Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "I-joist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An engineered wood joist, more commonly known as an I-joist, is a product designed to eliminate problems that occur with conventional wood joists. Invented in 1969, the I-joist is an engineered wood product that has great strength in relation to its size and weight. The biggest notable difference from dimensional lumber is that the I-joist carries heavy loads with less lumber than a dimensional solid wood joist. As of 2005, approximately 50% of all wood light framed floors used I-joists. I-joists were designed to help eliminate typical problems that come with using solid lumber as joists.

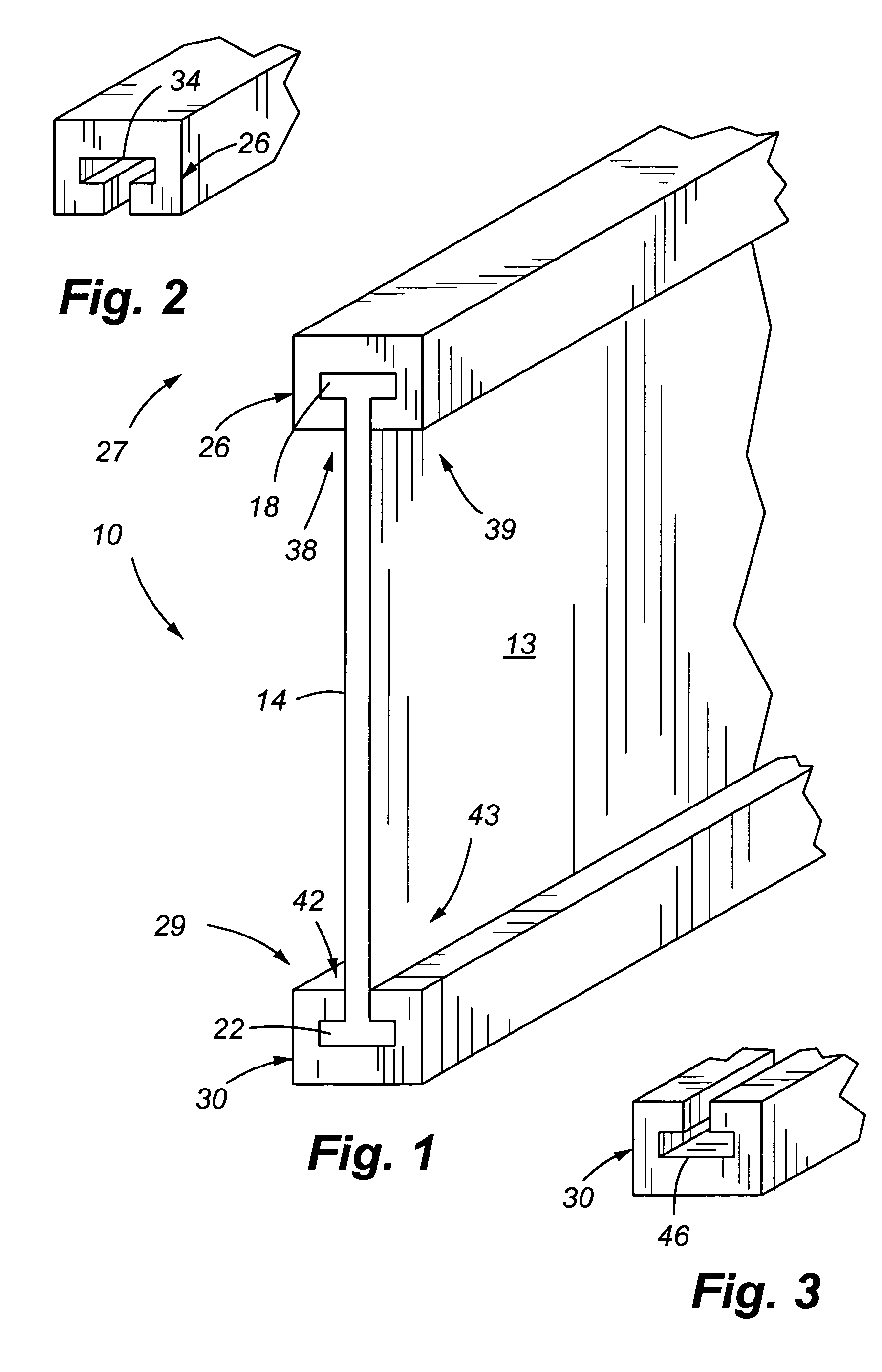

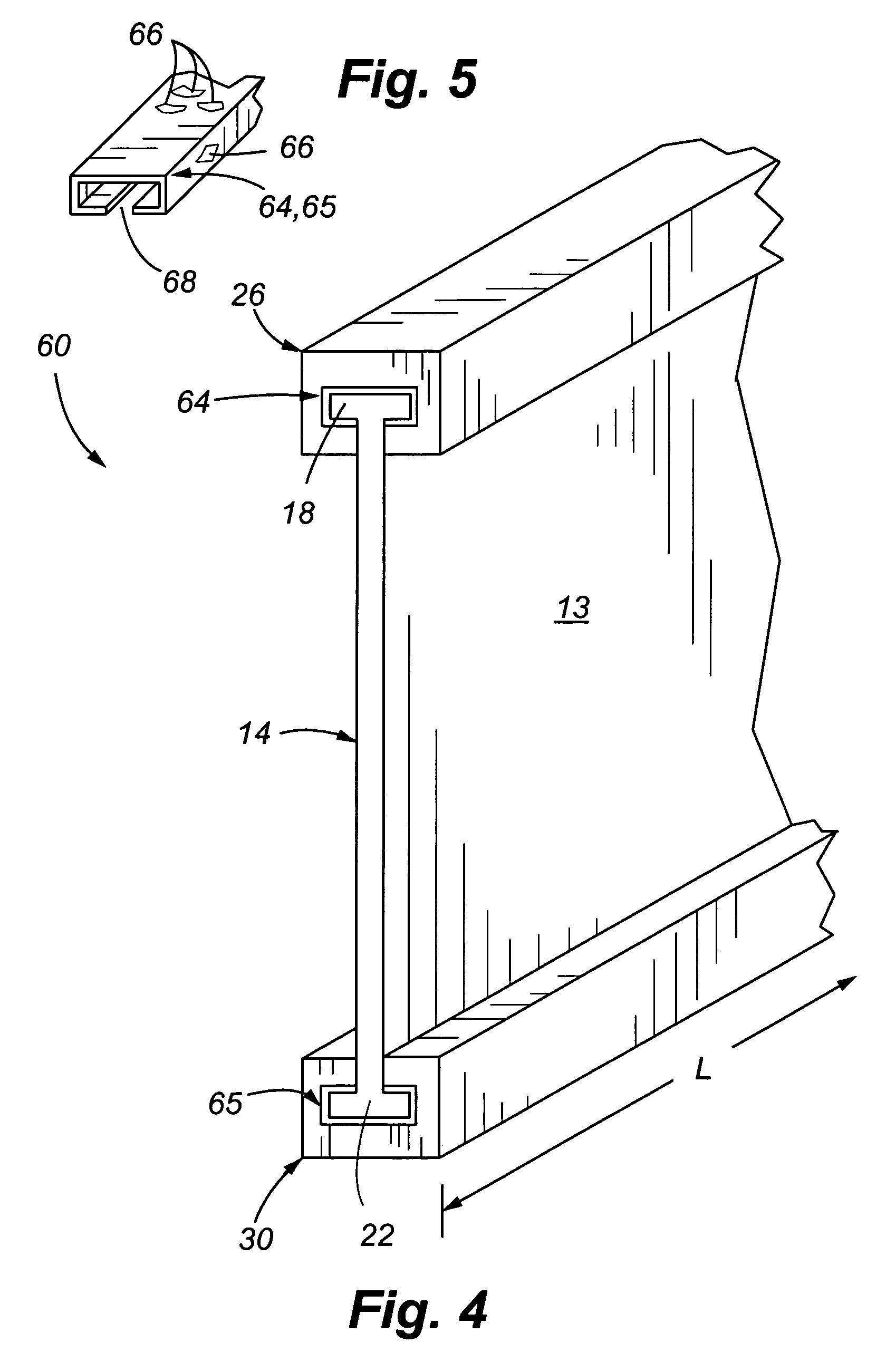

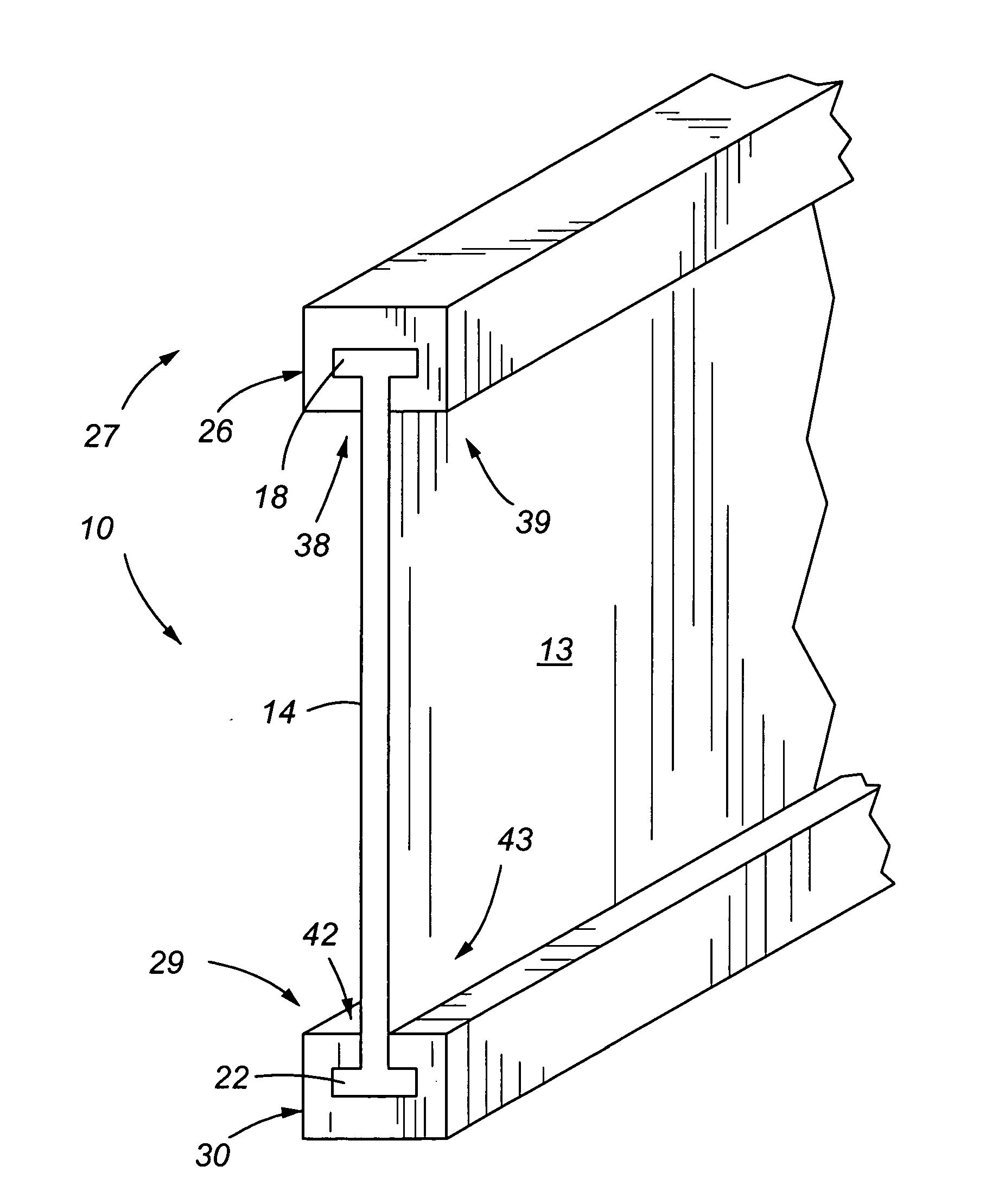

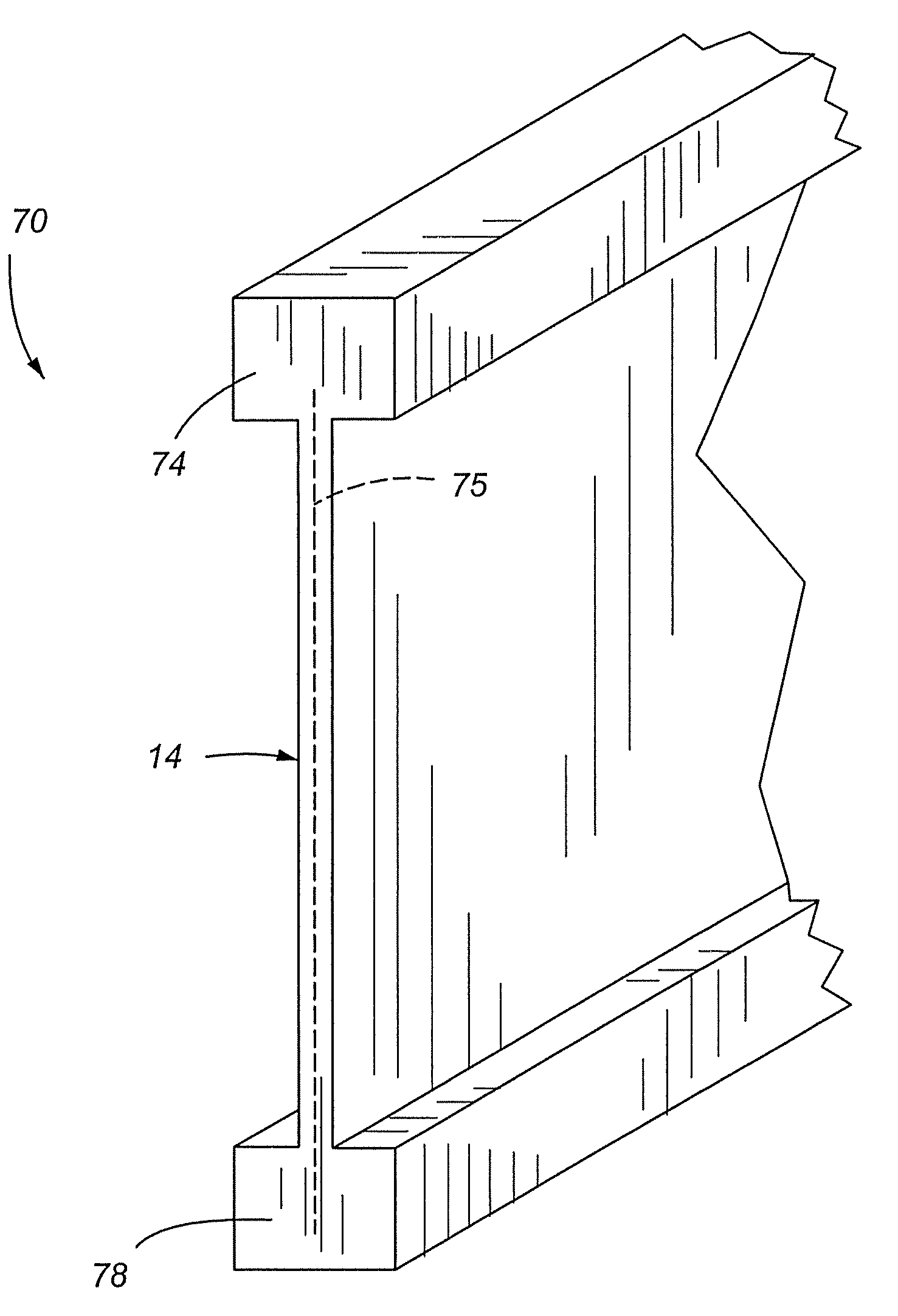

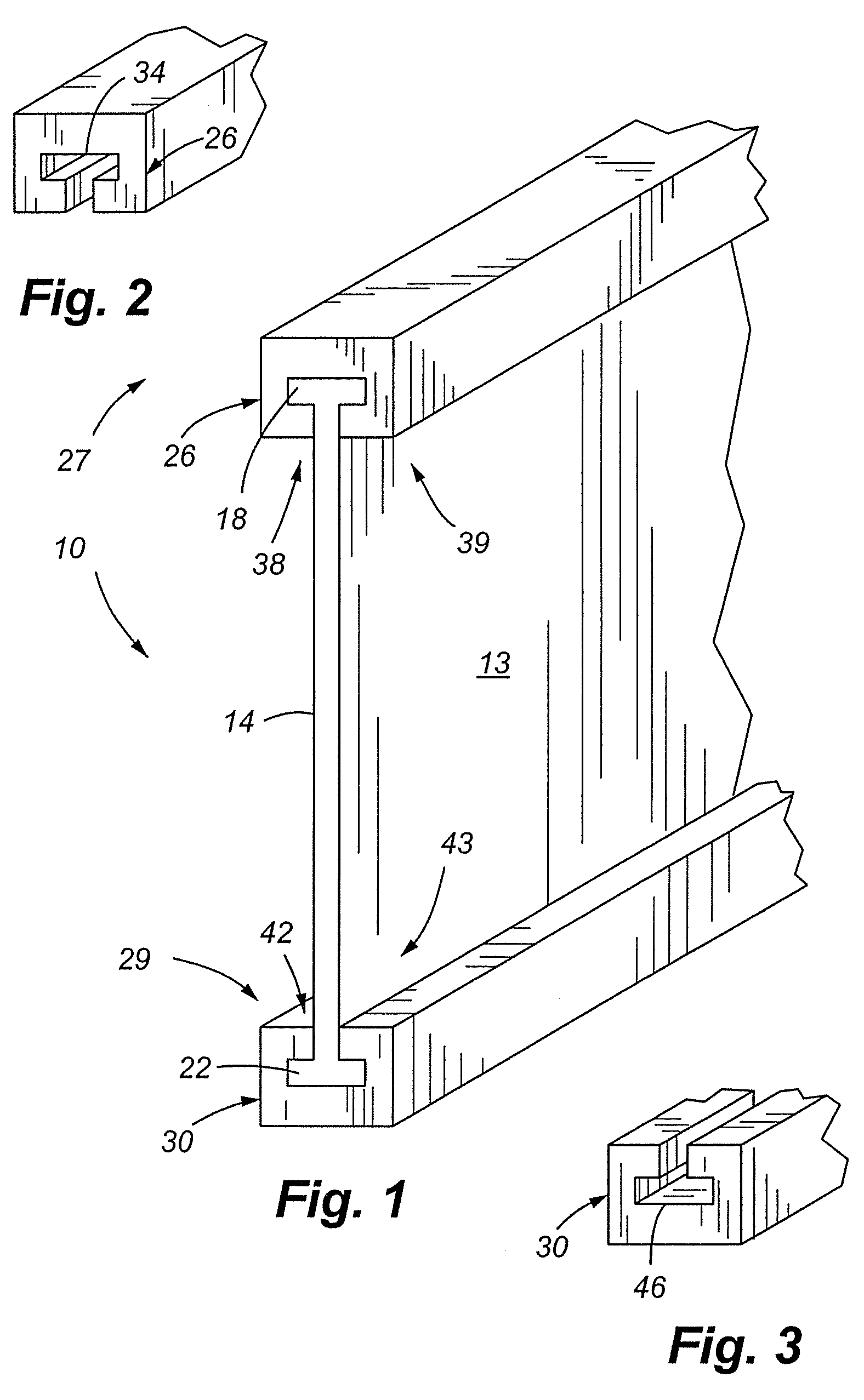

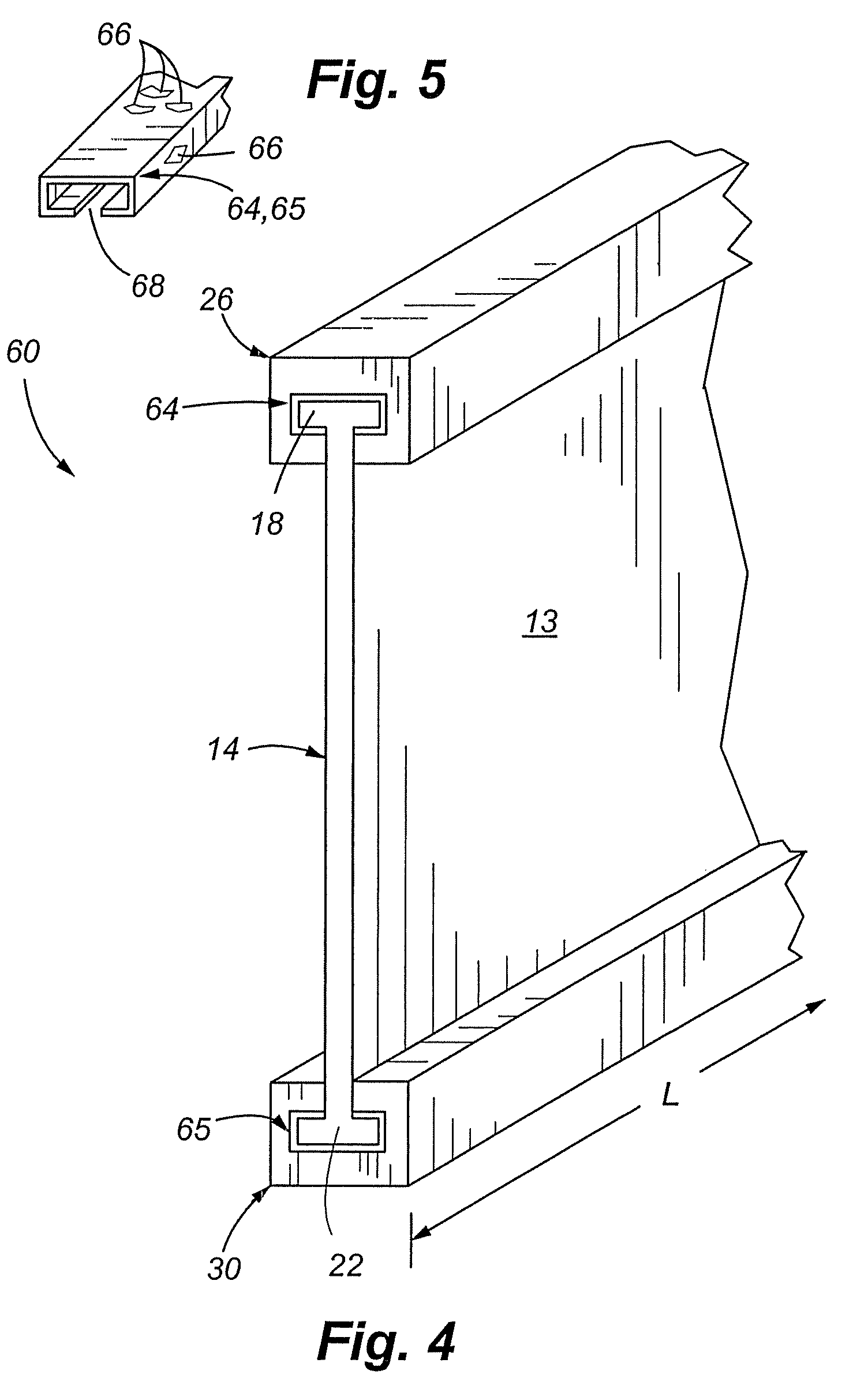

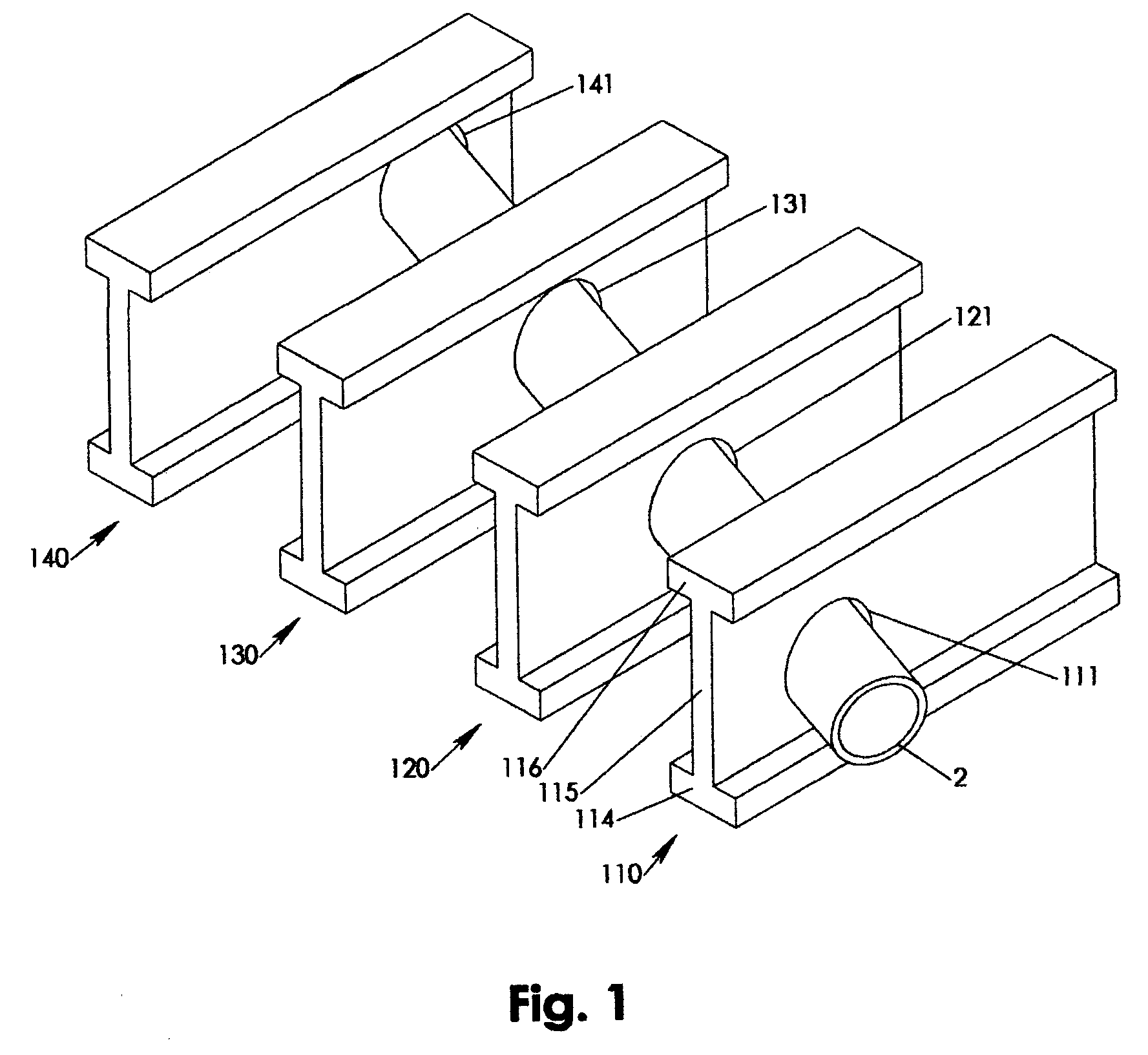

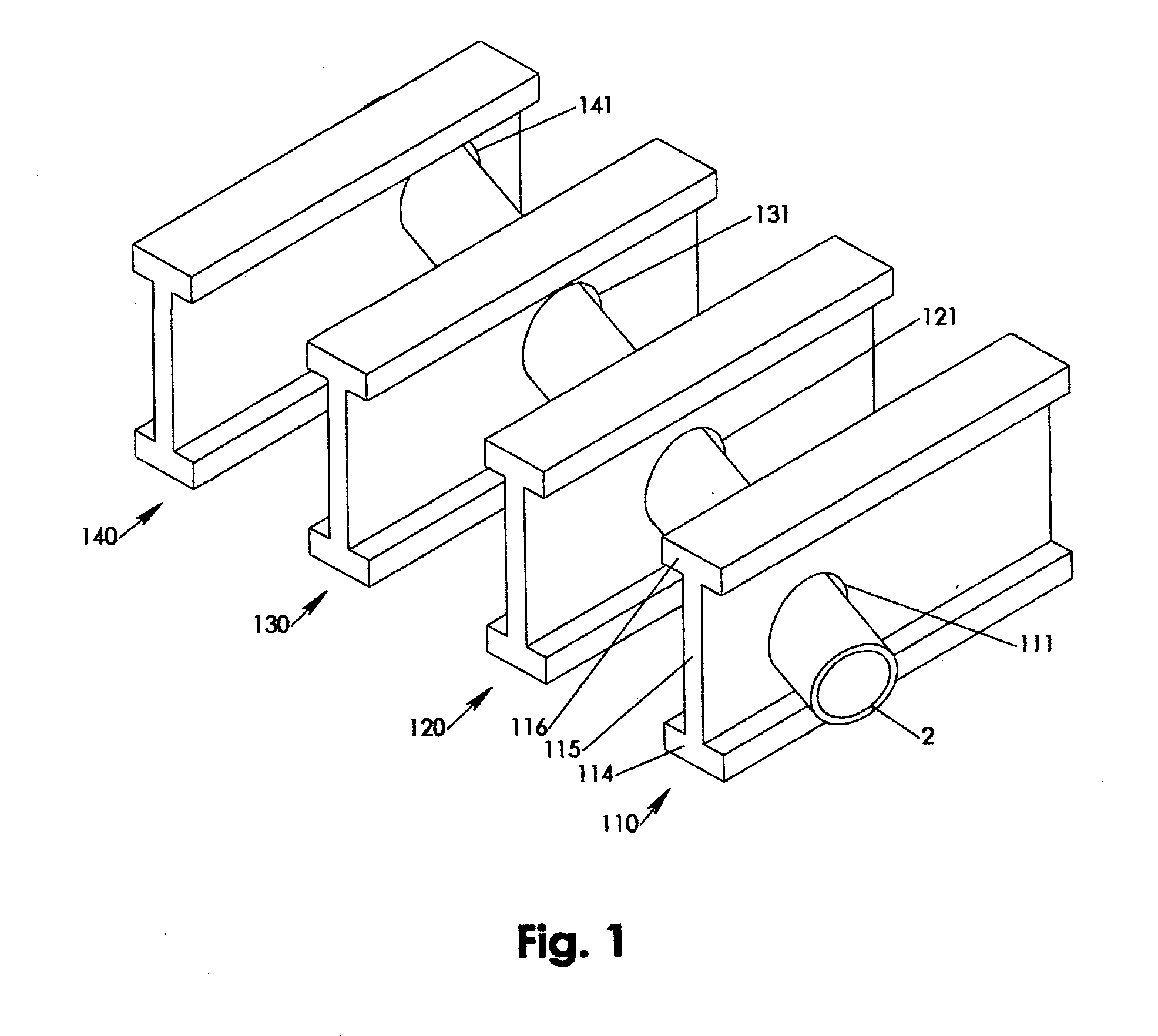

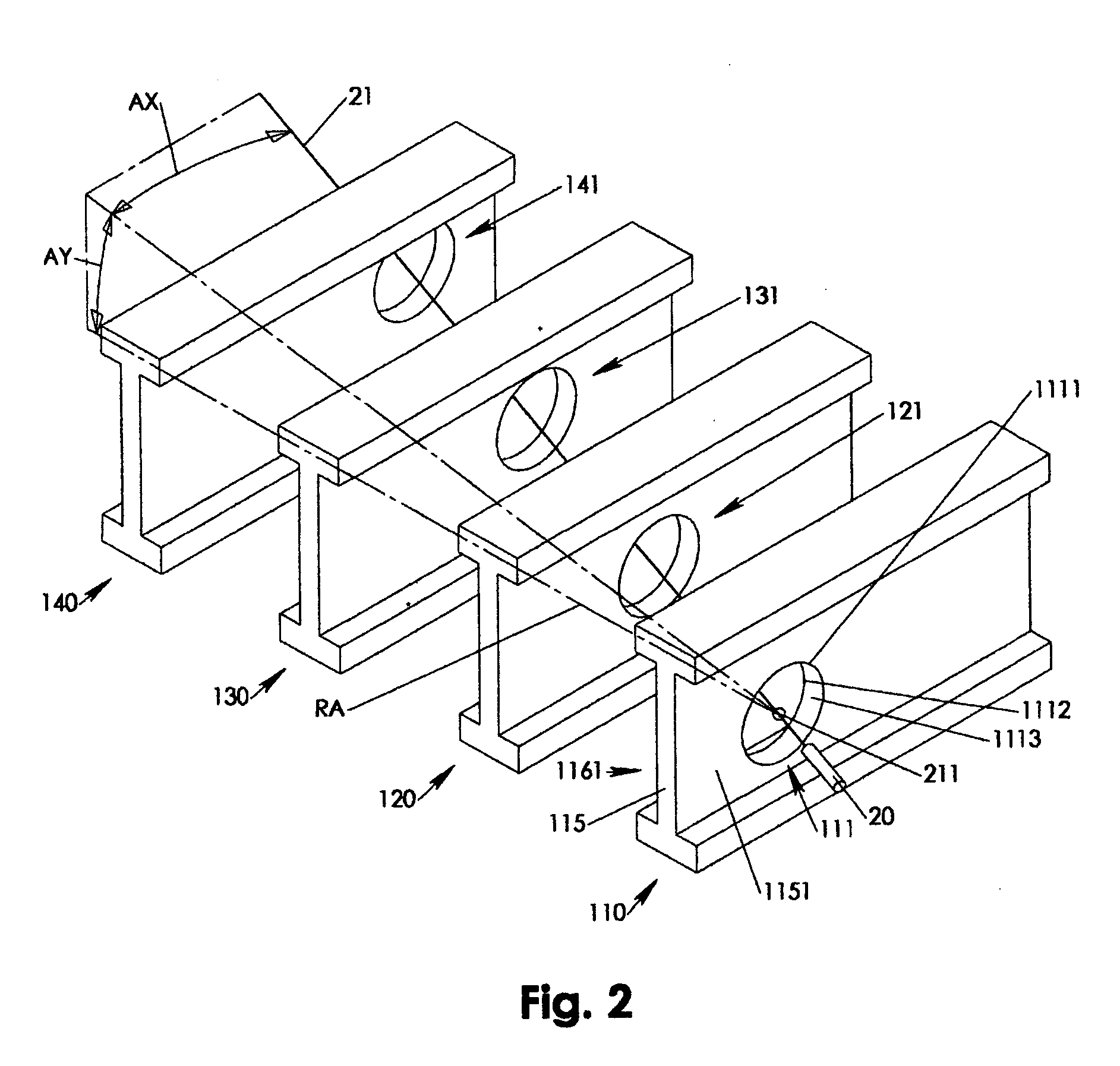

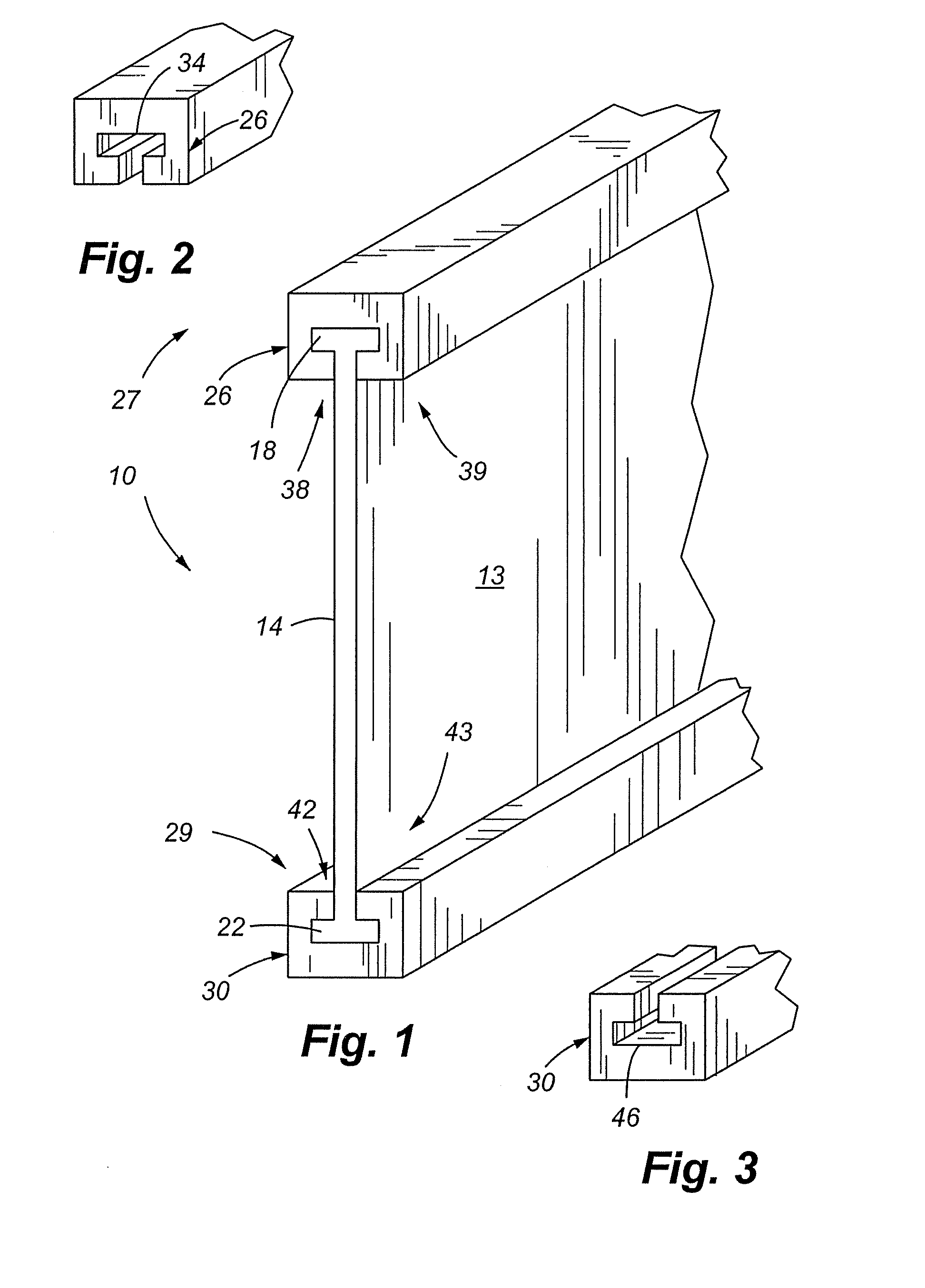

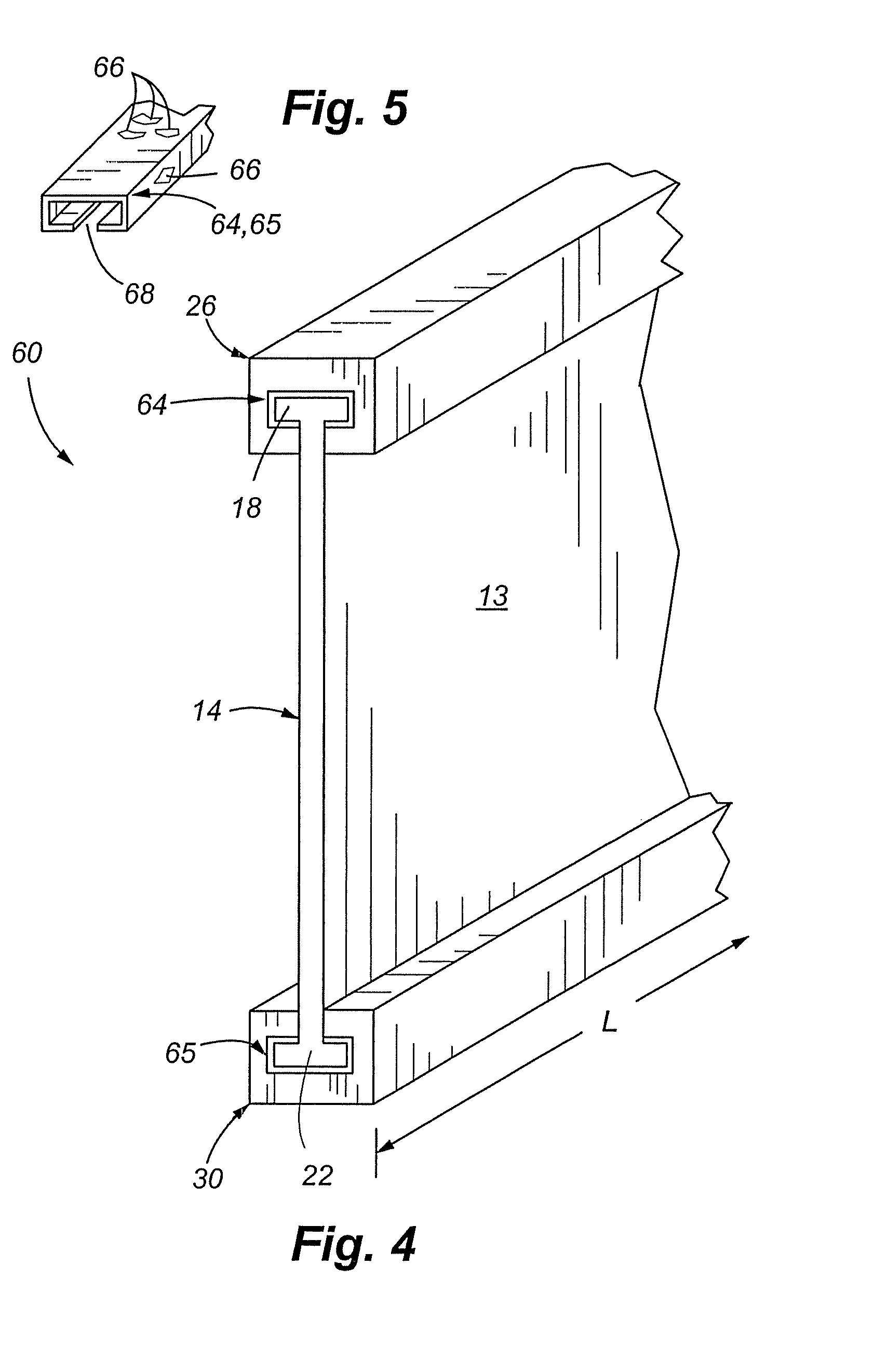

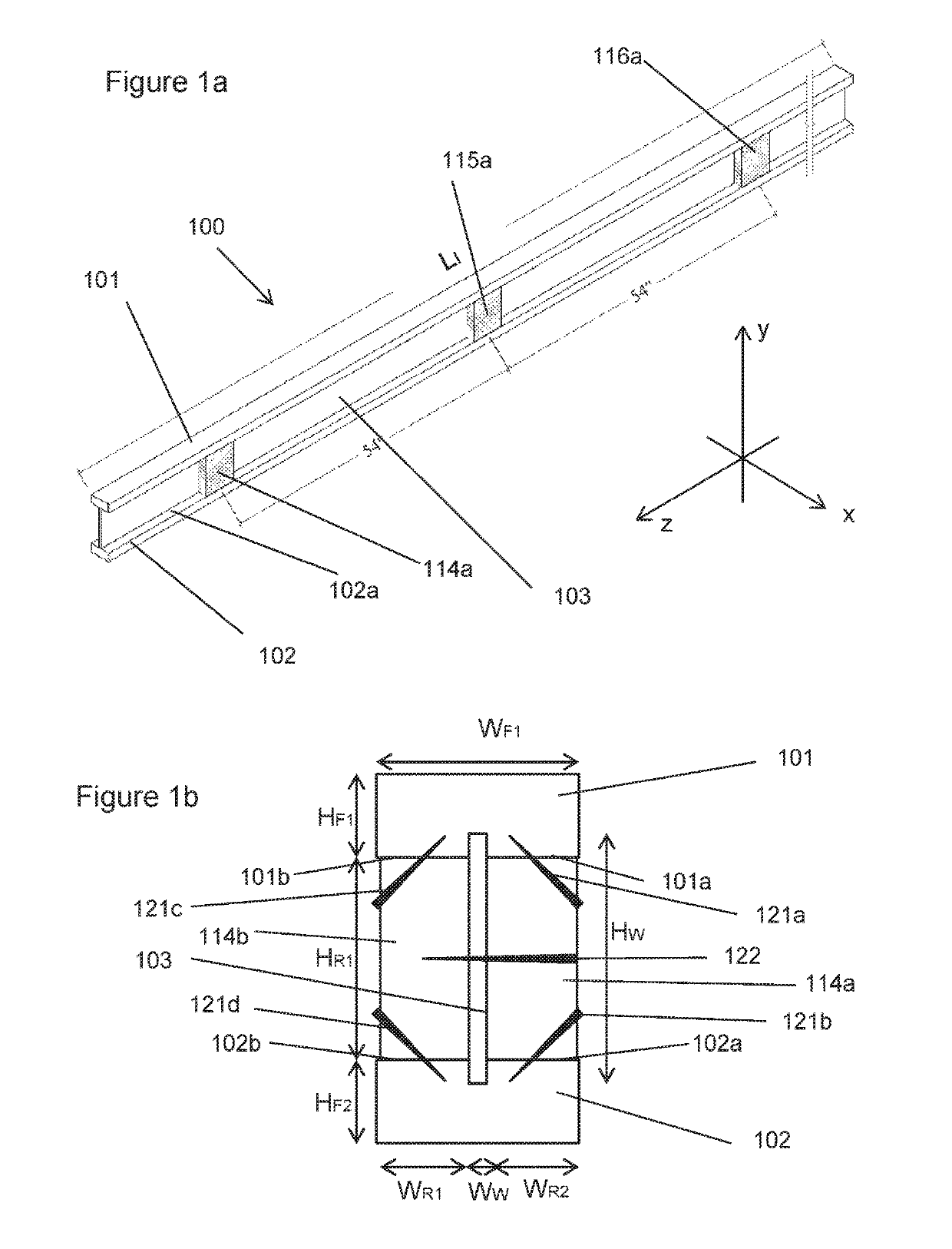

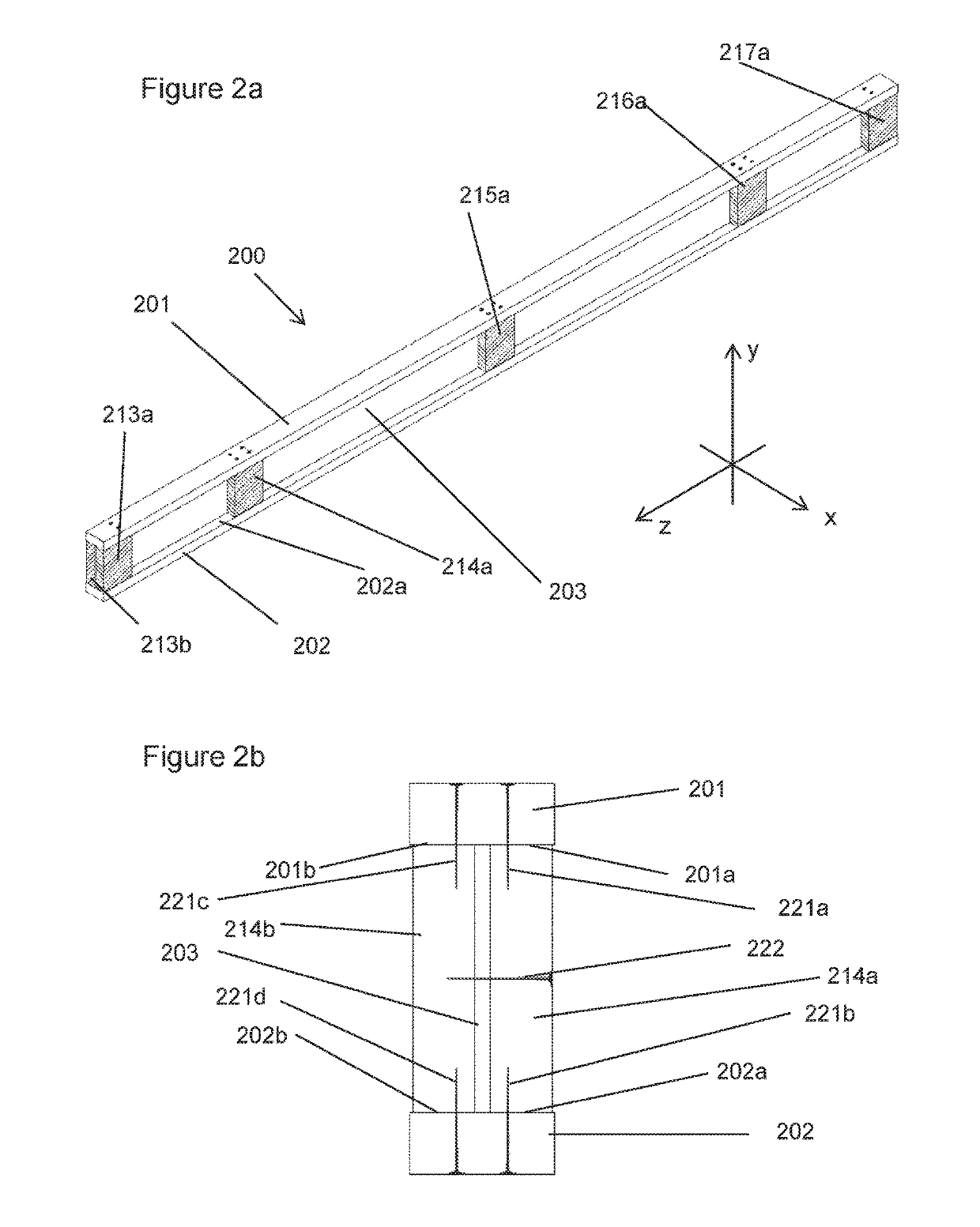

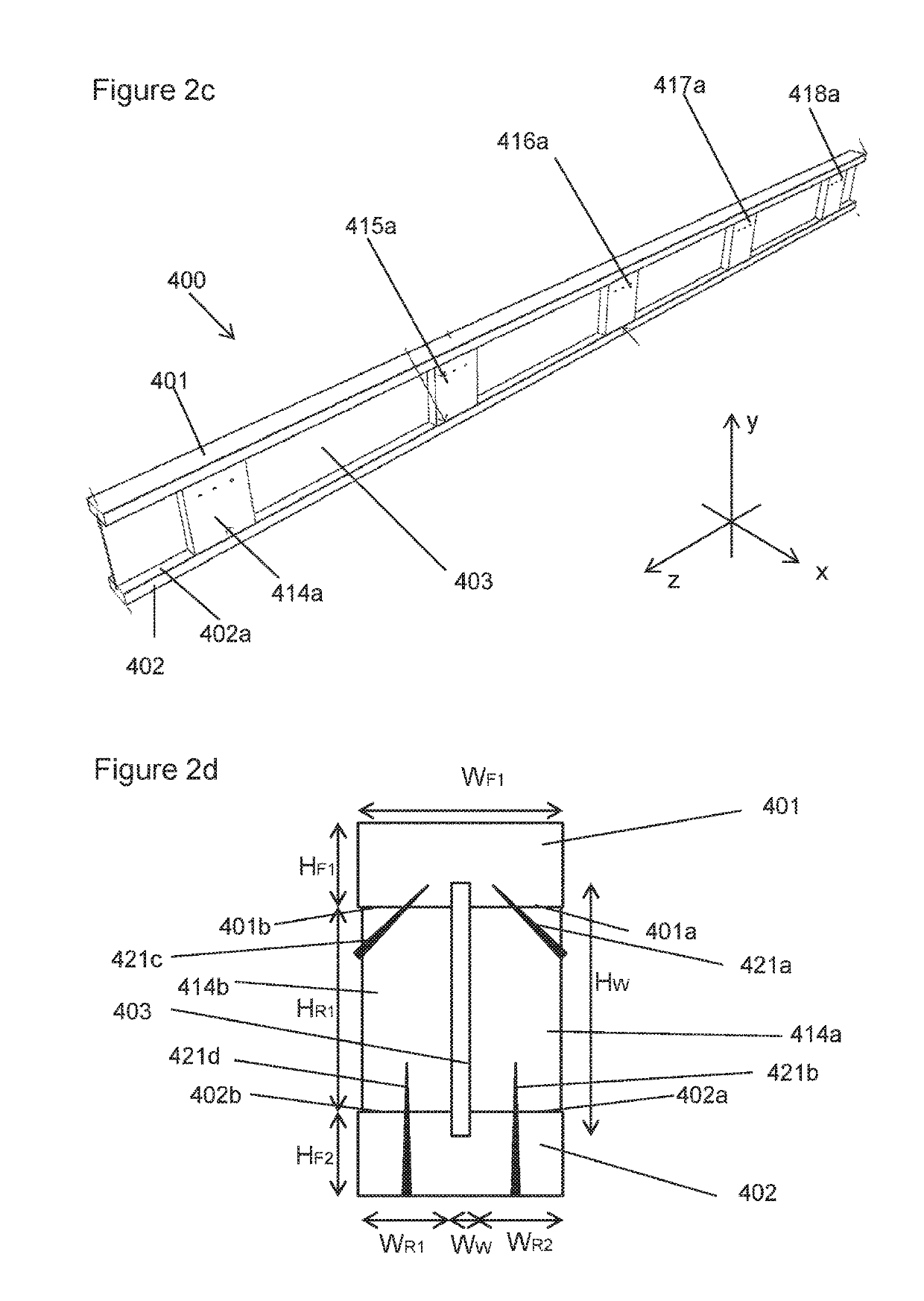

Engineered structural members and methods for constructing same

A system and method of manufacture providing reinforced structurally functional load-bearing members, including but not limited to using thermoplastic materials, such as High Density Polyethylene (HDPE), reinforced such as with an aluminum alloy or carbon fiber core element. Among its possible uses, the present invention has application for provision of structural support members, such as an illustrative I-joist product having a vertical center member preferably comprising HDPE, and top and bottom flanges having structurally meaningful reinforcement. The center member and flanges preferably comprising HDPE provides a relatively hard, durable, substantially weather-resistant structure.

Owner:TAC TECH

Engineered structural members and methods for constructing same

A system and method of manufacture providing reinforced structurally functional load-bearing members, including but not limited to using thermoplastic materials, such as High Density Polyethylene (HDPE), reinforced such as with an aluminum alloy or carbon fiber core element. Among its possible uses, the present invention has application for provision of structural support members, such as an illustrative I-joist product having a vertical center member preferably comprising HDPE, and top and bottom flanges having structurally meaningful reinforcement. The center member and flanges preferably comprising HDPE provides a relatively hard, durable, substantially weather-resistant structure.

Owner:TAC TECH

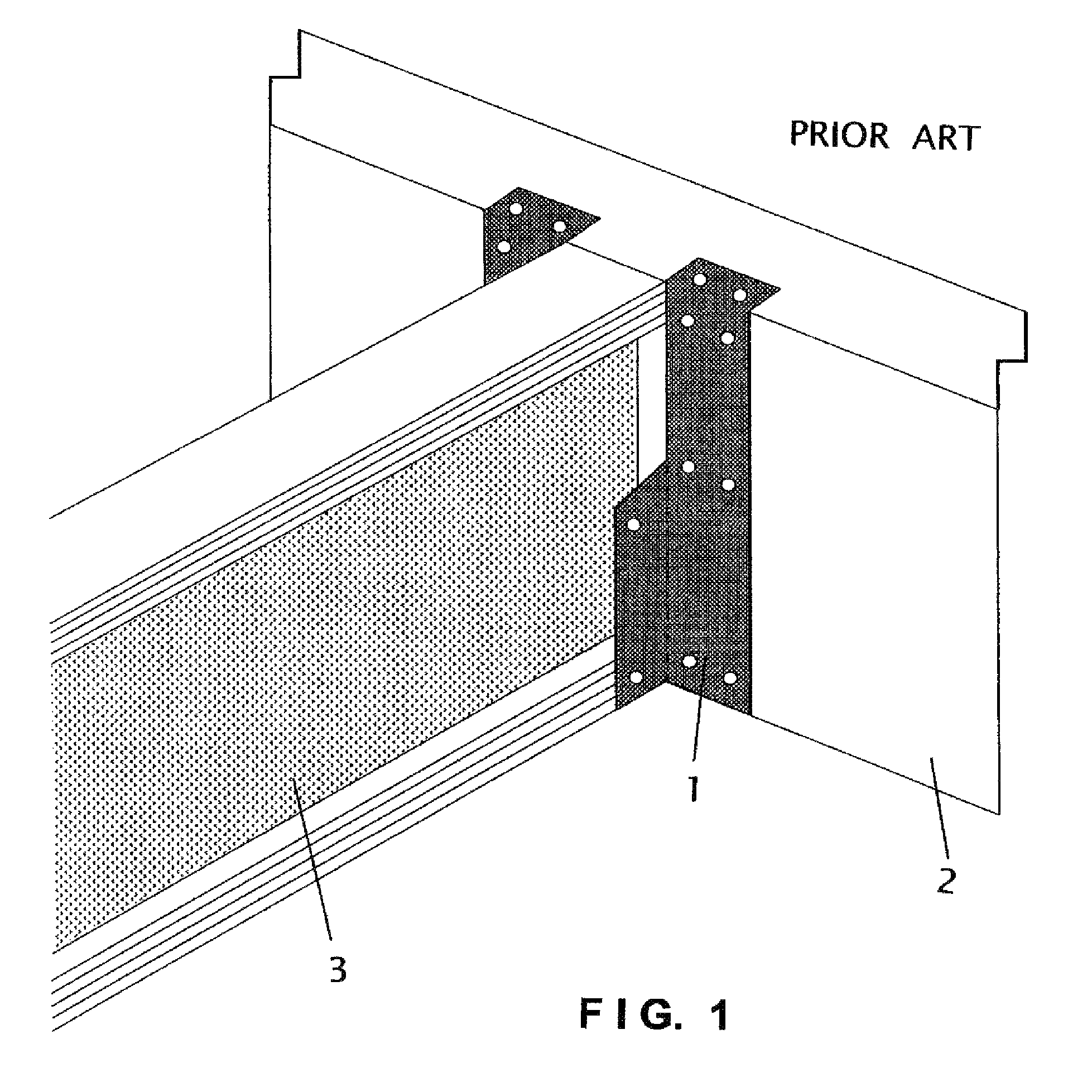

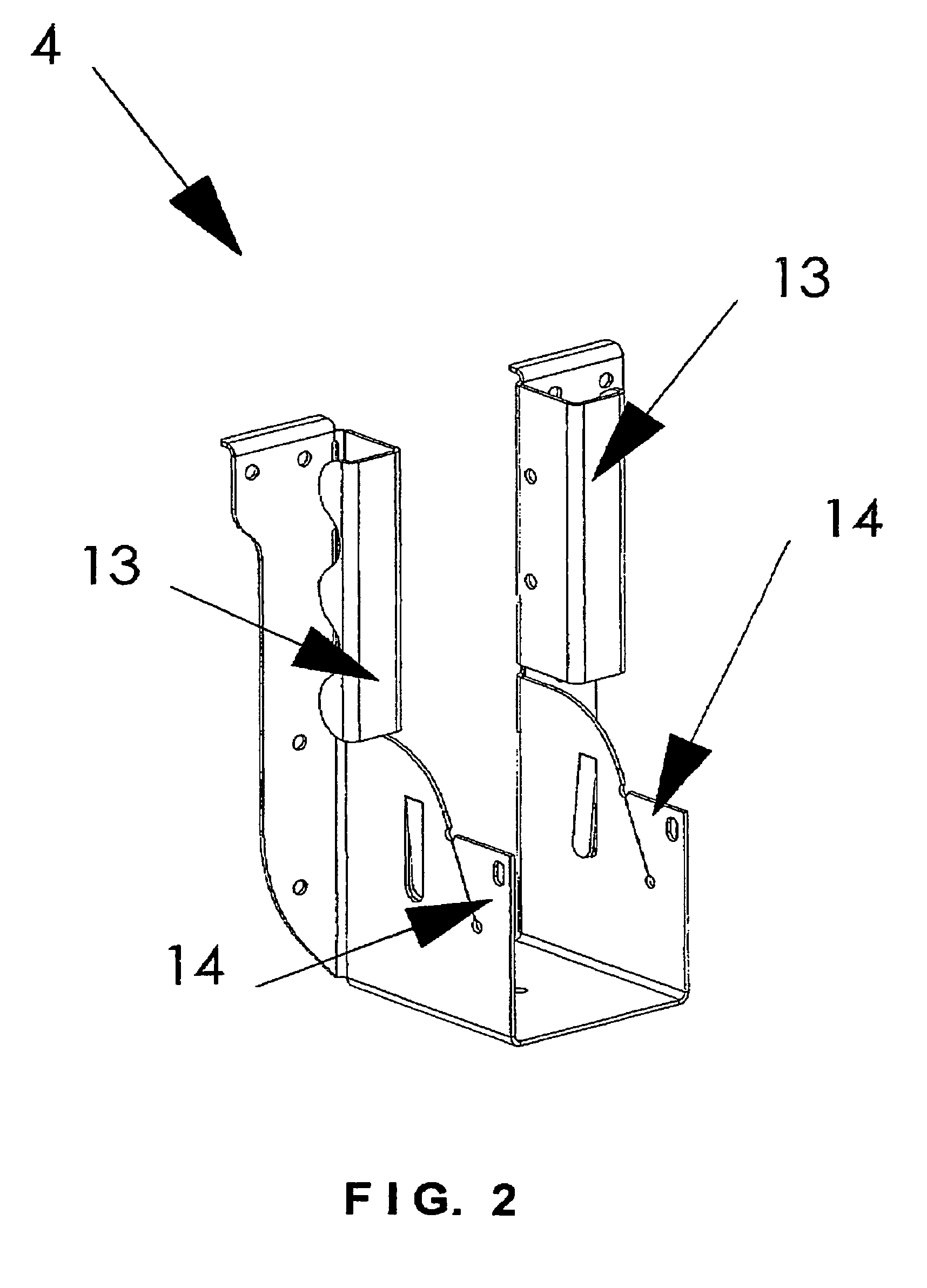

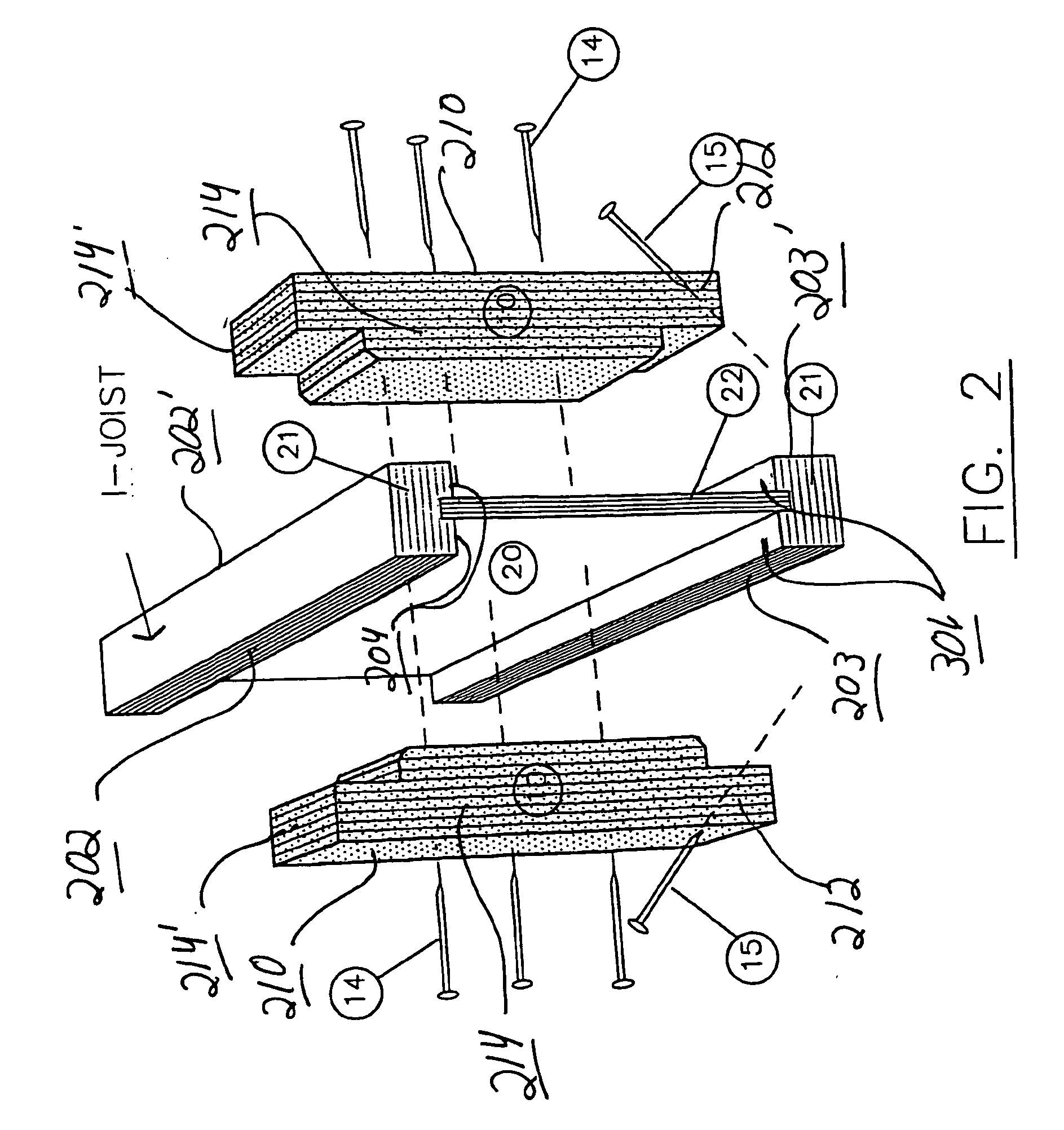

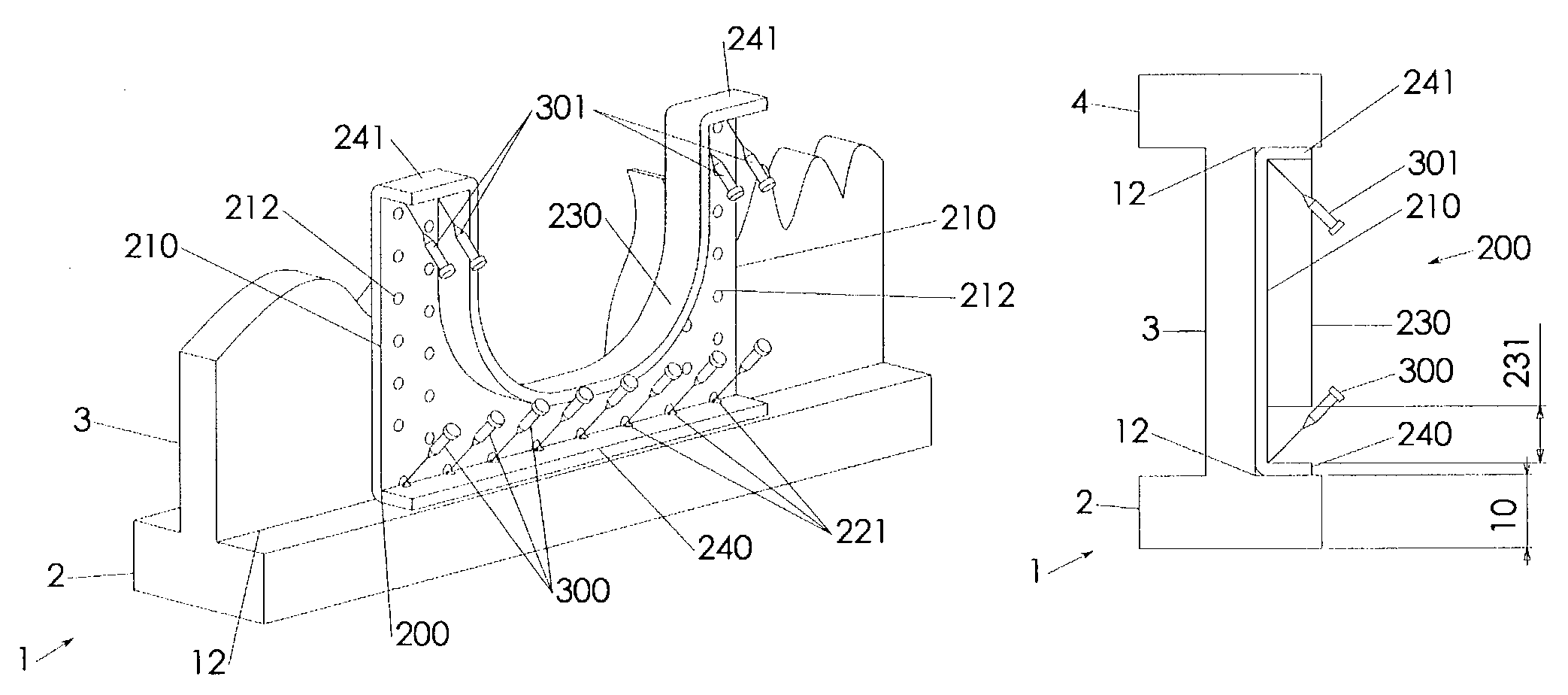

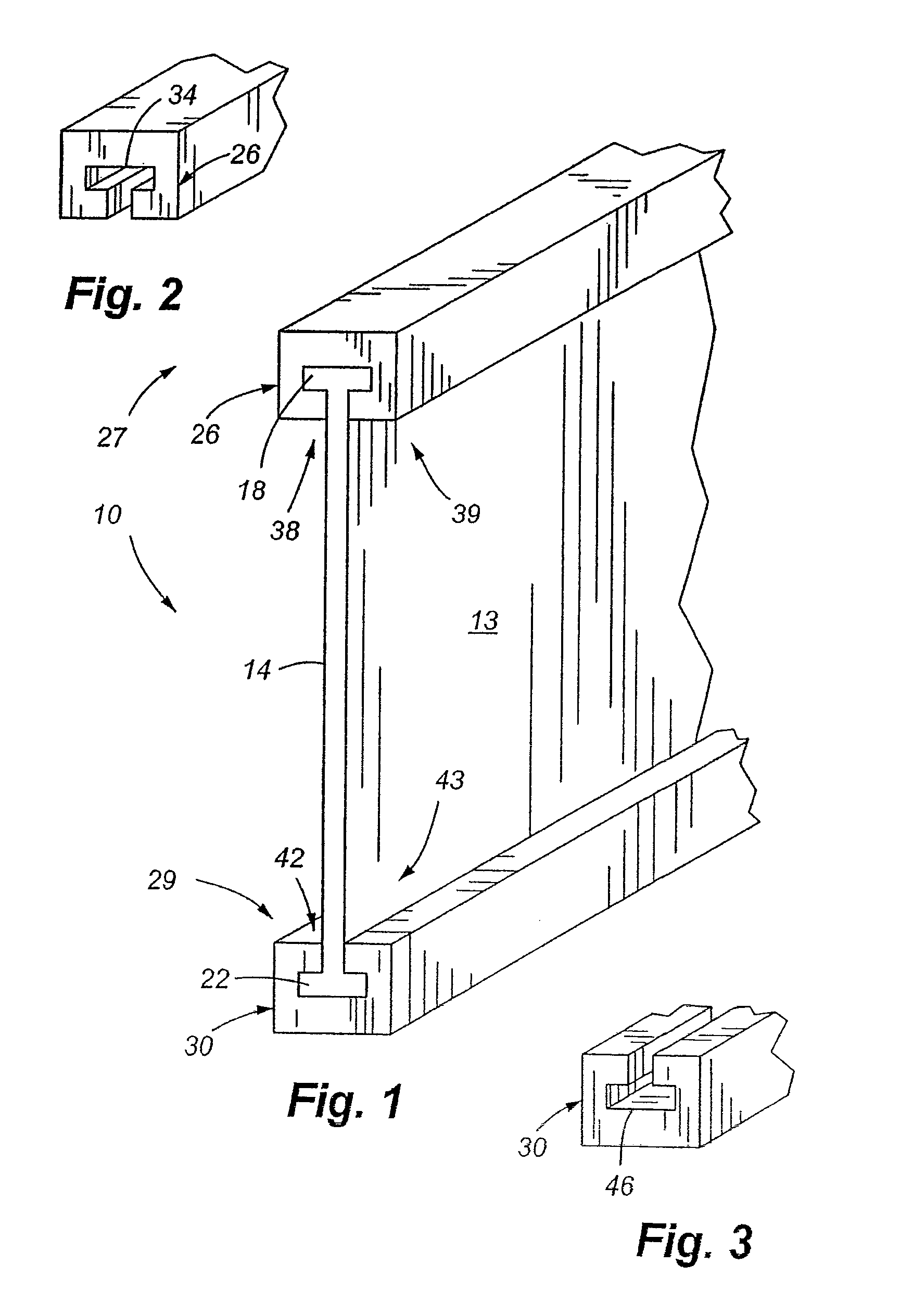

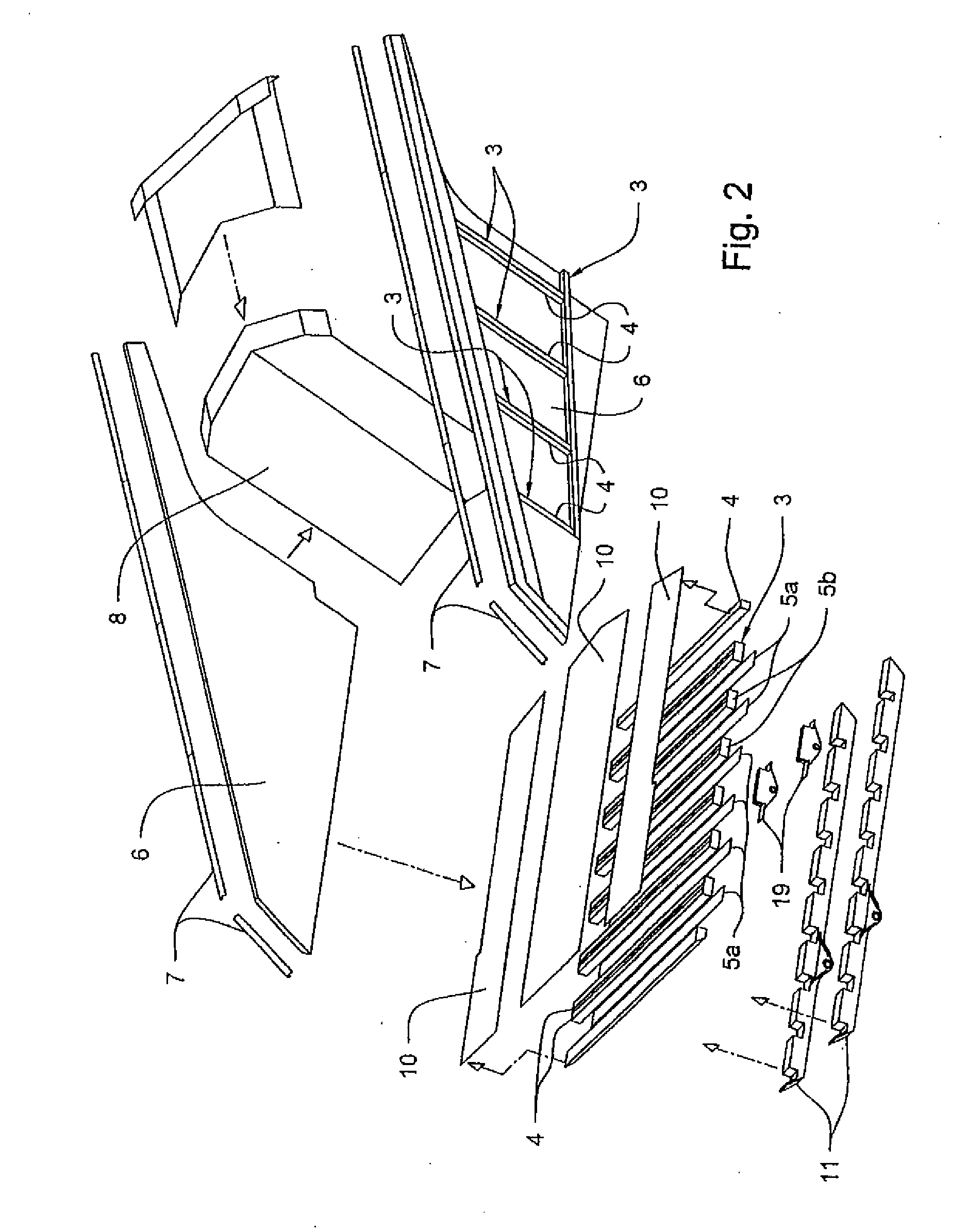

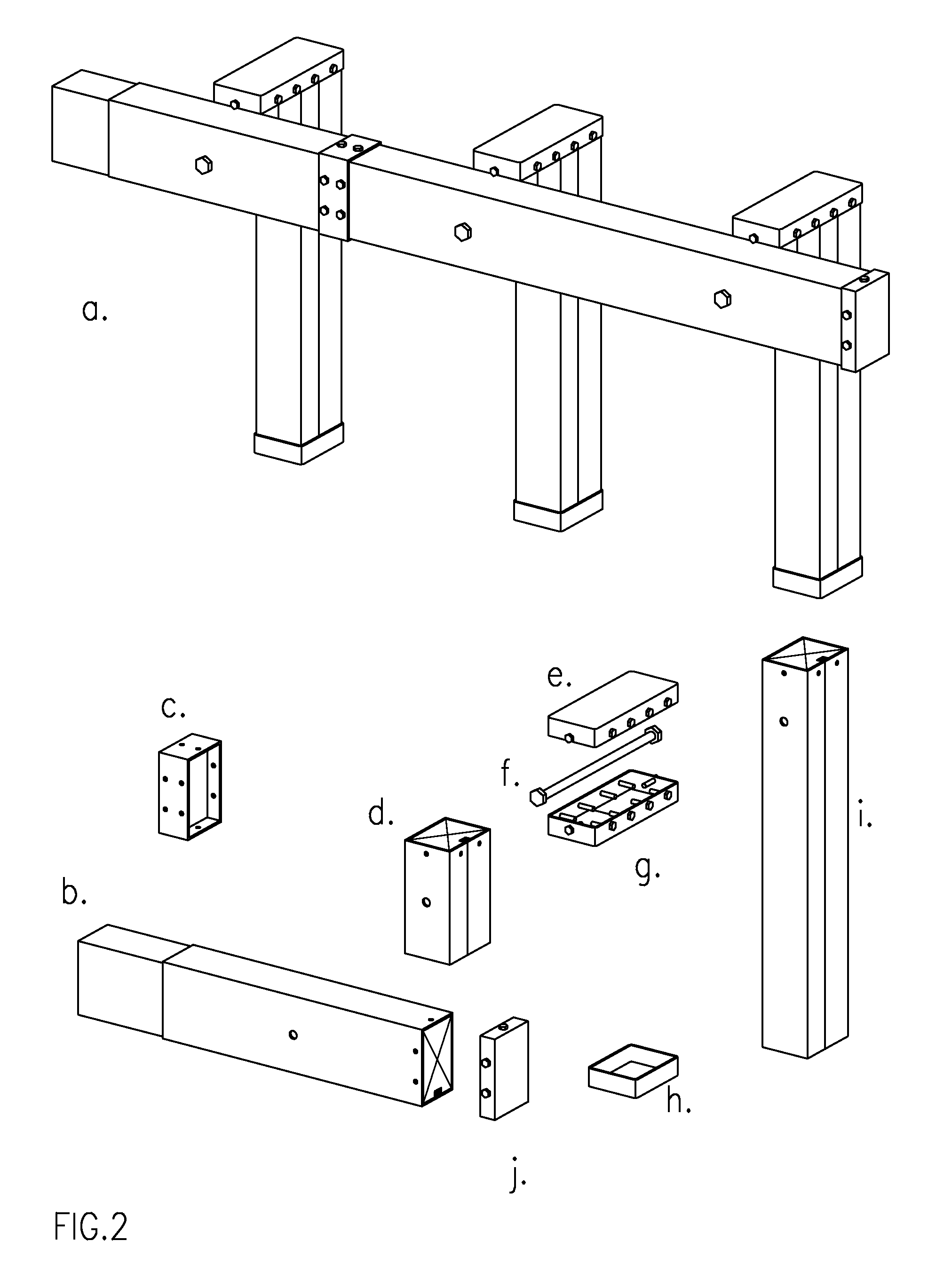

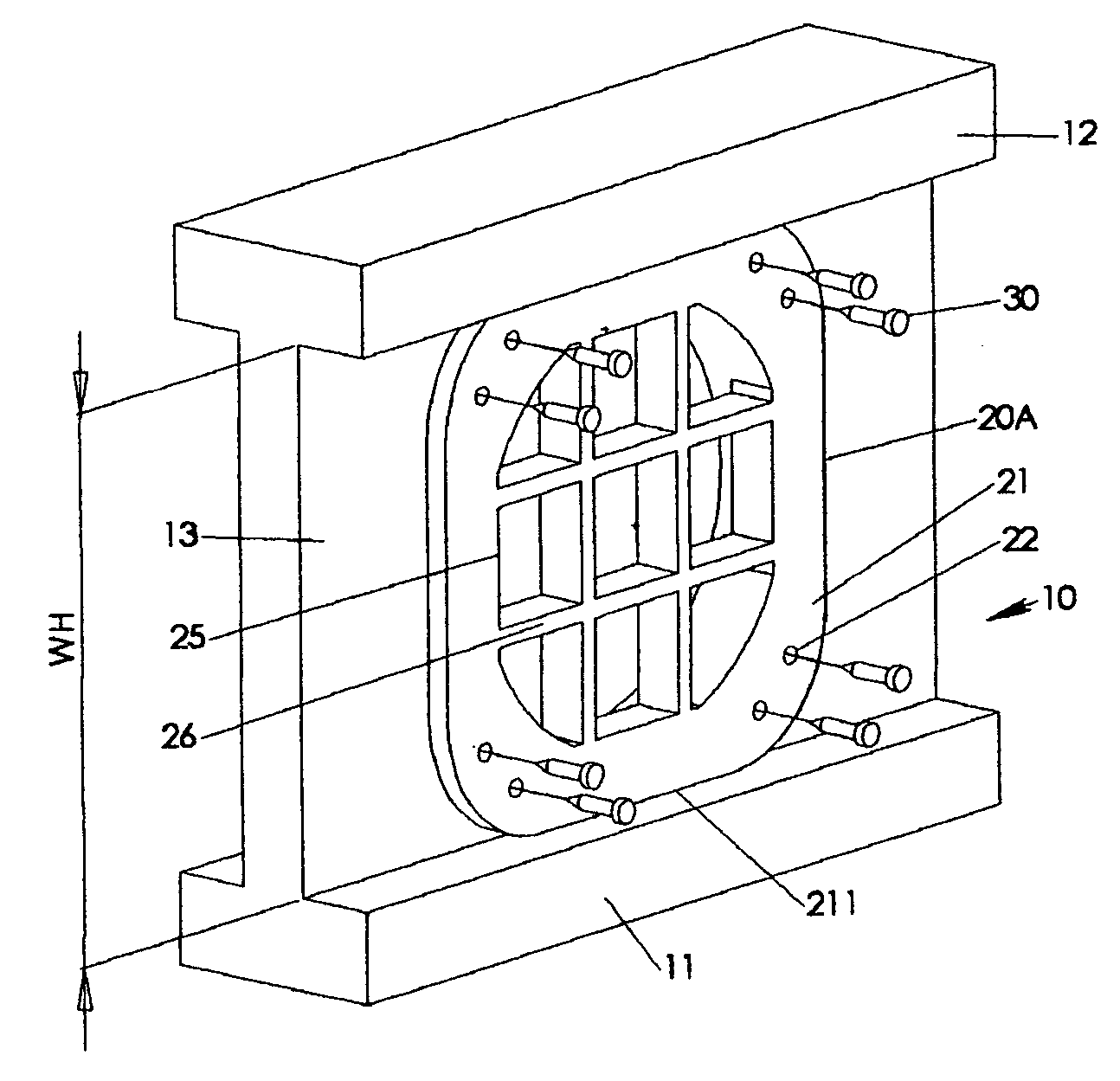

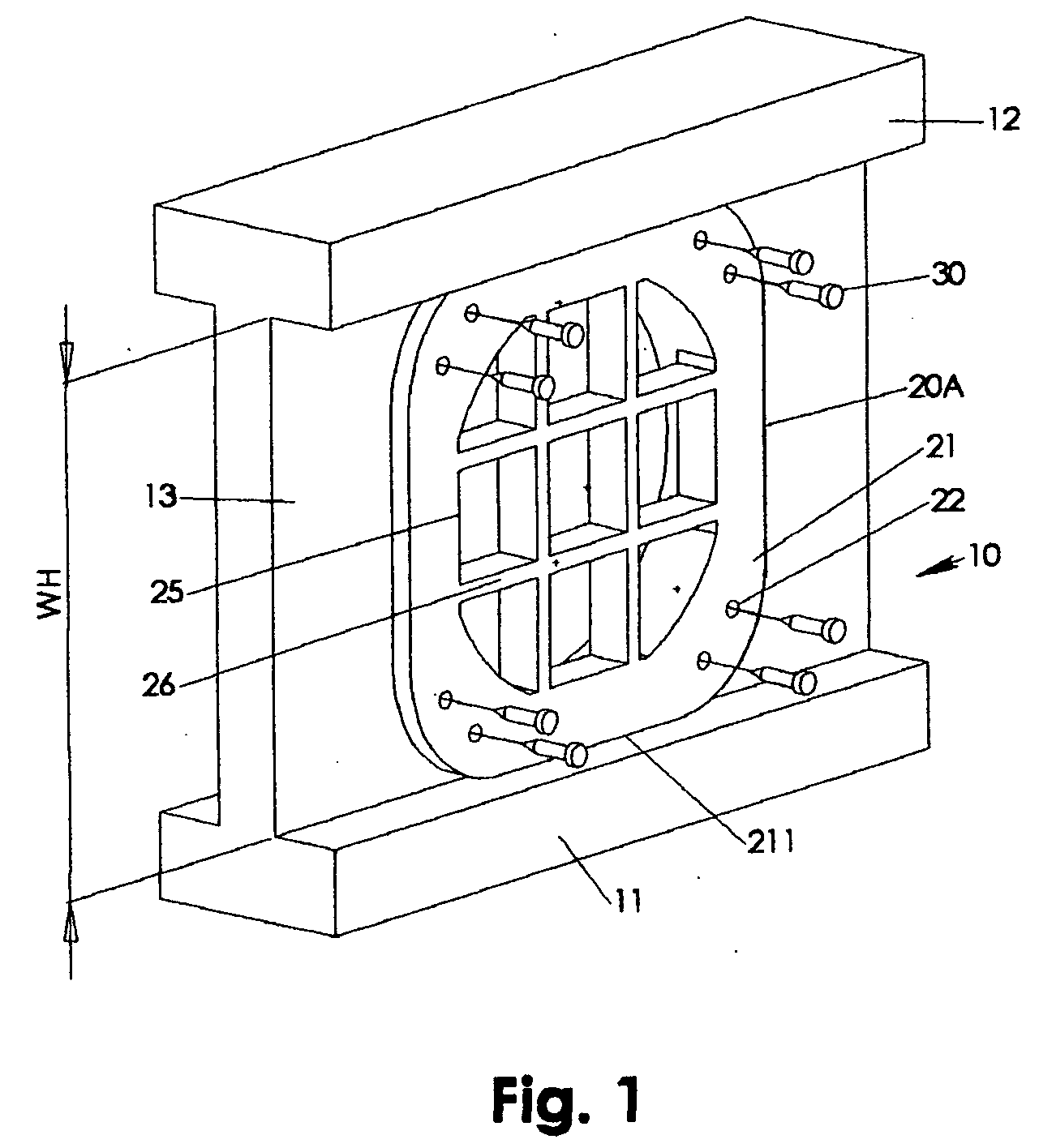

Method and system of framing components and hangers used in a structural interface

A system and method used in residential and commercial construction of floors, ceilings and roofs, where a beam and hanger together support a joist / rafter to which sheathing is applied. Hanger design features include bendable stiffeners that provide pinching structural support for opposing sides of an engineered wood I-joist web after the joist / rafter is seated into the bridge of the hanger, providing a superior structural interface connection, less material cost, and no contact between the hanger and sheathing which reduces unwanted noise in finished construction. Additional strengthening of the structural / load-bearing interface between the joist / rafter and beam may include selected horizontally-extending dato, groove, cut, or other detail formed in the support beams during their manufacture / milling and rearwardly-extending protections on the hanger configured to engage the detail.

Owner:ROBELL GLENN

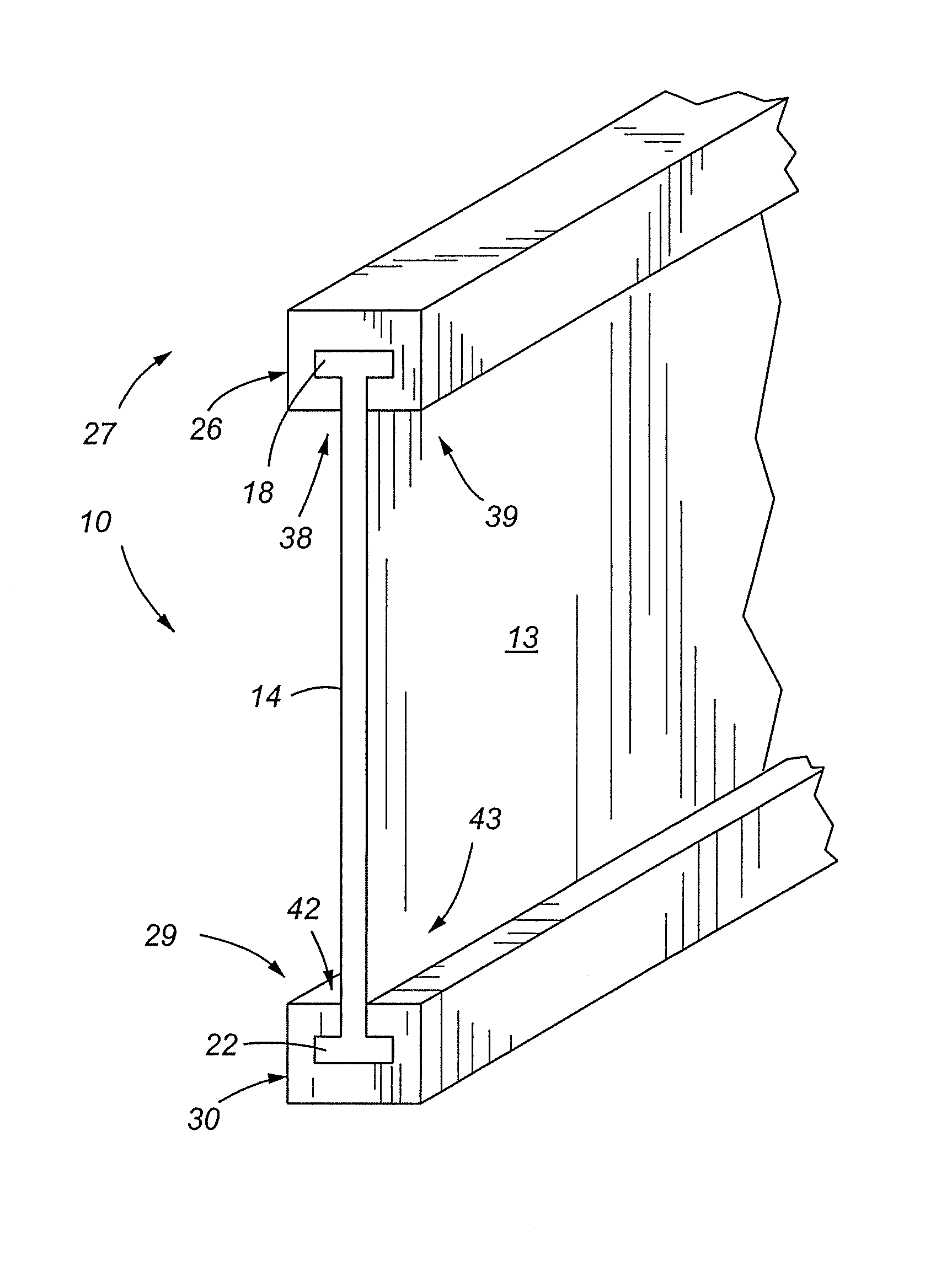

Fire-Resistant Wooden I-Joist

This application relates to I-joists which are configured to resist fire damage. Specifically, the present application relates to reinforcing I-joists with reinforcing members configured to provide structural support and / or to provide a physical barrier to fire. This may help the I-joists to maintain structural integrity during a fire and so help improve safety during evacuation of a building and during fire-fighting operations.

Owner:PINKWOOD LTD

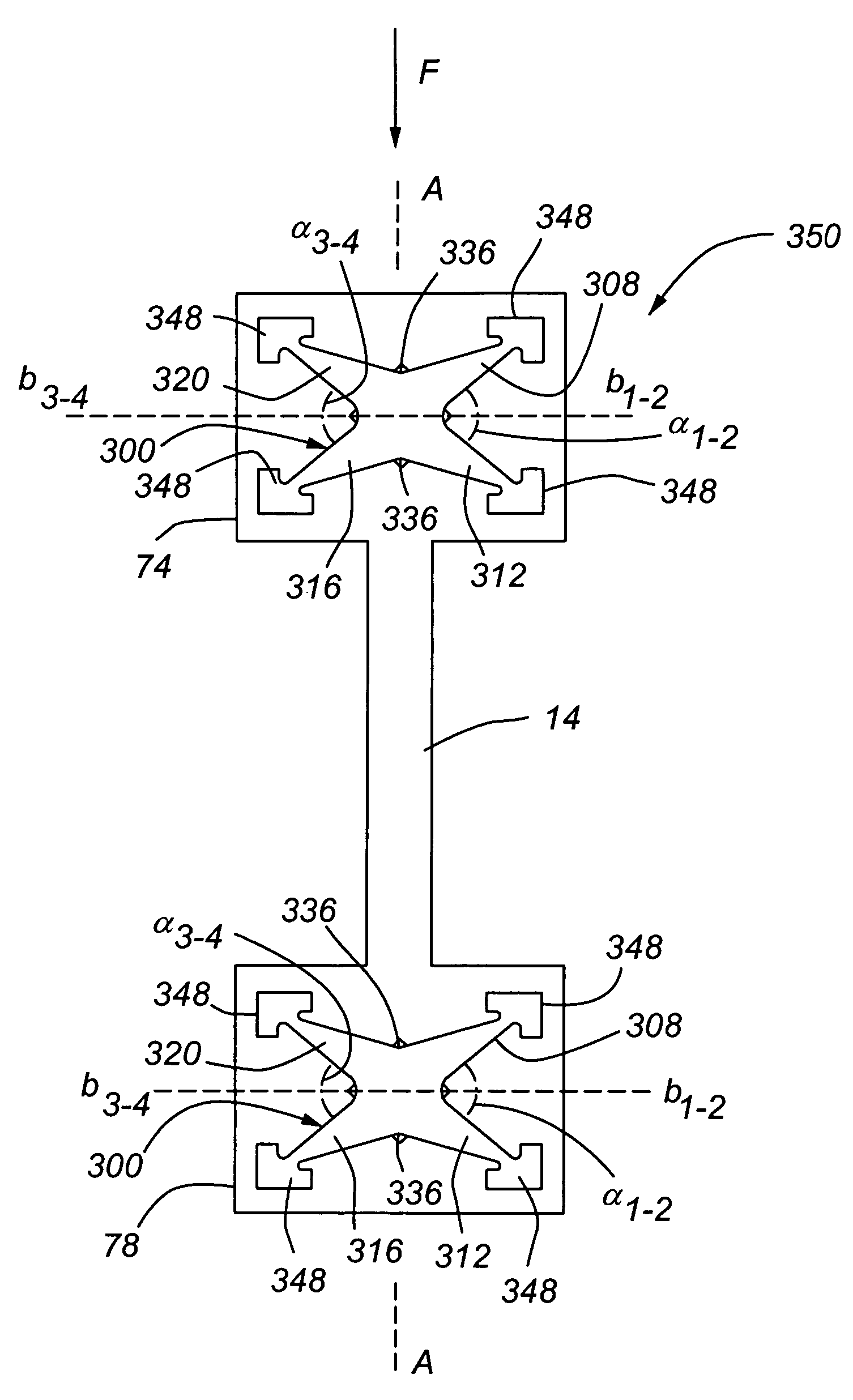

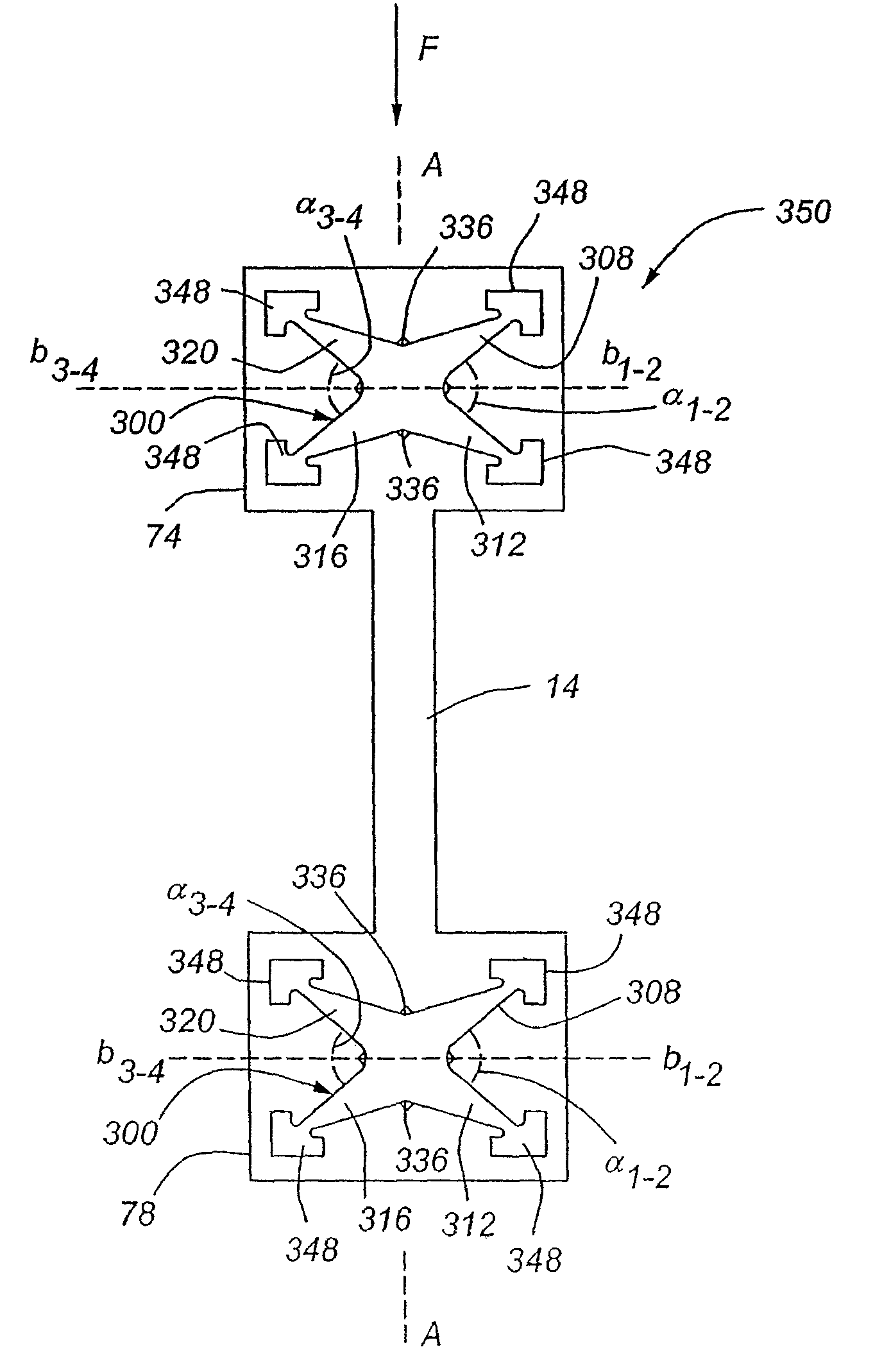

Engineered structural members and methods for constructing same

A system and method of manufacture providing reinforced structurally functional load-bearing members, including but not limited to using thermoplastic materials, such as High Density Polyethylene (HDPE) or polypropylene (PP), reinforced such as with an aluminum alloy, glass-reinforced polyurethane (foamed or unfoamed), or carbon fiber core element. Among its possible uses, the present invention has application for provision of structural support members, such as an illustrative I-joist product having a vertical center member preferably comprising a thermoplastic material, and top and bottom flanges having structurally meaningful reinforcement. The center member and flanges preferably comprising a thermoplastic material provides a relatively hard, durable, substantially weather-resistant structure. Certain embodiments of the present invention include reinforcing members having a plurality of lobes or arms. Additional embodiments include indentations along the reinforcing members, such as the arms, to aid in bonding between the thermoplastic outer material and reinforcing member within the thermoplastic material.

Owner:TAC TECH

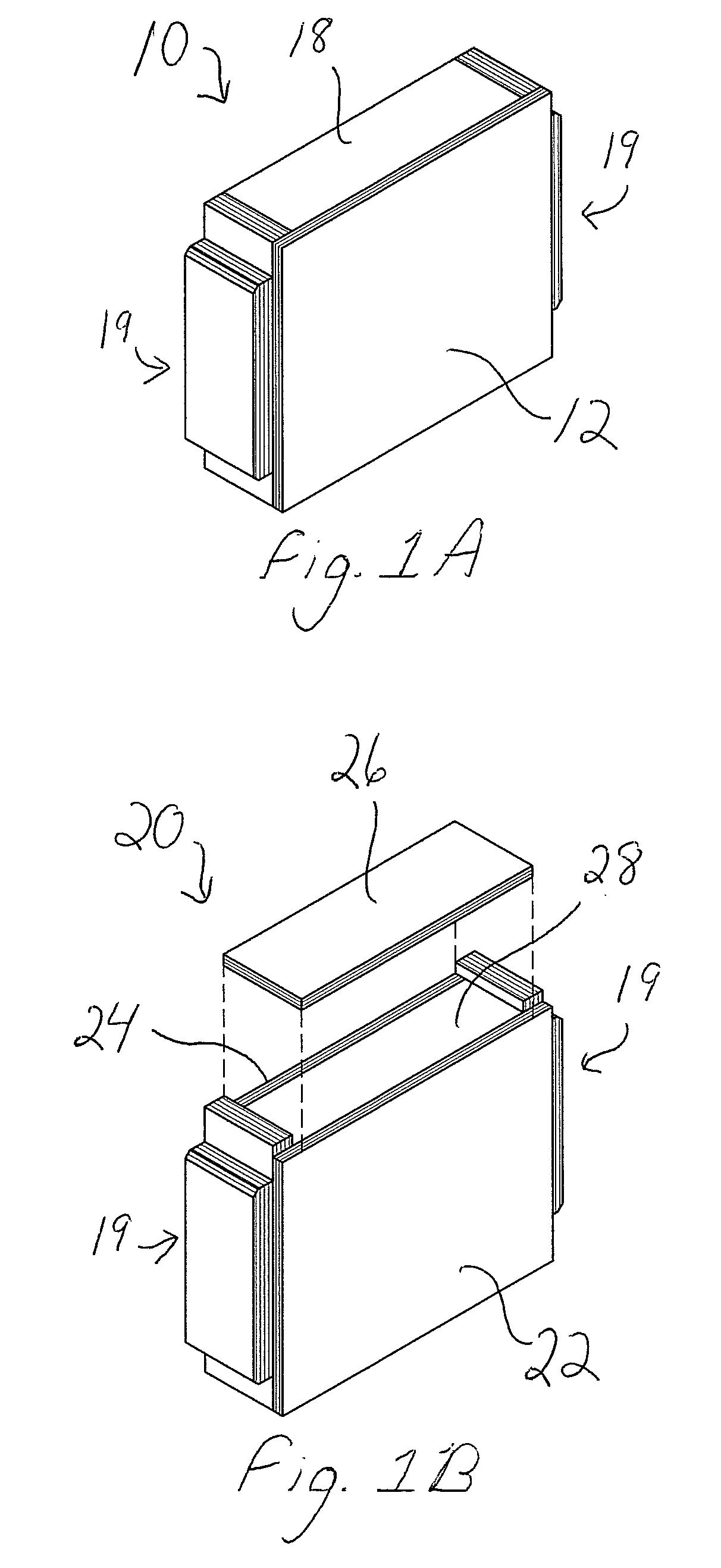

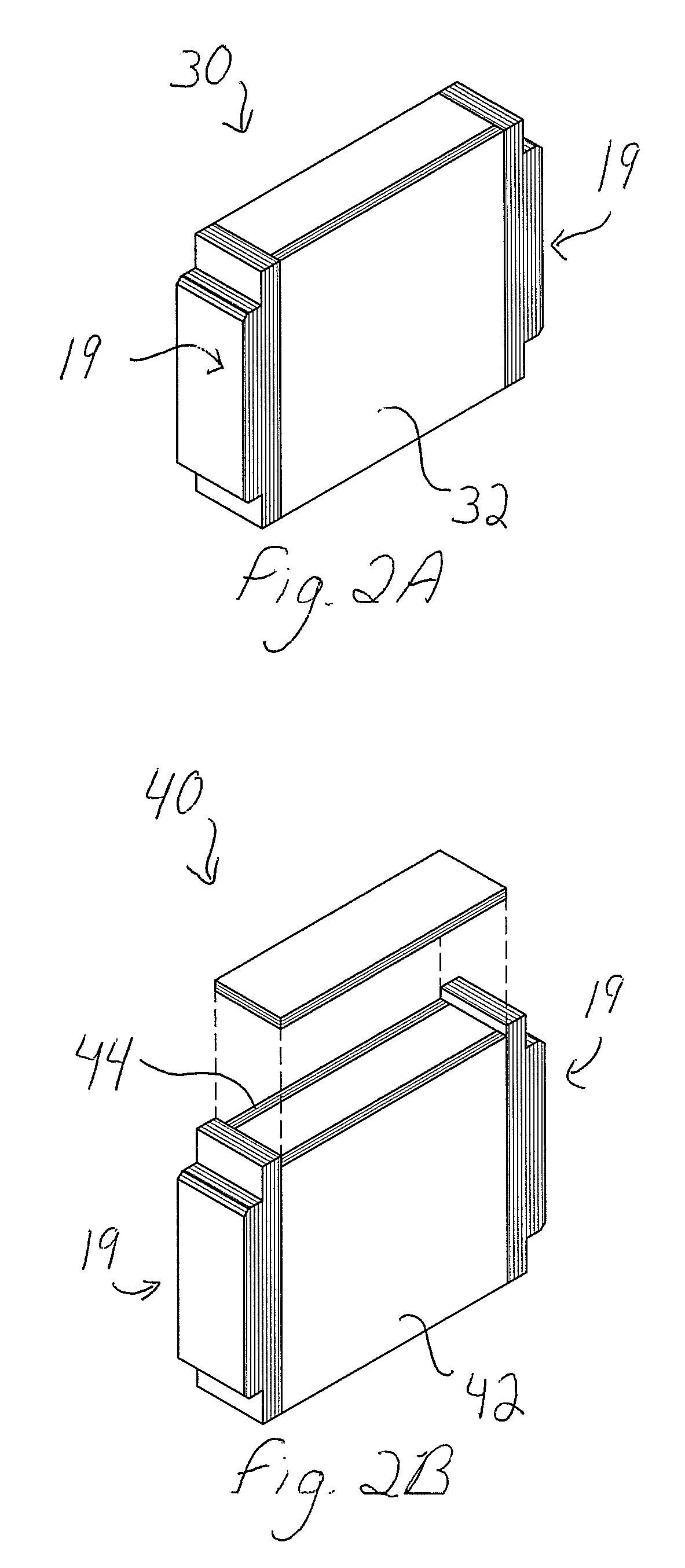

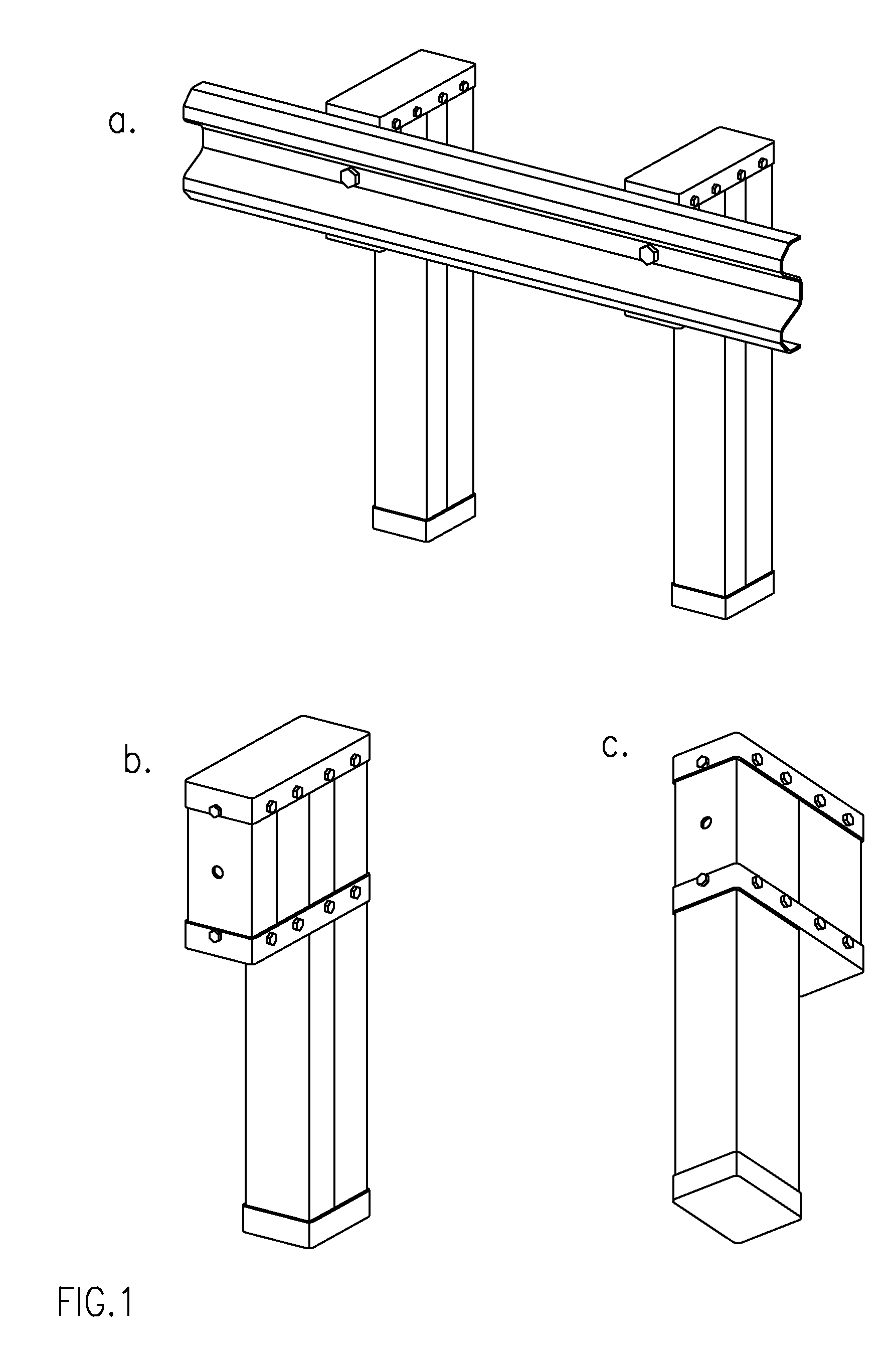

Prefabricated multi-purpose support block for use with I-joists

A multi-purpose, shaped, prefabricated, structurally-enhancing support block conforms to the side profiles of conventional I-joists. The support block is preferably installed by fastening it to the I-joist web, rather than to the I-joist flanges, thus preserving the integrity of the I-joist flanges. Further, support blocks may be used in mid-span where additional point-load support is needed, or at joist ends for additional load bearing and / or enhanced rim board, attachment and nailing capabilities. The preferred support block includes a load-jack portion for bearing compressive load and a web and flange support portion reinforcing the thin web of an I-joist to help prevent buckling, rolling, or twisting of the I-joist under peak load conditions.

Owner:SILPRO

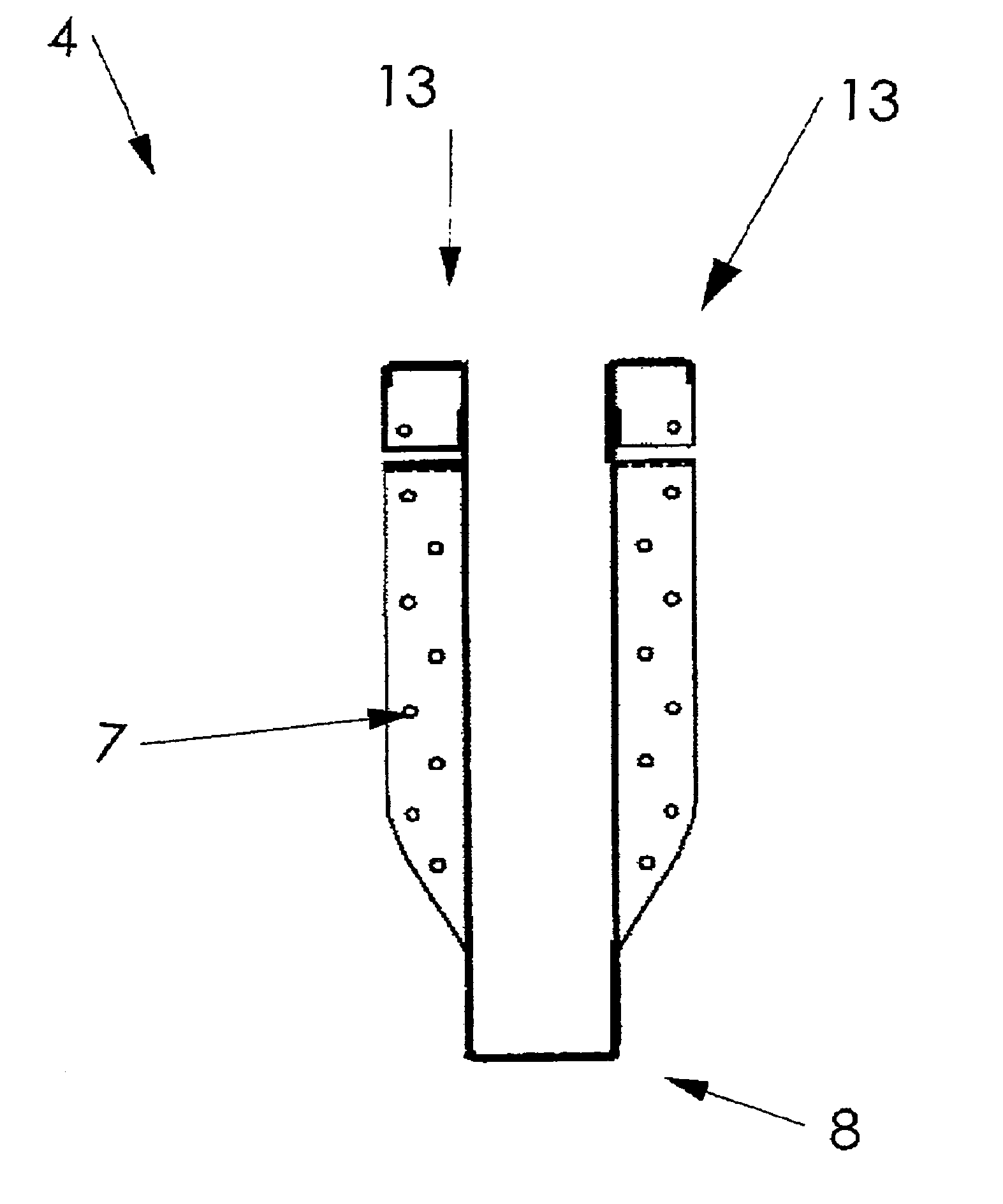

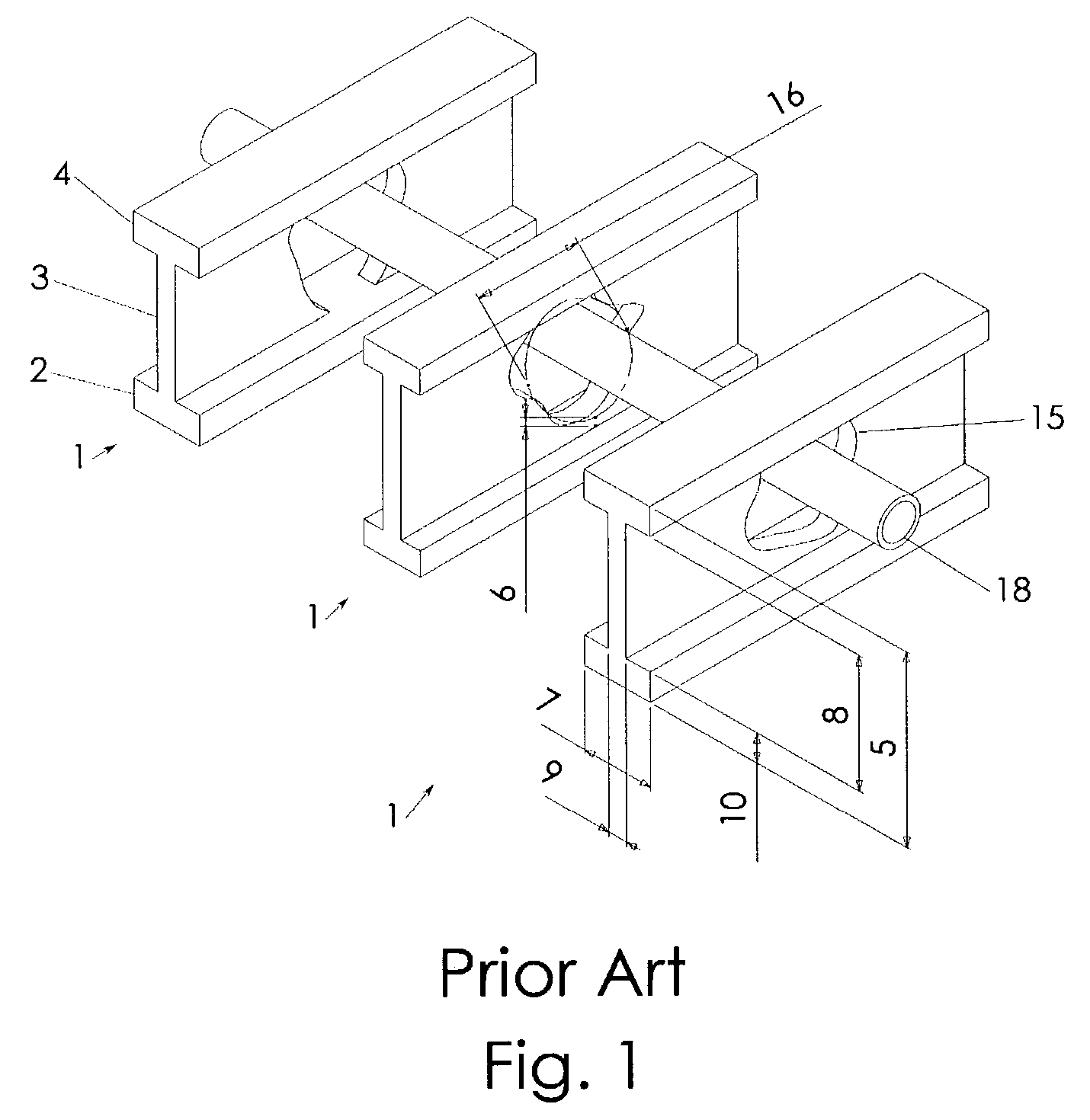

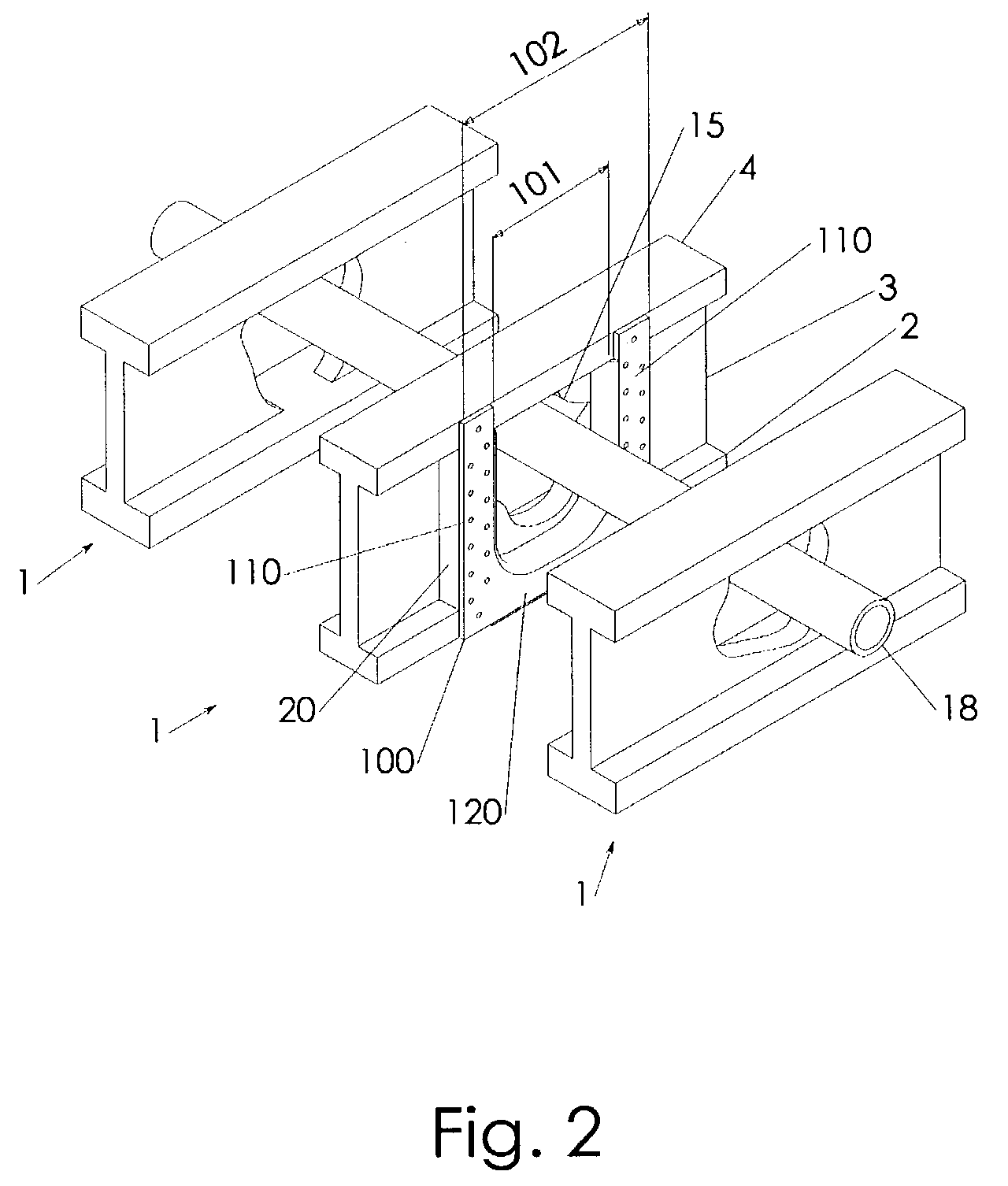

Buckling opposing support for I-joist

InactiveUS7293394B2Easy maintenanceReinforce an I-joist's web portionBuilding repairsGirdersJoistI-joist

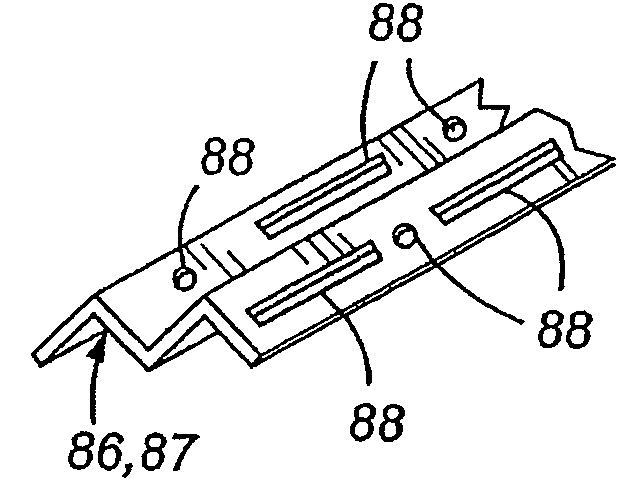

A support device is provided for the preferred application of buckling opposing support of an I-joist having an erroneously cut hole in its web portion. The support device may have an approximate U-shape with two substantially parallel bridging structures combined by a structure that combines the bridging structures and provides an alignment reference with the chords. In the case where an erroneously cut hole is identified, the support device may be laterally attached to the I-joist such that both bridging structures flank the erroneously cut hole. Once the bridging structures are attached to the web, the bridging structures define with the remainder of the web a buckling opposing interface. The support structure is preferably monolithically fabricated from sheet metal and scaled in conjunction with dimensional standards of commercially available I-joists.

Owner:DAVIS JOHN D

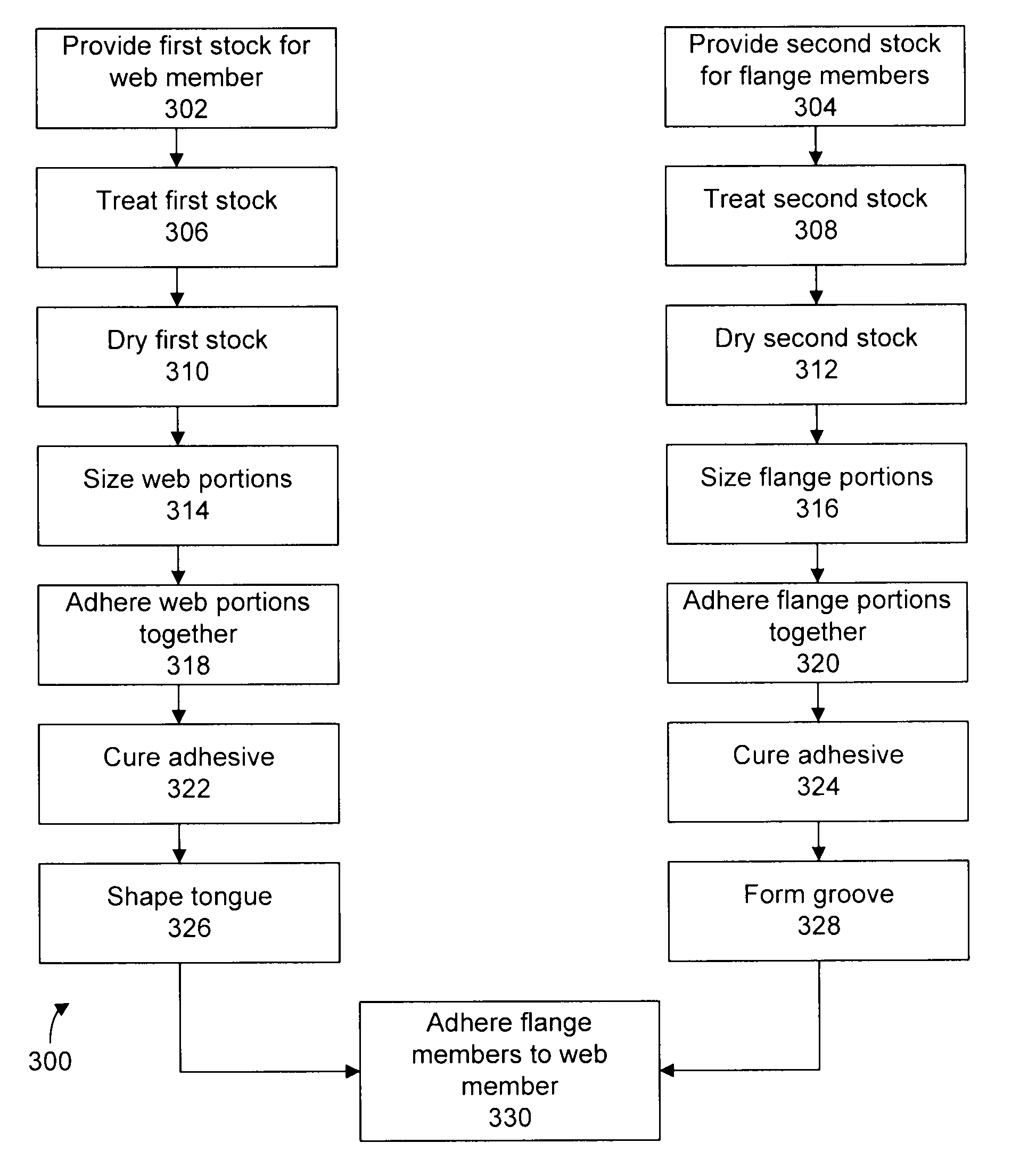

Structural member

ActiveUS8065848B2Sufficient constructionHigh strengthStrutsSynthetic resin layered productsFiberCarbon fibers

A system and method of manufacture providing reinforced structurally functional load-bearing members, including but not limited to using thermoplastic materials, such as High Density Polyethylene (HDPE) or polypropylene (PP), reinforced such as with an aluminum alloy, glass-reinforced polyurethane (foamed or unfoamed), or carbon fiber core element. Among its possible uses, the present invention has application for provision of structural support members, such as an illustrative I-joist product having a vertical center member preferably comprising a thermoplastic material, and top and bottom flanges having structurally meaningful reinforcement. The center member and flanges preferably comprising a thermoplastic material provides a relatively hard, durable, substantially weather-resistant structure. Certain embodiments of the present invention include reinforcing members having a plurality of lobes or arms. Additional embodiments include indentations along the reinforcing members, such as the arms, to aid in bonding between the thermoplastic outer material and reinforcing member within the thermoplastic material. Certain embodiments of the present invention include reinforcing members used in combination with a foamed area and a thermoplastic material.

Owner:TAC TECH

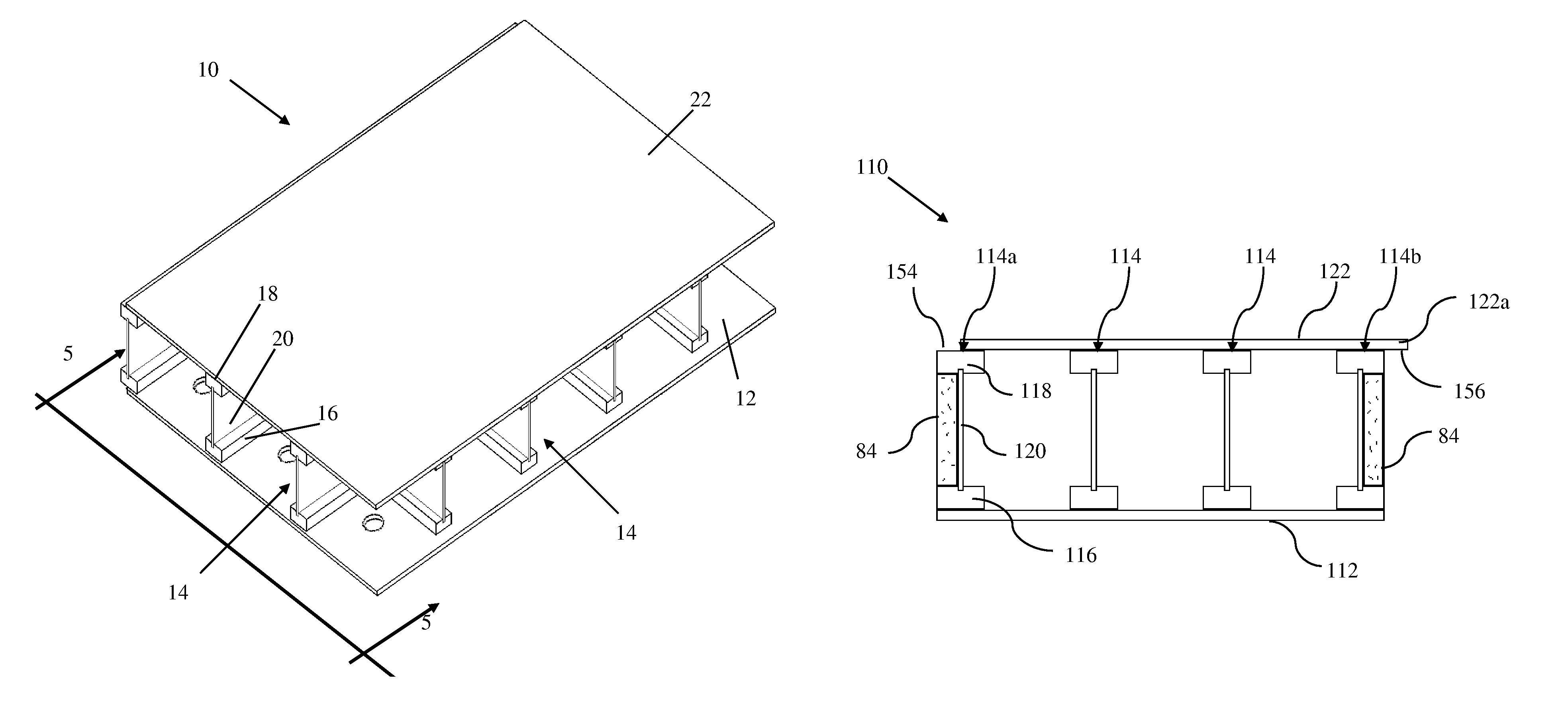

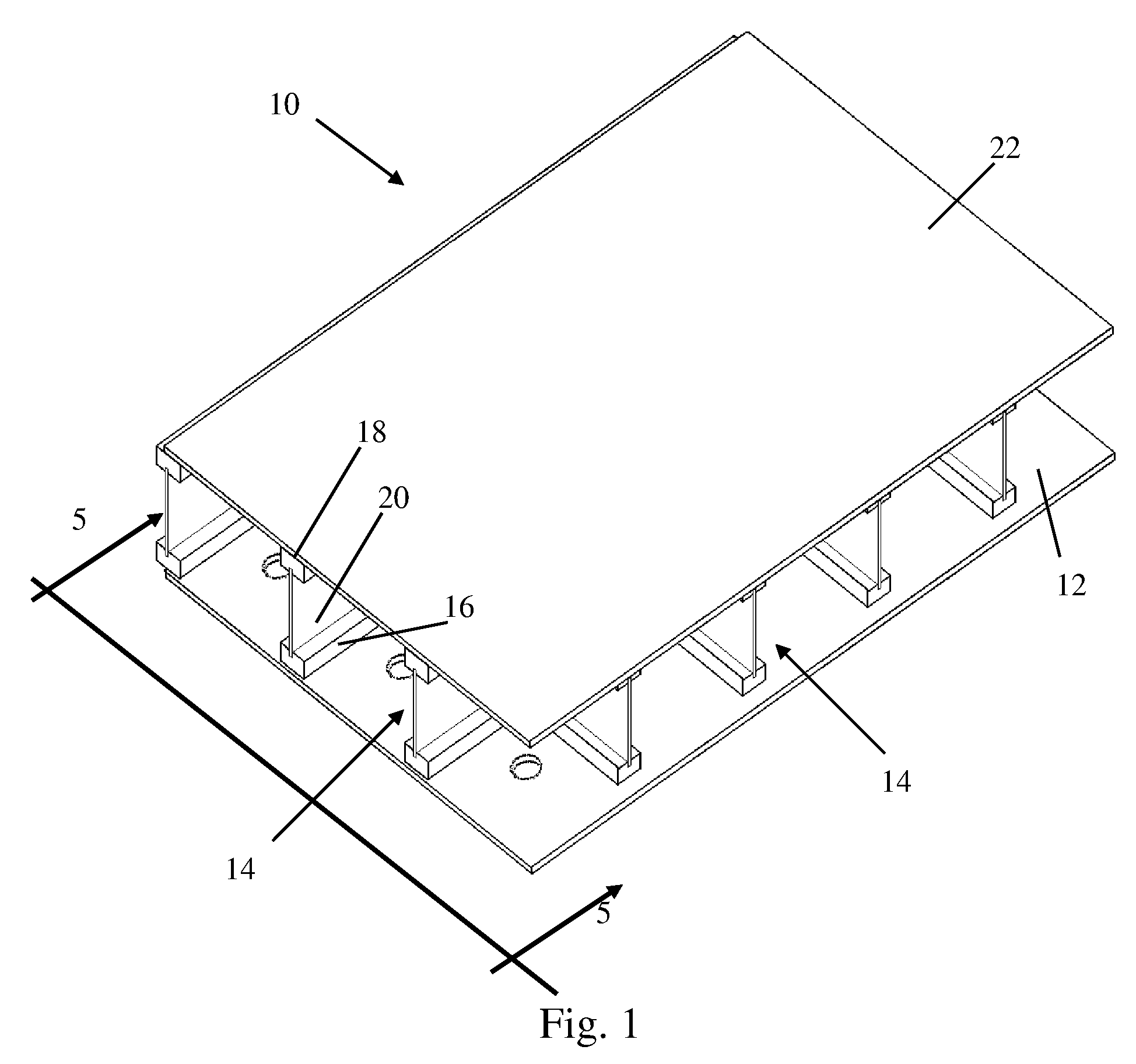

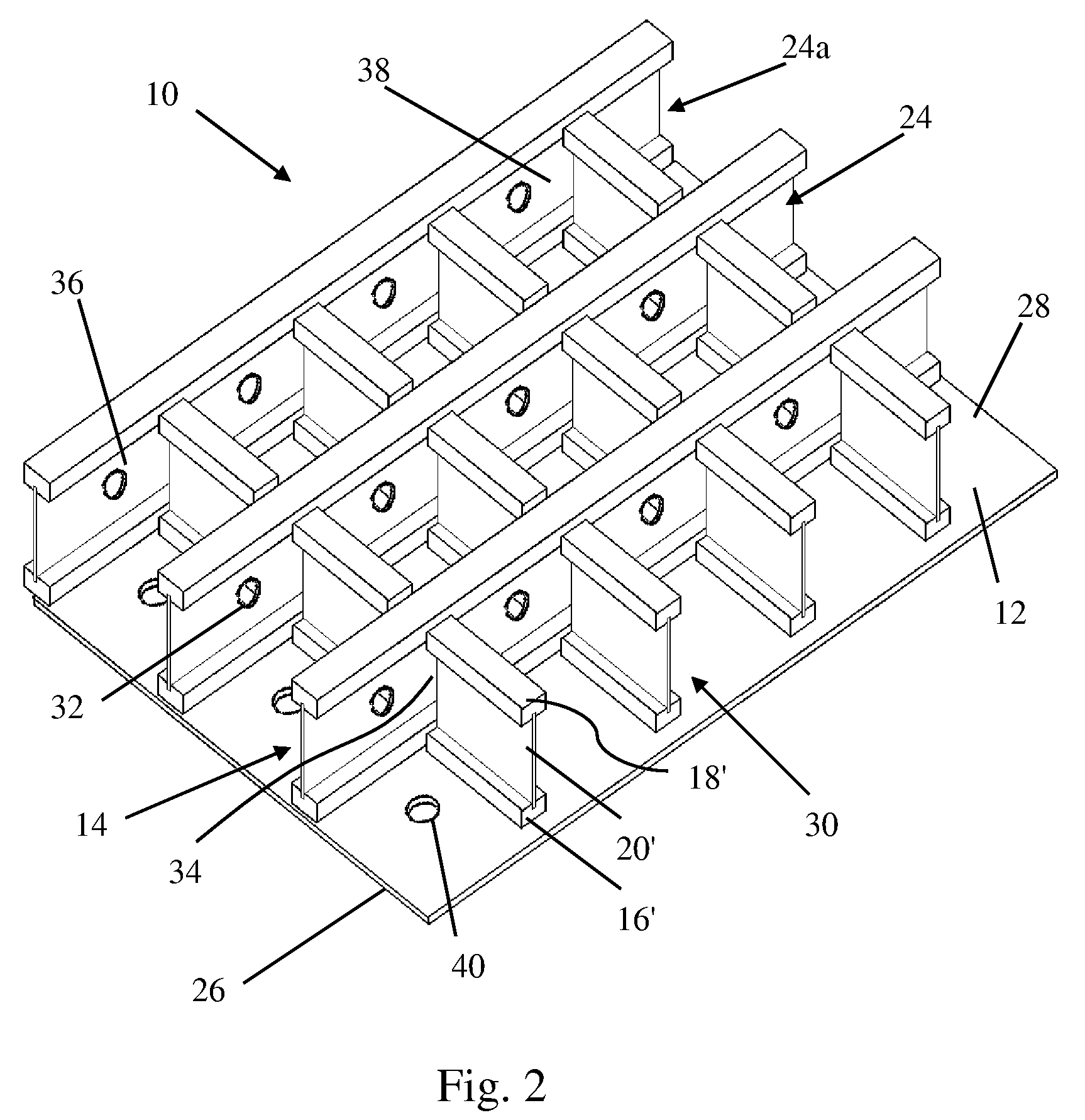

Roofing panel assembly

A roofing panel assembly is made of a base and a cap as well as a plurality of I-joists having an upper flange, a lower flange and a web. The base is attached to the lower flanges of one or more of the plurality of I-joists and the cap is attached to the upper flanges of one or more of the plurality of I-joists.

Owner:UNIVERSITY OF MAINE

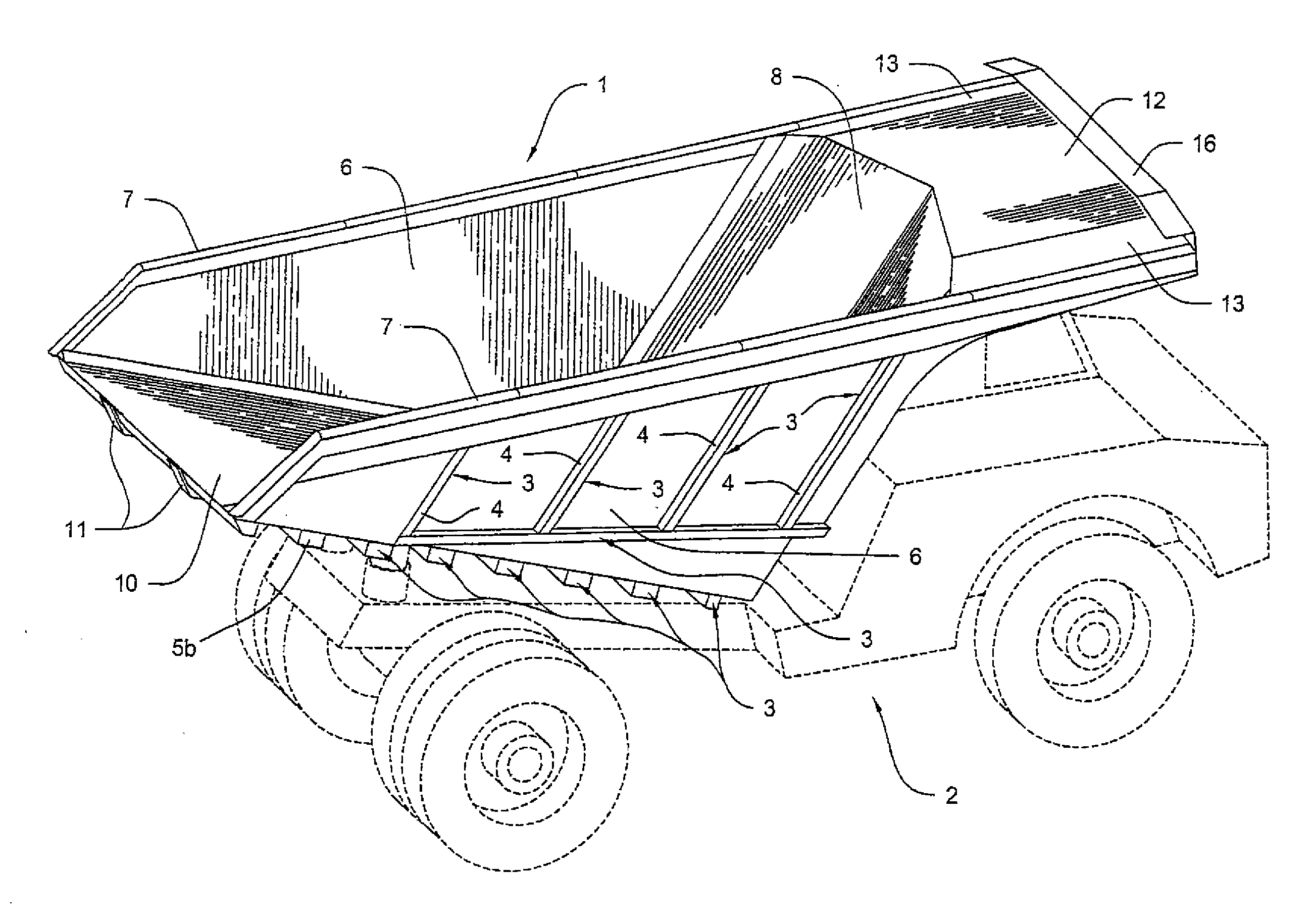

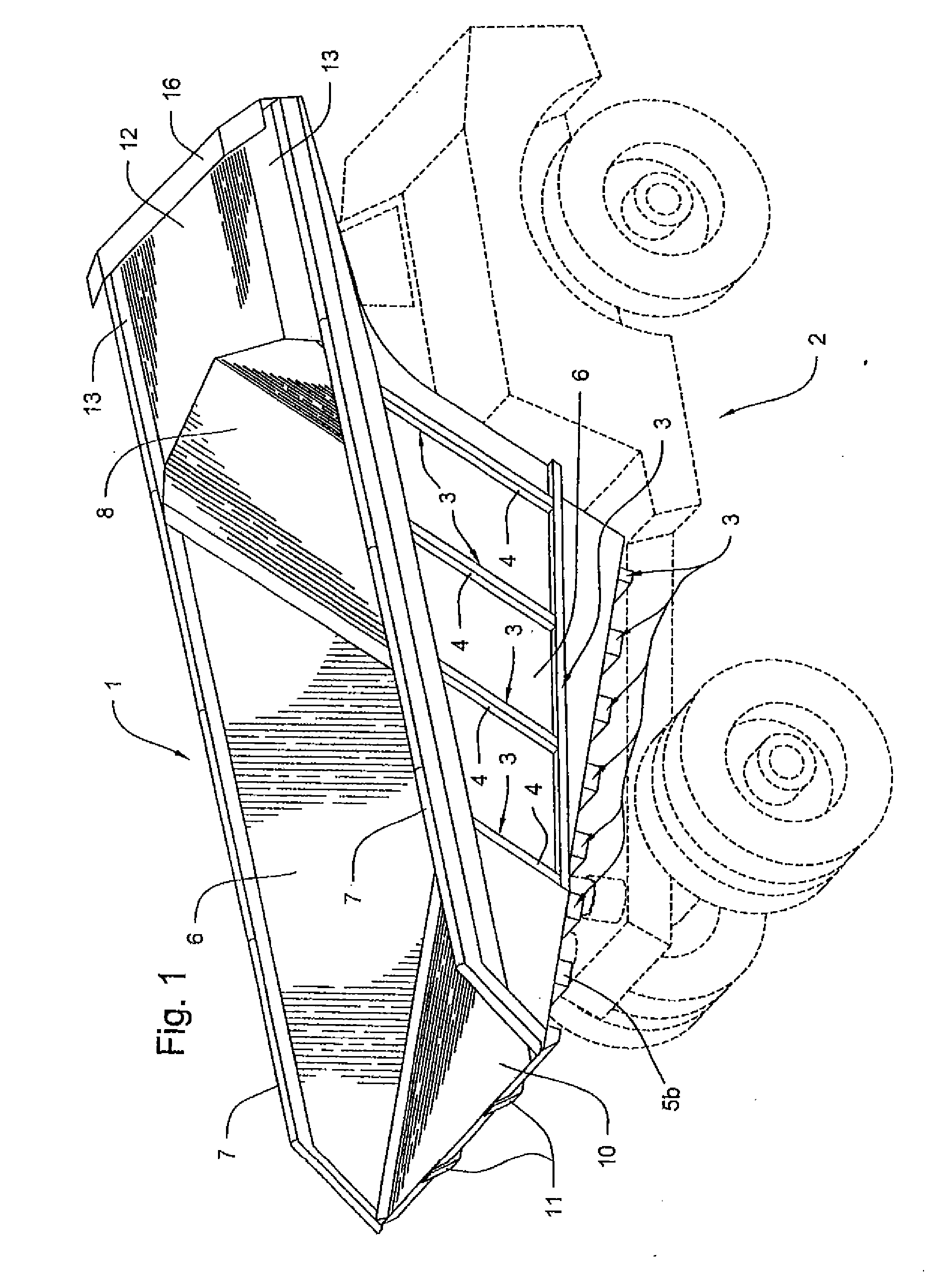

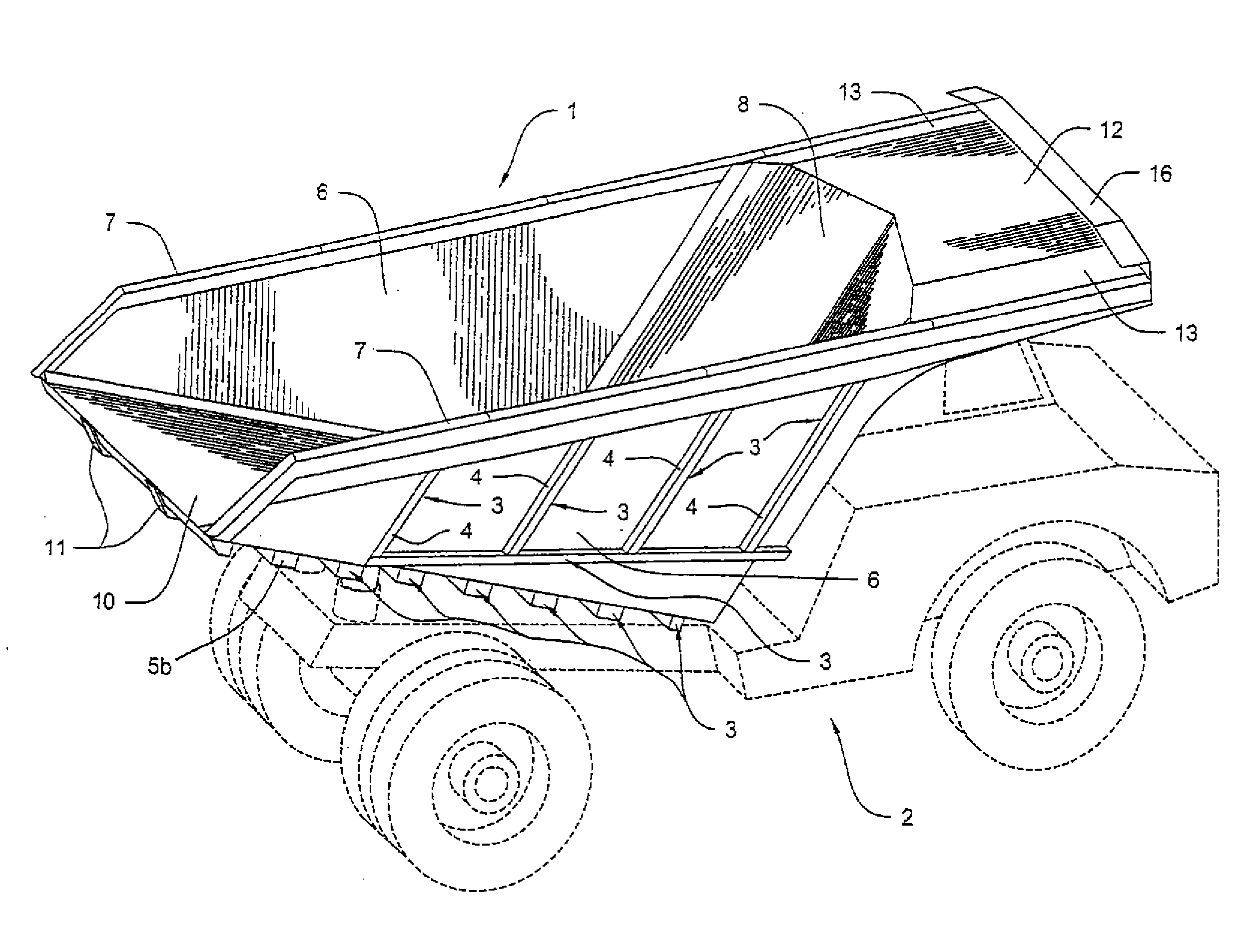

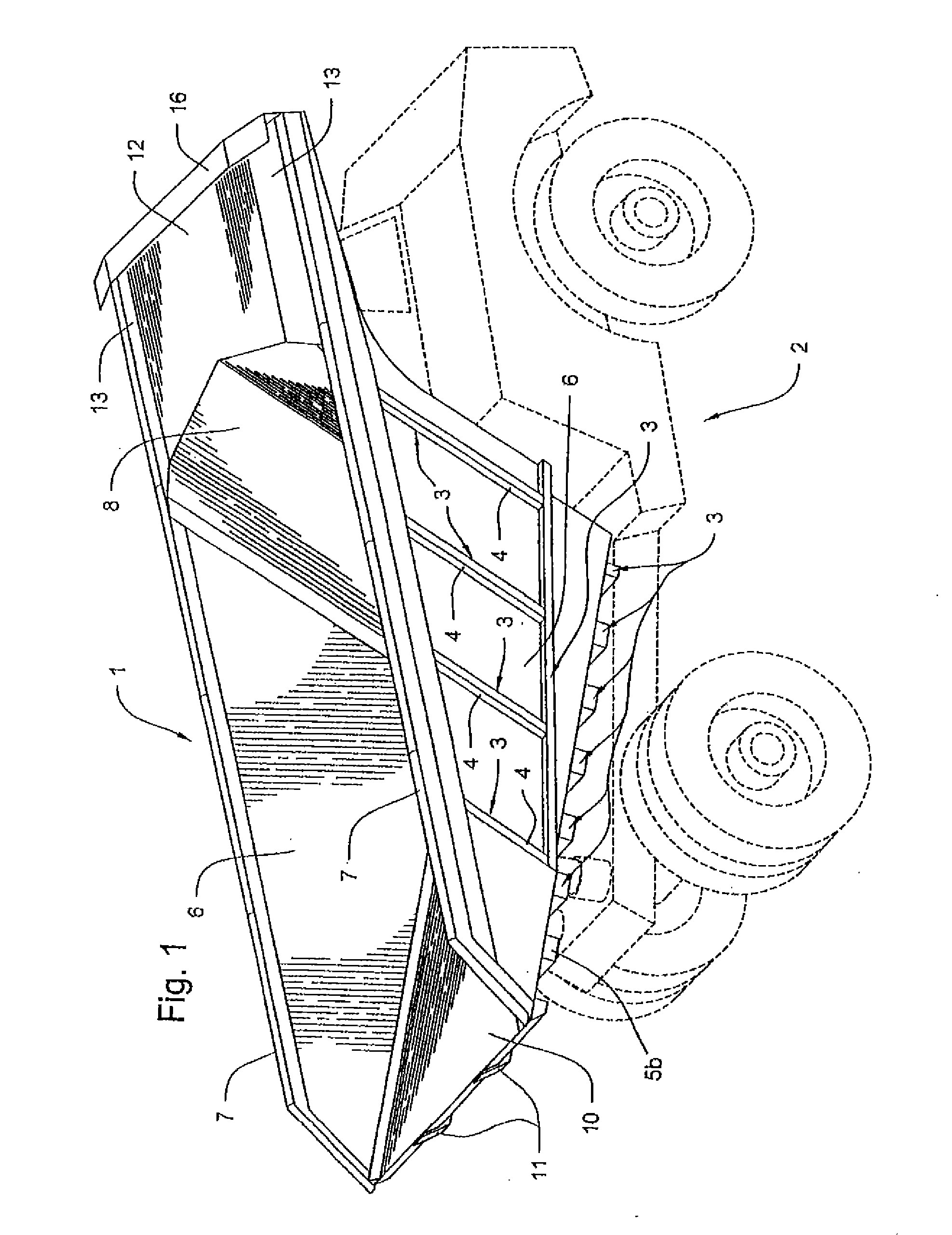

Tube-style truck body

An off-highway truck body comprising a plurality of tube-style support members, wherein each tube-style support member comprises one or two pieces of square tubing, wherein the truck body comprises two sidewalls, a floor, a front wall and a canopy, and wherein one side of each tube-style support member is welded to the outside of the sidewall, floor, front wall or canopy. The pieces of square tubing are preferably comprised of steel. The present invention optionally comprises a forward wedged front wall and a side-sloped canopy. The present invention also encompasses a tube-style tailgate and an alternate embodiment in which I-beams are used in lieu of square tubing.

Owner:THINK RITE INTPROP LLC

Engineered structural members and methods for constructing same

A system and method of manufacture providing reinforced structurally functional load-bearing members, including but not limited to using thermoplastic materials, such as High Density Polyethylene (HDPE), reinforced such as with an aluminum alloy or carbon fiber core element. Among its possible uses, the present invention has application for provision of structural support members, such as an illustrative I-joist product having a vertical center member preferably comprising HDPE, and top and bottom flanges having structurally meaningful reinforcement. The center member and flanges preferably comprising HDPE provides a relatively hard, durable, substantially weather-resistant structure.

Owner:TAC TECH

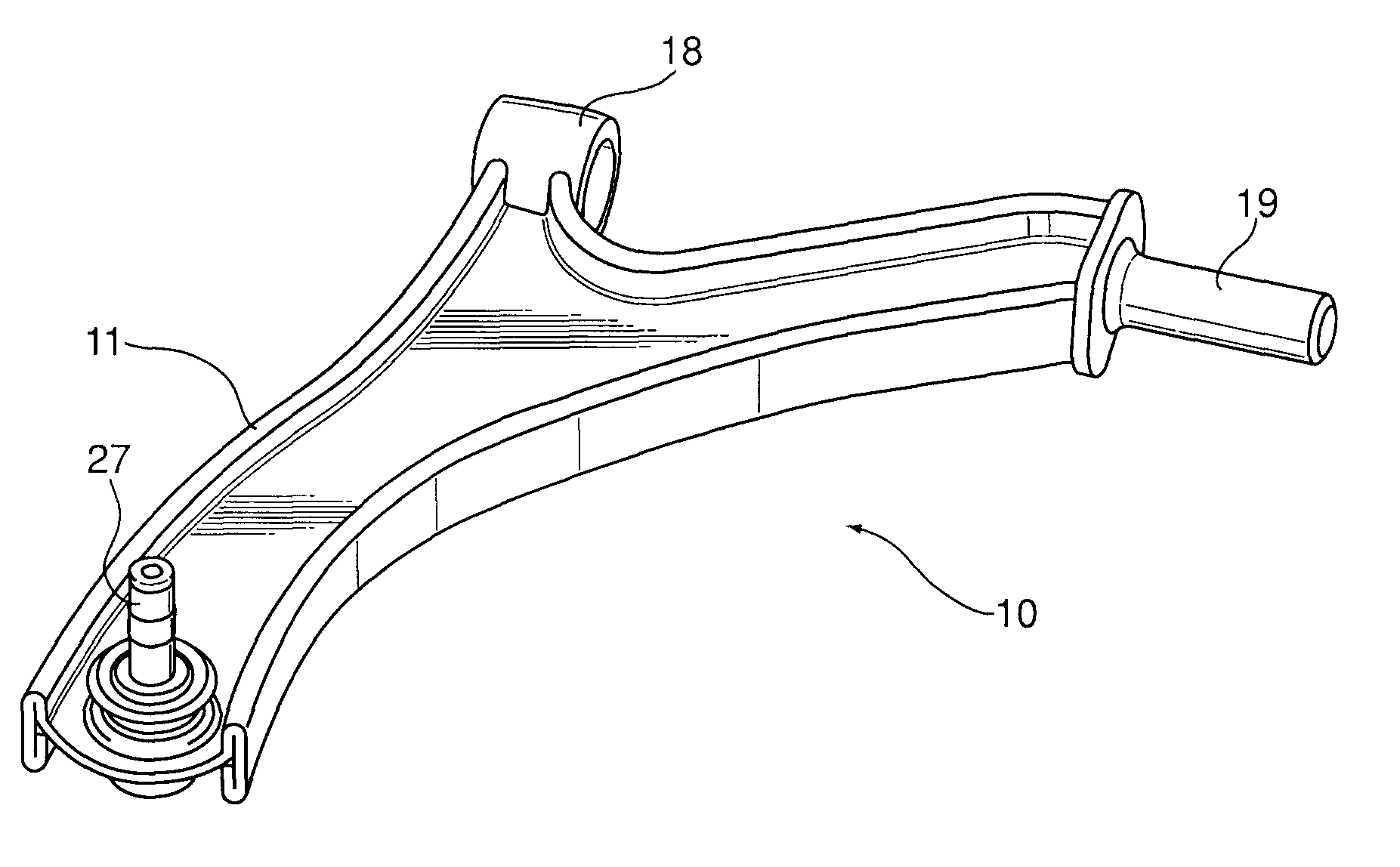

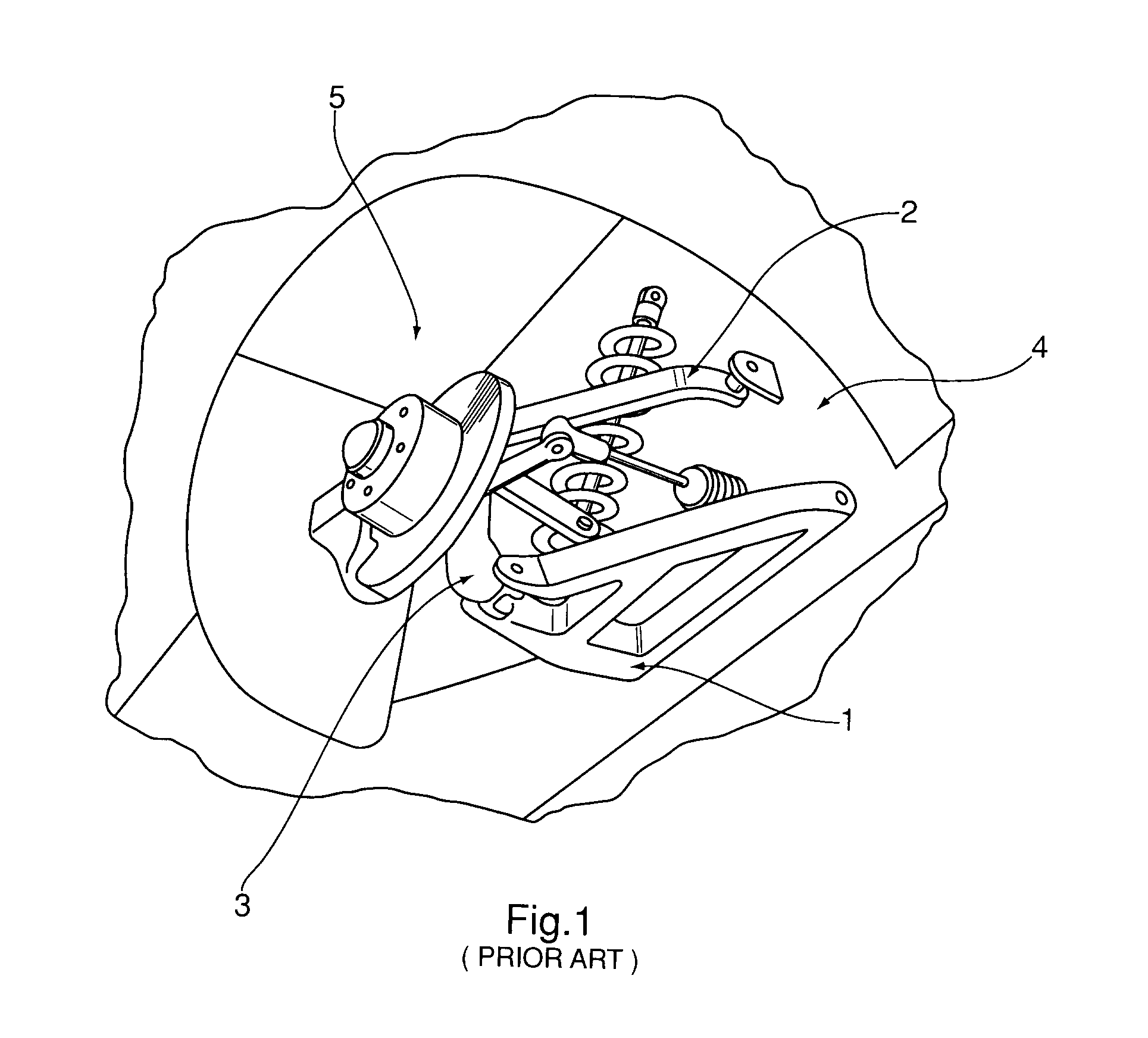

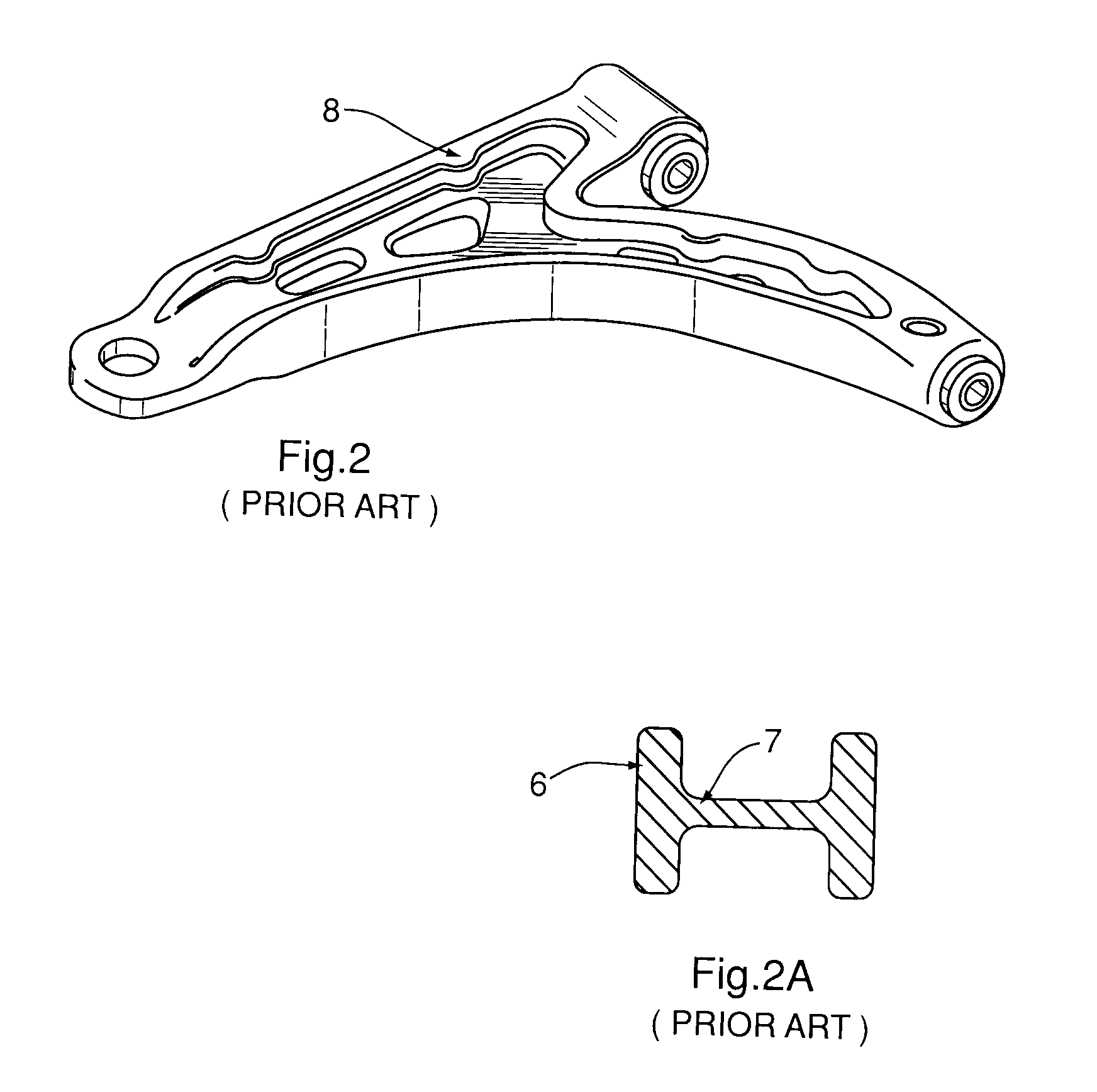

Structural i-beam automotive suspension arm

ActiveUS20100264615A1High inherent stiffness and strengthReduce quality problemsResilient suspensionsPivoted suspension armsControl armI-joist

A structural element comprising a vehicle suspension control arm is constructed from a complex, single piece, sheet metal stamped component formed from a material of uniform thickness. The stamping is configured with the correct plan view shape and formed into an I-beam cross-section comprising a central web portion and two flange portions. The central web portion is configured as a single material thickness and the flange portions comprise upstanding and downstanding closed sections with a continuous double returned segment. The open ends of the sheet metal terminate at or near the central web portion and are welded to the web portion, and in an alternative embodiment also to the continuous double returned segment, to create a favorable structural I-beam section with flange portions twice the thickness of the web portion.

Owner:MULTIMATIC INC

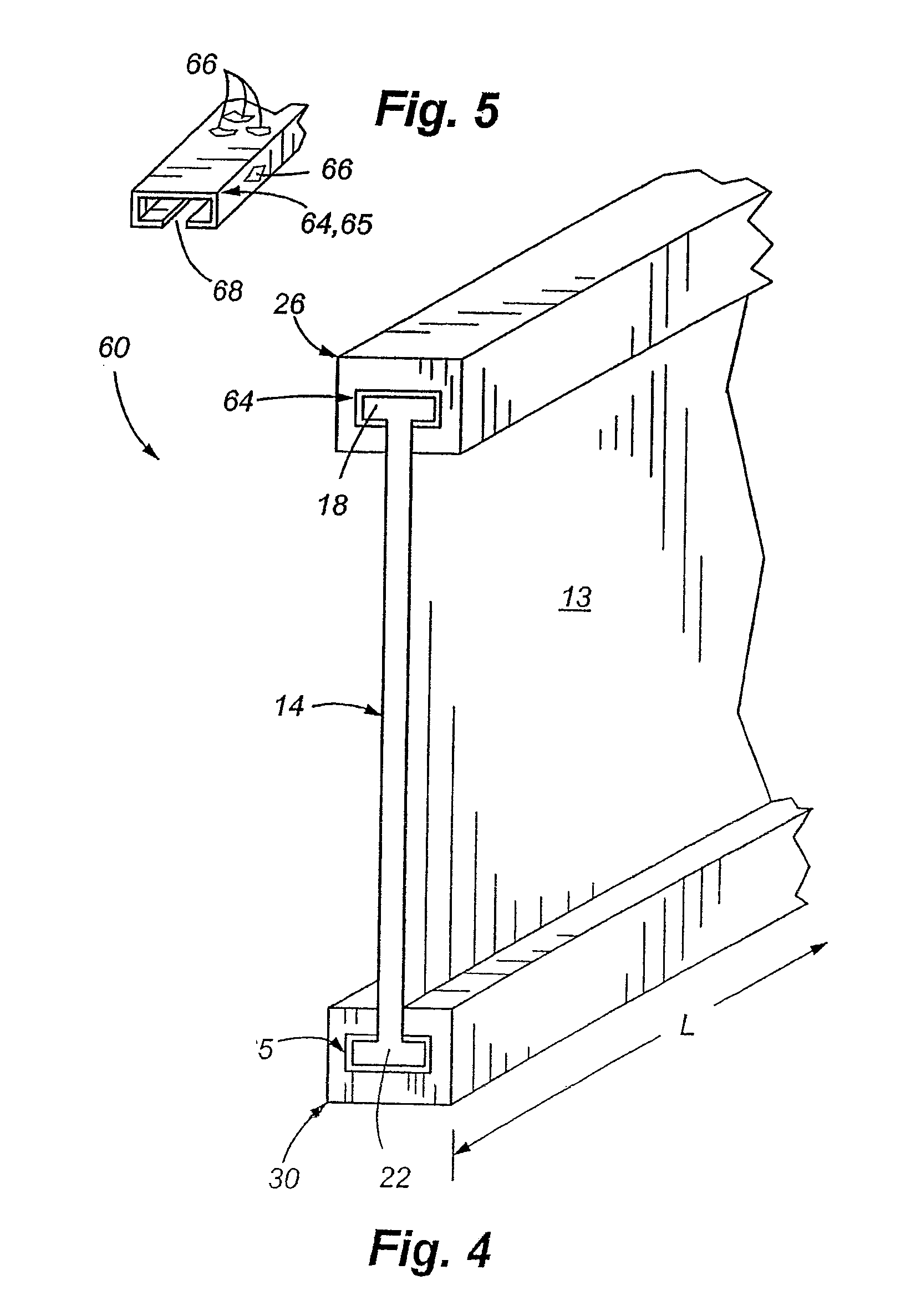

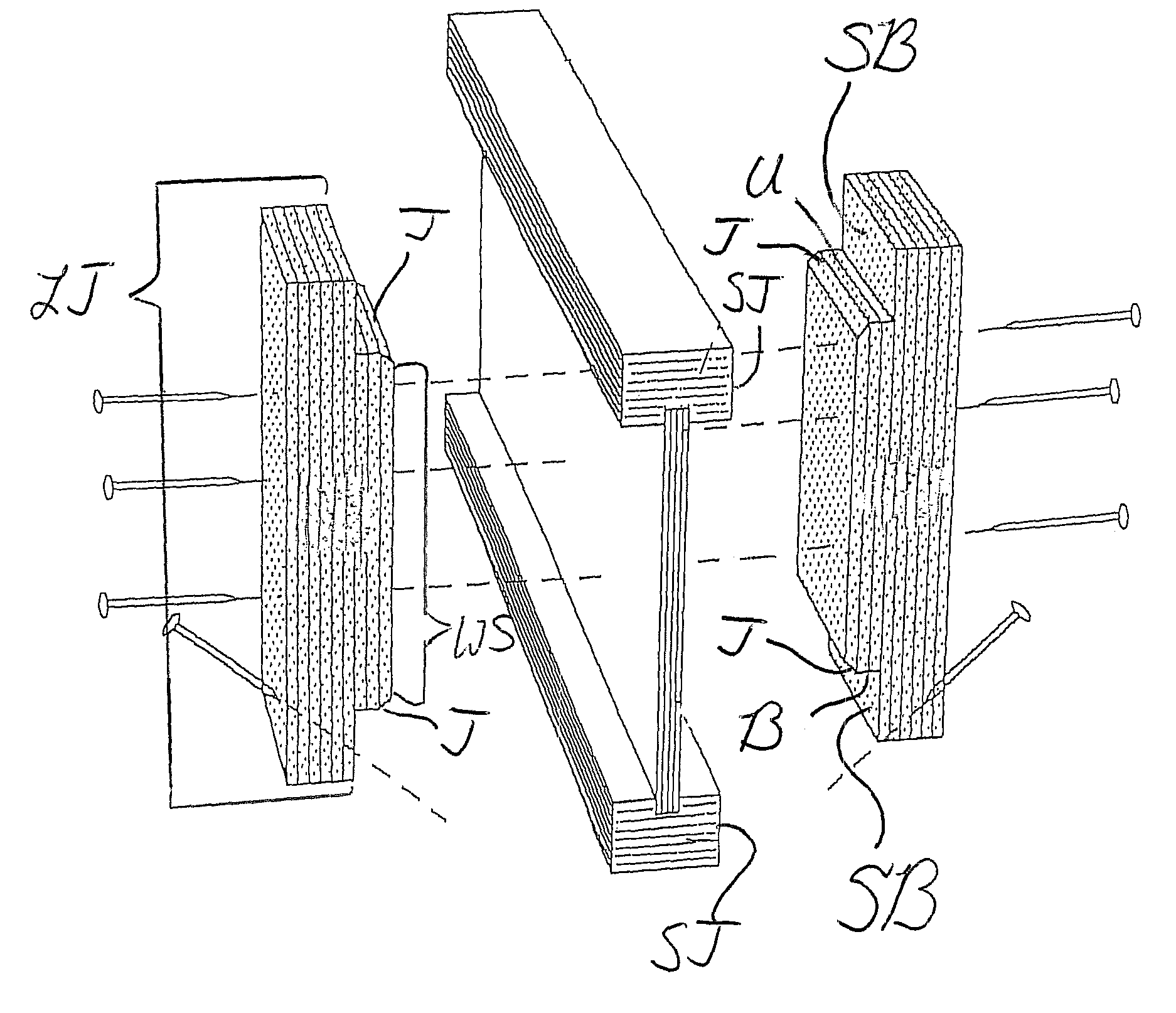

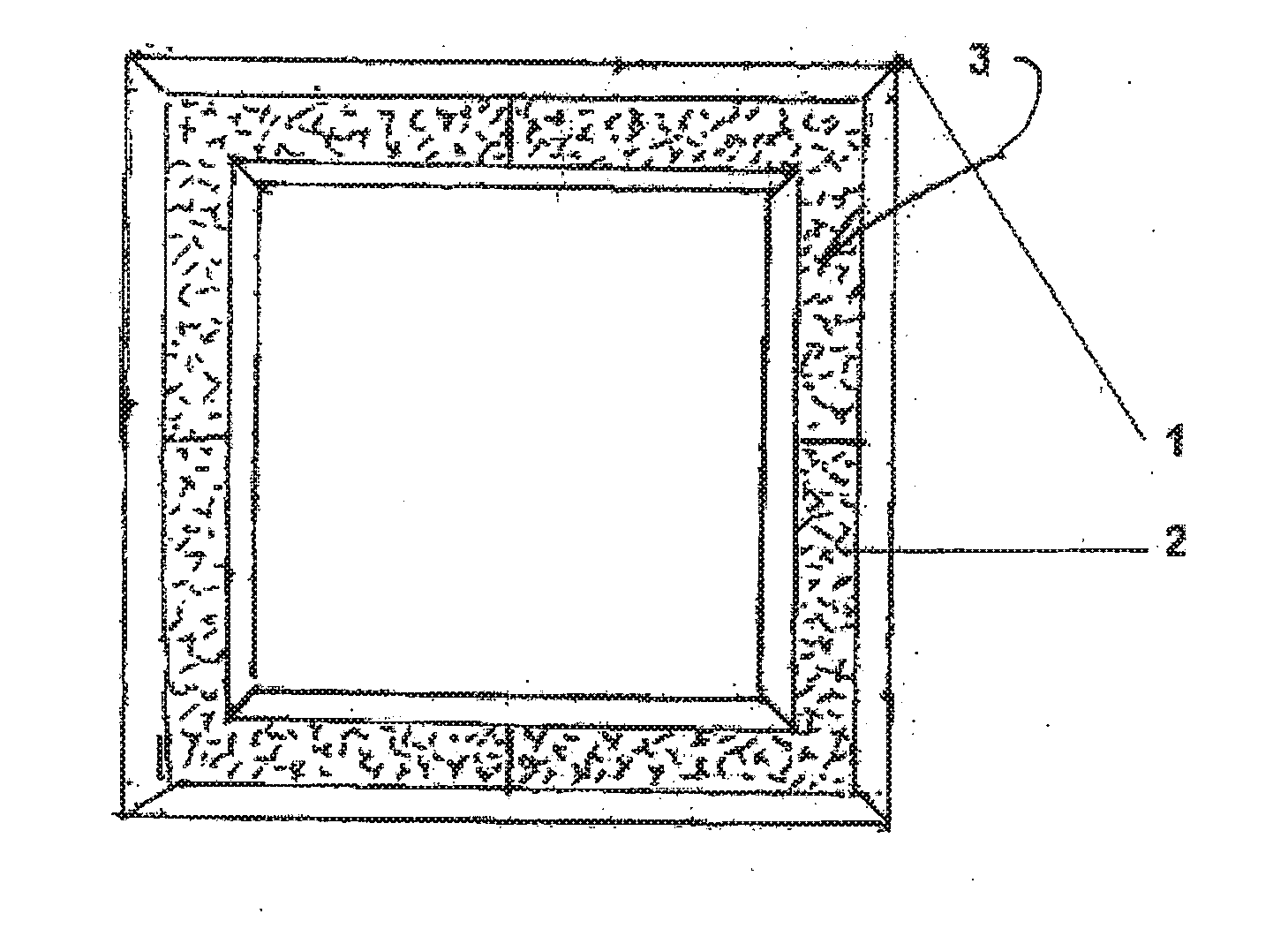

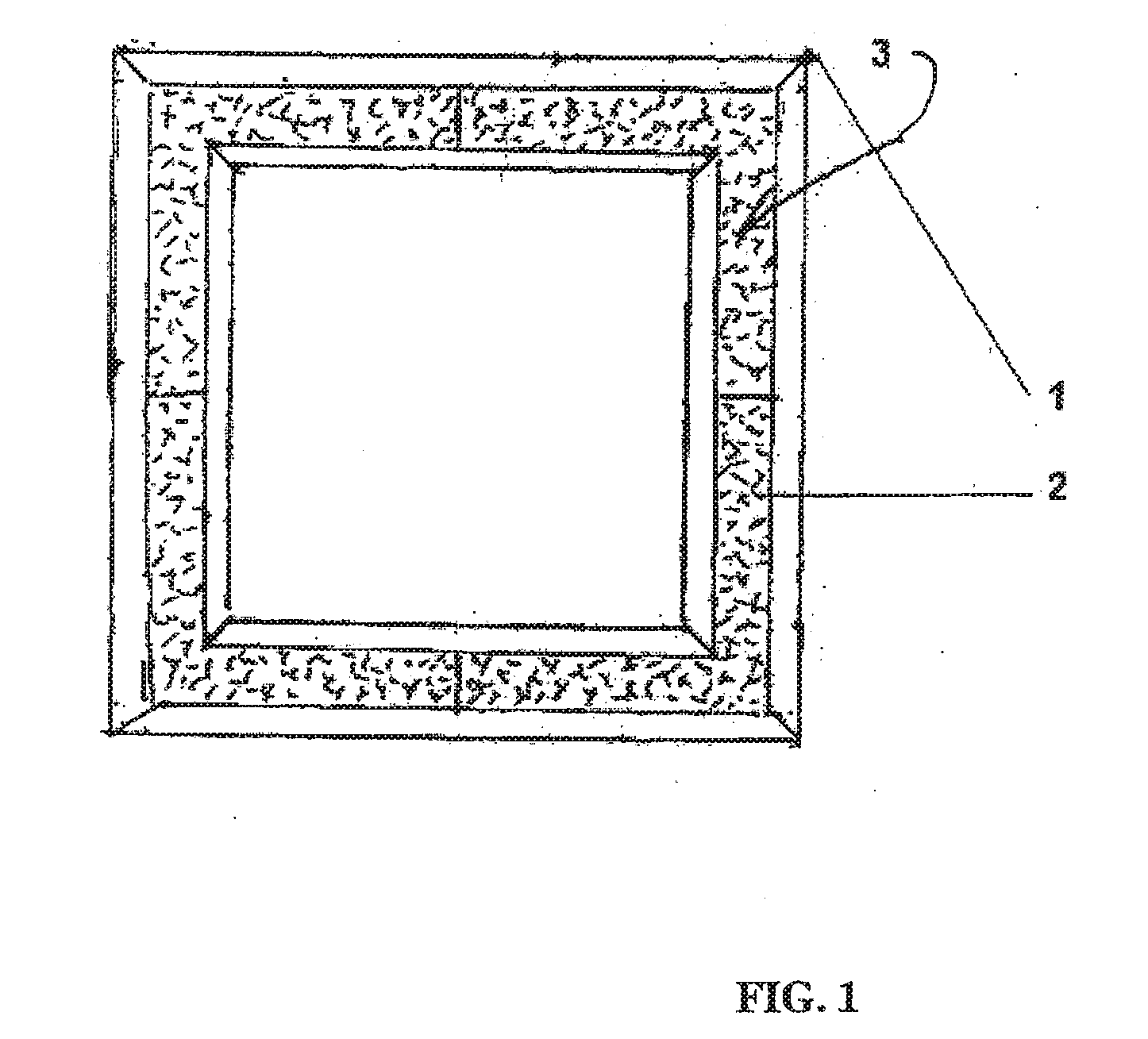

Insulated blocking panels and assemblies for I-joist installation in floors and ceilings and methods of installing same

InactiveUS7827763B2Shorten speedImprove insulation performanceBuilding roofsFloorsI-joistLateral shear

Apparatus and methods for spacing, securing, and stabilizing I-joists at their ends, and insulating and structural enhancing I-joist assemblies, are provided around the perimeter, or in the interior, of a floor or ceiling where ends of I-joists are located. Insulated blocking panels may comprise an insulating portion that provides a high-R-value and a structural portion which may comprise vertical panel(s) and optional integral support blocks that provide a profiled end surface for extending to the web of the I-joists. Alternatively, insulated blocking panels with flat, vertical end surfaces may be used with field-installed support blocks, or insulated blocking panels with profiled end surfaces may be used without any support blocks. The support blocks or profiled end surfaces of the insulated blocking panels extend to the web of each I-joist, to fill in the space between the I-joists near the I-joist ends, including a substantial amount of the space immediately adjacent the web of each I-joist. The preferred insulated blocking panels, therefore, insulated the outer perimeter of a floor or ceiling and also contribute vertical load carrying capability, and lateral shear and roll-over resistance.

Owner:SILPRO

I-joist frame system with bevelled front edge

InactiveUS20110056106A1Easily be un-assembled and re-assembledSave moneyPicture framesDomestic mirrorsI-joistJoist

This is a frame system that allows for the assembly of an artist frame and a surface material over the frame where there is no need for internal bracing of the frame and the contact area between the surface material and the frame is minimized. The framing system comprises pre-fabricated sections of a frame that incorporate an I-Joist design with a beveled edge lip on the front facing side. When these frame sections are assembled any stretchable material such as canvas, cloth, or plastic can be pulled over the front of the frame with the lip and connected to the back side at the top or bottom of the modular I-Joist frame.

Owner:BOSMA GEORGE THOMAS

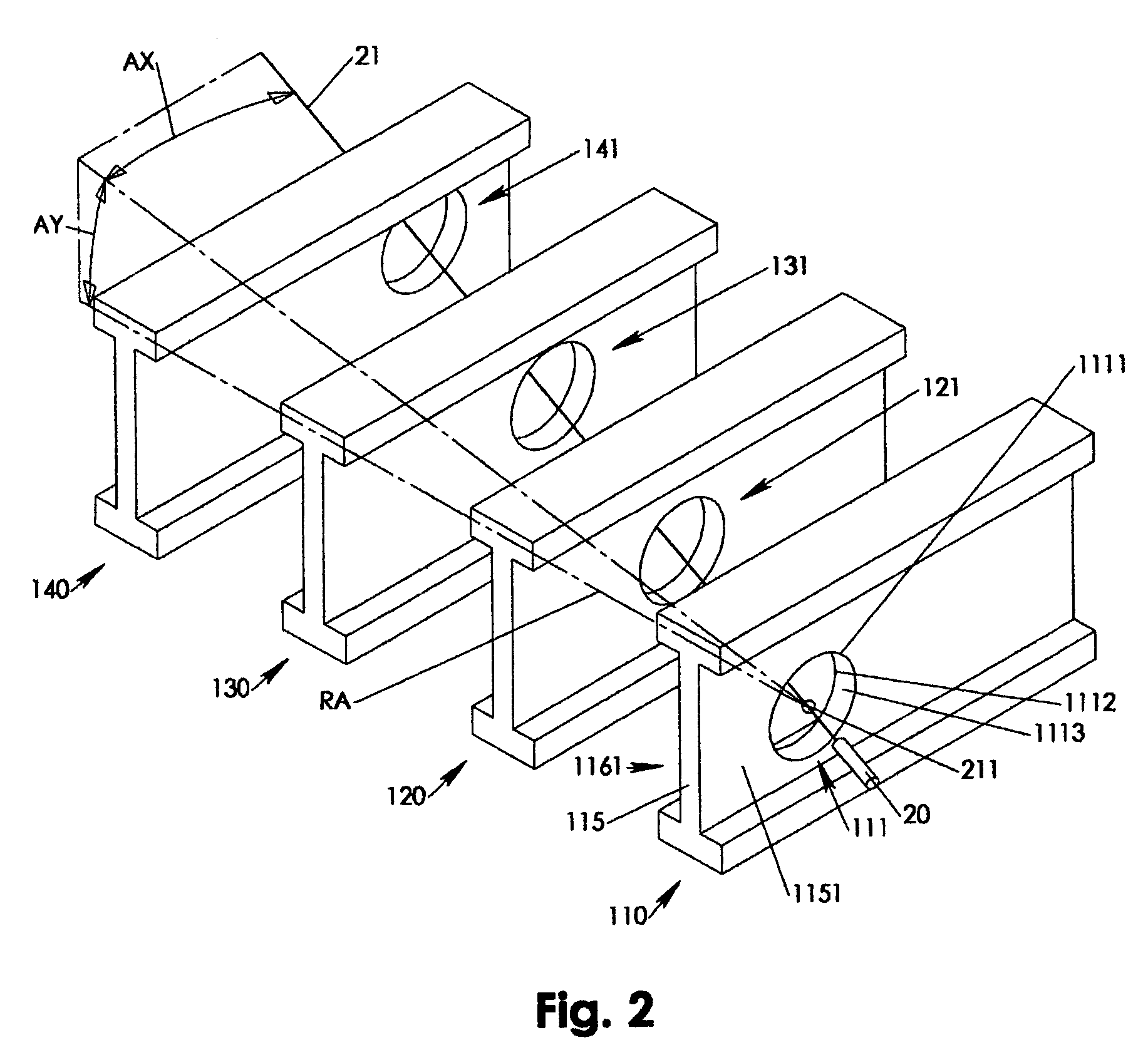

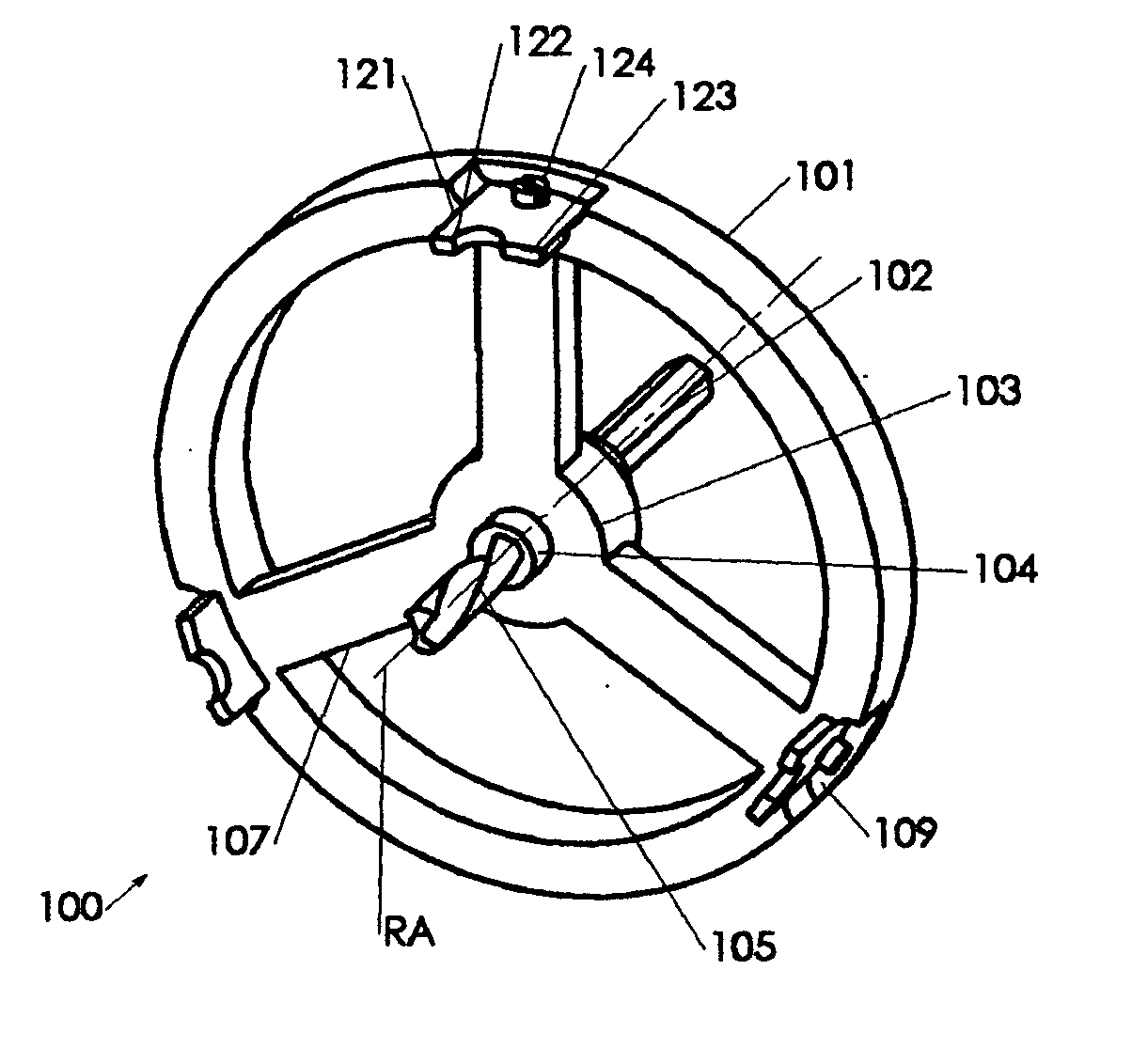

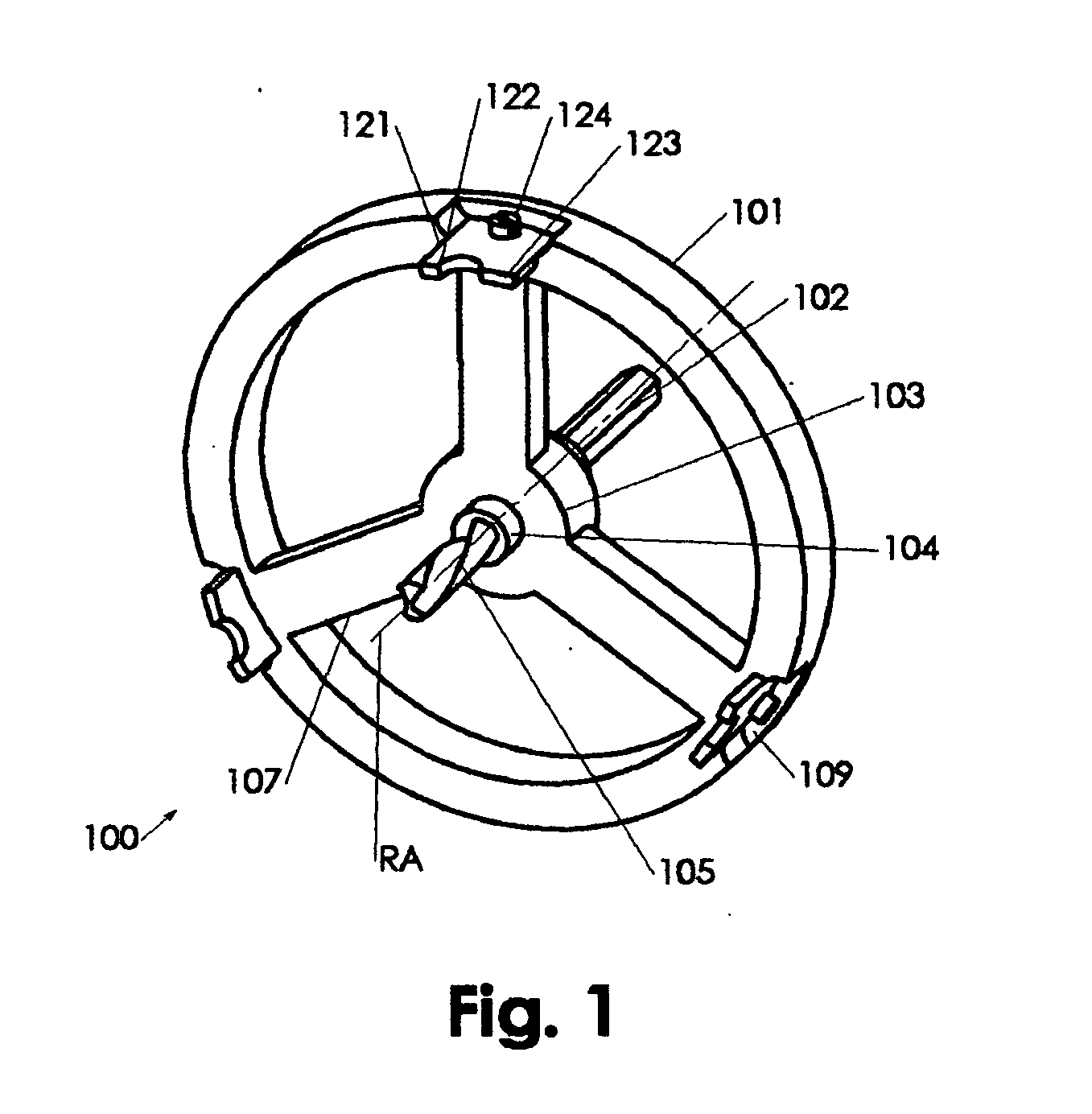

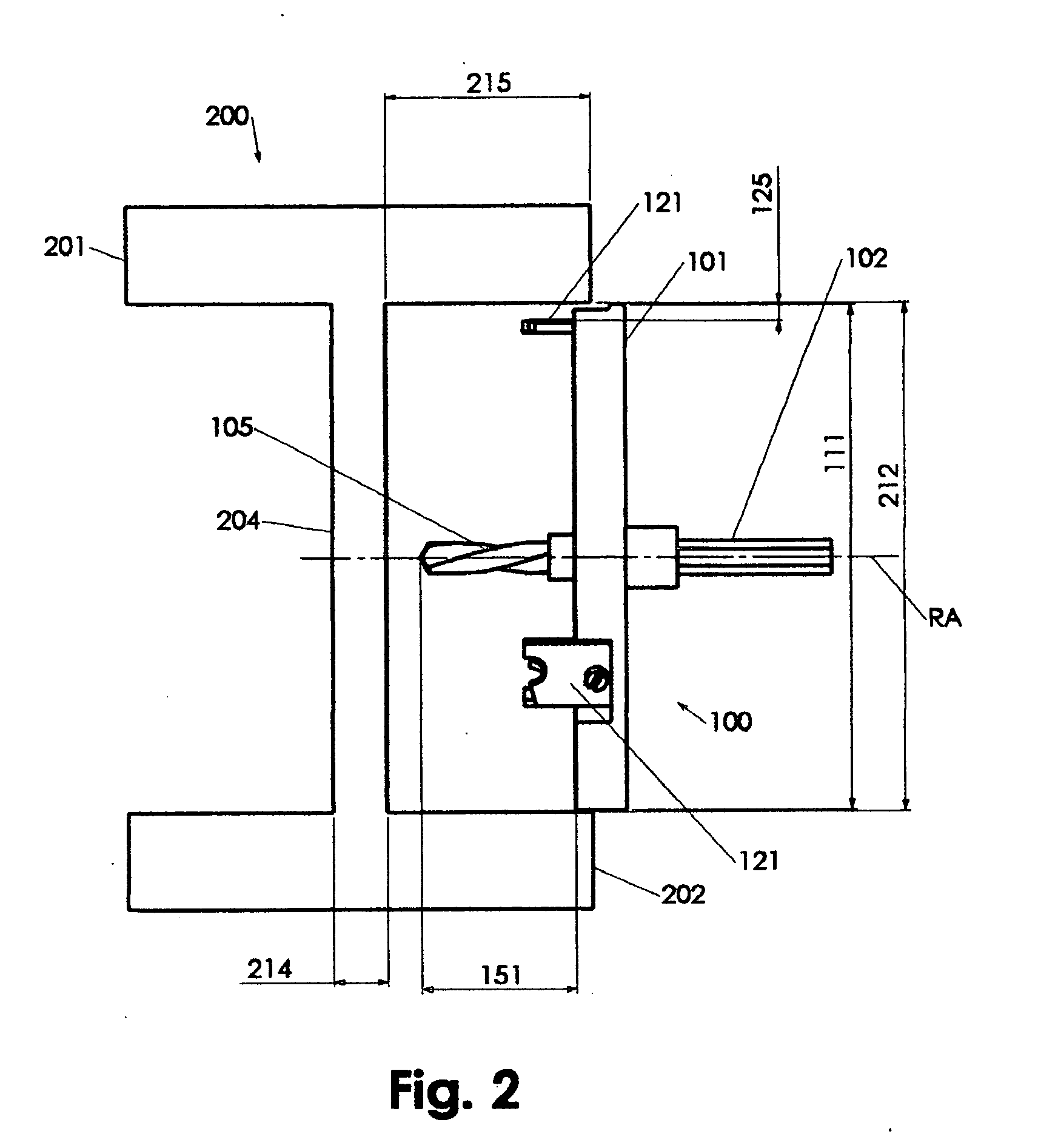

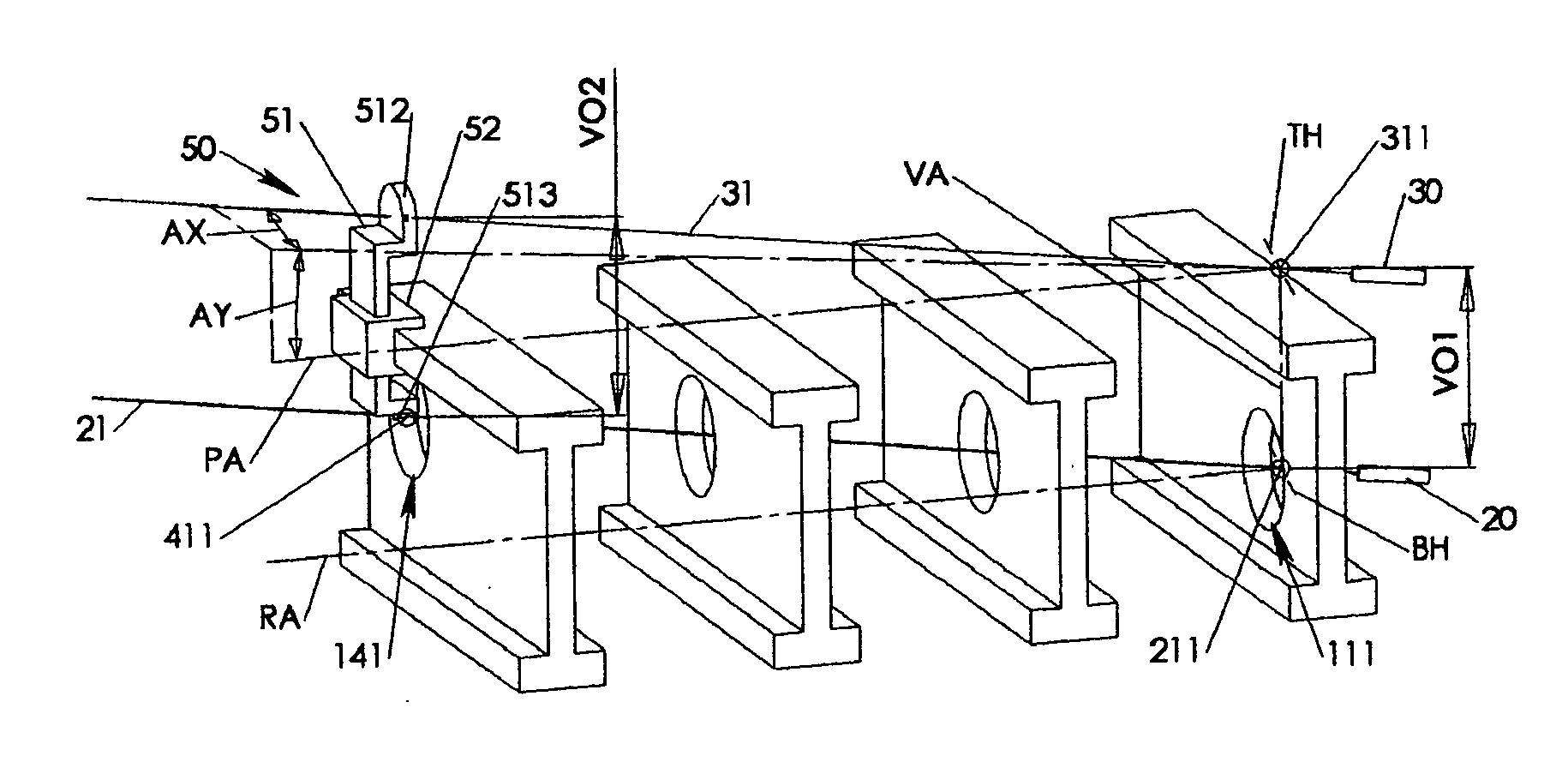

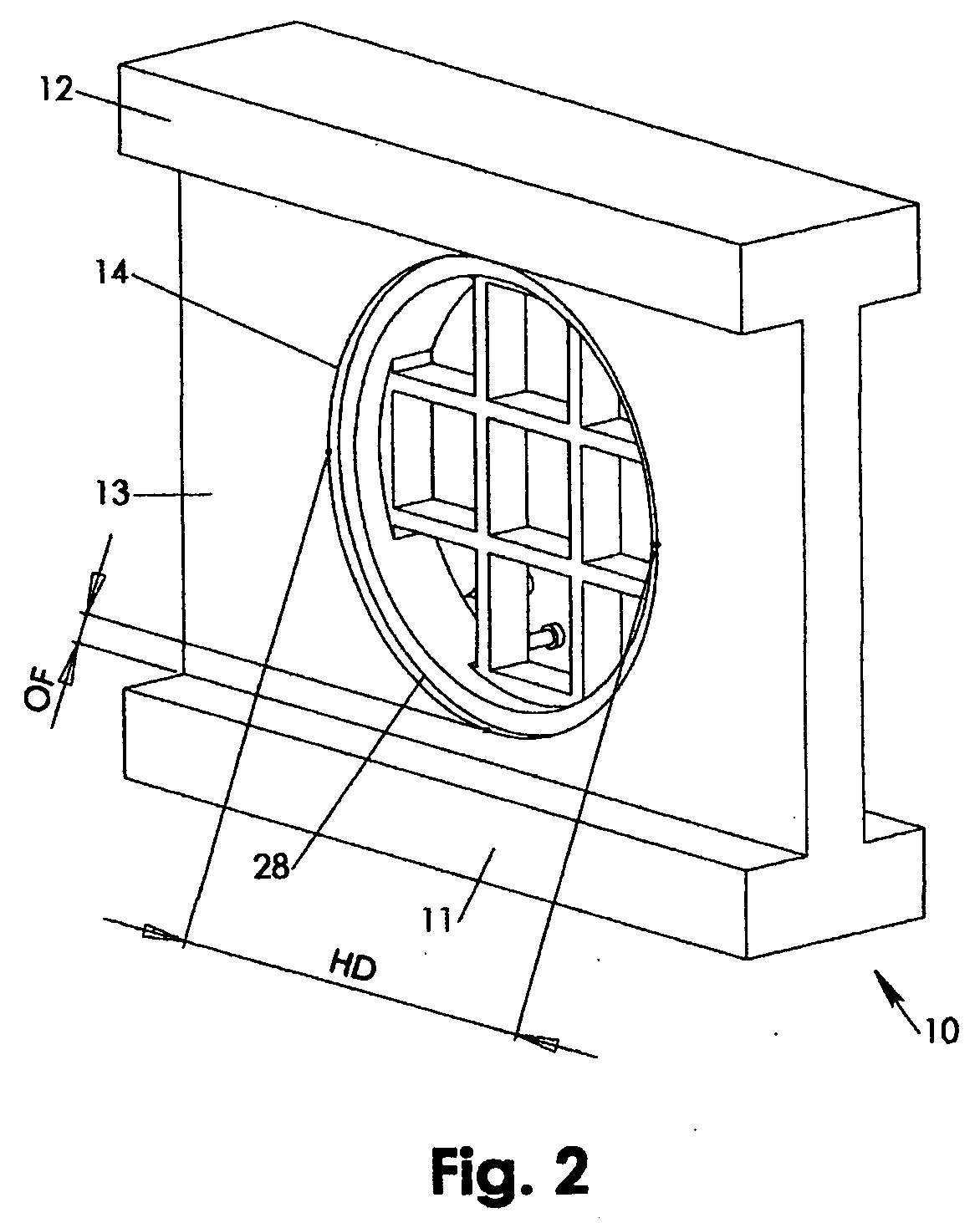

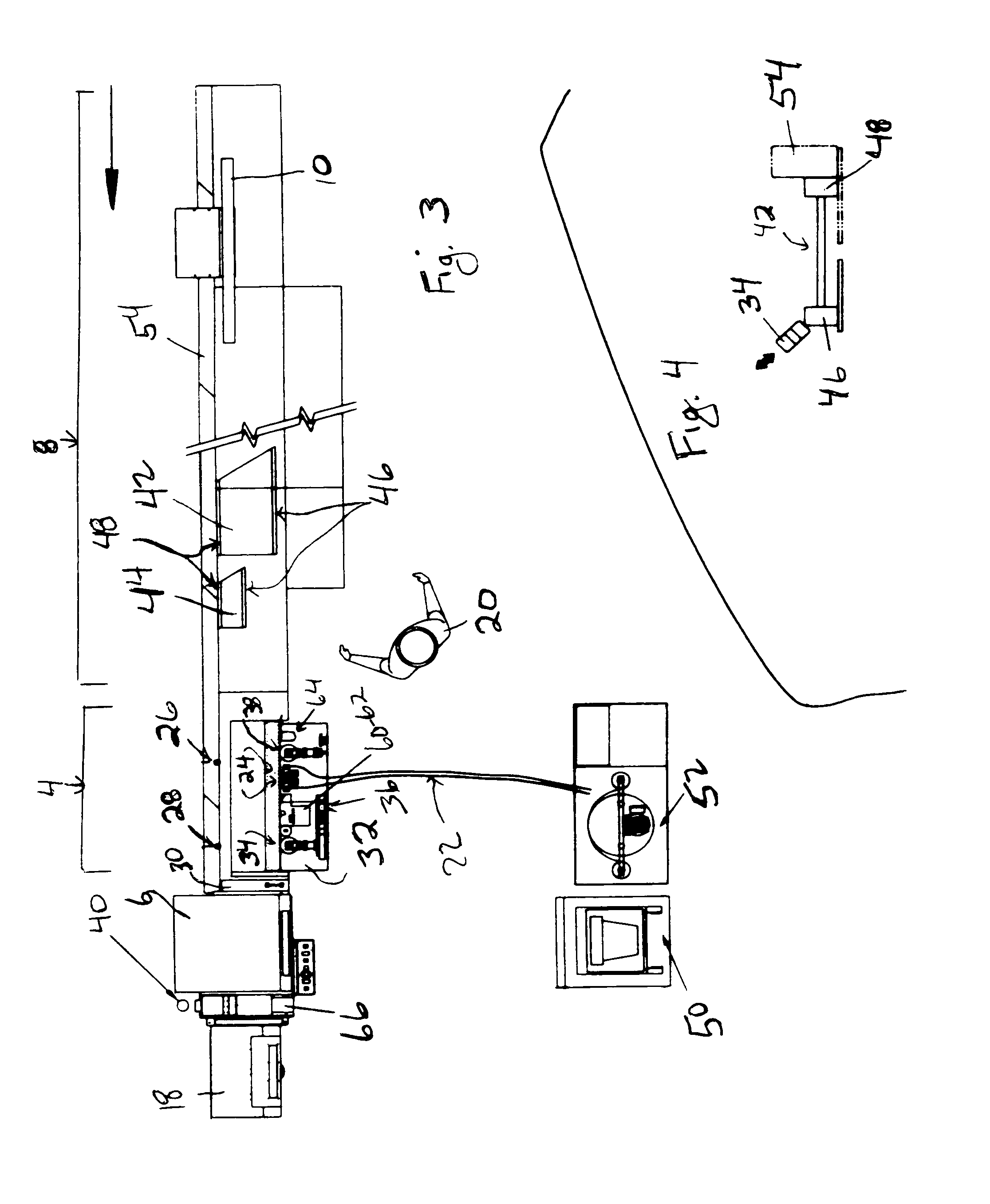

Laser marking device for serial I-joist cutouts

InactiveUS7194812B2Easy to operateMade preciselyAngles/taper measurementsActive open surveying meansJoistHole saw

A laser marking device includes a fixture for temporarily attaching the device in an initial cutout of a number of serial cutouts to be fabricated in adjacent assembled I-joists. Combined with the fixture is an angle gage that provides angular positioning of a marking laser. The angle gage is configured to hold the laser with its beam coinciding with the marking origin of the initial cutout, which in case of circular cutout may be the reference center at which the pilot drill of the hole saw is centered at the begin of the cutout operation. The marker laser may be horizontally and / or vertically oriented together with an eventual alignment laser and an eventual target marker temporarily affixed on the I-joist where a final reference point is determined for an axial orientation of the cutouts across the I-joists.

Owner:DAVIS JOHN D

Composite Guardrail Posts and Composite Floor I-Joist

The first product is Composite Guardrail Post (CGP). CGP is designed overcome all these drawbacks by substituting standard timber posts with metal jacket composite posts. The second product is Composite Floor Joist (CFI). The current invention (CFI) is similar to TJI in concept, but uses all composite material for both flanges and webs. Also, the connections between flange and web are much stronger, enabling the development of composite actions to the fullest extent.

Owner:YANG WEIHONG

I-joist hole cutting apparatus

InactiveUS20050105980A1Easy to replaceEqually distributedThread cutting toolsWood turning toolsHole sawI-joist

A hole saw for cutting standardized holes in the web portion of an I-joist features a light weight saw body having a flywheel configuration and preferably three inserted cutting blades fixed within clamp cavities in an offset to the circumference, which is dimensioned in accordance to standard web heights. The flywheel configuration provides for smooth operation at high rotational speeds in combination with intermittent actuation of the circumferentially arrayed cutting blades.

Owner:DAVIS JOHN D

Laser marking device for serial I-joist cutouts

InactiveUS20050223572A1Easy to operateMade preciselyAngles/taper measurementsActive open surveying meansI-joistHole saw

A laser marking device includes a fixture for temporarily attaching the device in an initial cutout of a number of serial cutouts to be fabricated in adjacent assembled I-joists. Combined with the fixture is an angle gage that provides angular positioning of a marking laser. The angle gage is configured to hold the laser with its beam coinciding with the marking origin of the initial cutout, which in case of circular cutout may be the reference center at which the pilot drill of the hole saw is centered at the begin of the cutout operation. The marker laser may be horizontally and / or vertically oriented together with an eventual alignment laser and an eventual target marker temporarily affixed on the I-joist where a final reference point is determined for an axial orientation of the cutouts across the I-joists.

Owner:DAVIS JOHN D

Engineered structural members and methods for constructing same

A system and method of manufacture providing reinforced structurally functional load-bearing members, including but not limited to using thermoplastic materials, such as High Density Polyethylene (HDPE) or polypropylene (PP), reinforced such as with an aluminum alloy, glass-reinforced polyurethane (foamed or unfoamed), or carbon fiber core element. Among its possible uses, the present invention has application for provision of structural support members, such as an illustrative I-joist product having a vertical center member preferably comprising a thermoplastic material, and top and bottom flanges having structurally meaningful reinforcement. The center member and flanges preferably comprising a thermoplastic material provides a relatively hard, durable, substantially weather-resistant structure. Certain embodiments of the present invention include reinforcing members having a plurality of lobes or arms. Additional embodiments include indentations along the reinforcing members, such as the arms, to aid in bonding between the thermoplastic outer material and reinforcing member within the thermoplastic material.

Owner:TAC TECH

Two-part bio-based furfuryl adhesive composition for engineered wood

InactiveUS20070299167A1Readily solubleViscosity of solutionWood layered productsAdhesivesFinger jointI-joist

Adhesive composition derived from tannin-furfuryl alcohol catalyzed by acid in a two-part aqueous system is used to bond a variety of wood substrates to give good bond strength and high percentage of wood failure. The reactivity of the mixed adhesive can be controlled by the proper selection of acid catalyst, catalyst concentration, and adhesive composition. This gives adhesive with a wide range of open time during processing. This adhesive system can be either cold set or heat activated. It can also be cured by radio frequency similar to typical industrial settings. These characteristics make this adhesive system suitable for a number of engineered wood applications such as finger joint, Glulam, I-joist, and LVL.

Owner:ASHLAND LICENSING & INTPROP LLC

I-joist web hole insert

An insert for I-joist web holes provides support and separation for piping, tubing and / or cabling guided through the installed I-joist's web. At the same time, the insert protects the web hole against destructive forces commonly related to the installation process and / or gravitational loads of piping, tubing and / or cabling.

Owner:DAVIS JOHN D

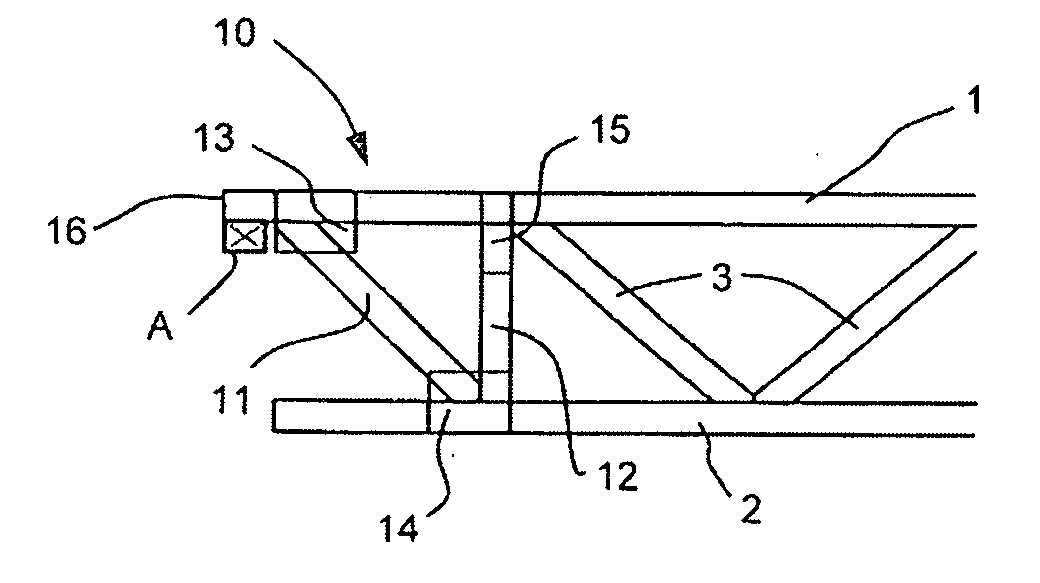

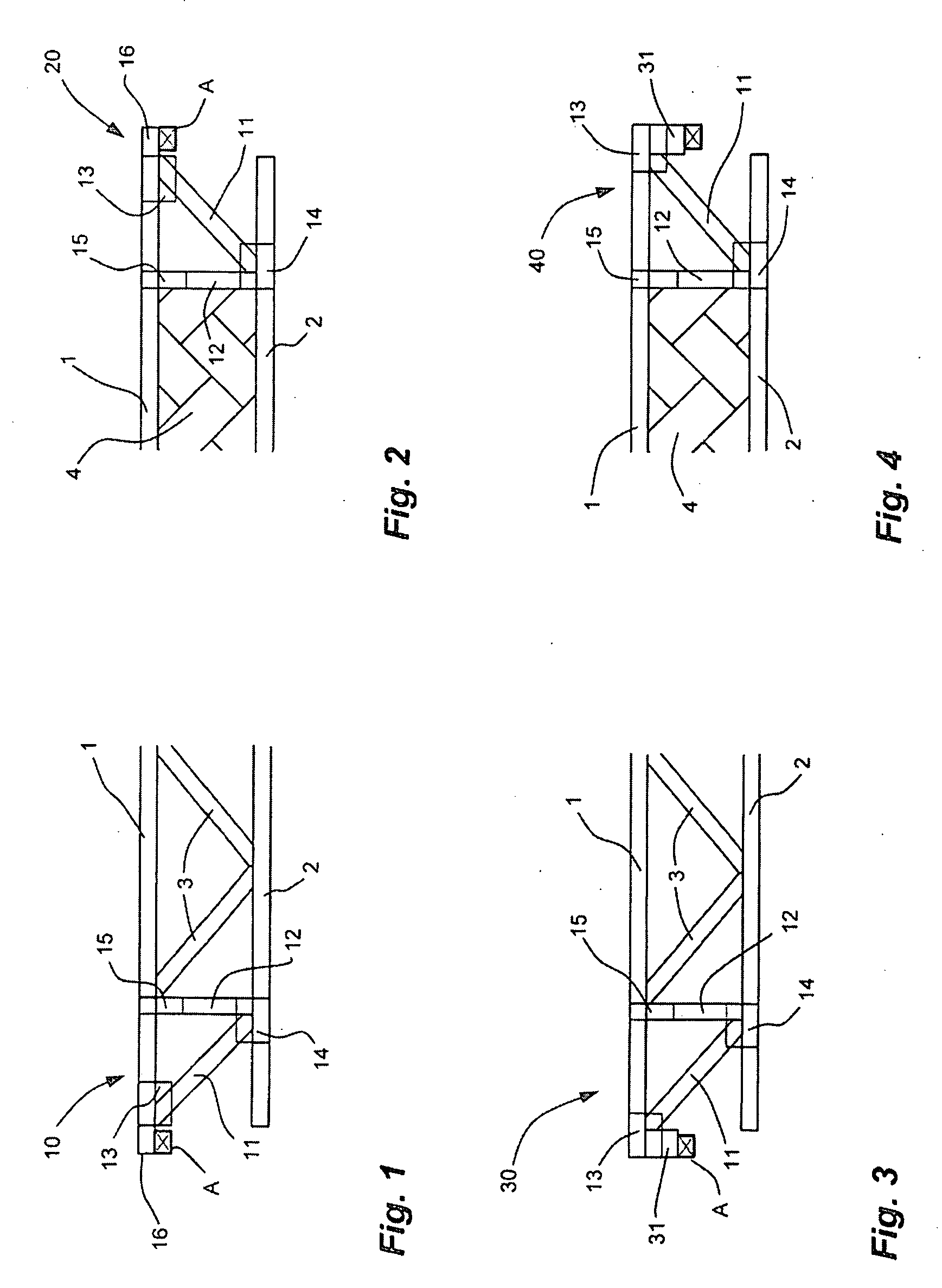

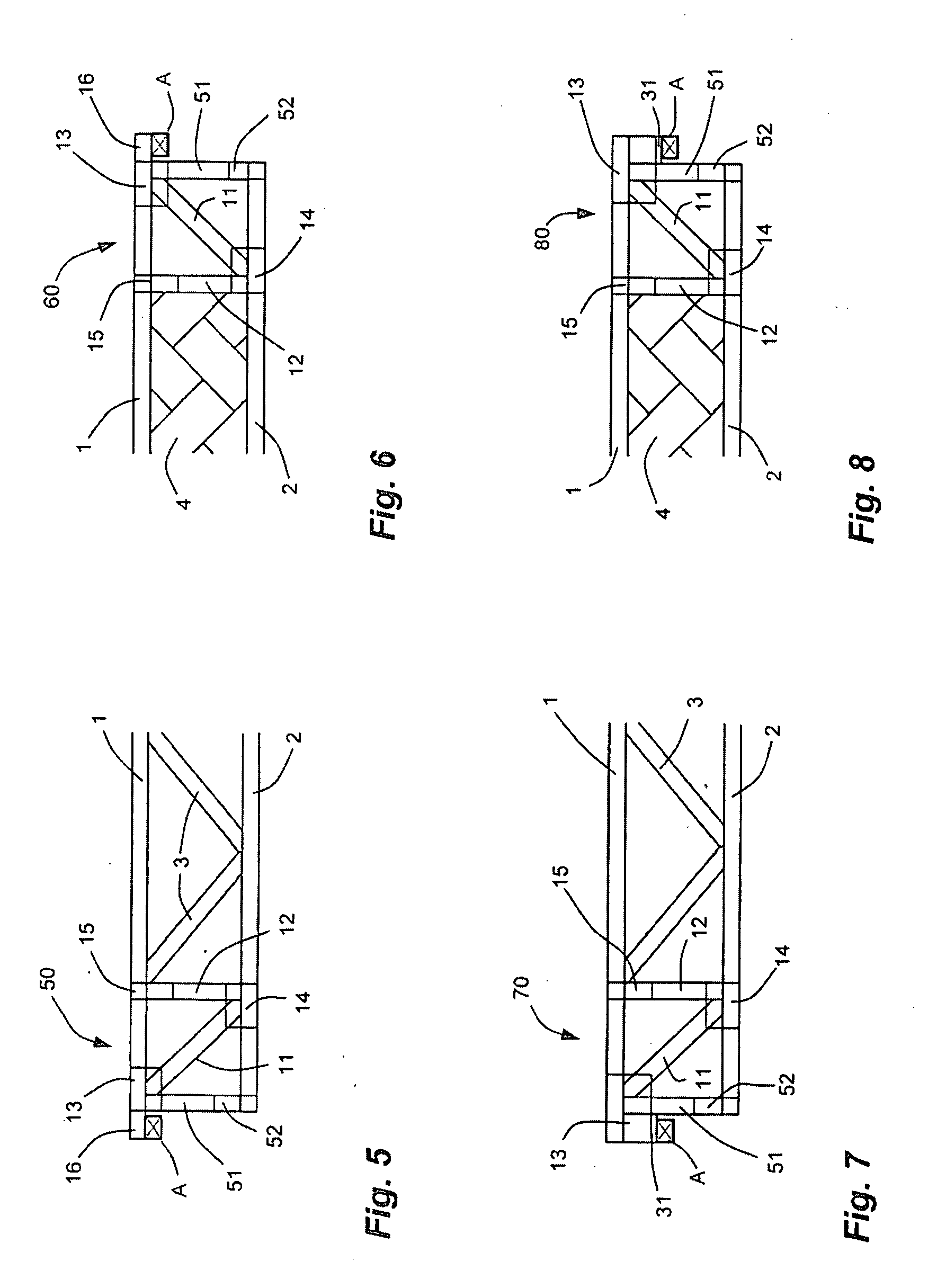

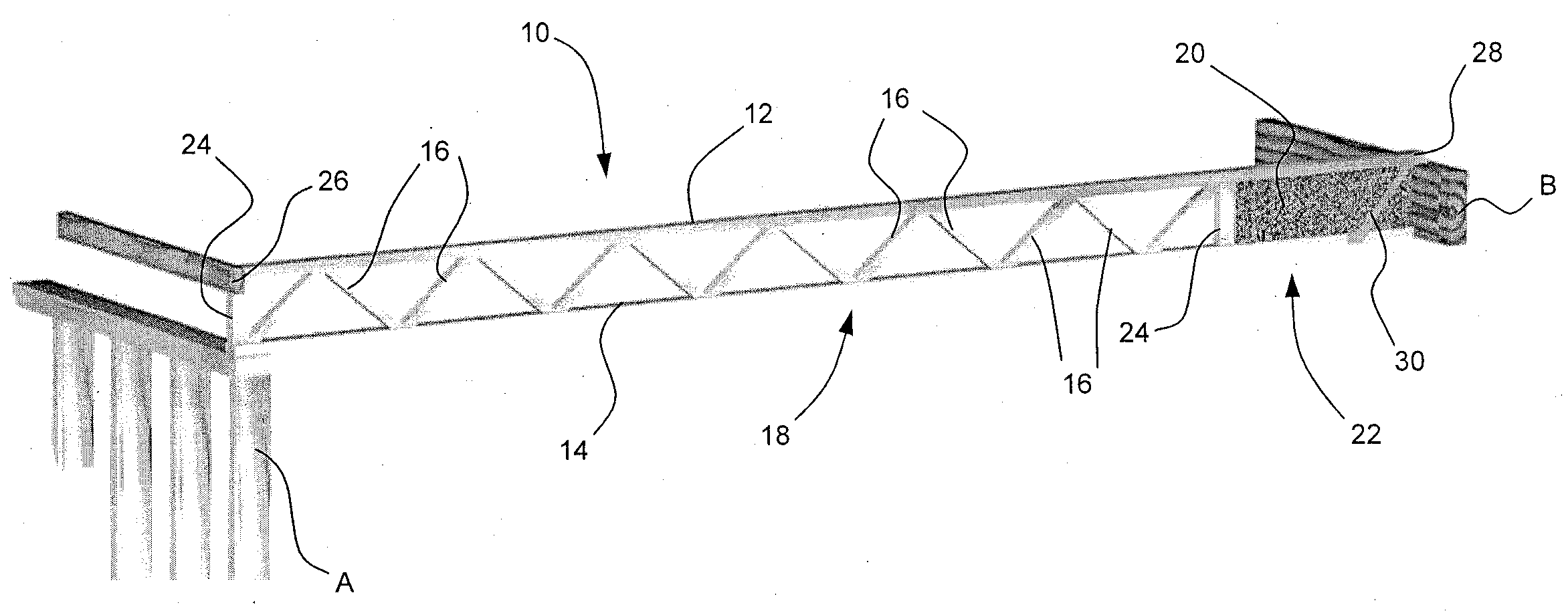

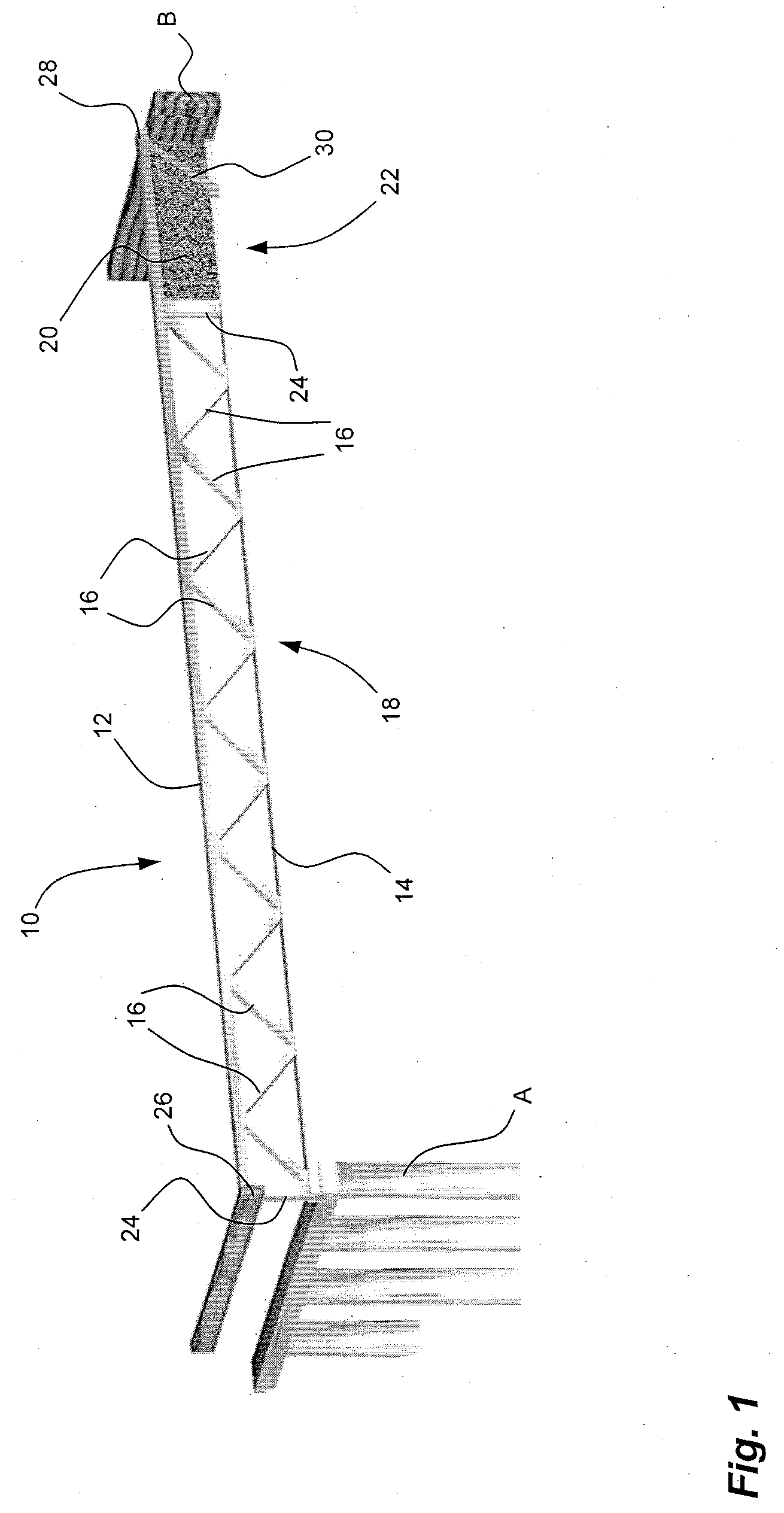

Top-chord bearing wooden joist and method

A wooden joist is described. The joist comprises a wooden top chord, a wooden bottom chord, and a main section comprising at least one of wooden boards and wooden webs adhesively connected to the wooden top chord and to the wooden bottom chord to form at least one of an I-joist subsection and an open-joist subsection along the main section of the wooden joist. An end configuration at one end of the main section comprises a wooden post extending generally perpendicularly between the wooden top chord and the wooden bottom chord and is adjacent to the main section. A wooden diagonal web extends diagonally from the wooden top chord to the wooden bottom chord. A first set of metal plates is in alignment on opposed sides of the wooden joist to connect the wooden top chord to the diagonal web. A second set of metal plates is in alignment on opposed sides of the wooden joist to connect the diagonal web and the post to the bottom chord. A third set of metal plates is in alignment on opposed sides of the wooden joist to connect the wooden top chord to the post. An extension is defined by the wooden top chord extending beyond the diagonal web at an end of the wooden joist. The wooden joist is adapted to be in a top-chord bearing relation with a beam by the extension being on top of the beam.

Owner:SOLIVE AJOUREE 2000

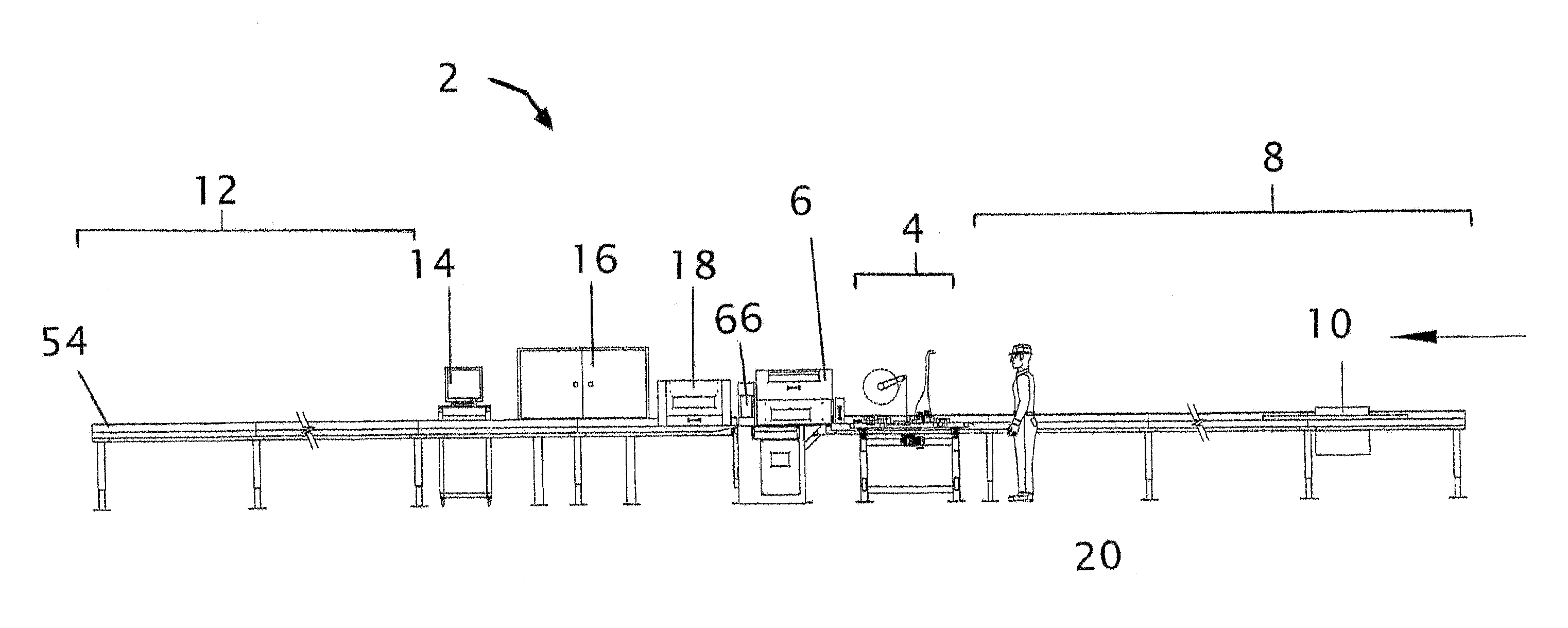

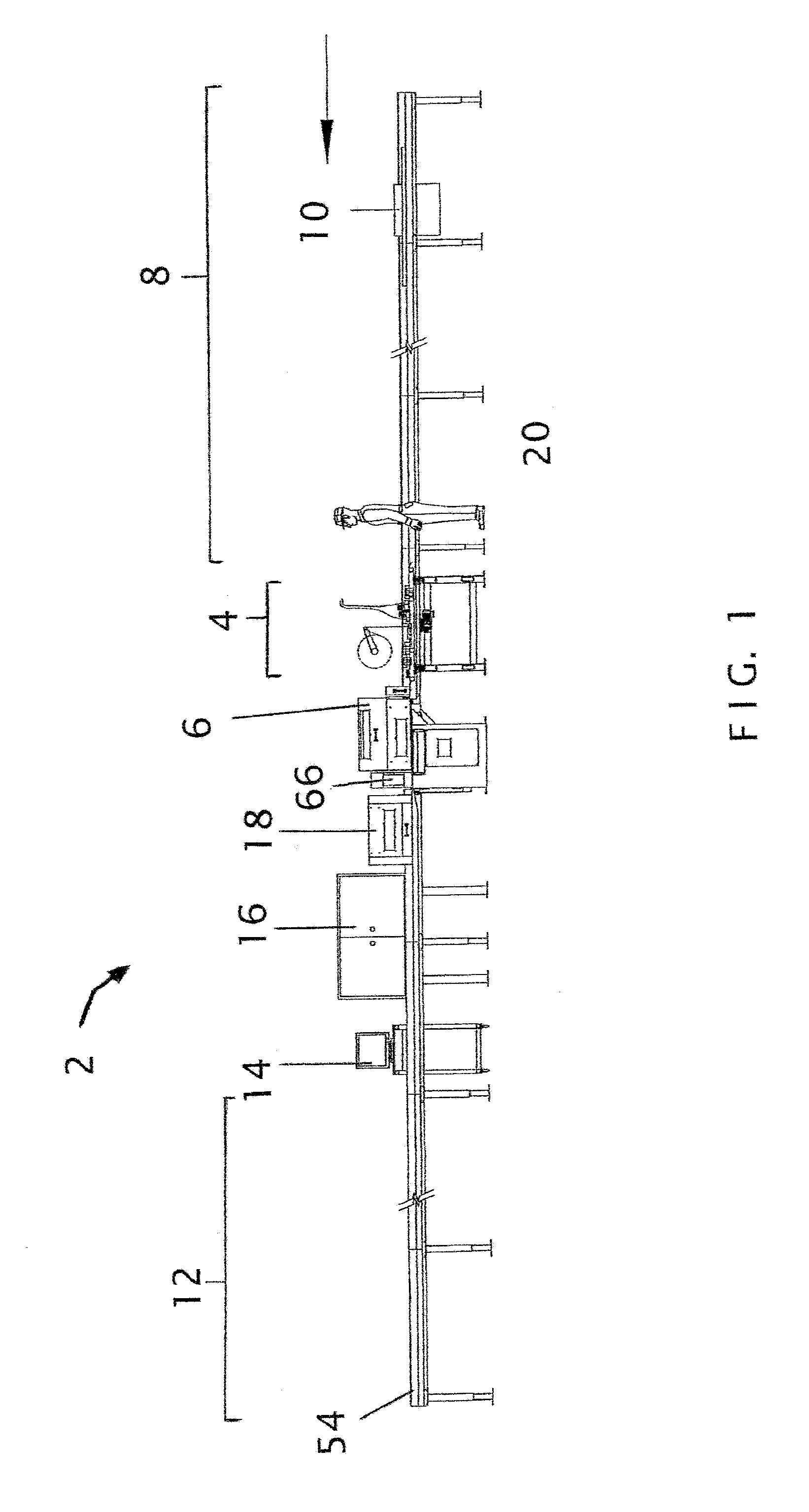

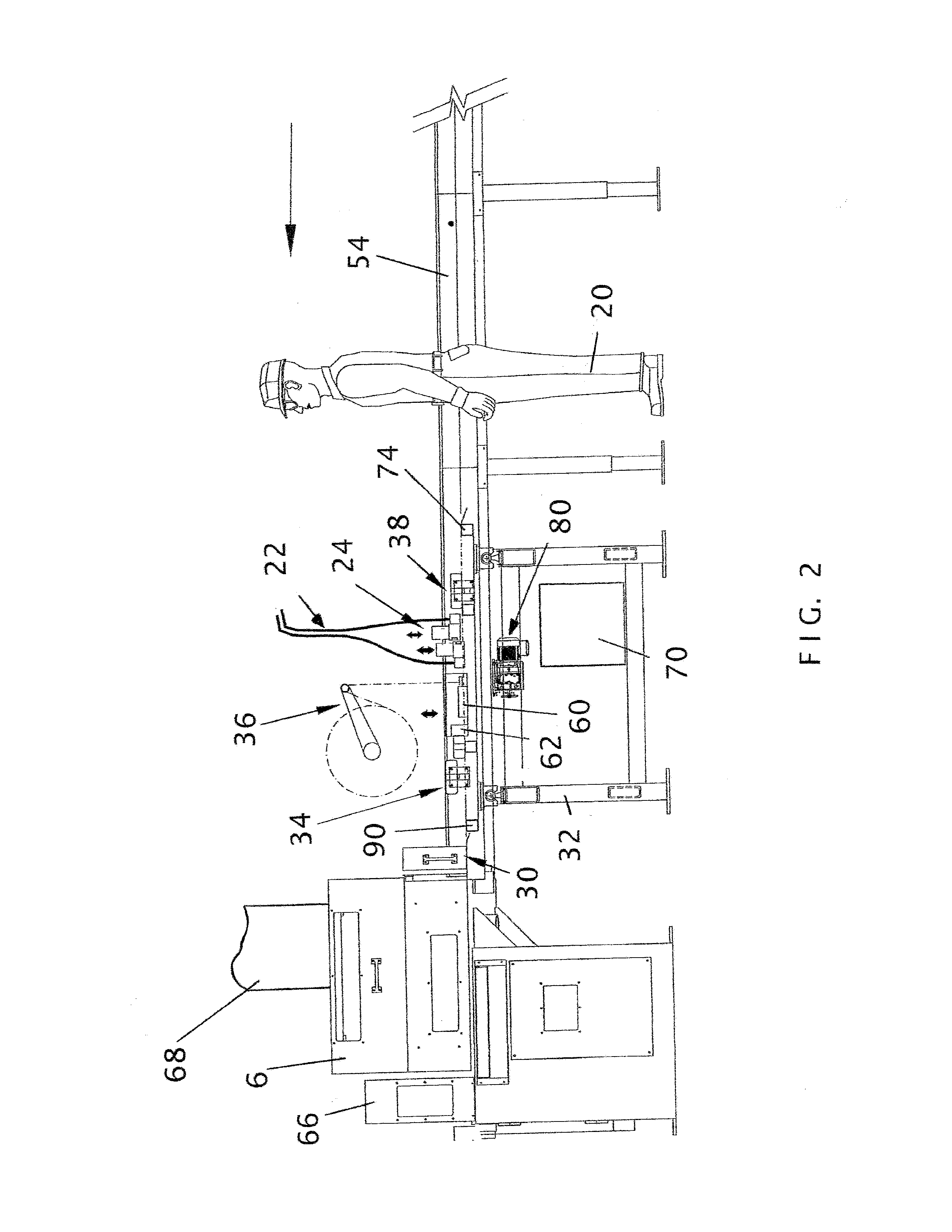

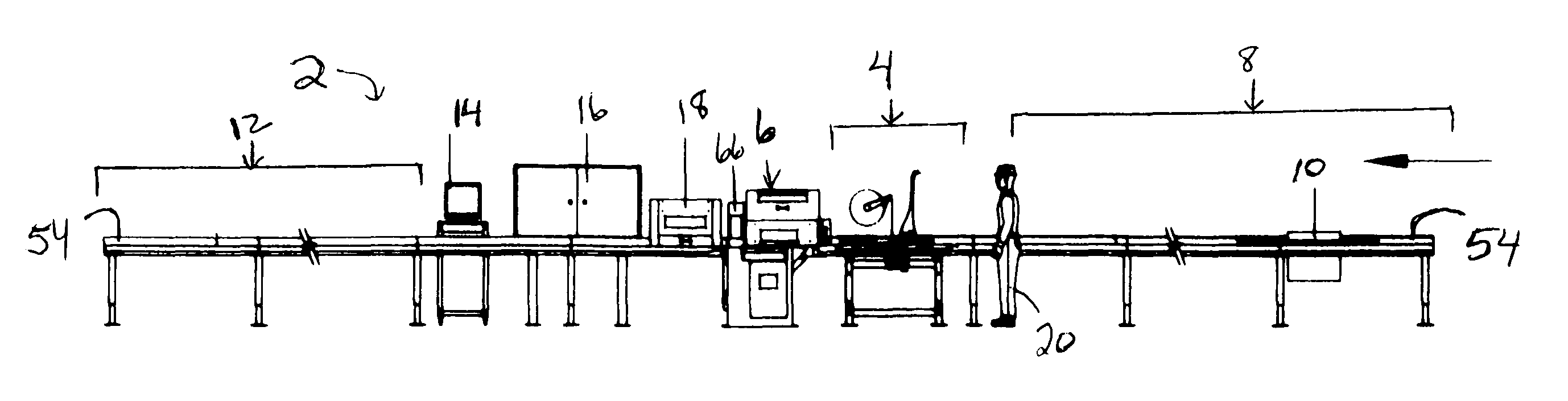

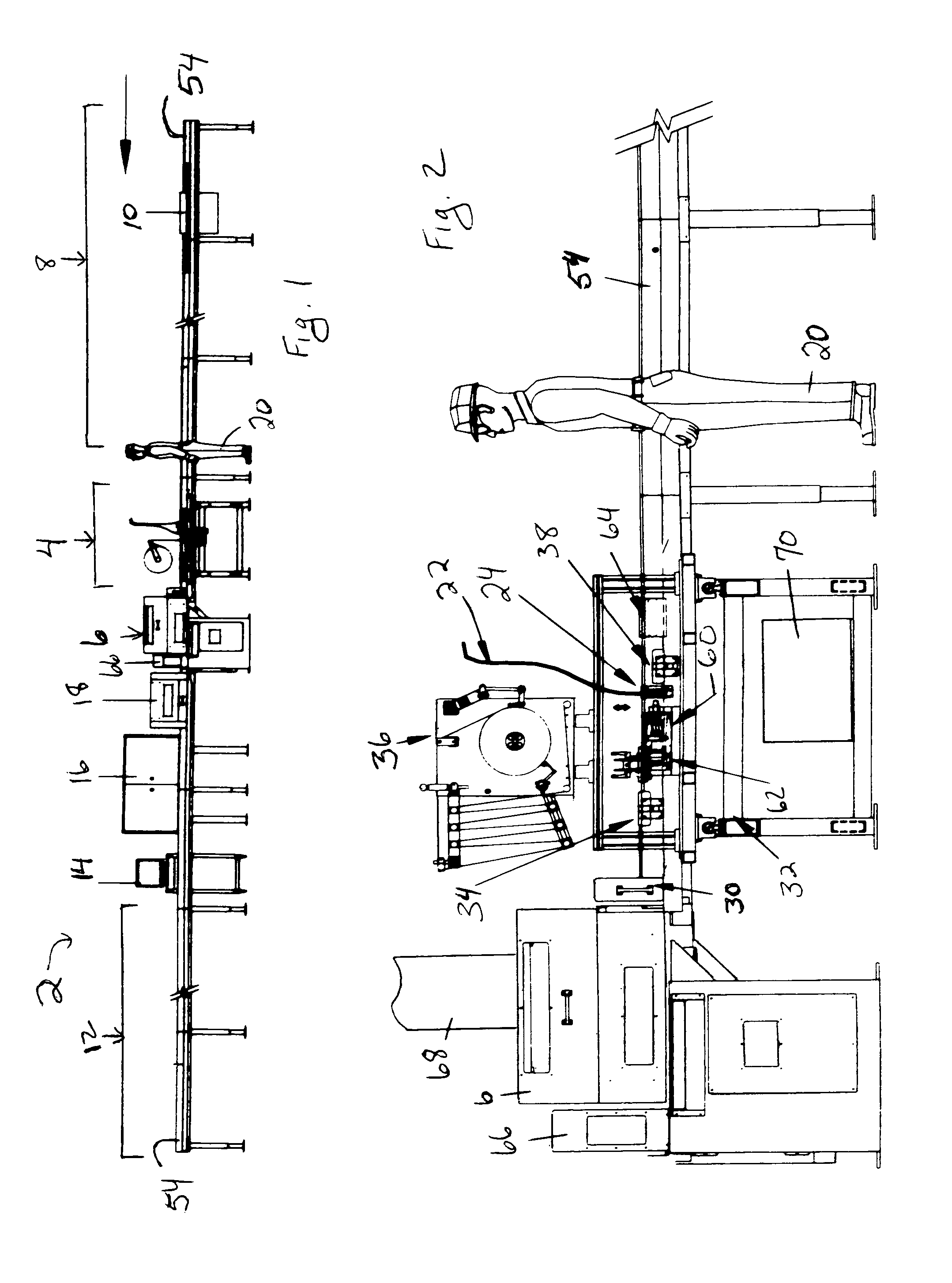

System and method for applying adhesive, buffer, and/or liner to I-joists

InactiveUS8915280B1Strong and more consistent bondLow costLiquid surface applicatorsGirdersJoistI-joist

A system and method for automated application of adhesive, buffer, and / or liner to I-joists, whereby a controlled amount of adhesive, glue, buffer material, and / or a protective liner, are successively applied to the exposed flange of an I-joist. An air-activated side pressure wheel first pushes one flange of an I-joist against an opposing friction-reduced straight edge, then at least one adhesive / glue head extrudes adhesive and / or buffer material onto the opposing exposed flange of the I-joist. An overhead liner applicator may then place a protective liner upon the applied adhesive and / or buffer material. An applicator roller bearing and a pressure roller bearing press the adhesive / buffer / liner to the desired mil thickness, after which the liner applicator cuts the protective liner according to the cut pattern instructions received from a controller. A cooler can be used to cool the adhesive / buffer before release liner application. The system may comprise coordinated mechanical, electrical, and pneumatic components.

Owner:ROBELL GLENN

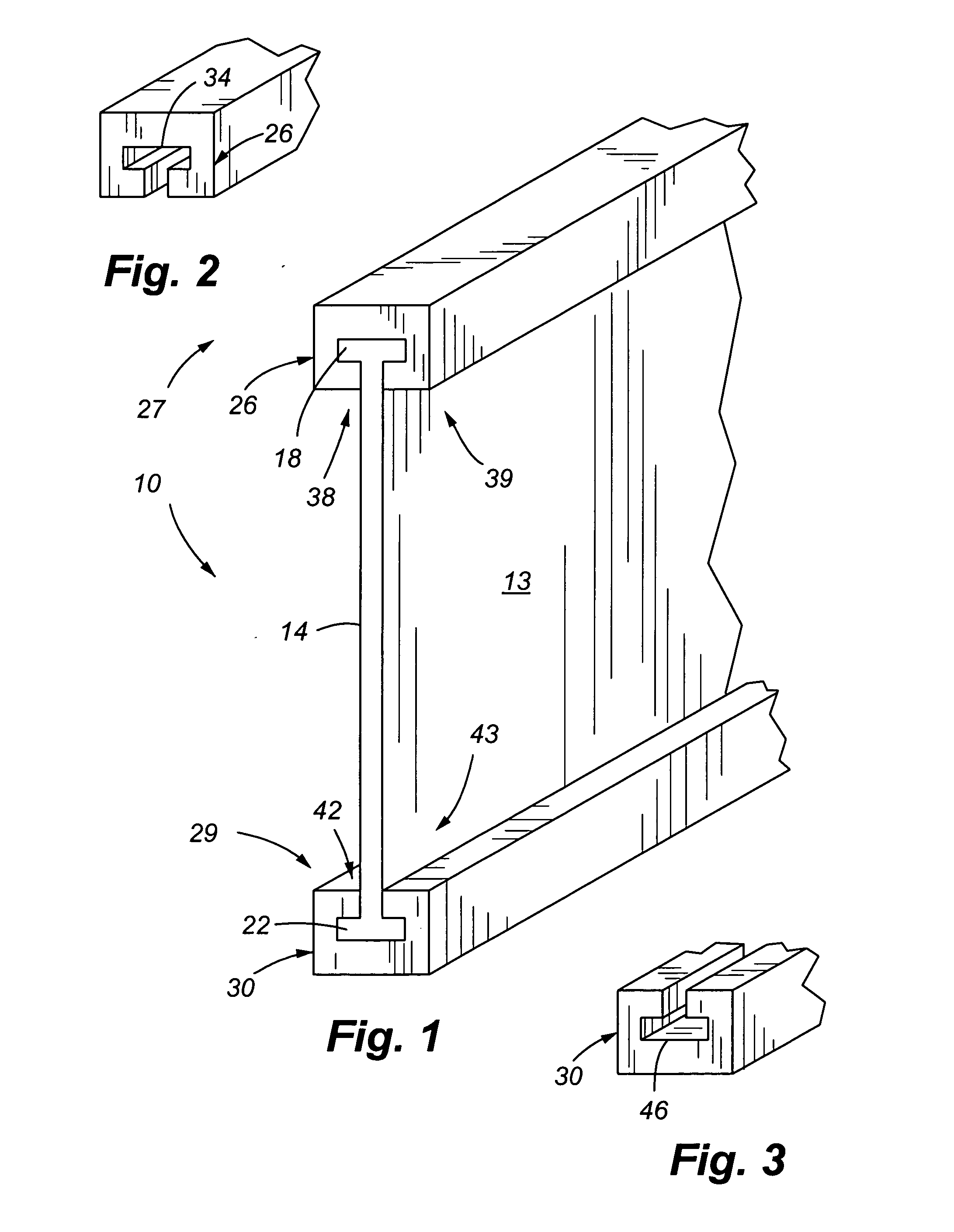

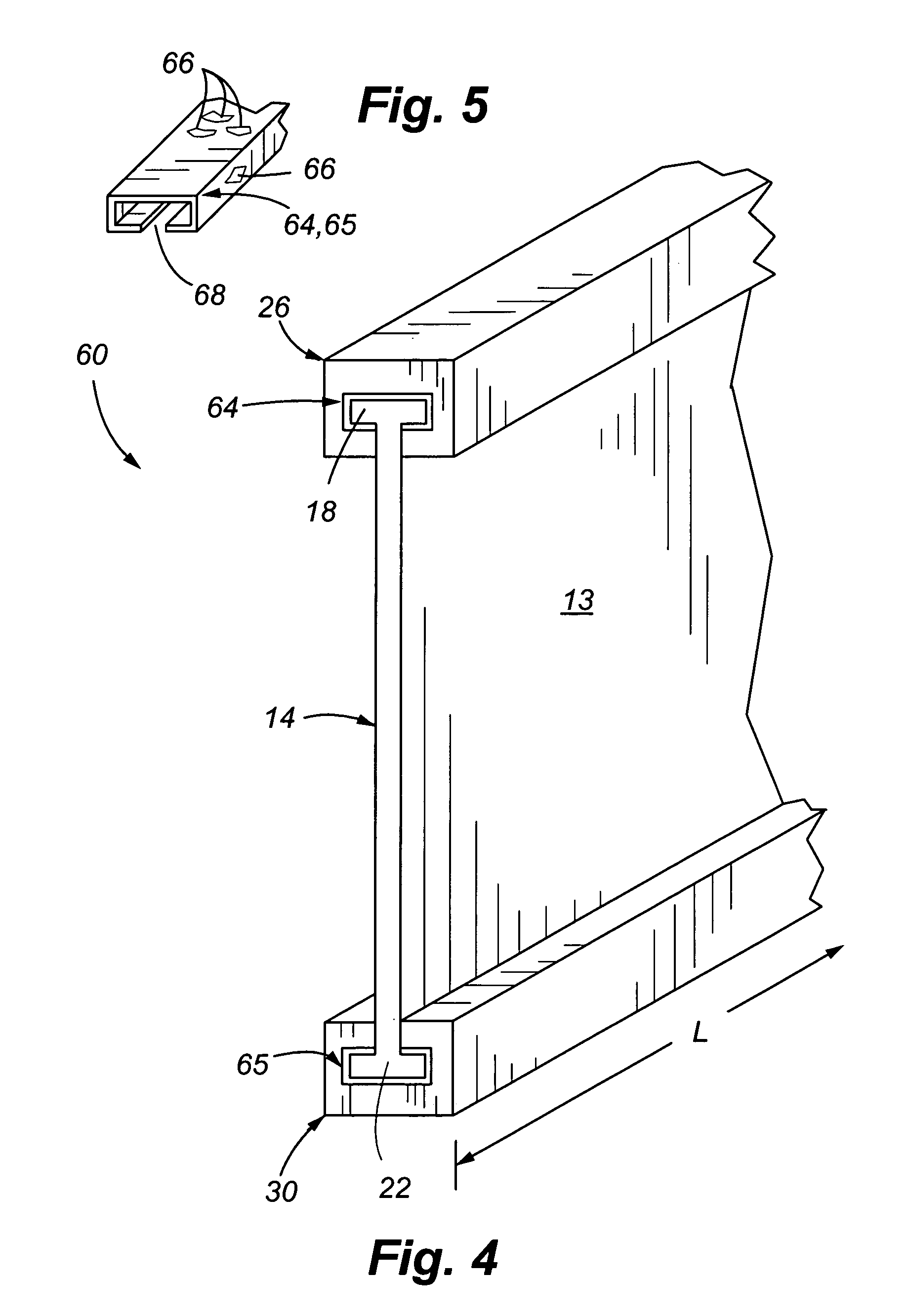

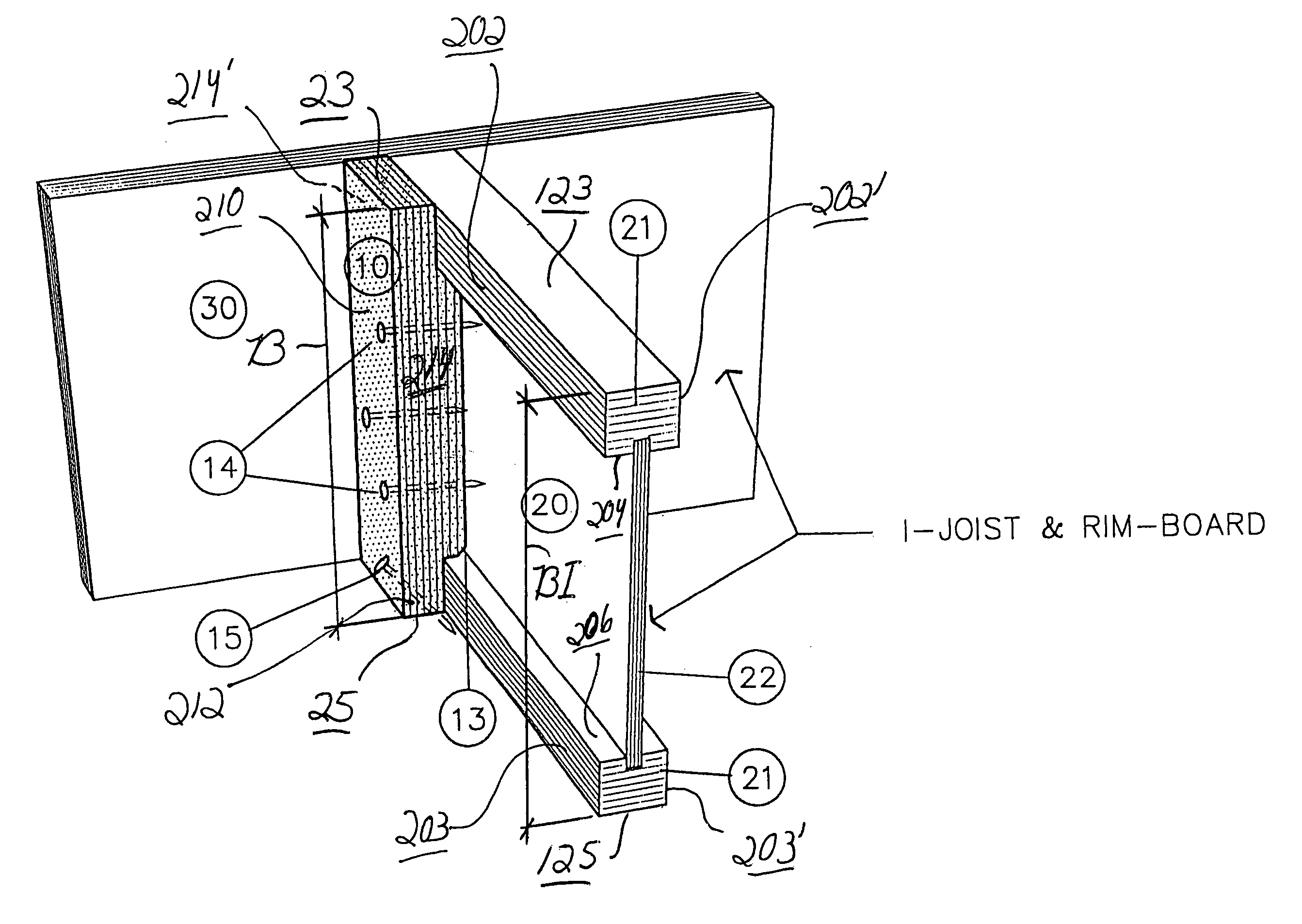

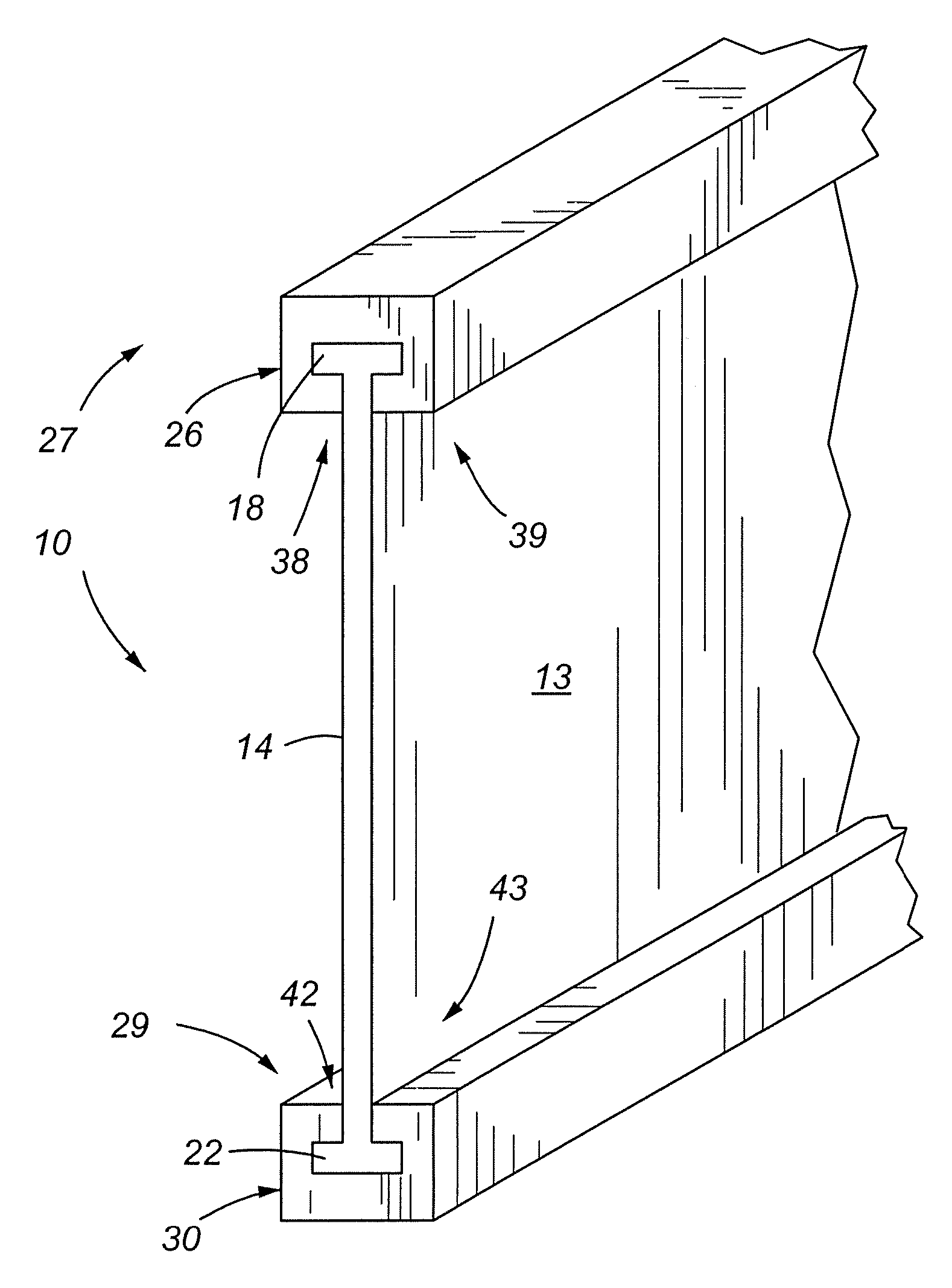

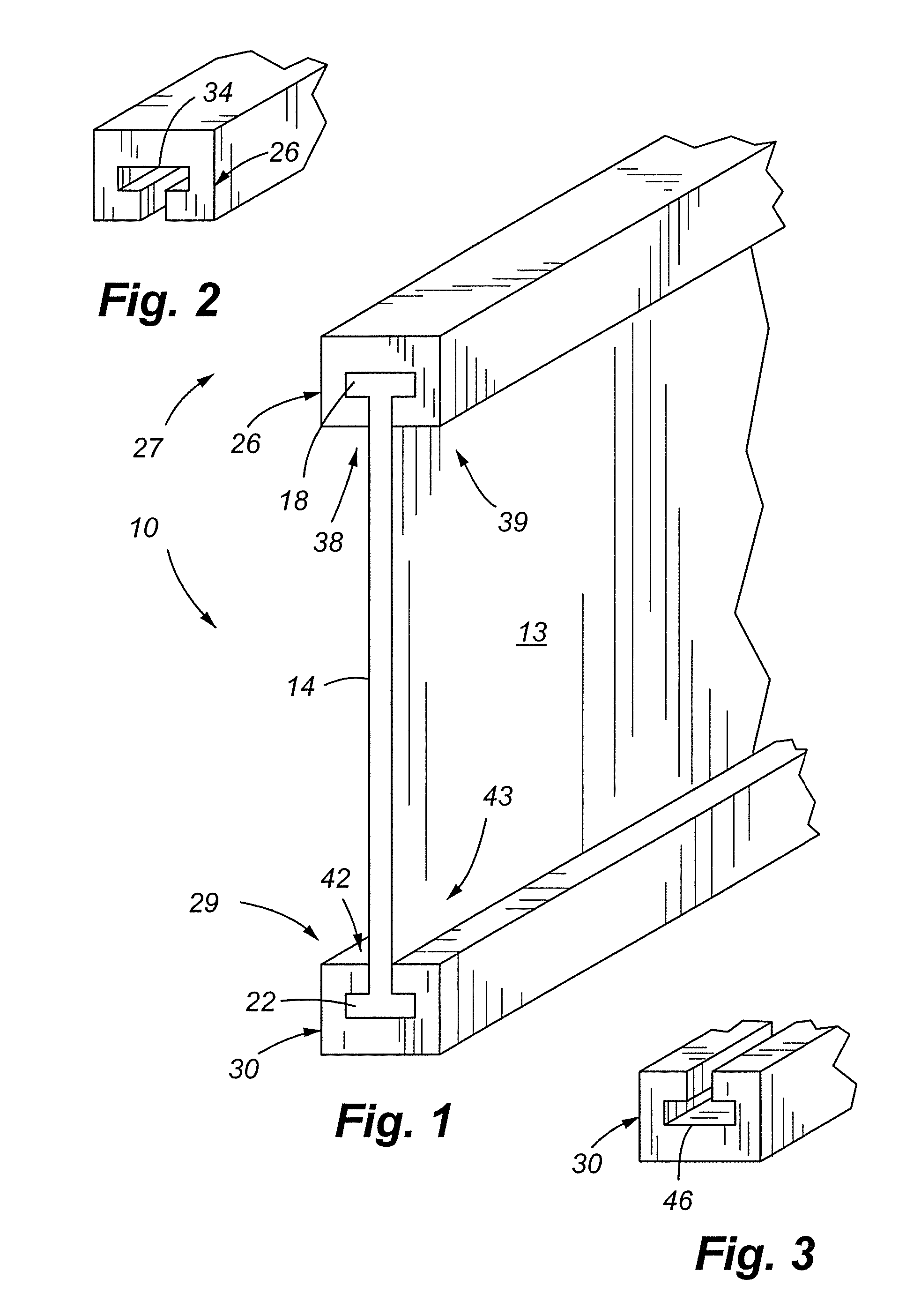

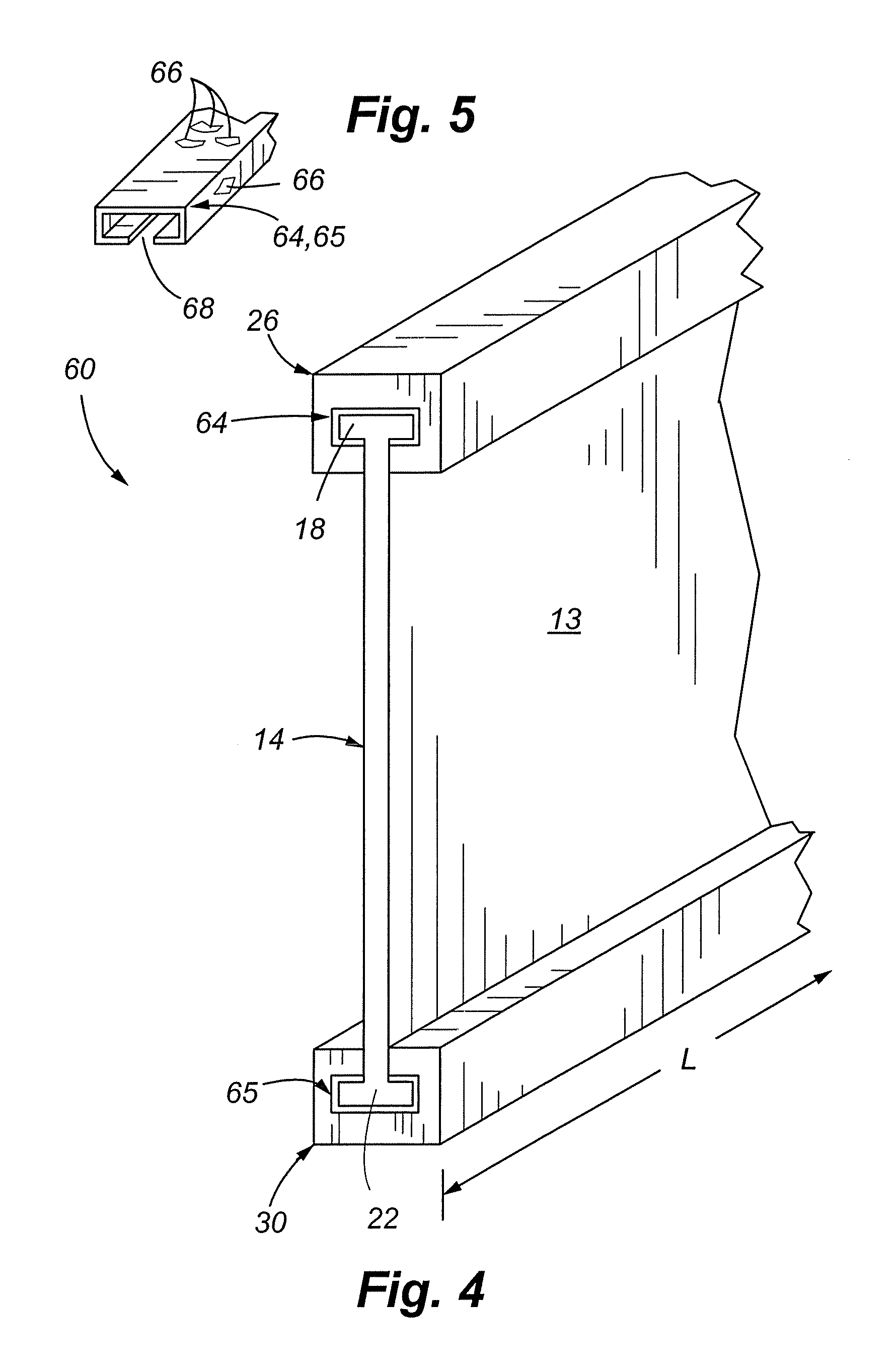

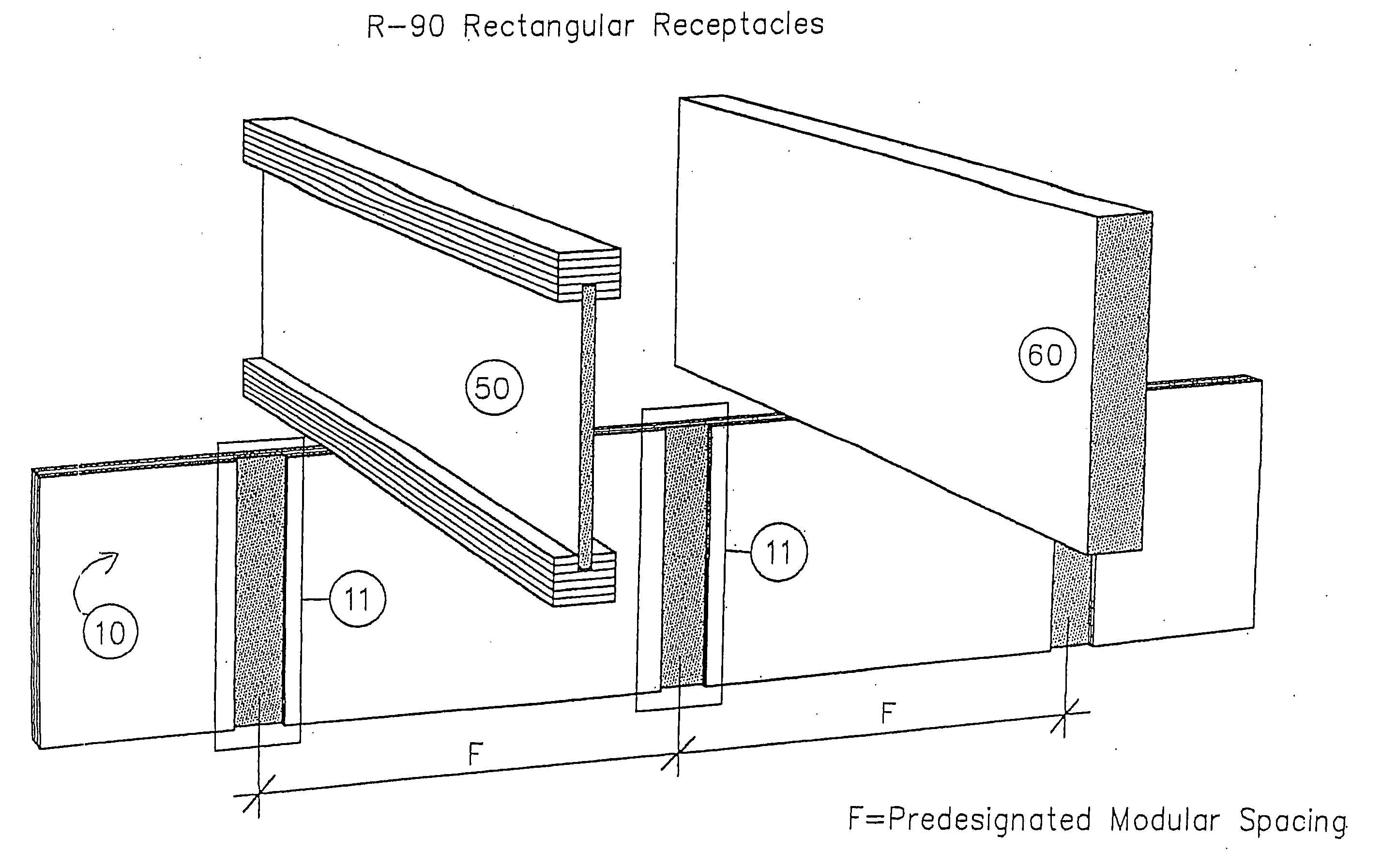

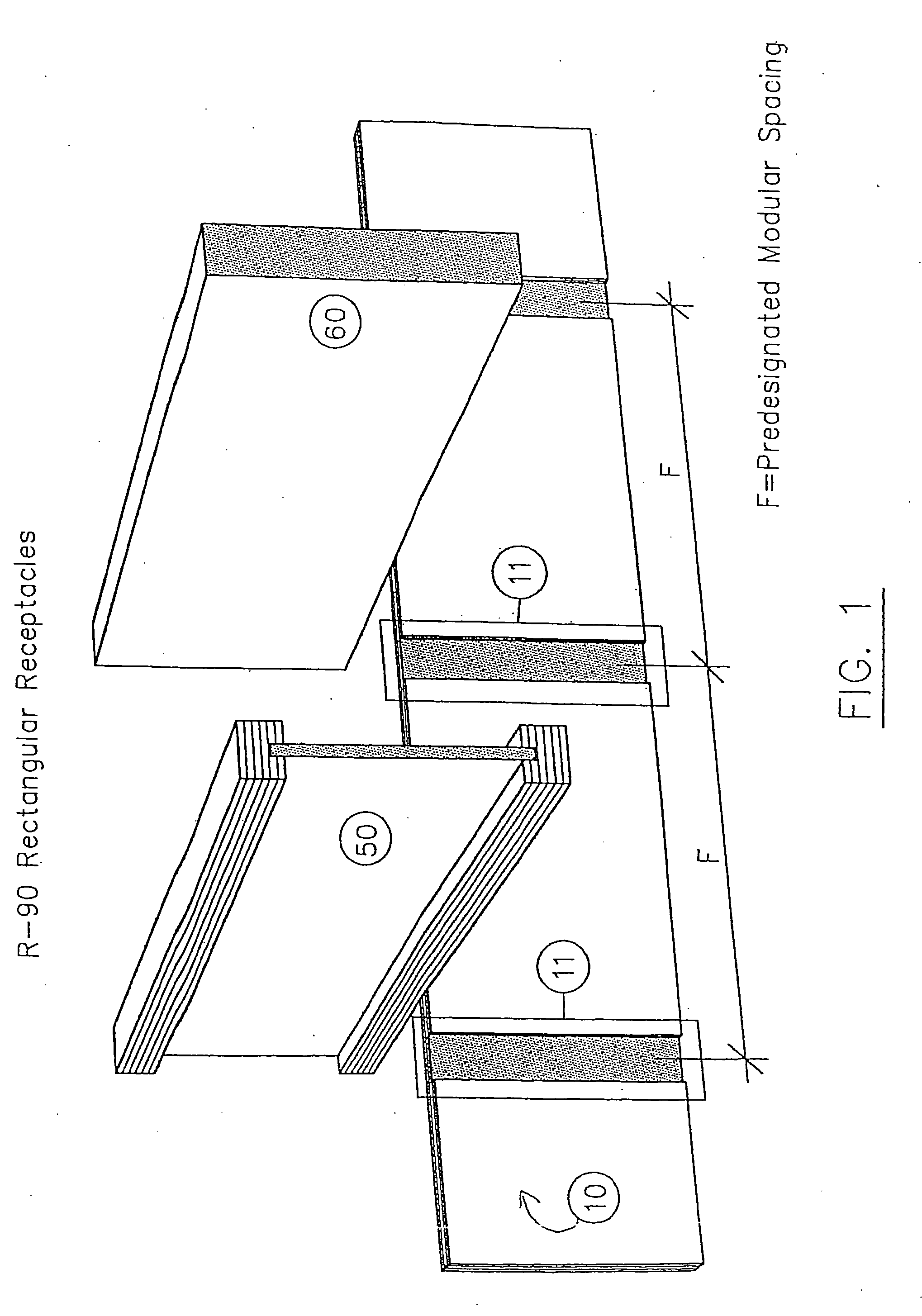

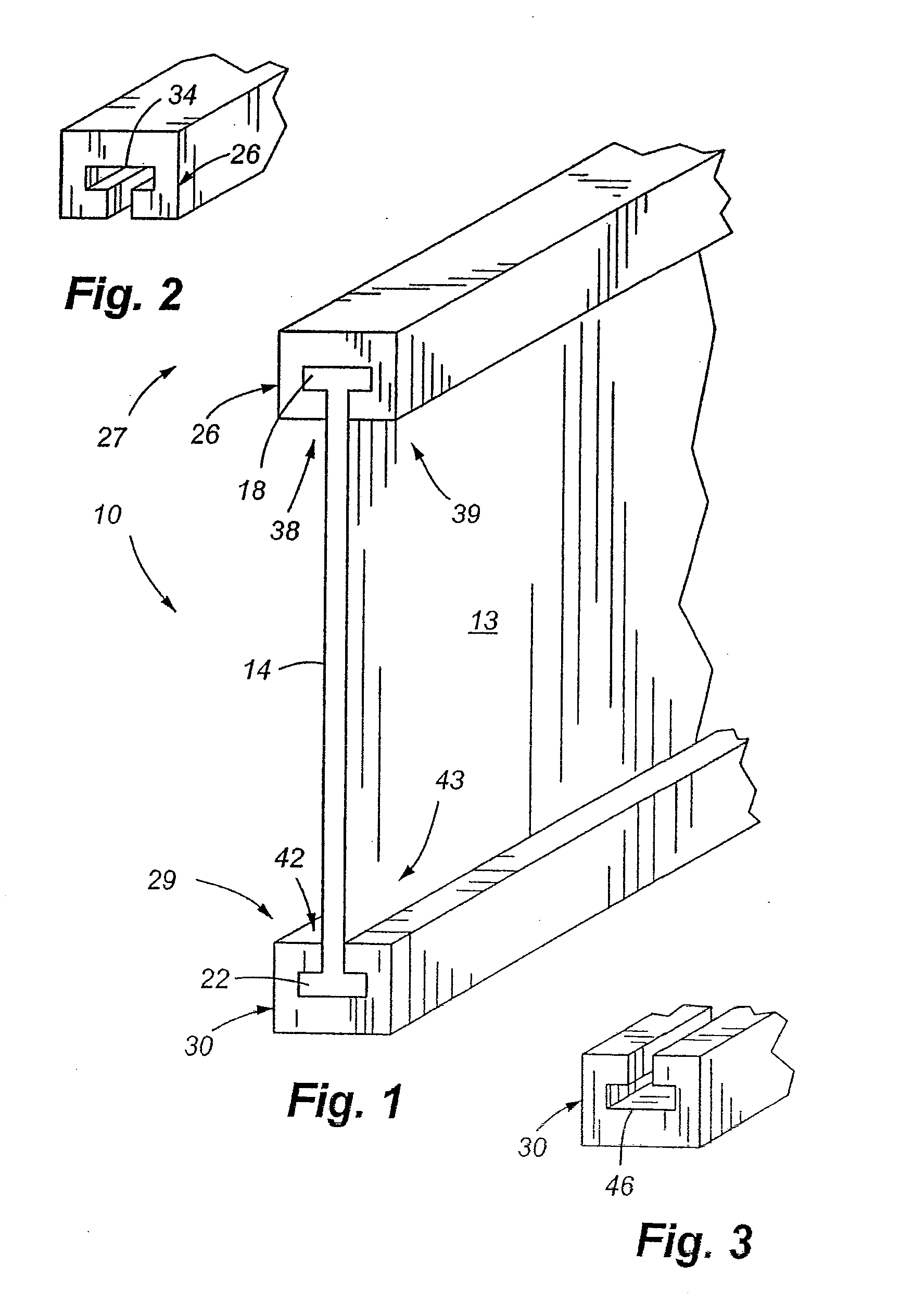

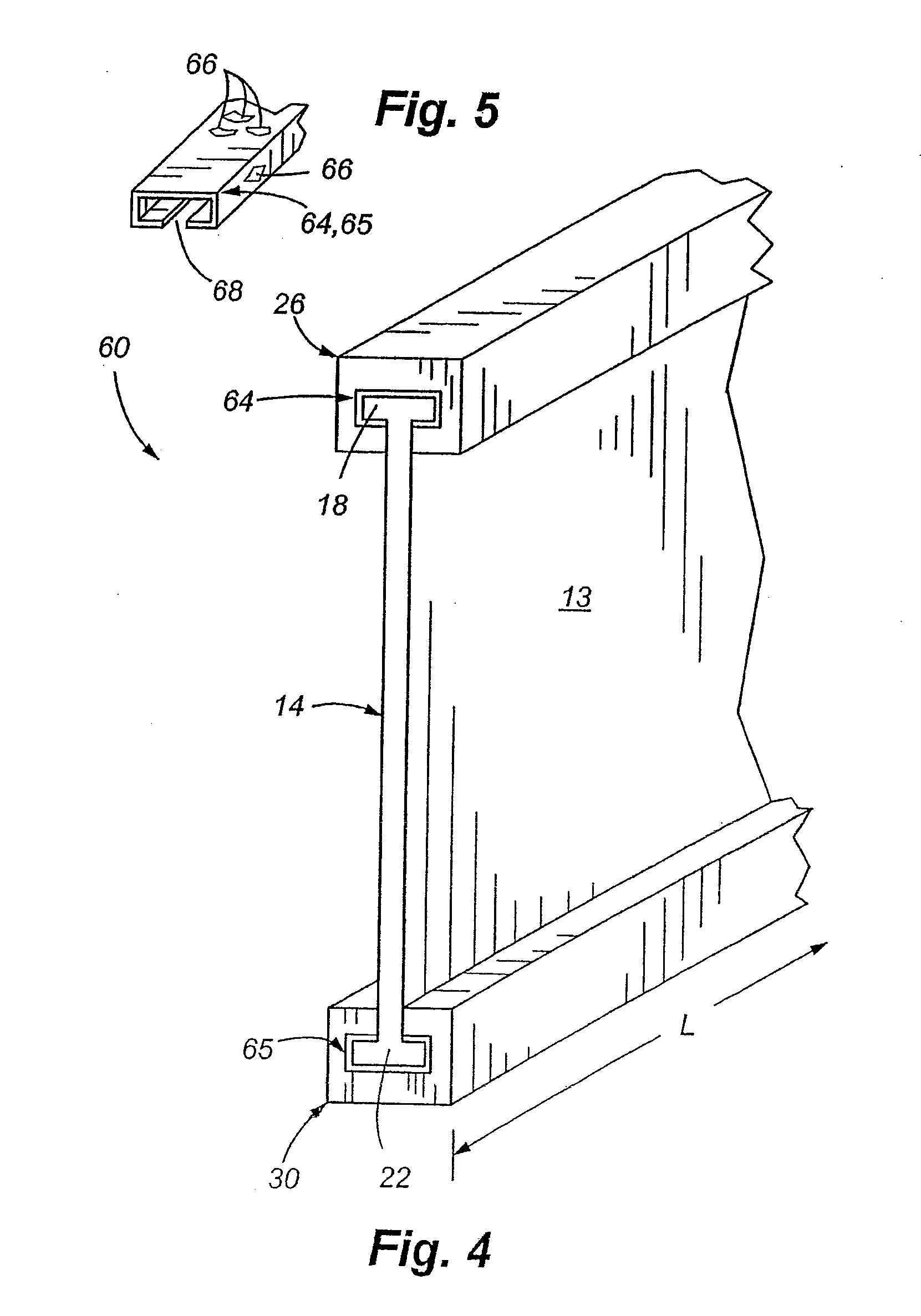

Modular rim board for floor and rafter systems

InactiveUS20050257442A1Cost effectiveImprove efficiencyRoof covering using slabs/sheetsBuilding roofsJoistI-joist

An engineered perimeter rim board with machined or otherwise-formed modular recessed receptacles receives and secures I-joists and other manufactured joists at pre-designated spaces along the length of the rim board. The rim board provides pre-measured joist securement locations and structural enhancements by “locking” the joists into position. Receptacles machined / cut into the rim board may be of various shapes, such as a rectangular recess with a flat planar back wall, a profiled recess with curved top and bottom compartments, and / or an angled recess wherein two sidewalls converge to create a recess without a back wall for receiving joists at positions other than perpendicular to the rim board. The preferred 90-degree receptacle profile provides an I-joist web receiving slot for additional lateral support to help prevent joists from buckling, twisting or rolling over.

Owner:BROWN COMER +1

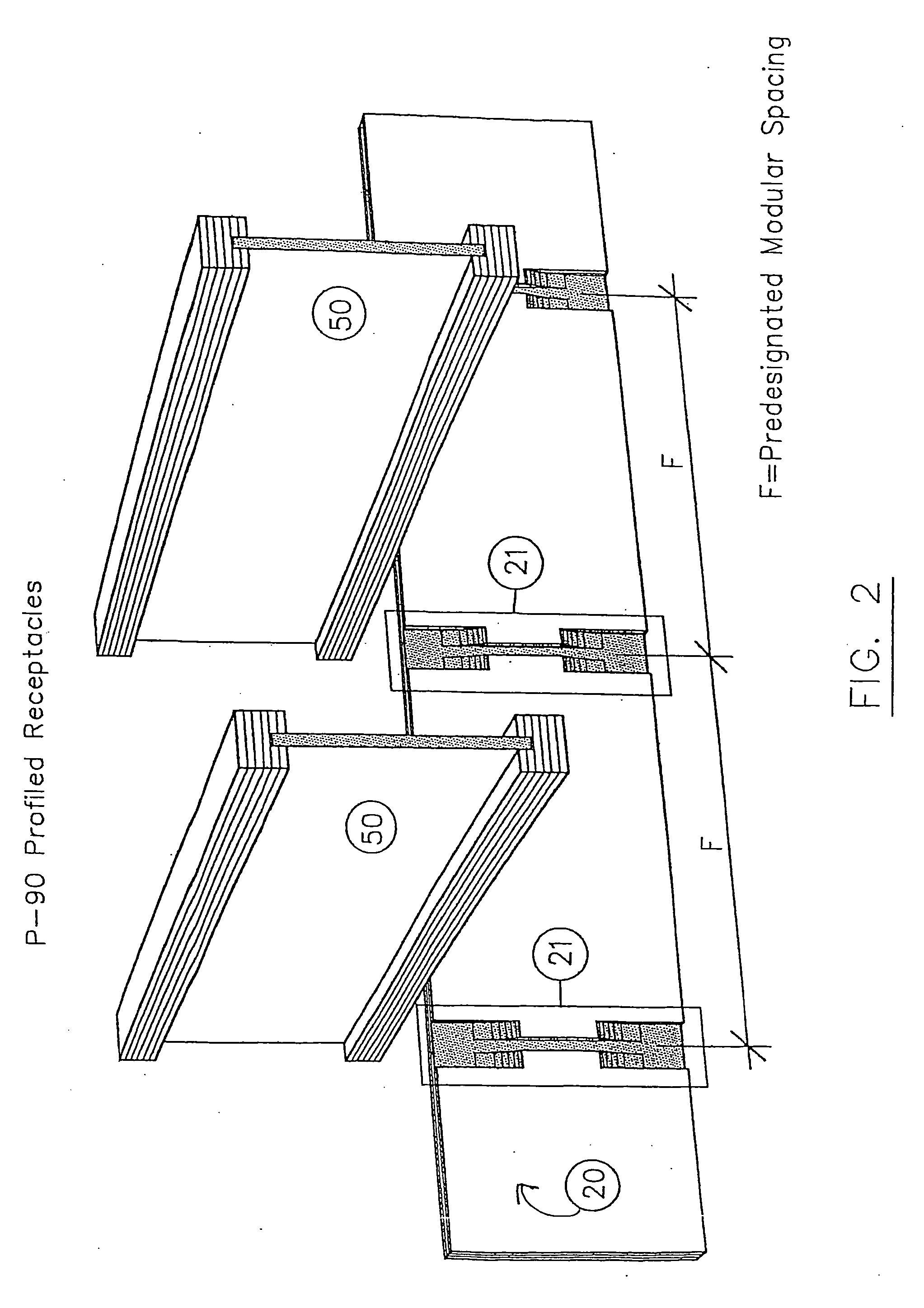

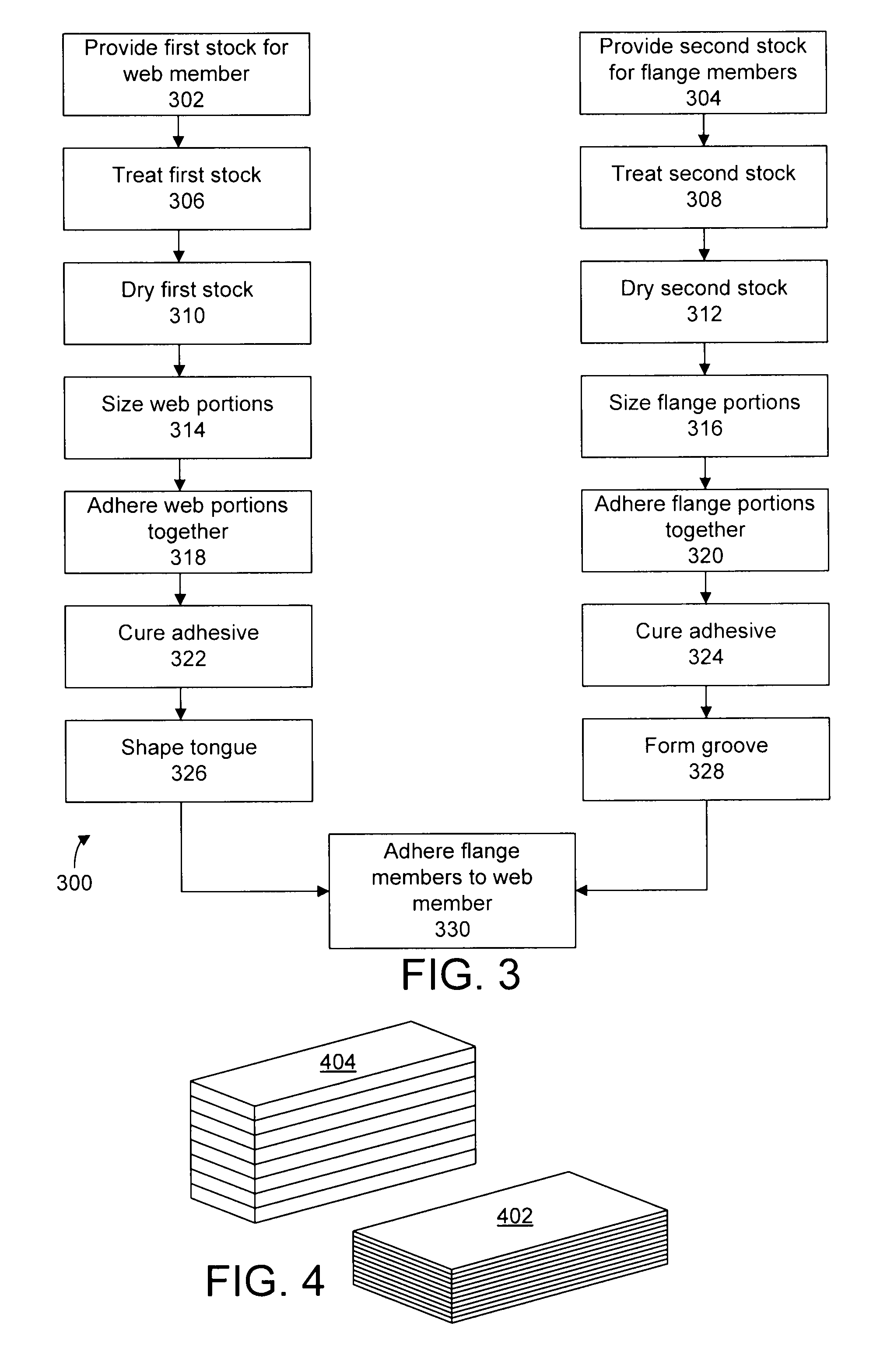

Preservative-treated i-joist and components thereof

A preservative-treated I-joist is produced by providing a web member and first and second flange members made of lignocellulosic material. Prior to assembly of the I-joist, a waterborne preservative is applied to the web and flange members, and thereafter the web and flange members are sized. The web and flange members may have a tongue-and-groove configuration for connecting the flange members to the web member. Sizing the web and flange members may include cutting one or more stocks of lignocellulosic material to produce the web and flange members, cutting grooves in the flange members, and trimming edge regions of the web member to form tongue portions to fit in the grooves. After the web and flange members are sized, the flange members are adhered to the web member to secure the web member and the flange members together.

Owner:ALII PACIFIC

Top-chord bearing wooden joist and method

A wooden joist comprises wooden top chord and bottom chords. Wooden boards are adhesively connected to the chords to form an I-joist section along a portion of the wooden joist. Wooden webs may be adhesively connected to the chords to form an open-joist section along another portion of the wooden joist. A bearing extension is defined by the wooden top chord extending beyond an end of the wooden joist Metal webs are in alignment on opposed sides of the wooden joist. Each metal web comprises a top connector end fixed to the bearing extension, a bottom connector end fixed to the bottom chord, and a structural arm between the connector ends. The metal webs are solely provided in an end region along the wooden joist, whereby the wooden joist is adapted to be in a top-chord bearing relation with a beam.

Owner:SOLIVE AJOUREE 2000

Tube-style truck body

ActiveUS20070182208A1Loading/unloading vehicle arrangmentMonocoque constructionsGusset platePipe fitting

An off-highway truck body comprising a plurality of tube-style support members, wherein each tube-style support member comprises one or two pieces of square or rectangular tubing, wherein the truck body comprises two sidewalls, a floor, a front wall and a canopy, and wherein one side of each tube-style support member is welded to the outside of the sidewall, floor, front wall or canopy. The pieces of tubing are preferably comprised of steel. The present invention optionally comprises a forward wedged front wall and a side-sloped canopy. The present invention also encompasses a tube-style tailgate, an alternate embodiment in which I-beams are used in lieu of square tubing, and an alternate embodiment in which a gusset is used in lieu of a cover plate for the double-size support members.

Owner:THINK RITE INTPROP LLC

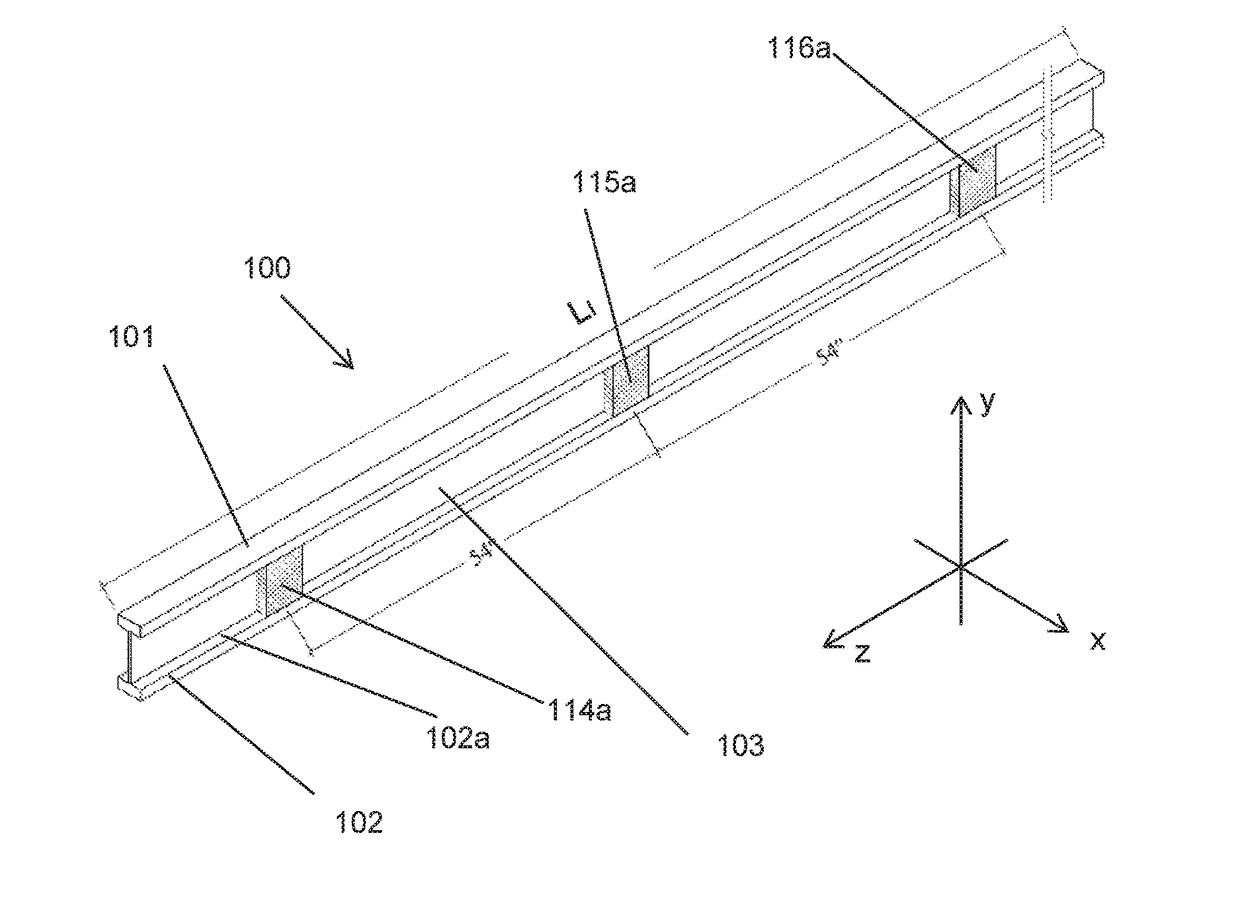

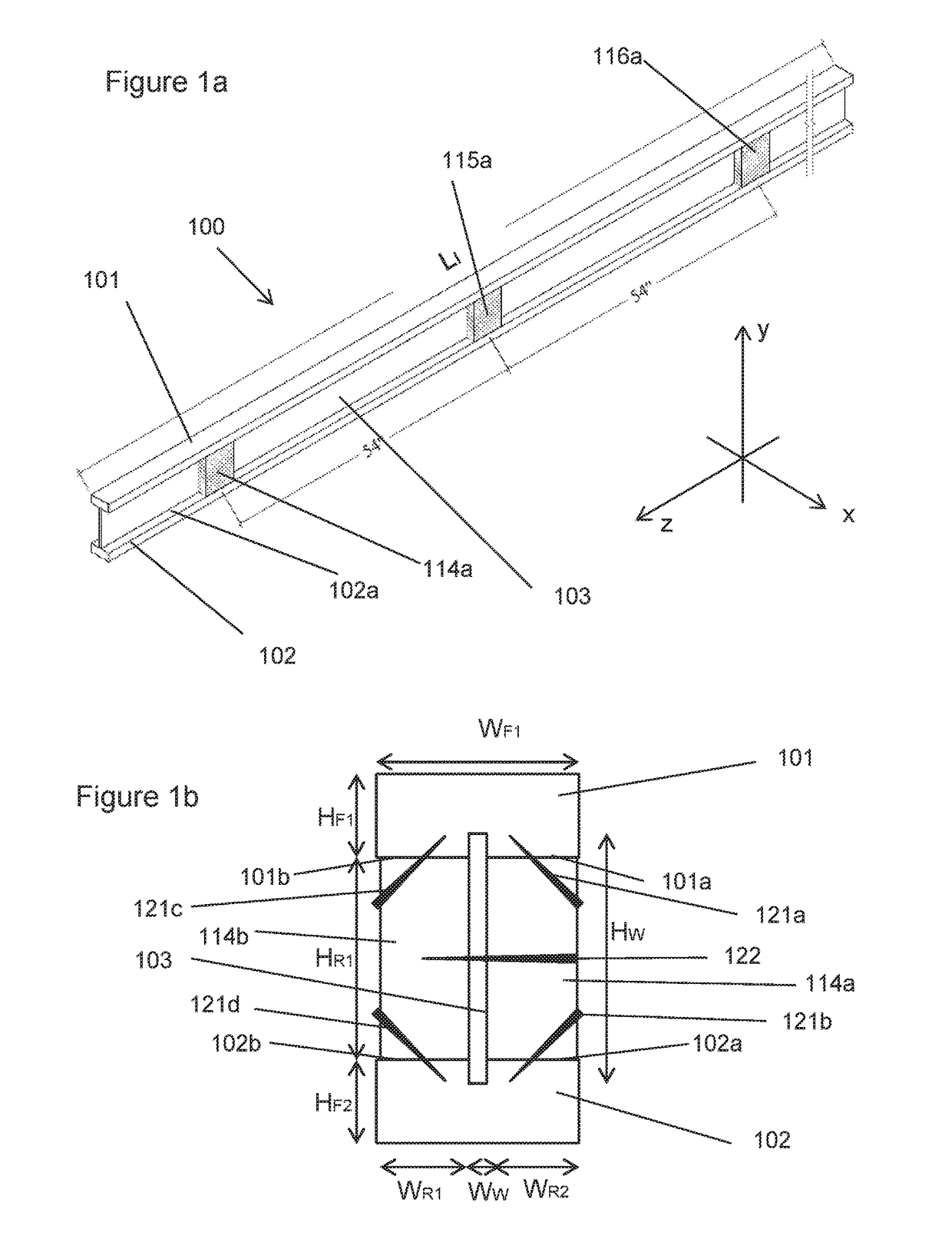

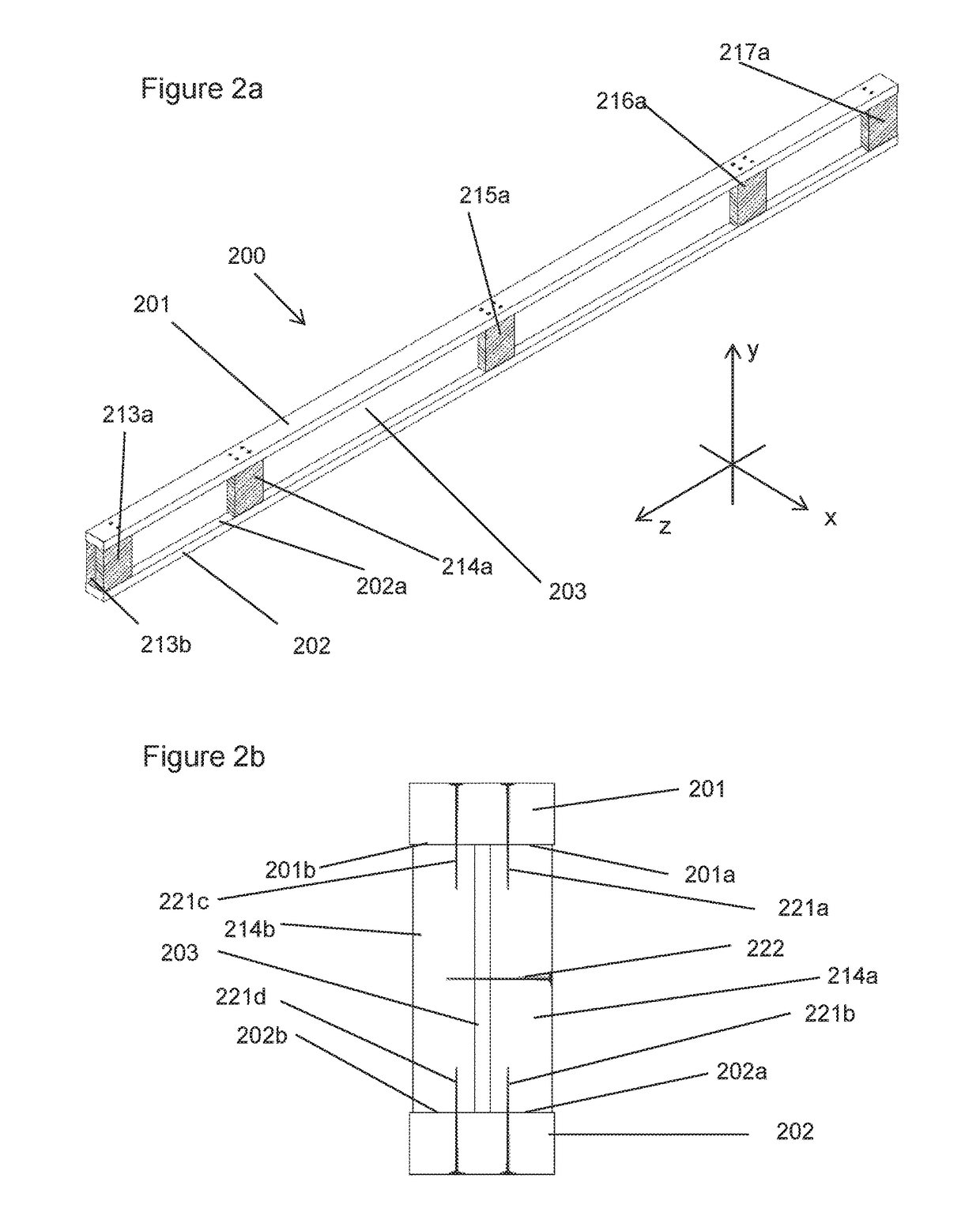

Fire-resistant wooden I-joist

This application relates to I-joists which are configured to resist fire damage. Specifically, the present application relates to reinforcing I-joists with reinforcing members configured to provide structural support and / or to provide a physical barrier to fire. This may help the I-joists to maintain structural integrity during a fire and so help improve safety during evacuation of a building and during fire-fighting operations.

Owner:PINKWOOD LTD

Structural member

ActiveUS20090075031A1Improve bindingImprove load bearing ratingStrutsSynthetic resin layered productsFiberCarbon fibers

A system and method of manufacture providing reinforced structurally functional load-bearing members, including but not limited to using thermoplastic materials, such as High Density Polyethylene (HDPE) or polypropylene (PP), reinforced such as with an aluminum alloy, glass-reinforced polyurethane (foamed or unfoamed), or carbon fiber core element. Among its possible uses, the present invention has application for provision of structural support members, such as an illustrative I-joist product having a vertical center member preferably comprising a thermoplastic material, and top and bottom flanges having structurally meaningful reinforcement. The center member and flanges preferably comprising a thermoplastic material provides a relatively hard, durable, substantially weather-resistant structure. Certain embodiments of the present invention include reinforcing members having a plurality of lobes or arms. Additional embodiments include indentations along the reinforcing members, such as the arms, to aid in bonding between the thermoplastic outer material and reinforcing member within the thermoplastic material. Certain embodiments of the present invention include reinforcing members used in combination with a foamed area and a thermoplastic material.

Owner:TAC TECH

Method and improvement to saw system used for cutting I-joists to size

InactiveUS7918960B1High strengthLow costMetal sawing devicesLamination ancillary operationsAdhesiveI-joist

A method and an improvement to saw systems configured to convert raw I-joists from inventory to pre-cut sizes and / or cut routed patterns in I-joists for utility pass-through applications prior to their shipment to a construction site or return to inventory, whereby a controlled amount of adhesive and a protective liner are automatically and successively applied to the top flange of each I-joist. The saw system improvement comprises coordinated mechanical, electrical, and pneumatic components.

Owner:ROBELL GLENN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com