Ectopic classification leaching repair complete process of arsenic and heavy metal contaminated soil

A technology for polluted soil and heavy metals, which is applied in the restoration of polluted soil and other directions, can solve the problems such as the lack of establishment of an integrated process system for leaching and remediation of composite polluted soil, save resources, solve the problems of regeneration and recycling, and can Strong control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

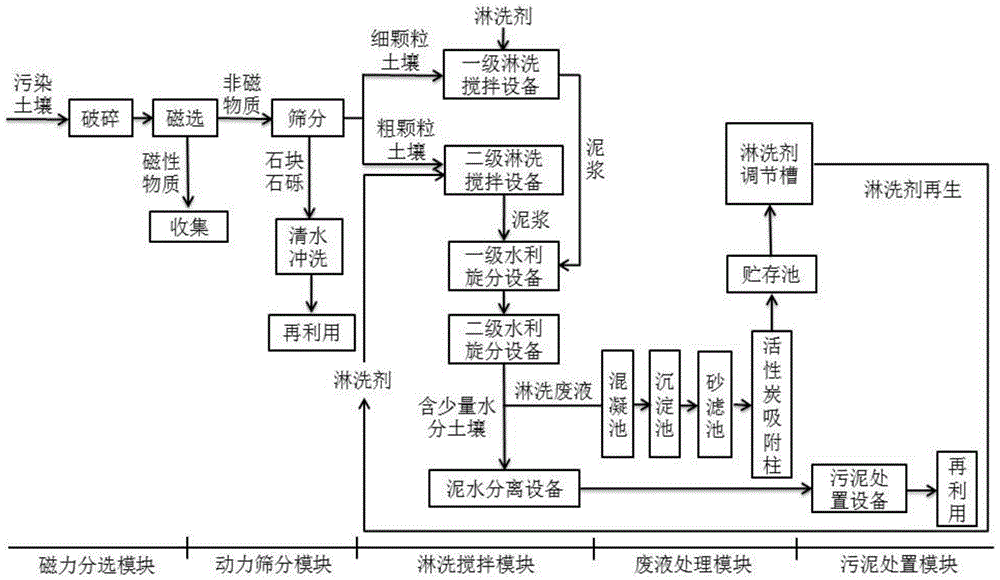

[0026] like figure 1 Shown is the process flow diagram of the present invention, and the specific embodiment of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] In this embodiment, a complete set of process for repairing arsenic and heavy metal contaminated soil by ectopic graded leaching includes the following steps:

[0028] (1) Magnetic separation: the excavated and crushed soil is put into a dry magnetic separator, and the magnetic target metals are extracted and recovered according to the difference in magnetic susceptibility. Further, the target metals extracted and recovered are zinc and nickel One or more of iron, manganese or precious metals;

[0029] (2) Dynamic screening: After magnetic separation, the remaining soil is directly sent to a multi-stage high-frequency vibrating screen, and is screened into three particle sizes: stone gravel, coarse-grained soil, and fine-grained soil. The particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com