Multi-component high-performance sizing agent

A high-performance, slurry technology, applied in fiber types, textiles and papermaking, fiber treatment, etc., can solve environmental pollution, difficult to handle and other problems, and achieve the effect of good fluidity, easy handling, and good anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put 70kg of corn starch, 17kg of creatine phosphate sodium, 8kg of phosphorus oxychloride, 3kg of Tween, and 2kg of calcium persulfate into the reaction tank respectively, carry out compound mixing reaction at room temperature for 1 hour, terminate the reaction, unload and pack, and store . When the customer is using it, add water to gelatinize and heat up to 95°C or add water in a high-pressure tank to heat up to 120°C and keep it warm for 15-30 minutes to carry out oxidation, cross-linking, esterification, emulsification, and polymerization to prepare the emulsion.

[0026] The mass ratio of clear water to multi-component high-performance slurry is 82:18.

Embodiment 2

[0028] Put 80kg of cornstarch, 12kg of diammonium phosphate, 5kg of chloroxypropane, 2kg of Tween, and 1kg of potassium hydrogen persulfate into the reaction tank respectively, carry out compound mixing reaction at room temperature for 2 hours, then terminate the reaction, unload and pack, and store . When the customer uses it, add clear water to gelatinize and heat up to 95°C or add clear water in a pressure cooker to heat up to 120°C and keep warm for 15-30 minutes to carry out oxidation, cross-linking, esterification, emulsification, and polymerization to obtain an emulsion.

[0029] The mass ratio of clear water to multi-component high-performance slurry is 85:15.

Embodiment 3

[0031] Put 90kg of cornstarch, 5kg of potassium dihydrogen phosphate, 2kg of phosphorus oxychloride, 2kg of Tween, and 1kg of ammonium persulfate into the reaction tank respectively, carry out compound mixing reaction at room temperature for 3 hours, then terminate the reaction, unload and pack, and store . When the customer is using it, add water to gelatinize and heat up to 95°C or add water in a high-pressure tank to heat up to 120°C and keep it warm for 15-30 minutes to carry out oxidation, cross-linking, esterification, emulsification, and polymerization to prepare the emulsion.

[0032] The mass ratio of clear water to multi-component high-performance slurry is 88:12.

[0033] Specific implementation of the product application program:

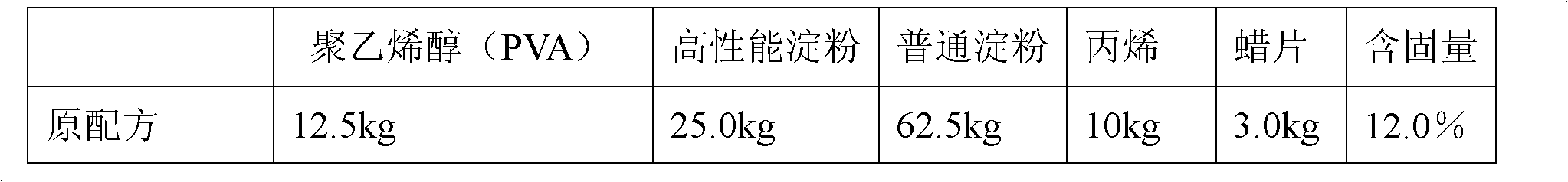

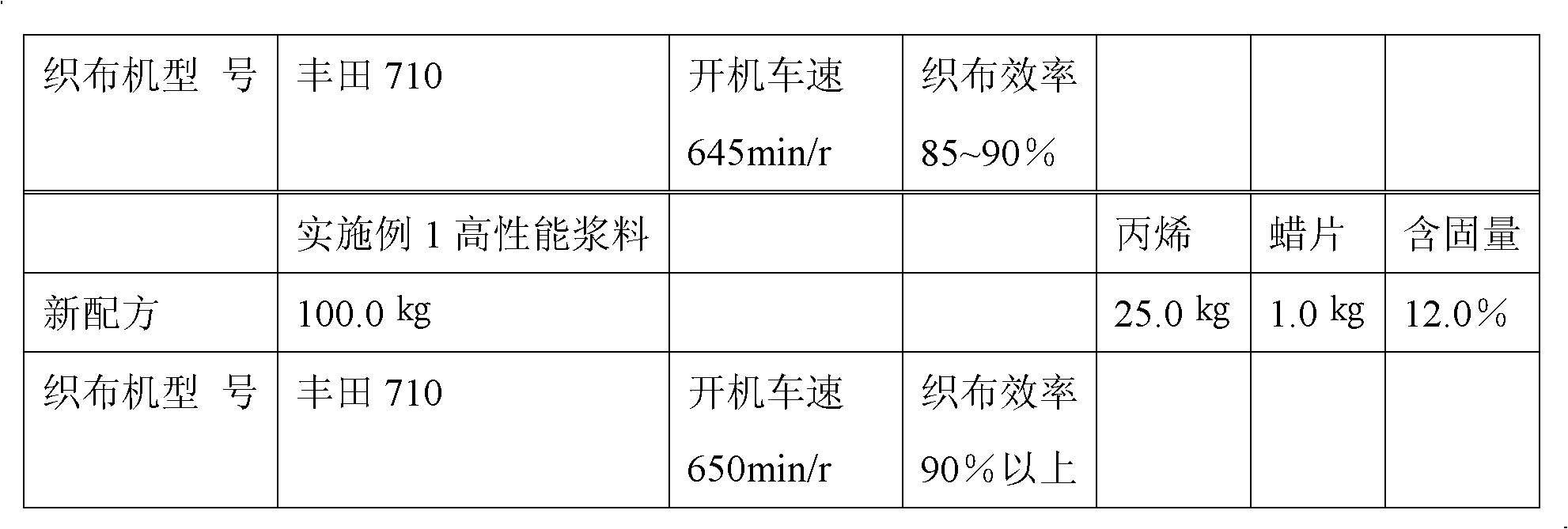

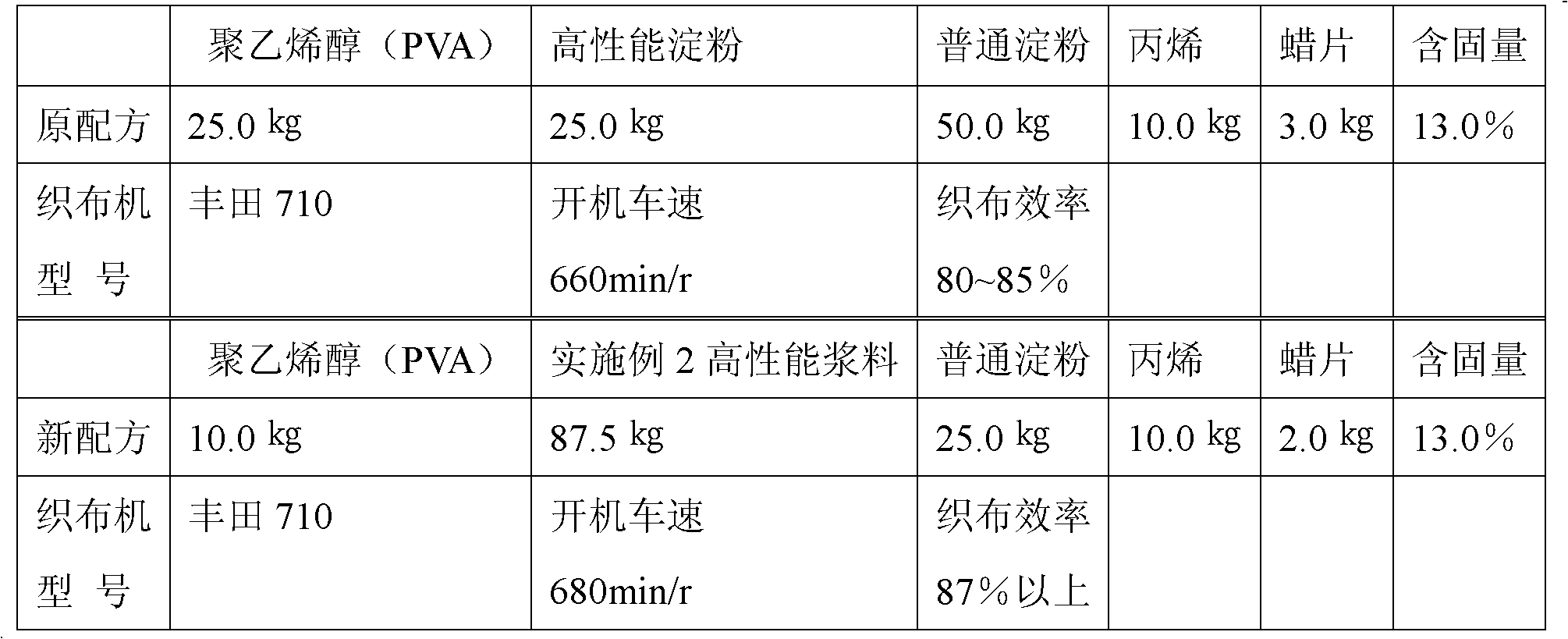

[0034] All or part of the emulsion size obtained in the above examples is used to replace the polyvinyl alcohol, high-performance starch and ordinary starch in the existing size formula, and the fabric is sized in actual production, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com