Smoke low-temperature residual heat utilization system with natural gas cooling-heating combined power device and operating method thereof

A technology for combined cooling, heating and power, and natural gas, applied in the thermal equipment and power generation fields, can solve the problems of not considering the combined supply of domestic hot water, no engineering practical value, poor technical and economic performance, etc., to improve flexibility and economy, large benefit, and the effect of improving power generation output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

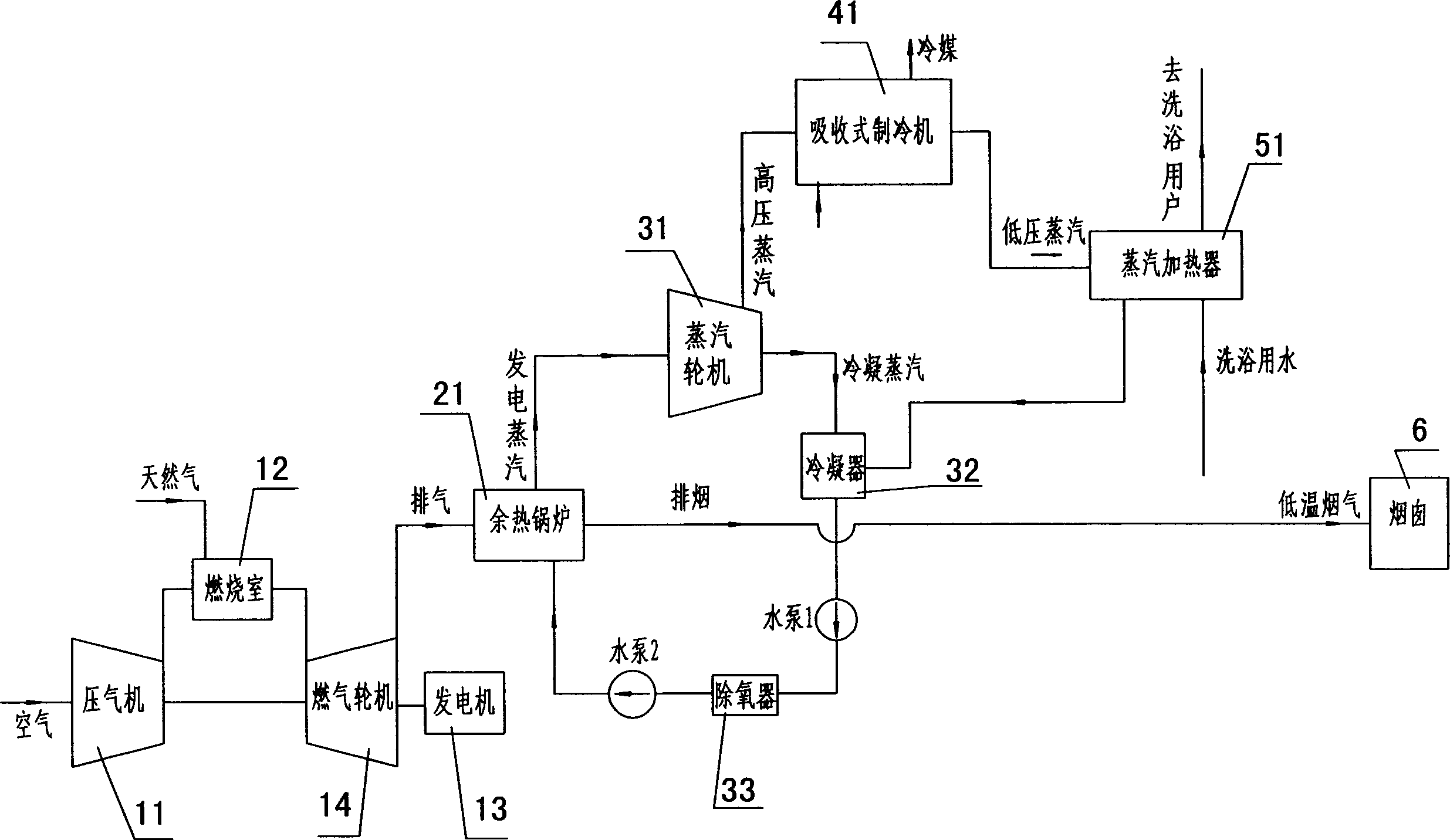

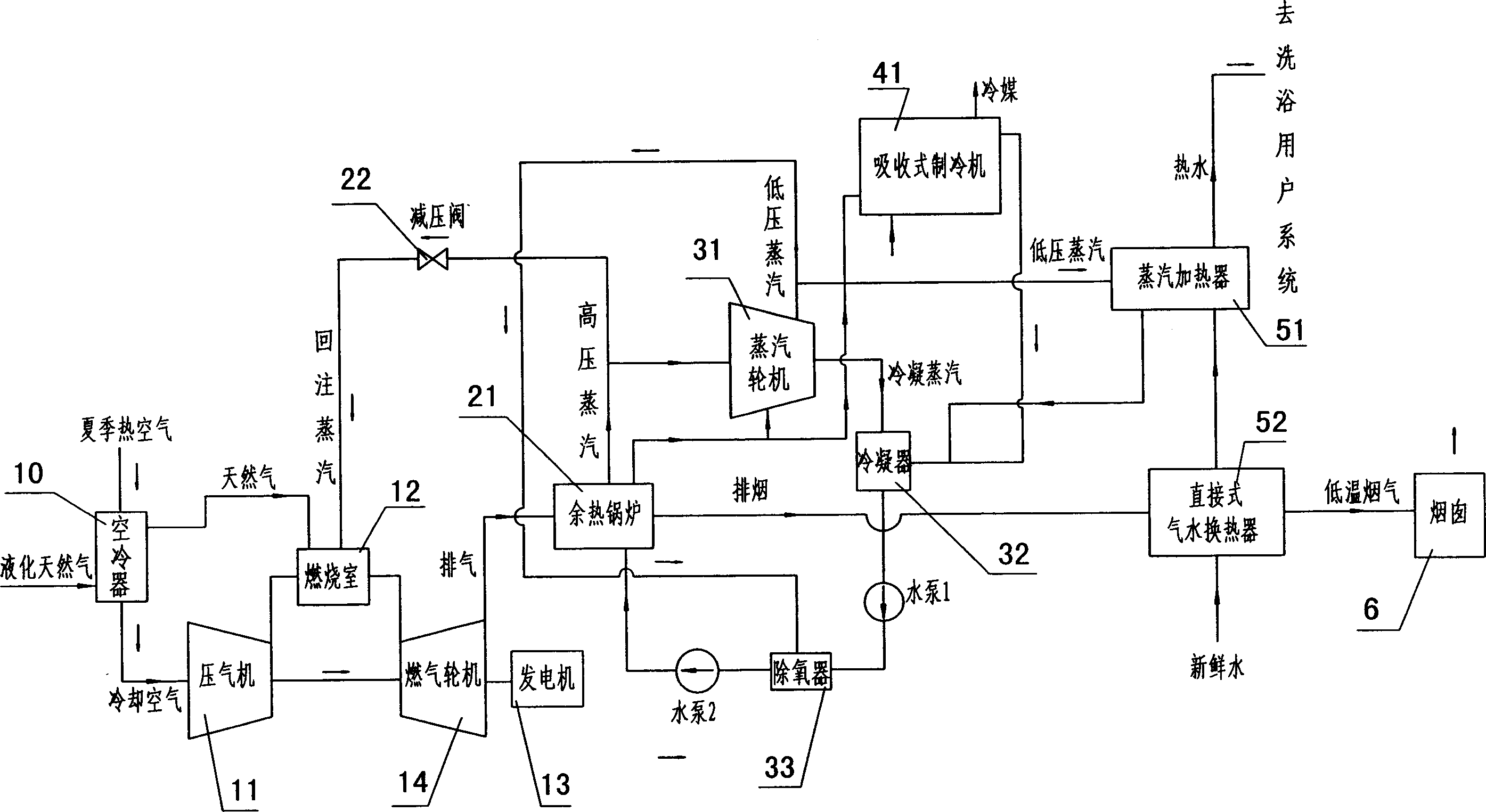

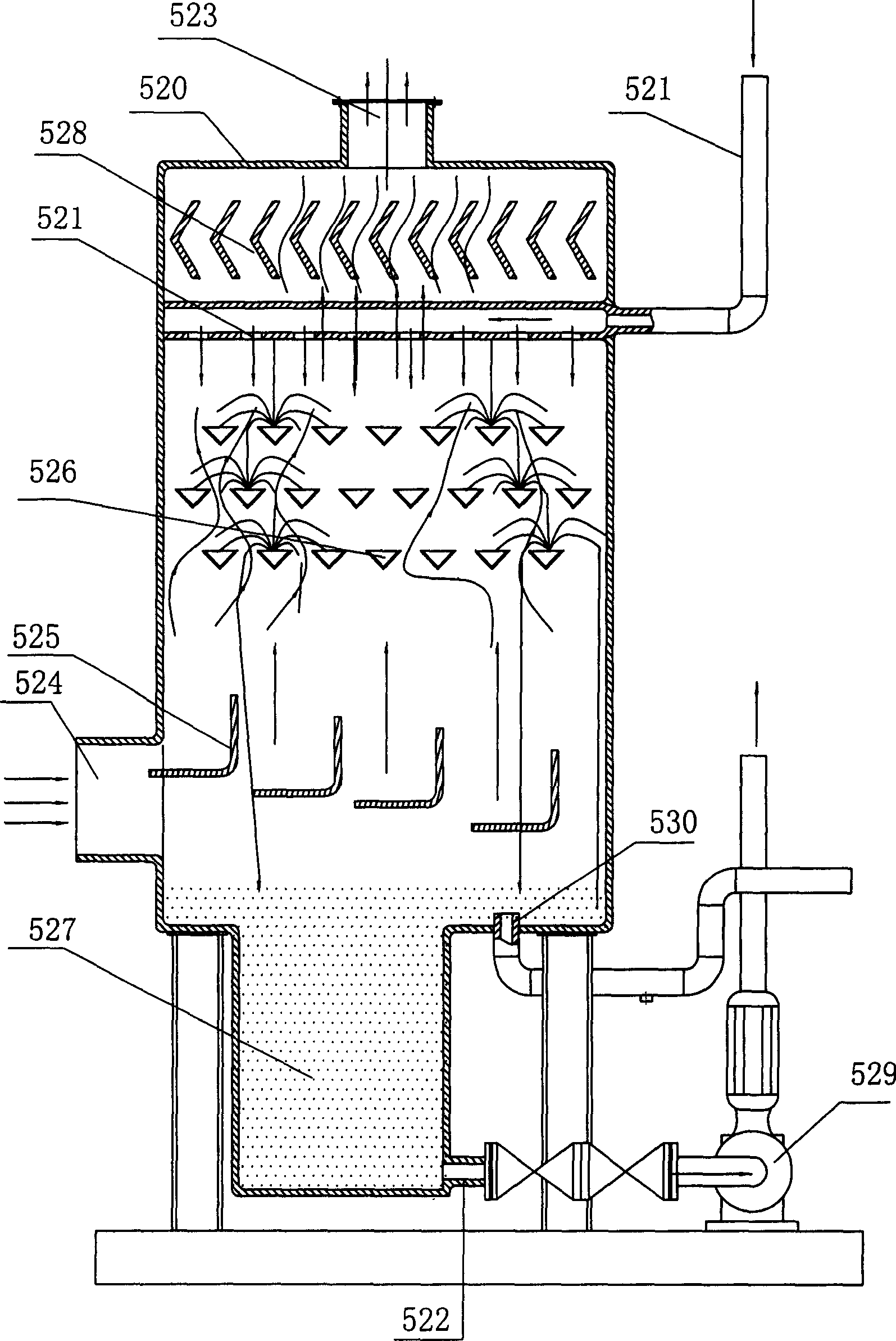

[0043] like figure 2, which shows the structure of a preferred embodiment of the flue gas low-temperature heat utilization system of combined cooling, heating and power supply of the present invention. The heat utilization system includes a gas-fired power generation device, a waste heat boiler, an absorption refrigeration device, and a heating water supply device; The power generation device includes a compressor 11, a combustion chamber 12, a generator 13, and a gas turbine 14; the inlet of the compressor 11 is connected to the atmosphere, and its outlet 11 is connected to the inlet of the combustion chamber 12; the inlet of the combustion chamber 12 is also connected to the natural gas nozzle The waste heat boiler 21 includes a flue gas inlet, a flue gas outlet, a condensed water inlet and a steam outlet. The steam path and pipeline of the pipe, steam turbine 31 are connected with the absorption refrigeration device 41 and the steam heater 51 as the heating water supply de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com