Method for separating ethyl acetate-ethyl alcohol compound

An ethyl acetate and mixture technology, which is applied in the field of novel extractant for separating ethyl acetate-ethanol mixture, can solve the problems of reduced tower efficiency, small processing capacity, and high operating cost, achieves optimized production process, simple production device, and is beneficial to industrialization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

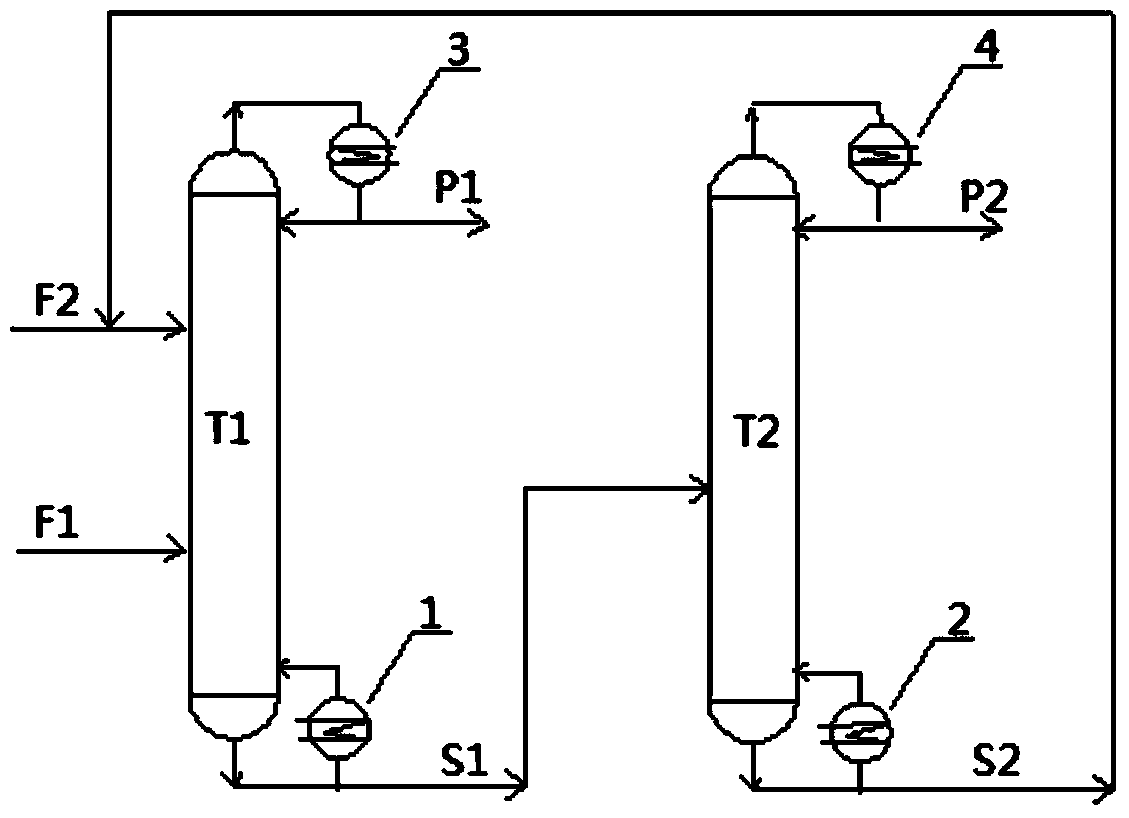

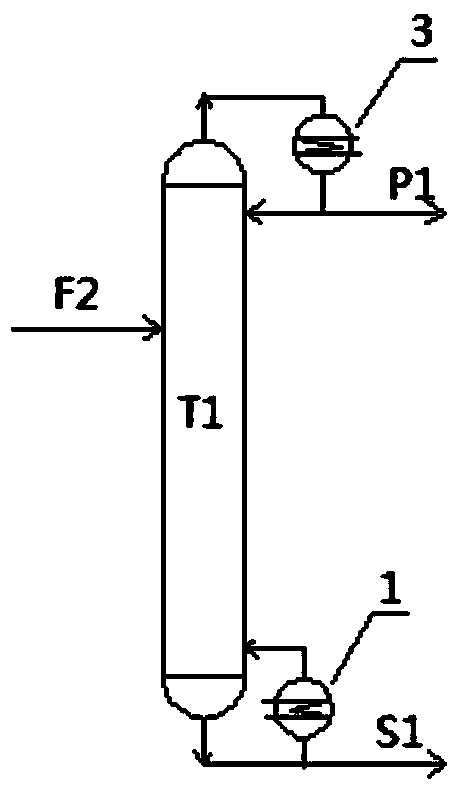

[0029] According to attached figure 1 As shown, in a rectification column equipped with 50 theoretical plates, the operating pressure is 101.3kPa, and the ethyl acetate-ethanol mixture (mass fraction is 71% and 29%) flows from the rectification column at a rate of 1000kg / h Feed from 25 theoretical plates, the extractant 1-ethyl-3-methylimidazolium tetrafluoroborate is fed from the 10th theoretical plate of the rectification tower, the solvent ratio is 1, the reflux ratio is 0.5, ethyl acetate The ester is extracted from the top of the rectification tower at a rate of 708.5kg / h, and the composition is 99.80% ethyl acetate, 0.21% ethanol, and the yield of ethyl acetate is 99.58%; Enter the recovery tower equipped with 19 theoretical plates at the 10th theoretical plate, the operating pressure is 101.3kPa, the reflux ratio is 2.0, ethanol is extracted from the top of the recovery tower at a rate of 287.7kg / h, and the composition is ethyl acetate Ester 0.13%, ethanol 99.87%, etha...

Embodiment 2

[0031] According to attached figure 1 As shown, in a rectifying tower equipped with 55 theoretical plates, the operating pressure is 85kpa, and the ethyl acetate-ethanol mixture (mass content is 55% and 45% respectively) flows from the rectifying tower 44 at a rate of 1000kg / h. Feed at the first theoretical plate, the extractant is a complex solvent composed of 1-ethyl-3-methylimidazolium tetrafluoroborate and N-methylpyrrolidone mixed with a volume ratio of 1:1, from the 11th block of the rectifying tower Feed at the theoretical plate, the solvent ratio is 1, the reflux ratio is 1, ethyl acetate is extracted from the top of the rectification tower at a rate of 656.9kg / h, and the composition is ethyl acetate 99.88%, ethanol 0.12%, ethyl acetate The yield is 99.42%; the extractant-ethanol mixture enters the recovery tower equipped with 19 theoretical plates at the 10th theoretical plate after being extracted from the rectifying tower tank, the operating pressure is 65kPa, the r...

Embodiment 3

[0033] According to attached figure 1 As shown, in a rectification column equipped with 40 theoretical plates, the operating pressure is 101.3kPa, and the ethyl acetate-ethanol mixture (mass content is 85% and 15%) flows from the rectification column at a rate of 1000kg / h Feed at 30 theoretical plates, the extractant is a composite solvent composed of 1-ethyl-3-methylimidazole acetate and 1,3-dimethylimidazole phosphate dimethyl salt at a volume ratio of 1:1, from Feed at the 10th theoretical plate of the rectification tower, the solvent ratio is 0.5, the reflux ratio is 0.2, ethyl acetate is withdrawn from the top of the rectification tower at a rate of 847.9kg / h, and the composition is ethyl acetate 99.91%, ethanol 0.09%, the yield of ethyl acetate is 99.67%; the extractant-ethanol mixture enters the recovery tower equipped with 15 theoretical plates at the 7th theoretical plate after being extracted from the rectifying column tank, the operating pressure is 85kPa, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com