Composite Guardrail Posts and Composite Floor I-Joist

a guardrail and composite floor technology, applied in the field of composite floor ijoists and composite guardrail posts, can solve the problems of shortening the service life, and reducing the service life of the guardrail, and achieve the effects of increasing the strength and ductility of the system, reducing the cost of maintenance, and being more environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

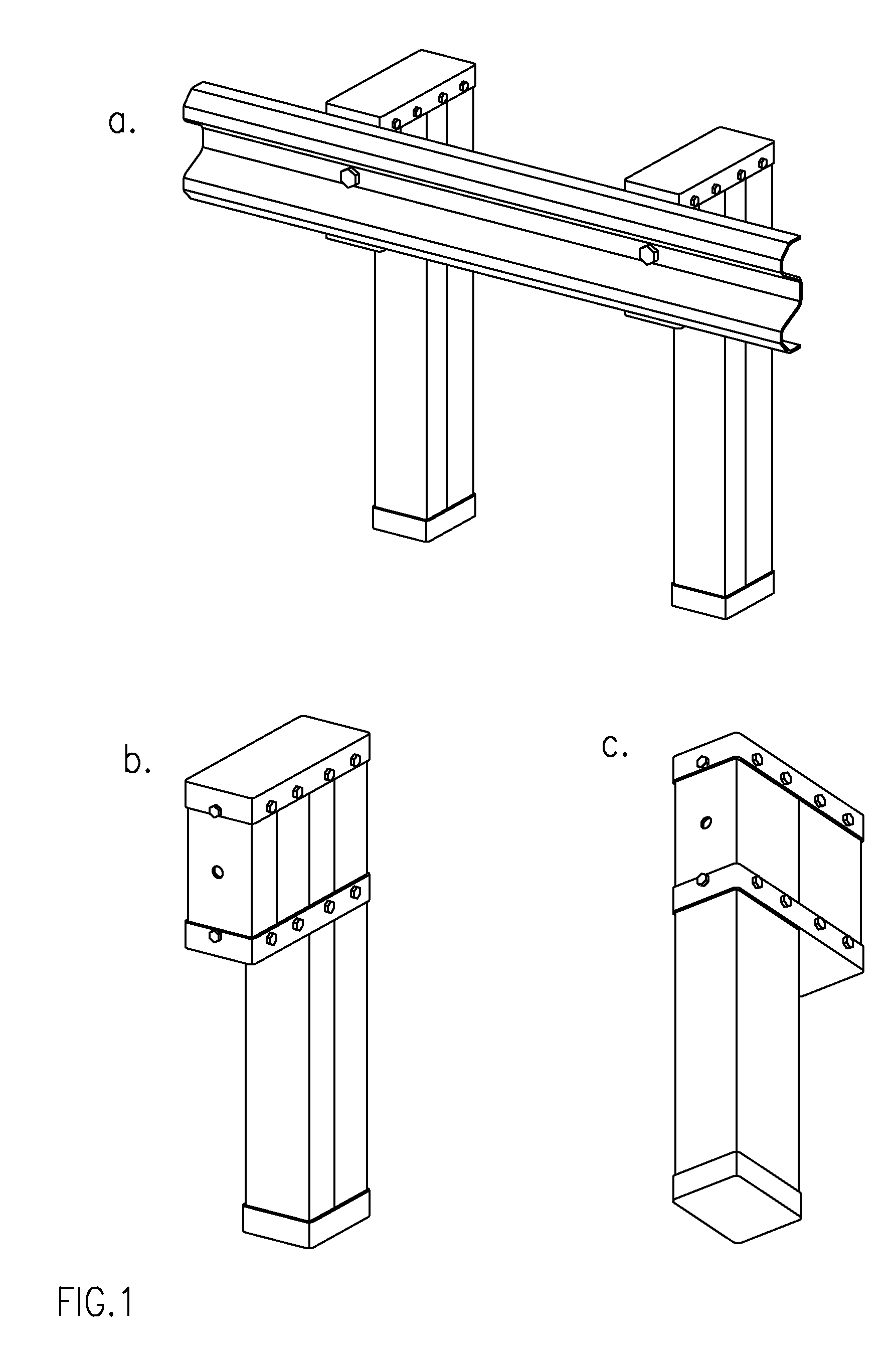

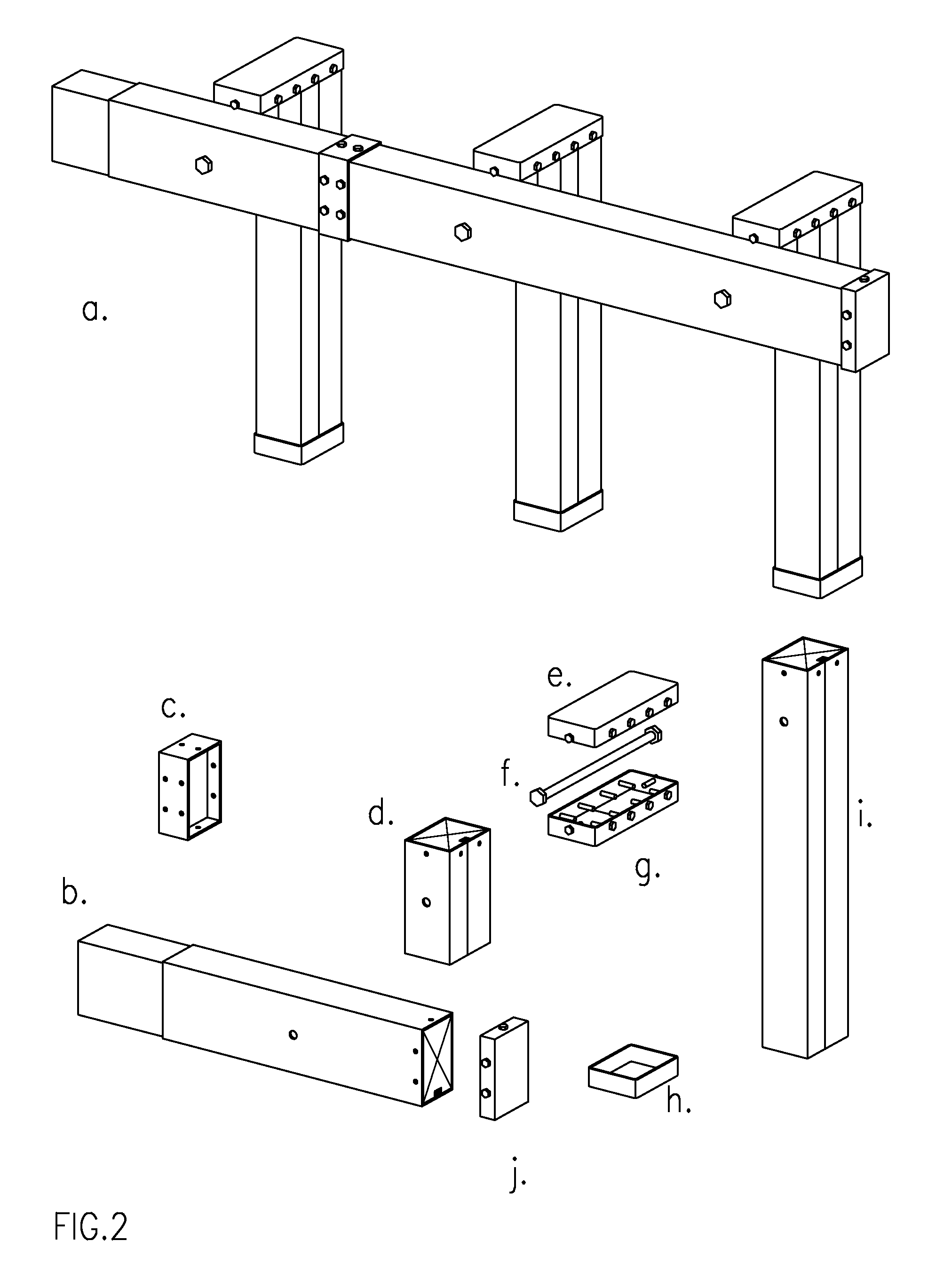

[0017]The first product is Composite Guardrail Post (CGP). Traditionally, highway guardrail posts are constructed using pressure treated timbers of standard sizes. This traditional construction has several drawbacks. For example, shorter durability, lower capacity, and negative environmental impact. CGP is designed overcome all these drawbacks by substituting standard timber posts with metal jacket composite posts. Not only will it last longer and look better, but also be very cost effective. The reasons are as the followings: (1) while traditional method required high quality timber and need to be treated using chemicals for erosion resistance, the new system can use recycled material which is cheaper and more environmental friendly; (2) Since the composite mechanism can significantly increase the strength and ductility of the system, the required spacing of the posts can be increased, the result of which is less material (i.e. posts) be used for the same length of road way. (3) Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com