Annealing method for improving white points of crystalline silicon double-sided battery

A double-sided cell and annealing technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of limited effect, change of phosphorus source distribution, and low gas flow, so as to reduce the proportion of white spots, reduce the time used, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

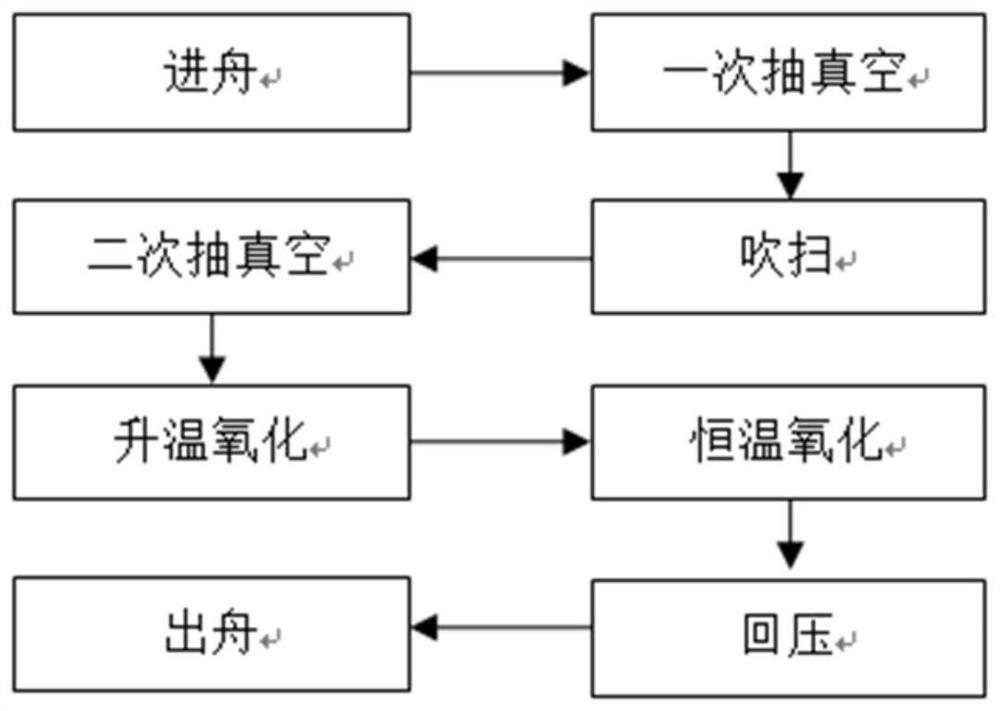

[0082] This embodiment provides an annealing method for improving the white point of a crystalline silicon double-sided battery. The process flow chart of the annealing method is as follows figure 1 shown.

[0083] Described annealing method comprises the following steps:

[0084] (1) Entering the boat: Insert the silicon wafer after alkali polishing into the quartz boat and send it into the furnace tube. During the boat entering process, 2500 sccm of nitrogen gas is introduced, and the boat entering time is 450s;

[0085] (2) One-time vacuuming: use a vacuum pump to vacuumize for 200s, heat up to 580°C during the vacuuming process, and the pressure in the furnace tube after vacuuming is 75mbar;

[0086](3) Purge: Use nitrogen to purge for 250s, the flow rate of the nitrogen is 16SLM, close the gas outlet pipe and heat up to 625°C during the purge process, after purge, the pressure in the furnace tube rises to 750mbar;

[0087] (4) Secondary vacuuming: use a vacuum pump to v...

Embodiment 2

[0093] This embodiment provides an annealing method for improving the white point of a crystalline silicon double-sided battery, and the annealing method includes the following steps:

[0094] (1) Entering the boat: Insert the silicon wafer after alkali polishing into the quartz boat and send it into the furnace tube. During the boat entering process, 1000 sccm of nitrogen gas is introduced, and the boat entering time is 300s;

[0095] (2) One-time vacuuming: use a vacuum pump to evacuate for 150s, heat up to 550°C during the vacuuming process, and the pressure in the furnace tube after vacuuming is 50mbar;

[0096] (3) Purge: Use nitrogen to purge for 200s, the flow rate of the nitrogen is 11SLM, close the outlet pipe during the purge and heat up to 600°C, after purge, the pressure in the furnace tube rises to 700mbar;

[0097] (4) Secondary evacuation: Use a vacuum pump to evacuate for 150s. After evacuating, the pressure in the furnace tube is 100mbar. During the vacuuming ...

Embodiment 3

[0103] This embodiment provides an annealing method for improving the white point of a crystalline silicon double-sided battery, and the annealing method includes the following steps:

[0104] (1) Entering the boat: Insert the silicon wafer after alkali polishing into the quartz boat and send it into the furnace tube. During the boat entering process, 4000 sccm of nitrogen gas is introduced, and the boat entering time is 600s;

[0105] (2) One-time vacuuming: use a vacuum pump to evacuate for 250s, heat up to 600°C during the vacuuming process, and the pressure in the furnace tube after vacuuming is 100mbar;

[0106] (3) Purge: Use nitrogen to purge for 300s, the flow rate of the nitrogen is 20SLM, close the outlet pipe during the purge and heat up to 650°C, after purge, the pressure in the furnace tube rises to 800mbar;

[0107] (4) Secondary vacuuming: use a vacuum pump to vacuumize for 250s. After vacuuming, the pressure in the furnace tube is 200mbar. During the vacuuming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com