Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

343results about "Forced-flow steam boiler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

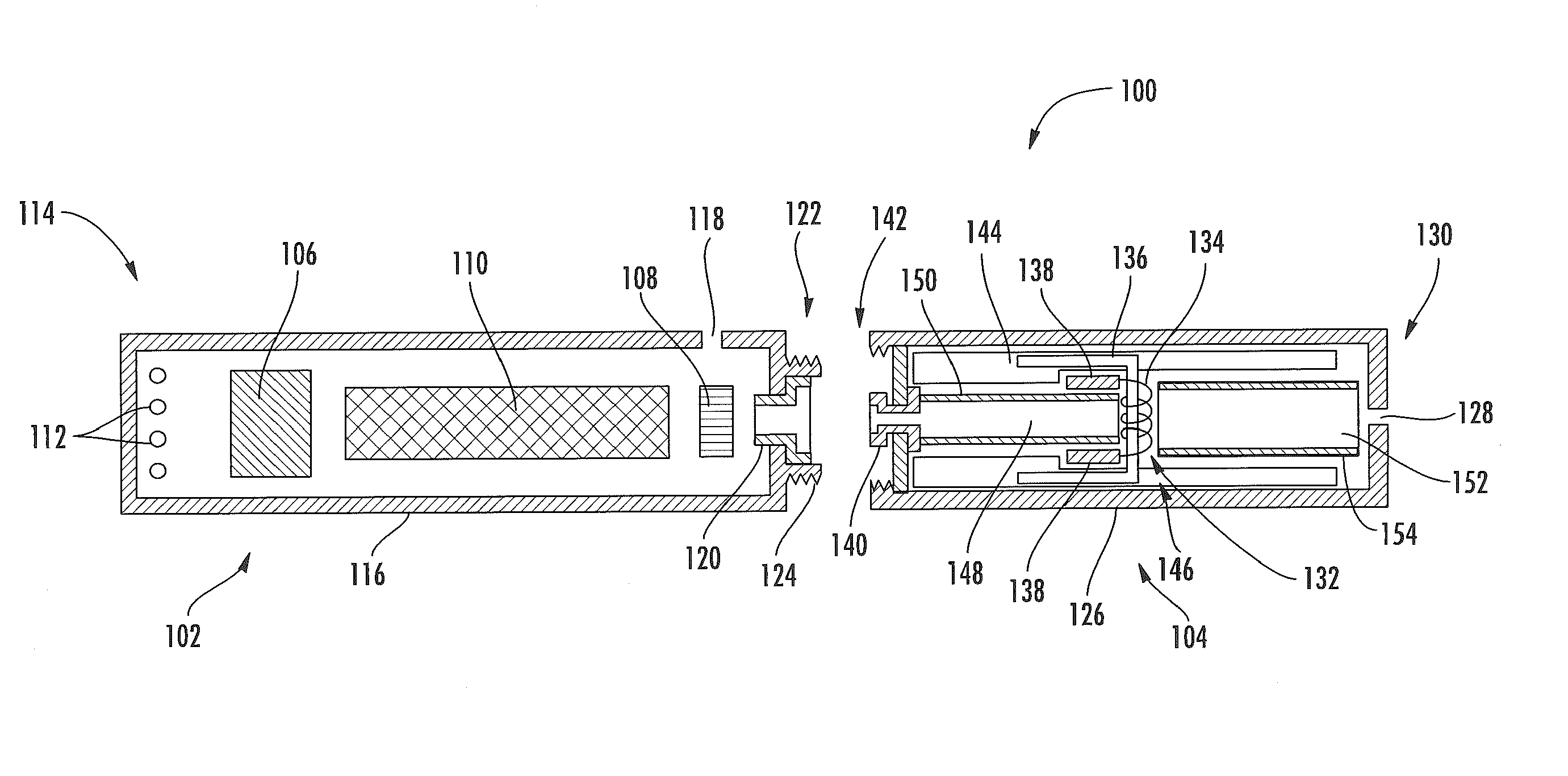

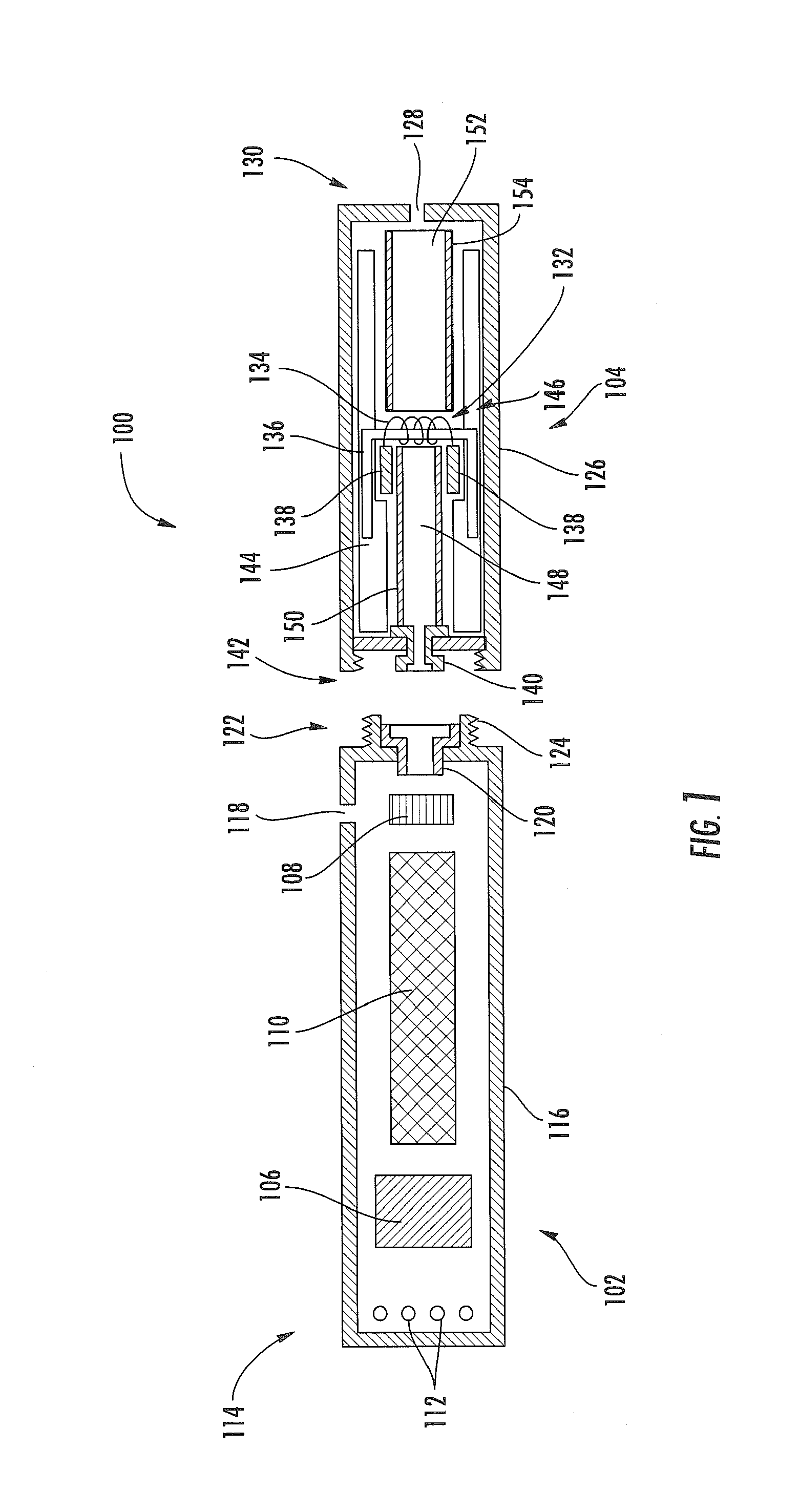

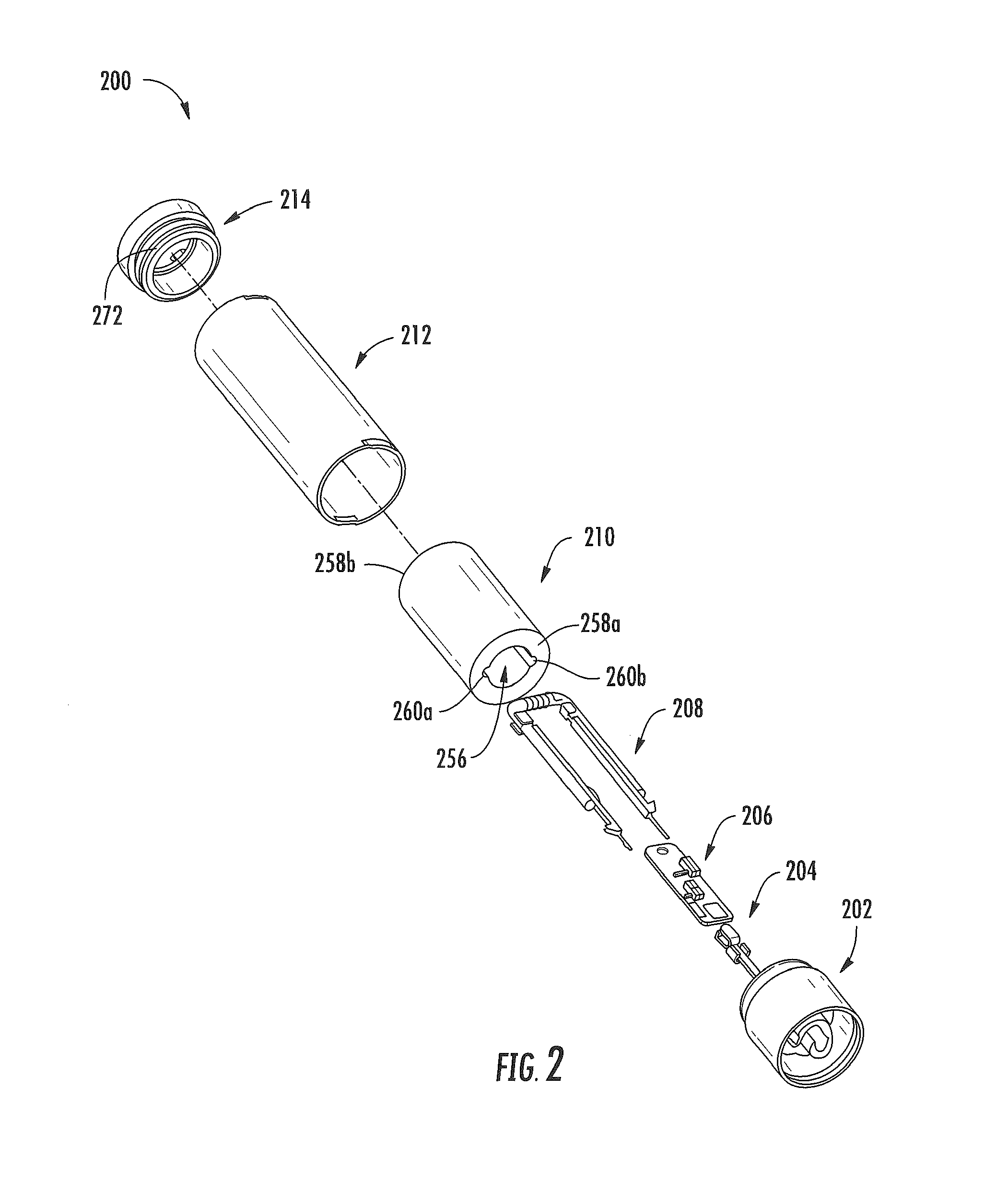

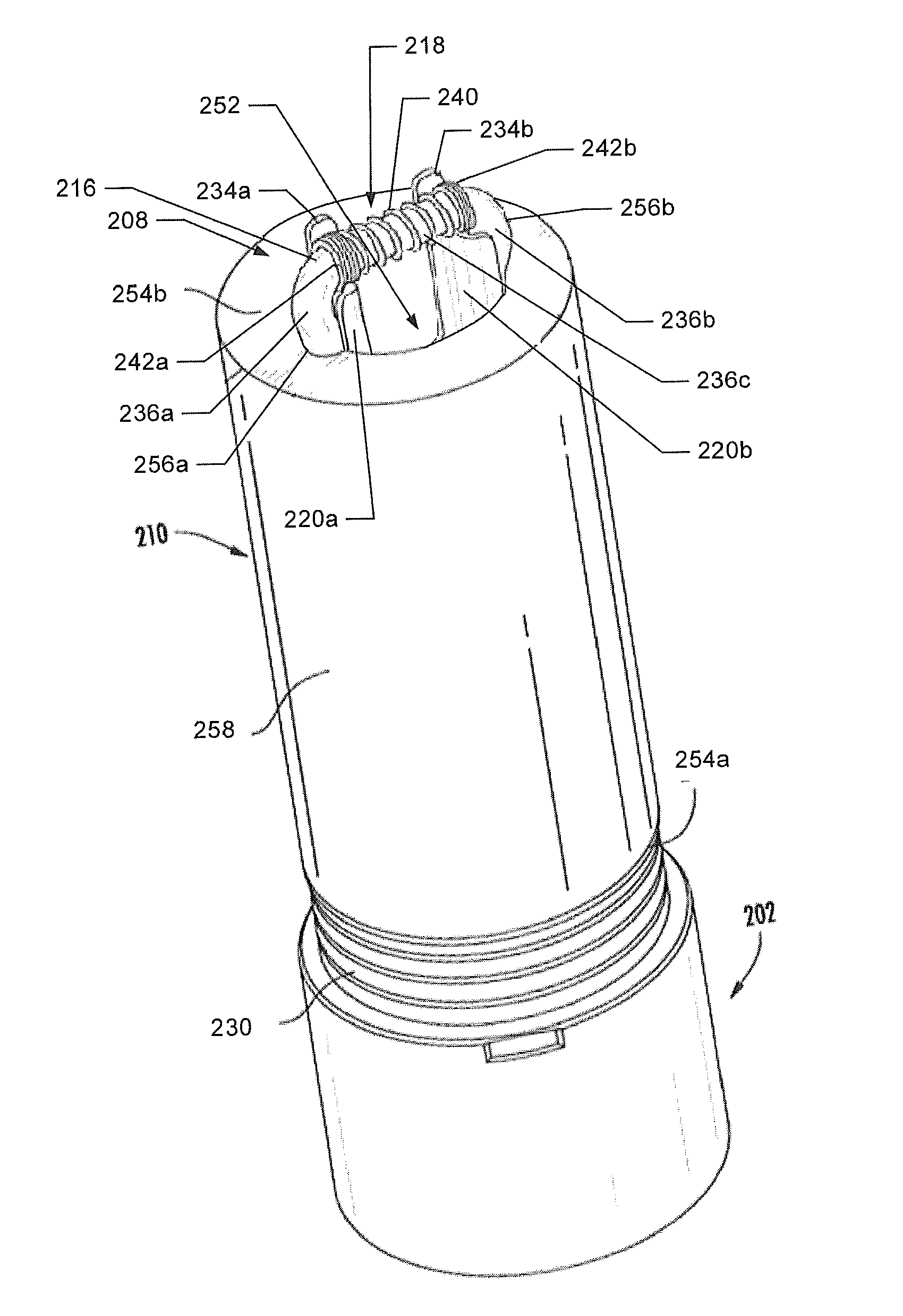

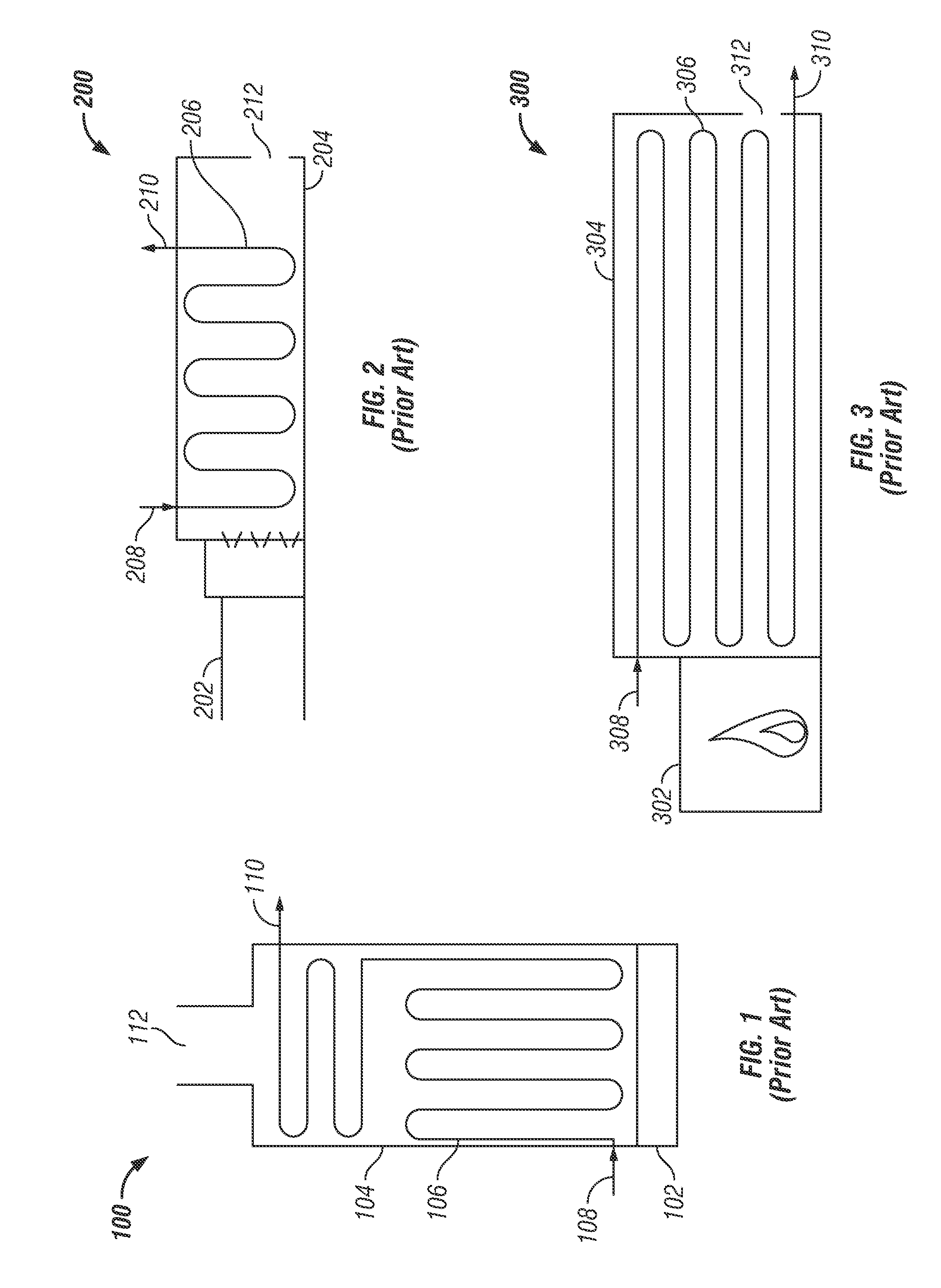

Heating elements formed from a sheet of a material and inputs and methods for the production of atomizers

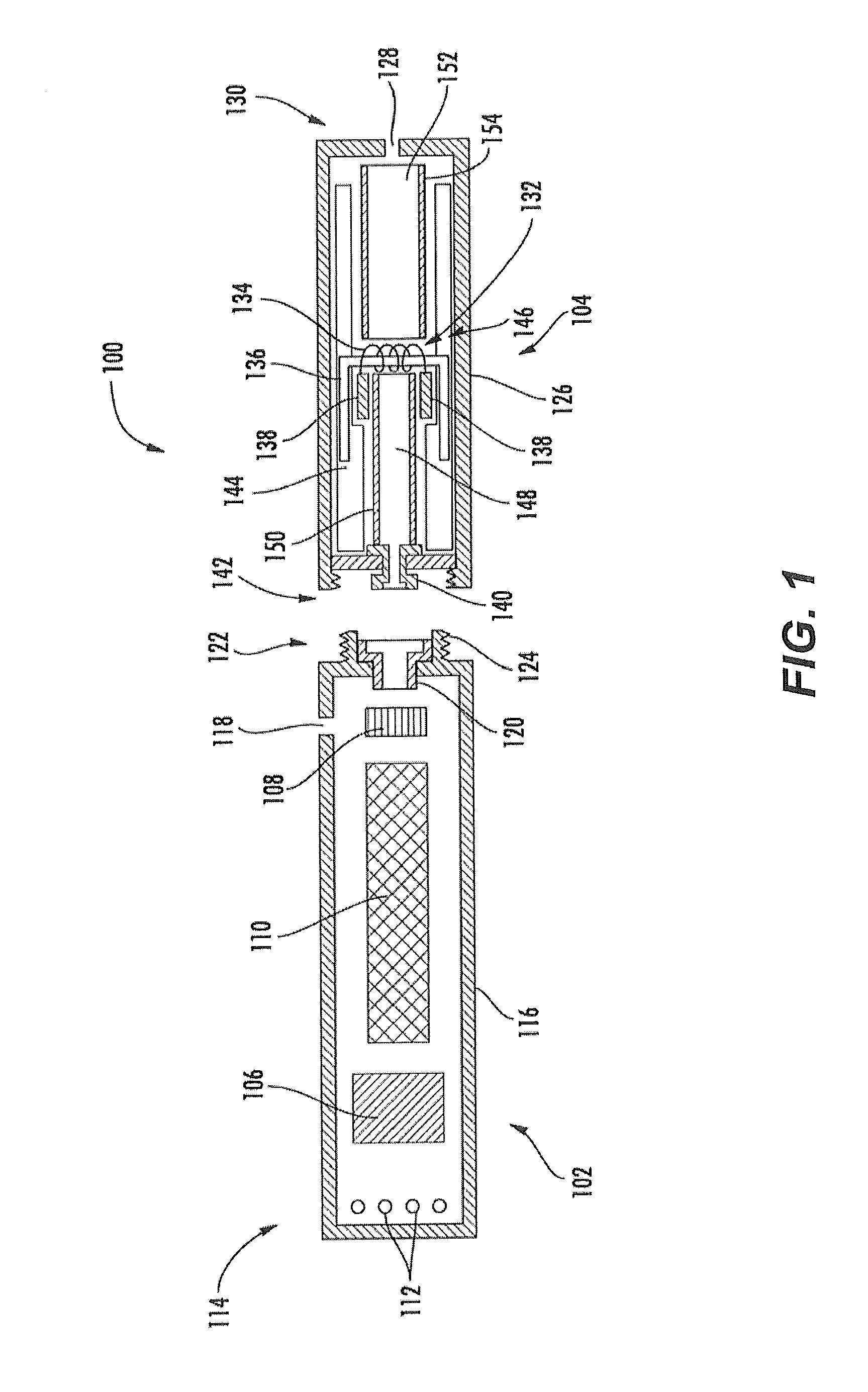

The present disclosure relates to an input for production of atomizers and atomizers formed from a sheet of a material, and which may be employed in an aerosol delivery device such as a smoking article. The input may include a carrier and heating elements coupled thereto. The heating elements may include first and second ends and interconnected alternating loops disposed therebetween. The heating elements may be oriented parallel to a longitudinal axis of the carrier, or perpendicular thereto. The heating elements may be coupled to a liquid transport element by bending the interconnected loops at least partially around the liquid transport element. The ends of the heating element may be coupled to heater terminals. A related method for forming atomizers is also provided.

Owner:RAI STRATEGIC HLDG INC

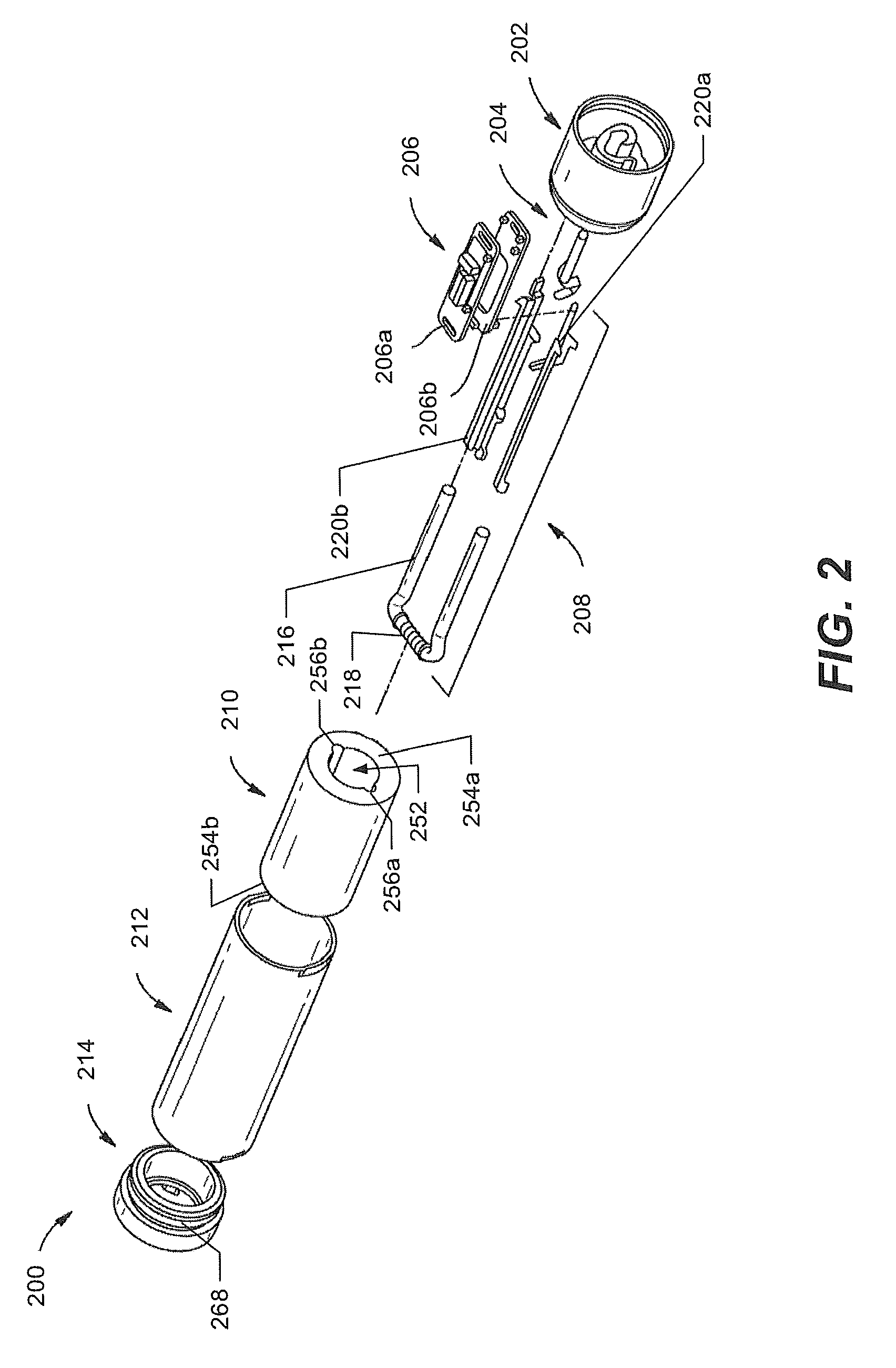

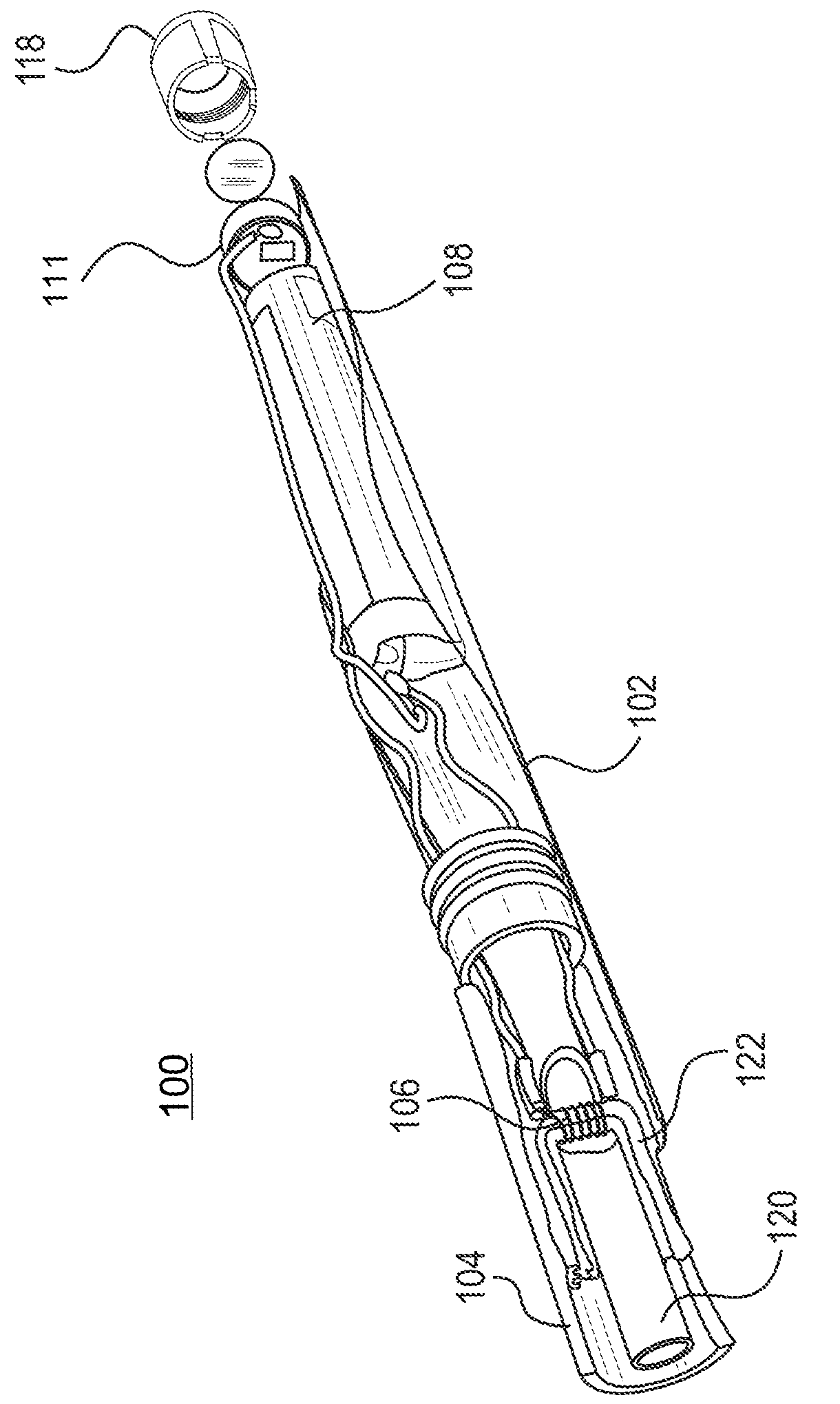

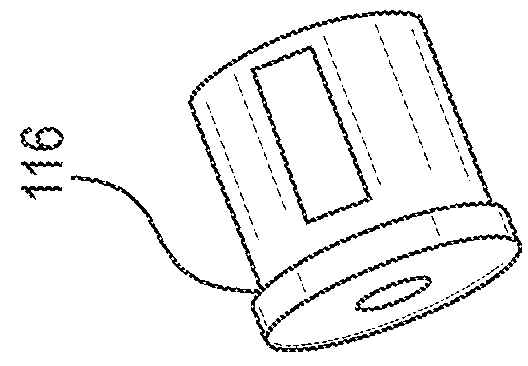

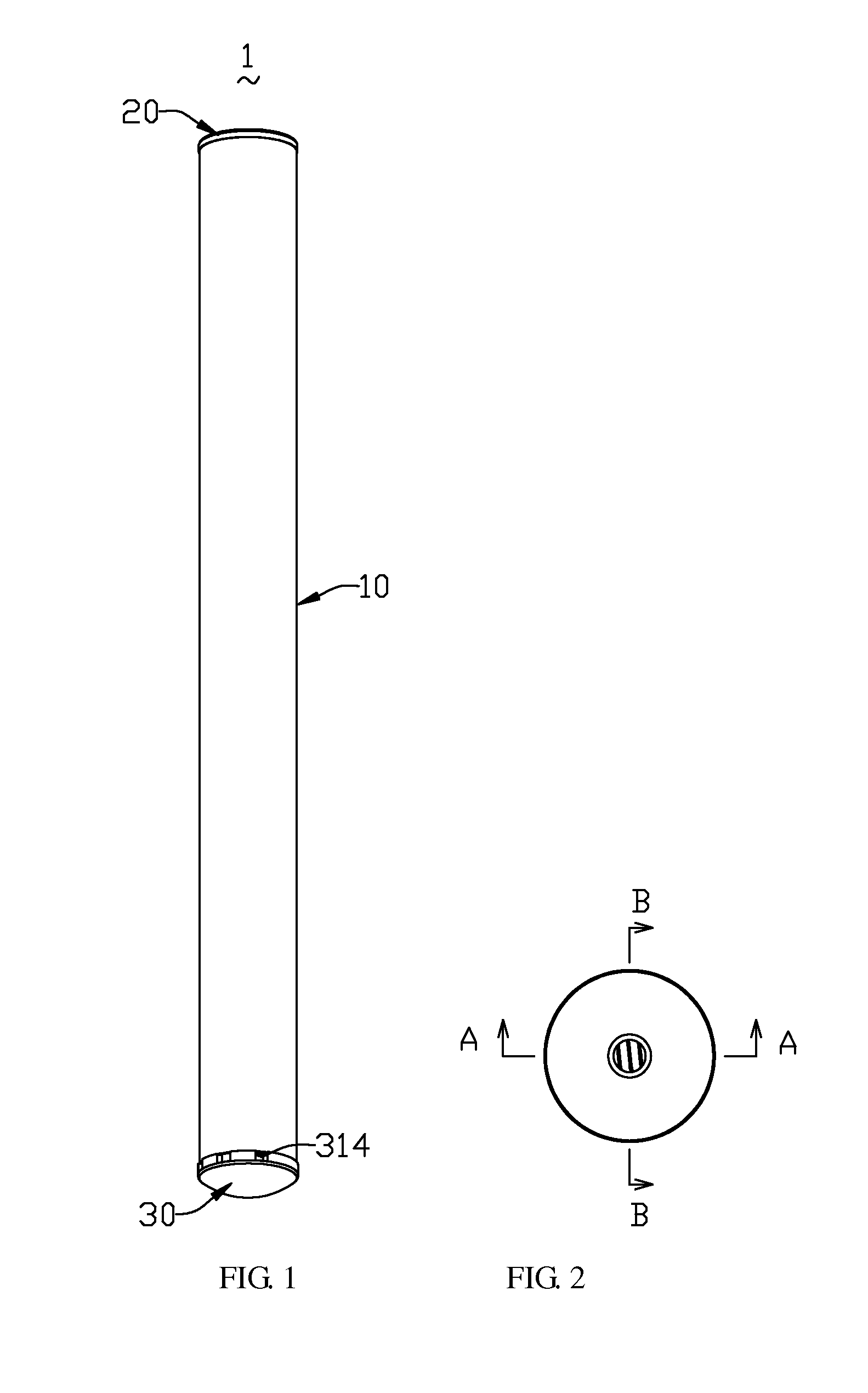

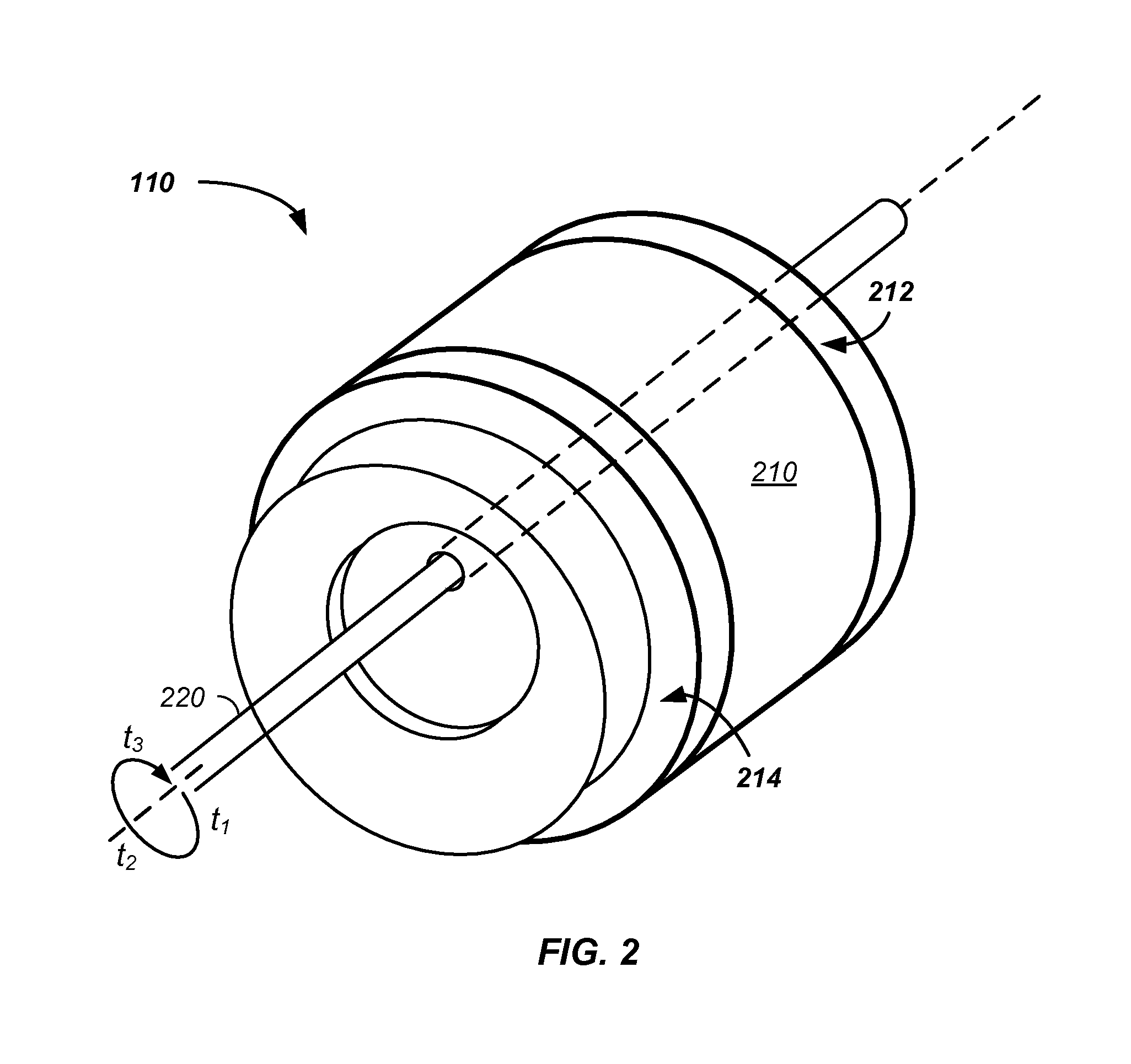

Atomizer for an aerosol delivery device and related input, aerosol production assembly, cartridge, and method

The present disclosure relates to atomizers for an aerosol delivery device such as a smoking article. The atomizer may include a liquid transport element and a wire extending along at least a portion of a longitudinal length thereof. The wire may define contact portions configured to engage heater terminals and a heating portion configured to produce heat. The heating portion may include a variable coil spacing. In other atomizers, the wire may extend at least partially through the liquid transport element proximate the contact portions. Related inputs, cartridges, aerosol production assemblies, and methods of forming atomizers are also provided.

Owner:RAI STRATEGIC HLDG INC

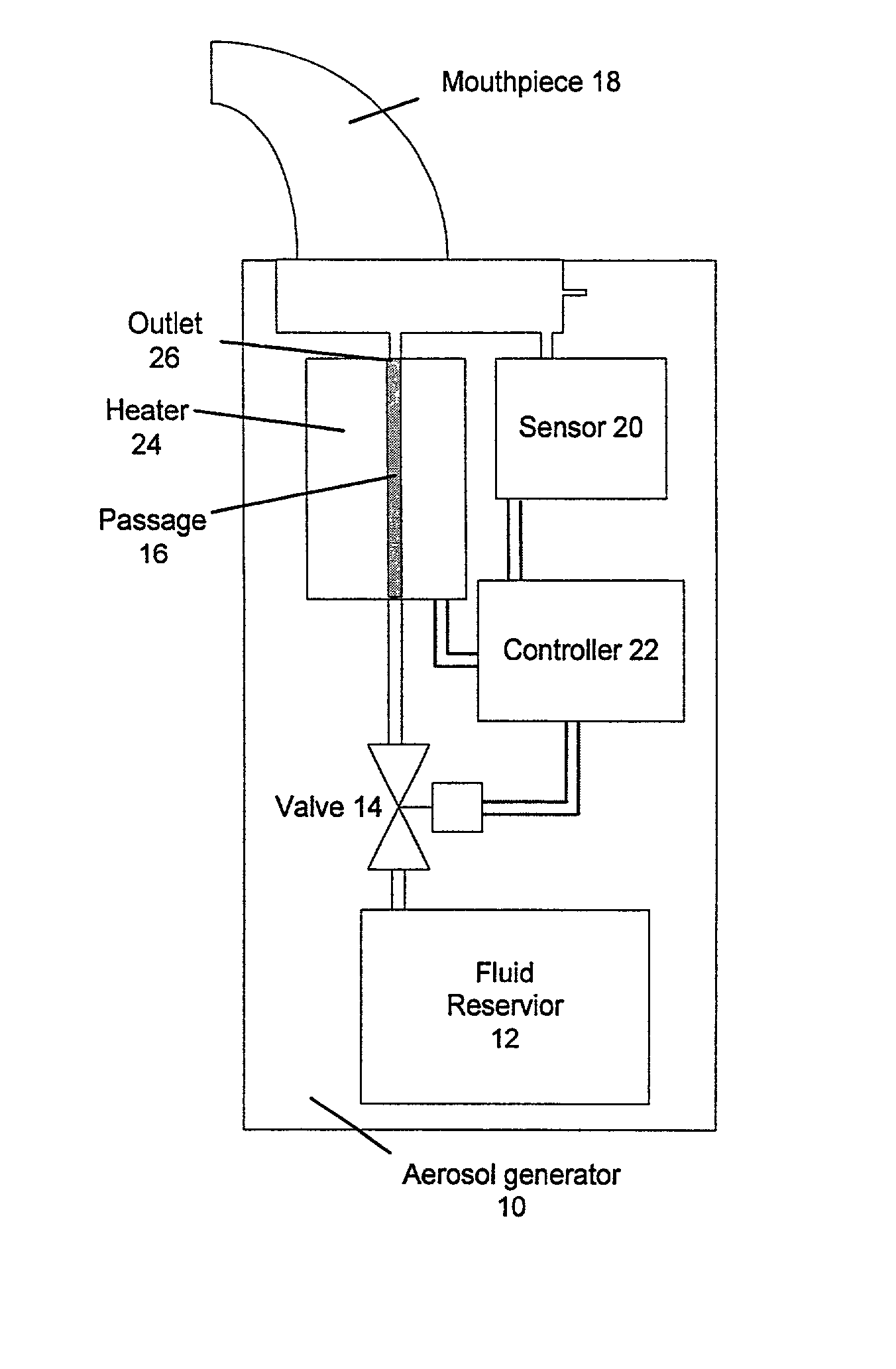

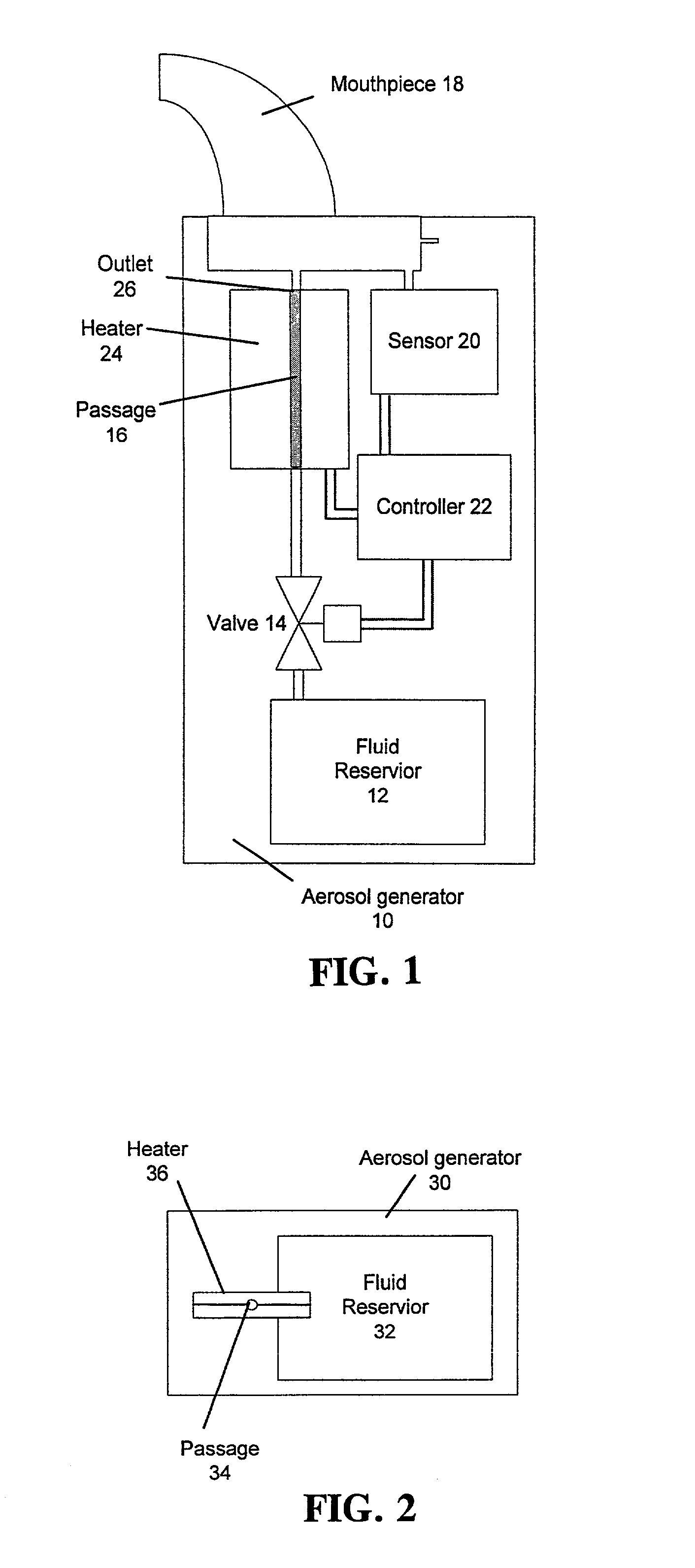

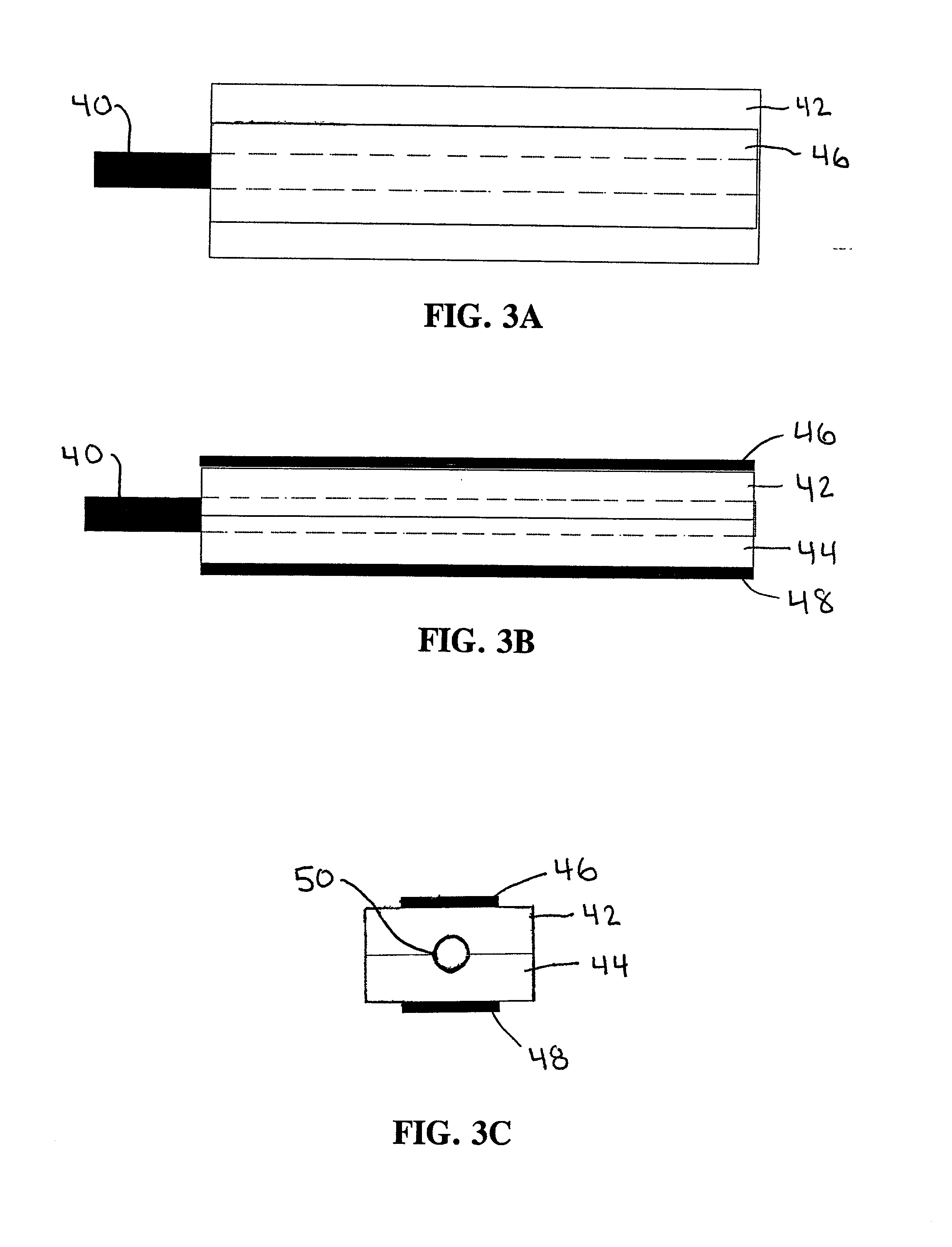

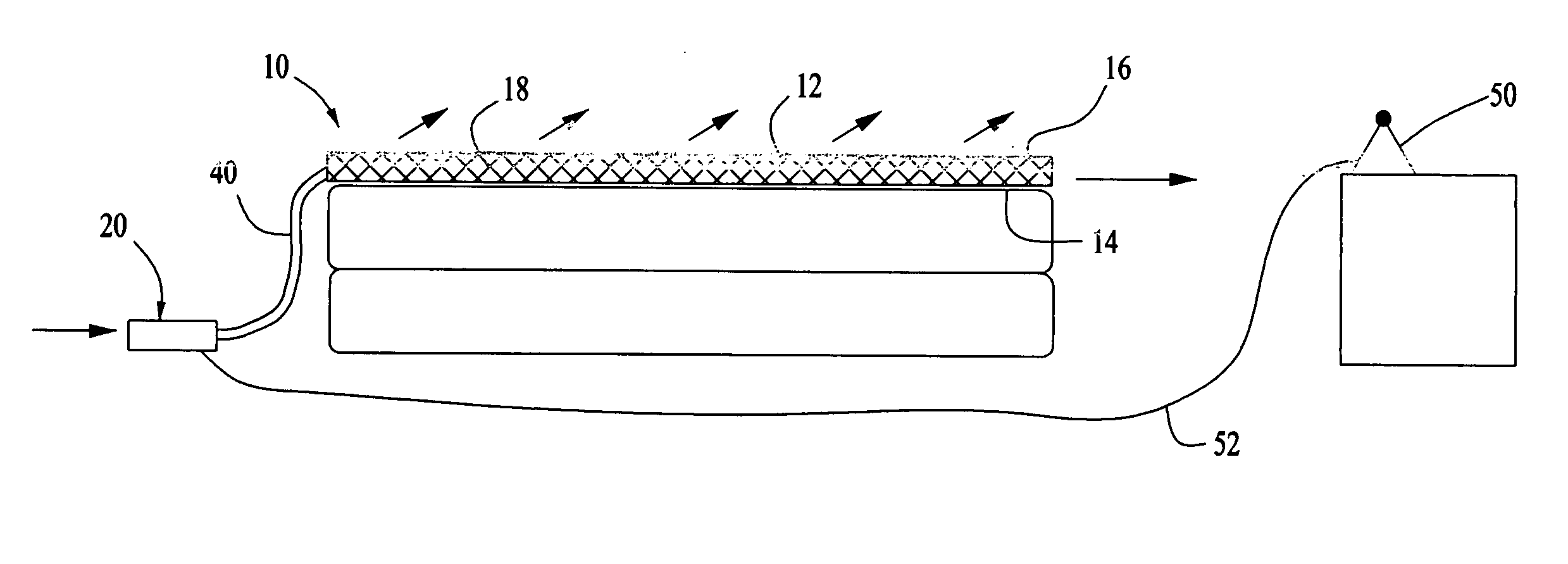

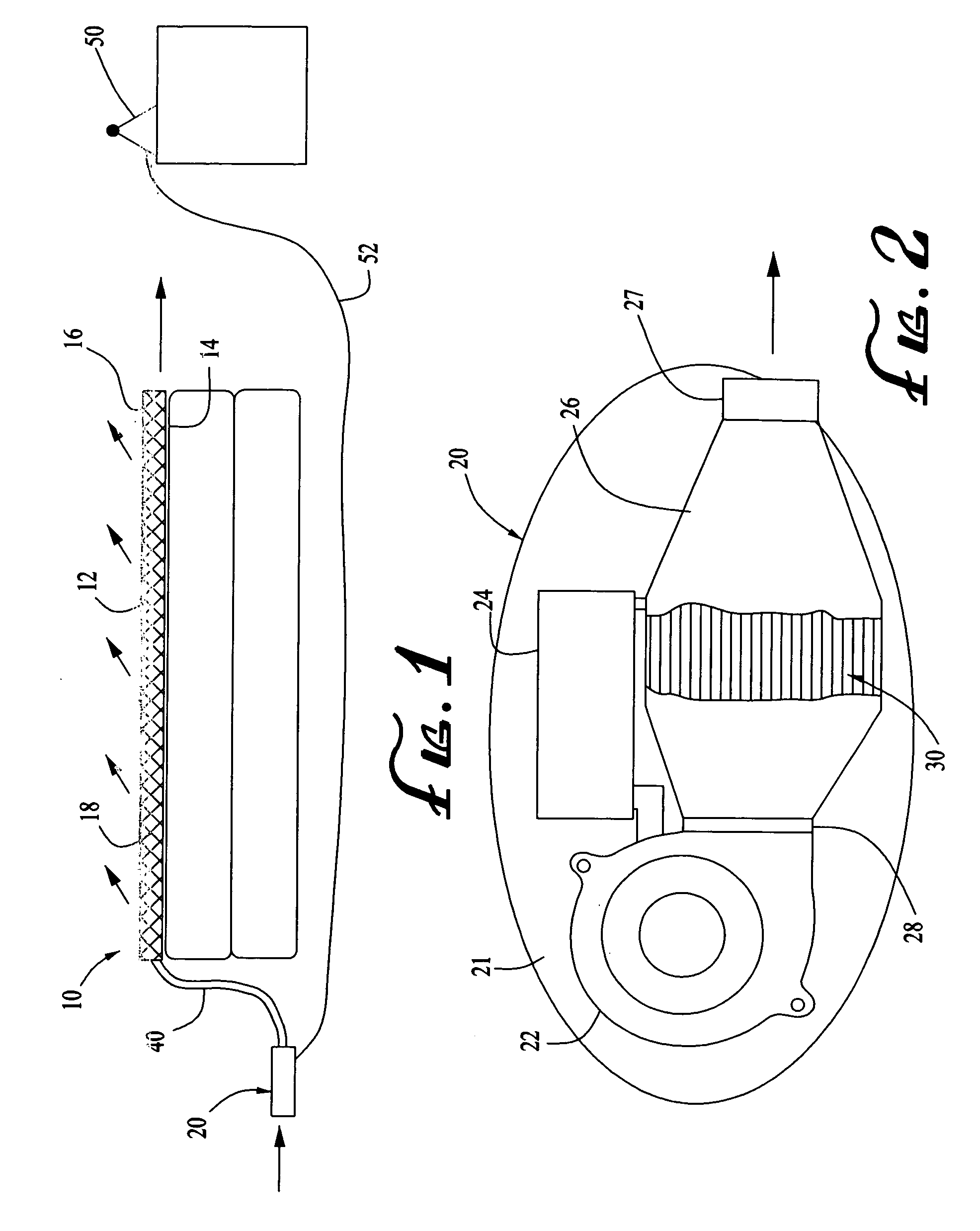

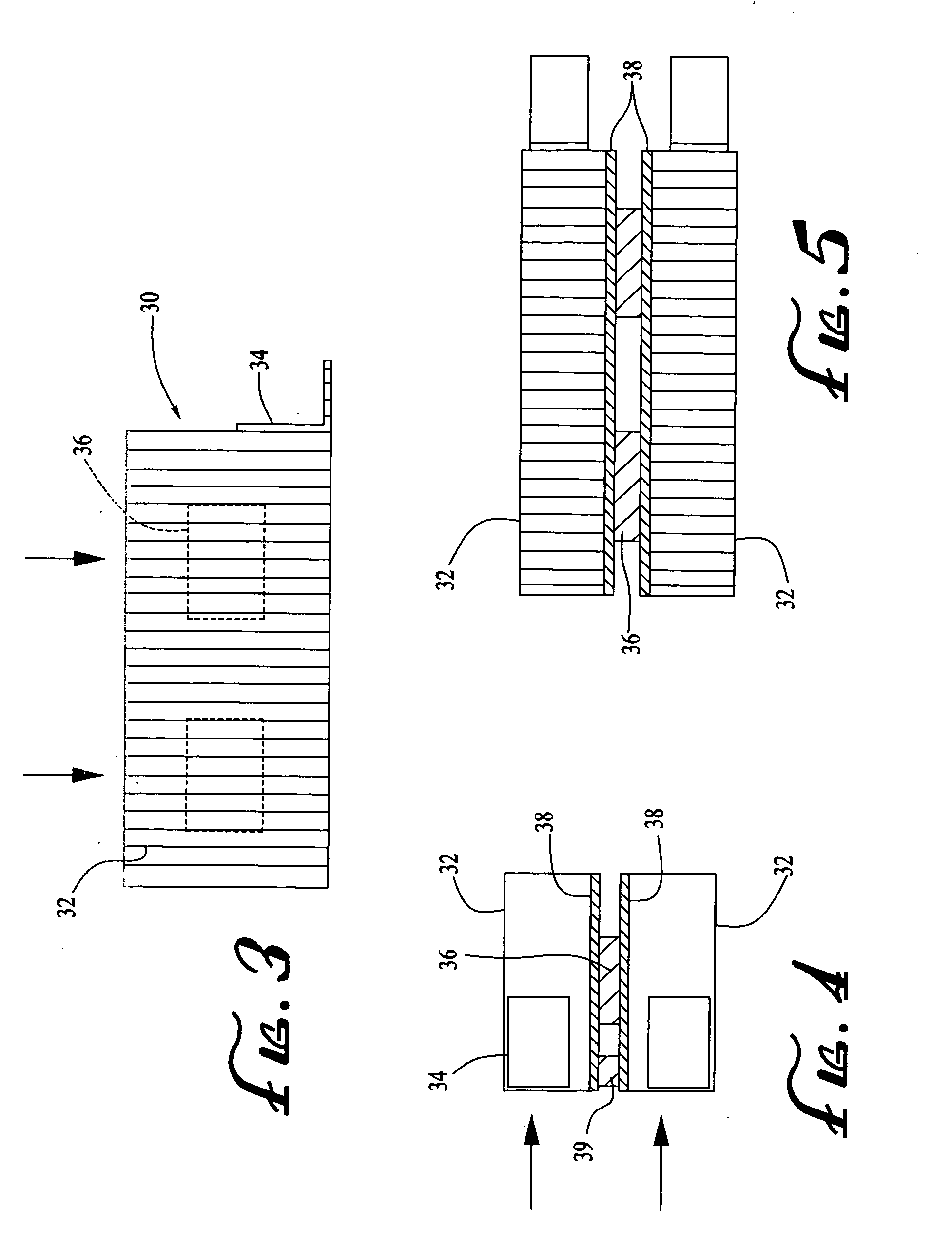

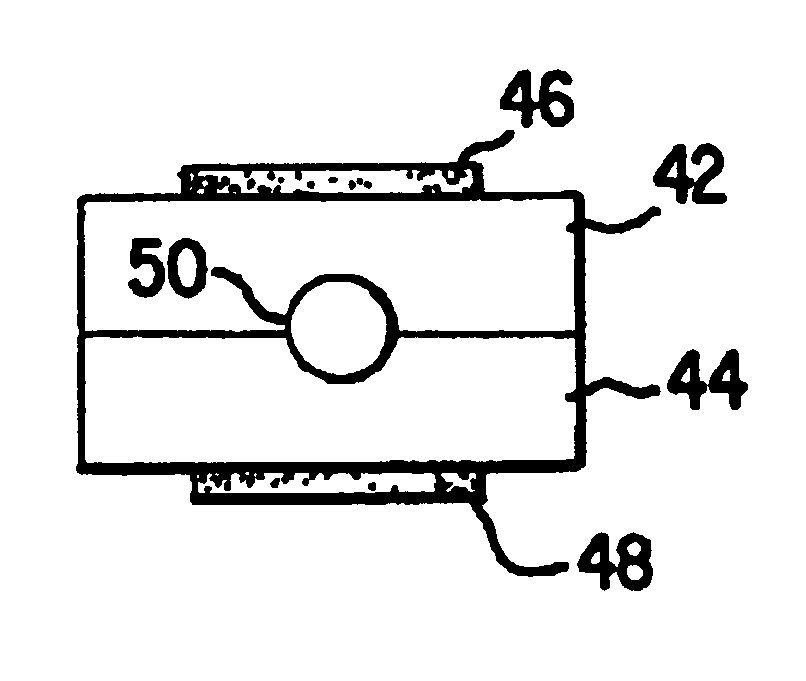

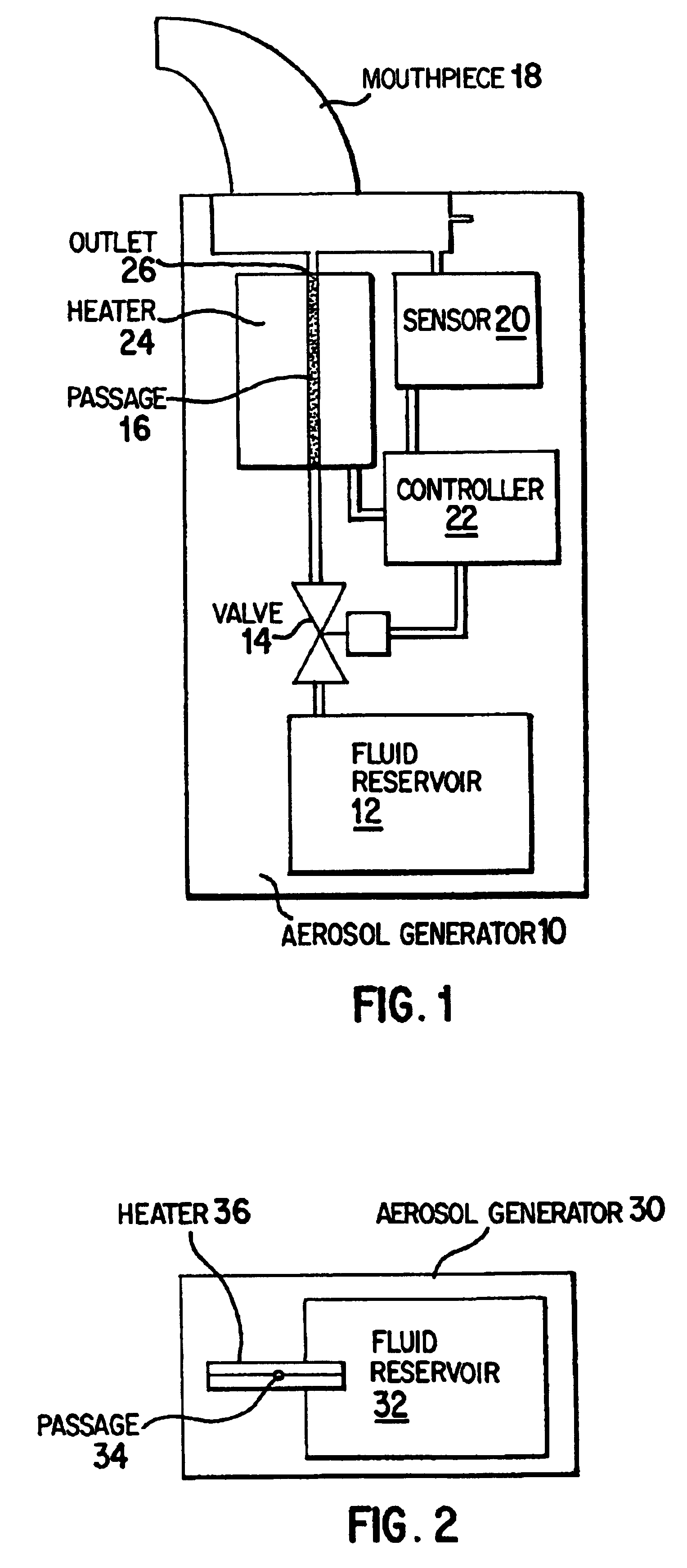

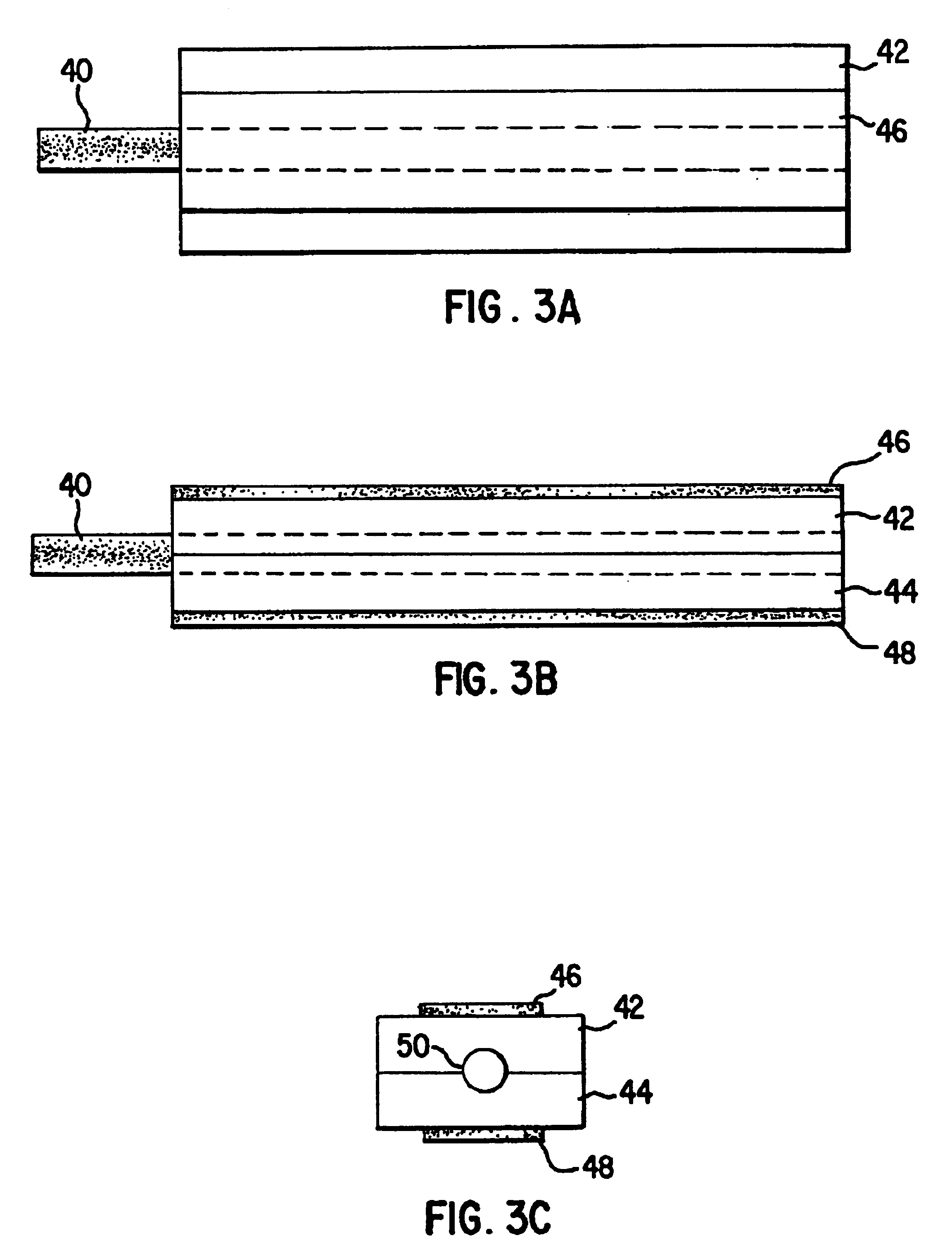

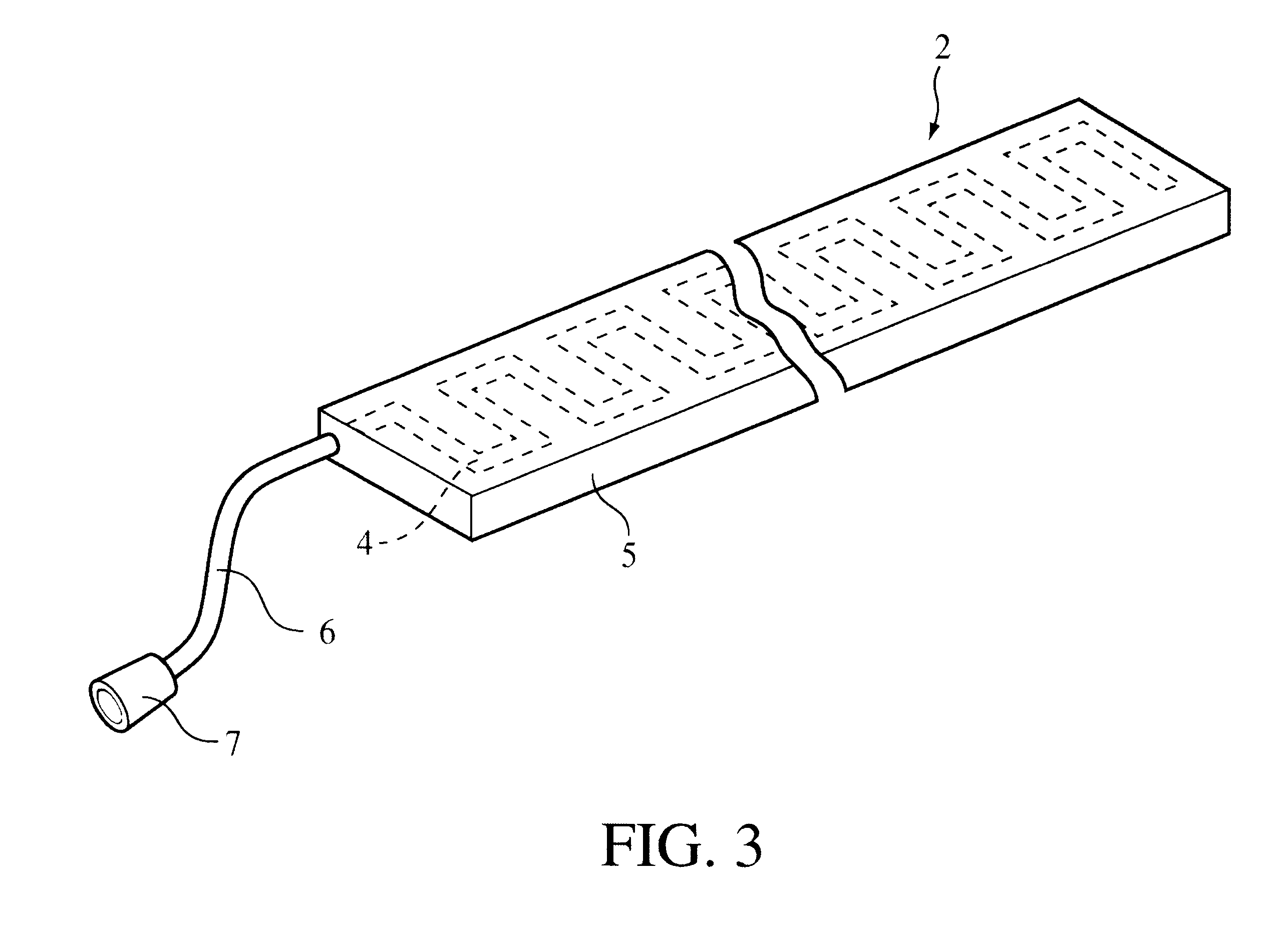

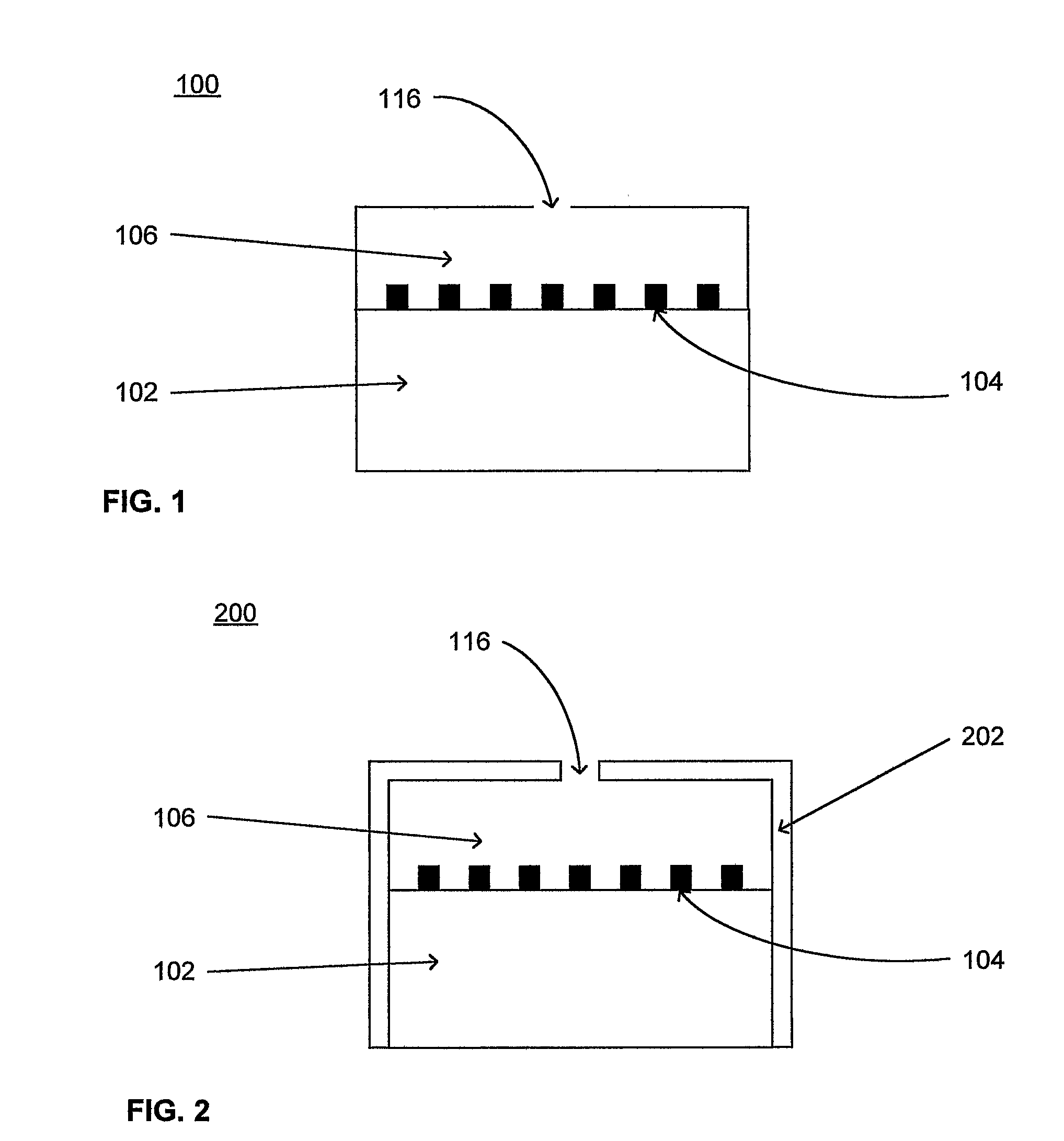

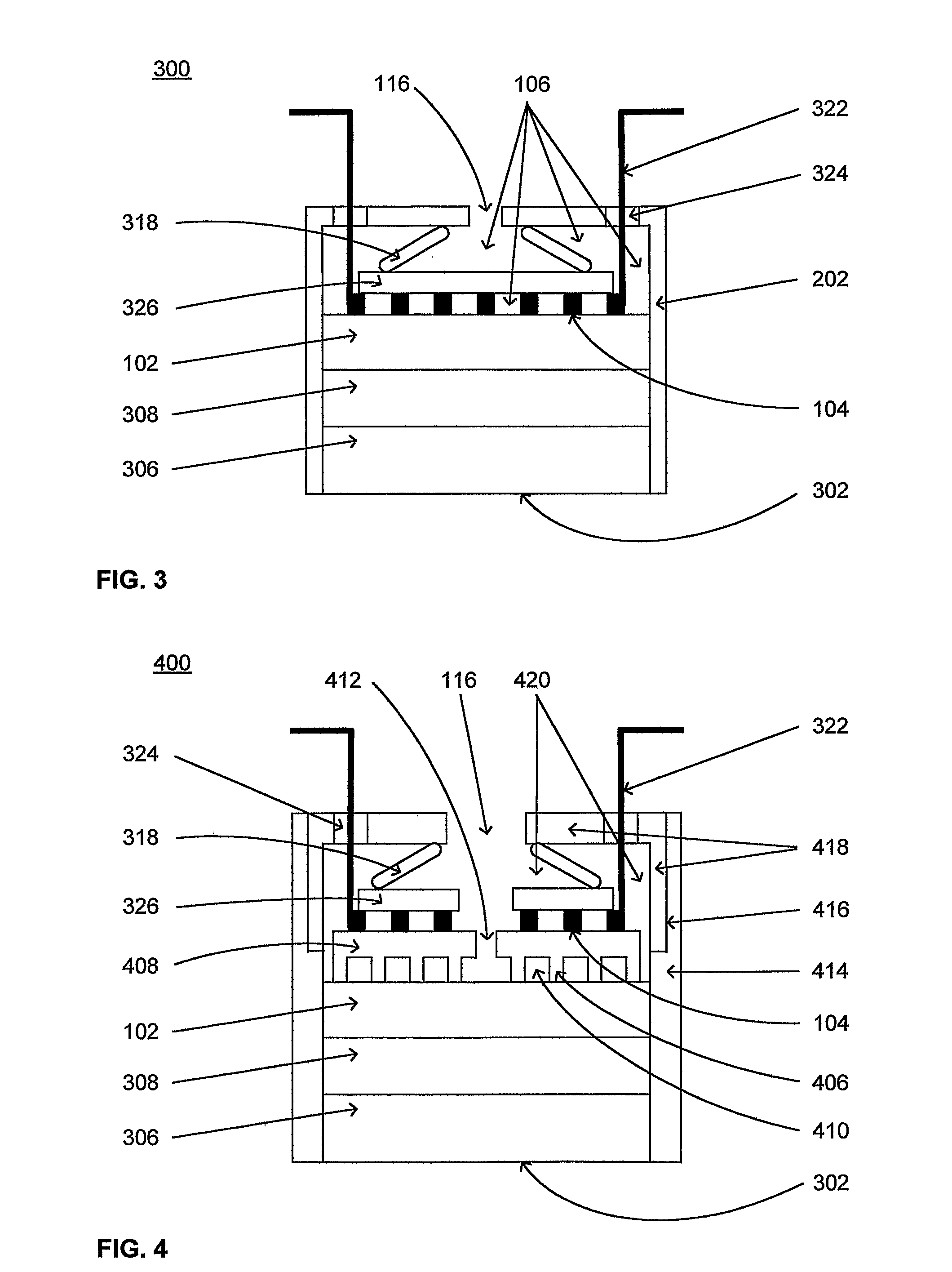

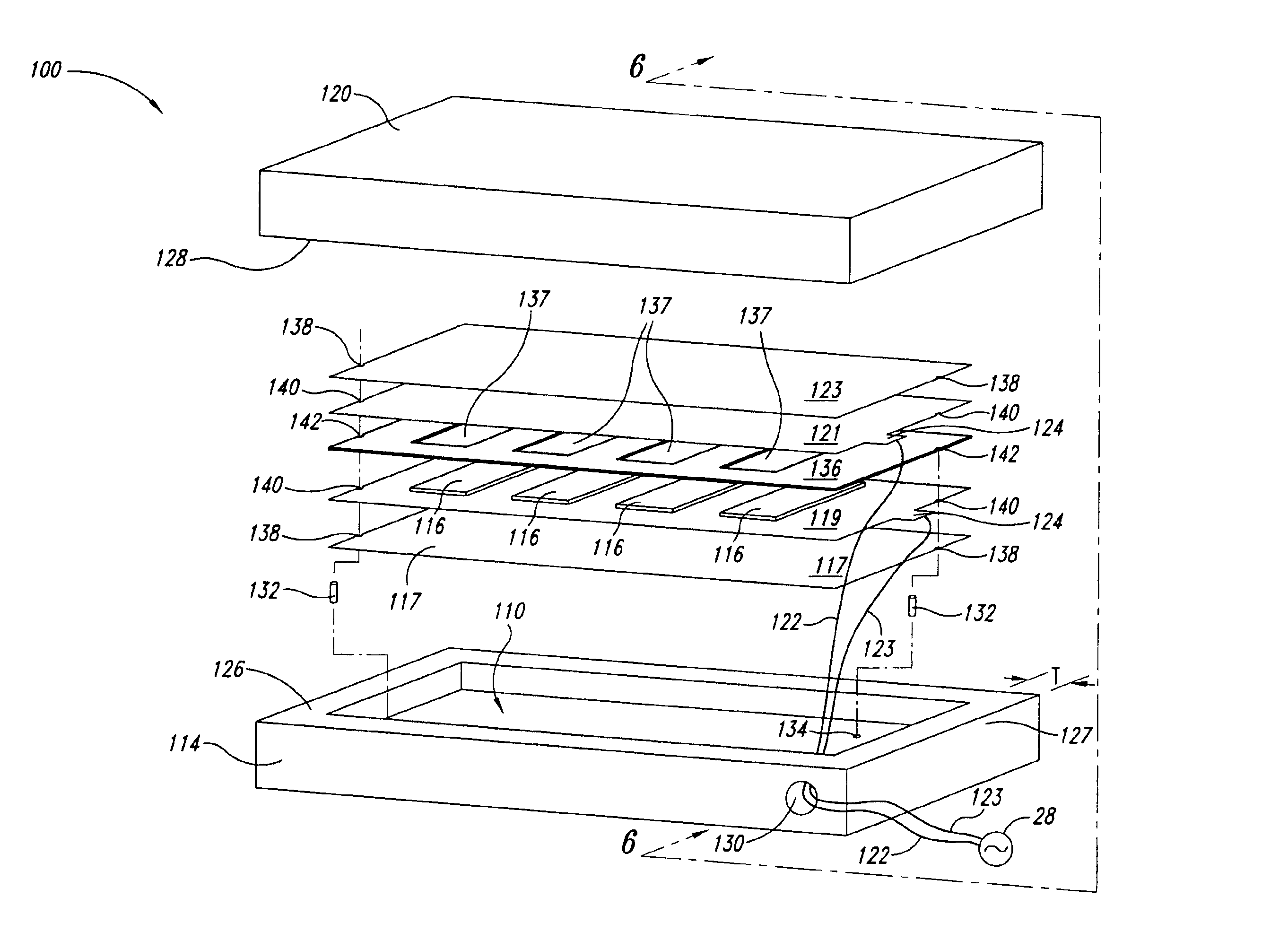

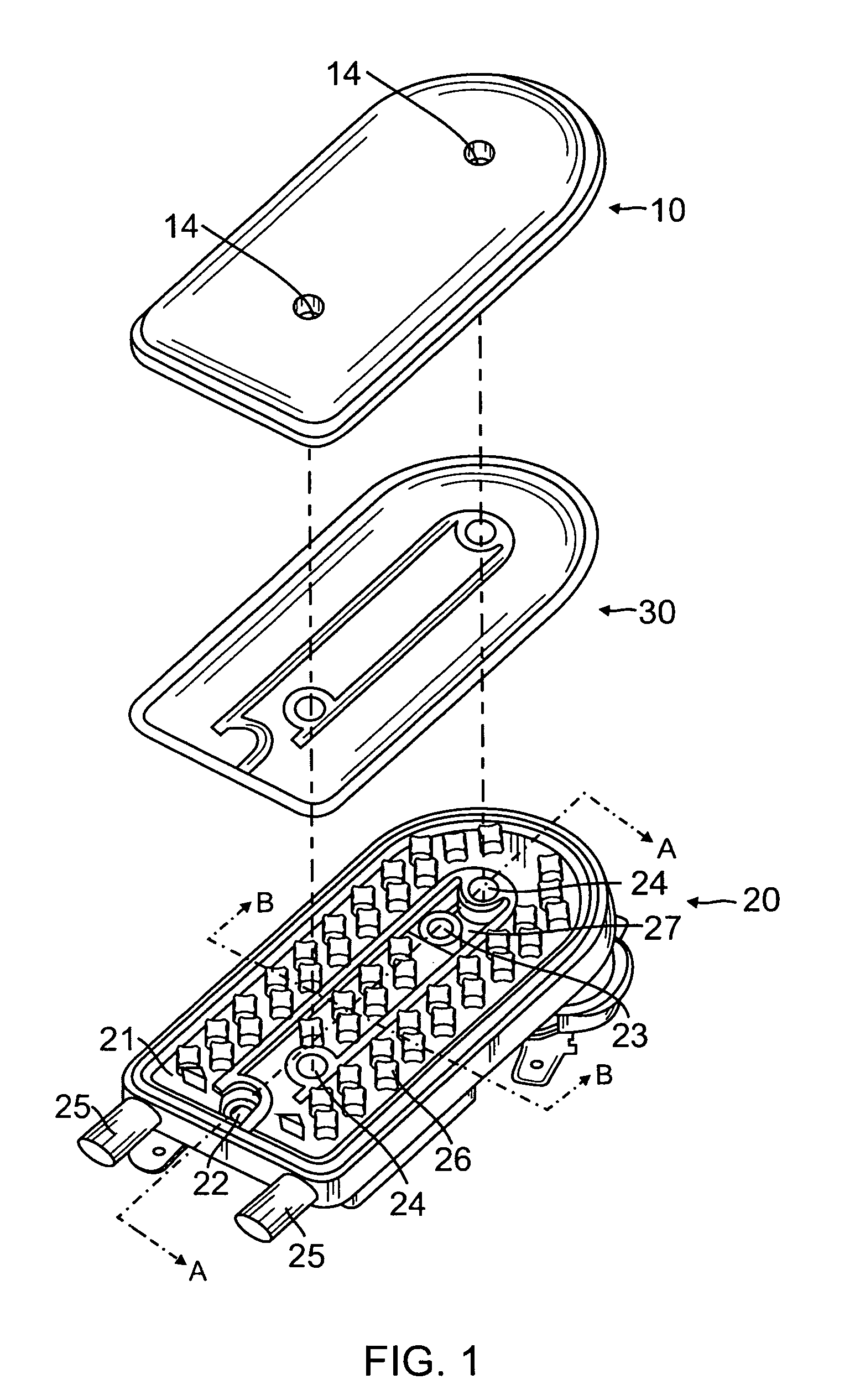

Aerosol generator having heater arranged to vaporize fluid in fluid passage between bonded layers of laminate

InactiveUS20030108342A1Internal combustion piston enginesWater-tube boilersCapillary TubingEngineering

An aerosol generator includes a fluid supply which supplies fluid to a fluid passage and a heater which heats the fluid into a gaseous state, the fluid passage being located between opposed layers of a laminate. The fluid passage can be a capillary sized passage formed by locating a mandrel between opposed layers of the laminate, bonding the layers together and removing the mandrel such that the space previously occupied by the mandrel forms the fluid passage. The opposed layers of the laminate can be copper sheets and ceramic layers can be provided on the outside of the copper layers. The aerosol generator can be used to generate aerosols containing medicated materials.

Owner:PHILIP MORRIS USA INC

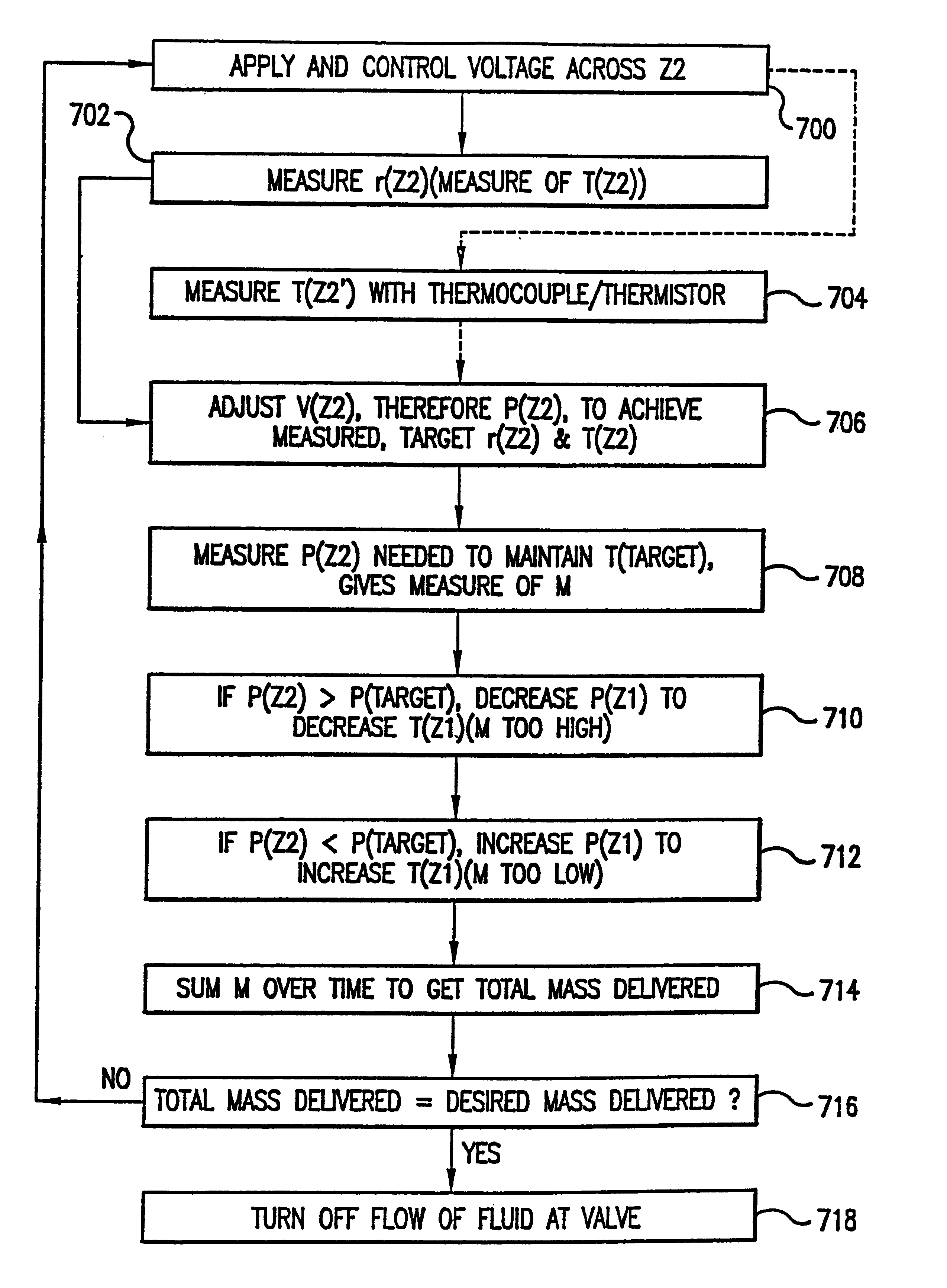

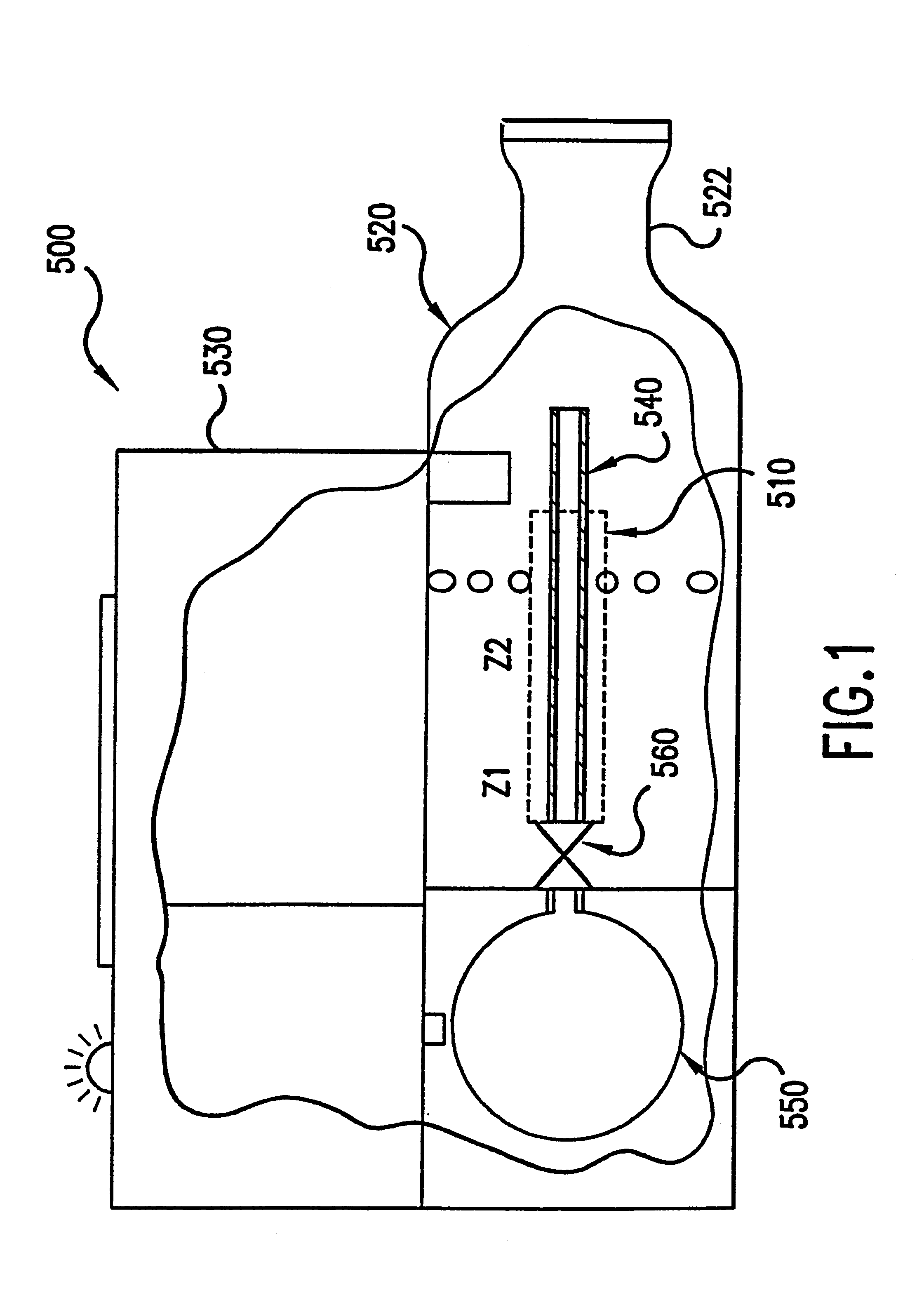

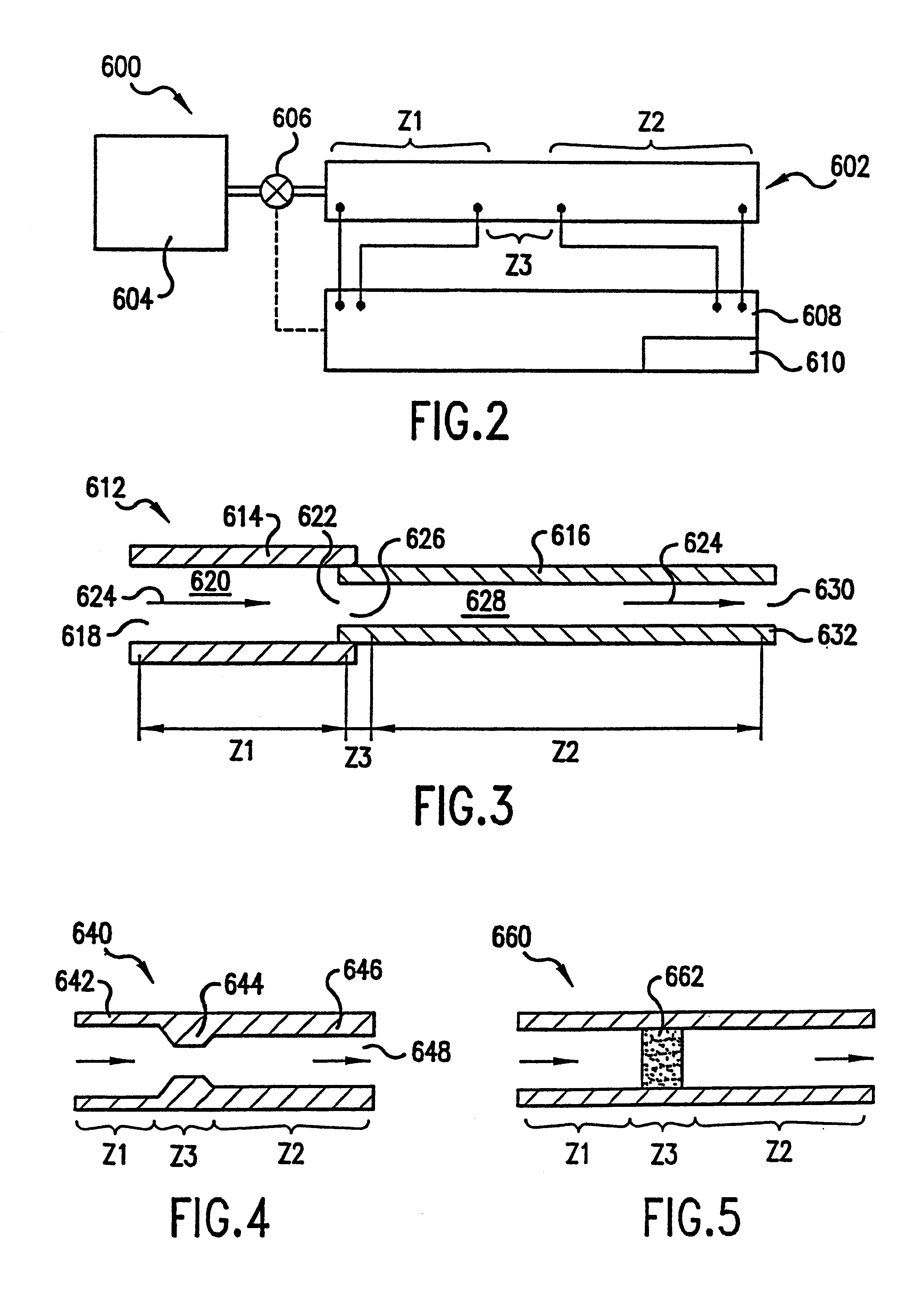

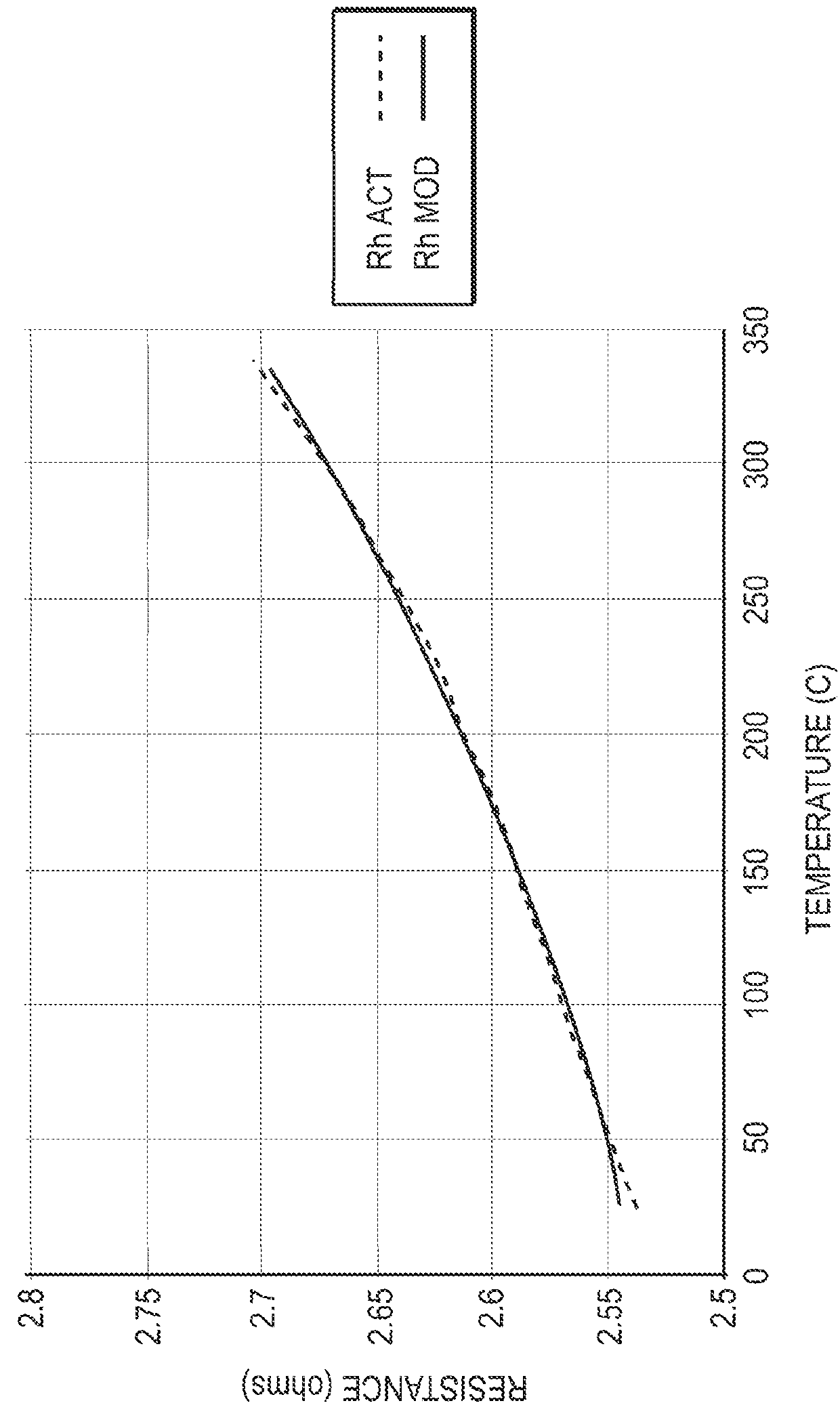

Aerosol generator having temperature controlled heating zone and method of use thereof

InactiveUS7173222B2Medical devicesBoiler controlTemperature controlElectrical resistance and conductance

A temperature and flow rate controlled capillary aerosol generator includes two heating zones optionally separated by a region in which a pressure drop is induced. Power is metered or applied to the downstream, second zone to achieve a target resistance, and therefore a target temperature, while power is metered or applied to the upstream, first zone to achieve a target mass flow rate exiting the second zone. A target temperature is achieved in the second zone to generate an aerosol from the liquid flowing through the generator at the desired mass flow rate.

Owner:PHILIP MORRIS USA INC

Convective cushion with positive coefficient of resistance heating mode

InactiveUS20070086757A1Eliminate useUse minimizedVehicle seatsStuffed mattressesElectrical resistance and conductanceRemote control

A cushion that is heated convectively using a positive temperature coefficient of resistance type resistive heating element that is provided with heat exchanging surfaces, includes a mattress pad, seat or the like with a bottom surface secured around its perimeter to an air permeable top surface, forming a plenum and containing tubular spacer material or other air flow structure therein. The plenum is connected to a power unit housing a blower, a heating module and a controller unit. The heating module includes a PTC type heating element in conduction with a base plate and a number of heat exchanger fins. Preferably the heating element is sandwiched between a pair of the base plates and the heat exchanger fins, and there is a seal between the base plates to minimize air flow from the blower from passing there between. A remote control for the user's convenience may be provided, and a foldable antenna attachable to the convective unit facilitates wireless communication between the remote control and controller unit. The user resting atop the cushion is able to control the blower and heating module to deliver air of a desired temperature and quantity to the cushion and through the top surface. The invention advantageously replaces the current carrying, conductive wires and insulation found inside prior art heated mattresses, enhancing safety and performance while at the same time offering a cooled or ventilated capability.

Owner:FEHER STEVE

Heating control for vaporizing device

ActiveUS20160053988A1Machines/enginesGaseous substancesElectrical resistance and conductanceElectronic communication

The temperature of a vaporizing device, e.g., the temperature of a heating element of the vaporizing device, may be controlled according to various aspects of the present disclosure. The vaporizing device may comprise a heating element, a power source, at least one sensor in electronic communication with the heating element and the power source, and a processor configured to control the temperature of the heating element. The method of controlling the temperature may comprise receiving a resistance measurement of the heating element from the at least one sensor, determining the temperature of the heating element based on the resistance measurement, and adjusting the amount of power supplied to the heating element based on the determined temperature of the heating element.

Owner:NJOY LLC

Aerosol generator having heater arranged to vaporize fluid in fluid passage between bonded layers of laminate

An aerosol generator includes a fluid supply which supplies fluid to a fluid passage and a heater which heats the fluid into a gaseous state, the fluid passage being located between opposed layers of a laminate. The fluid passage can be a capillary sized passage formed by locating a mandrel between opposed layers of the laminate, bonding the layers together and removing the mandrel such that the space previously occupied by the mandrel forms the fluid passage. The opposed layers of the laminate can be copper sheets and ceramic layers can be provided on the outside of the copper layers. The aerosol generator can be used to generate aerosols containing medicated materials.

Owner:PHILIP MORRIS USA INC

Humidification control unit and method of manufacturing same

A humidity regulating unit including a heating element housed inside a covering that has a porous retaining wall through which water does not pass but steam or gas passes. In one embodiment, the covering has several bulges along the circumference of the heating element that protrudes outward from the outer surface of heating element to form several water routes along the outer surface of heating element. The covering and the outer surface of heating element are bonded between adjacent water routes so that the outer surface of heating element is used as part of the wall of the water routes. As a result, the size of heating element does not restrict making the cross section of each water route as small as possible, and even if the covering breaks, the amount of water leaking from the humidity regulating unit is minimized.

Owner:KK METRAN

Electromagnetically responsive heating apparatus for vaporizer

InactiveUS6906296B2Increase productionReduced resistive electrical power loadSteam generation heating methodsGrinding feed controlParticulatesMicrowave

A vaporizer heating apparatus is comprised of electromagnetically responsive material and electrically non-conductive material. A antimicrobial fluid to be vaporized, such as water or hydrogen peroxide solution, is supplied to the heating apparatus where it is converted to a vapor. In one embodiment of the present invention, electromagnetically responsive material particulate is embedded into the electrically non-conductive material. In another embodiment of the present invention, a microwave generator is used to produce heat.

Owner:AMERICAN STERILIZER CO

Capillary force vaporizers

ActiveUS20090220222A1Easy to assembleEliminate needSpace heating and ventilationMedical devicesCapillary networkEngineering

The present invention concerns capillary force vaporizers for use in vaporizing liquids and emitting pressurized vapors. In one embodiment, the inventive capillary force vaporizer includes a porous member, a heater component to convey heat to the porous member, and a vapor containment region. The porous member further includes a capillary network, a surface for receiving liquid and a vaporization area in which vapor is produced from the liquid. The vapor is collected and pressurized within the vapor containment region, which includes one or more openings for the release of vapor at a velocity greater than zero. Several different embodiments for capillary force vaporizers and systems comprising capillary force vaporizers are disclosed along with methods for their use.

Owner:VAPORE

Heating cooker having a steam generating unit

Owner:SAMSUNG ELECTRONICS CO LTD

Electronic Cigarette and Atomizer Assembly Thereof

ActiveUS20160058073A1Easy to installSteam generation heating methodsTobacco pipesElectronic cigaretteEngineering

The present invention provides an electronic cigarette and an atomizer assembly thereof. The atomizer assembly includes an air flowing pipe, a wick extending laterally through a sidewall of the air flowing pipe, and a heating member disposed within the air flowing pipe and engaging with the wick. The air flowing pipe defines opposite holes. The wick extends through the holes with opposite ends extending out of the air flowing pipe. The sidewall of the air flowing pipe further defines a cut communicating with the holes, to enable the wick being placed laterally into the holes. By virtue of the cut, two parts of the air flowing pipe divided by the cut are split off to form an open communicating with the closed holes, and the wick can be placed laterally into the holes via the open. Thus, the wick is easily installed without aligning and extending through the holes.

Owner:SHENZHEN SMOORE TECH LTD

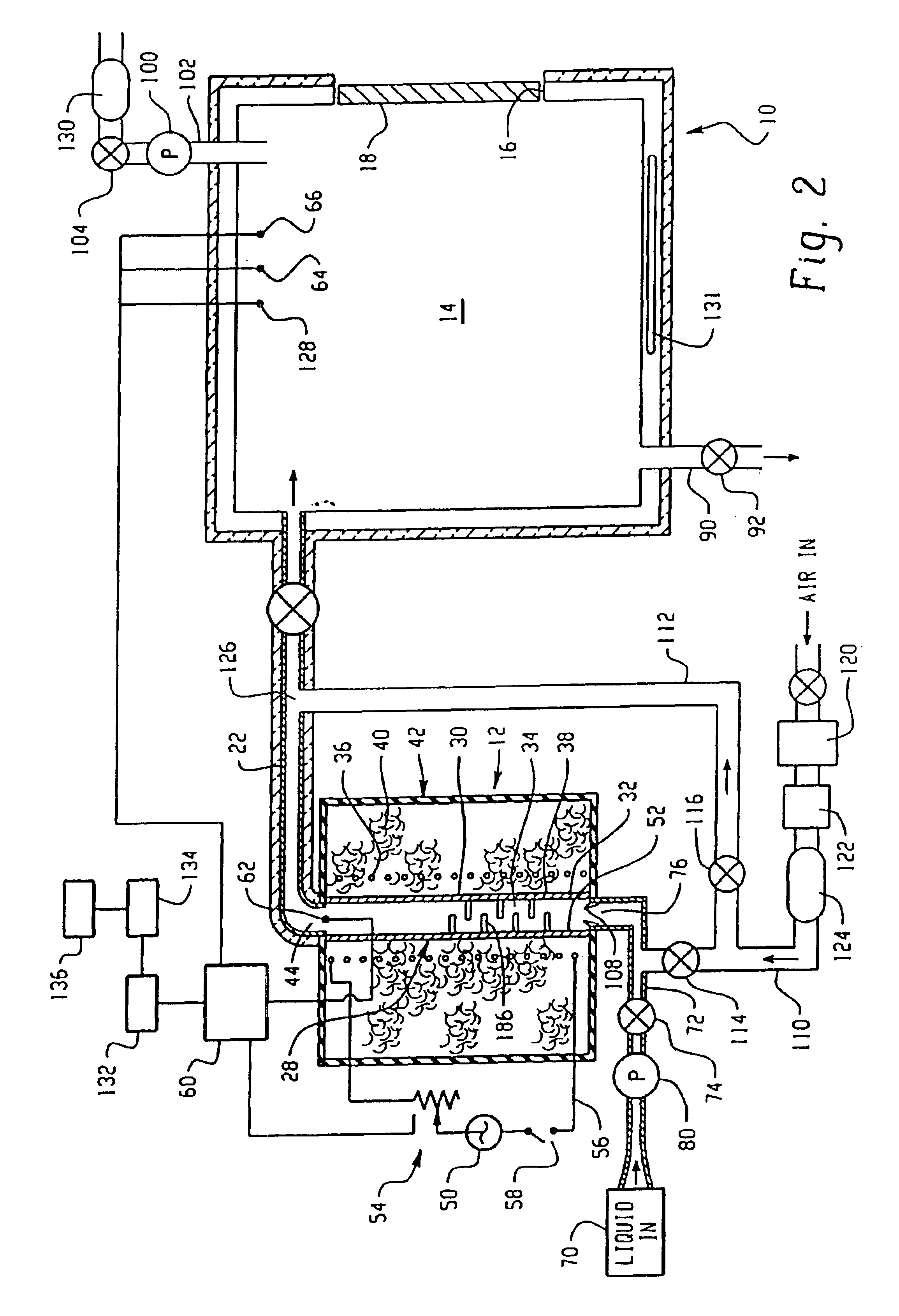

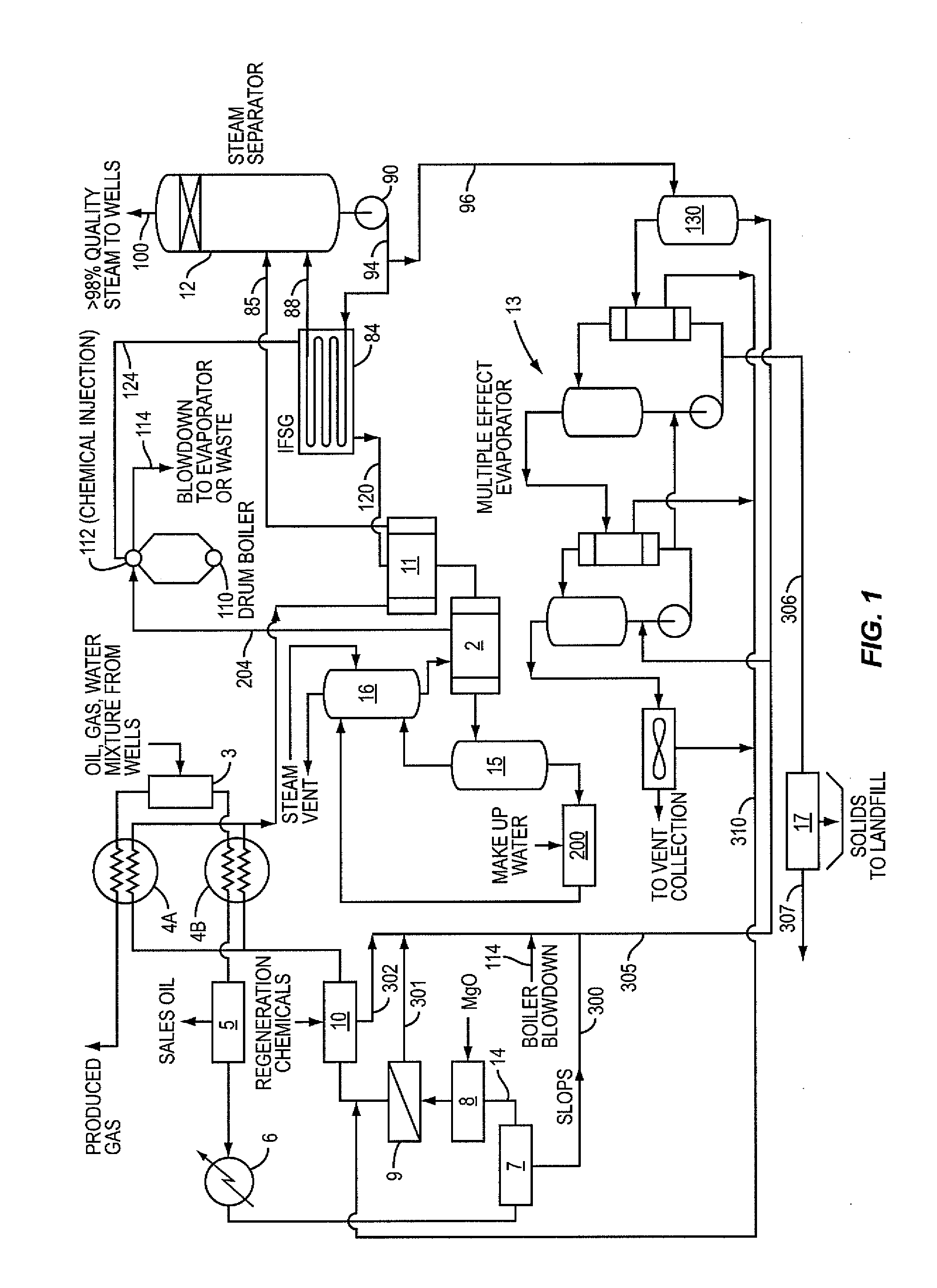

Method and System for Recovering Oil and Generating Steam from Produced Water

Owner:HIPVAP TECH INC

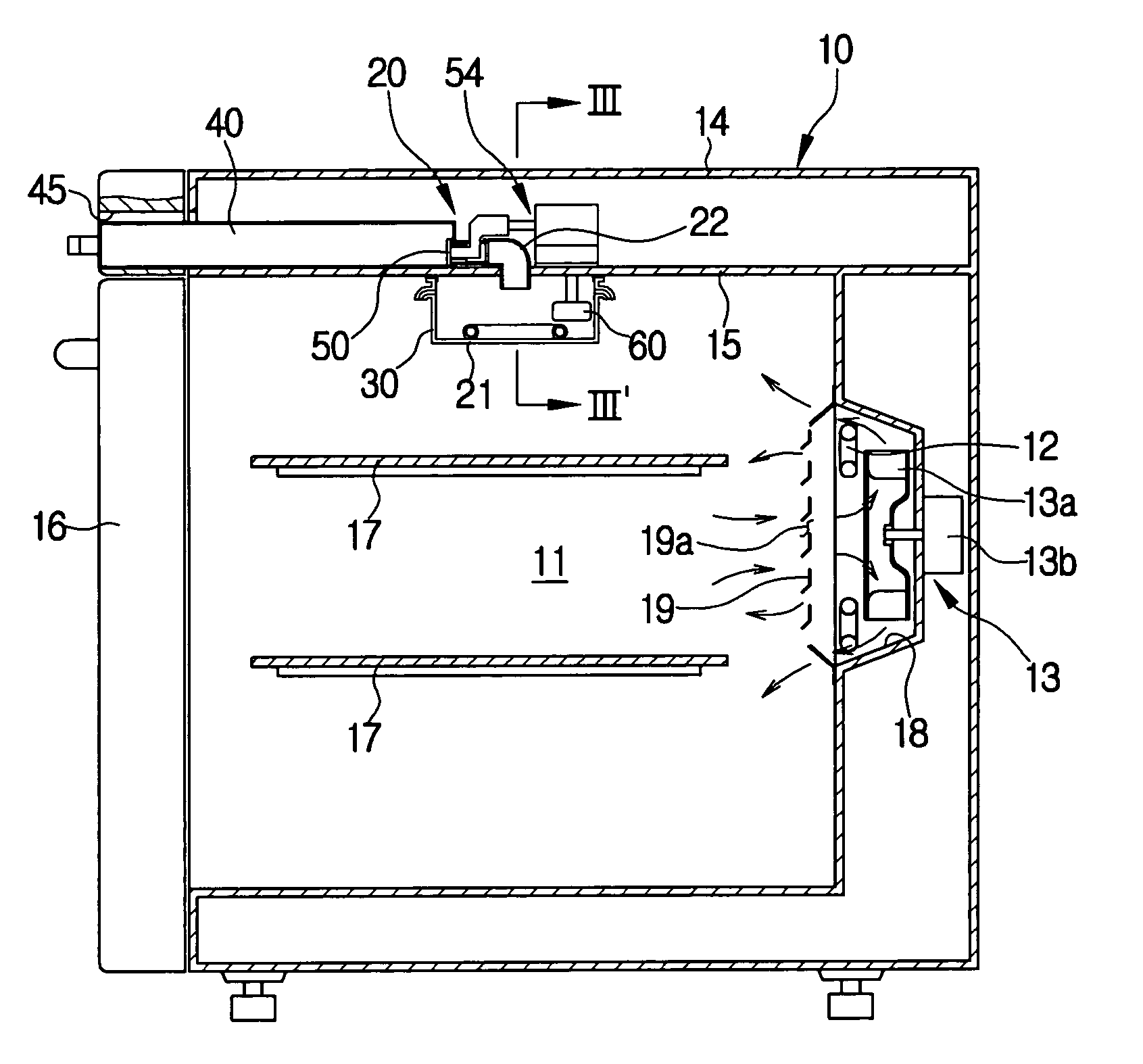

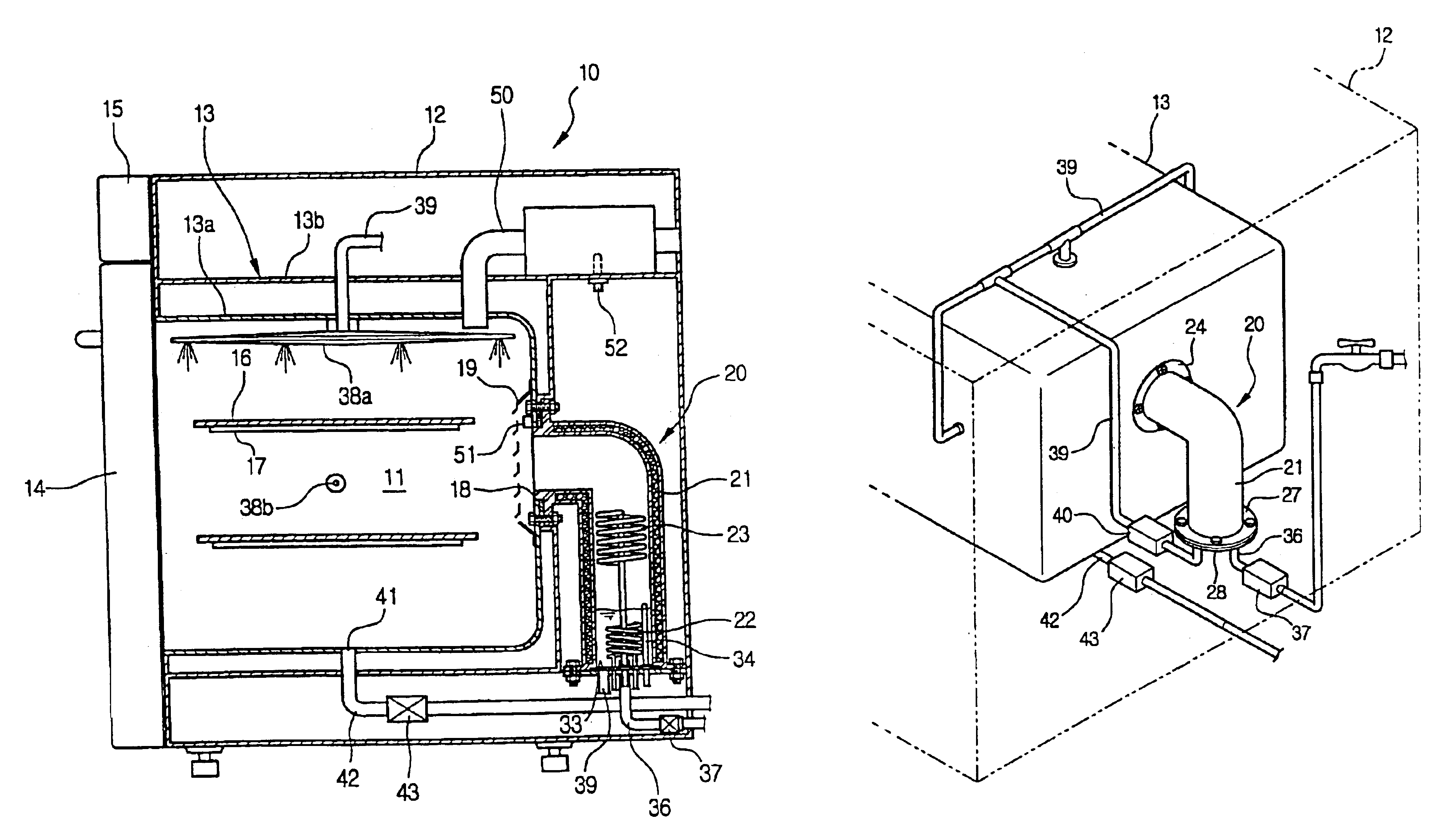

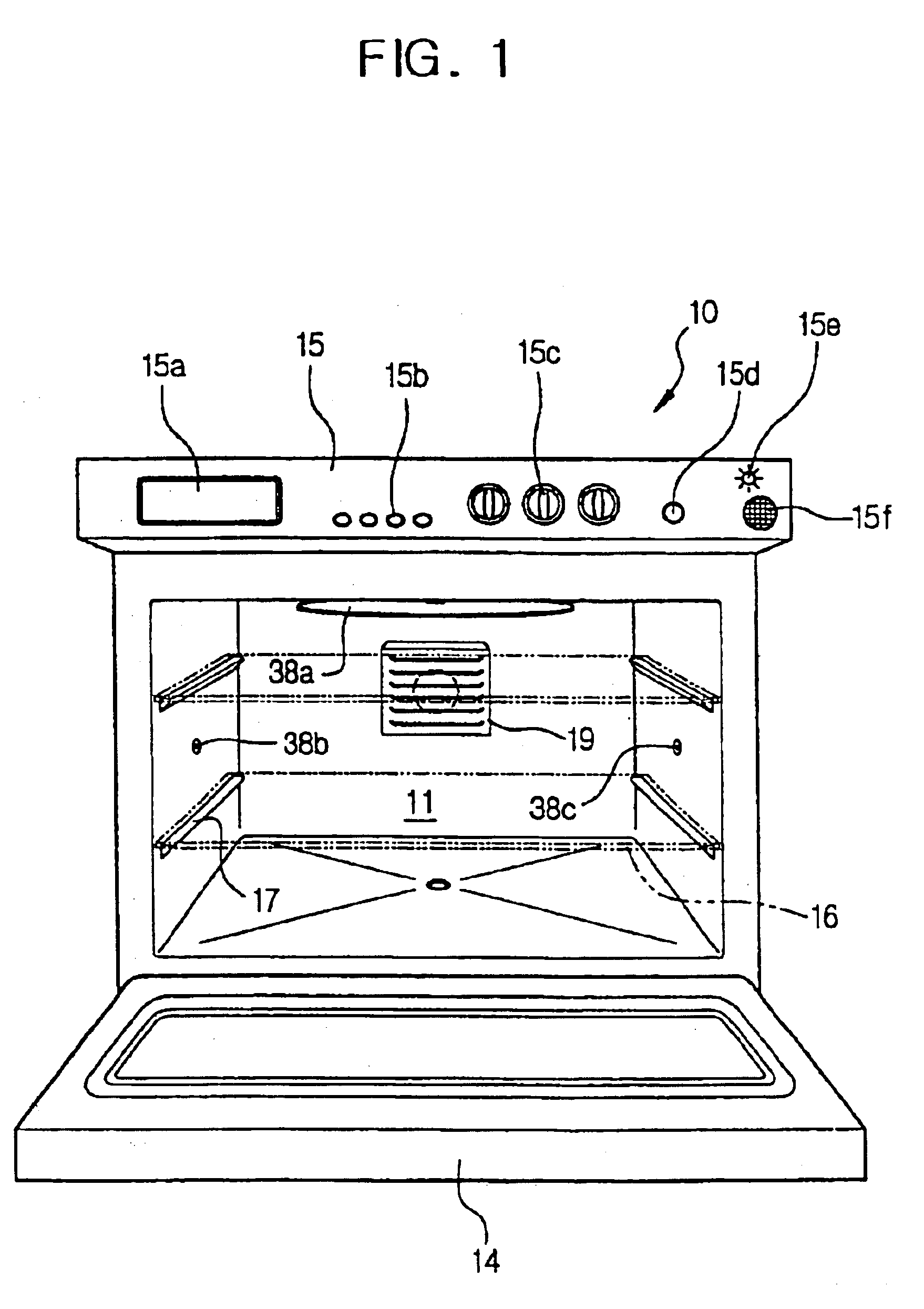

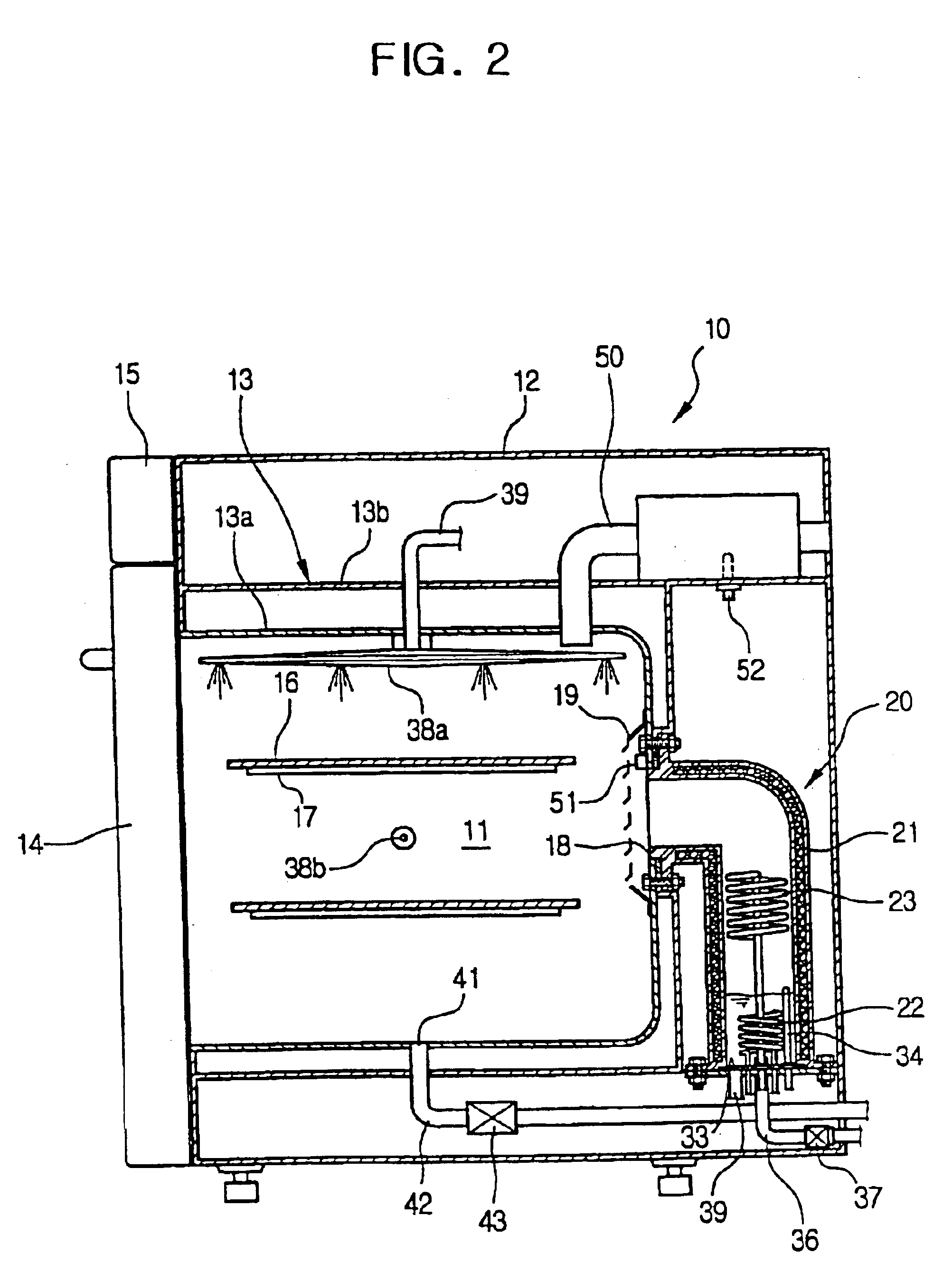

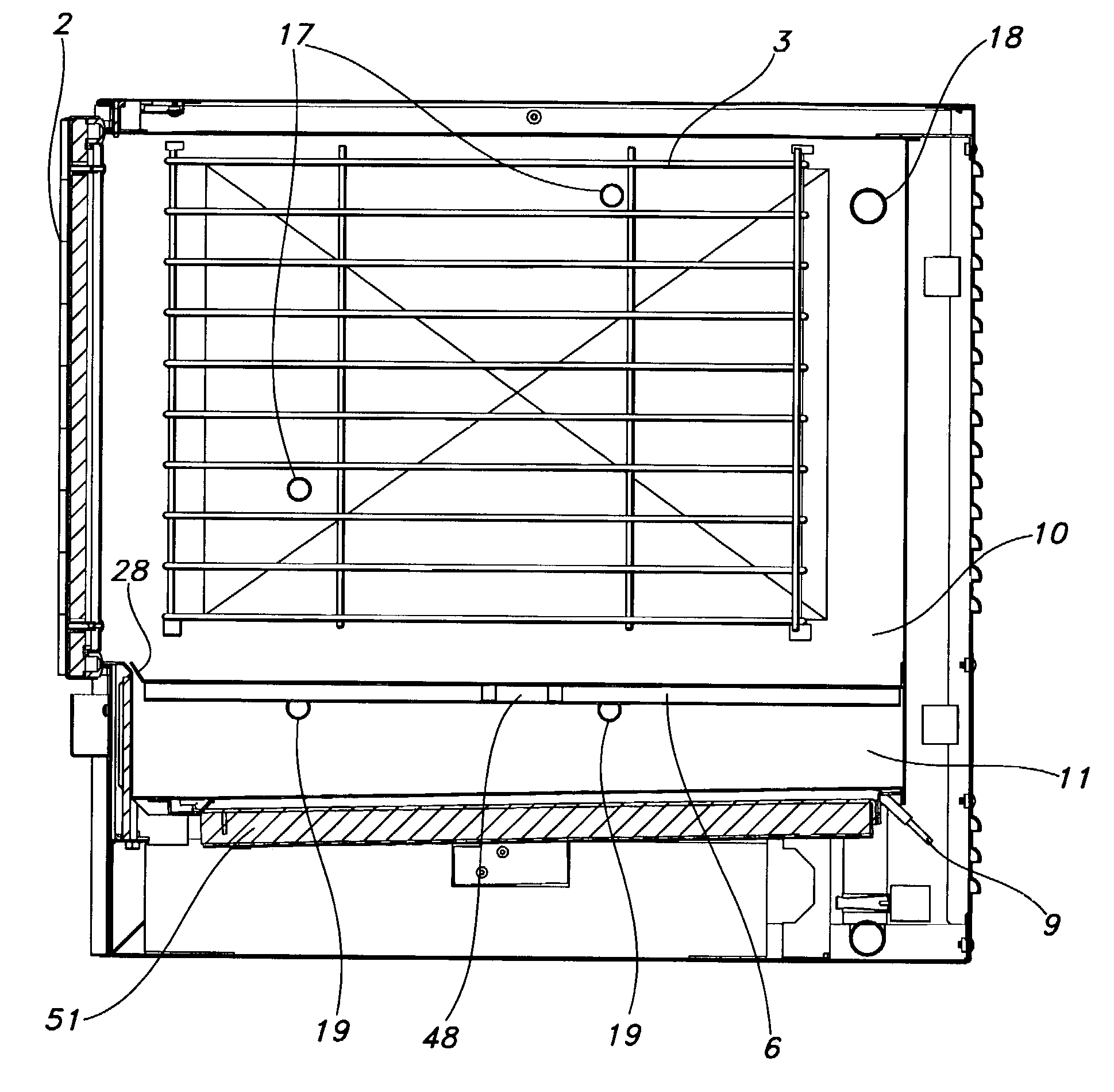

Overheated steam oven and method of controlling the same

InactiveUS6909071B2Self-cleaning stoves/rangesOven air-treatment devicesProcess engineeringSuperheated steam

An overheated steam oven which cleans an interior of a cooking cavity of the overheated steam oven using hot water and overheated steam, and executes a cooking operation using the overheated steam. The overheated steam oven includes a cabinet to define the cooking cavity therein, an overheated steam generator to supply overheated steam into the cooking cavity, and a cleaning unit to spray water from an interior of the overheated steam generator into the cooking cavity to clean the interior of the cooking cavity. A control method of the overheated steam oven includes spraying the water into the cooking cavity by use of the cleaning unit in response to a cleaning start signal, thus cleaning the interior of the cooking cavity, and supplying the overheated steam from the overheated steam generator into the cooking cavity after the cooking cavity is cleaned, thus drying the interior of the cooking cavity.

Owner:SAMSUNG ELECTRONICS CO LTD

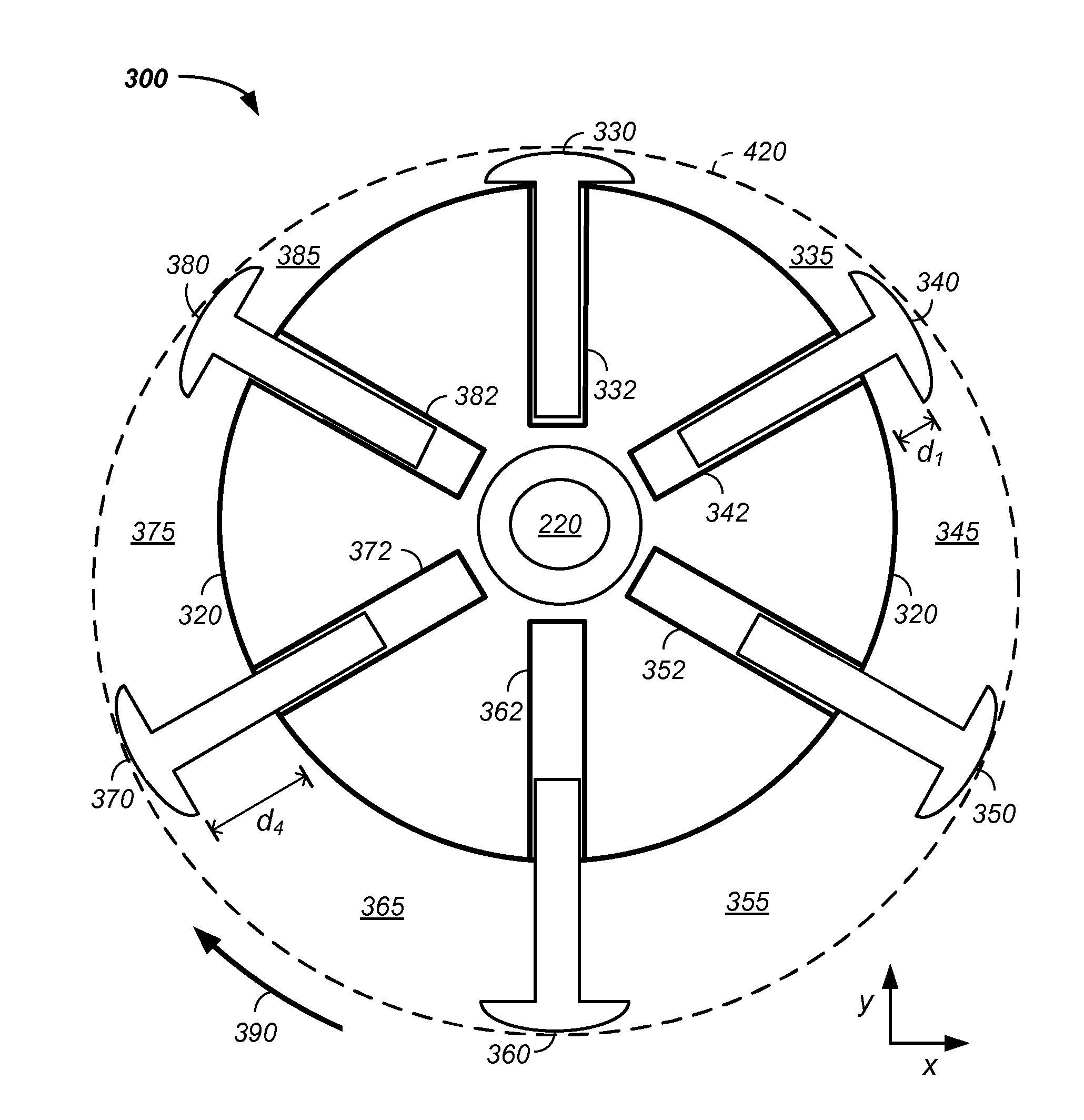

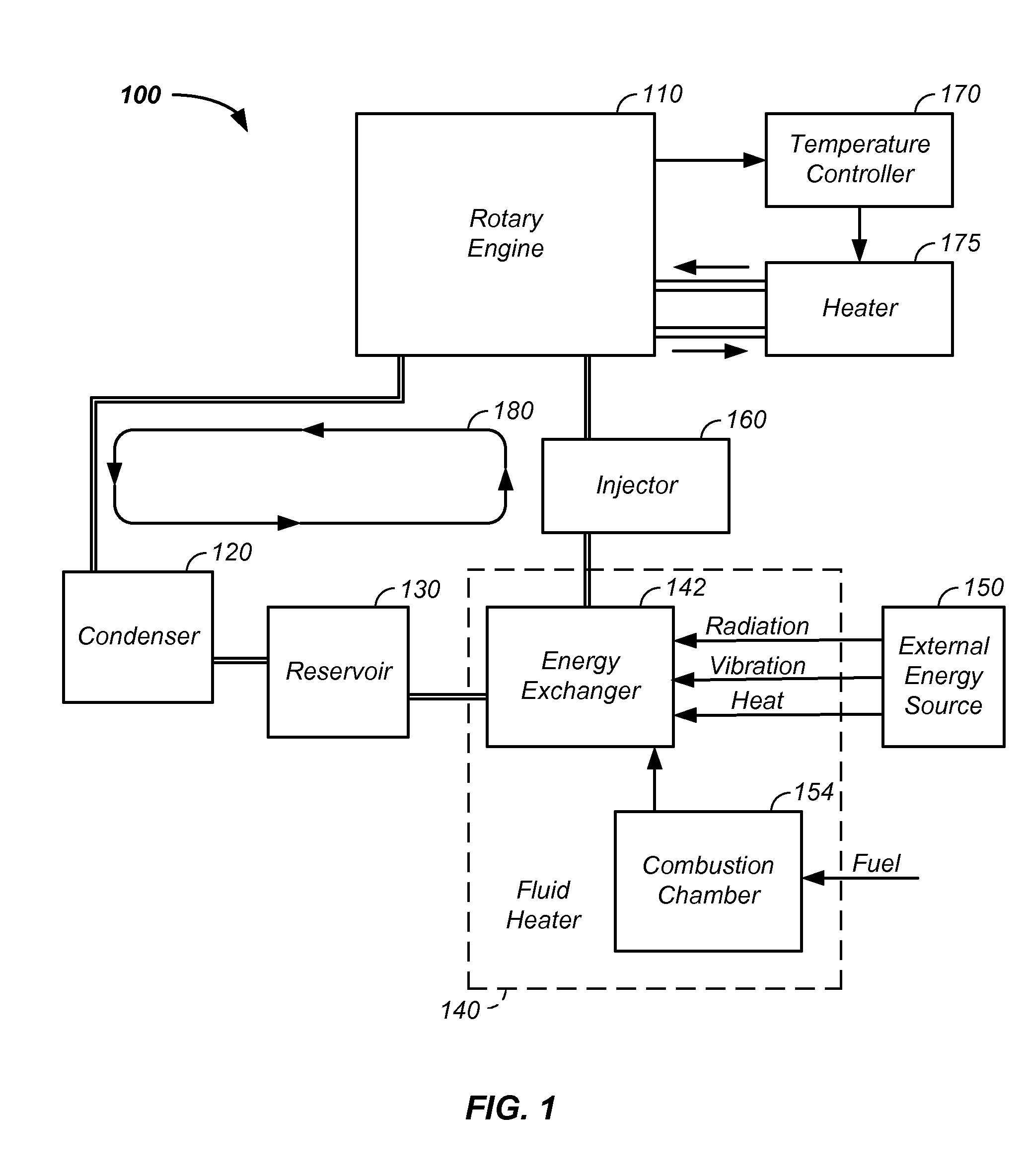

Rotary engine lip-seal apparatus and method of operation therefor

ActiveUS20110200473A1Oscillating piston enginesSealing arrangement for pumpsRotary engineCombined use

The invention comprises a rotary engine method and apparatus configured with a lip seal. A lip seal restricts fuel flow from a fuel compartment to a non-fuel compartment and / or fuel flow between fuel chambers, such as between a reference expansion chamber and any of an engine: rotor, vane, housing, and / or a leading or trailing expansion chamber. In separate states, high pressure and low pressure force sealing movement of the lip seal, respectively. The lip seal is optionally used in combination with a cap seal to form a dynamic seal. The dynamic seals ability to track a noncircular path are particularly beneficial for use in a rotary engine having an offset rotor and with a non-circular inner rotary engine compartment having engine wall cut-outs and / or build-ups. The dynamic sealing forces further provide cap sealing forces over a range of temperatures, pressures, fuel flow rates, varying loads, and operating engine rotation rates.

Owner:PEKRUL MERTON W

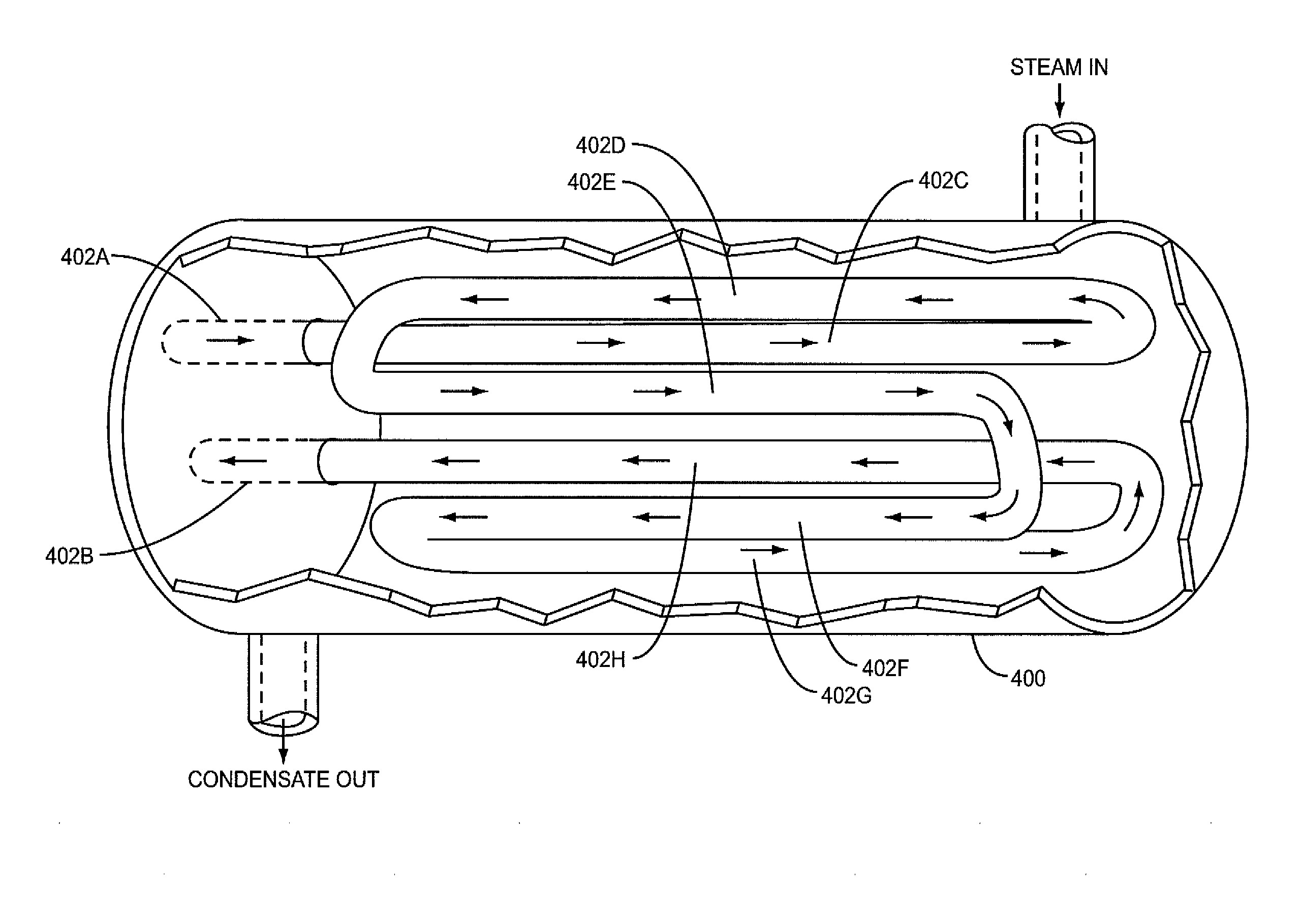

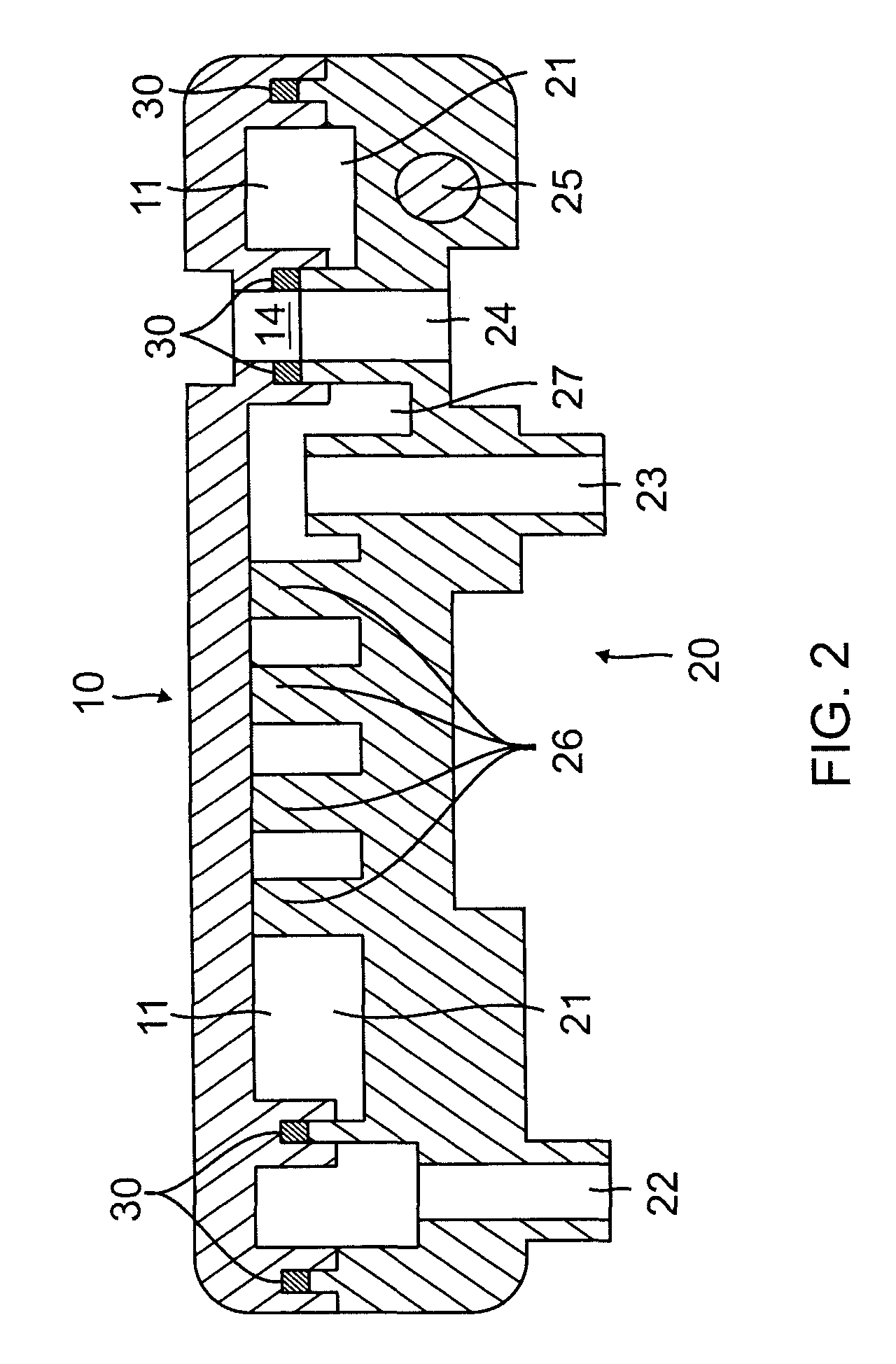

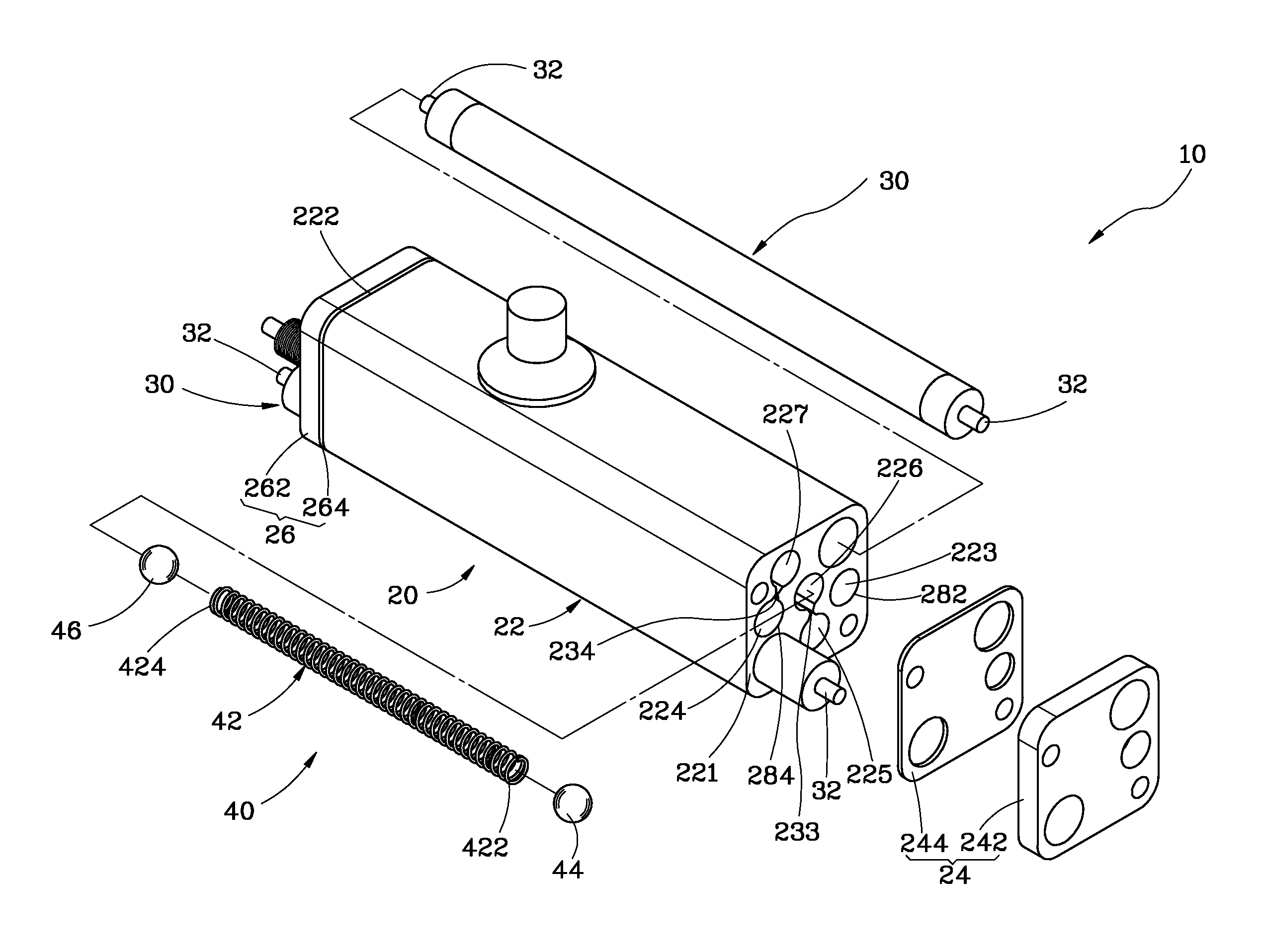

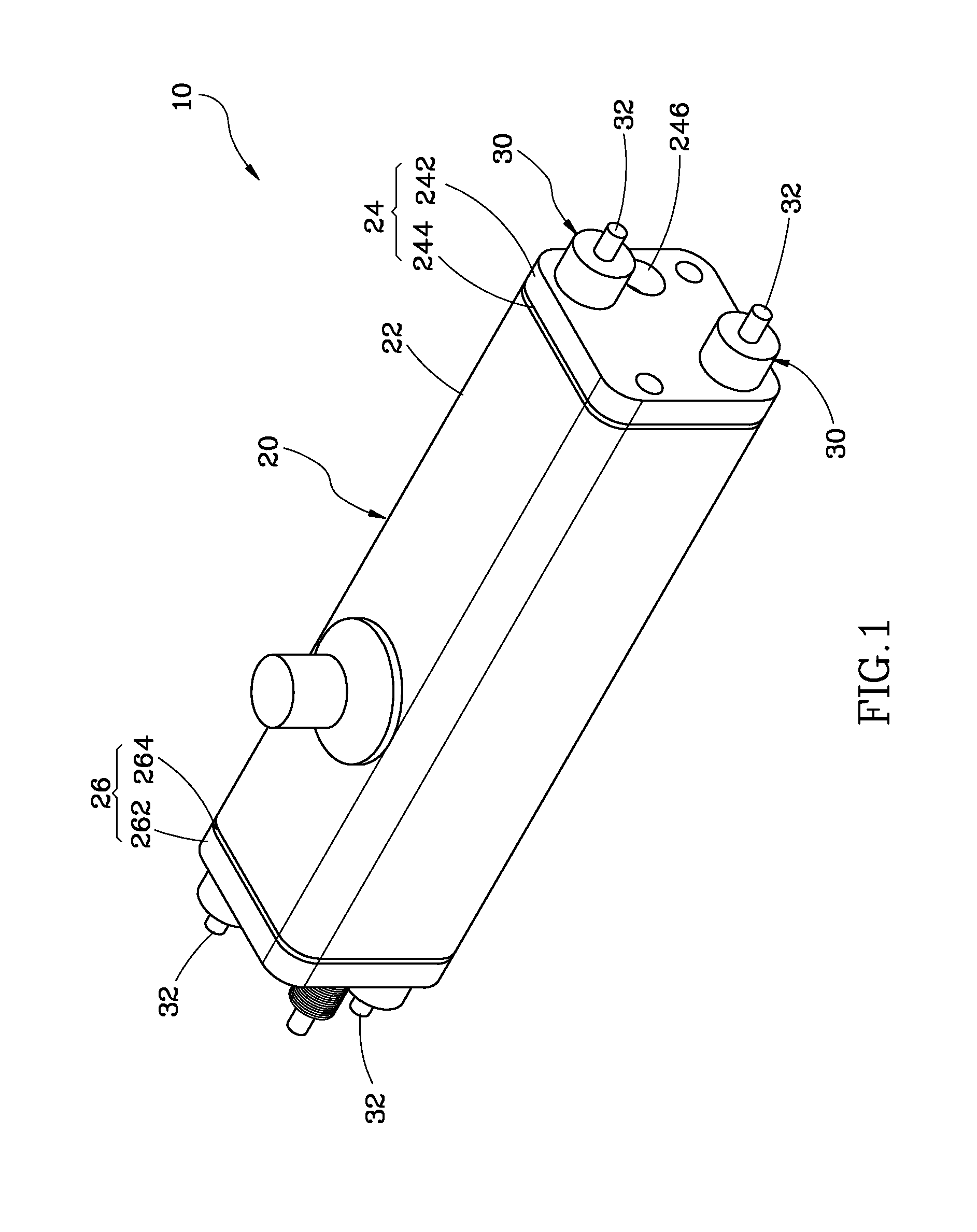

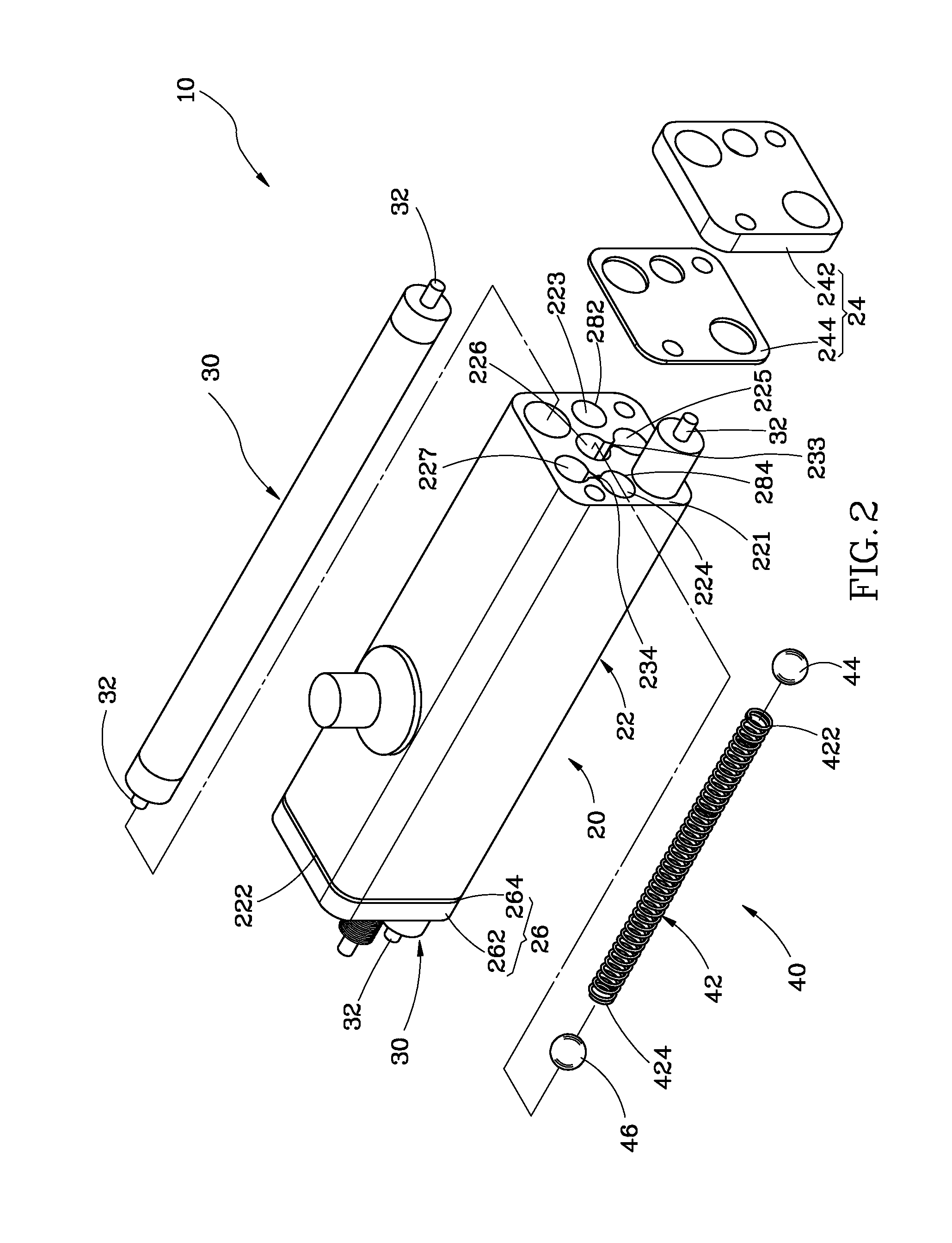

Fluid heater

A fluid heater having a first heat exchanger block with a fluid heating tube encased therein, and having a first surface, a second heat exchanger block with a fluid heating tube encased therein and having a second surface adjacent to the first surface. A cavity is formed in the surface of the first block, or, alternatively, formed in each of the surfaces of the first and second blocks. A heating element is positioned within the cavity and completely encapsulated by the first and second blocks. The heating element may include first and second bus plates and a plurality of PTC elements sandwiched between the bus plates in an electrically parallel configuration, each PTC element including first and second conductive plates, and a plurality of positive temperature coefficient heating stones sandwiched between the conductive plates in an electrically parallel configuration.

Owner:ALGAS SDI INT

Method for starting a continuous steam generator and continuous steam generator for carrying out said method

The invention relates to a continuous steam generator provided with an evaporator through flow heating surface which is disposed in a heating gas channel which can be cross flown in an approximately vertical manner in a heating gas device, said evaporator through flow heating surface comprising a plurality of parallel connected steam generating pipes enabling a flow medium to flow through, and an overheating heating surface which is arranged downstream from the evaporator through flow heating surface comprising a plurality of parallel connected overheating pipes enabling the evaporated flow medium to flow through, also enabling production and operational costs to be reduced and enabling the temperature of the steam on the outlet of the overheating heating surface to be controlled in a comparatively simple and flexible manner. The steam end-point of the flow medium is displaced to the overheating pipe, if required. The continuous heating surfaces and the overheating heating surfaces are combined to form one functional unit such that the overheating heating surface can be used as a steam heating surface in a continuous steam generator which is particularly suitable for carrying out said method.

Owner:SIEMENS AG

Boilerless steamer apparatus

InactiveUS7024104B2Easy accessEasy to cleanOven air-treatment devicesGaseous substancesProcess engineeringSteam generation

Owner:UNIFIED BRANDS

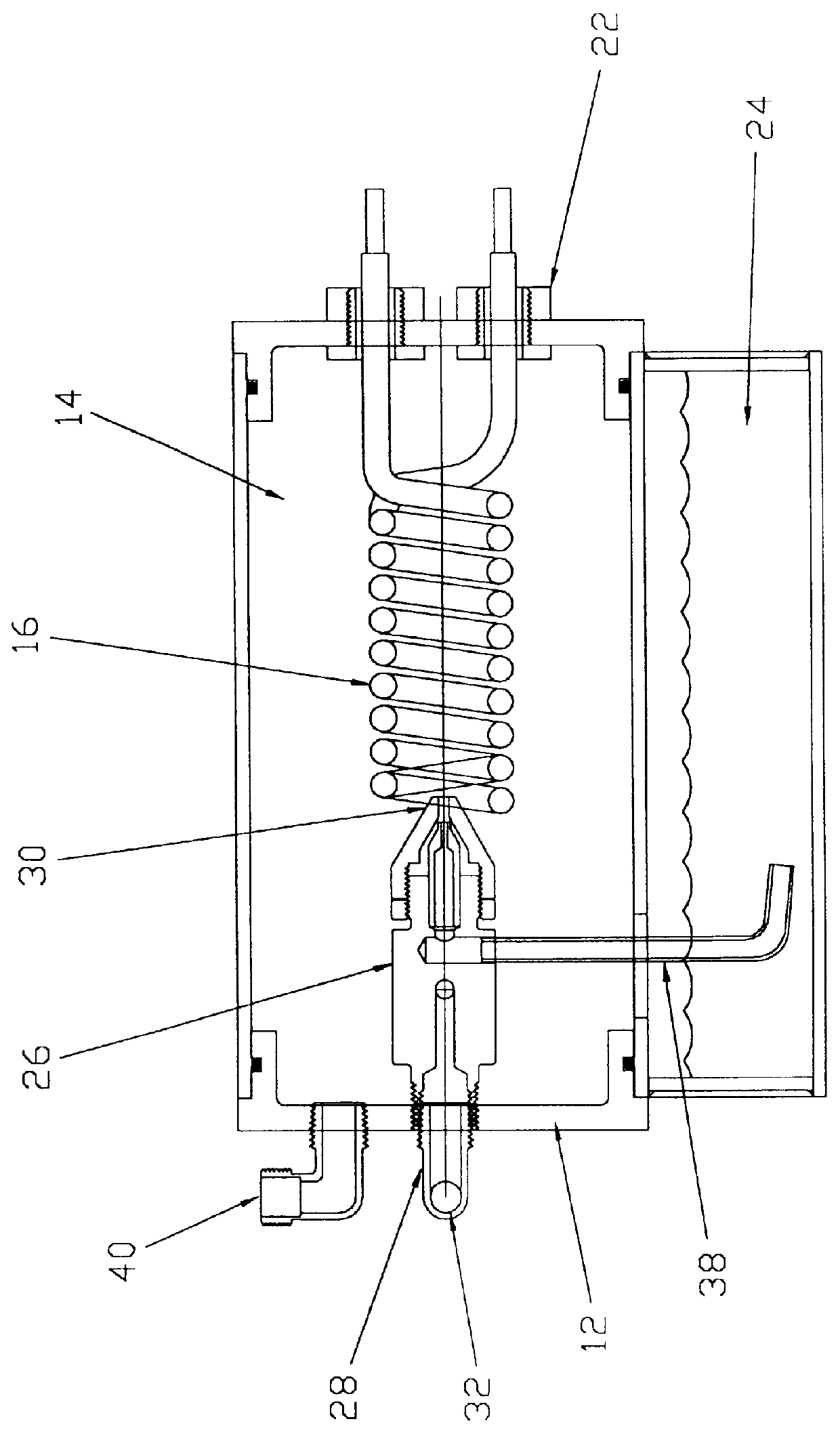

Instantaneous steam boiler

InactiveUS7813628B2Shorten the lengthSuppress formationBoiler water tubesWater-tube boilersVaporizationEngineering

The present invention relates to an instantaneous steam boiler generating steam in a steam cleaner, a steam-vacuum cleaner, a steam iron, etc. The instantaneous steam boiler includes a U-shaped heater and a separate flow tube arranged in parallel and contact with said heater. The flow tube may be arranged orthogonally or at a 180 degree opposite direction and may include a circular or square-shaped end with rounded edges, thereby increasing the heating / vaporization efficiency of the device.

Owner:HAAN

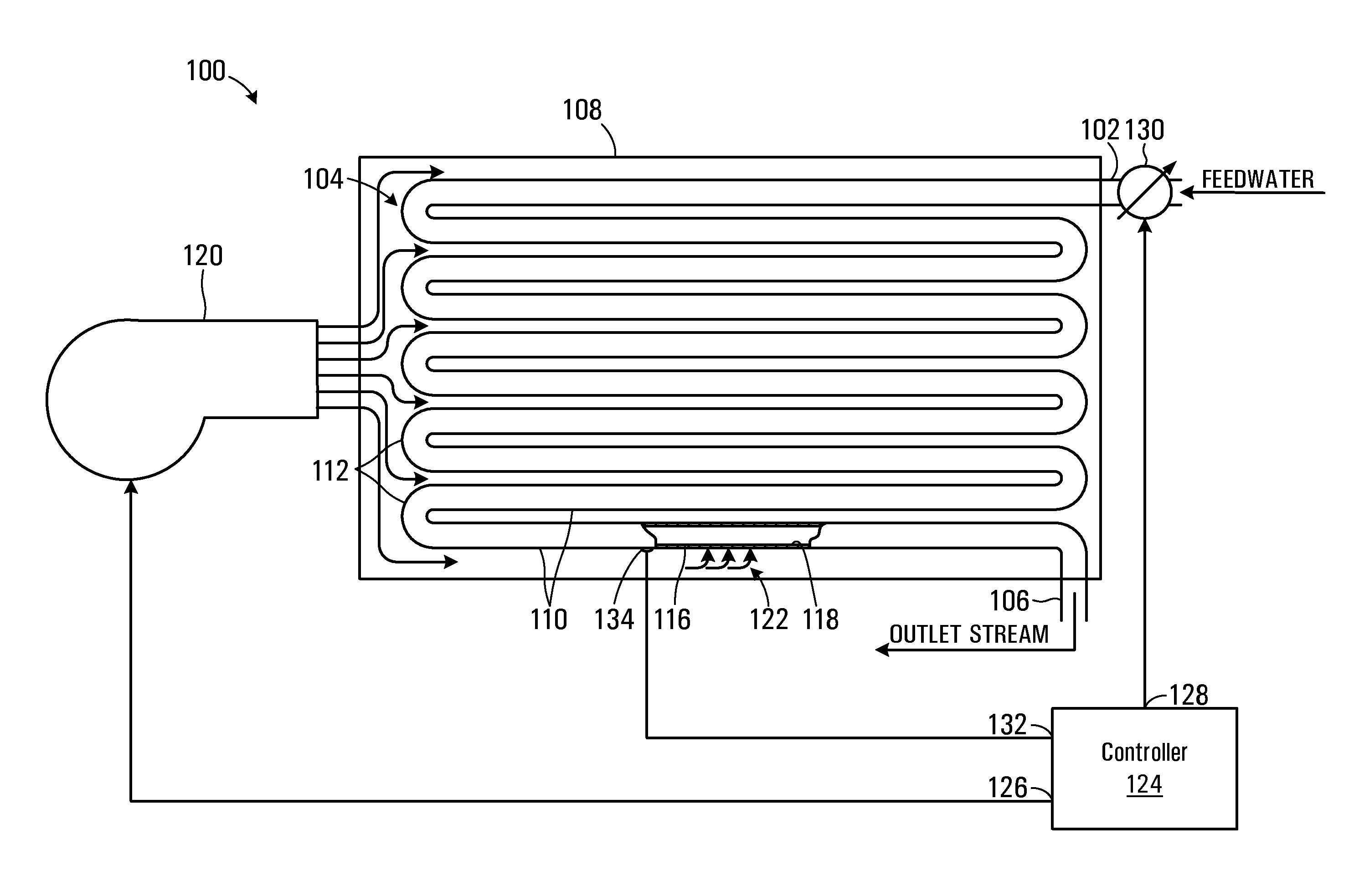

Steam generator and method for generating steam

ActiveUS20130161009A1Improve cooling effectReduce problem sizeBoiler water tubesBoiler cleaning apparatusHeat fluxEvaporation

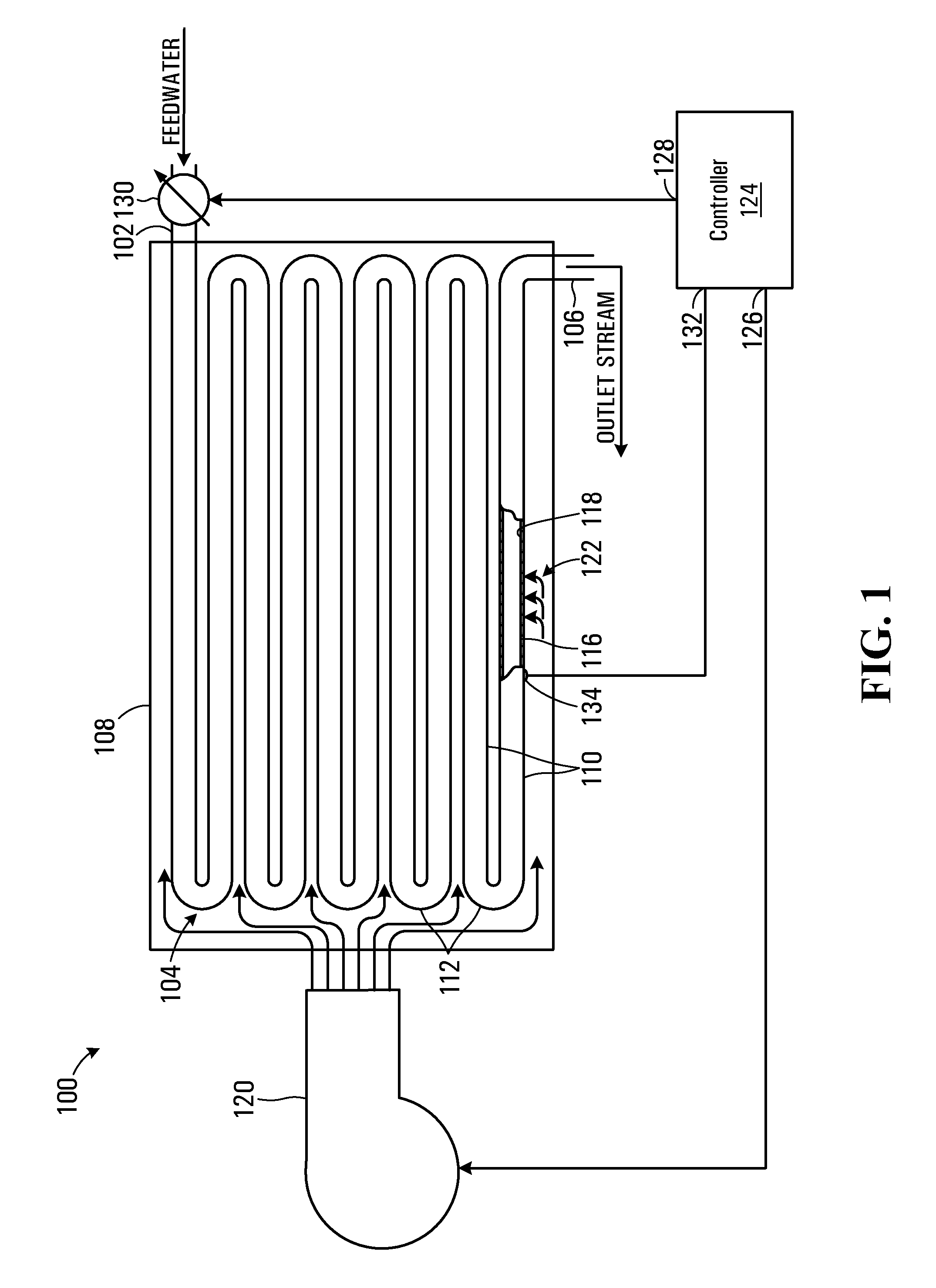

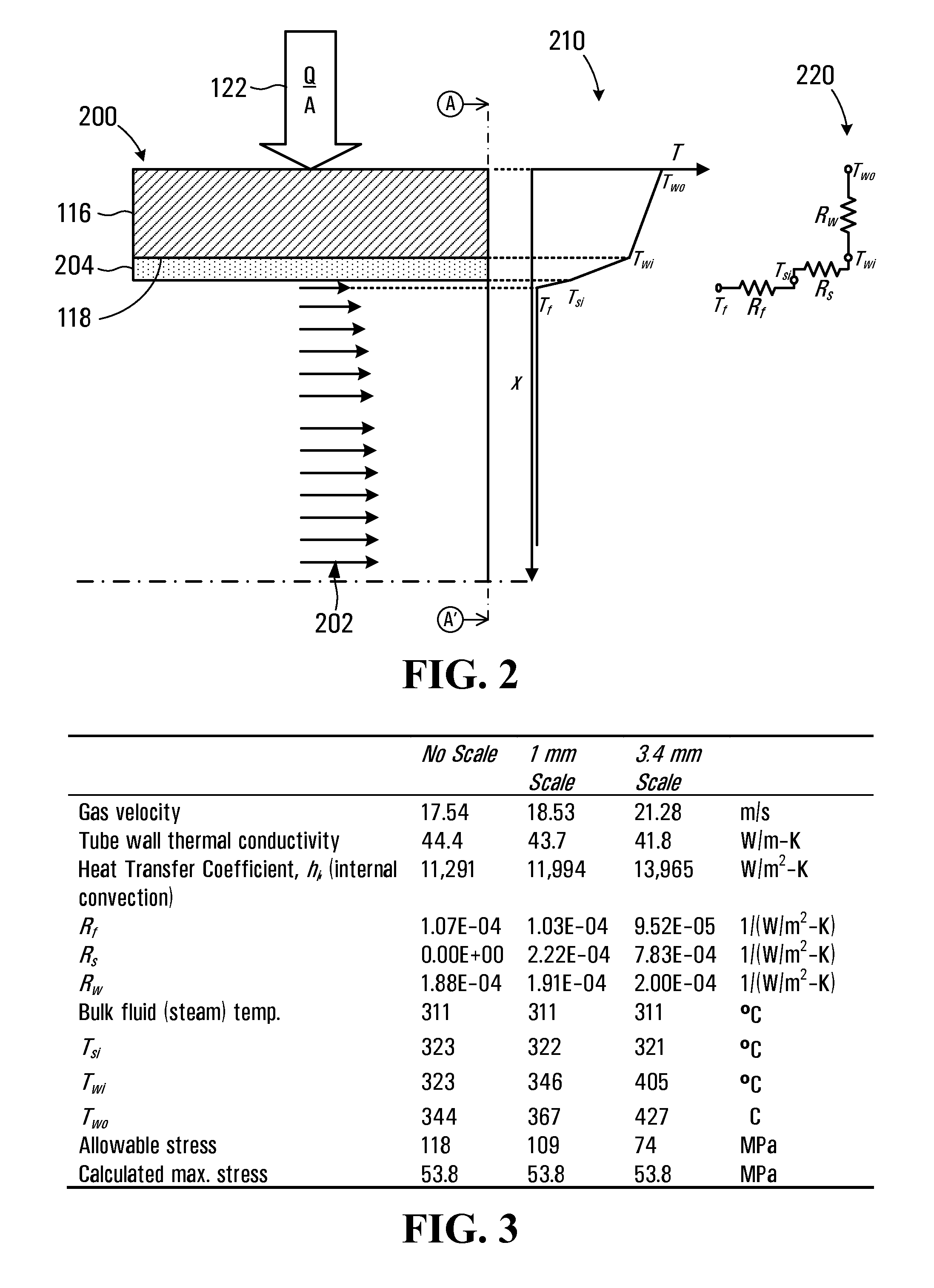

A method for generating steam from a feedwater inlet stream including impurities is disclosed. The method involves receiving the feedwater inlet stream at an inlet of a steam generator and causing the feedwater stream to flow through a tubing circuit to an outlet of the tubing circuit, the tubing circuit having a substantially un-rifled bore defined by a metal wall. The method also involves delivering a heat flux to the feedwater stream through the metal wall of the tubing circuit to generate steam by causing evaporation of feedwater within the tubing circuit, and controlling at least one of a flow rate of the feedwater stream and the heat flux to cause generation of an outlet stream at the outlet includes a steam portion and liquid phase portion, the steam portion being greater than about 80% of the outlet stream by mass. The steam portion provides sufficient cooling of the metal wall to maintain a wall temperature at less than a threshold temperature.

Owner:FCCL PARTNERSHIP

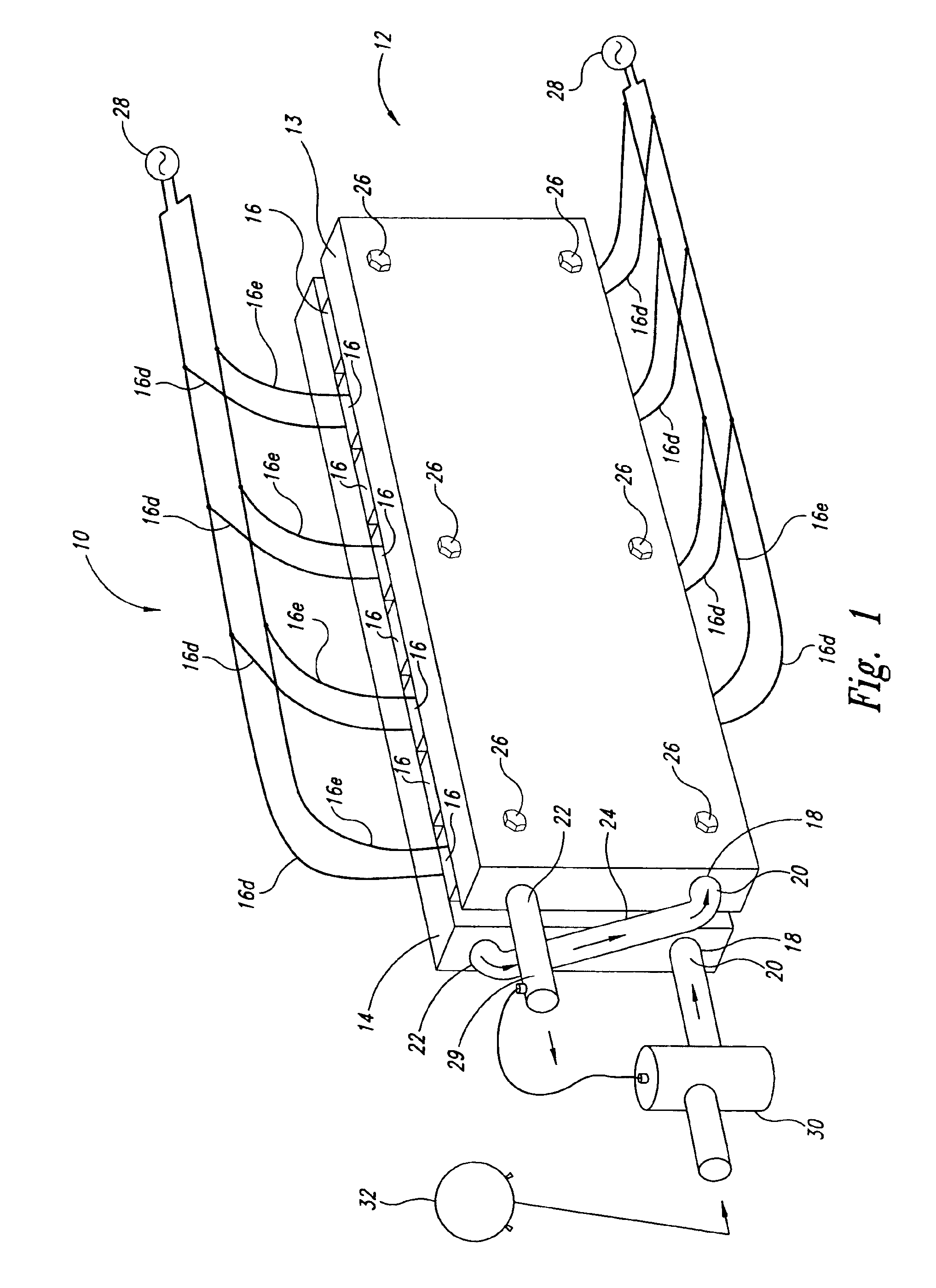

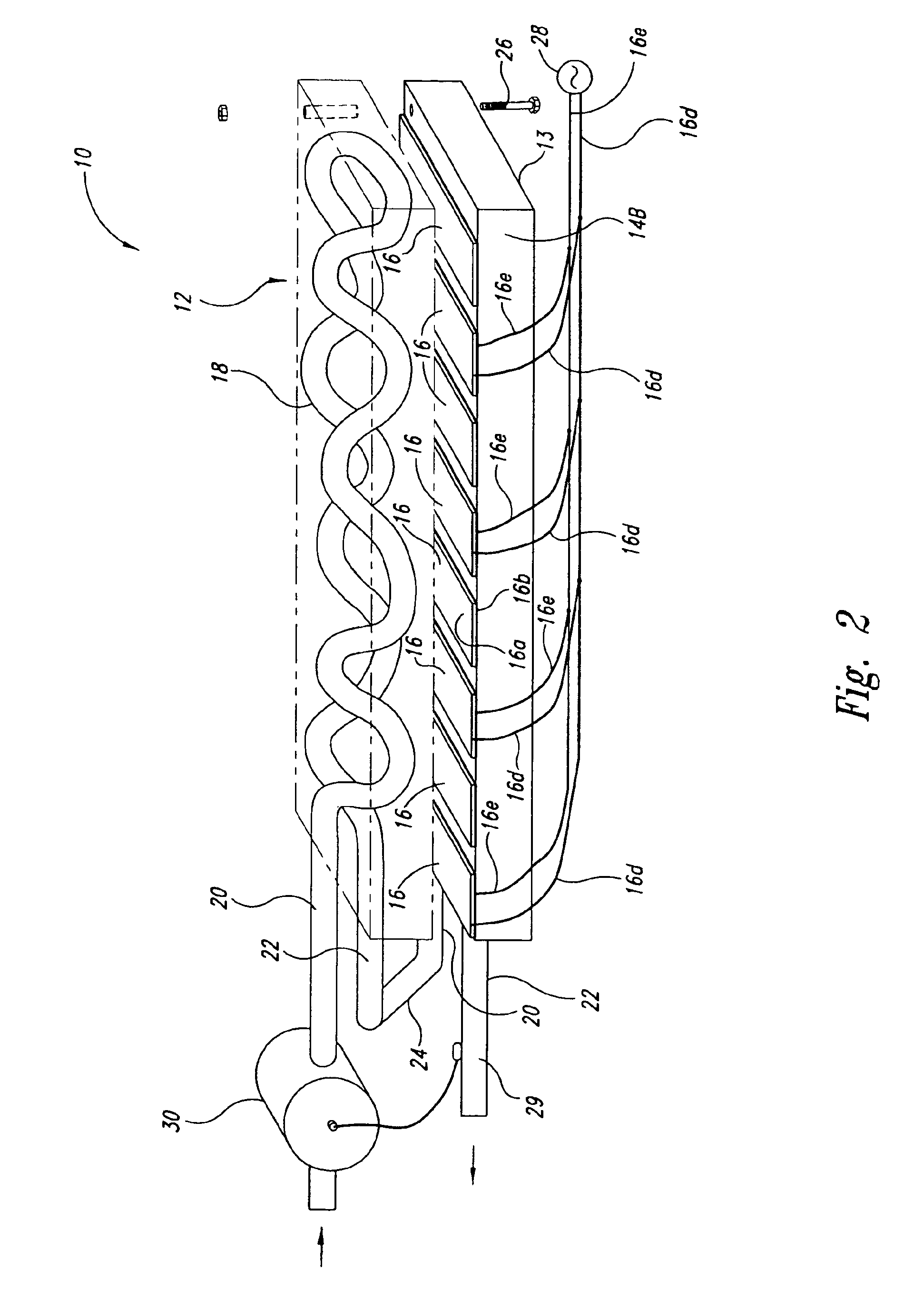

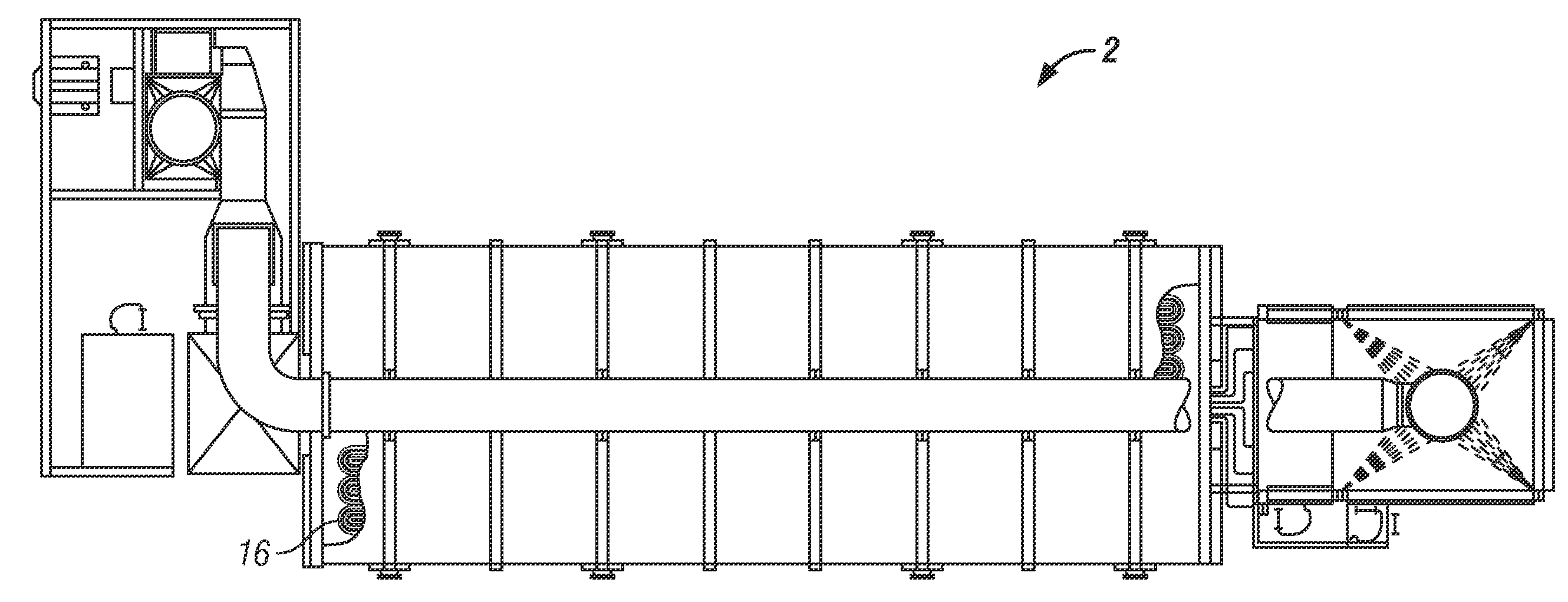

Online pigging system and method

The disclosure provides a heat transfer system having a tubing coil for heating fluid flowing therein, where the tubing coil can be pigged (descaled) while operationally online, instead of offline. The online system uses an assembly of valves and associated equipment to connect to a pig launcher and pig receiver while the system is online. A valve opens and the pig launches into the flow stream under pressure through the valve and travels along the tube with the fluid. The system continues to produce heated fluid with the pig in the flow path. A pig receiver receives the pig after the pigging, and then is isolated from the flow path of the heated fluid by another valve. The pig launcher, pig receiver, and pig are removed, and this process is repeated for any other passes in the tubing coil.

Owner:TECH FRANCE SA

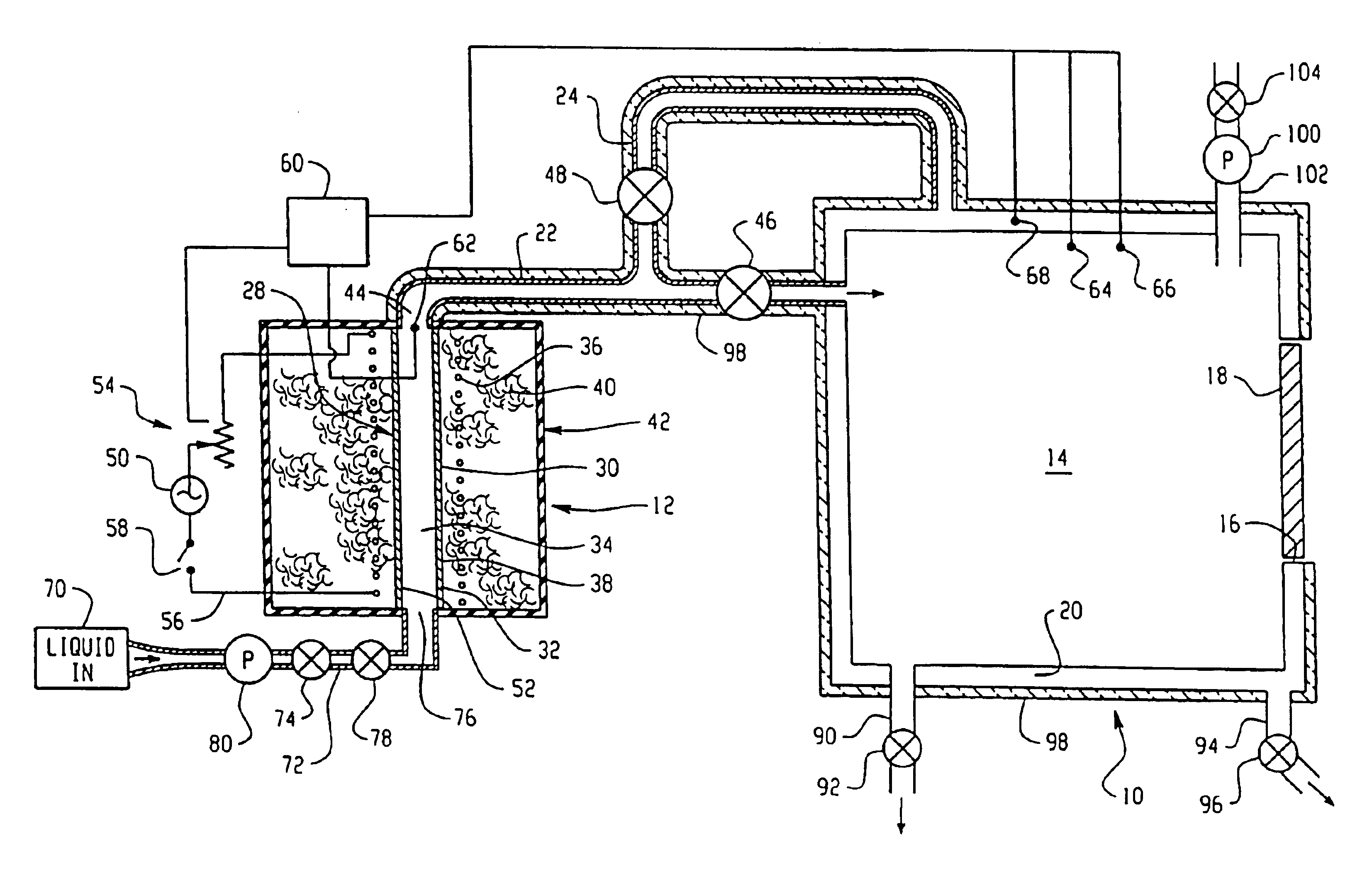

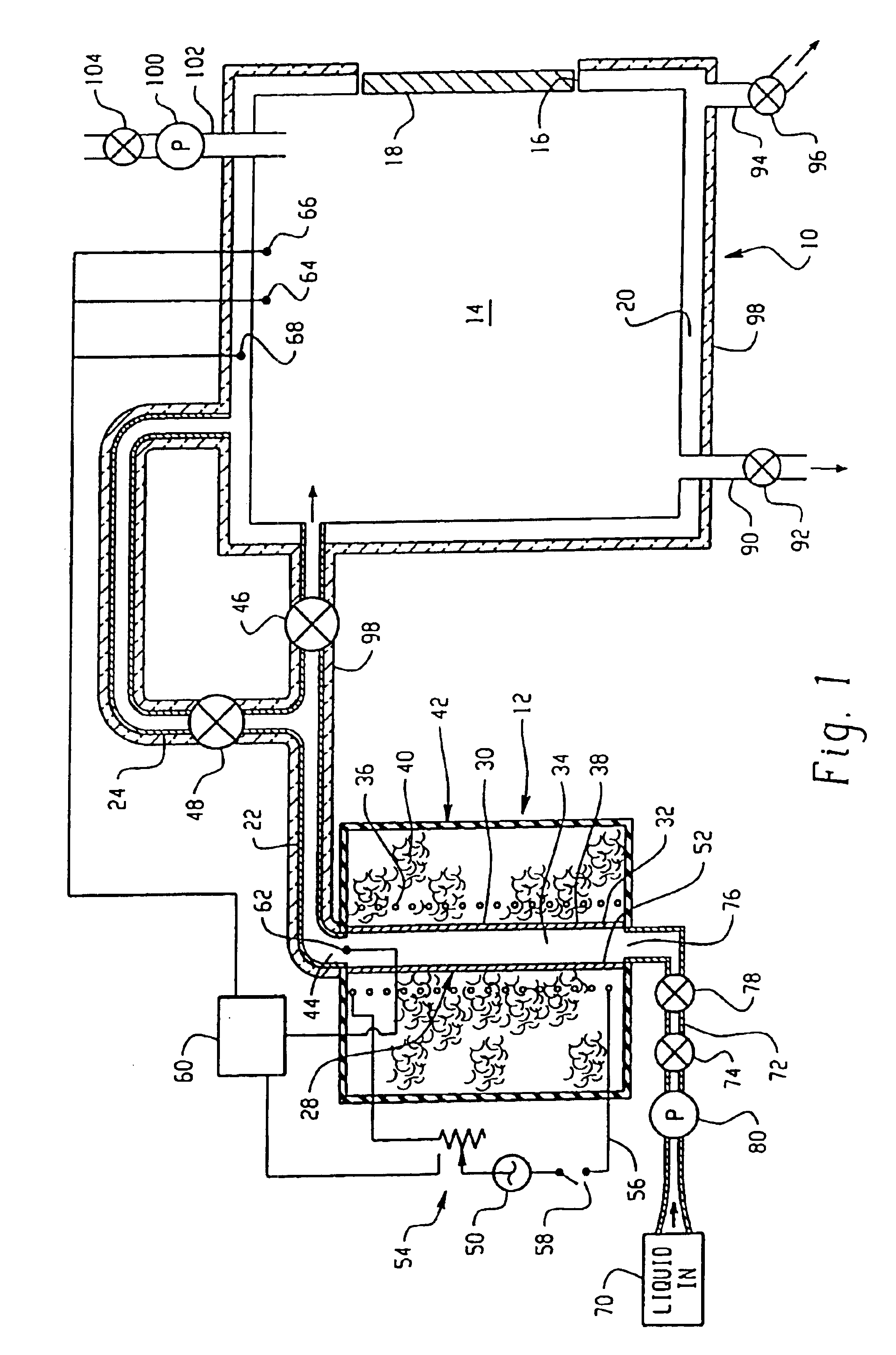

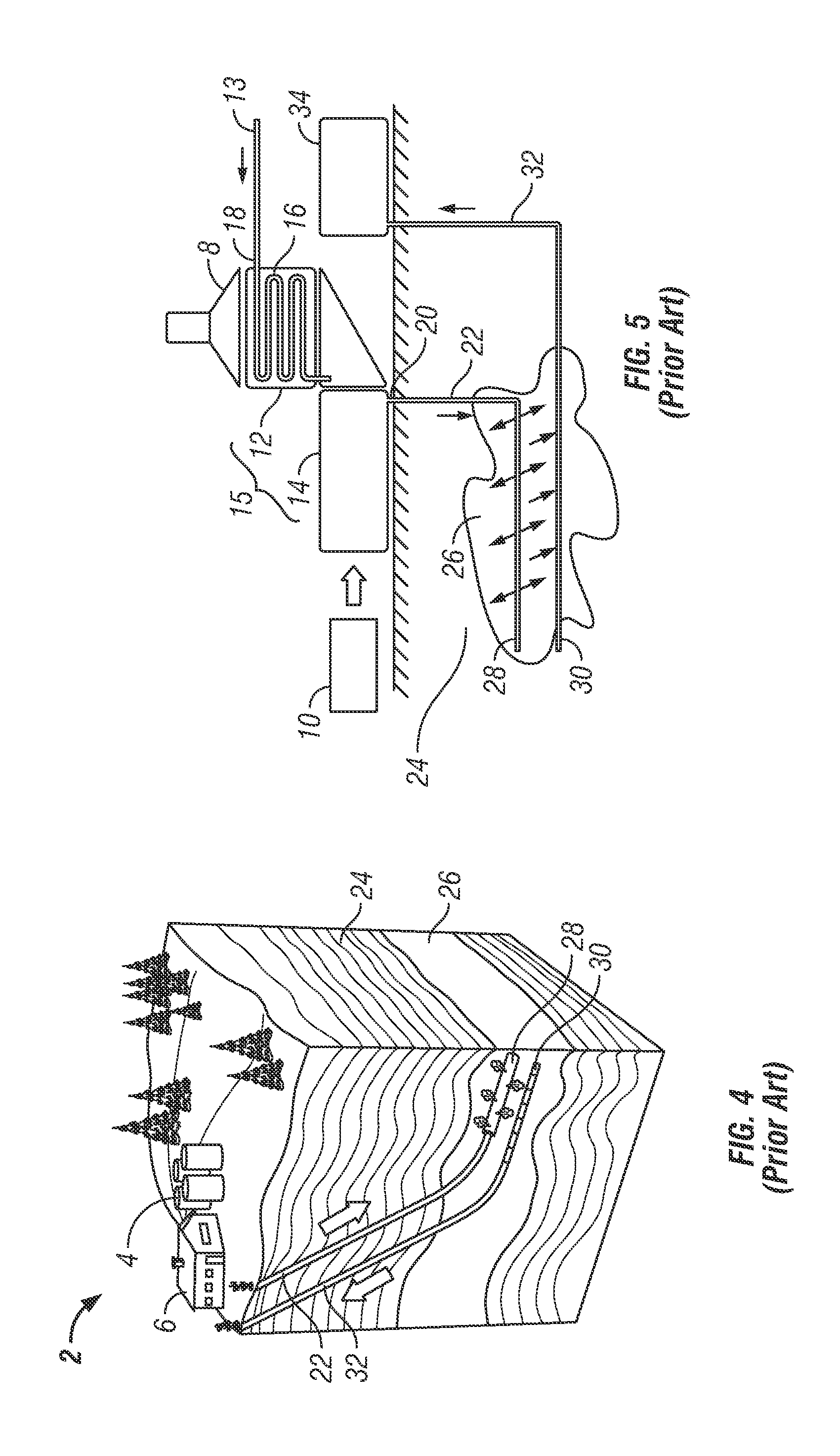

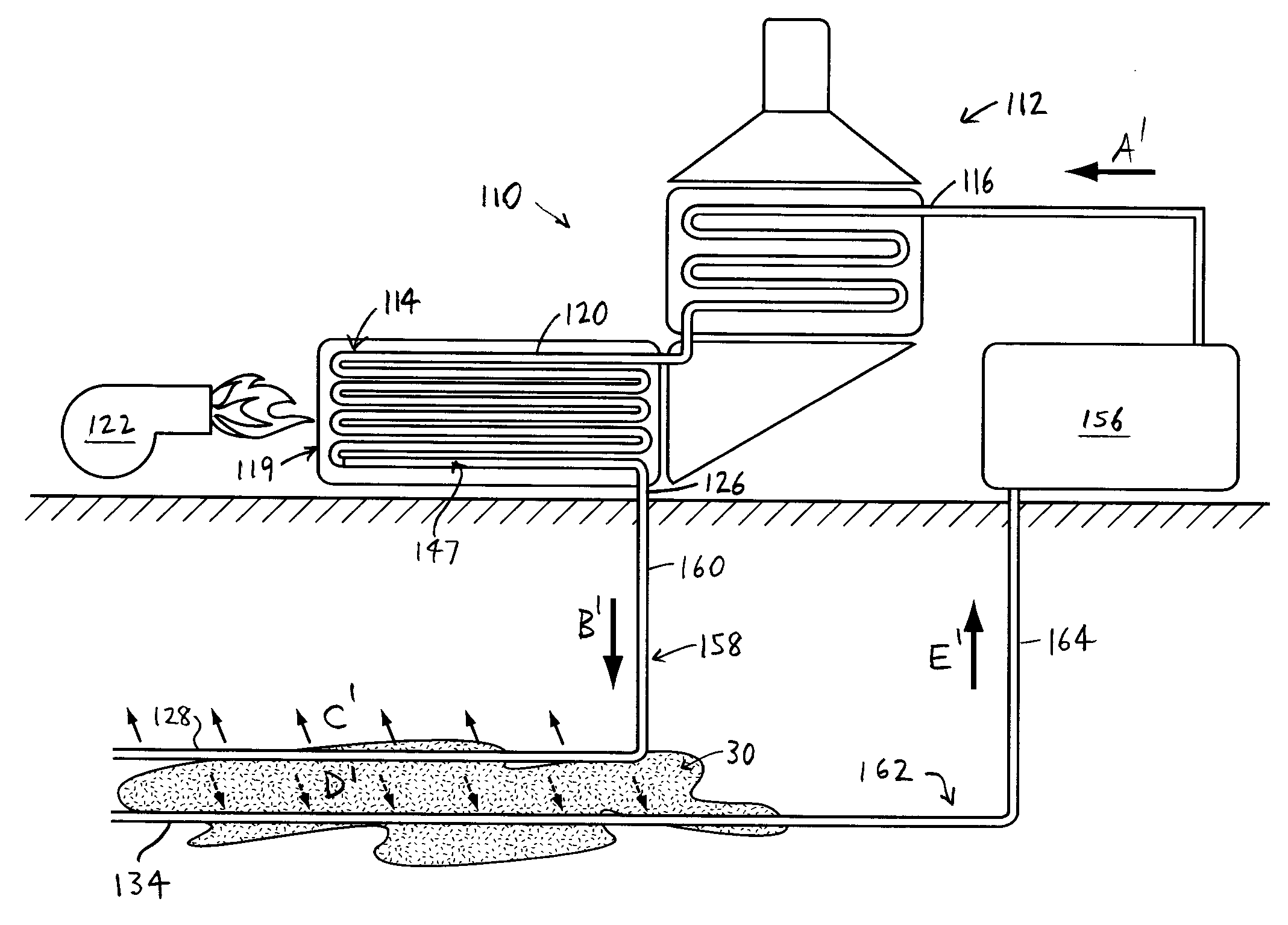

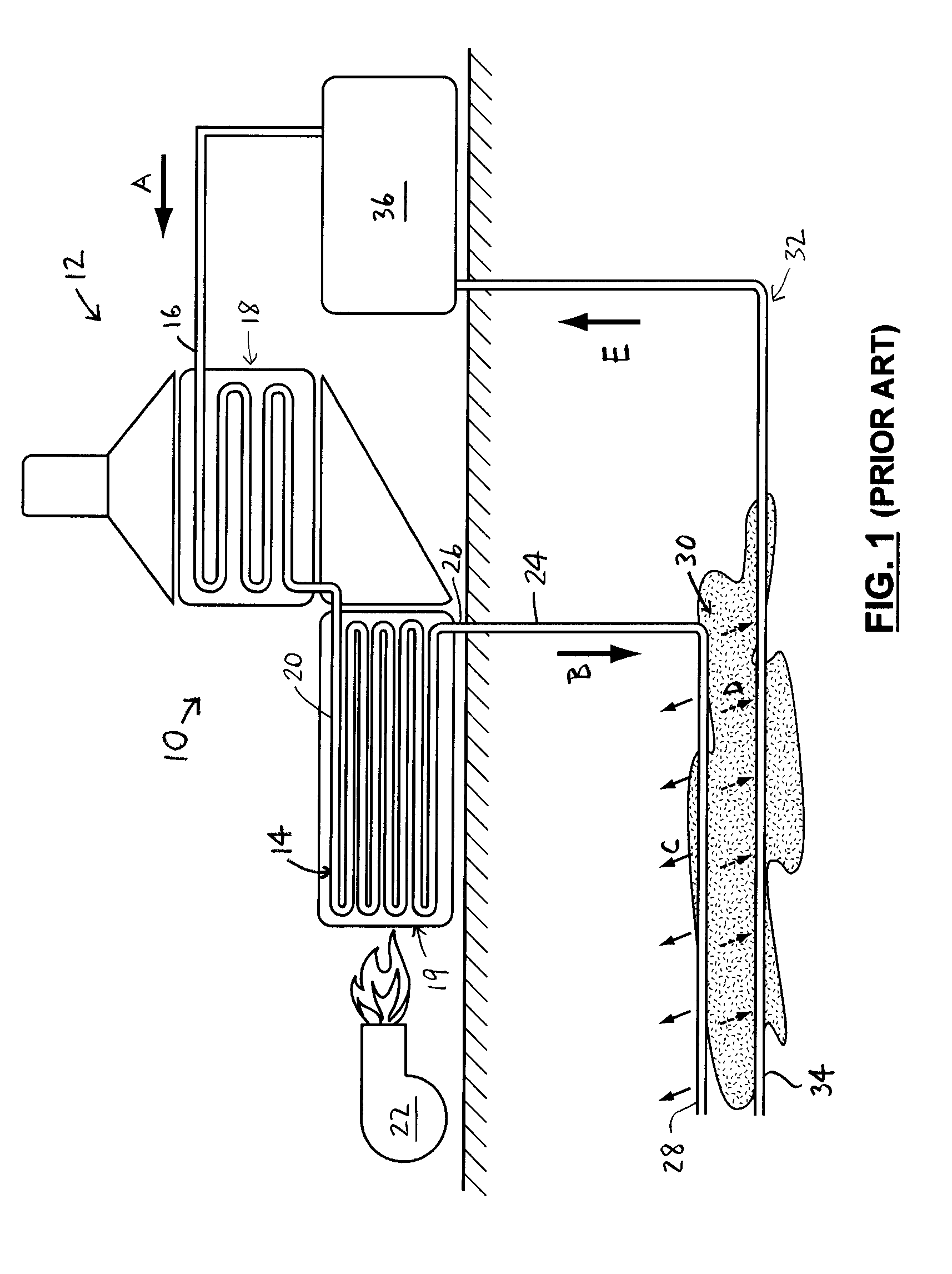

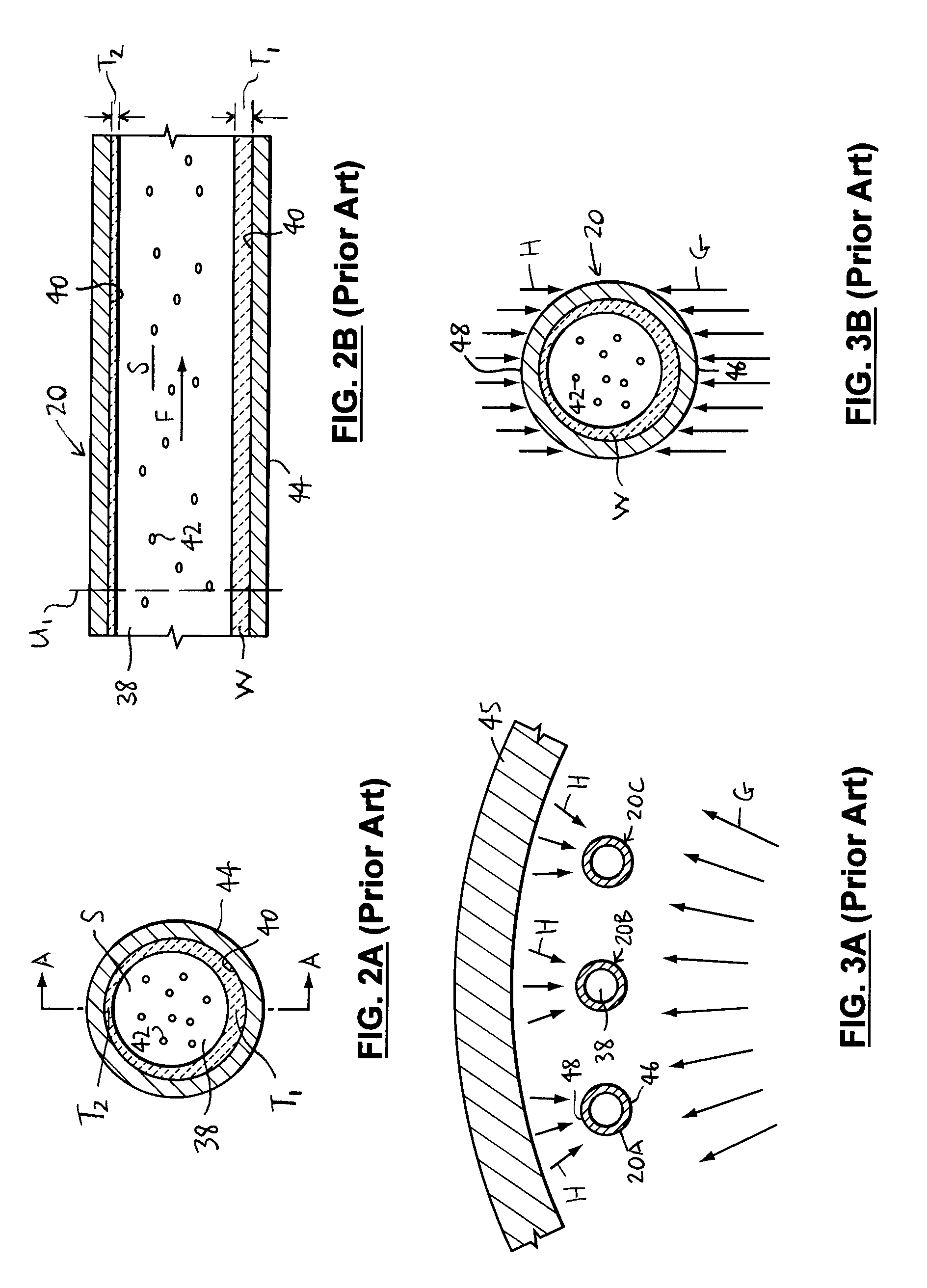

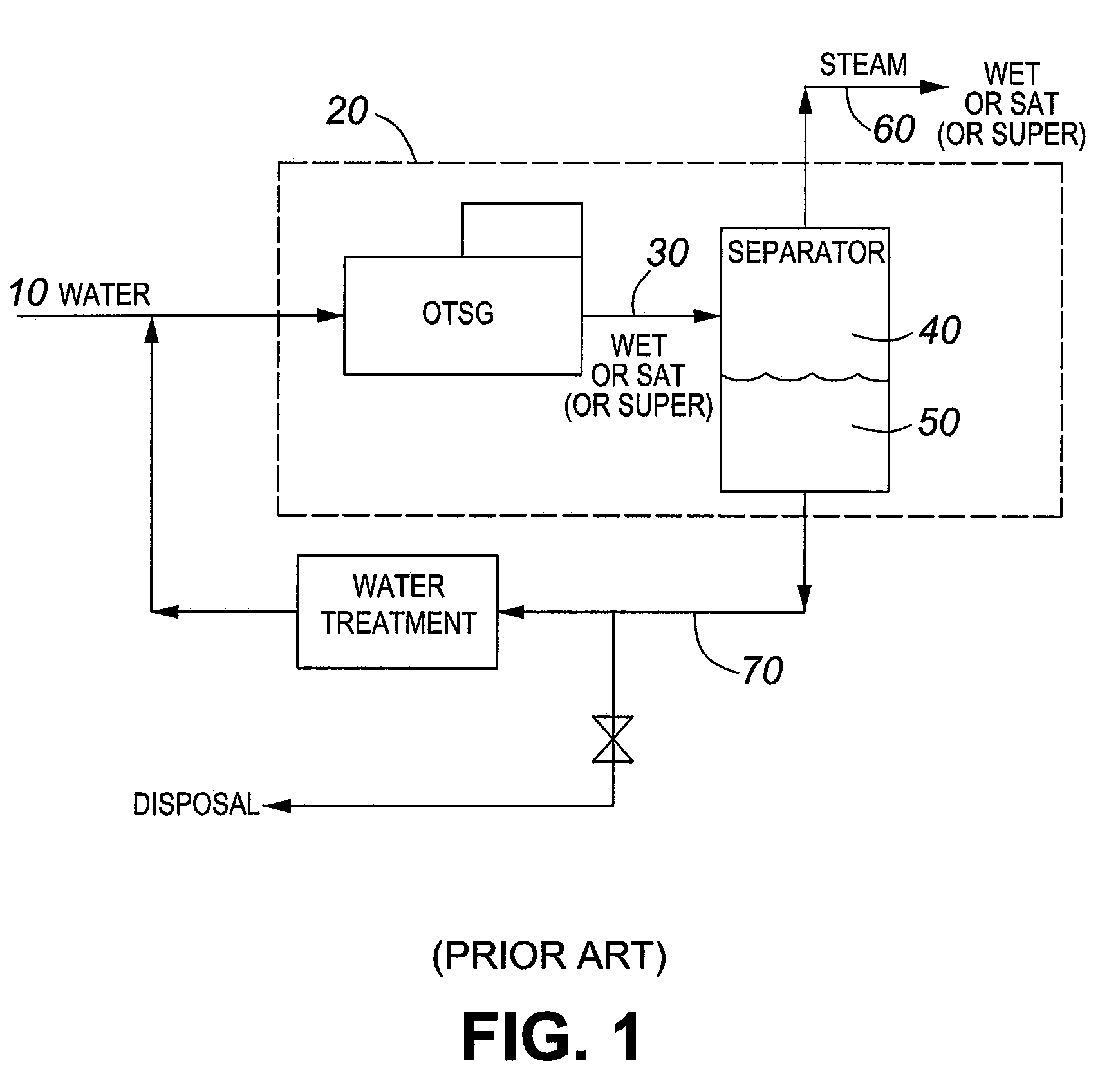

System and method for enhanced oil recovery with a once-through steam generator

ActiveUS20110017449A1High exit steam qualityEnhanced overall recoveryWater circulationInsulationEngineeringImpurity

A once-through steam generator including one or more steam-generating circuits extending between inlet and outlet ends thereof and including one or more pipes, the steam-generating circuit having a heating segment at least partially defining a heating portion of the once-through steam generator, and one or more heat sources for generating heat to which the heating segment is subjected. The steam-generating circuit is adapted to receive feedwater at the inlet end, the feedwater being subjected to the heat from the heat source to convert the feedwater into steam and water. The pipe has a bore therein at least partially defined by an inner surface, and at least a portion of the inner surface has ribs at least partially defining a helical flow passage. The helical flow passage guides the water therealong for imparting a swirling motion thereto, to control concentrations of the impurities in the water.

Owner:PROPAK SYST

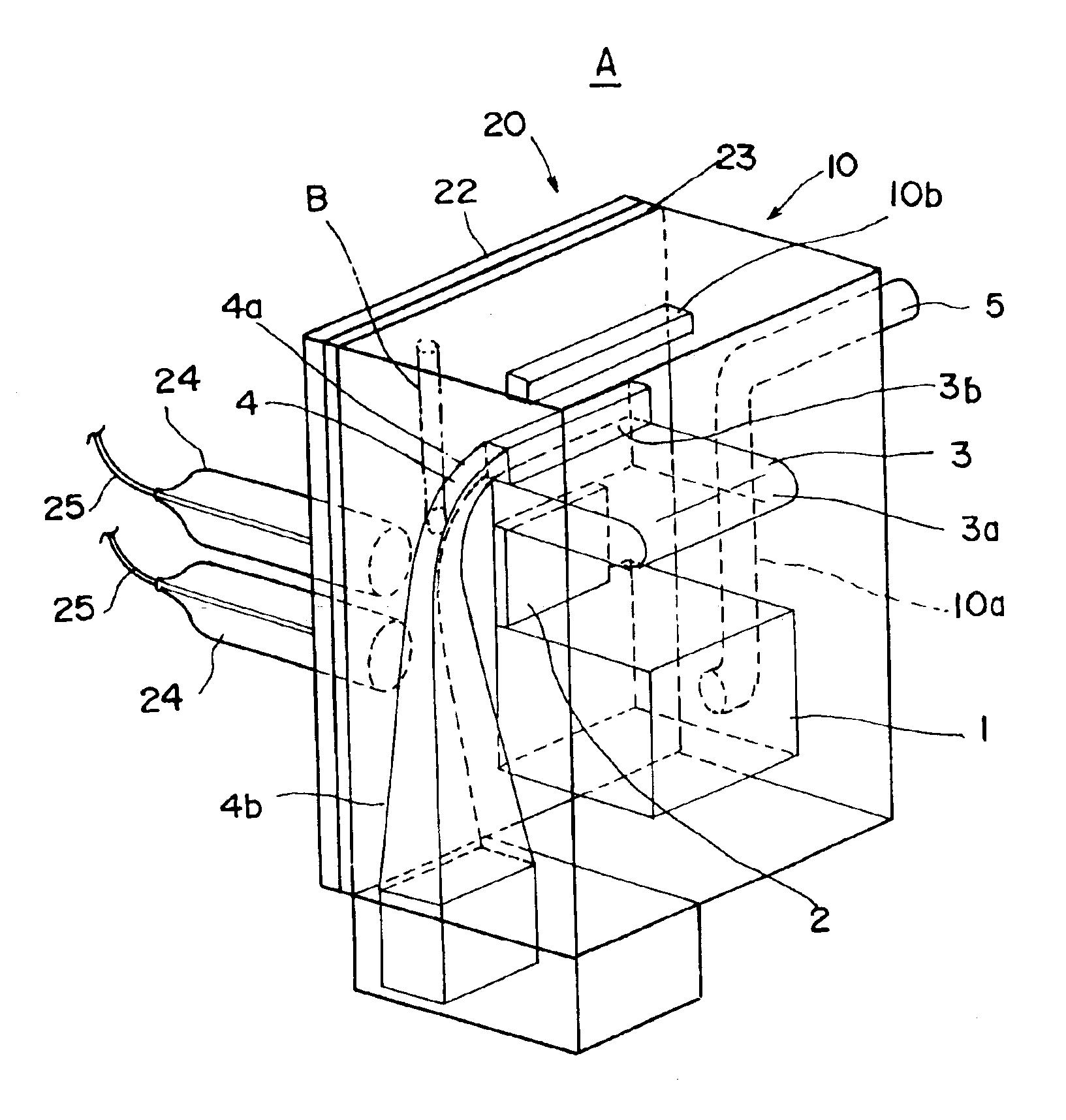

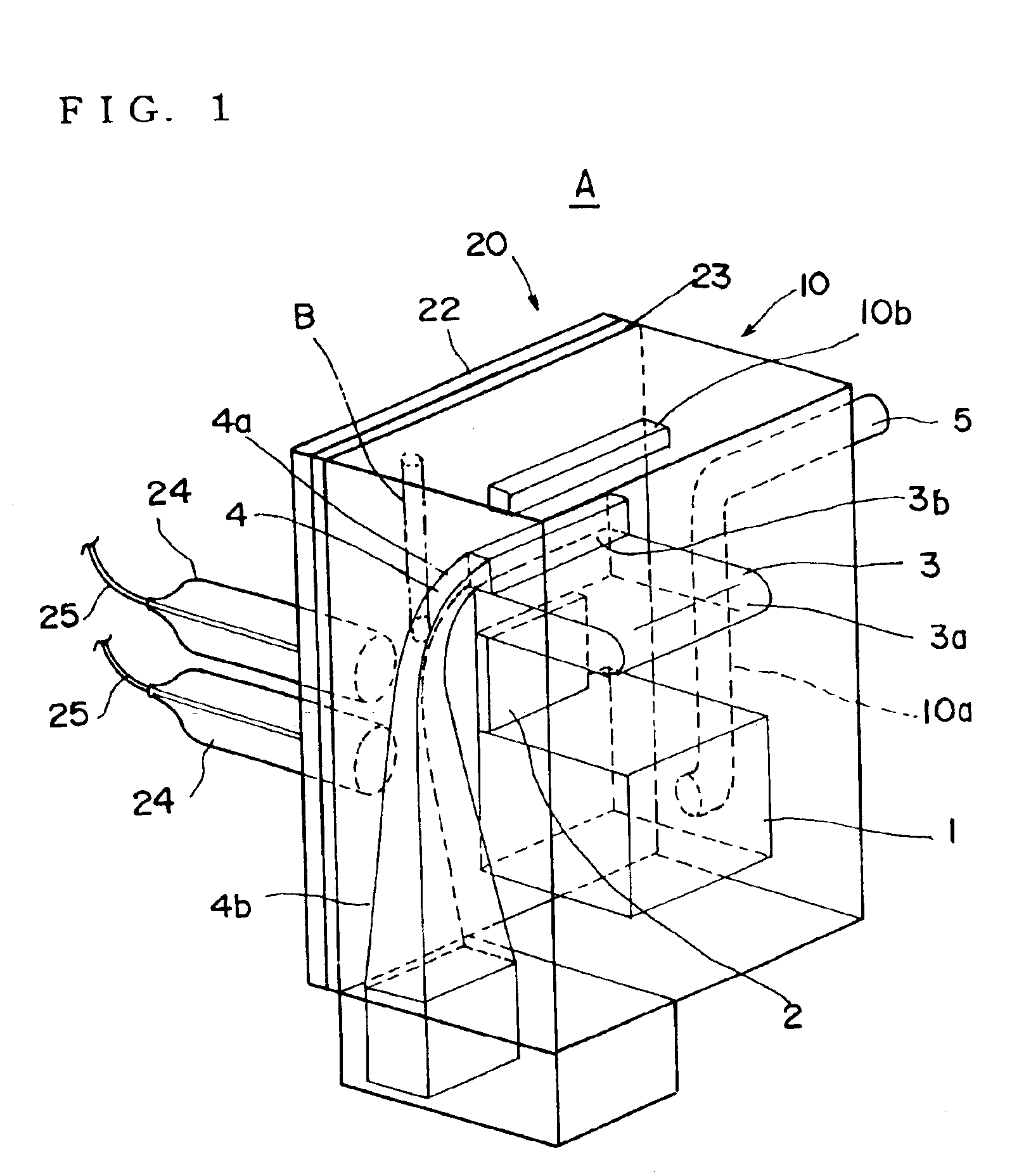

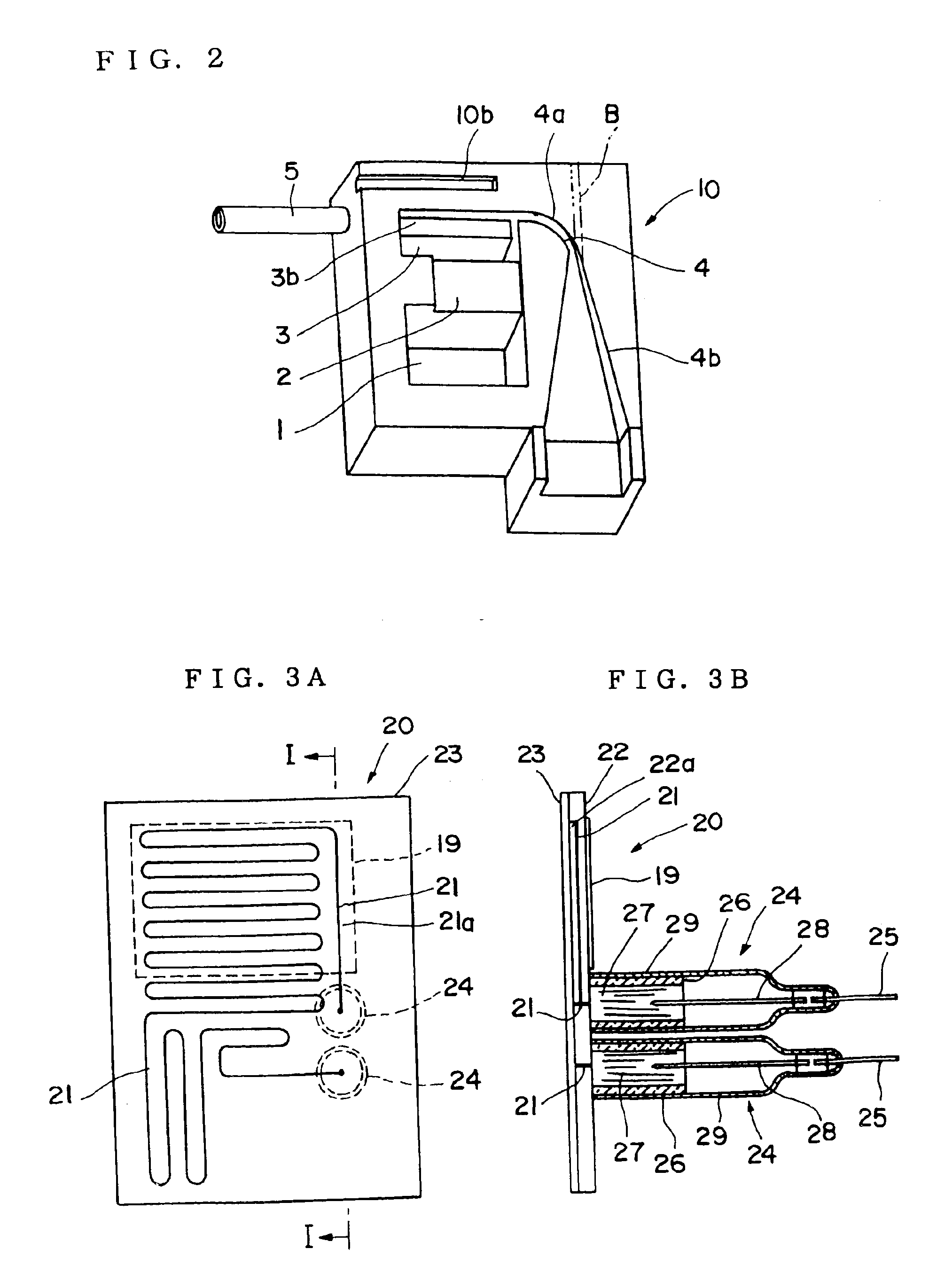

Steam generator and mixer using the same

InactiveUS6961516B2Generating in short periodEasy constructionExhaust apparatusMachines/enginesLiquid tankEngineering

A steam generating apparatus includes: a liquid tank portion 1 for storing a liquid; an evaporator portion 2 which is directly connected to the liquid tank portion, heats the liquid supplied from the liquid tank portion, and generates steam; a steam storage portion 3 which is directly connected to the evaporator portion, and stores the steam generated by the evaporator portion; a passageway 4 which is directly connected to the steam storage portion and outwardly passes the generated steam; a liquid pathway 10b which is connected to the liquid tank portion, and supplies the liquid; and a heater unit 20 which is provided on one side of the evaporator portion, and heats at least the evaporator portion. The liquid tank portion 1, the evaporator portion 2, the steam storage portion 3, the passageway 4, and the liquid pathway 10b are formed within an integral member of a translucent material.

Owner:COVALENT MATERIALS CORP

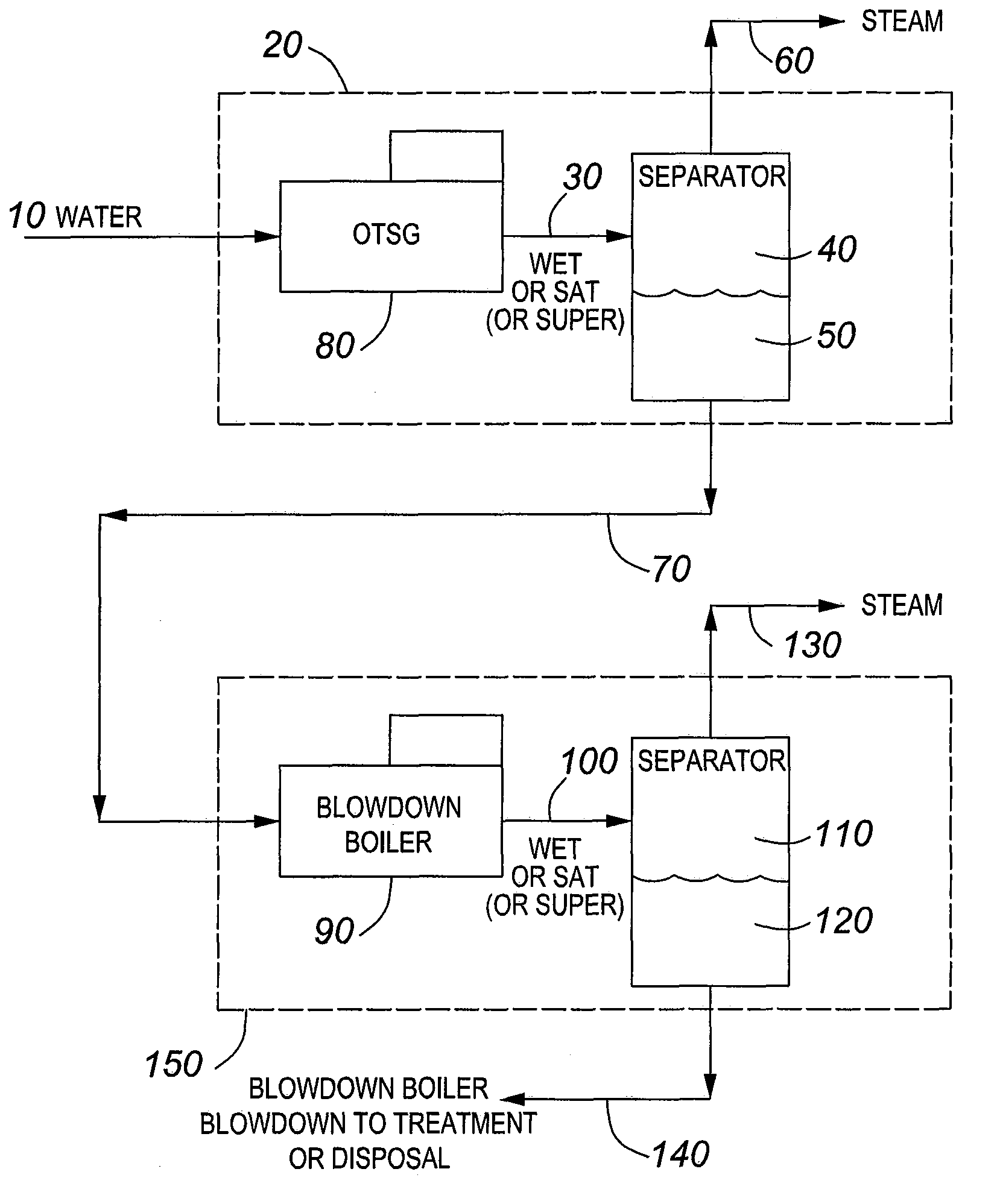

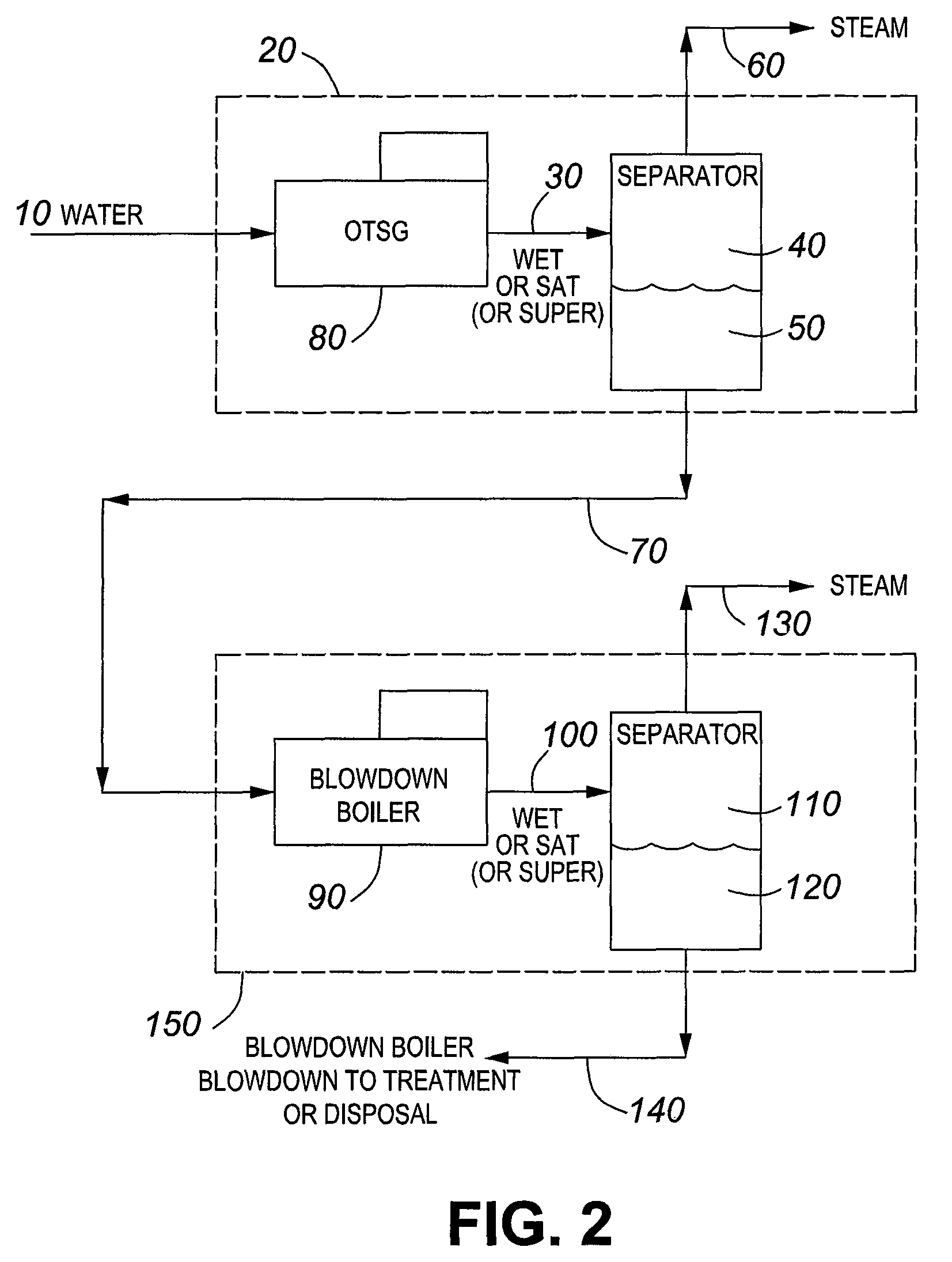

Method and apparatus for steam generation

ActiveUS8166925B2Reduce in quantityIncrease volumeWater circulationFuel injection apparatusBoiler blowdownHardness

A method, apparatus, and system and operation of surface equipment to generate steam while reducing the quantity of boiler blowdown and thereby increasing the amount of feedwater that is re-used or re-cycled in generating said steam. The present invention teaches that, on a sustained basis, the blowdown stream at the outlet of a once-through steam generator can be routed to the inlet of a second once-through steam generator that is in series with the first, that blowdown stream can be used to generate additional steam in the second once-through steam generator and further reduce the amount of blowdown, and that this can be accomplished without need of any treatment that reduces hardness or silica levels of the blowdown stream prior to its entering or during its entry into the inlet of the second once-through steam generator. The output of this second steam generator is a substantially dry saturated steam vapor stream and, complementarily, a blowdown stream whose mass rate has been reduced substantially from that of the blowdown stream exiting the first steam generator.

Owner:FCCL PARTNERSHIP

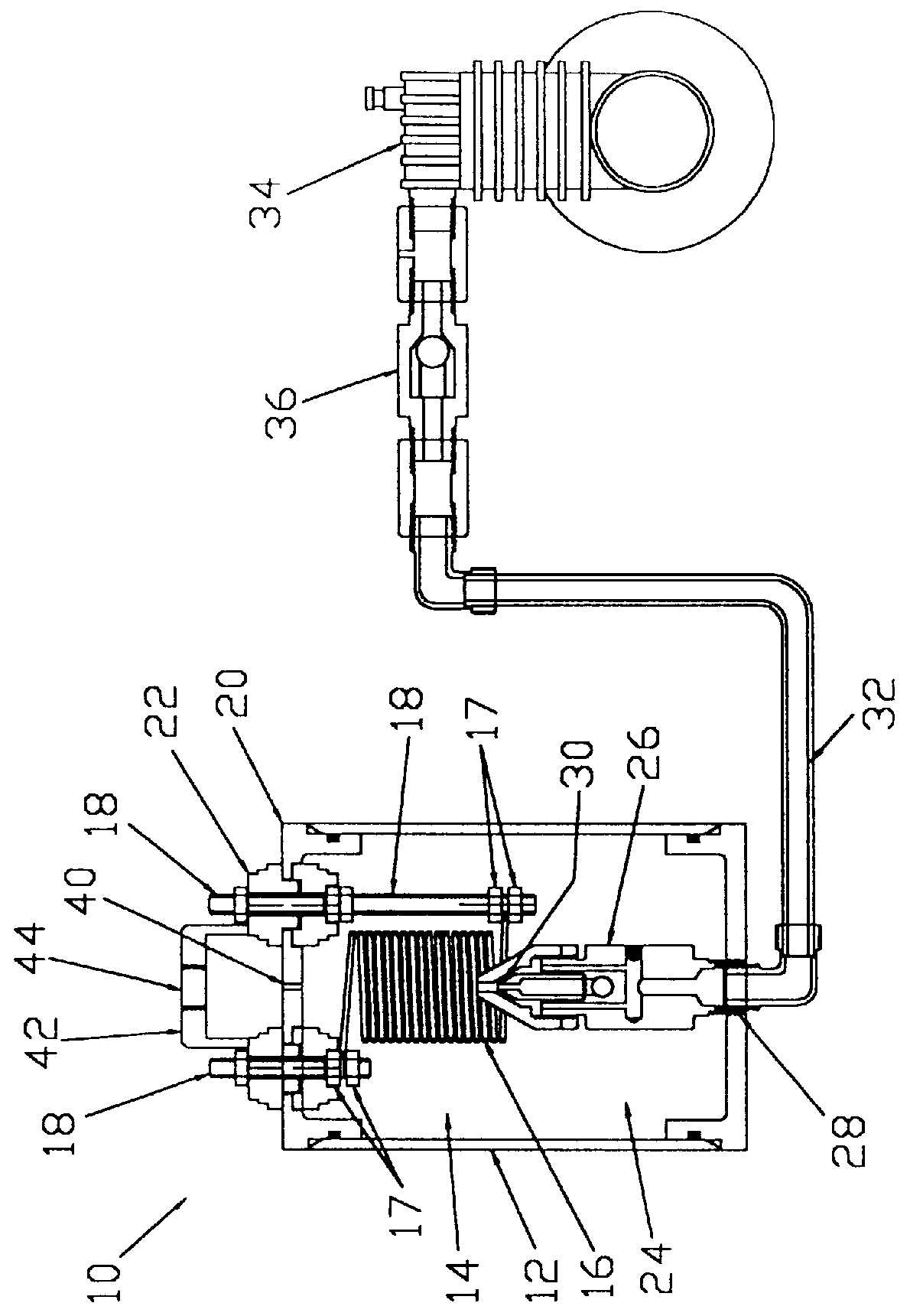

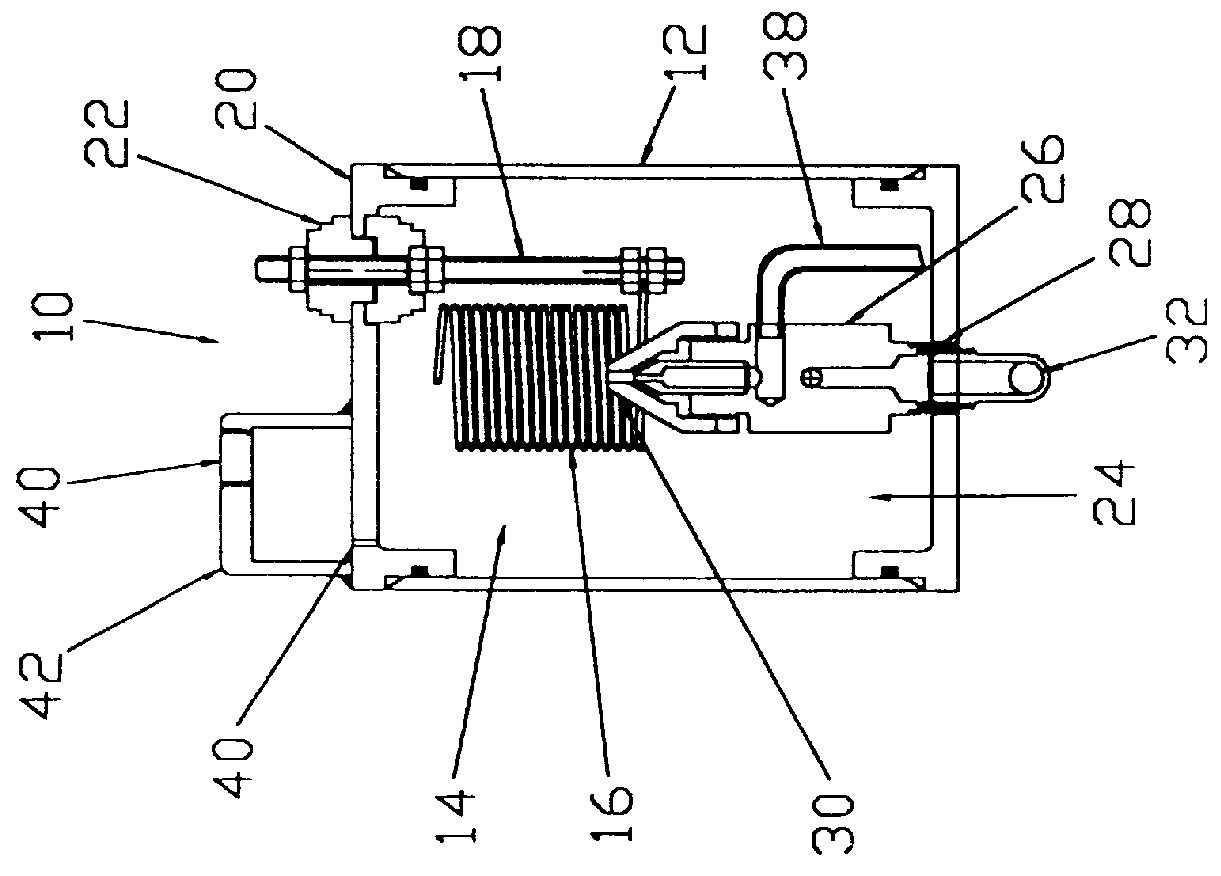

Smoke generating apparatus

InactiveUS6142009AEliminate riskIncrease in smoke generationDetection of fluid at leakage pointLiquid surface applicatorsEngineeringMechanical engineering

A smoke generating apparatus includes a housing having an interior cavity. A heated substrate is disposed within the interior cavity of the housing. A reservoir is provided to hold smoke generating liquid. An atomizing nozzle is disposed within the interior cavity of the housing. The nozzle has an inlet end and an outlet end. The outlet end points toward the heated substrate, such that fluid medium discharged through the outlet of the nozzle strikes the heated substrate. The inlet end of the nozzle is coupled to a source of gas under pressure. A liquid flow passage is provided which connects the nozzle with the reservoir. A flow of gaseous medium through the nozzle atomizes smoke generating liquid drawn from the reservoir.

Owner:CPS PRODS +1

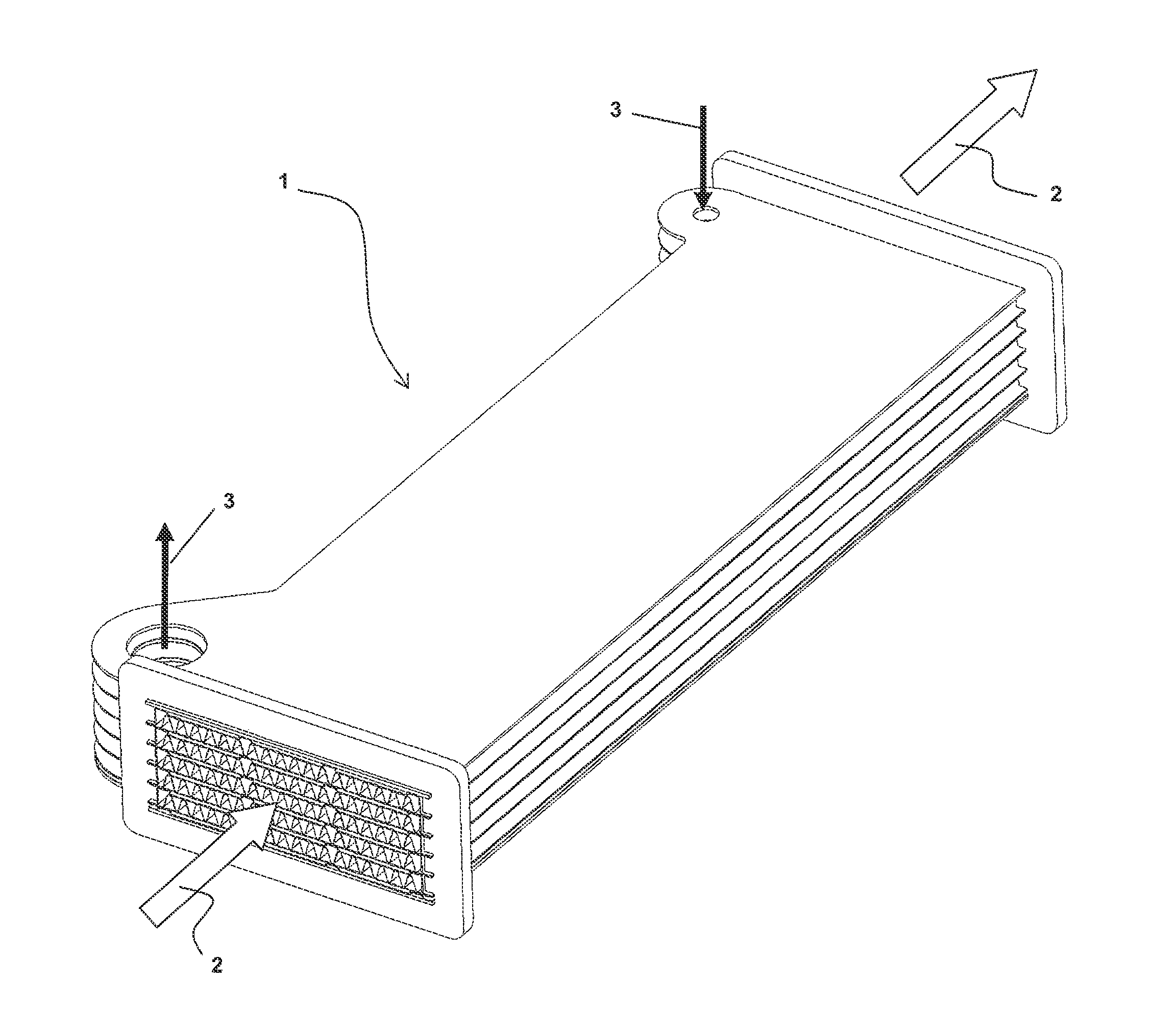

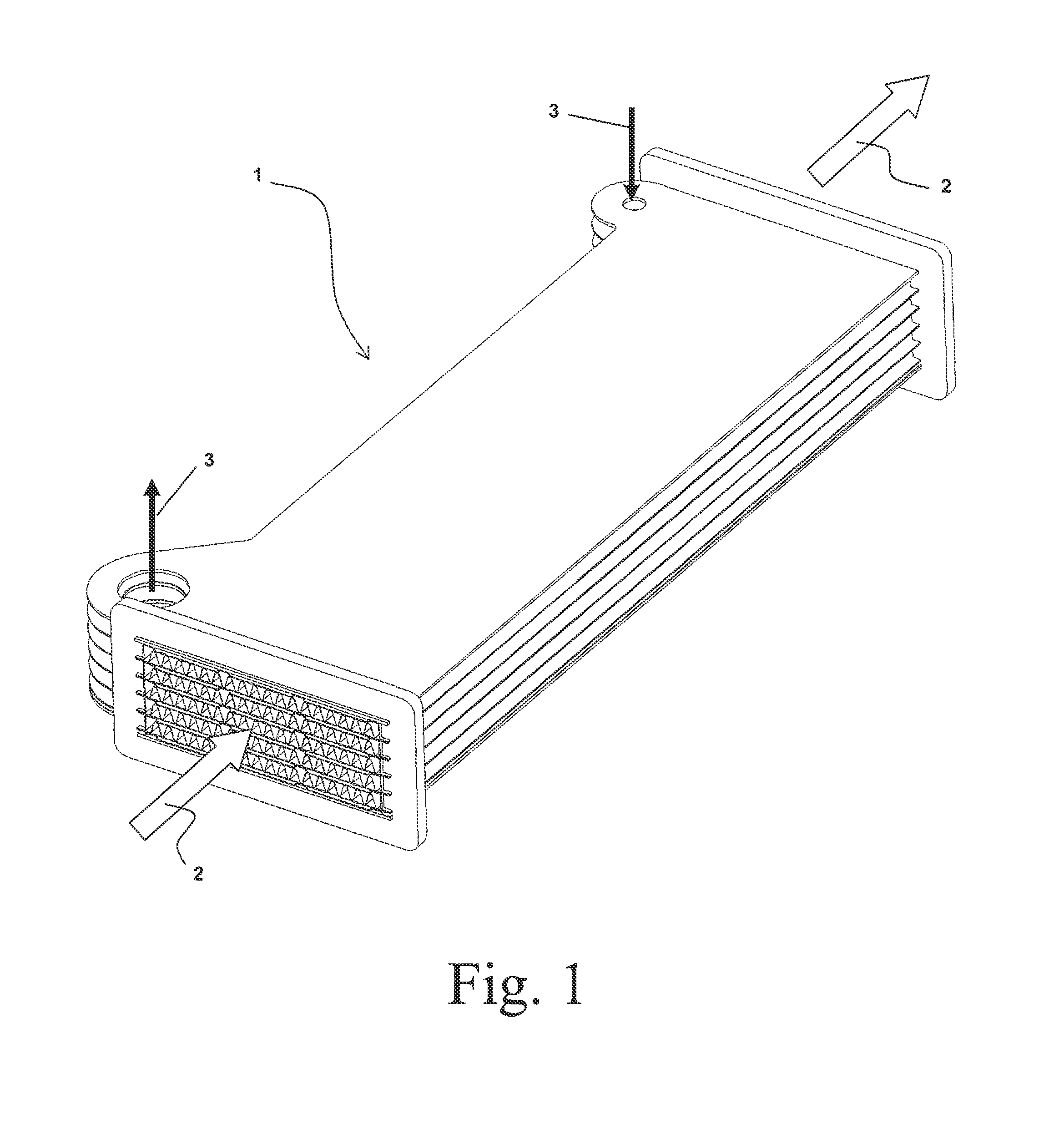

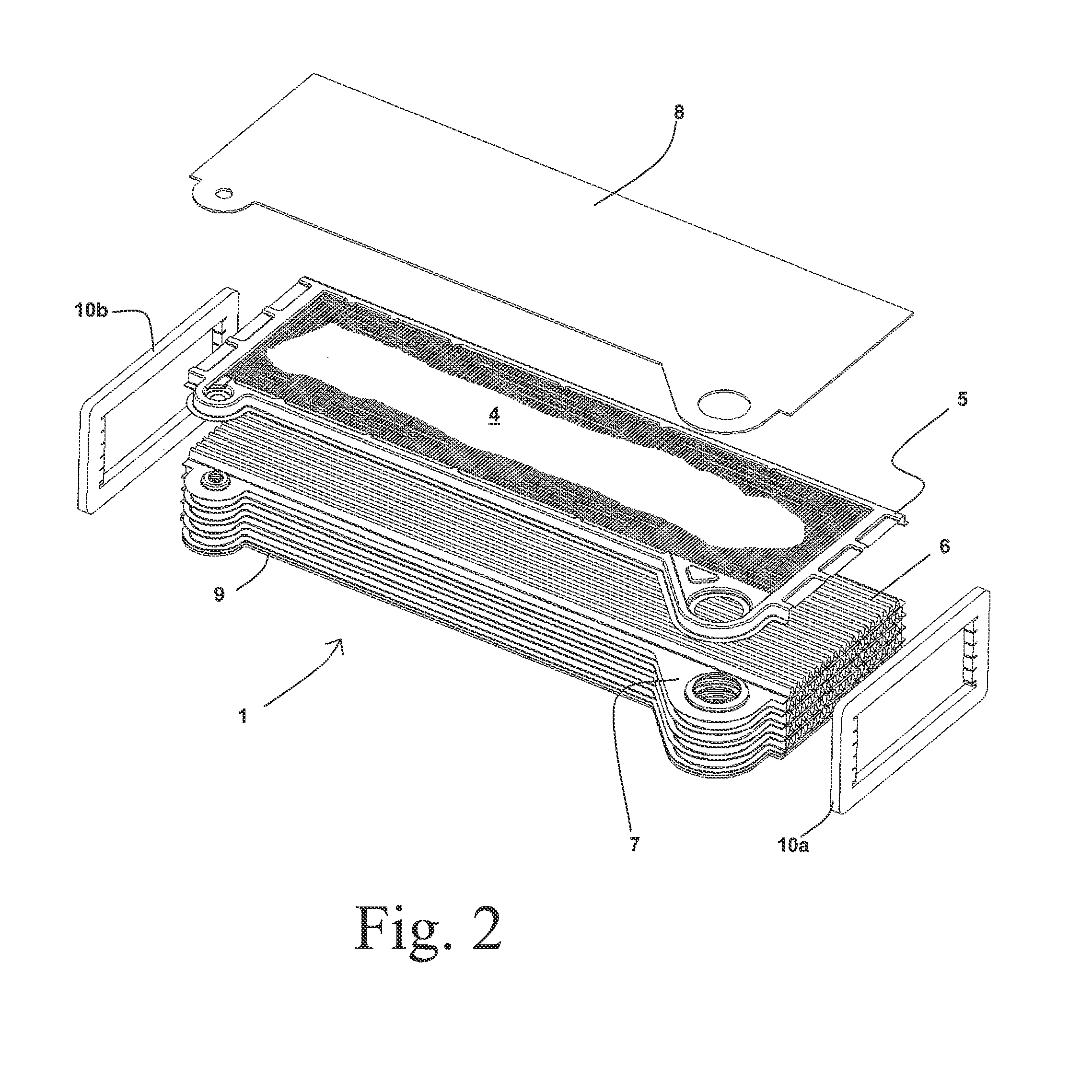

Heat exchanger and method of operating the same

InactiveUS20140060789A1Increase heatIncrease resistanceSteam generation heating methodsRecuperative heat exchangersEngineeringMicro heat exchanger

An evaporative heat exchanger includes first and second stacked plates forming a first fluid flow path between a first end and a second end. The first stacked plate defines a plane. Third and fourth stacked plates define a second fluid flow path. A fluid flow plate is positioned between the first and second stacked plates, and has a plurality of flow channels extending substantially parallel to the plane between the first end and the second end. At least one of the first and second stacked plates defines slots that form a portion of the first fluid flow path so that fluid flowing along the first fluid flow path flows along the flow channels in the first direction, then flows along at least one of the slots, then flows into adjacent flow channels and then along the adjacent flow channels in a second direction parallel to the first direction.

Owner:MODINE MFG CO

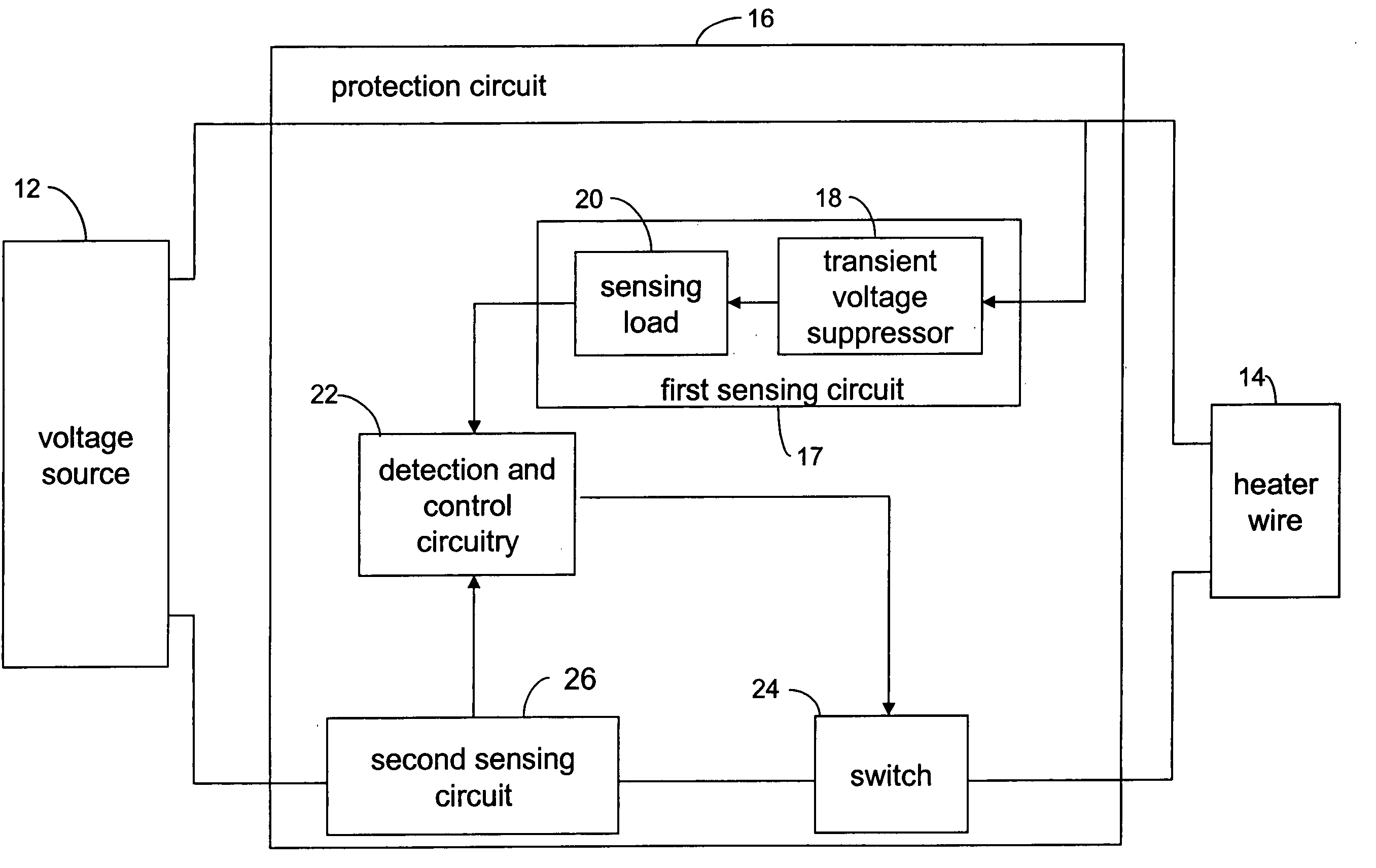

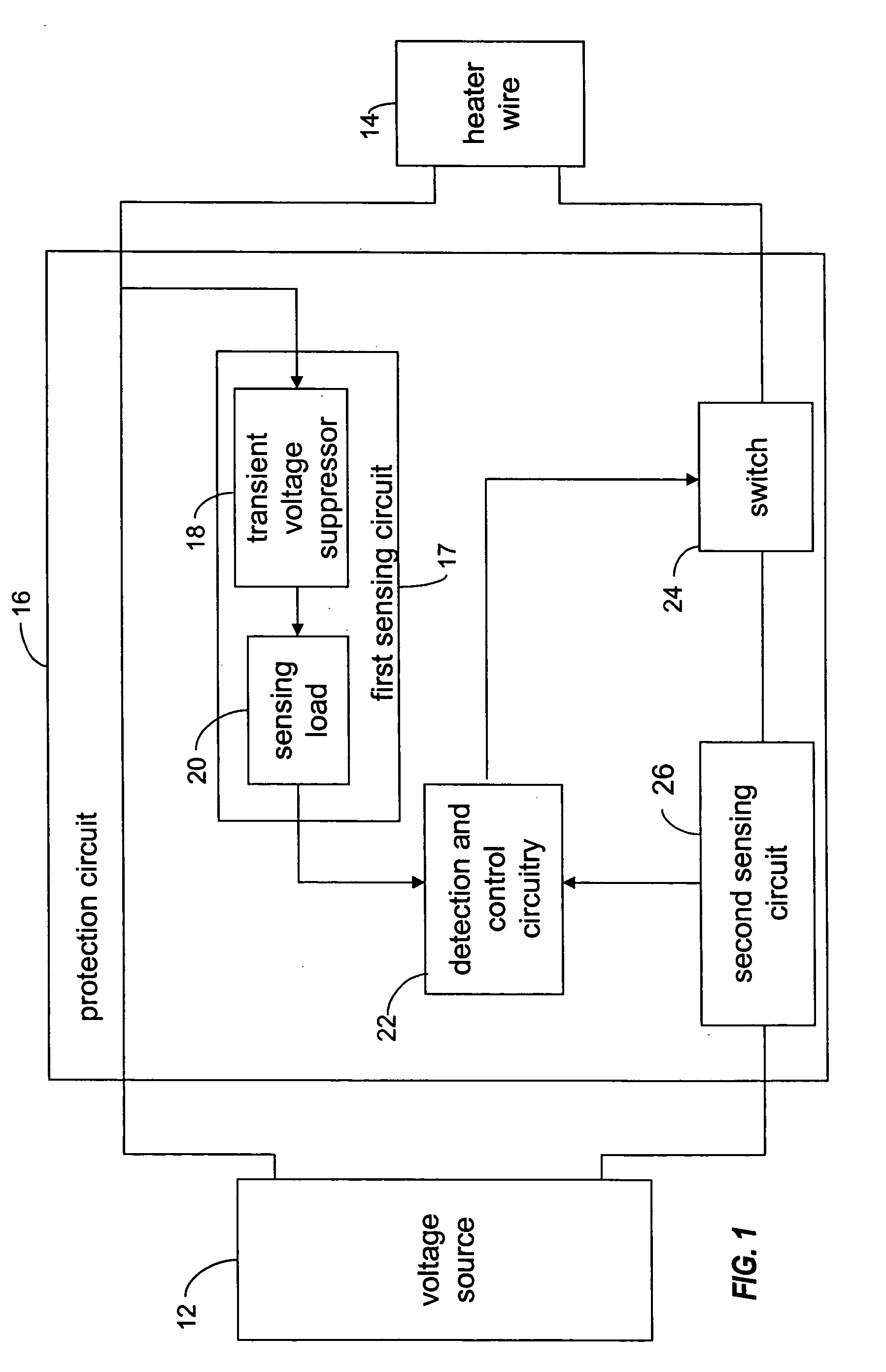

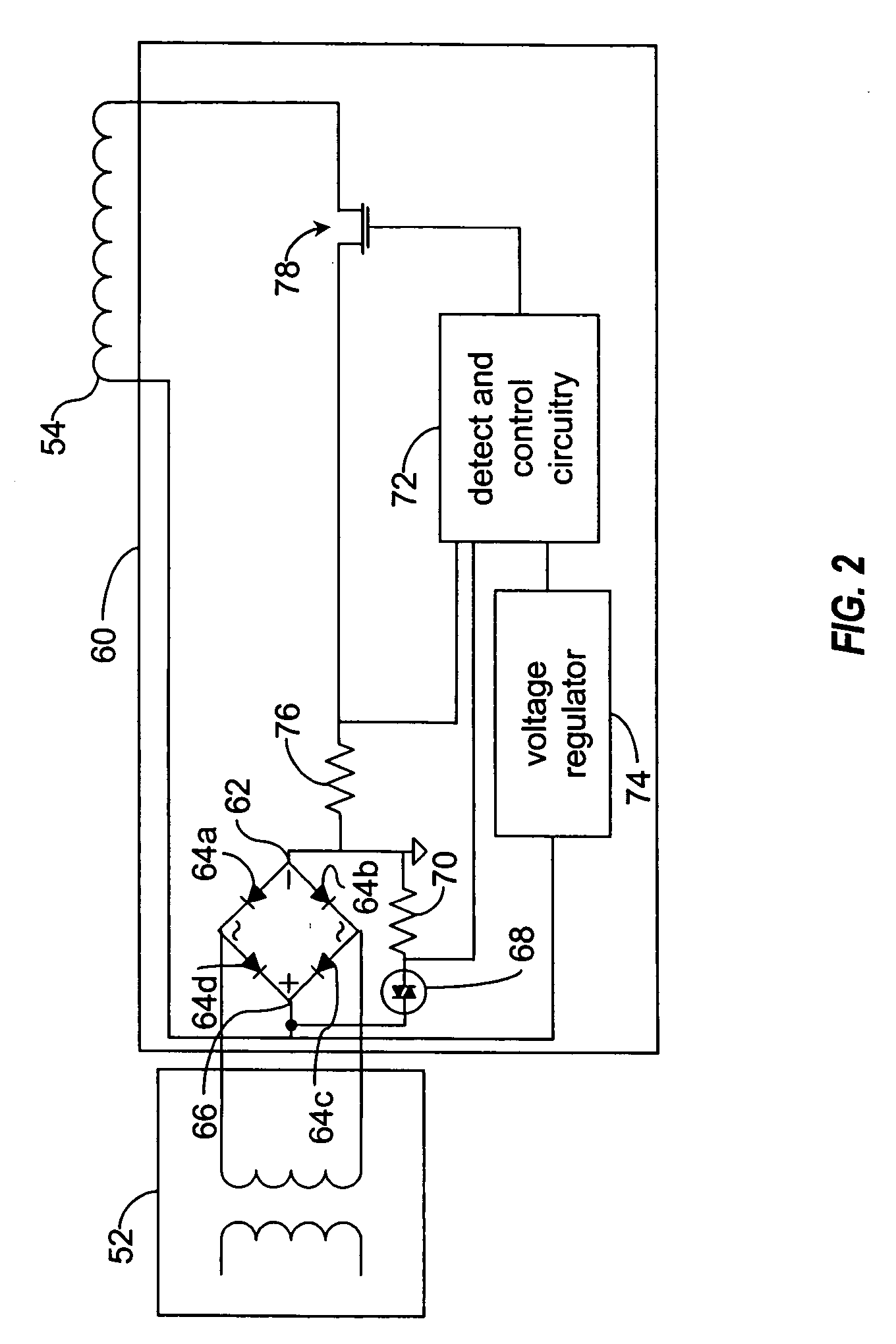

Electrical arcing protection circuit

A protection circuit, configured to detect and suppress electrical pre-arcing and arcing conditions in a resistive heater wire circuit, comprises a transient voltage suppressor, signal level sensing load coupled to the output of the voltage suppressor, detection and control circuitry, and a high-speed switch or electrical gate. The control circuitry is configured to control the operation of the switch, coupled between said control circuitry and the heater wire, wherein the switch is opened in response to an electrical pre-arcing or arcing condition or a short circuit condition.

Owner:TELEFLEX MEDICAL INC

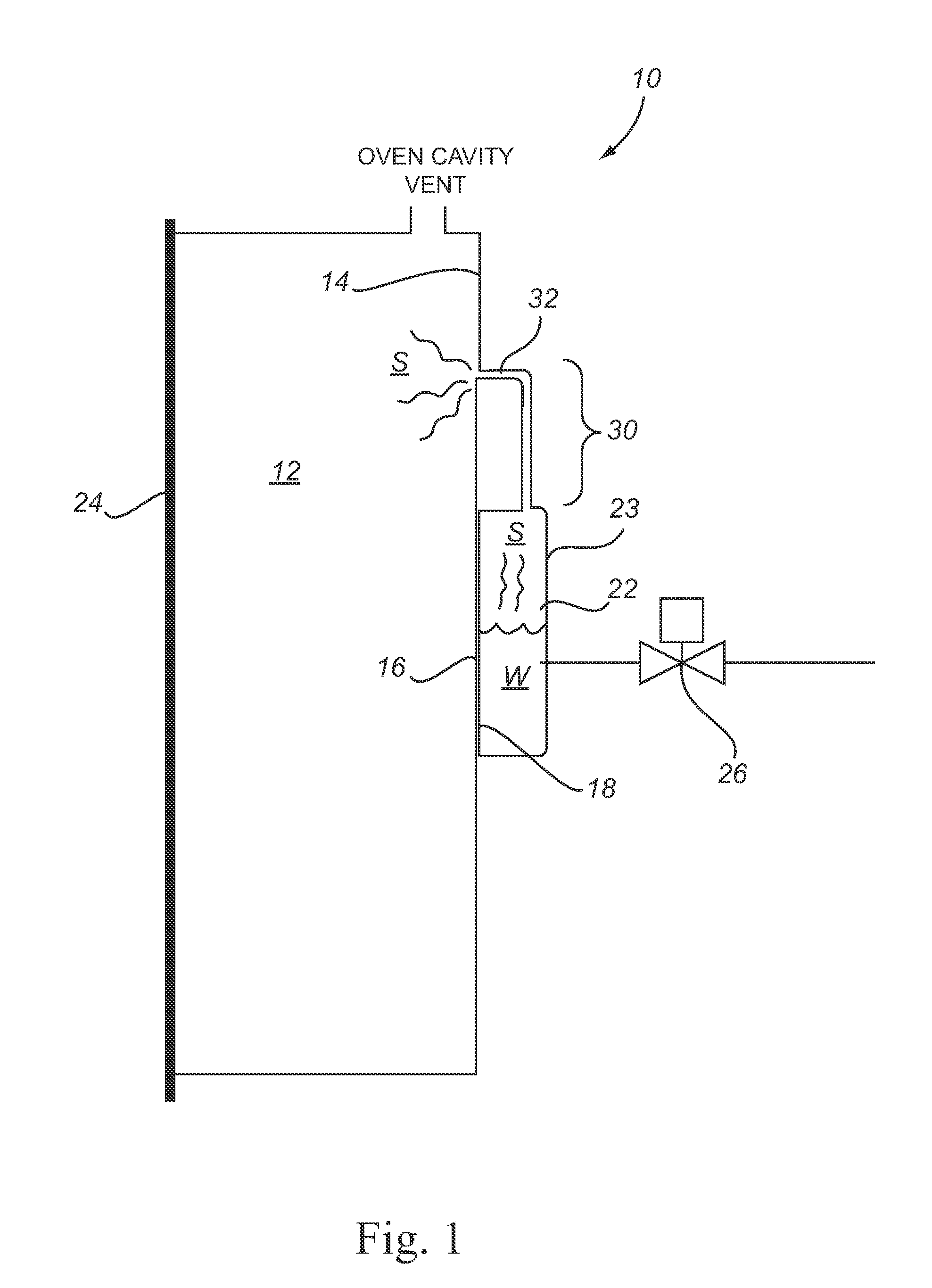

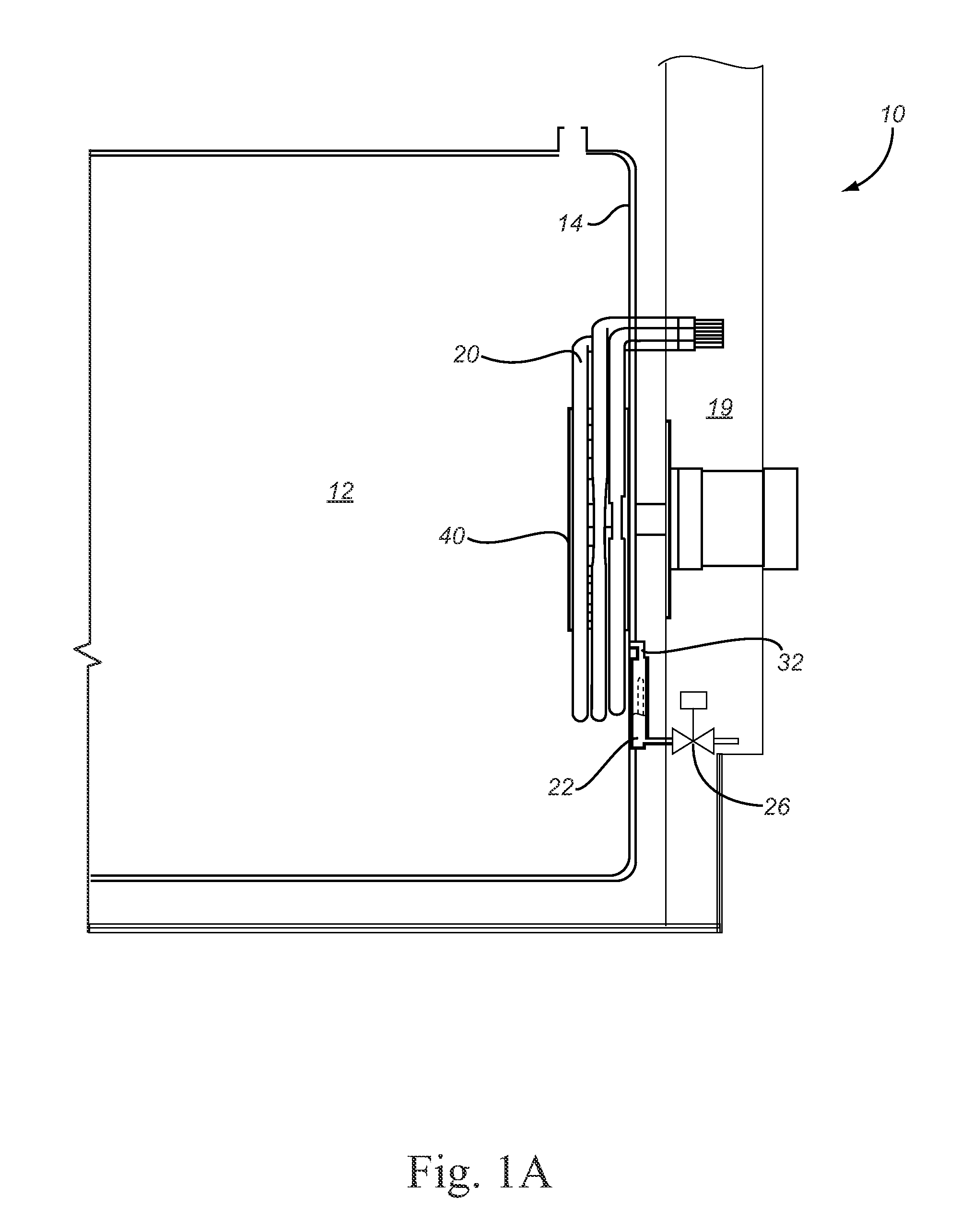

Oven Steam Generator Systems and Methods

ActiveUS20100230396A1Domestic stoves or rangesSpace heating and ventilationEmbodiment designEngineering

Embodiments of the present invention relate generally to steam ovens, and particularly to steam ovens configured to generate and deliver steam directly to the oven using a water reservoir in close proximity to an existing oven heat generating system. The steam ovens described may be designed so that they inject steam directly into the oven cavity, and in some instances, generate the steam directly in the oven cavity as well. Certain embodiments are designed with a water reservoir in close proximity to an oven heat generating system such that water in the reservoir is heated, turned to steam, and delivered to the oven cavity via a steam delivery system.

Owner:SAFRAN CABIN GALLEYS US INC

Steam generator

InactiveUS20110274416A1Prolonging steam generator lifespanExtend your lifeSteam generation heating methodsBoiler controlEngineering

Owner:CHEN HSI FU

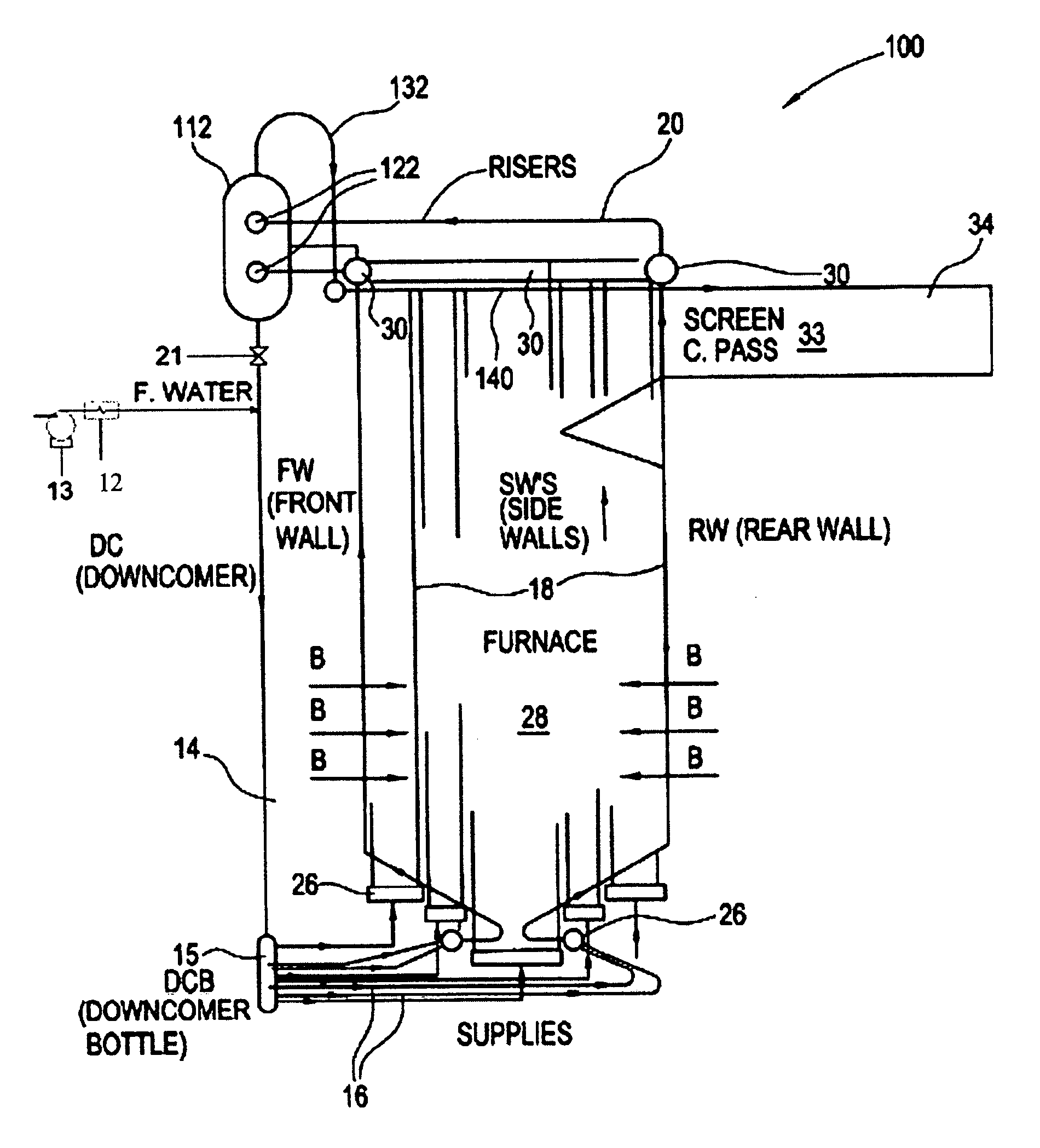

Circulation system for sliding pressure steam generator

InactiveUS20070283906A1High densityImprove abilitiesWater circulationFuel injection apparatusBoiler feedwater pumpEngineering

A steam generator circulation system is provided and includes a boiler feed pump for forcing water through an economizer, and through the waterwall tubes of an evaporator. A separator receives a mixture of steam and water and sends the steam to a steam utilization unit such as a superheater. A valve is provided below the separator. If the valve is open, the saturated water from the separator is mixed with feedwater and recirculated through the tubes of the evaporator. If the valve is closed, recirculation is terminated. At loads below the critical point, the valve below the separator system would be open and the boiler would operate like a natural circulation drum boiler. At loads above the critical point, the valve below the separator system would be closed resulting in a boiler that operates like a once-through boiler.

Owner:THE BABCOCK & WILCOX CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com