Regeneration method of MnOx/TiO2 based low-temperature denitration catalyst

A denitration catalyst, low temperature denitration technology, applied in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of increasing catalyst utilization cost, environmental pollution, etc., to improve activity and anti-poisoning. capacity, good denitration effect, and the effect of saving heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

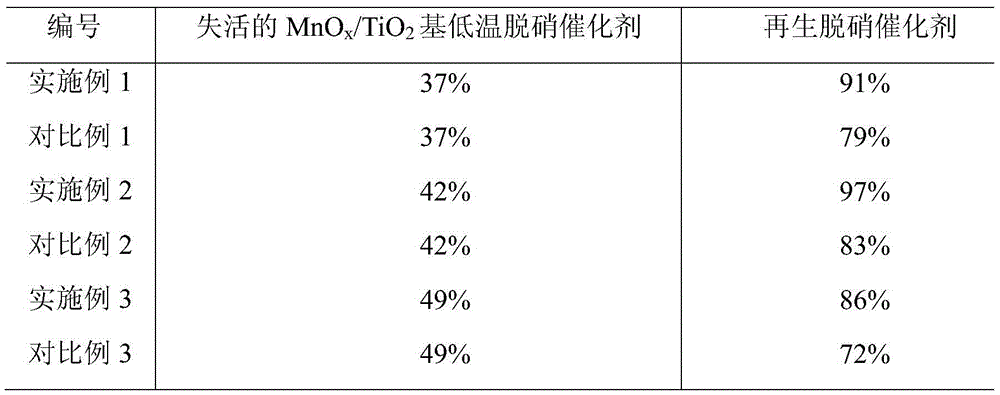

Embodiment 1

[0034] A kind of MnO x / TiO 2 A regeneration method for a low-temperature denitration catalyst based on deactivated MnO with a denitration rate of 37% x / TiO 2 Based low-temperature denitration catalyst, specifically comprising the following steps:

[0035] 1) Deactivate MnO by purging with dry compressed air x / TiO 2 Based on low-temperature denitrification catalyst, the pressure of compressed air is 1KPa, and the purging time is 70min; then under the condition of 500W ultrasonic vibration, the deactivated MnO x / TiO 2 The low-temperature denitrification catalyst was immersed in deionized water for 120 minutes to remove other impurities and soluble substances on the surface of the catalyst, and then dried;

[0036] 2) The deactivated MnO treated in step 1) x / TiO 2 Immerse the base-based low-temperature denitration catalyst into the activation solution (active sol of the Mn-Ti component) for activation treatment, and the immersion activation treatment time is 10 hours...

Embodiment 2

[0043] A kind of MnO x / TiO 2 A regeneration method based on low-temperature denitrification catalyst, aiming at deactivated MnO with a denitrification rate of 42% x / TiO 2 Based low-temperature denitration catalyst, specifically comprising the following steps:

[0044] 1) Deactivate MnO by purging with dry compressed air x / TiO 2 Based on low-temperature denitrification catalyst, the pressure of compressed air is 2KPa, and the purging time is 60min; then under the condition of 400W ultrasonic vibration, the deactivated MnO x / TiO 2 The base low-temperature denitrification catalyst was immersed in deionized water for 90 minutes to remove other impurities and soluble substances on the surface of the catalyst, and then dried;

[0045] 2) The deactivated MnO treated in step 1) x / TiO 2 Immerse the base-based low-temperature denitrification catalyst into the activation solution (active sol of Mn-Ti component) for activation treatment, and the immersion activation treatment...

Embodiment 3

[0052] A kind of MnO x / TiO 2 A regeneration method for a low-temperature denitrification catalyst based on deactivated MnO with a denitrification rate of 49% x / TiO 2 Based low-temperature denitration catalyst, specifically comprising the following steps:

[0053] 1) Deactivate MnO by purging with dry compressed air x / TiO 2 Based on low-temperature denitrification catalyst, the pressure of compressed air is 3KPa, and the purging time is 40min; then under the condition of 300W ultrasonic vibration, the deactivated MnO x / TiO 2 The base low-temperature denitrification catalyst was immersed in deionized water for 180 minutes to remove other impurities and soluble substances on the surface of the catalyst, and then dried;

[0054] 2) The deactivated MnO treated in step 1) x / TiO 2 Immerse the base-based low-temperature denitrification catalyst into the activation solution (active sol of Mn-Ti component) for activation treatment, and the soaking and activation treatment t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com