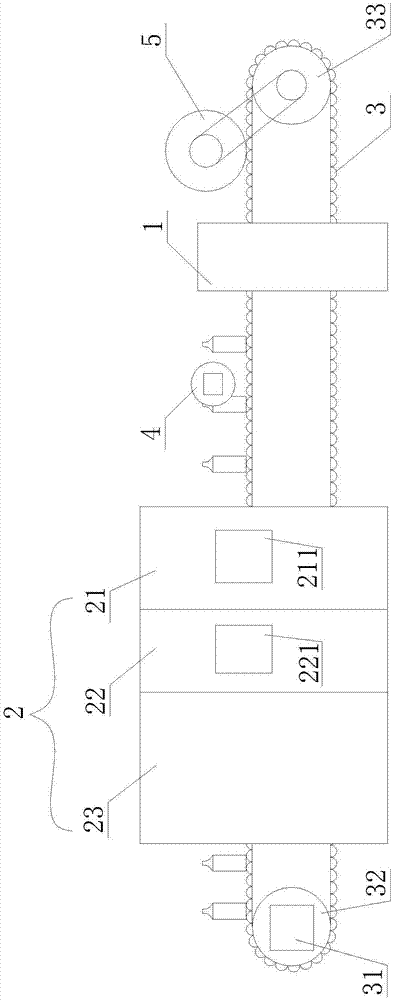

Annealing and cooling treatment system for two-stage hot wind circulation of glass ceramic tunnel crystallization kiln

The invention belongs to the technical filed of glass ceramic annealing by a sintering method, and discloses an annealing and cooling treatment system for two-stage hot wind circulation of a glass ceramic tunnel crystallization kiln. The treatment system is characterized in that the upper part and the lower part of kiln walls at two sides of a quench zone are respectively installed with a row of fast cold wind blowing openings which are communicated with fast cold wind blowing opening branch pipes, the fast cold wind blowing openings are all communicated with the output ports of second hot wind circulation pipes; the kiln walls at two sides of the slow cooling segment of a cooling zone are respectively provided with three rows of hot circulation wind blowing openings which are communicated with the hot circulation wind blowing opening branch pipes, all hot circulation wind blowing opening branch pipes are communicated with the output ports of first hot wind circulation pipes; the first hot circulation wind suction opening blowing branch pipes are all communicated with the input ports of the first hot wind circulation pipes; and the second hot circulation wind suction opening blowing branch pipes are all communicated with the input ports of the second hot wind circulation pipes. The annealing and cooling treatment system can improve product quality, and reduce deformation, burst and other defects of the products.

Owner:WUHAN UNIV OF TECH

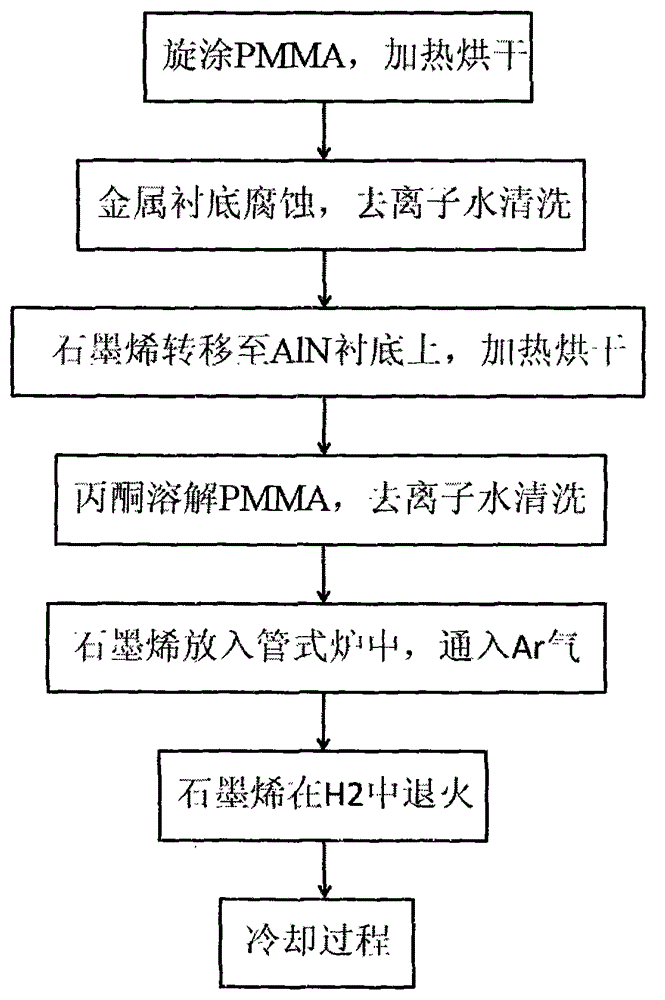

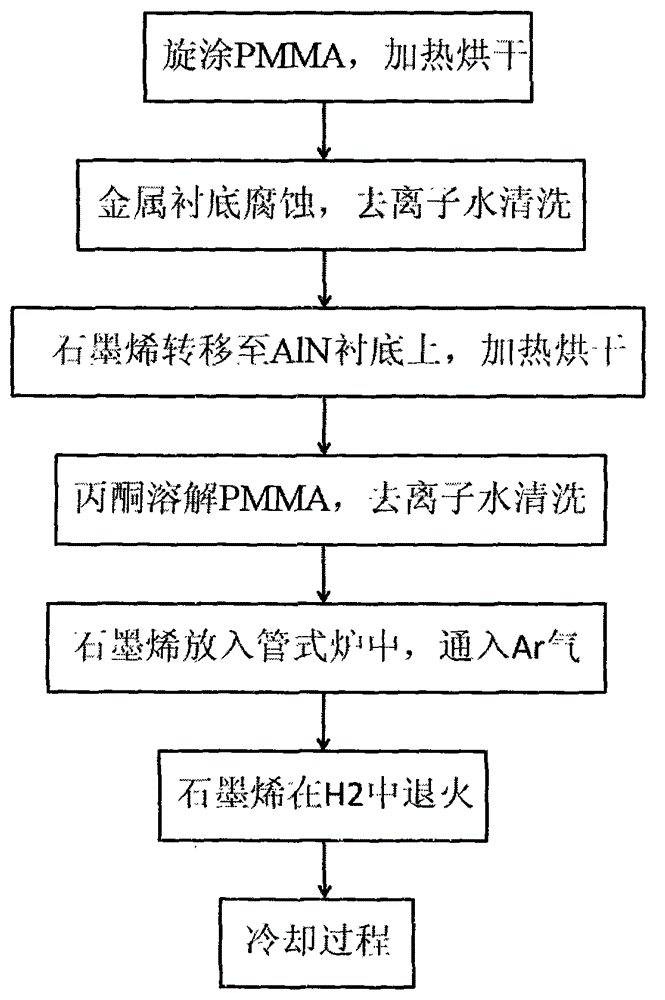

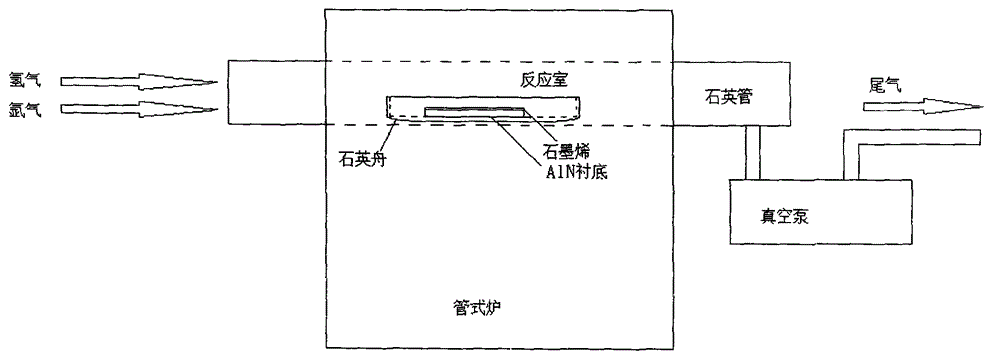

AlN (aluminum nitride) substrate based graphene transfer and annealing method and manufactured device

InactiveCN102915926AEasy to prepareQuality improvementSemiconductor/solid-state device manufacturingPolymethyl methacrylateSingle layer graphene

The invention discloses an AlN (aluminum nitride) substrate based graphene transfer and annealing method which is implemented through transferring large-area single-layer graphene to an AlN substrate by using a wet-process transfer method; and by way of low-pressure and low-temperature atmosphere annealing, adjusting the annealing temperature and the time of annealing treatment for the AlN substrate through optimizing atmosphere conditions so as to remove a PMMA (polymethyl methacrylate) residual photoresist in the process of transferring and reduce the doping effects of residues and the substrate on graphene as far as possible, thereby obtaining a graphene material with the optimal performance. By using the graphene subjected to transferring and annealing treatment, PMMA residues attached to the surface of the graphene can be removed better, and a good adhesion relation between the graphene and the substrate is kept well, thus the doping effects of adsorbates on the surface of the graphene and the substrate are minimized.

Owner:XIDIAN UNIV

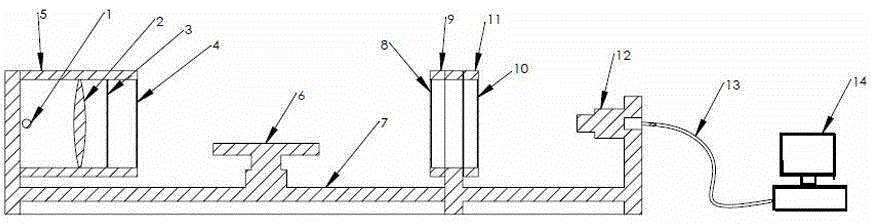

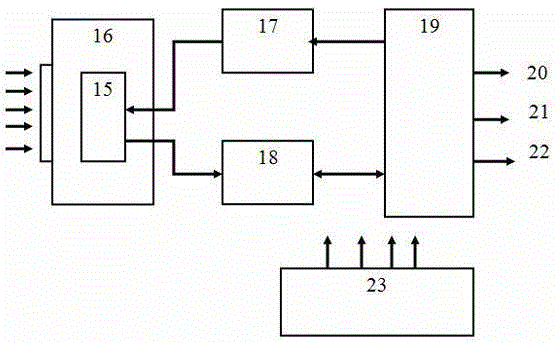

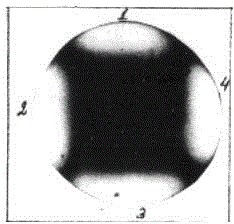

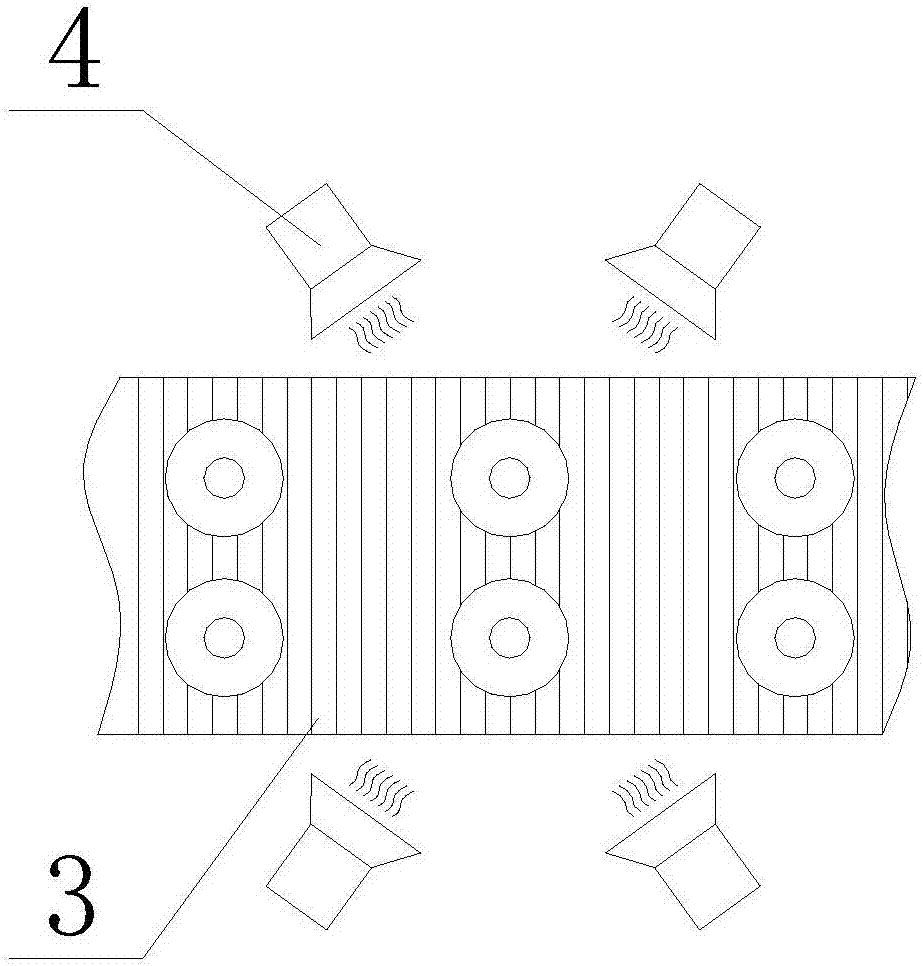

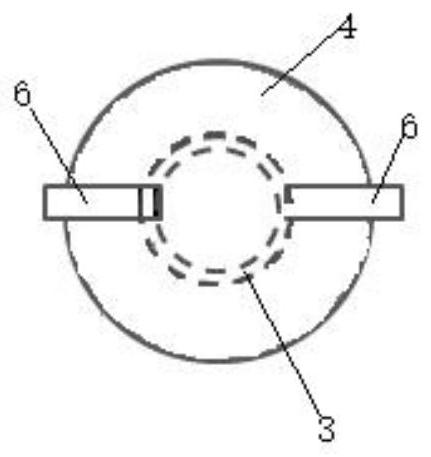

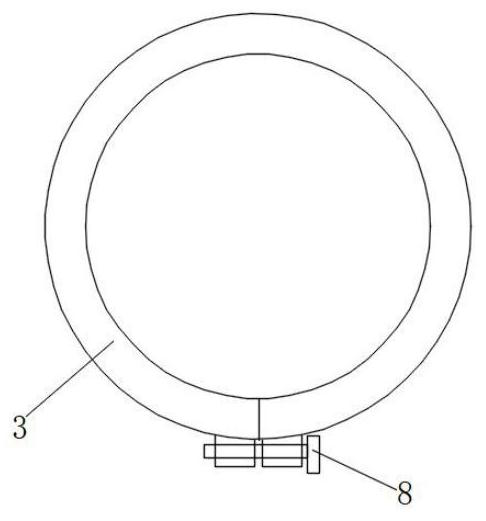

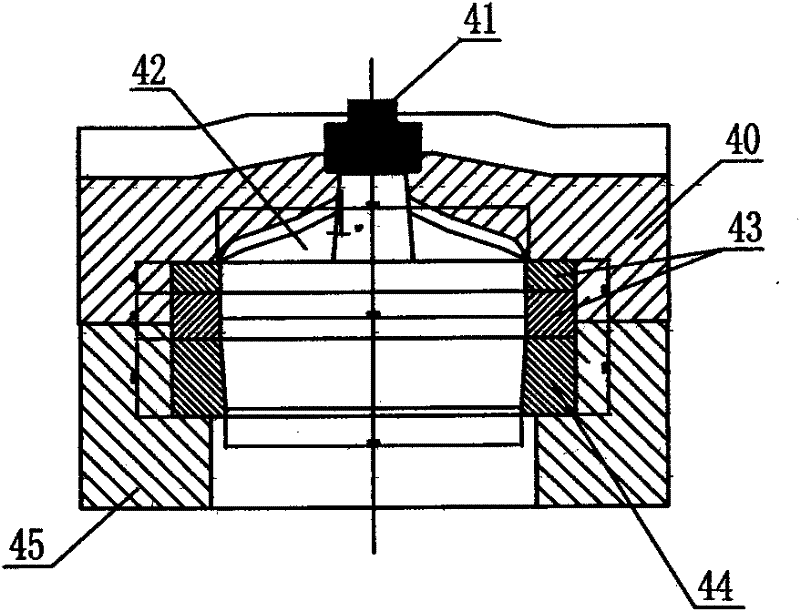

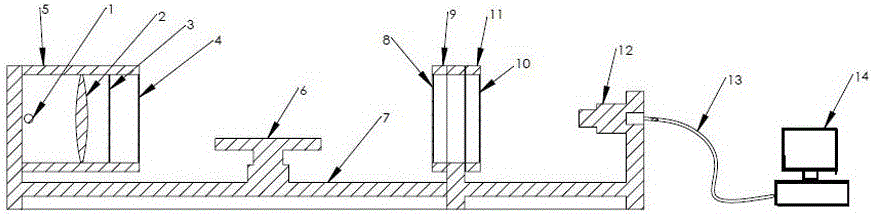

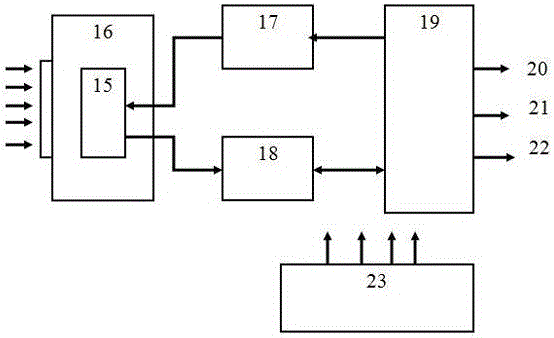

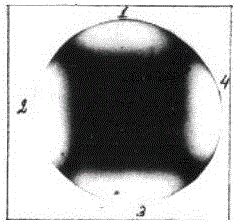

Device and method for testing stress of infrared optical material

ActiveCN104535232AMeet the Response RequirementsEasy to operateForce measurement by measuring optical property variationImaging qualityPolarizer

The invention relates to a device and method for testing the stress of an infrared optical material, belongs to the technical field of infrared optical material test, and aims at solving the problems in testing the stress of the infrared optical material through which visible light cannot be transmitted in the prior art. The device is mainly characterized by comprising an infrared light source, an infrared optical system, a signal reception system, a computer acquisition, processing and display system and a test platform. Test is carried out based on the principle of angular measurement compensation of a polarization analyzer, when an angle of 45 degree is formed between an infrared polarizer and an infrared polarization analyzer, namely a vector stress is include, elliptically polarized light generates a stroke difference, and thus, the stress of the material can be calculated. The device is characterized by simple operation and convenient test, the stress of the infrared optical material, through which visible light cannot be transmitted, can be tested, stress test can be used to guide and optimize production technology, glass of a lower stress can be produced, the imaging quality of the infrared material can be further improved, and a high-level infrared imaging system can be produced on the basis.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

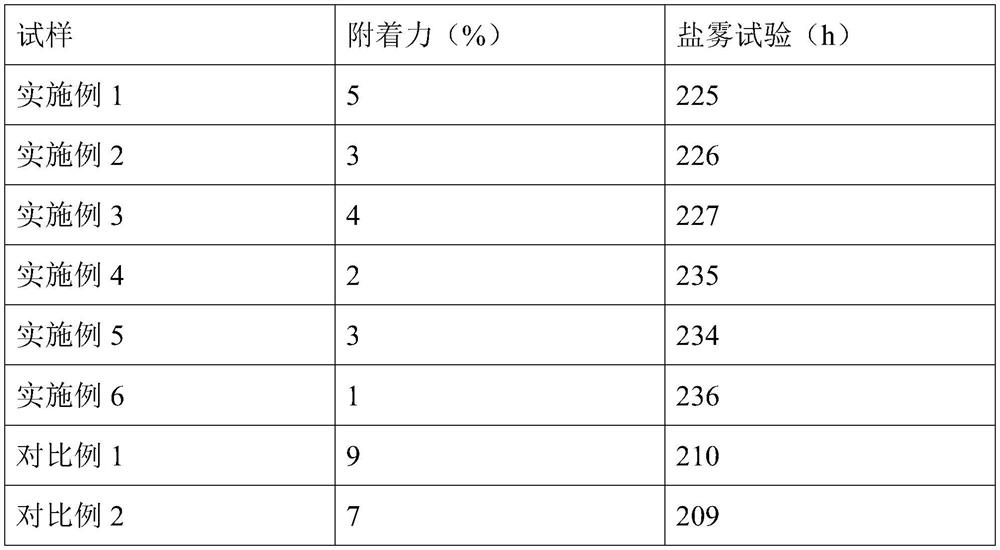

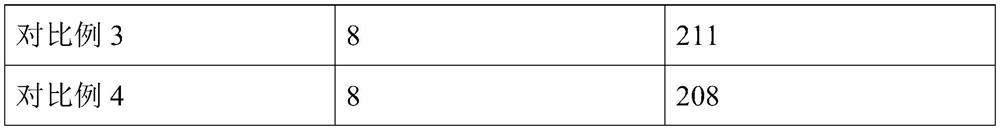

Hot galvanized high-strength steel plate with high surface quality and excellent corrosion resistance and manufacturing method thereof

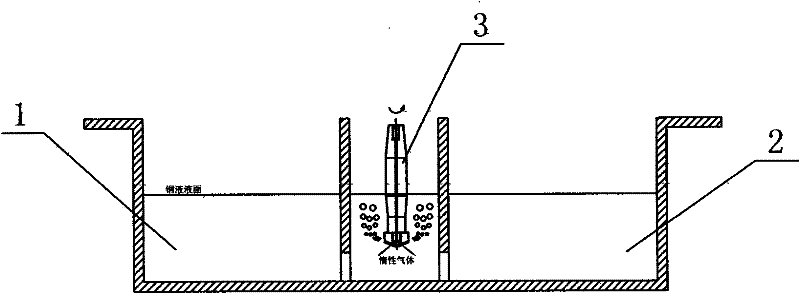

ActiveCN110760773AIncrease contactIncreasing the thicknessHot-dipping/immersion processesSuperimposed coating processChemical compositionUltimate tensile strength

The invention discloses a hot galvanized high-strength steel plate with high surface quality and excellent corrosion resistance and a manufacturing method thereof. The hot galvanized high-strength steel plate sequentially comprises a substrate, a pre-metallization layer and Fe-Al barrier layer and a galvanized layer from bottom to top, wherein the chemical composition of the substrate comprises the following chemical components of, in percentage by weight, 0.15 wt% to 0.25wt% of C, 1.00 wt% to 2.00 wt% of Si, 1.50 wt% to 3.00 wt% of Mn, less than or equal to 0. 015 wt% of P, less than or equalto 0.012 wt% of S, 0.03 wt% to 0.06 wt% of Al and the balance Fe and inevitable impurities, and the pre-metallization layer is a metal Ni layer. The hot galvanized high-strength steel plate is good in surface quality, uniform and complete in plating layer, and better in corrosion resistance compared with a conventional hot galvanized product; and the yield strength of the hot galvanized steel plate is 600-900 MPa, the tensile strength is 980 MPa or above, the elongation is 15-22%, the surface quality and corrosion resistance are superior to those of conventional hot galvanized high-strength steel, and the hot galvanized teel plate is suitable for automobile structural parts and outer plates with higher requirements on surface quality, corrosion resistance and formability.

Owner:BAOSHAN IRON & STEEL CO LTD

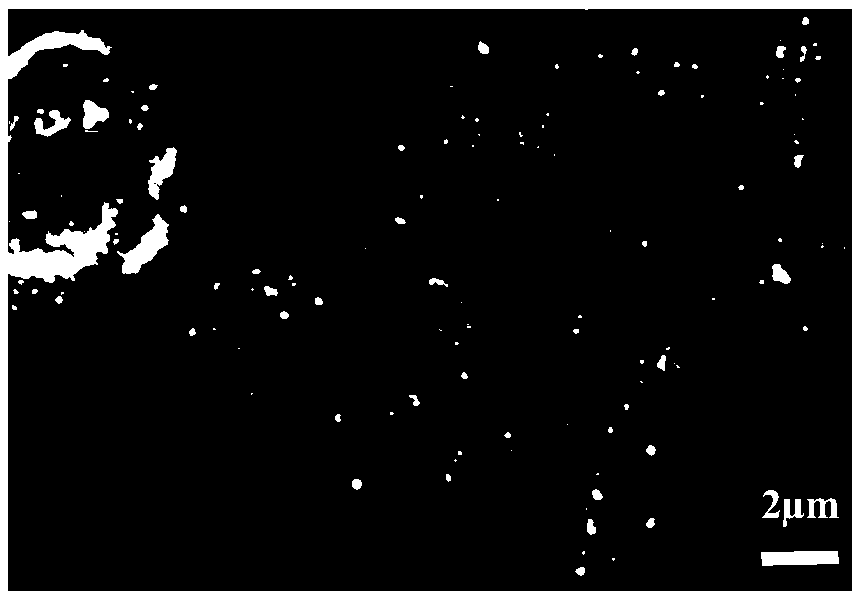

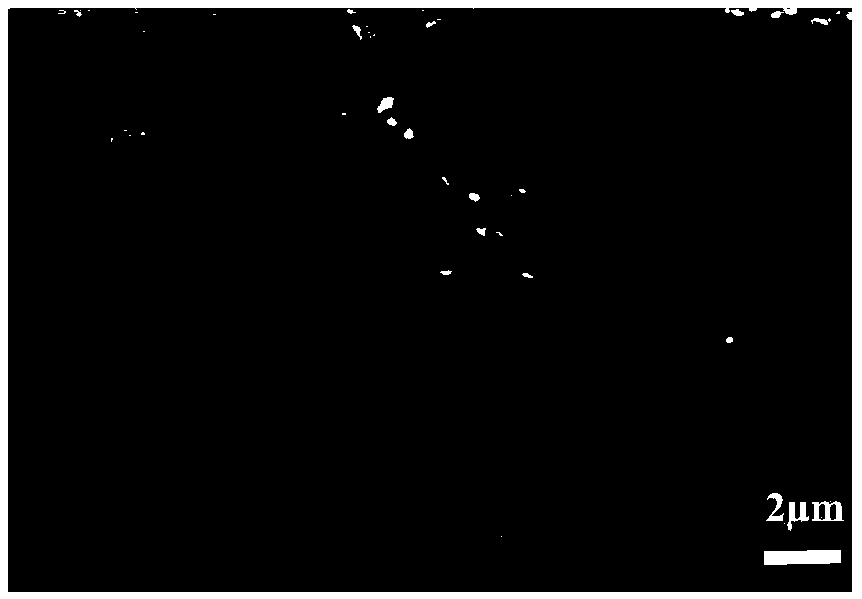

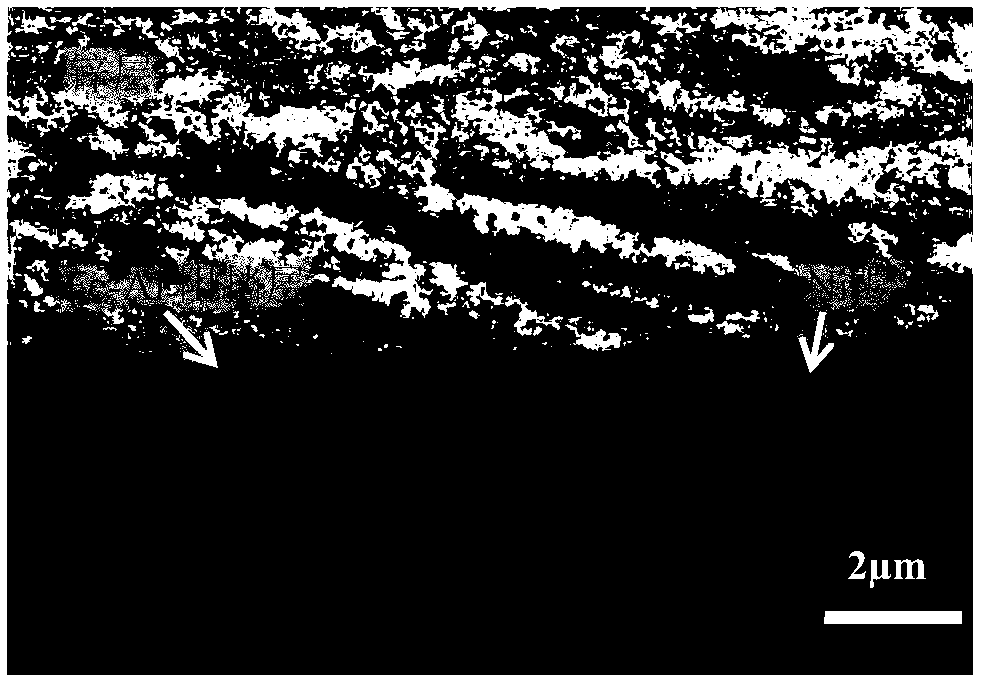

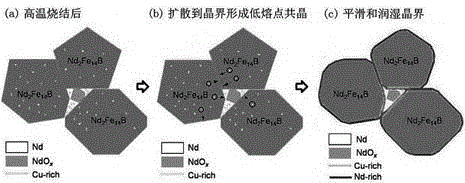

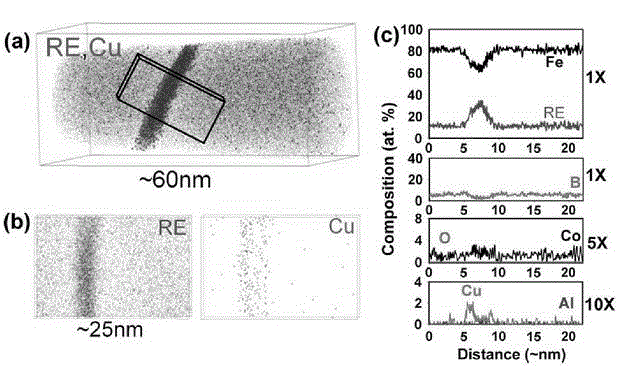

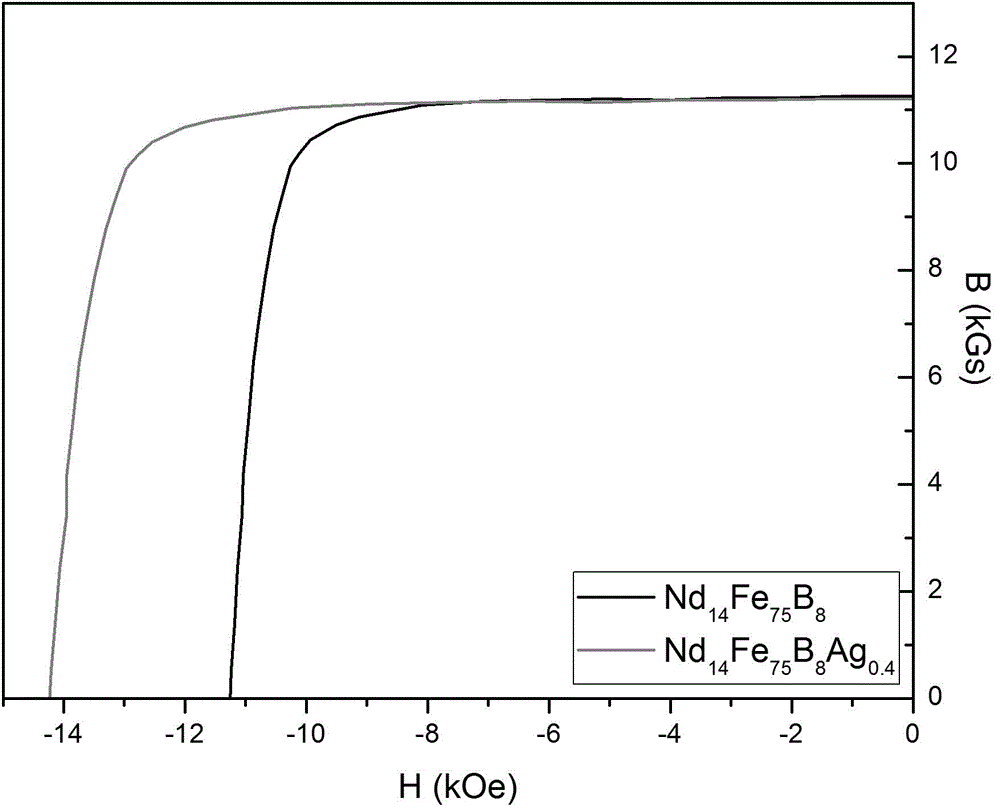

High coercivity low dysprosium (terbium) NdFeB magnet based on crystal boundary modification

ActiveCN104934175AResidue reductionDoes not affect magnetismPermanent magnetsMagnetic materialsDysprosiumAg element

The invention relates to material capable of improving intrinsic coercivity of high NdFeB magnet. The high coercivity low arrowhead (terbium) NdFeB magnet based on crystal boundary modification is characterized in that a certain amount of Ag element is located in a crystal boundary on the basis of raw magnet; precipitation of Fe elements in the crystal boundary can be basically eliminated; the magnet possesses higher intrinsic coercivity than un-modified alloy; less dysprosium (terbium) is required, so intrinsic coercivity can be improved and dysprosium (terbium) element use amount can be reduced; and the magnet can be applied to various occasions requiring high intrinsic coersivity, low cost and high use temperature.

Owner:JIANGXI UNIV OF SCI & TECH

Machining process of stainless steel material special for faucets

InactiveCN108950417AImprove mechanical propertiesThinning the pickling passivation layerCorrosionThermal treatment

The invention discloses a machining process of a stainless steel material special for faucets. The machining process comprises the following steps that (1) a steel blank raw material is smelted; (2) coarse-smelted molten steel is subjected to refining; (3) pouring is carried out to obtain a steel blank; (4) the steel blank is subjected to first annealing treatment; (5) the steel blank is subjectedto thermal treatment and then hot rolling; (6) hot-rolled stainless steel is subjected to first acid pickling; (7) the stainless steel is cold-rolled; (8) the stainless steel is subjected to secondary annealing treatment; (9) the stainless steel is subjected to electrolysis and secondary acid pickling; and (10) the surface of the stainless steel is subjected to polishing and burr removal, and thus the stainless steel material special for the faucets is obtained. The prepared stainless steel is dense in material structure, smooth in surface, good in corrosion resistance, excellent in mechanical performance and easy to machine.

Owner:合肥久新不锈钢厨具有限公司

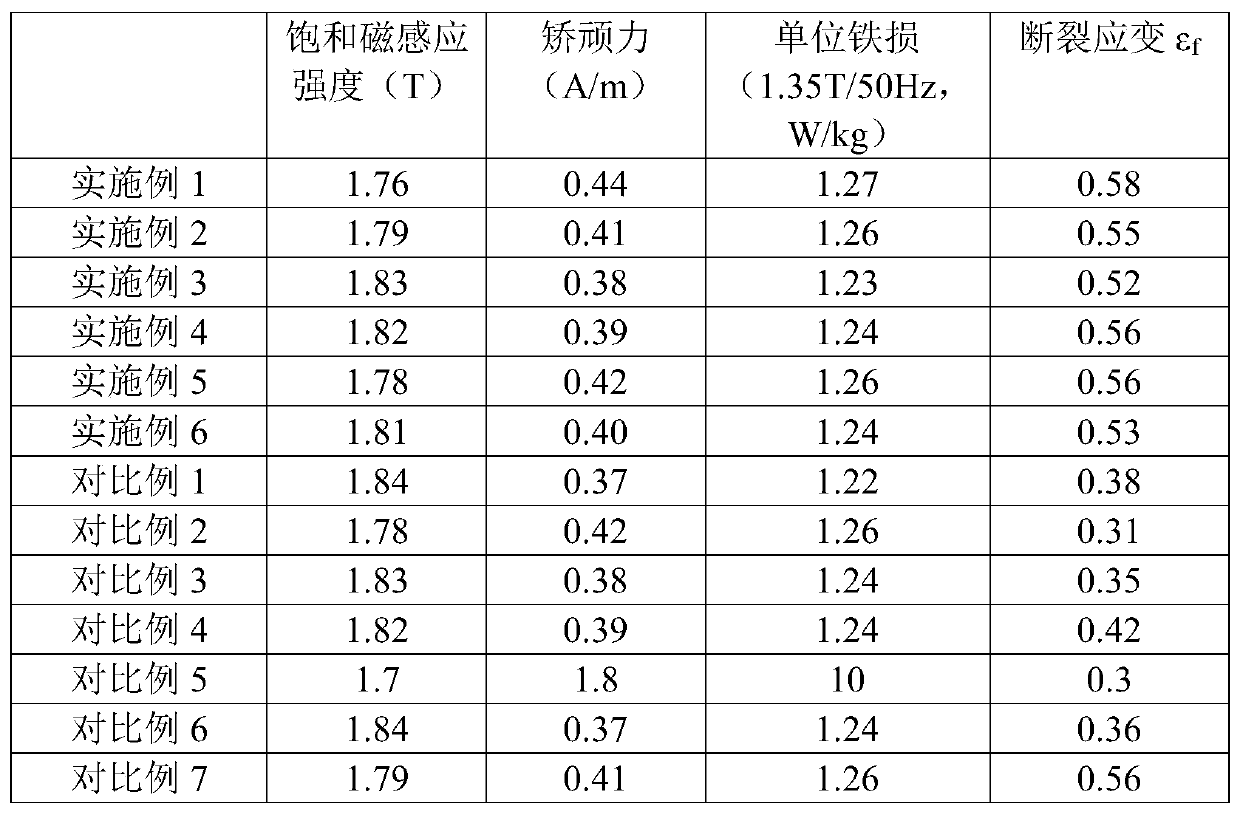

Amorphous alloy with favorable toughness and preparation method thereof

ActiveCN109778085AImprove toughnessOptimized annealing processMagnetic materialsMaterials preparationToughness

The invention provides an amorphous alloy with favorable toughness and a preparation method thereof, and belongs to the technical field of magnetic material preparation. The amorphous alloy is prepared from the following element components in percentage by mass: 2.5 to 7.5 percent of Ni, 8.2 to 10.5 percent of Si, 1.5 to 3.8 percent of B, 1.0 to 1.7 percent of Mn, 1.3 to 2.0 percent of Sn, and thebalance Fe. Through optimizing the alloy element components and the matching ratio and adopting an annealing process, the amorphous alloy product with an excellent soft magnetic performance and favorable toughness is obtained.

Owner:安徽智磁新材料科技有限公司

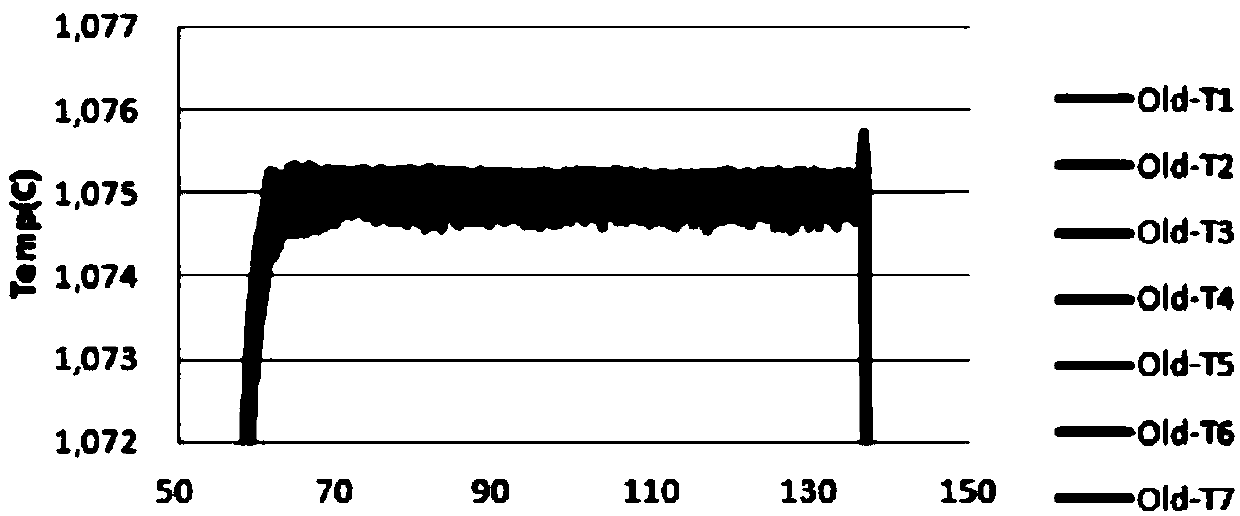

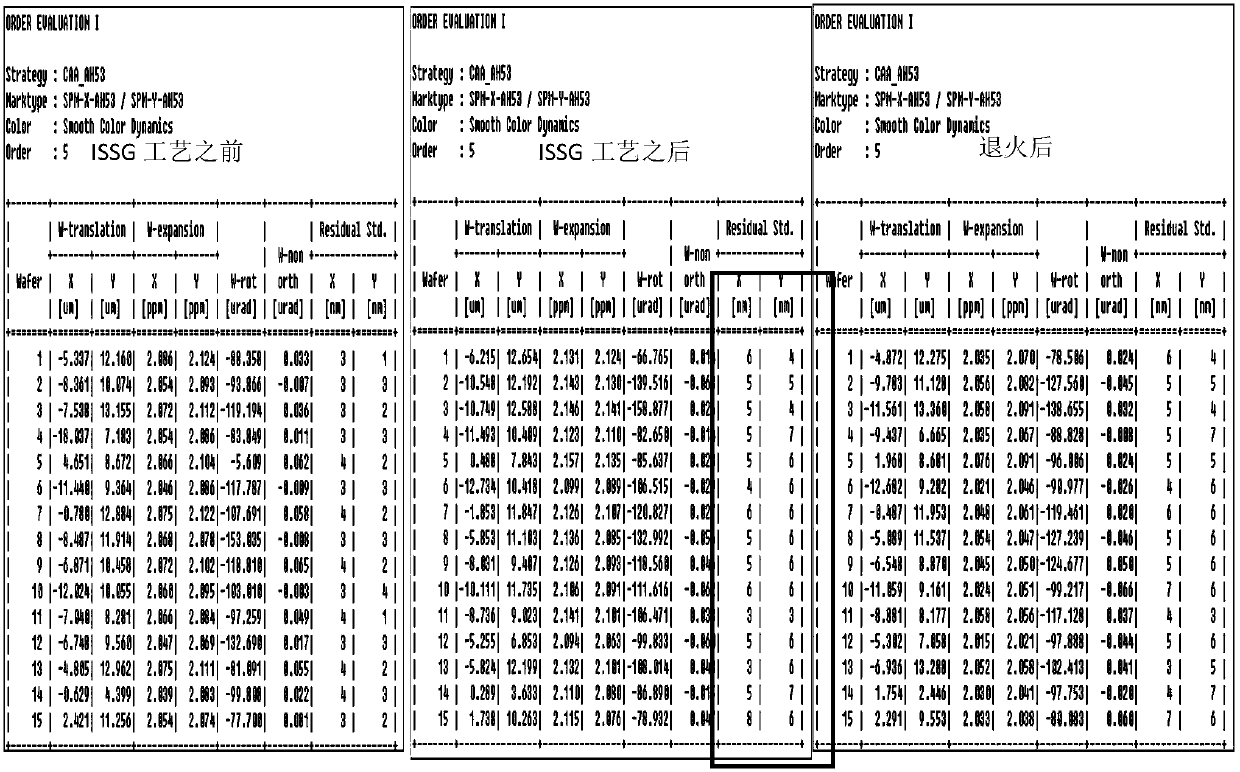

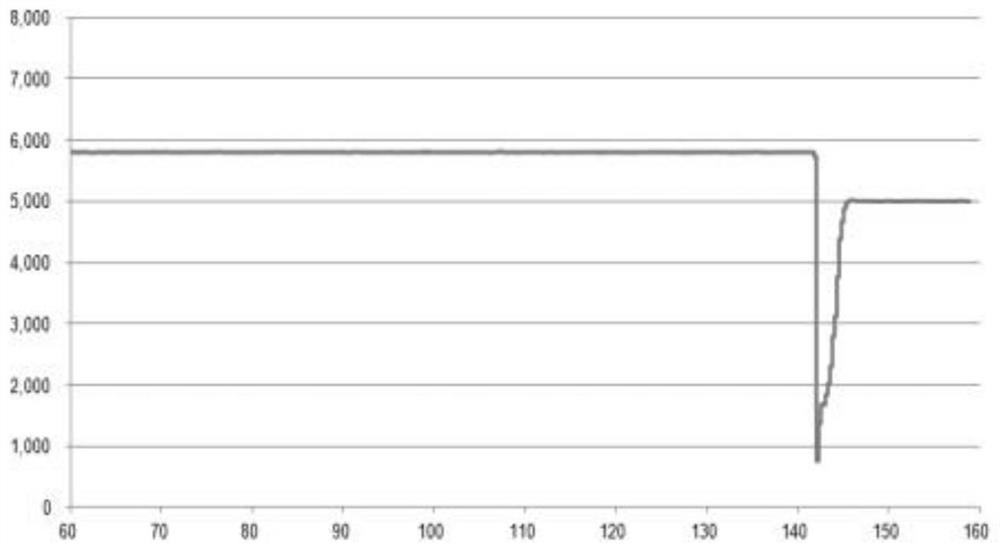

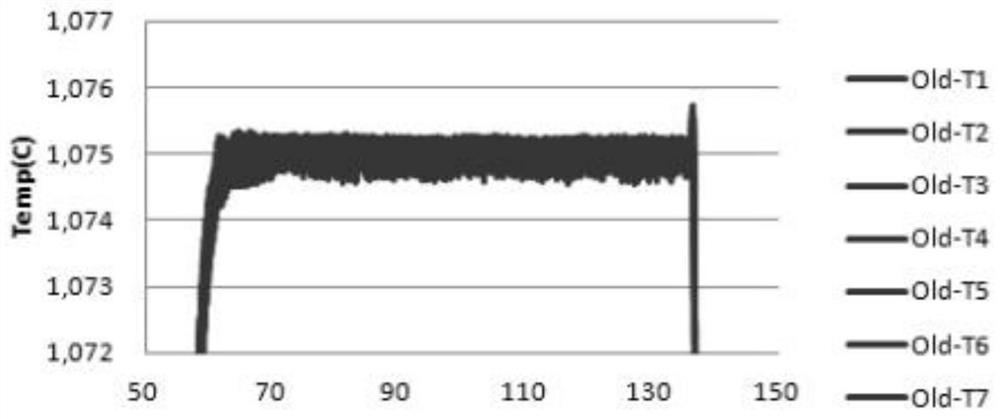

Method for relieving wafer shaking in tunnel oxide layer growth process

ActiveCN108054121AOptimized annealing processFix jitterSemiconductor/solid-state device manufacturingPneumatic pressureNitrogen gas

The invention discloses a method for relieving wafer shaking in a tunnel oxide layer growth process. The method comprises the following steps of performing the tunnel oxide layer growth process on a semiconductor substrate firstly; then performing an annealing process on the semiconductor substrate which is subjected to the tunnel oxide layer growth process; performing heating on the reaction cavity, and pumping hydrogen and oxygen to enable the air pressure in the reaction cavity to be kept unchanged; performing an annealing reaction for a certain time; stopping heating on the reaction cavityto lower the temperature in the reaction cavity; closing hydrogen and reducing the oxygen pumping amount, and meanwhile, pumping nitrogen to enable the air pressure in the reaction cavity to be keptunchanged; and after cooling is completed, completing the annealing process. By virtue of improvement of the ISSG annealing process and by performing technical analysis and understanding on wafer deformation, a defect-causing reason is found and then technical flow and parameters are changed, so that the problem of shaking of a silicon wafer in the high-temperature process can be solved; and afterthe method is adopted, the yield of the silicon wafer can be improved by 5% or above.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

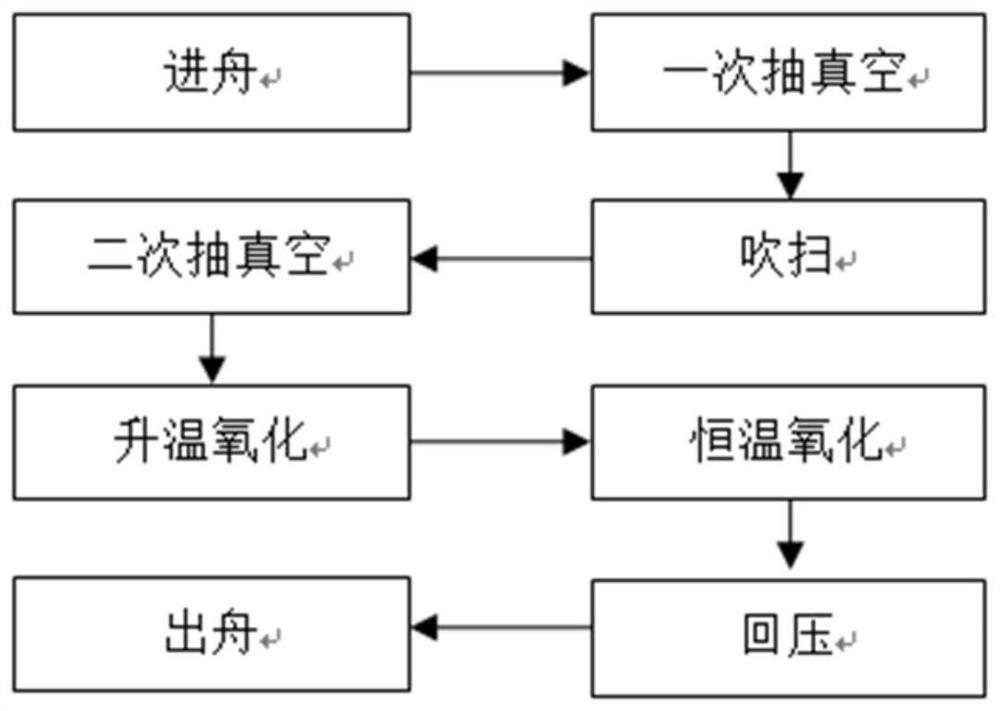

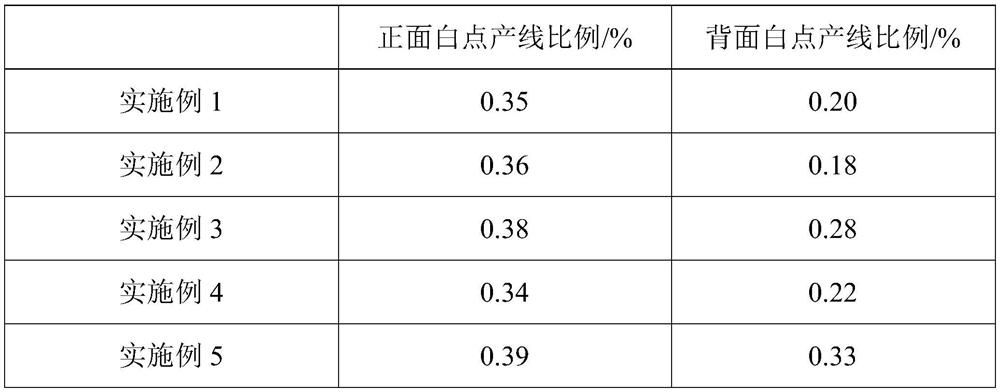

Annealing method for improving white points of crystalline silicon double-sided battery

ActiveCN112382702AReduce the ratioImprove electrical performanceFinal product manufactureSemiconductor devicesMetallurgyPhysical chemistry

The invention provides an annealing method for improving white points of a crystalline silicon double-sided battery. The annealing method comprises the following steps of (1) feeding into a boat; (2)vacuumizing for the first time; (3) purging; (4) vacuumizing for the second time; (5) heating and oxidizing; (6) carrying out constant-temperature oxidation; (7) returning pressure; (8) discharging from the boat, wherein the stage from primary vacuumizing in the step (2) to constant-temperature oxidation in the step (6) is a continuous heating stage. According to the annealing method, an annealingprocess is optimized, the whole process is in the continuous heating stage from the step (2) to the step (6), heating and then cooling are not needed, the process time is saved, and the productivityis improved; meanwhile, the white dot proportion of the double-sided battery is obviously reduced, the industrial large-scale production is facilitated, and the annealing method has better industrialapplication prospect.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

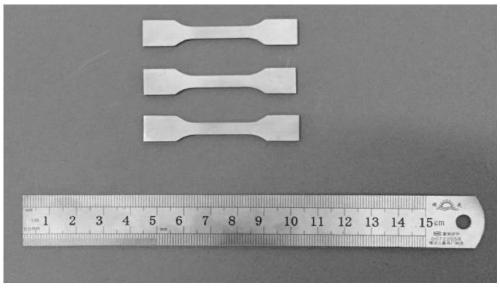

Short-flow rolling preparation process of high-strength and high-plasticity AlN/AZ91D magnesium base composite material plate

ActiveCN107747071AQuality improvementHigh quality and high performanceMagnesium matrix compositeIngot

The invention relates to a short-flow rolling preparation process of a high-strength and high-plasticity AlN / AZ91D magnesium base composite material plate; solid solution and water quenching processesof a cast ingot before rolling are formulated; subsequent rolling and annealing processes are optimized; and a set of cold rolling process for preparing a high-strength and high-plasticity magnesiumbase composite material rolled plate is provided. The cold rolling process is high in reduction in pass, few in annealing times among passes and short in annealing time, and can realize industrial short-flow preparation. In particular, through the patent technology, namely the optimal ratio of solid solution process parameters to water quenching process parameters to rolling process parameters toannealing process parameters, the edge cracking problem in the cold rolling process is solved when the high-strength and high-plasticity cold-rolled plate is obtained, and finally, the high-quality and high-performance magnesium alloy composite material cold-rolled plate can be obtained with high efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

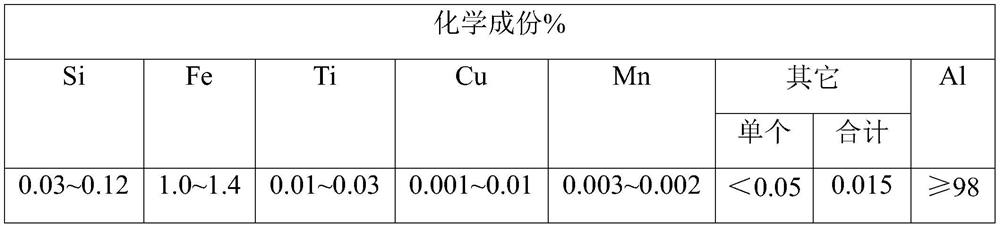

Aluminum foil for high-extension high-deep-drawing-power aluminum-plastic film and production process of aluminum foil

The invention discloses an aluminum foil for a high-elongation high-deep-drawing power aluminum-plastic film and a production process of the aluminum foil. The aluminum foil for the high-elongation high-deep-drawing power aluminum-plastic film comprises the following raw material alloys in percentage by weight: 0.03-0.12% of Si, 1.0-1.4% of Fe, 0.01-0.03% of Ti, 0.001-0.01% of Cu, 0.003-0.02% of Mn, less than 0.05% of other single aluminum, 0.015% of other aluminum and more than or equal to 98% of Al. The aluminum foil for the power aluminum-plastic film has the advantages of good surface quality, good stability, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, high tensile strength, and the product consistency is good, the deep drawability can reach 7.5 mm or above, and the ductility is 20% or above. By systematically improving a casting, hot rolling and cold rolling production process, an aluminum-plastic film aluminum foil rolling process and an annealing process, the aluminum foil for the power aluminum-plastic film has relatively excellent cold stamping forming capacity and good quality stability and consistency, and has important significance in replacing an imported aluminum foil for the power aluminum-plastic film.

Owner:XIAMEN XIASHUN ALUMINUM FOIL

Glass bottle stress annealing method and system

The invention discloses a glass bottle stress annealing method. A bottle maker completes forming of glass bottles and conveys the glass bottles onto a conveying belt; the conveying belt conveys the glass bottles to a heating element; the heating element uniformly heat the bottle body of every glass bottle; the conveying belt conveys the glass bottles to an annealing furnace, and the glass bottles are processed through heating in a heating chamber, annealing in a heat insulating chamber and furnace cooling in a cooling chamber to complete the entire annealing process. The glass bottle stress annealing system comprises the bottle maker, the annealing furnace, the conveying belt sequentially penetrating through the bottle maker and the annealing furnace, a motor at the tail end of the conveying belt, and the heating element, wherein the heating element is arranged on the conveying belt and between the bottle maker and the annealing furnace; the annealing furnace is provided with the heating chamber for heating the glass bottles, the heat insulating chamber for annealing treatment, and the cooling chamber for furnace cooling. The glass bottle stress annealing method has the advantages of being high in yield and low in energy consumption.

Owner:长兴华众玻璃有限公司

Annealing process of cold-rolled stainless steel coil cover type annealing furnace

PendingCN114045379AAvoid large gapsMeet the use requirementsFurnace typesBundling machine detailsMetallurgySS - Stainless steel

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

Hot tinning process of ultrafine copper wire

The invention discloses a hot tinning process of an ultrafine copper wire, and belongs to the field of tinned copper wires. The process comprises the following steps: taking a copper wire for paying off, then placing the copper wire into an annealing tube for annealing, drying the copper wire after annealing, placing the copper wire into tin liquid for tinning, and taking up the copper wire after cooling to prepare the ultrafine copper wire. Before annealing, the surface of the copper wire is continuously coated with ethanol during paying off; at least three temperature sections are arranged in the annealing tube for annealing, and the temperature of the copper wire out of the annealing tube is controlled to be 40 DEG C or below. According to the hot tinning process, the internal stress of the copper wire can be fully released by adopting multi-section temperature annealing, so that the surface stress of the copper wire is reduced, subsequent processing is facilitated, and the quality of the tinned copper wire is improved.

Owner:JIANGXI FUHONG METAL CO LTD

Method for eliminating heat treatment mixed crystals of W9Cr4V2Mo steel bearing part

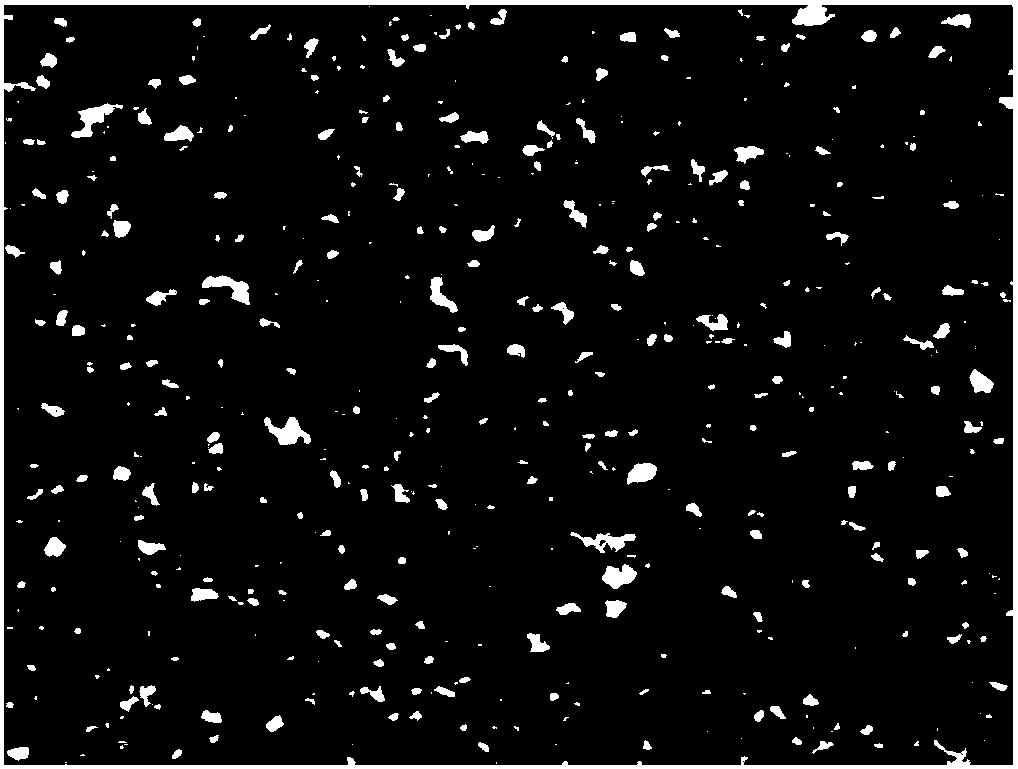

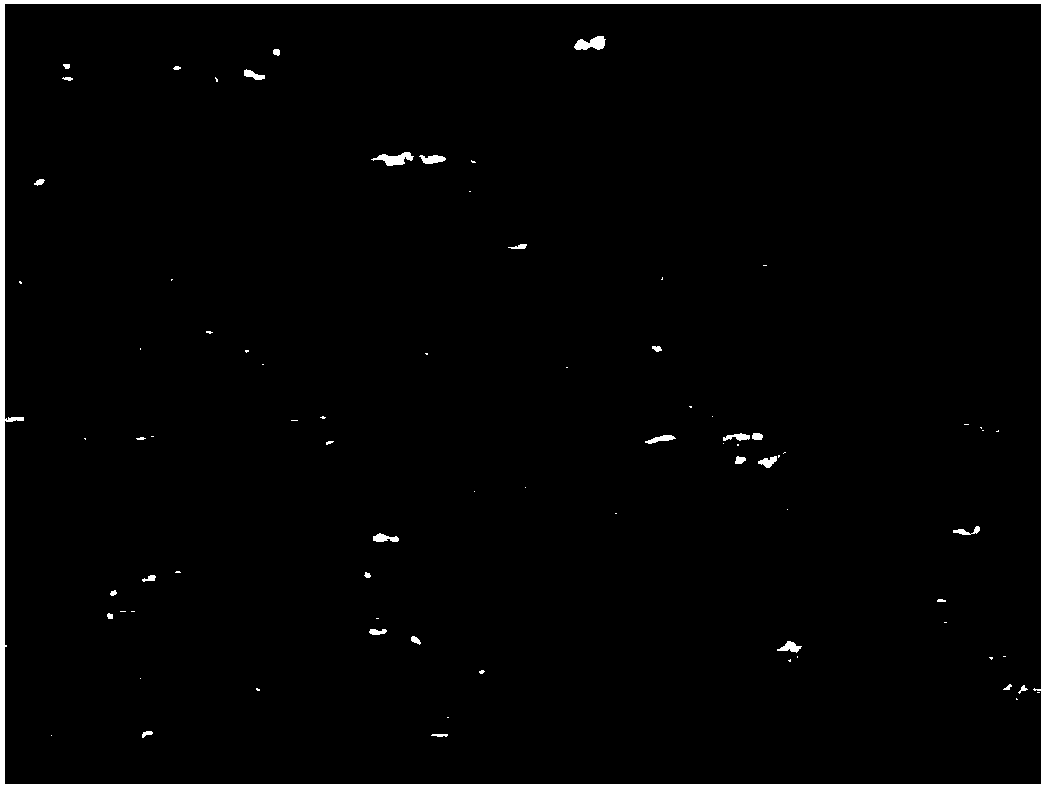

InactiveCN113061712AOptimized annealing processEliminate mixed crystal structureFurnace typesHeat treatment furnacesMetallic materialsAustenite

The invention provides a method for eliminating heat treatment mixed crystals of a W9Cr4V2Mo steel bearing part, belongs to the technical field of metal material heat treatment, and particularly relates to the method for eliminating the heat treatment mixed crystals of the W9Cr4V2Mo steel bearing part. The method aims at solving the problem that in the heat treatment process of the W9Cr4V2Mo steel bearing part, the serious mixed crystal phenomenon improving effect is not obvious. According to the method, the W9Cr4V2Mo steel bearing part needs to be subjected to annealing treatment before the mixed crystals appear in a vacuum gas quenching furnace through quenching, and the annealing technological process comprises preheating, complete austenitizing, primary isothermal treatment, incomplete austenitizing, secondary isothermal treatment and cooling. The method is used for eliminating the heat treatment mixed crystals of the W9Cr4V2Mo steel bearing part.

Owner:AVIC HARBIN BEARING

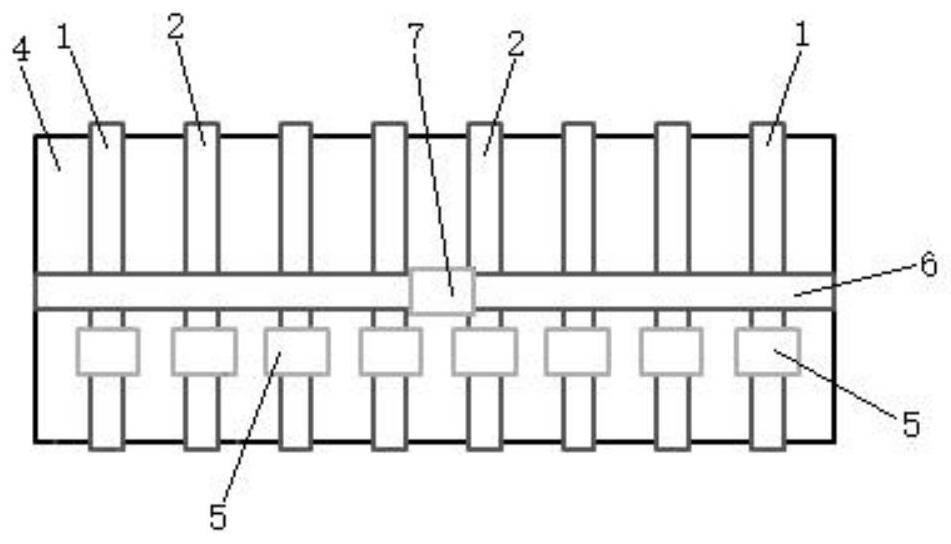

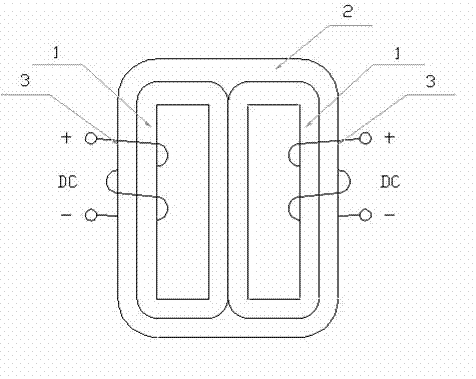

Annealing process for three-phase three-column amorphous alloy iron core

InactiveCN102412061AOptimized annealing processPerformance is not affectedFurnace typesInductances/transformers/magnets manufactureThermal treatmentThree-phase

The invention discloses an annealing process for a three-phase three-column amorphous alloy iron core. The annealing process comprises the following steps of: preparing one big-frame iron core and two small-frame iron cores; splicing the big-frame iron core and the small-frame iron cores into a three-phase three-column amorphous iron core; winding conductor bars with corresponding number of turns on the three-phase three-column amorphous iron core, well connecting the conductor bars, and thermally treating the three-phase three-column iron core integrally; and performing final treatment on the three-phase three-column amorphous iron core subjected to the thermal treatment to make the three-phase three-column amorphous iron core immobilized in performance, and then coating epoxy resin to complete the entire annealing process. The annealing process disclosed by the invention has no influence on the performance of the iron core, so that the quality of the iron core is ensured.

Owner:CEEG JIANGSU

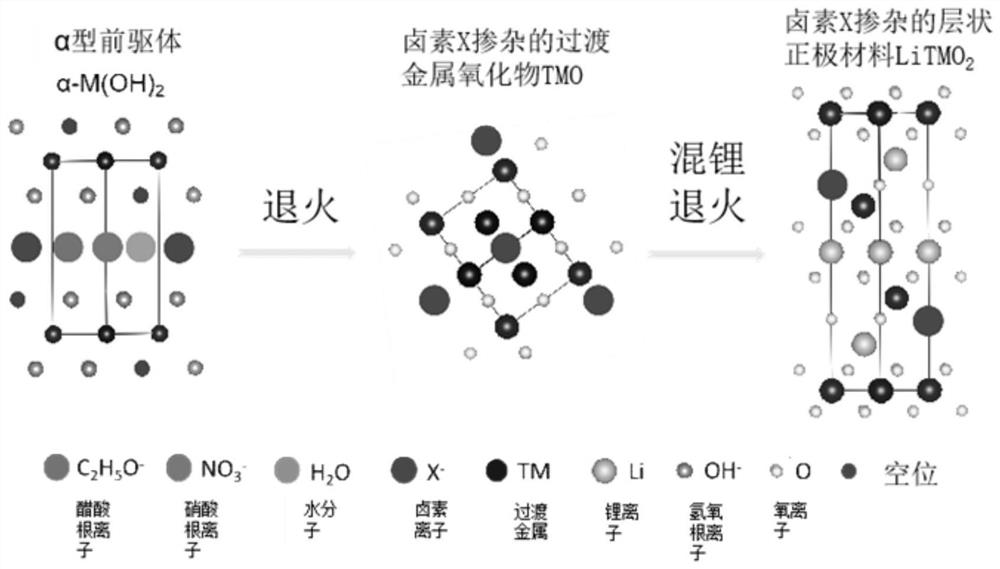

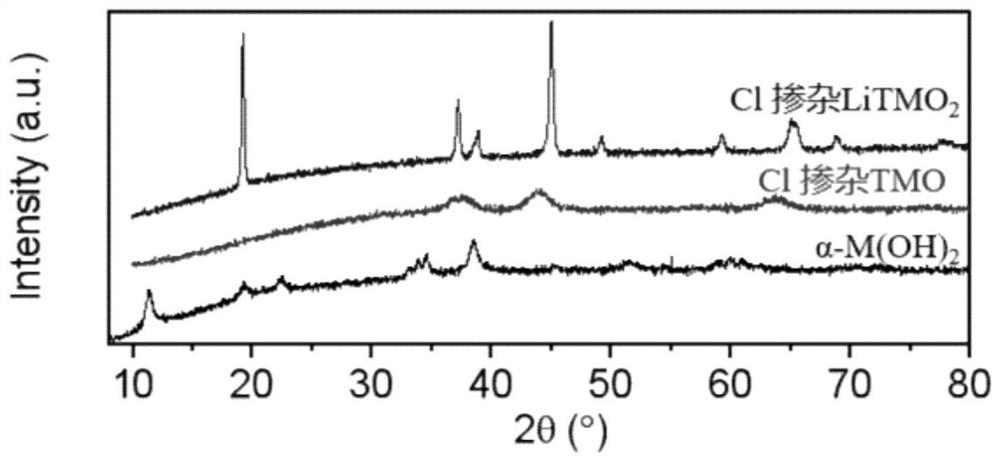

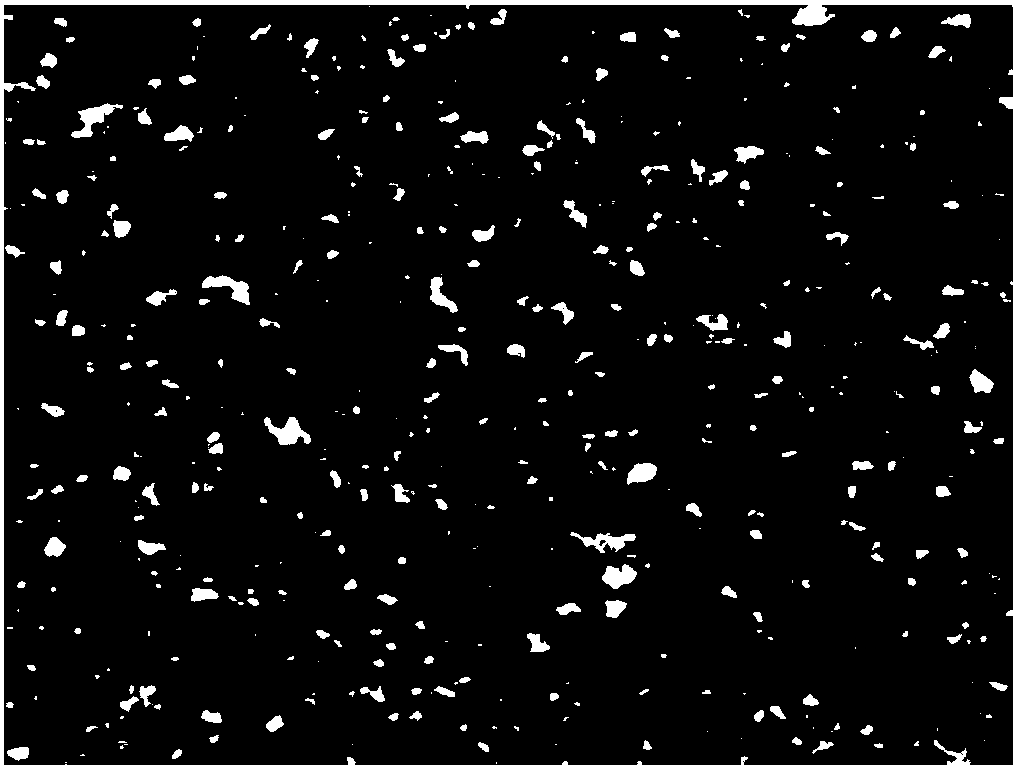

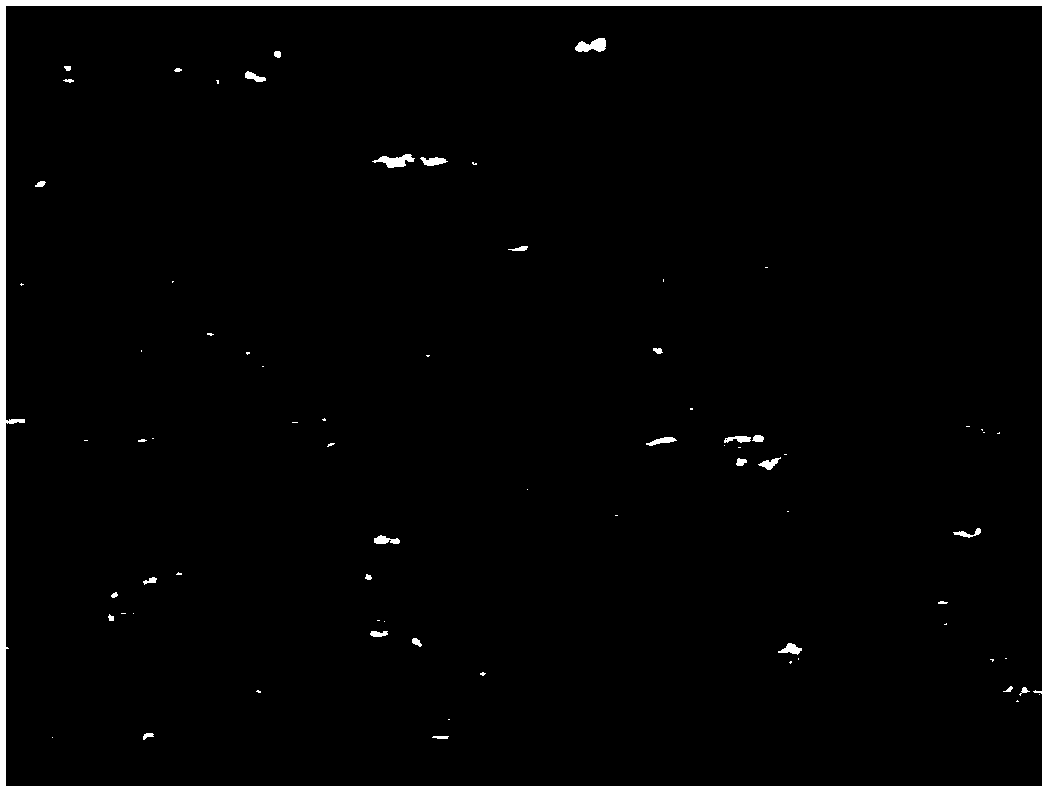

Method for doping anion in positive electrode material of lithium ion battery, positive electrode and battery

ActiveCN112978810BEvenly dopedOptimized annealing processSecondary cellsPositive electrodesElectrical batteryLithium-ion battery

The invention provides a method for doping anions in the cathode material of a lithium ion battery, the cathode and the battery. The method includes: configuring a mixed solution containing nickel salt, cobalt salt, and manganese salt; configuring NaOH solution; configuring ammonia solution; adding the mixed solution, NaOH solution and ammonia solution to the water, and under the protection of an inert atmosphere, the Reaction for 5h-15h under the condition of pH value 7.5-9, after washing, suction filtration and drying, the precursor is obtained; the precursor is annealed for 2h-6h in an oxygen atmosphere at 200°C-400°C to obtain an oxide; The oxide is ground and mixed with the lithium salt, and sintered in two stages under an oxygen atmosphere to obtain an anion-doped lithium-ion battery cathode material. The method of the invention can realize homogeneous and single doping of anions without other doping sources and treatment processes, has low cost, simple and easy operation, non-toxicity, and is suitable for large-scale production.

Owner:香港城市大学深圳研究院

5182 aluminum alloy

ActiveCN106834825BHigh strengthImprove performance uniformityTemperature control deviceRolling mill drivesUltimate tensile strengthImpurity

The invention discloses a 5182 aluminum alloy. The aluminum alloy is composed of Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, and remaining Al and some inevitable impurities. A preparing technology of a tank cover material strip through the 5182 aluminum alloy comprises the steps of firstly, taking of the 5182 aluminum alloy; secondly, hot rolling, cooling and obtaining a blank for cold rolling; thirdly, primary cold rolling, and obtaining a cold-rolled intermediate product, wherein the total deformation amount ranges from 66% to 78%; fourthly, air cushion furnace annealing; fifthly, secondary cold rolling, wherein the total deformation amount ranges from 71% to 76%; sixthly, stretch bending and correcting. According to the 5182 aluminum alloy and the preparing technology of the tank cover material strip through the 5182 aluminum alloy, through high alloying, the alloy strength is improved, meanwhile, the content of Fe and Si is reasonably controlled, and bank mark generation is restrained; continuous air cushion furnace annealing is adopted, through high-temperature short-time annealing, the grains are adjusted and controlled, uniformity of the strip performance is improved, and meanwhile the strip surface quality is ensured.

Owner:广西南南铝加工有限公司

A kind of hot-dip galvanized high-strength steel with excellent fe-al alloy layer characteristics and its manufacturing method

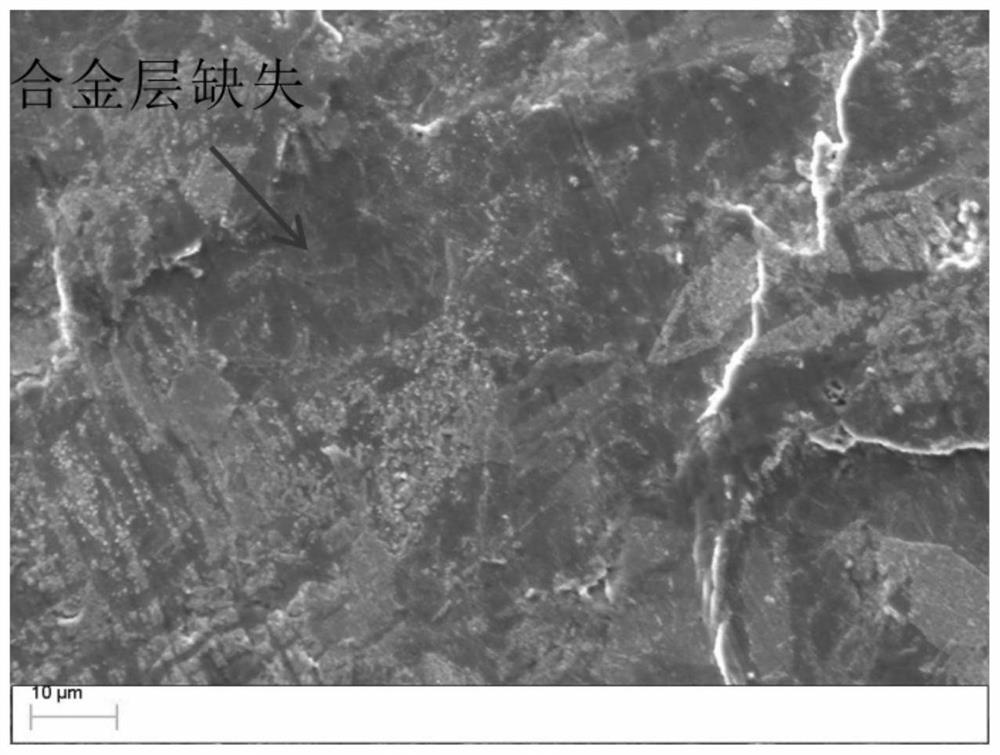

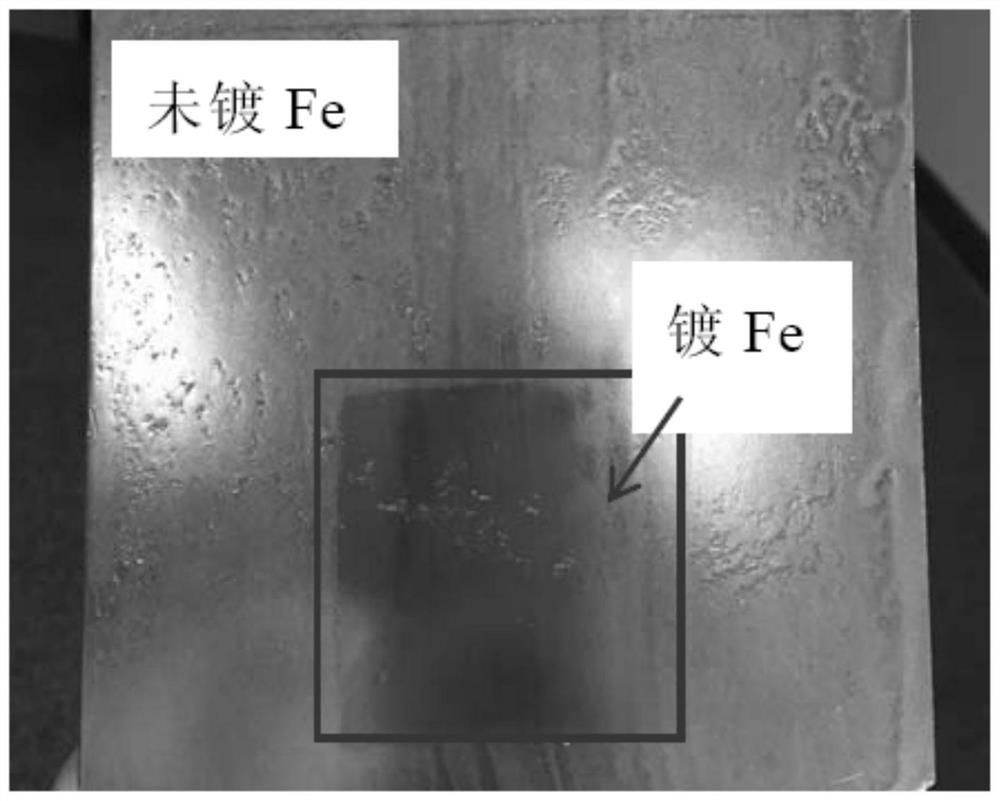

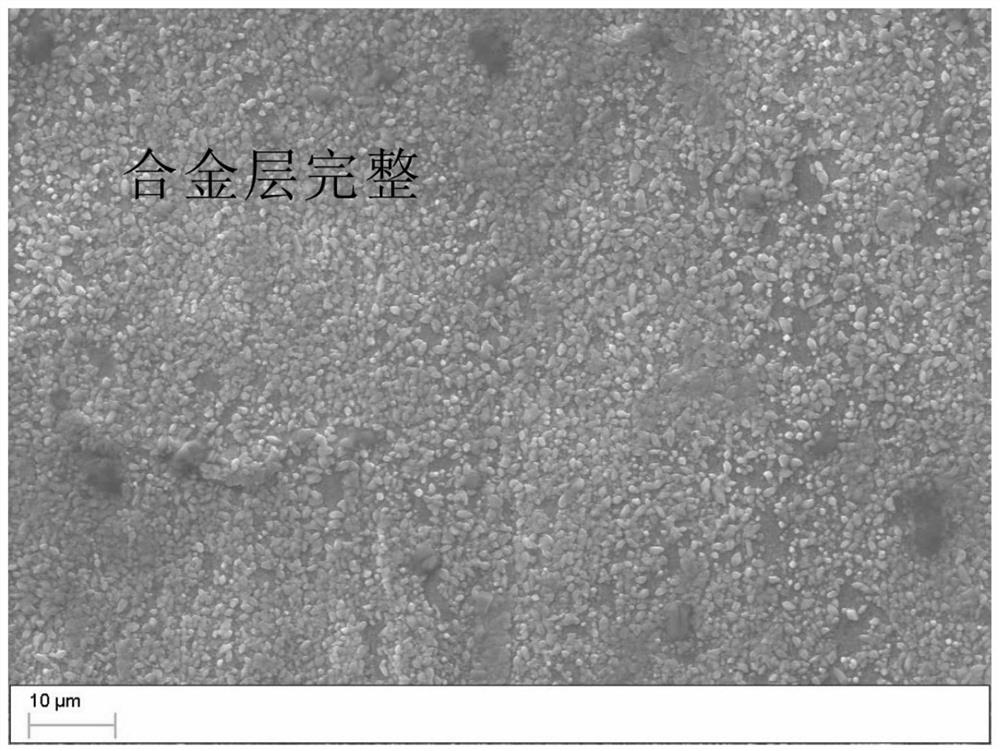

ActiveCN110760771BReduce contentIncrease contentHot-dipping/immersion processesSuperimposed coating processChemical compositionAlloy

A hot-dip galvanized high-strength steel having the characteristics of an excellent Fe-Al alloy layer and a manufacturing method thereof, the hot-dip galvanized high-strength steel sequentially comprises a substrate, an Fe-Al alloy layer and a galvanized layer, and the chemical composition of the substrate is weight percent are: C: 0.15-0.25wt%, Si: 1.00-2.00wt%, Mn: 1.50-3.00wt%, P≤0.015wt%, S≤0.012wt%, Al: 0.03-0.06wt%, the rest are Fe and Impurities are unavoidable; the missing area of the Fe-Al alloy layer is less than 5%, the Fe-Al alloy layer is uniform, complete, and has consistent appearance characteristics, and the hot-dip galvanized steel sheet obtained after hot-dip galvanizing has good appearance quality, no leakage plating, Defects such as pitting and chromatic aberration are suitable for automotive structural parts and outer panels that have high requirements on surface quality and formability.

Owner:BAOSHAN IRON & STEEL CO LTD

Production technique of copper strips for solar modules

InactiveCN101719527BHigh purityImprove conductivityFinal product manufactureSemiconductor devicesElectrolysisLow oxygen

The invention discloses a production technique of copper strips for solar modules, which belongs to the technical field of nonferrous metal processing and comprises the following steps: drawing-up of continuous-casting oxygen-free copper bar: using high-quality electrolytic copper as the raw material, melting at 1150+ / -10 DEG C, keeping the temperature, covering the copper liquid surface with charcoal and graphite scales to ensure the vacuum state during melting, degassing on line, deoxidizing, stirring, and drawing up the copper bar with a tractor set in an on-off vacuum way; continuous extrusion of copper strip blanks: using oxygen-free copper rods as the raw material, producing copper strip blanks by using a continuous extruder set, cooling the extruded copper strip blanks through a vacuum oxidation-resisting pipe and a water tank, drying and coiling; and rough-rolling the copper strip blanks, medium-rolling, interstage annealing, finish rolling, degreasing, washing, annealing the finished product, washing, grinding the surface to passivate, and longitudinally cutting to obtain the finished product. The product of the invention has the advantages of high purity, low oxygen content and high electrical conductivity.

Owner:浙江力博实业股份有限公司

Preparation method of low carbon low silicon no-aluminum half-technique non oriented electrical steel

ActiveCN101306434BStrong magnetismLow costTemperature control deviceMetal rolling arrangementsRare-earth elementChemical composition

Owner:SHOUGANG CORPORATION

A method to solve the problem of TSV delamination and copper surface depression after cmp

ActiveCN104112696BSolve layeringOptimize the baking processSemiconductor/solid-state device manufacturingRoom temperatureIsolation layer

Owner:SEMICON MFG INT (SHANGHAI) CORP

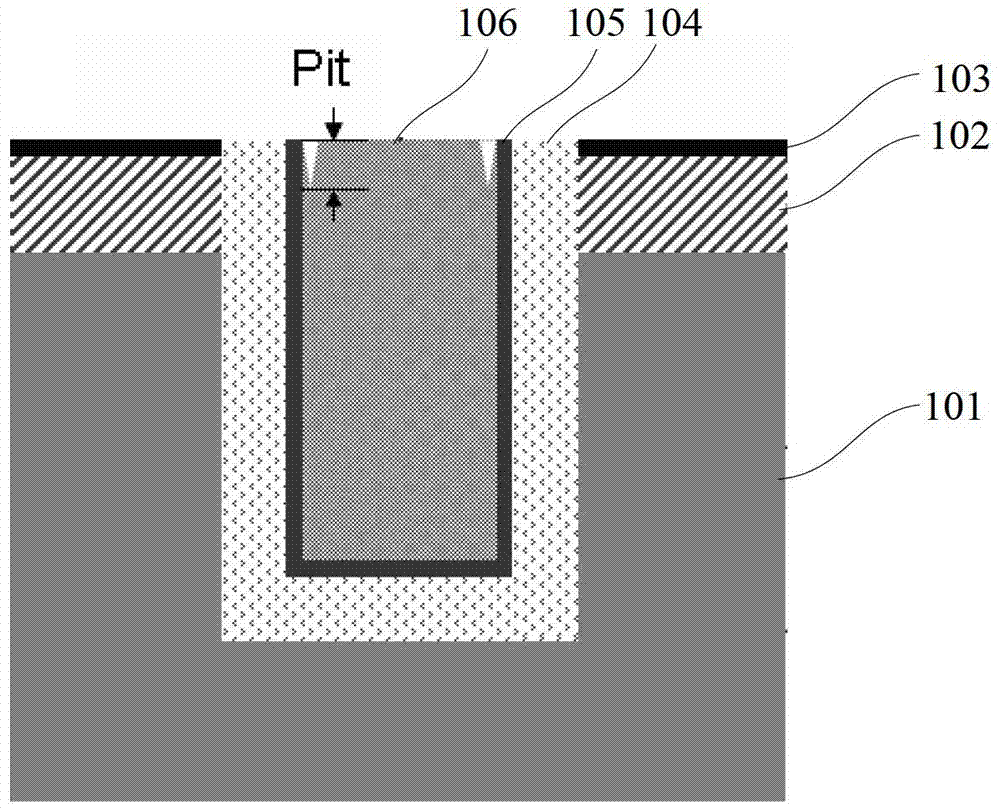

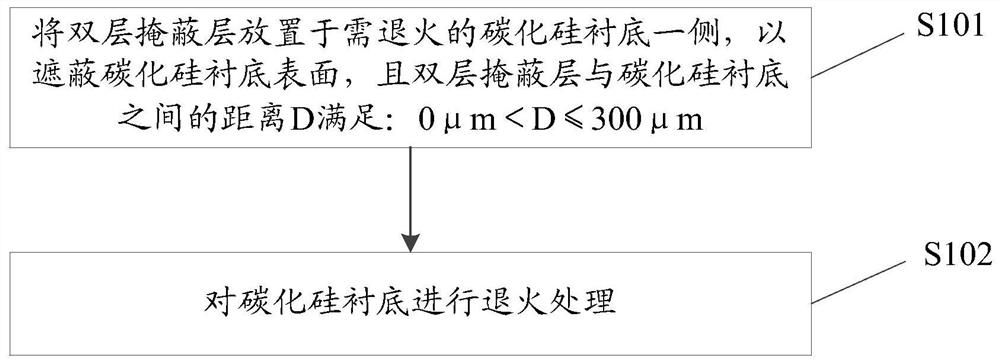

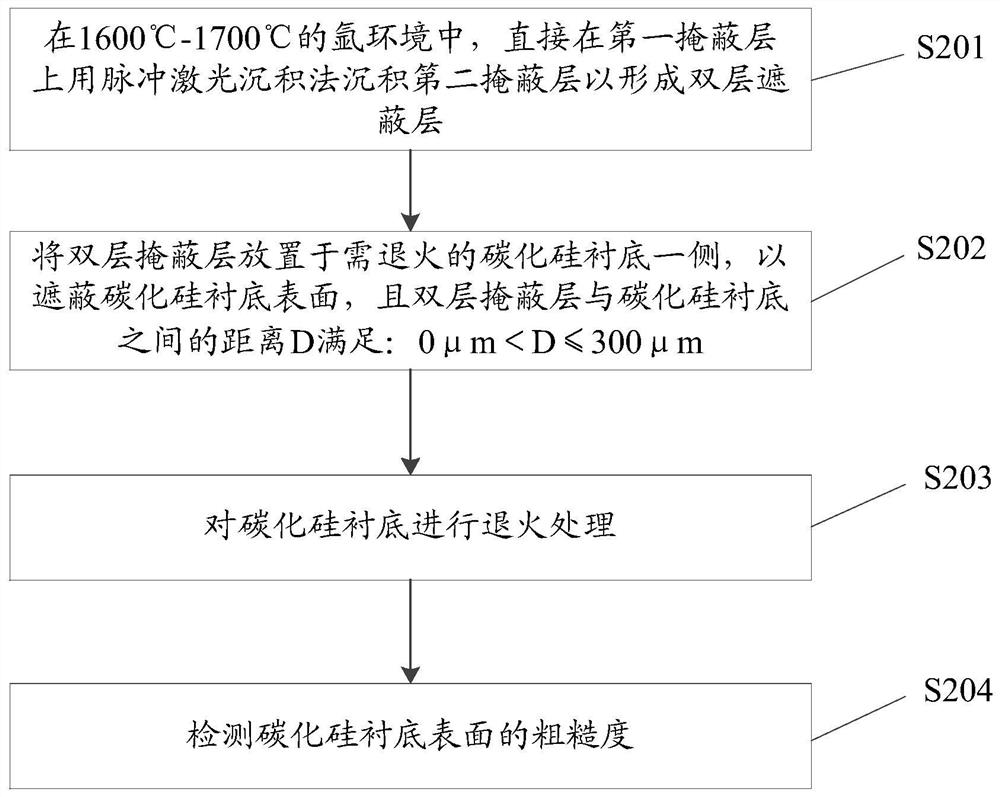

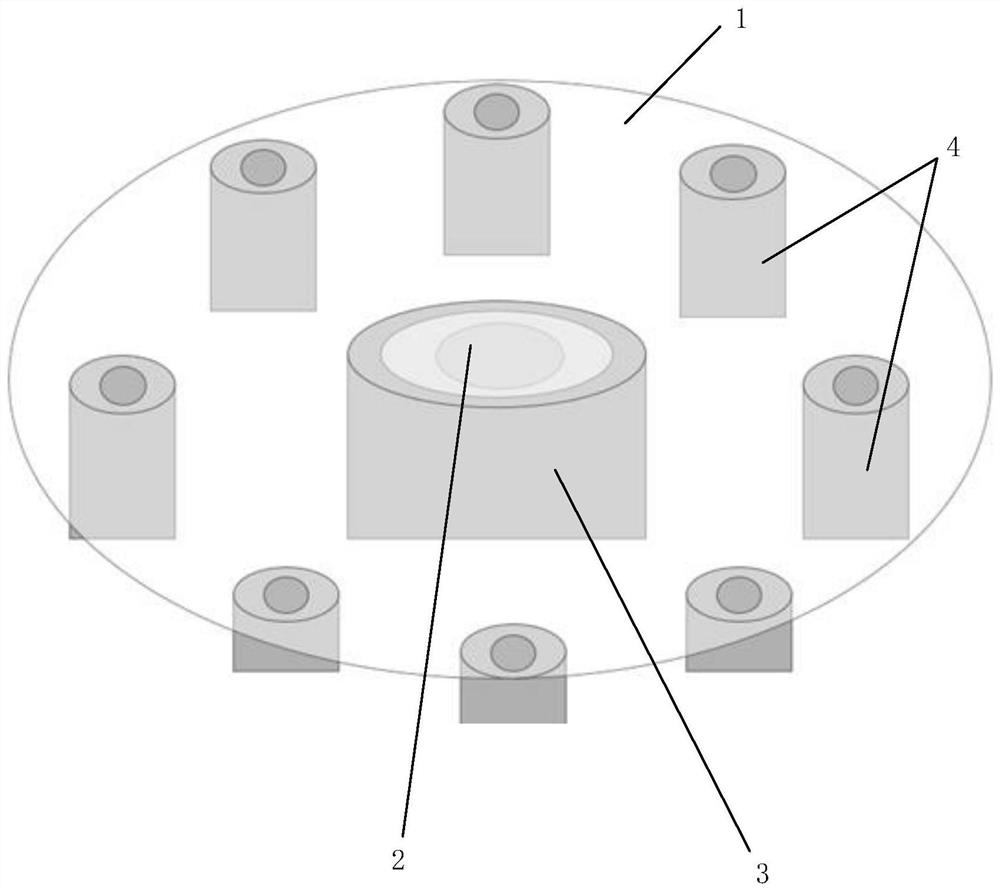

Silicon carbide substrate annealing process and silicon carbide substrate annealing equipment

InactiveCN113066720AOptimized annealing processThe process takes a short timeSemiconductor/solid-state device manufacturingCarbide siliconBi layer

The invention relates to the field of semiconductors, and discloses a silicon carbide substrate annealing process and silicon carbide substrate annealing equipment. The silicon carbide substrate annealing process specifically comprises the steps that double masking layers are placed on one side of a silicon carbide substrate needing to be annealed so as to shield the surface of the silicon carbide substrate, the distance D between the double masking layers and the silicon carbide substrate is more than 0 [mu] m and less than or equal to 300 [mu] m; and the silicon carbide substrate is annealed. The distance between the silicon carbide substrate and the double-layer masking layer can be adjusted, so that the purpose of improving the surface roughness of the silicon carbide substrate is achieved. Therefore, after the silicon carbide substrate is annealed, a complicated masking layer removal process is not needed, and only the double masking layers need to be directly taken away, so that the process is optimized to reduce the process cost under the condition of ensuring the same effect.

Owner:GREE ELECTRIC APPLIANCES INC

An infrared optical material stress testing device and testing method thereof

ActiveCN104535232BMeet the Response RequirementsEasy to operateForce measurement by measuring optical property variationImaging qualityPolarizer

The invention relates to a device and method for testing the stress of an infrared optical material, belongs to the technical field of infrared optical material test, and aims at solving the problems in testing the stress of the infrared optical material through which visible light cannot be transmitted in the prior art. The device is mainly characterized by comprising an infrared light source, an infrared optical system, a signal reception system, a computer acquisition, processing and display system and a test platform. Test is carried out based on the principle of angular measurement compensation of a polarization analyzer, when an angle of 45 degree is formed between an infrared polarizer and an infrared polarization analyzer, namely a vector stress is include, elliptically polarized light generates a stroke difference, and thus, the stress of the material can be calculated. The device is characterized by simple operation and convenient test, the stress of the infrared optical material, through which visible light cannot be transmitted, can be tested, stress test can be used to guide and optimize production technology, glass of a lower stress can be produced, the imaging quality of the infrared material can be further improved, and a high-level infrared imaging system can be produced on the basis.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

A kind of graphene transfer annealing method and manufactured device based on Aln substrate

InactiveCN102915926BEasy to prepareQuality improvementSemiconductor/solid-state device manufacturingPolymethyl methacrylateSingle layer graphene

Owner:XIDIAN UNIV

A Method for Improving Wafer Jitter in Tunneling Oxide Growth Process

ActiveCN108054121BOptimized annealing processFix jitterSemiconductor/solid-state device manufacturingPhysical chemistryEngineering

The invention discloses a method for improving wafer shaking in a tunneling oxide layer growth process, which comprises the following steps: firstly performing a tunneling oxide layer growth process on a semiconductor substrate; and then performing the tunneling oxide layer growth process on all The annealing process of the above-mentioned semiconductor substrate: heating the reaction chamber, feeding hydrogen and oxygen at the same time, so that the air pressure in the reaction chamber remains constant; annealing reaction for a certain period of time; stopping heating the reaction chamber to reduce the temperature in the reaction chamber ; Turn off the hydrogen, reduce the amount of oxygen ventilation, and feed nitrogen at the same time, so that the pressure in the reaction chamber remains constant; after cooling down, the annealing process is completed. The present invention improves the ISSG annealing process. Through the technical analysis and understanding of the wafer deformation, after finding the cause of the defect, the process flow and parameters are changed to solve the problem of silicon wafer shaking during the high-temperature process. After using this method , The yield rate of silicon wafers can be increased by more than 5%.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Short-process rolling method of high-strength plastic aln/az91d composite material

ActiveCN107747071BQuality improvementHigh quality and high performanceMagnesium matrix compositeIngot

The invention relates to a short-flow rolling preparation process of a high-strength and high-plasticity AlN / AZ91D magnesium base composite material plate; solid solution and water quenching processesof a cast ingot before rolling are formulated; subsequent rolling and annealing processes are optimized; and a set of cold rolling process for preparing a high-strength and high-plasticity magnesiumbase composite material rolled plate is provided. The cold rolling process is high in reduction in pass, few in annealing times among passes and short in annealing time, and can realize industrial short-flow preparation. In particular, through the patent technology, namely the optimal ratio of solid solution process parameters to water quenching process parameters to rolling process parameters toannealing process parameters, the edge cracking problem in the cold rolling process is solved when the high-strength and high-plasticity cold-rolled plate is obtained, and finally, the high-quality and high-performance magnesium alloy composite material cold-rolled plate can be obtained with high efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com