High-speed precise numerical-control stamping machine mechanismstructure capable of realizing dynamic lower dead point precision compensation

A dynamic precision, precise numerical control technology, applied in the field of mechanical pressure processing, can solve the problems of low processing precision, inability to process high-precision parts, and no automatic compensation of bottom dead center, so as to achieve the effect of small impact and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

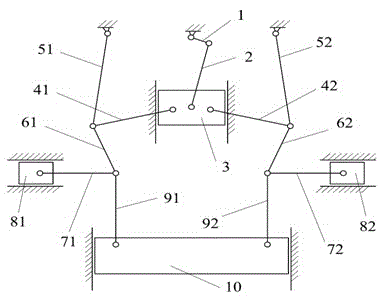

[0019] The present invention can realize the general structure of the high-speed precision numerical control punch mechanism of bottom dead center dynamic precision compensation as follows figure 1 As shown, in addition to the above-mentioned structural features, when the auxiliary slider 3 in the slider crank mechanism moves to the top dead center position, the first upper link 51 and the second upper link 52 in the two sets of multi-bar mechanisms are respectively simultaneously Swing from the outside to the inside, and drive the stamping slider 10 to move downward, the sub-slider 3 is opposite to the movement direction of the stamping slider 10, which can balance the inertial force in the vertical direction. In addition, the first push rod 41 and the second push rod 42 mainly bear tensile stress during stamping.

Embodiment 2

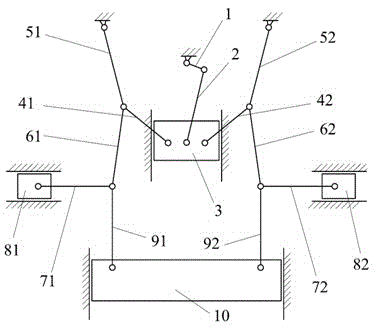

[0021] The present invention can realize the general structure of the high-speed precision numerical control punch mechanism of bottom dead center dynamic precision compensation as follows figure 2 As shown, in addition to the above-mentioned structural features, when the auxiliary slider 3 in the slider crank mechanism moves to the top dead center position, the first upper link 51 and the second upper link 52 in the two sets of multi-bar mechanisms are respectively simultaneously Swing from inside to outside, and drive the stamping slider 10 to move downward, the sub-slider 3 is opposite to the movement direction of the stamping slider 10, which can balance the inertial force in the vertical direction. In addition, the first push rod 41 and the second push rod 42 are mainly subjected to compressive stress during the stamping process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com