Lithium ion battery cathode material rich in lithium and manganese and preparation method thereof

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low discharge specific capacity and poor rate performance, and achieve the effects of rich sources, good rate performance, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

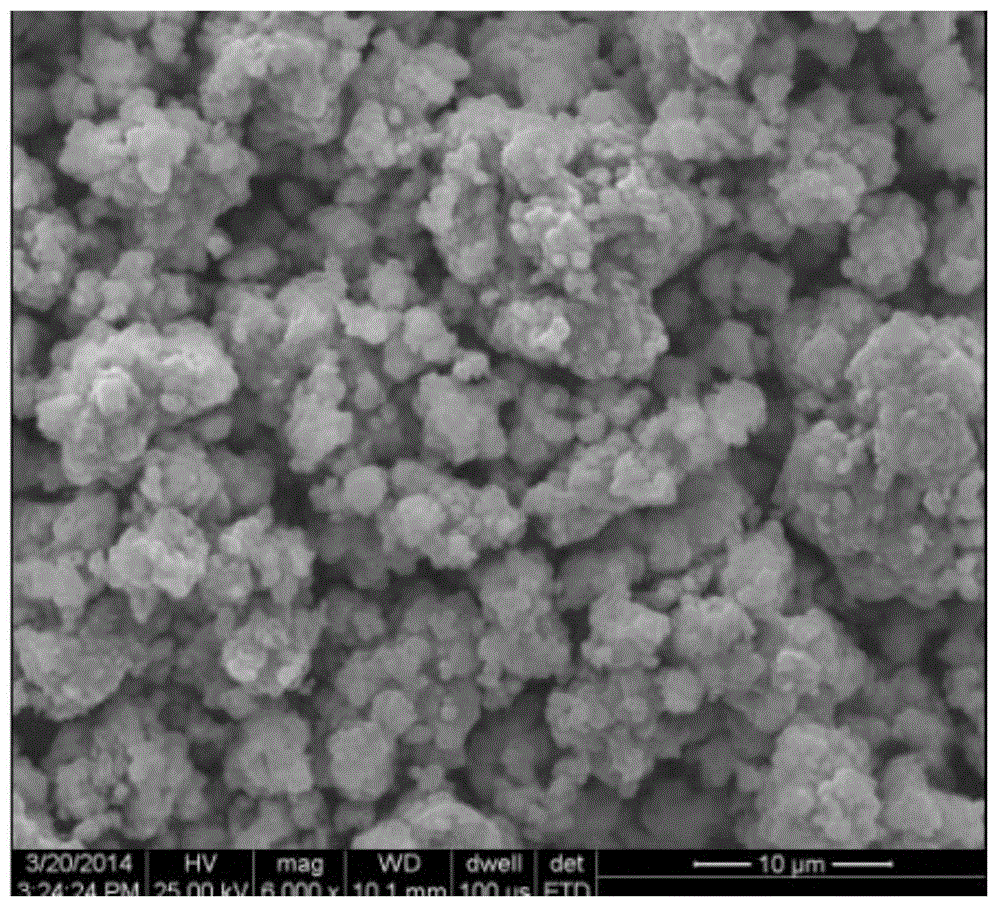

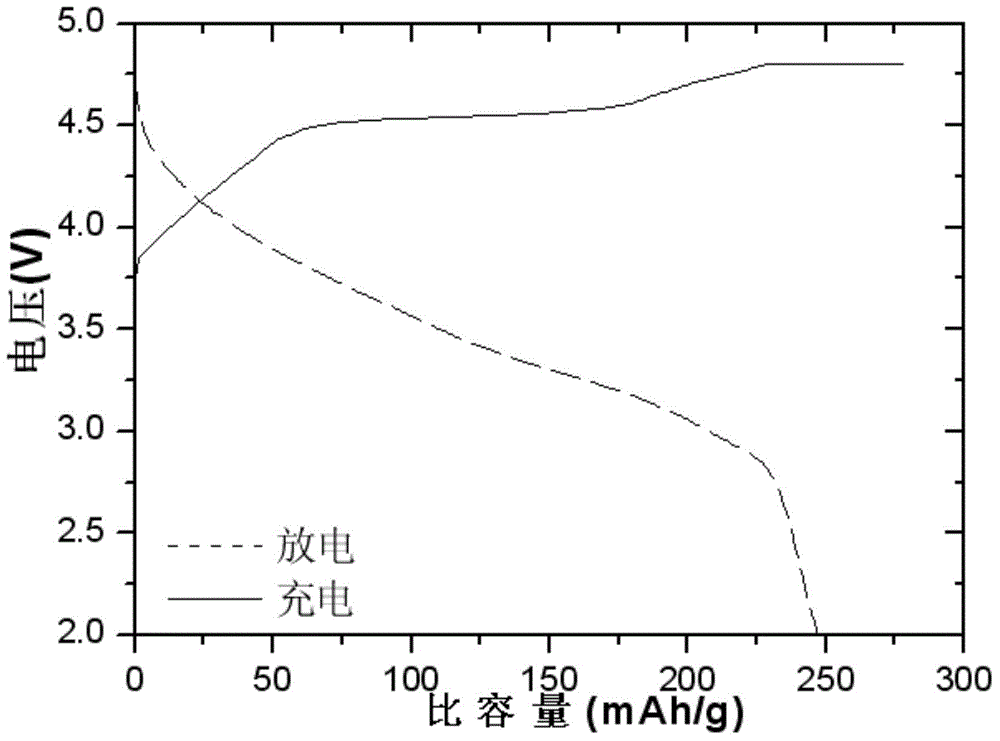

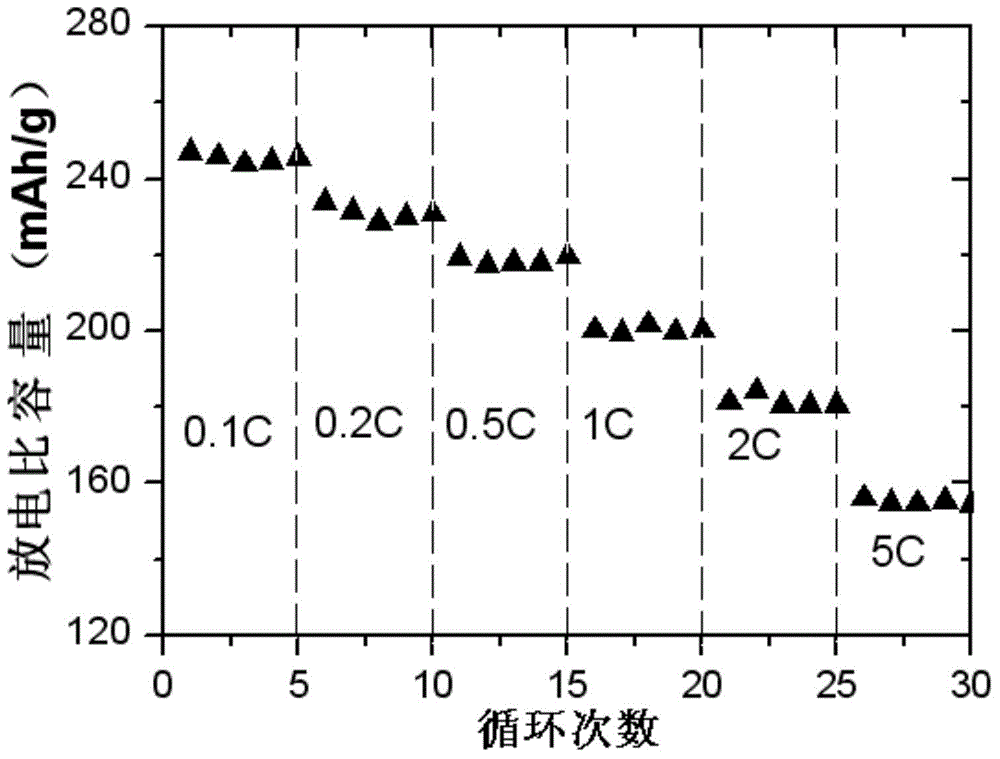

Image

Examples

preparation example Construction

[0034] The second aspect of the present invention provides a preparation method of the lithium-ion battery lithium-rich manganese cathode material according to the first aspect of the present invention, the preparation method comprising the following steps:

[0035] Step (1), according to xLi 2 MnO 3 ·(1-x)LiNi 0.5-a / 2 mn 0.5-a / 2 Fe a o 2 The stoichiometric ratio of lithium salts, nickel salts, iron salts and manganese salts is dissolved in water to obtain an aqueous solution of metal ions, and the total concentration of metal ions in the aqueous solution of metal ions is 0.2 to 3 mol / L;

[0036] Step (2), adding a chelating agent into the metal ion aqueous solution, stirring and dispersing evenly; the ratio of the amount of substances of the chelating agent to the total amount of metal ions is 1 to 1.2:1;

[0037] Step (3), drying the mixed solution obtained in step (2) with a spray dryer to obtain the precursor material of the lithium-rich manganese cathode material; th...

Embodiment 1

[0052] This embodiment provides a lithium-ion battery rich manganese cathode material and its preparation method, the prepared lithium-rich manganese cathode material has a chemical formula: 0.5Li 2 MnO 3 0.5LiNi 0.49 mn 0.49 Fe 0.02 o 2 , the preparation method is as follows:

[0053] Step (1), according to the ratio of Li:Ni:Fe:Mn=1.575:0.245:0.01:0.745 (molar ratio, the same below), lithium acetate, nickel chloride, ferric chloride and manganese nitrate are dissolved in deionized water to obtain A metal ion aqueous solution with a total concentration of metal ions of 1 mol / L; wherein, the excess of lithium salt is 5%, to compensate for a small amount of volatilization of lithium salt when calcined at high temperature;

[0054] Step (2), adding citric acid to the metal ion aqueous solution, stirring and dispersing evenly; the ratio of the amount of citric acid to the total amount of metal ions is 1.05:1;

[0055] Step (3), drying the mixed solution obtained in step (2)...

Embodiment 2

[0062] This embodiment provides a lithium-ion battery rich lithium manganese positive electrode material and its preparation method, the chemical formula of the prepared lithium rich manganese positive electrode material is: 0.2Li 2 MnO 3 0.8LiNi 0.48 mn 0.48 Fe 0.04 o 2 , the preparation method is as follows:

[0063] Step (1), according to the ratio of Li:Ni:Fe:Mn=1.224:0.384:0.032:0.584 lithium nitrate, nickel acetate, ferric chloride and manganese sulfate are dissolved in deionized water to obtain a total concentration of metal ions of 2.0mol / The metal ion aqueous solution of L; Wherein, lithium salt excess 2%, to compensate a small amount of volatilization when lithium salt is calcined at high temperature;

[0064] Step (2), adding acrylic acid to the metal ion aqueous solution, stirring and dispersing evenly; the ratio of the amount of acrylic acid to the total amount of metal ions is 1.01:1;

[0065] Step (3), drying the mixed solution obtained in step (2) with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com