Hydrocracking method of high-yield high-quality chemical raw material

A technology of hydrocracking and chemical raw materials, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment. It can solve problems such as complex process flow, improve economic efficiency, reduce dry gas production rate, and reduce quenching hydrogen consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

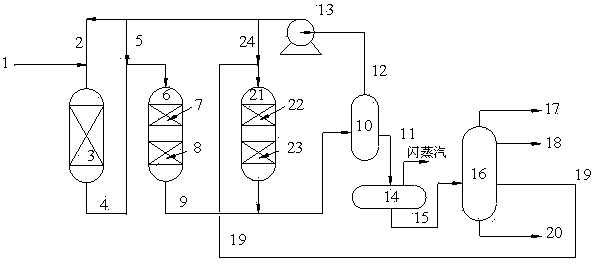

[0039] Embodiment 1~5 adopts figure 1 In the schematic process shown, the properties of the raw oil used are shown in Table 1, and FF-46 hydropretreatment catalyst, hydrocracking catalyst I / hydrocracking catalyst II catalyst system with different volume ratios are selected, and the composition and properties of the catalyst are shown in Table 1. 2. The processing condition and product property of embodiment 1~5 are listed in table 3. The distillation ranges of the fractions in the examples are: light naphtha350°C.

[0040] The results of Examples 1 to 5 show that by using the hydrocracking method of the present invention, the heavy raw oil can be converted into high-quality high-value-added chemical raw materials such as light naphtha, heavy naphtha and hydrogenated tail oil.

[0041] Table 1 Main properties of raw oil.

[0042] Raw oil Iran VGO Victory VGO Density(20℃) / g·cm -3 0.9072 0.9241 Distillation range / ℃ 285~537 350~550 Sulfur, wt% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com