Method for doping anion in positive electrode material of lithium ion battery, positive electrode and battery

A lithium-ion battery and cathode material technology, applied in the field of anion doping, can solve the problems of no anion doping method, etc., and achieve the effect of low equipment price, simple process, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

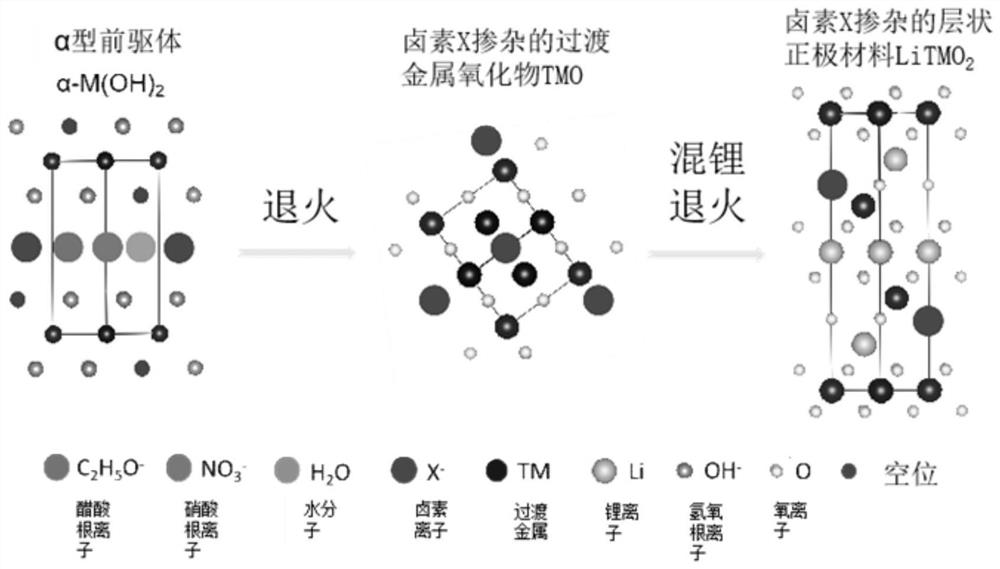

[0037] This embodiment provides a kind of Cl - The preparation method of the doped nickel-rich cathode material, the technological process is as follows figure 1 shown, including the following steps:

[0038] (1) 2M Ni(NO) with Ni:Co:Mn molar ratio of 65:30:5 was configured 3 ) 2 , Co(NO 3 ) 2 , MnCl 2 Mixed solution, configure 4M NaOH solution as precipitant, configure 0.2M ammonia water as complexing agent;

[0039] (2) 100mL of deionized water was added to the reaction kettle as the bottom liquid, mixed solution, NaOH solution, and ammonia water were added to the reaction kettle at the same rate (feeding at a rate of 10mL / h for 8h) at the same time, and nitrogen was passed through the process for protection, The temperature was 60°C, the pH was 7.5, and the reaction was carried out for 8 hours. After the reaction, the product was washed, filtered and dried to obtain the precursor;

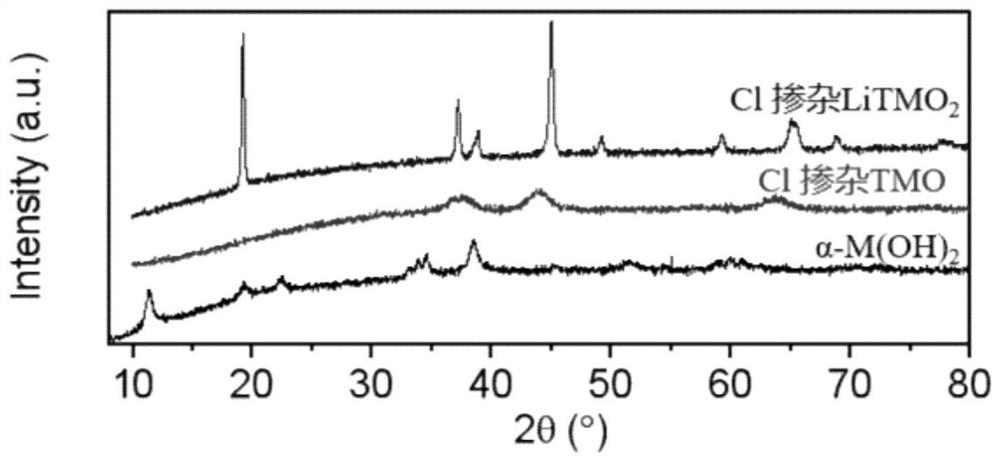

[0040] (3) putting the precursor obtained in step (2) into a tube furnace for anneali...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that the annealing temperature in step (3) is 500°C.

[0046] The Cl of the nickel-rich cathode material obtained in this example - The proportion of ions is less than 1% (such as image 3 shown), indicating that the doping content can be changed by adjusting the annealing process of step (3).

Embodiment 3

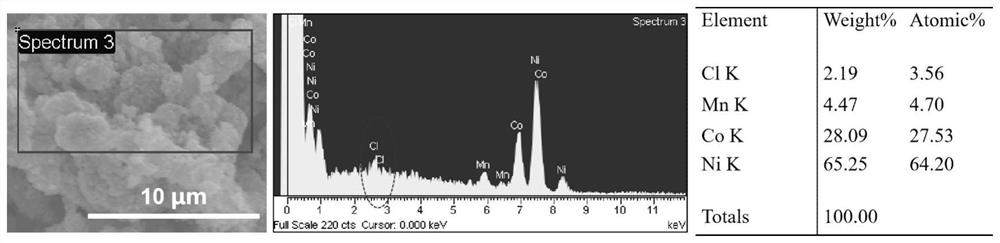

[0048] The difference between this embodiment and embodiment 1 is that: step (1) adopts 1M Ni(C 2 H 5 O 2 ) 2 , Co(C 2 H 5 O 2 ) 2 , MnCl 2 mixture.

[0049] This example obtained 2.03 at. % of Cl - Doped nickel-rich cathode materials (such as Figure 4 shown).

[0050] The above-mentioned embodiment is based on Cl - For example, a homogeneous phase doping was successfully achieved, and other halide ions were similar, and the doping of other anions could be achieved by replacing chlorides with fluorides or nitrates, phosphates, and oxalates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com