Process for waste oxidation treatment and steam co-production by using supercritical circulating water

A technology for oxidative treatment and circulating water, which is applied in the fields of environmental protection and chemical industry to achieve the effect of solving the danger, improving the service life and having good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

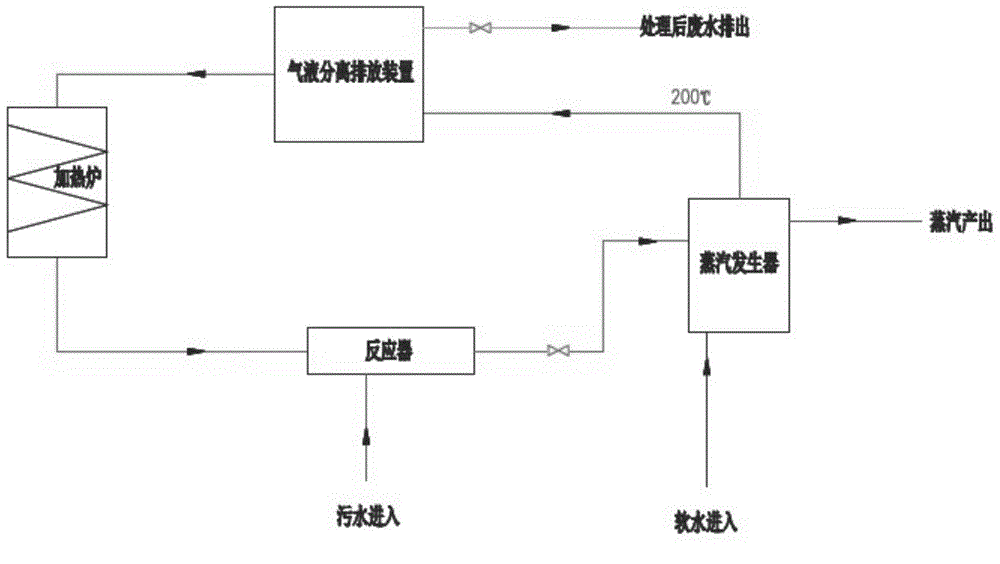

[0036] See attached figure 1 , A supercritical circulating water oxidation treatment waste and steam co-production process. The supercritical circulating water oxidation treatment system includes a heating device, a reactor, a steam generator and a gas-liquid separation device, a heating device, a reactor, a steam generator and a gas The liquid separation device is connected end to end in sequence through pipelines to form a circulating treatment system. The process includes the following steps:

[0037] Step 1 heating step

[0038] The heating furnace is filled with circulating water, and the heating furnace is turned on to heat the circulating water. The heated circulating water overflows through the pipeline to the reactor and other follow-up equipment to promote circulation in the circulating water system, heating to 395°C-450°C, and the pressure to Greater than 22.1Mpa;

[0039] Step 2 reaction step

[0040] The sewage and oxidant are fed into the reactor at the same time, and ...

Embodiment 2

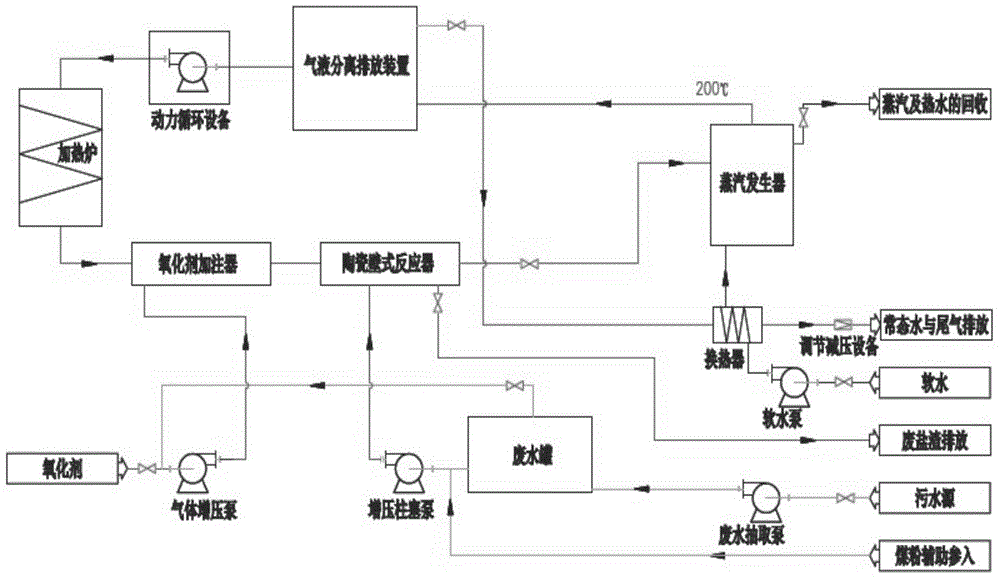

[0048] See attached figure 2 , A supercritical circulating water oxidation treatment waste and steam cogeneration process, including the following steps:

[0049] Step 1 Inject the circulating water into the heating furnace through the power circulation device, and fill the subsequent equipment and pipelines until the pressure relief device is separated. After the circulating water fills the heating furnace, close the circulating water inlet valve, stop the injection, and heat the water in the heating furnace , Raise the temperature to 395℃-450℃; during the heating process, the circulating water will flow into the next equipment due to the increase in temperature and the decrease in density, which will cause a part of the water to overflow in the separation pressure relief device during the heating process. It flows out from the orifice, and the pressure of the entire pipeline device will increase to the discharge pressure set by the device (at least greater than 22.1Mpa); durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com