Method and system for contaminant removal by injecting high-temperature dry gas into soil

A dry gas and pollution repelling technology, applied in the field of soil remediation, can solve problems such as difficult operation, difficult installation, ecological environment and human health hazards, and achieve the effects of low energy consumption, reduced adsorption characteristics, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below through specific embodiments.

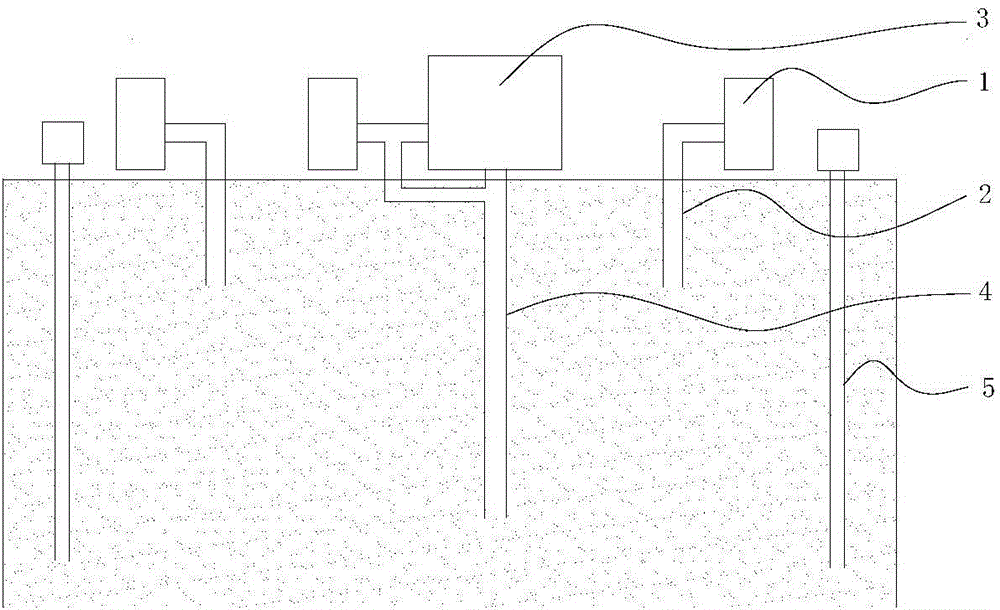

[0032] 1. Layout of injection well and extraction well

[0033]In order to avoid cross-contamination, the whole repair project mainly includes 2 dry gas injection wells (gas injection wells can also be used as extraction wells) and 6 polluted gas extraction wells according to the 1:3 configuration of gas injection wells and extraction wells. All kinds of well group setting equipment are hollow drilling rigs and double-casing auger drilling rigs, and stainless steel well tubes and screens are installed. The depth of the well is set to 18 meters according to the degree of soil contamination. In addition, in order to be able to grasp the changes in parameters such as temperature in the soil layer in the treatment area of the test site, 6 sets of formation thermometers and other measuring instruments were specially installed, distributed around the treatment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com