Suspension body of hot water circulating pump provided with groove structure on inner wall surface

A technology of hot water circulation pump and suspension body, which is applied in the direction of parts, pumps, pump elements, etc. of the pumping device used for elastic fluid, and can solve the problems of cooling pipeline blockage, cooling, mechanical seal and bearing damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

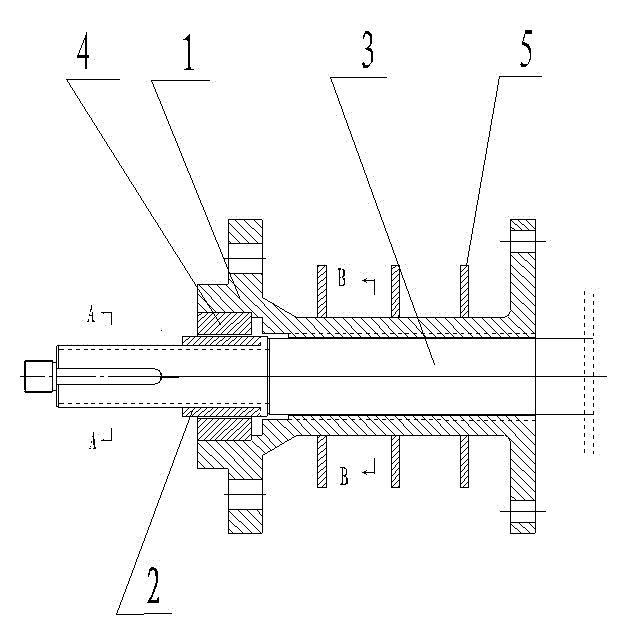

[0012] The specific embodiment of the present invention is to connect the suspension body with the groove structure on the inner wall surface involved in the present invention to the main shaft of the hot water circulating pump through the guide bearing. The left side of the suspension body is connected with the pump cover through bolts, and the right side is connected with the hot water The mechanical seal seat of the circulating pump is connected to the bearing housing.

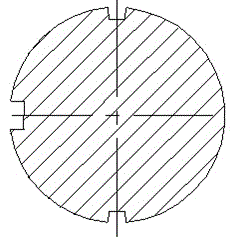

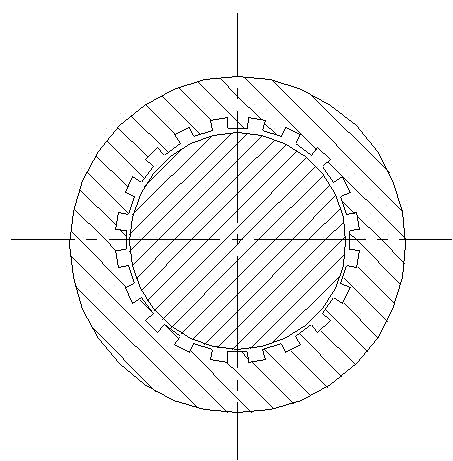

[0013] Such as figure 1 , The present invention includes: a suspension body 1, a shaft sleeve 2, a pump main shaft 3, a guide bearing 4, and an annular cooling fin 5. Suspension body 1 separates the pump running area with high temperature from the working area of mechanical seal and bearing. A through hole is arranged in the axial direction of the suspension body 1, and grooves are processed on the inner wall of the through hole along the axial direction, and the depth of the groove is 0.1*(D o -D), who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com