Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

208results about How to "Avoid paper jams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

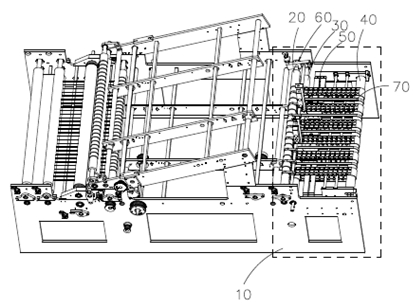

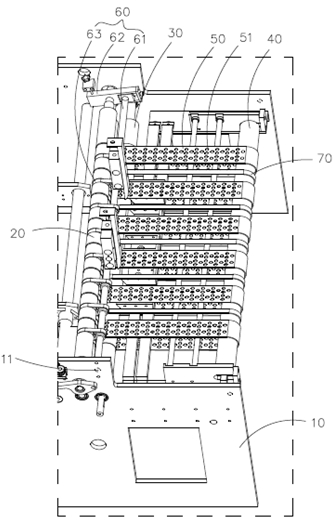

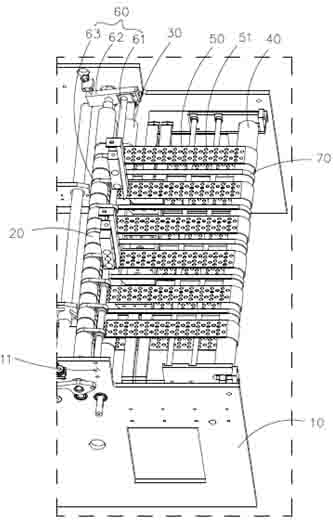

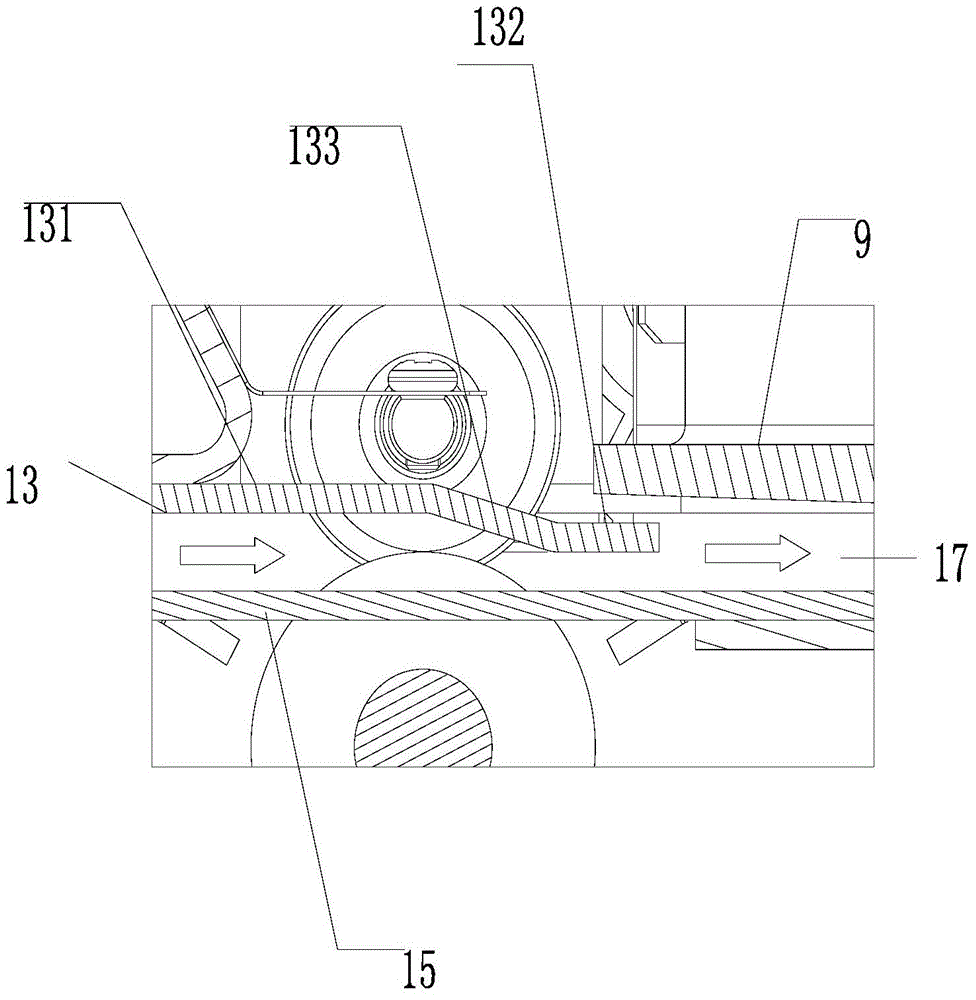

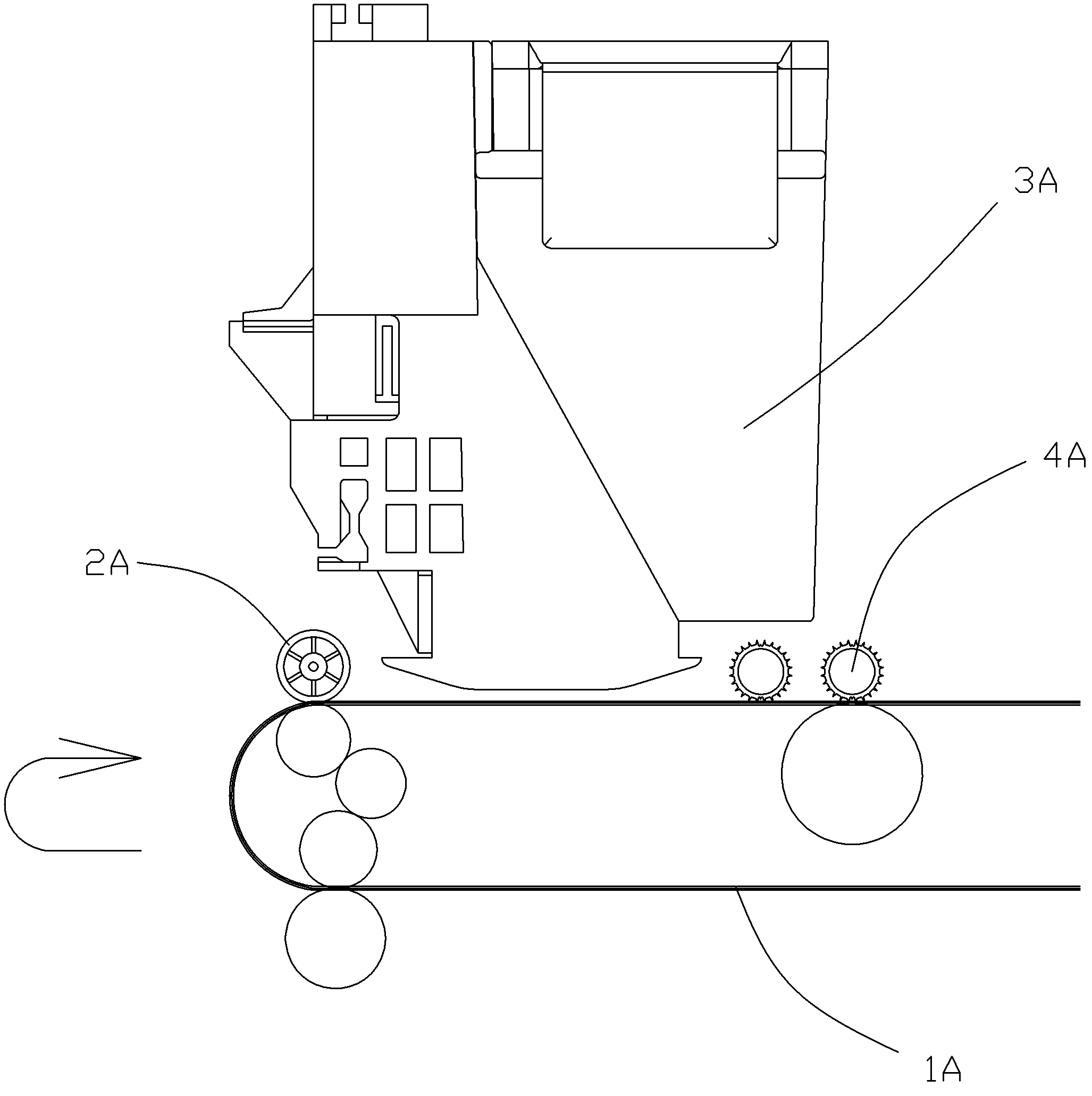

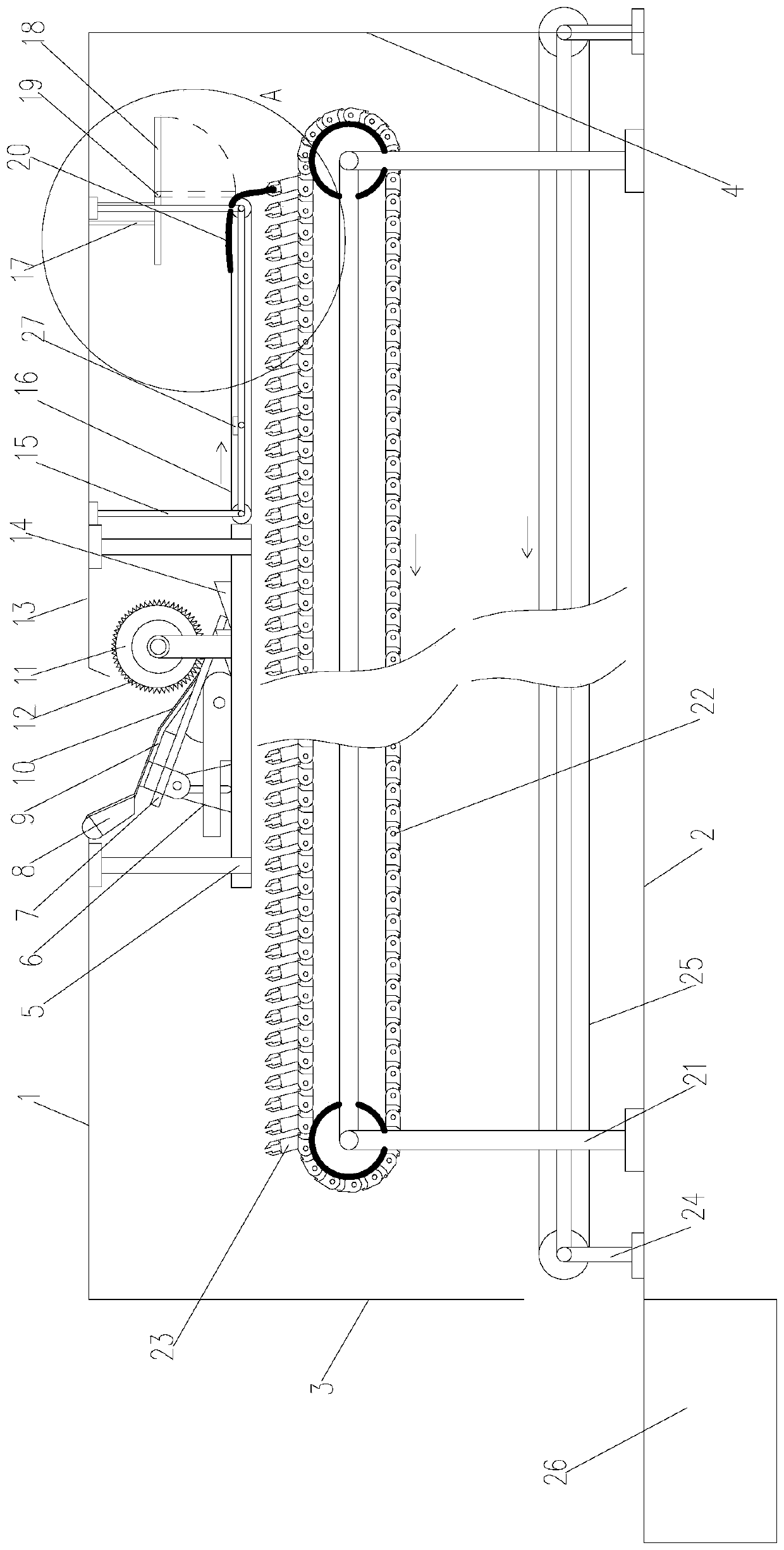

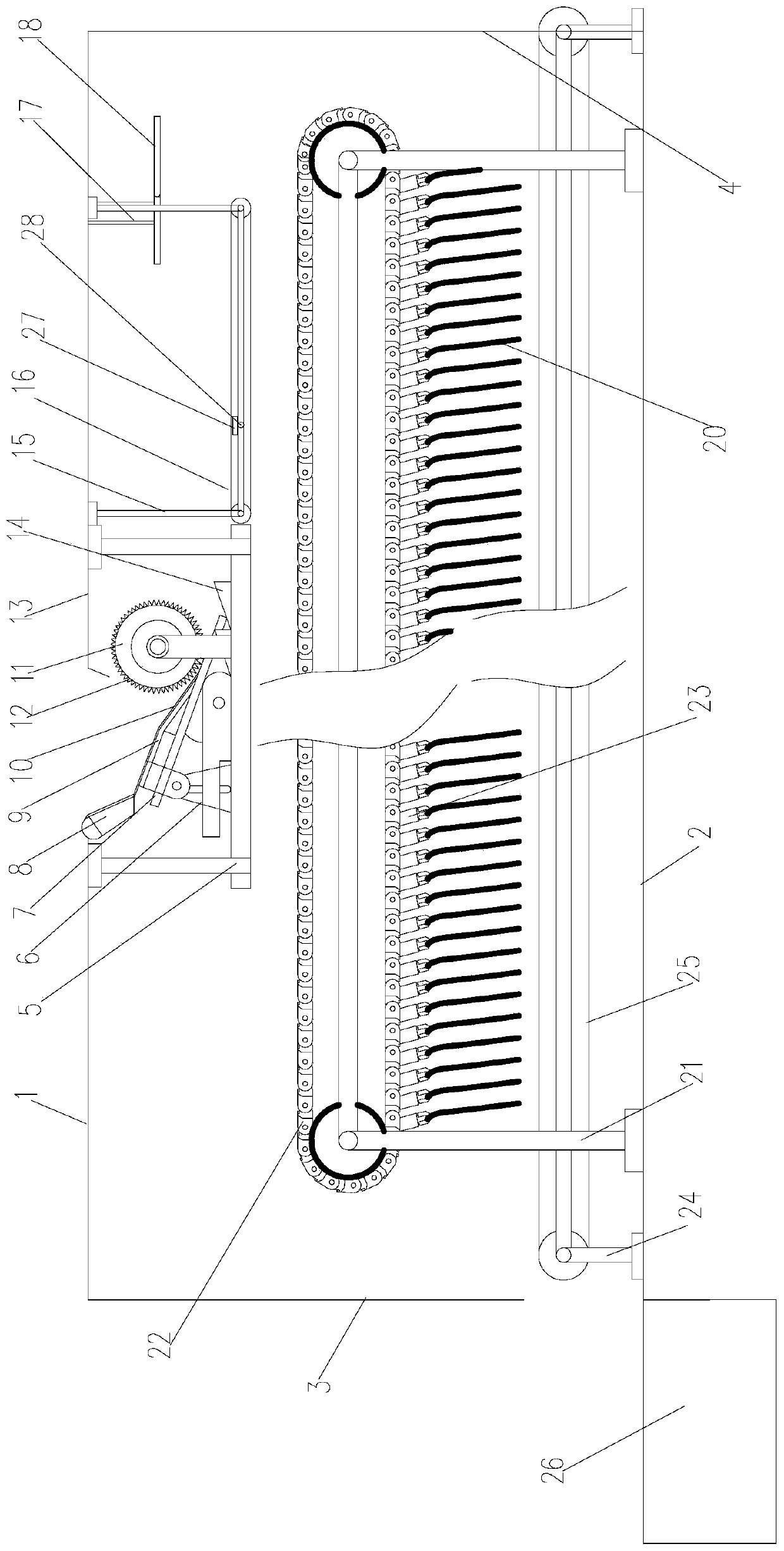

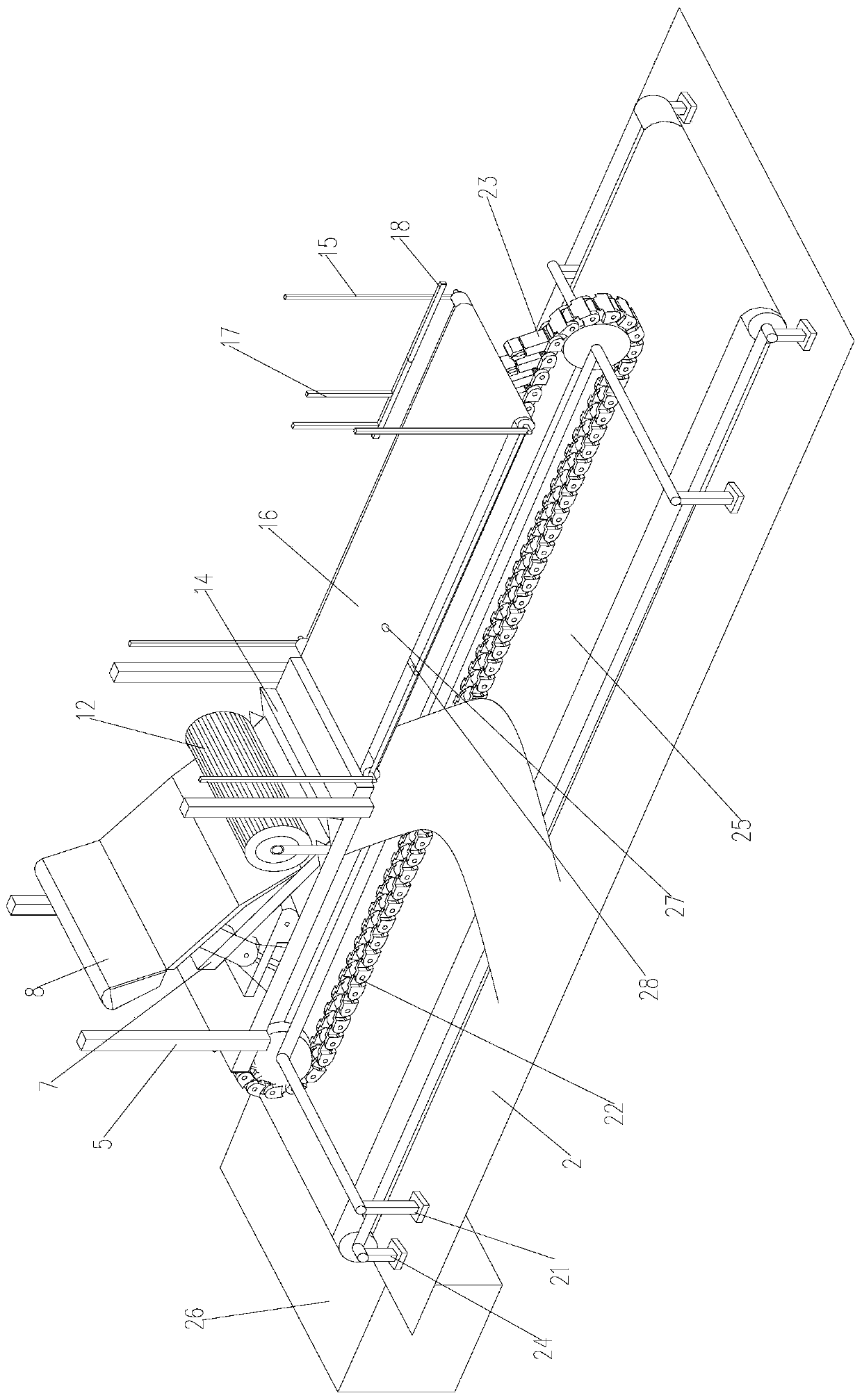

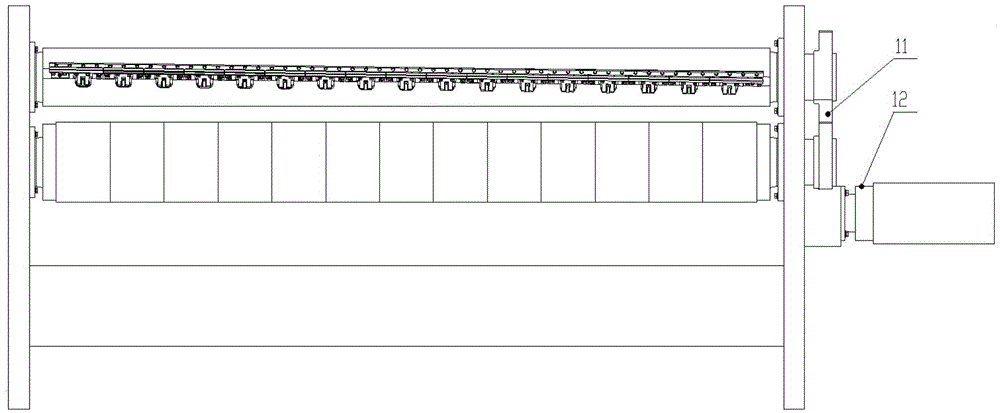

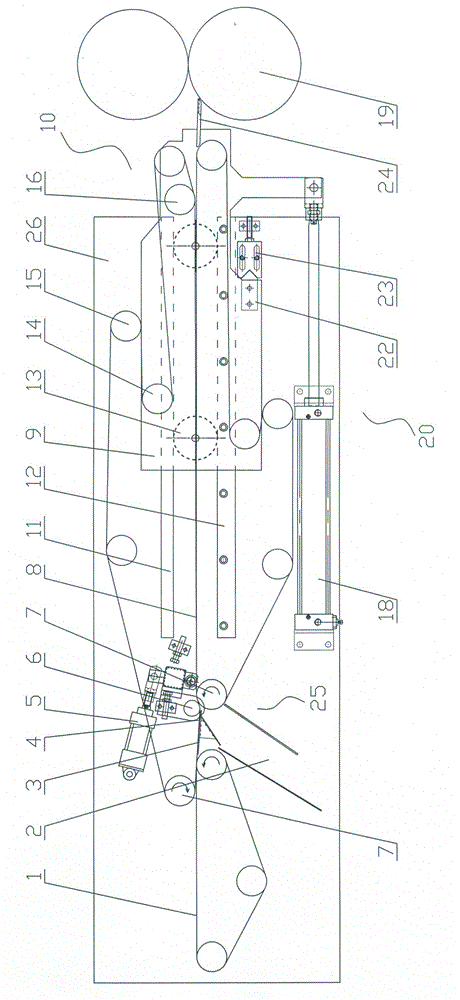

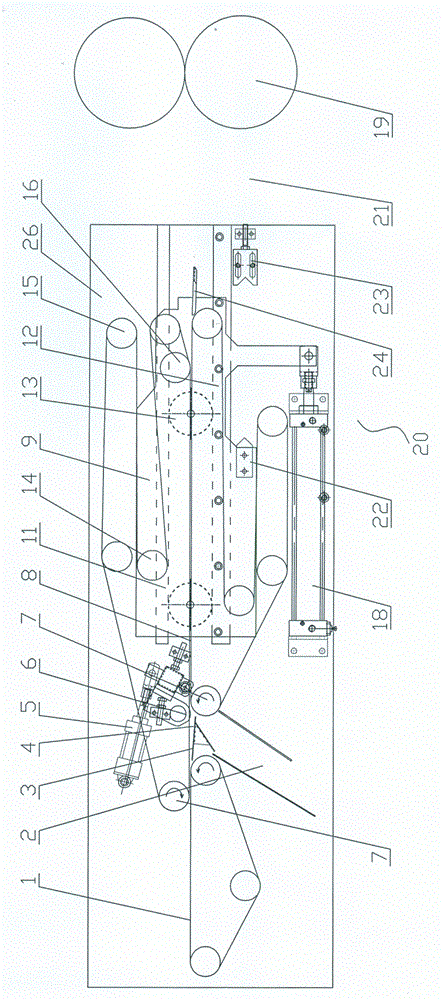

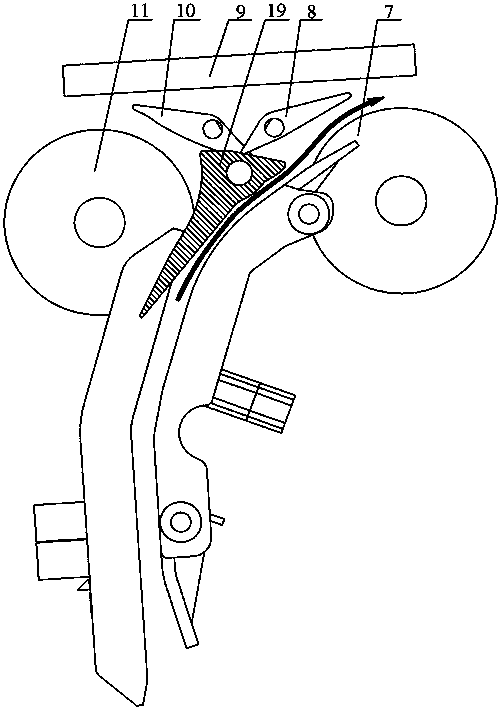

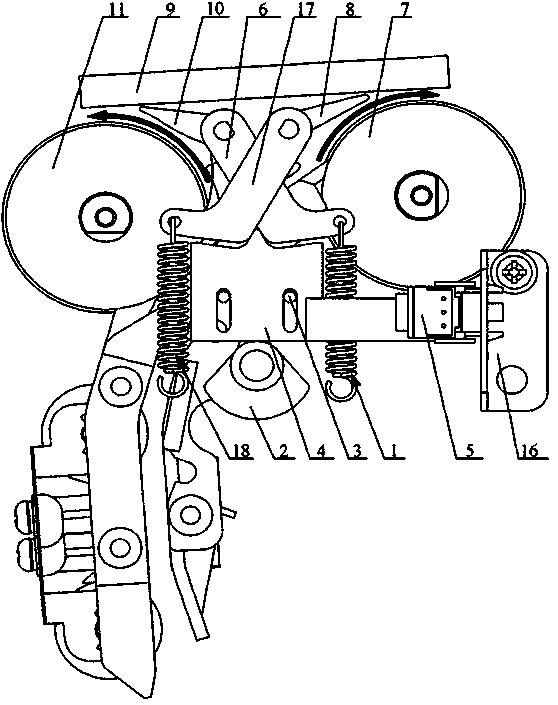

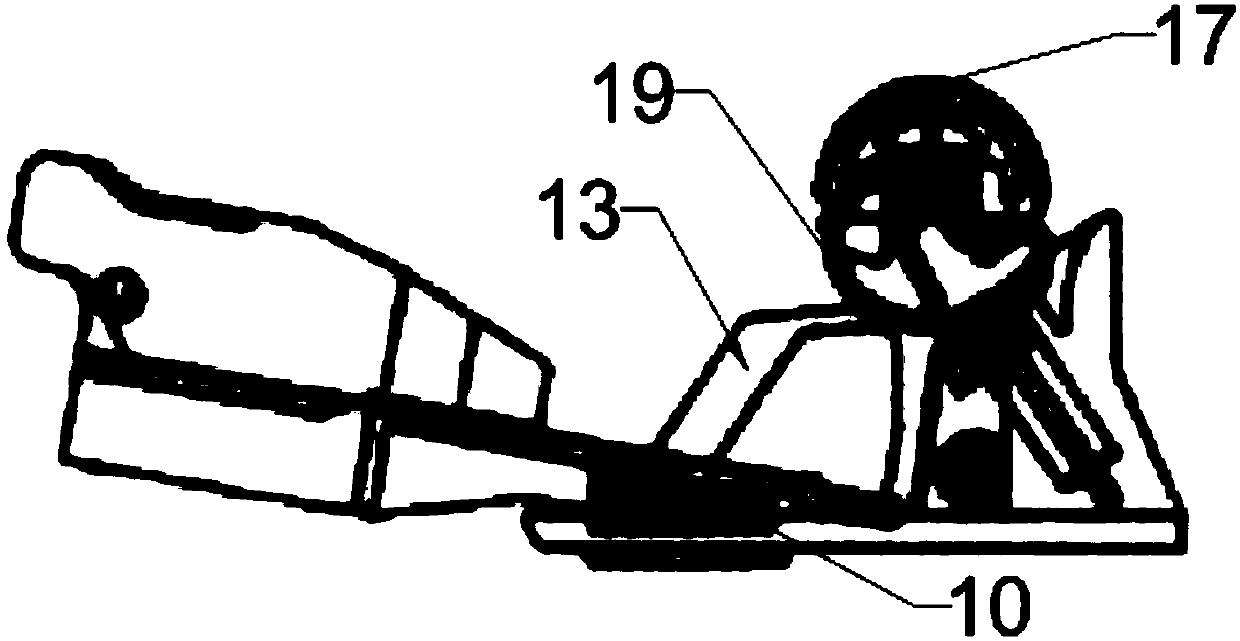

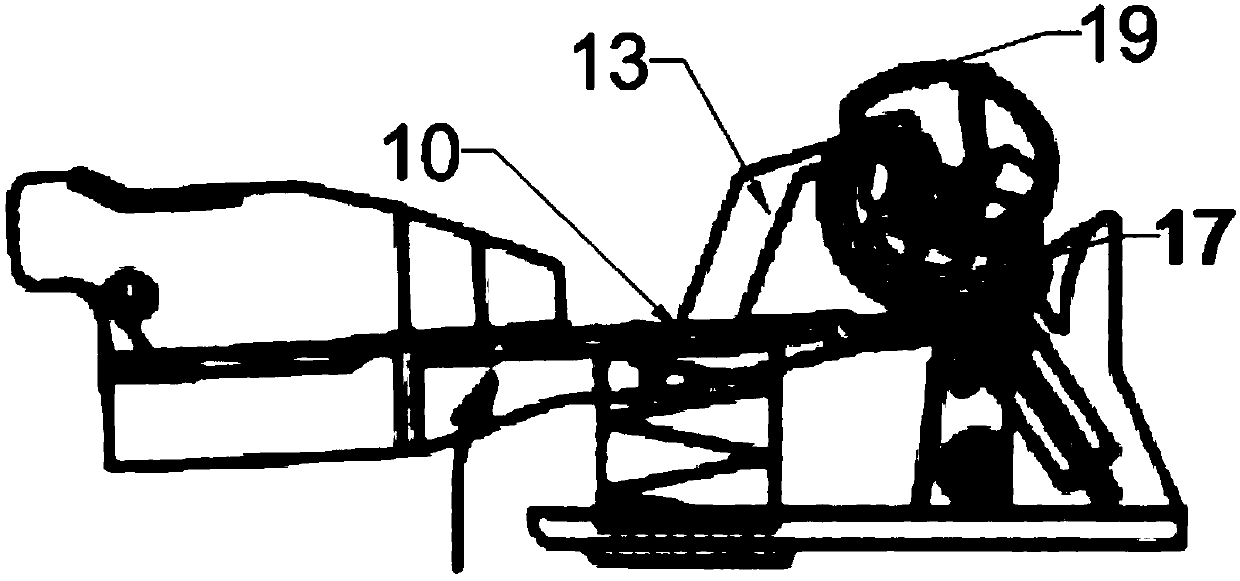

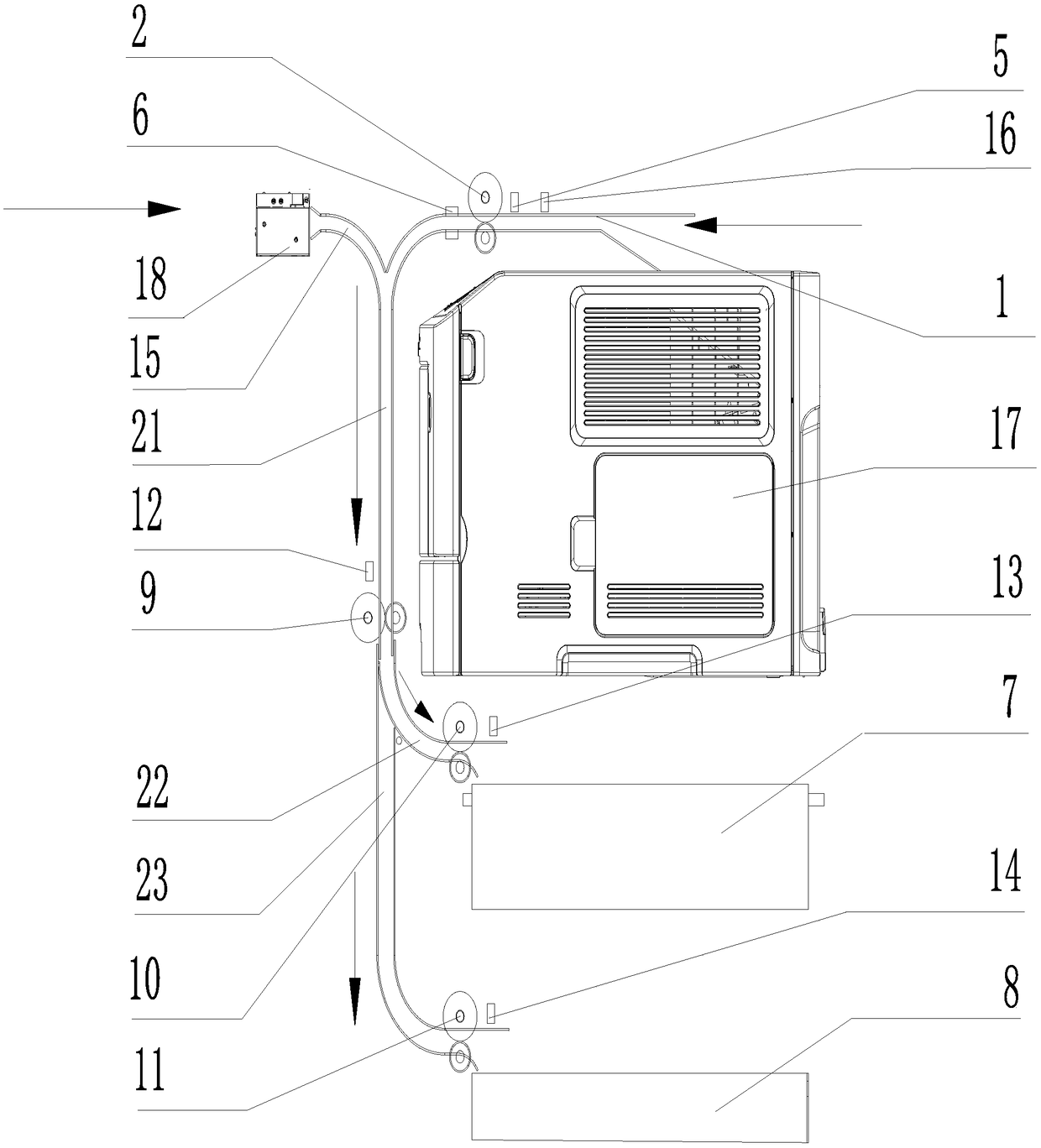

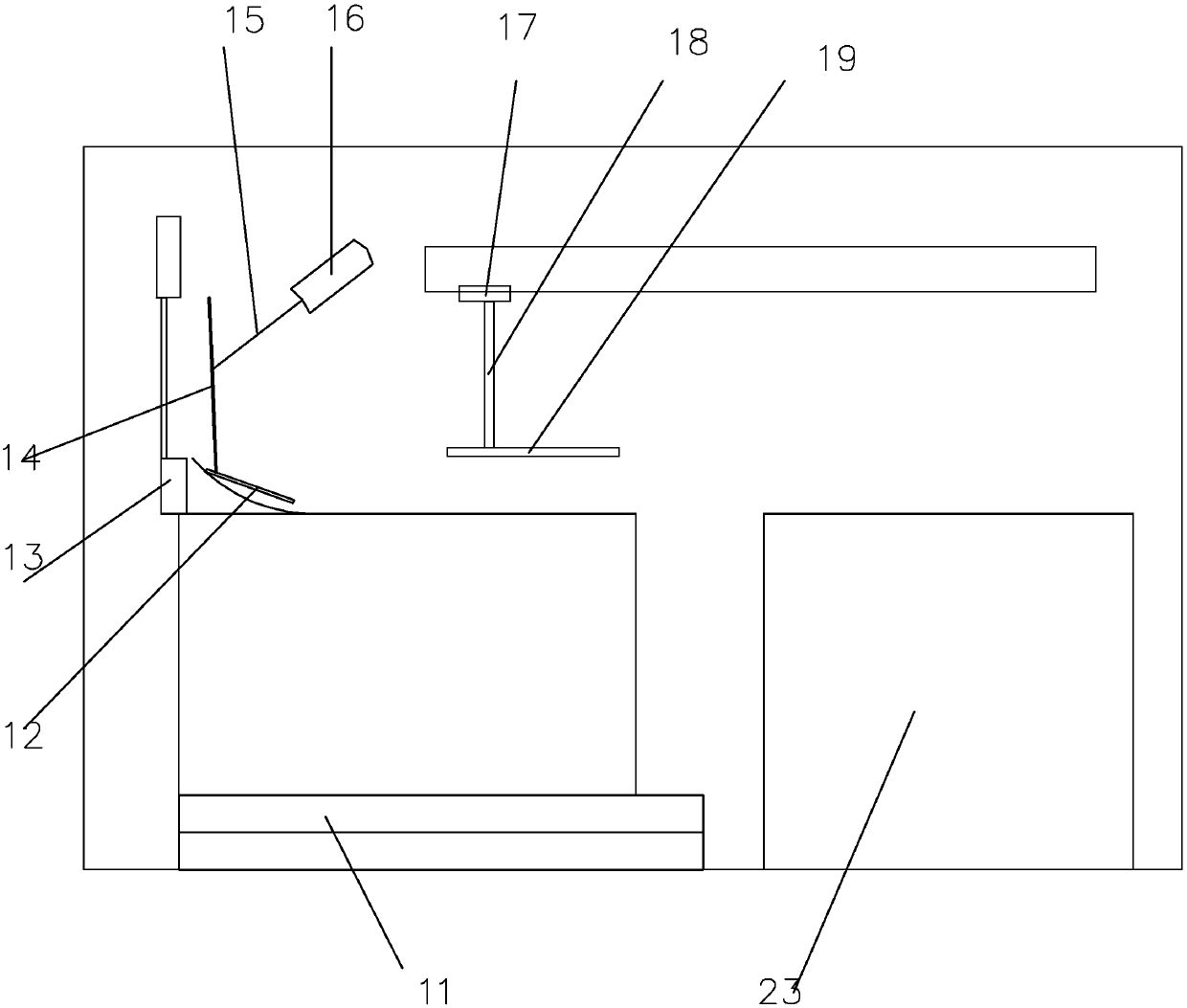

Backing paper feeding mechanism of paper pasting machine

The invention discloses a backing paper feeding mechanism of a paper pasting machine, which comprises a rack, wherein a paper feeding roller, a driving roller, a driven roller, an annular paper conveying belt and a paper pressing adjustment mechanism are arranged on the rack, the driving roller and the driven roller are arranged in parallel, the annular paper conveying belt is sleeved on the driving roller and the driven roller, the paper pressing adjustment mechanism is arranged above the annular paper conveying belt, the paper pressing adjustment mechanism comprises a paper pressing shaft, an adjusting hand wheel and a conveying belt, the paper pressing shaft is fixedly connected with the adjusting hand wheel, the adjusting hand wheel is used for adjusting a gap between the paper pressing shaft and the annular paper conveying belt, and the conveying belt is sleeved on the paper pressing shaft and the paper feeding roller. According to the invention, the paper pressing adjustment mechanism is arranged above the annular paper conveying belt, backing paper is positioned by the paper pressing shaft, and the backing paper is guided by the conveying belt to be conveyed below the paper feeding roller, so that the phenomenon of the paper blockage caused by the deformation of the backing paper is prevented, and a manual paper leveling operation on the deformed paper is avoided, therefore, the labor intensity is reduced, the production efficiency is improved, and the product quality is guaranteed.

Owner:段玉芳

Automatic stamping method

InactiveCN102815106AImprove clarityAvoid paper jamsOther printing apparatusStampingStampingComputer printing

The invention discloses an automatic stamp method, comprising the steps of: firstly outputting paper by a printer at the speed of V, and feeding the paper into the paper feeding channel of a stamping machine; then synchronously driving the paper to continue move forwards by a drive mechanism in the paper feeding channel at the speed of V; when the paper is at the position to be stamped, and the position is matched with the position of the stamping mechanism of the stamping machine, stopping the drive mechanism to stop conveying the paper, so that the stamping mechanism can be contacted with the paper, and then stamping; after delaying a segment of time, ending stamping; when the stamping mechanism leaves the paper, restarting the drive mechanism; if stamping is needed on the next position on the same paper, feeding the paper to move forwards by the drive machine at a faster speed of V1, and then stamping at the next position to be stamped; and if the stamping of the same paper ends, feeding the paper to move forwards by the drive mechanism at the speed of V unit the paper is output outside the stamping machine.

Owner:苏州合亚信息技术有限公司

Printer structure

The invention provides a printer structure. When printing is performed, a roller applies a driving force on a thermal head and ensures the thermal head to move a certain distance backward, then an elastic device applies an opposite acting force on the thermal head to ensure that the thermal head closely sticks to the roller; and the flatness can be automatically adjusted through the opposite acting force of the elastic device. Therefore, the thermal head and the roller can be at the same level and the paper jamming phenomenon in the printing process can be avoided.

Owner:EDAN INSTR

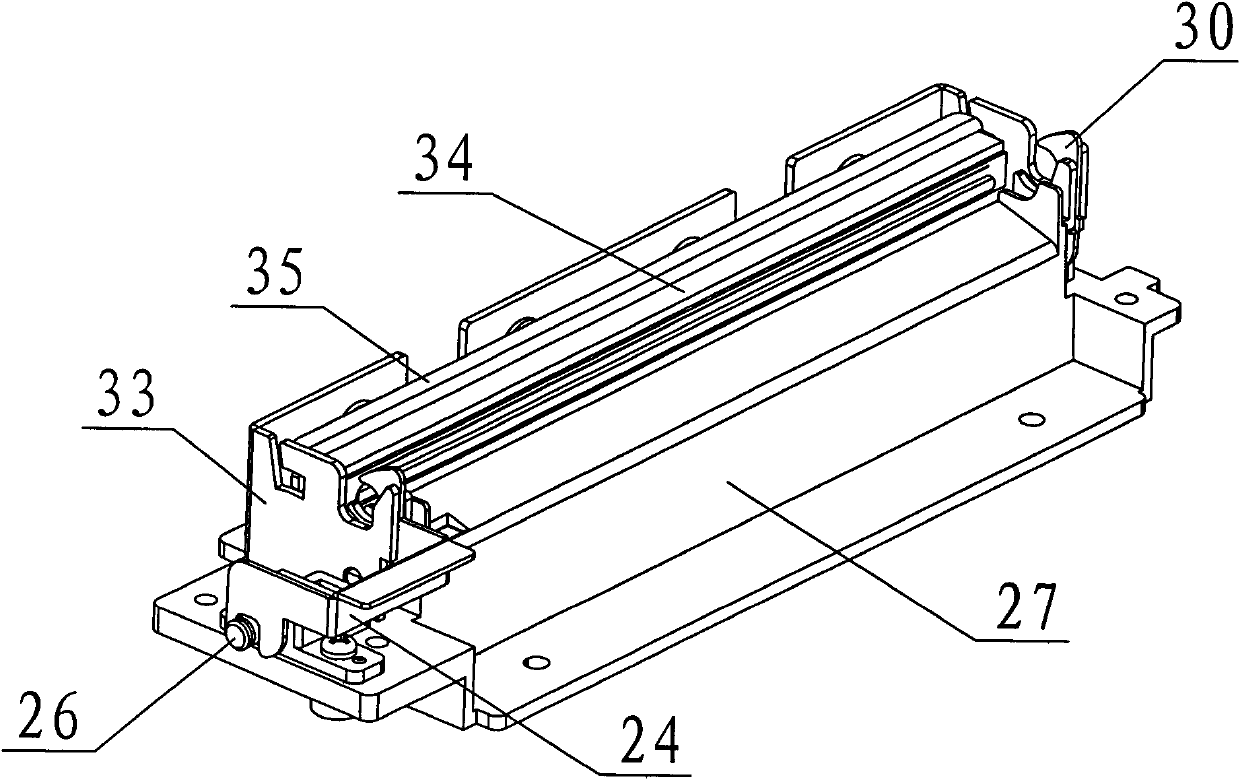

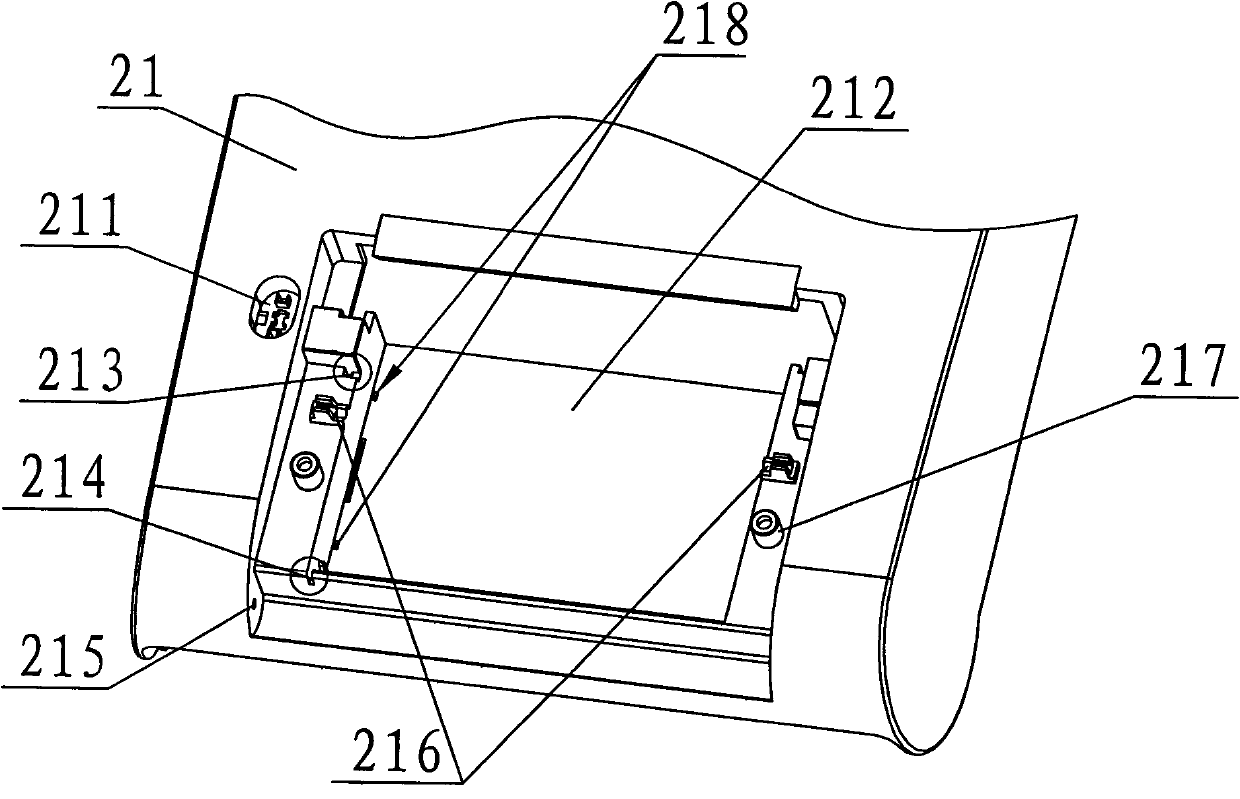

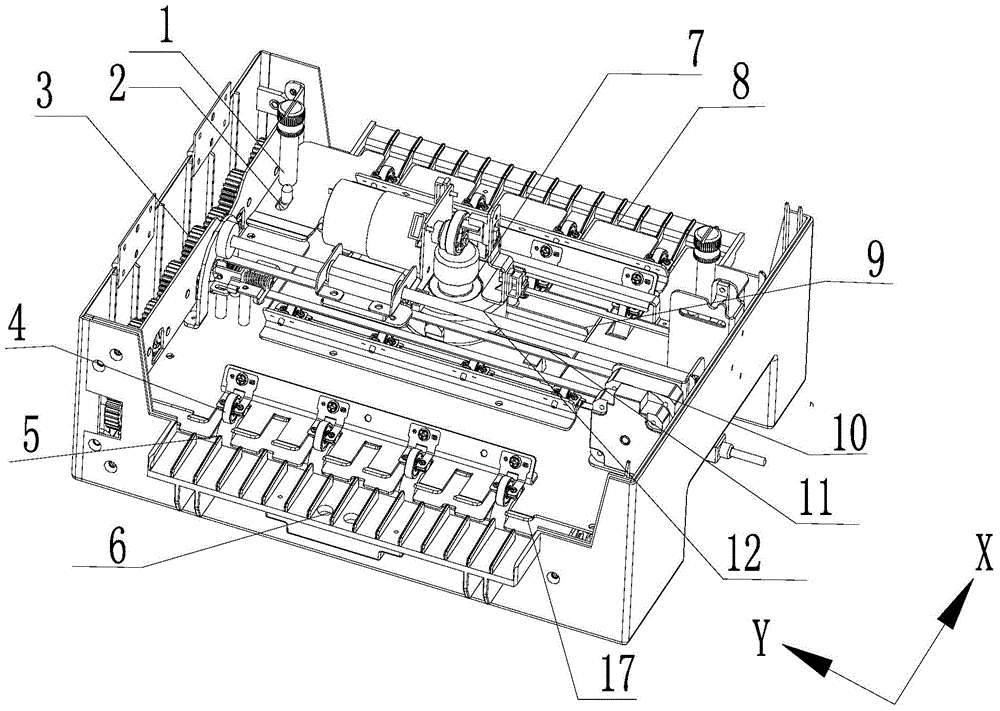

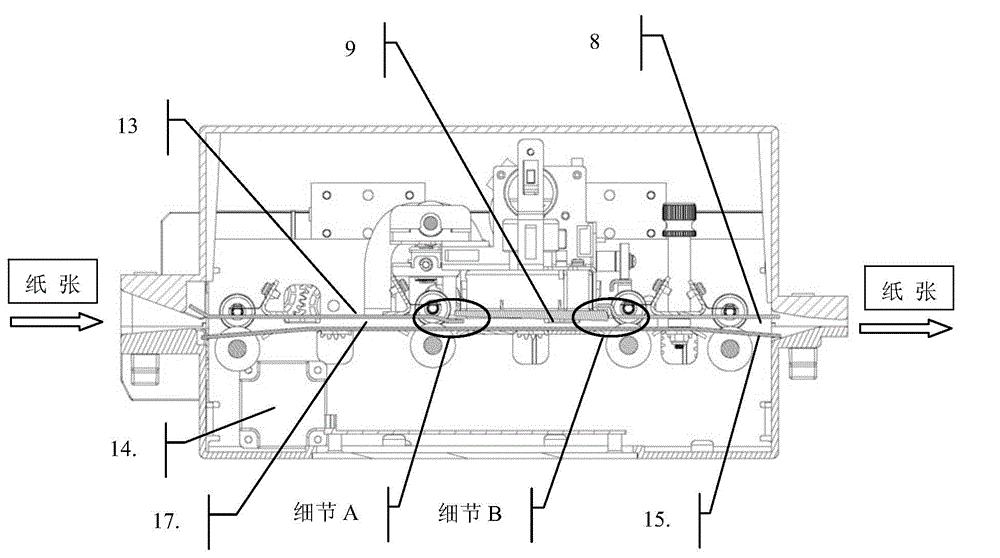

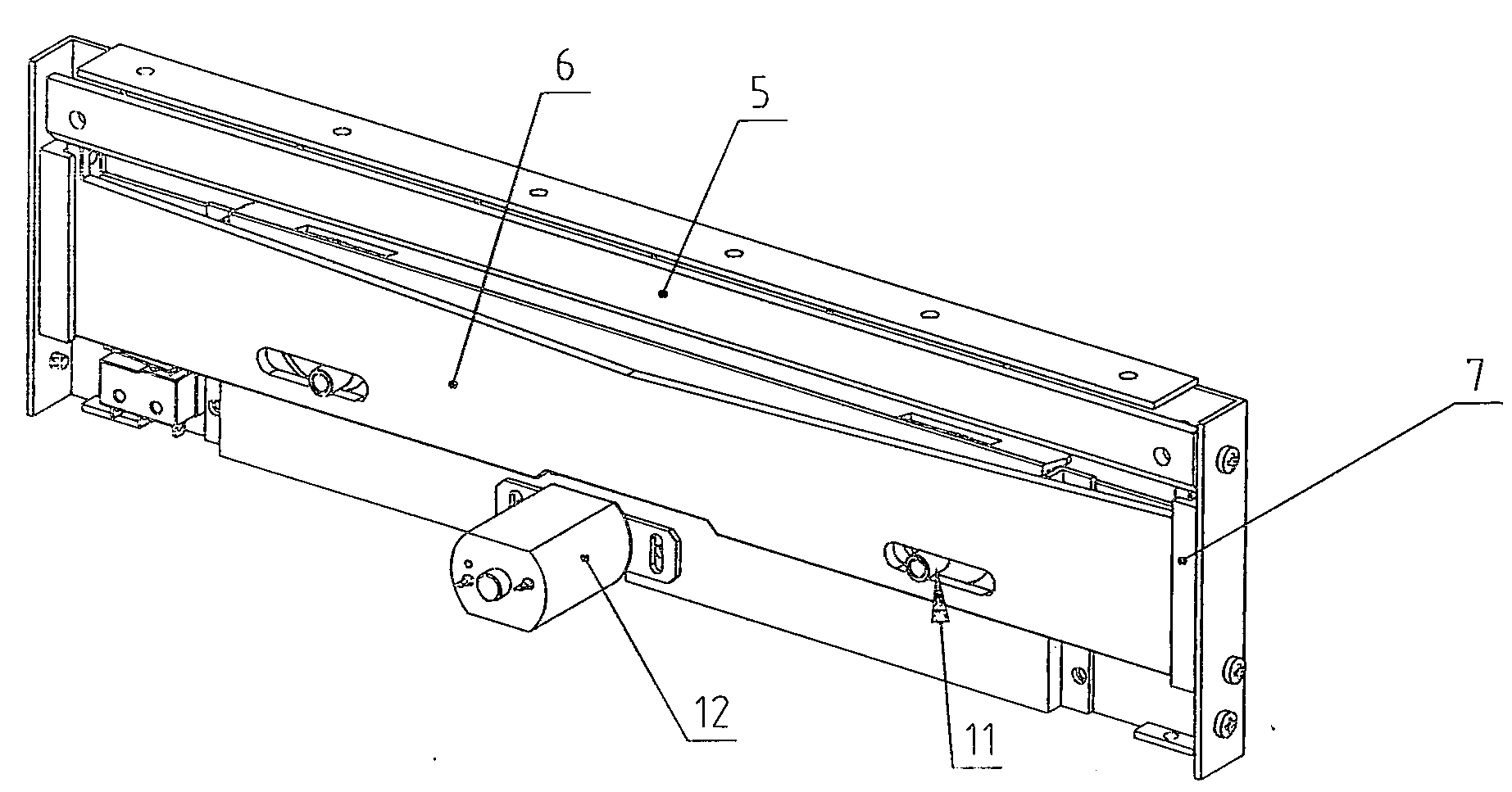

Full-breadth stamping device

ActiveCN103552390AAvoid paper jamsRealize full-format stamping functionStampingPulp and paper industry

The invention provides a full-breadth stamping device. The outer part of the full-breadth stamping device comprises a paper inlet, a paper outlet and a casing, and the inner part of the full-breadth stamping device comprises a X-axis direction moving component, a Y-axis direction moving component and a stamping mechanism, wherein the X-axis direction moving component is used for detecting whether paper enters the paper inlet and driving the paper to move in the X-axis direction when paper entering the paper inlet is detected; the Y-axis direction moving component is used for driving the stamping mechanism to move in the Y-axis direction after the paper moves to a preset X-axis position; the stamping mechanism is used for stamping after the paper moves to a preset Y-axis position. According to the full-breadth stamping device, the stamping mechanism can realize the full-breadth stamping function of paper in the X-axis and Y-axis directions; a channel of the stamping device adopts a unidirectional imbricated design, which can effectively prevent paper from being stuck in the channel, and is suitable for paper of various specifications such as A4 and B4; besides, a stamp changing mechanism adopts a hand-twisting type detachable design, and has the characteristic of the maintenance of rapid stamp changing.

Owner:GRG BAKING EQUIP CO LTD

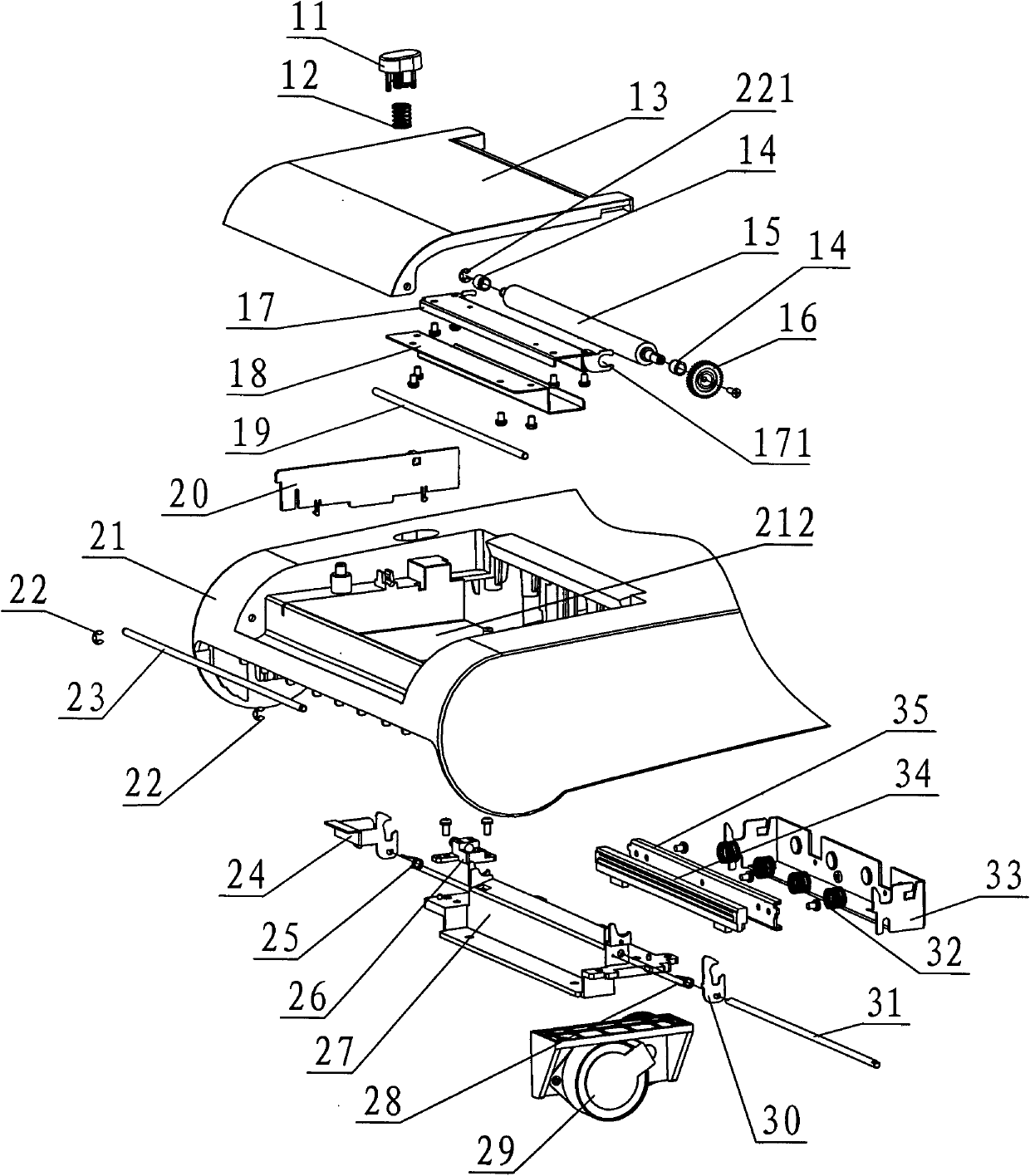

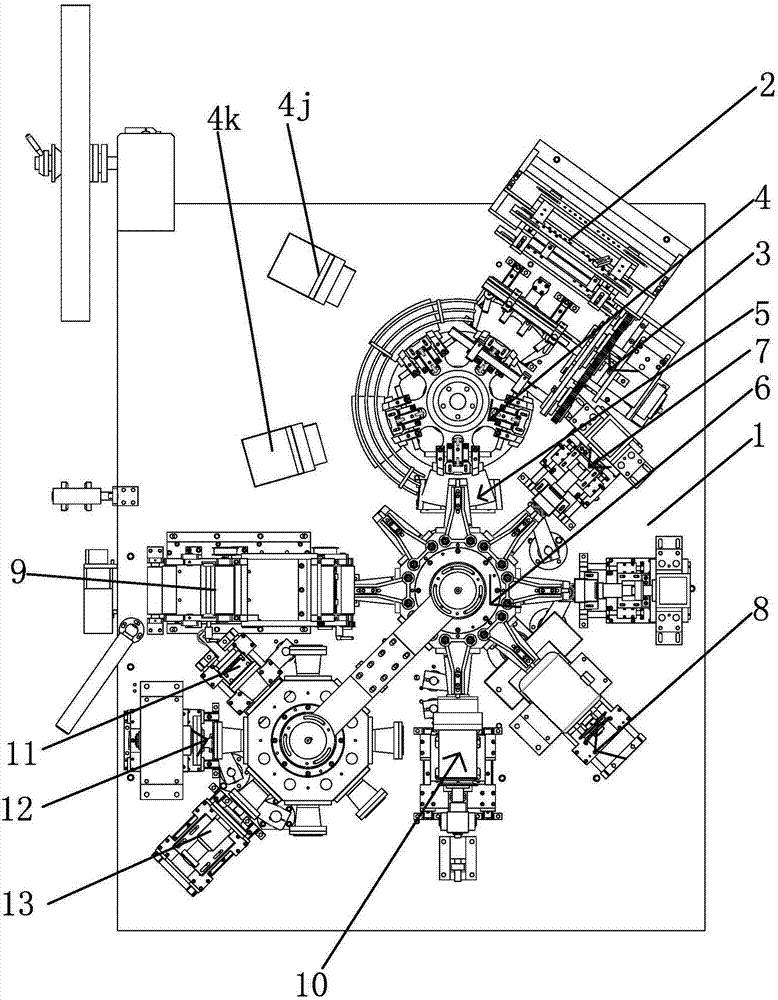

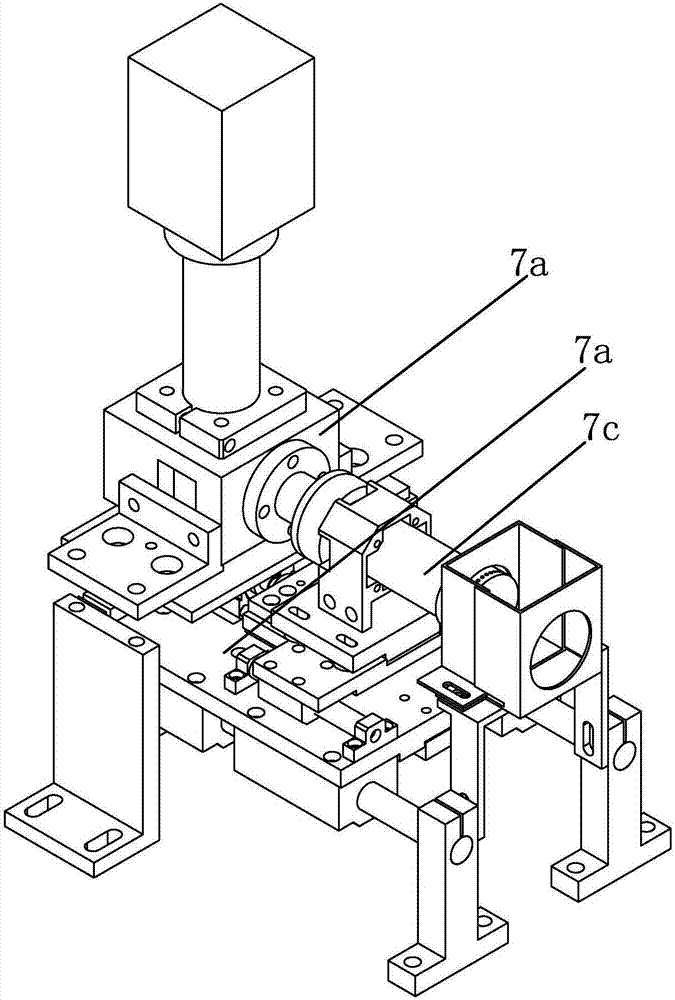

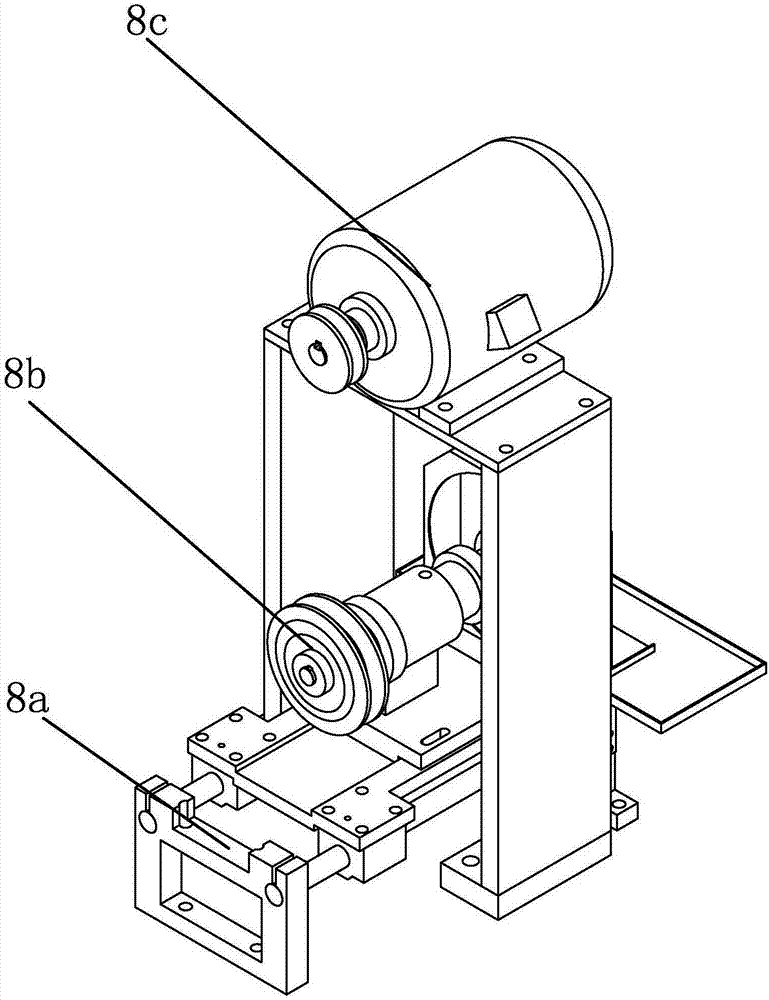

Paper cup machine

InactiveCN107303738AIncrease productivityReduce cumbersome operationsPaper/cardboard articlesPaper cupPaper sheet

The invention provides a paper cup machine and belongs to the technical field of the paper cup machine. The paper cup machine is used for solving the problem of low manufacturing efficiency of the paper cup machine in the prior art. The paper cup machine comprises a workbench and a paper storage rack fixedly arranged on the workbench; the workbench is equipped with an outlet; a paper-absorbing mechanism which is used for absorbing and conveying the paper sheet from the paper storage rack is arranged on one side of the outlet; a conveying mechanism which is used for conveying the paper sheet is arranged under the paper-absorbing mechanism; a cup body embracing mechanism which is used for bending and embracing the paper sheet is arranged on one side of the conveying mechanism; a gluing mechanism which is used for gluing the paper cup body is arranged on one side of the cup body embracing mechanism; the gluing mechanism comprises a working plate; a first driving mechanism which is used for driving the working plate to rotate is arranged under the working plate; a plurality of paper cup molds are fixedly arranged on the outer periphery of the working plate; a pressing cutter is arranged above the paper cup molds; a second driving mechanism which can drive the pressing cutter to move up and down is arranged on the working plate. The paper cup machine has the advantage of high manufacturing efficiency.

Owner:海宁诚达机械有限公司

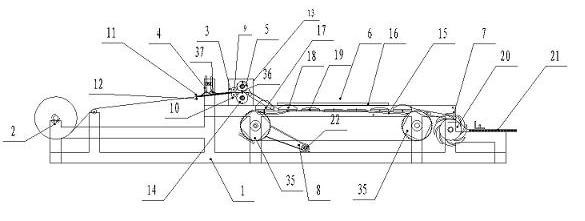

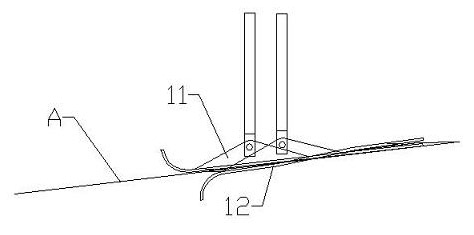

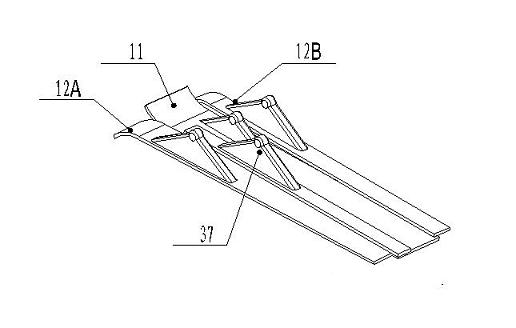

Paper ingot folding machine

InactiveCN102431215ARun at a constant speedAvoid efficiencyPaper/cardboard articlesPulp and paper industryIngot

The invention discloses a paper ingot folding machine. The paper ingot folding machine comprises a machine frame, wherein a scroll fixing device, a paper belt drawing device, a parallel paper edge folding device, a paper belt cutting device, a paper sheet obliquely folding device, a paper sheet obliquely coiling device and a power driving device are sequentially arranged on the machine frame. Thepaper ingot folding machine can perform parallel paper edge folding, continuous cutting and oblique diagonal folding on paper sheets, has multiple functions and is convenient to operate and maintain;the quality of finished products is high; and the paper ingot folding machine has the characteristics of reliable performance, consistency in folding size of the paper sheets, orderliness in paper sheet folding, high production efficiency, convenience in mechanical operation and maintenance and the like.

Owner:韩立斌

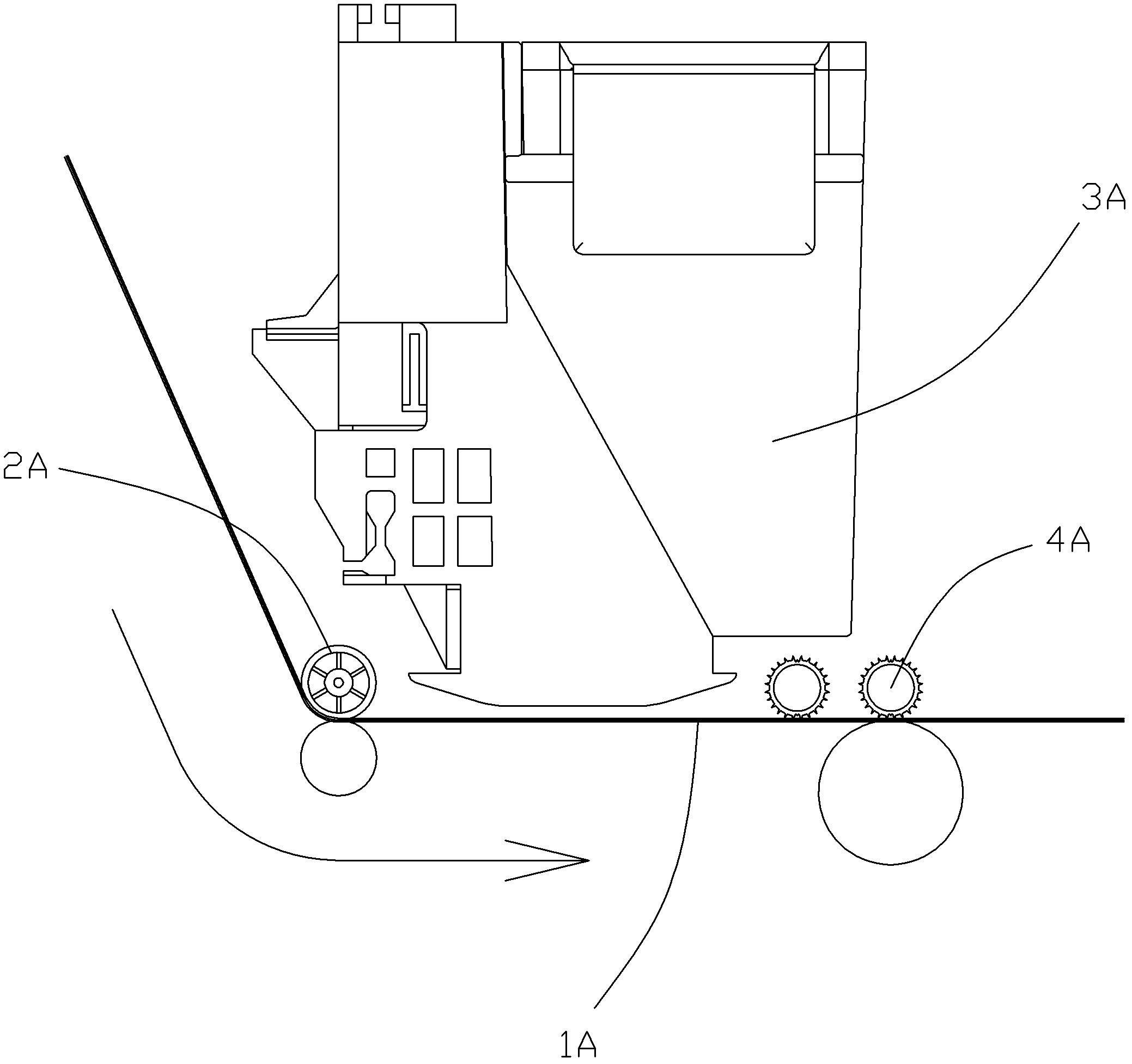

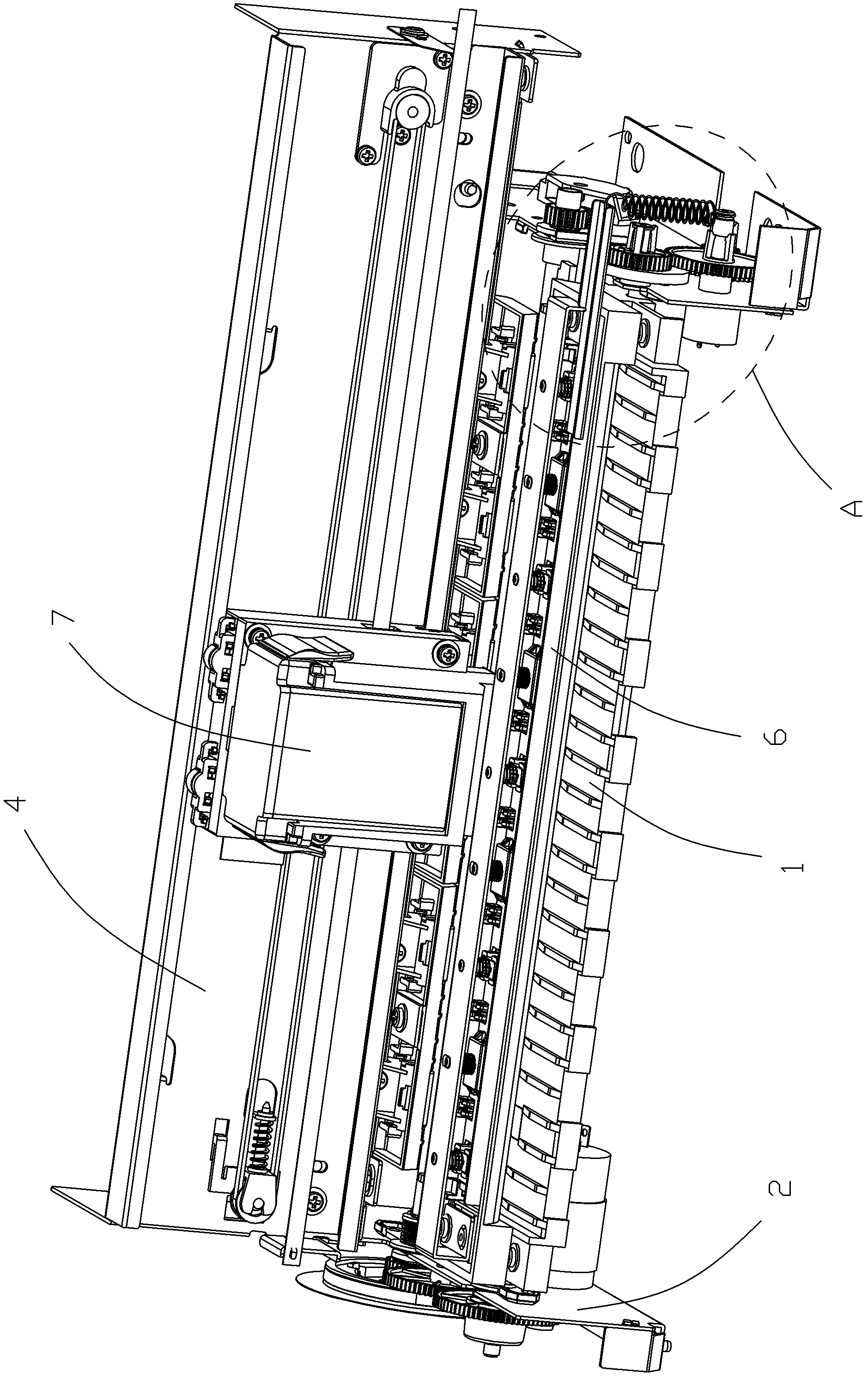

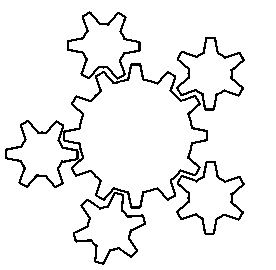

Flat-bed printer

ActiveCN102616006AReduce softness limitsReduce restrictionsOther printing apparatusCardboardGear wheel

The invention discloses a flat-bed printer which comprises a paper guide plate, a left side plate, a right side plate and a support seat, wherein a front upper paper guide base provided with a paper pickup star wheel is fixedly arranged on the paper guide plate; an ink jet head is arranged on the support seat; a front paper guide roller which is positioned in front of the ink jet head and is matched with the paper pickup star wheel is arranged between the left side plate and the right side plate; a top plate is hinged to the upper paper guide base; a batten is formed on the top plate; a front paper pickup roller which can be lifted along with the action of the top plate is arranged on the top plate; the front paper pickup roller penetrates through the square hole in the front upper paper guide base and then is matched with the front paper guide roller; an eccentric wheel abutted against the bottom end surface of the batten is arranged on the right side plate; a gear is formed on the side wall of the eccentric wheel; the gear is connected with the output end of a motor on the right side plate through a gear set; a rear paper guide roller positioned at the rear part of the ink jet head is also arranged between the left side plate and the right side plate; a rear upper paper guide base is fixedly arranged on the bottom side of the support seat; and a rear paper pickup roller matched with the rear paper guide roller is arranged on the rear upper paper guide base.

Owner:KONG YUE ELECTRONICS & INFORMATION IND XIN HUI

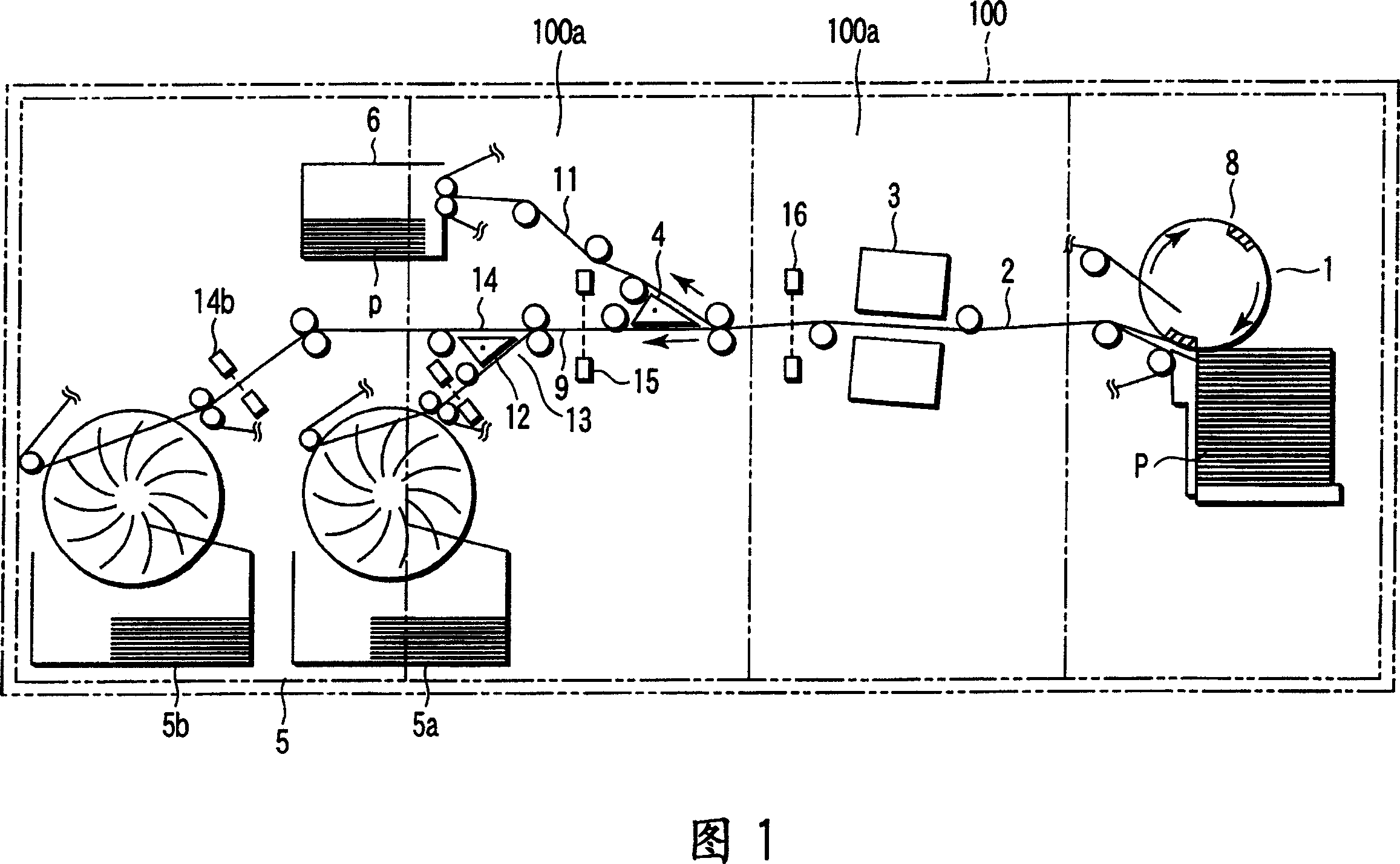

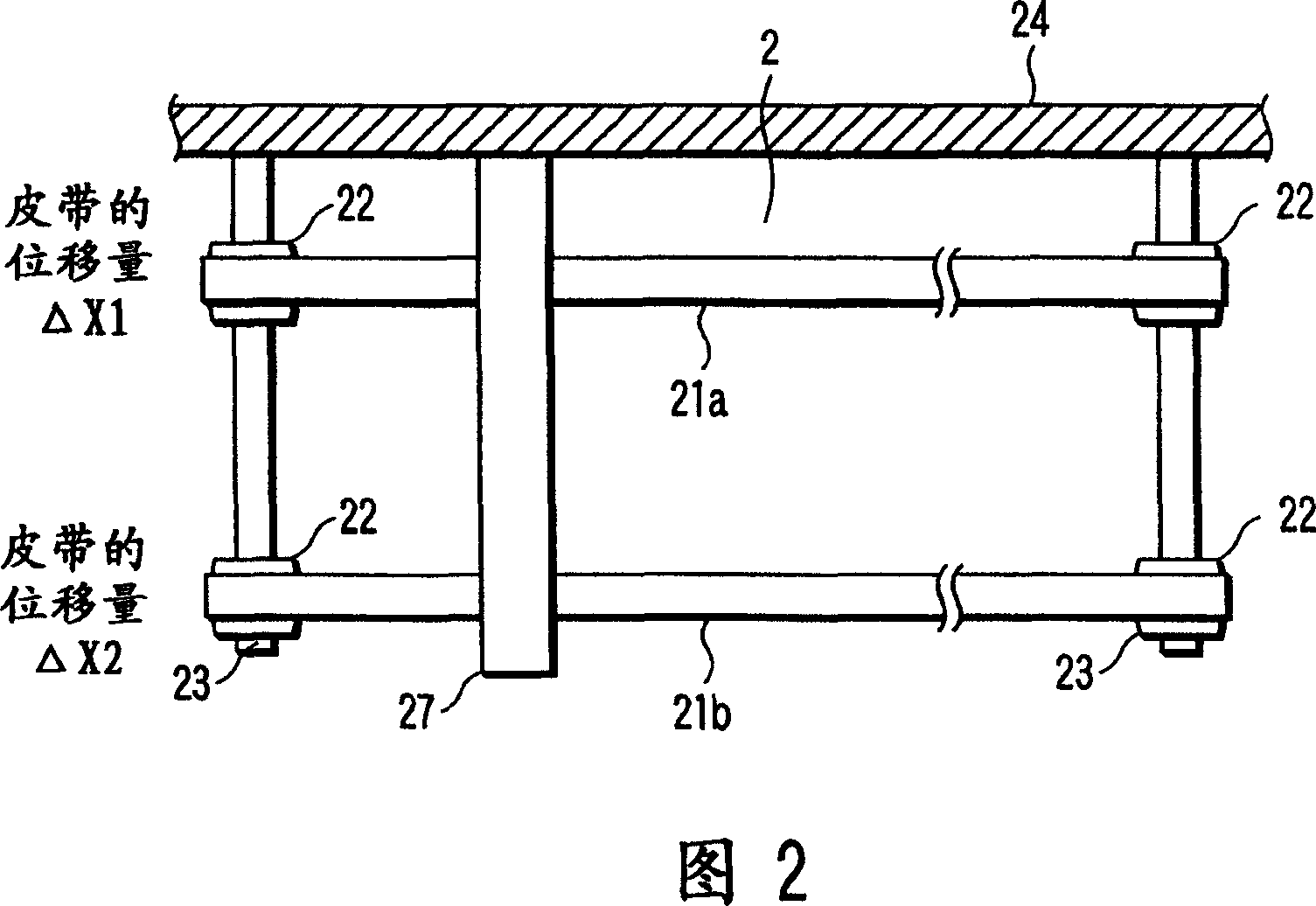

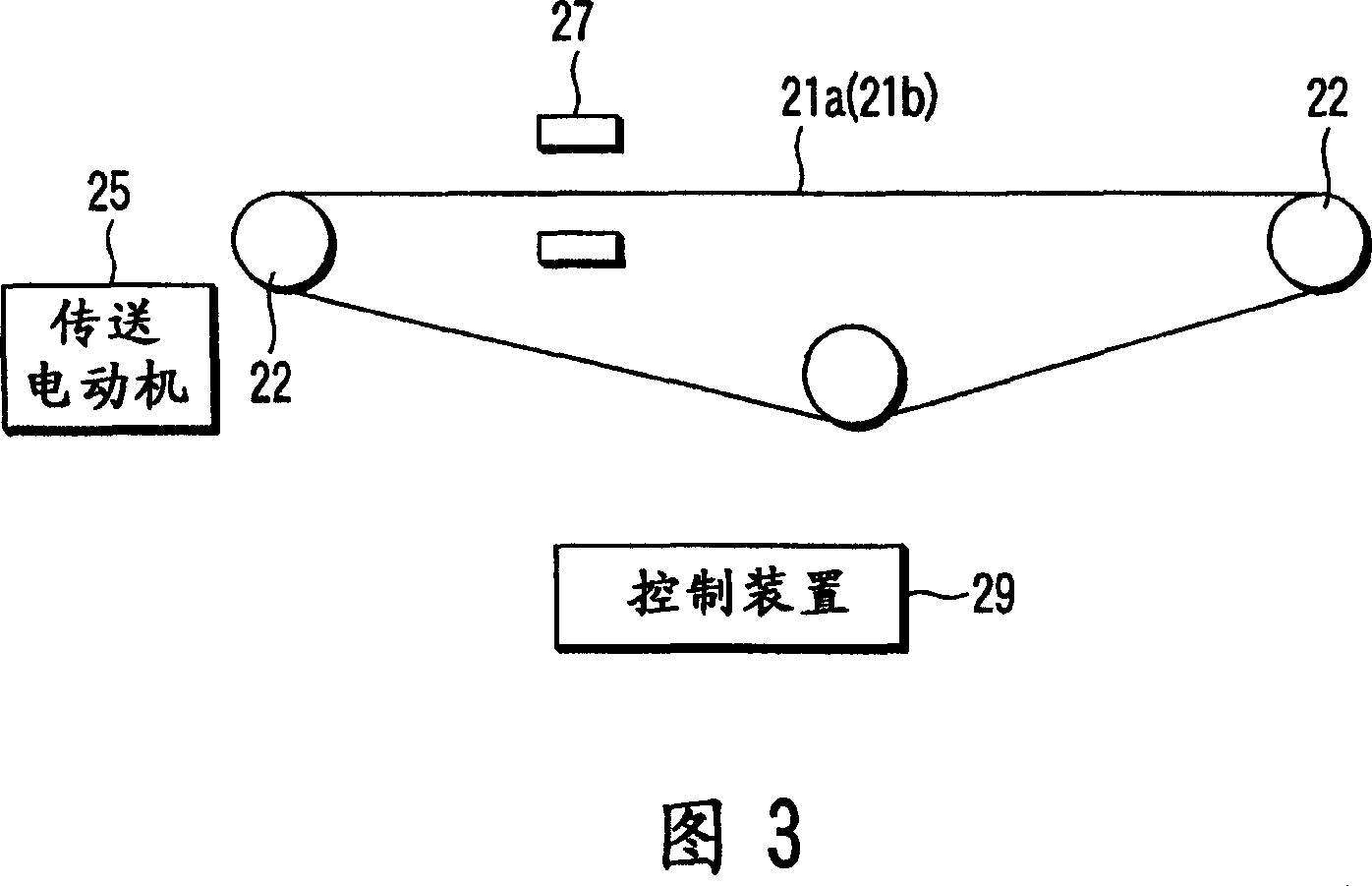

Paper sheet conveying apparatus

A paper sheet conveying apparatus has a conveying belt (21a, 21b) which moves and conveys a paper sheet, a detection sensor (27) which detects the amount of displacement of the conveying belt (21a, 21b) from a reference position while moving, and a control device (29) which drives the conveying belt (21a, 21b) at a low speed when a new device is installed as a conveying belt and initially started up, and after the low-speed driving, variably controls the speed of the conveying belt (21a, 21b) based on the amount of displacement of the conveying belt (21a, 21b) detected by the detection sensor (27).

Owner:KK TOSHIBA

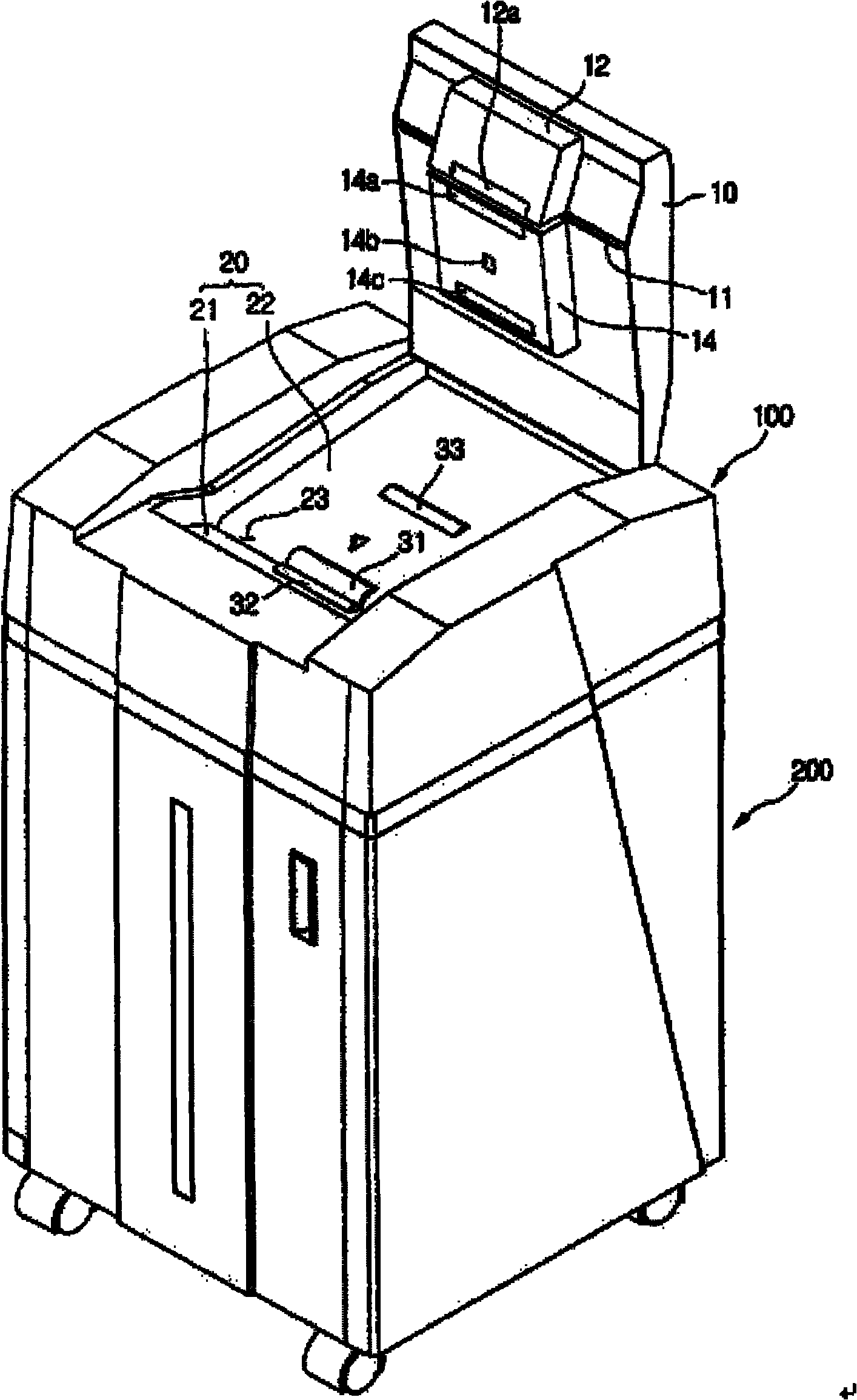

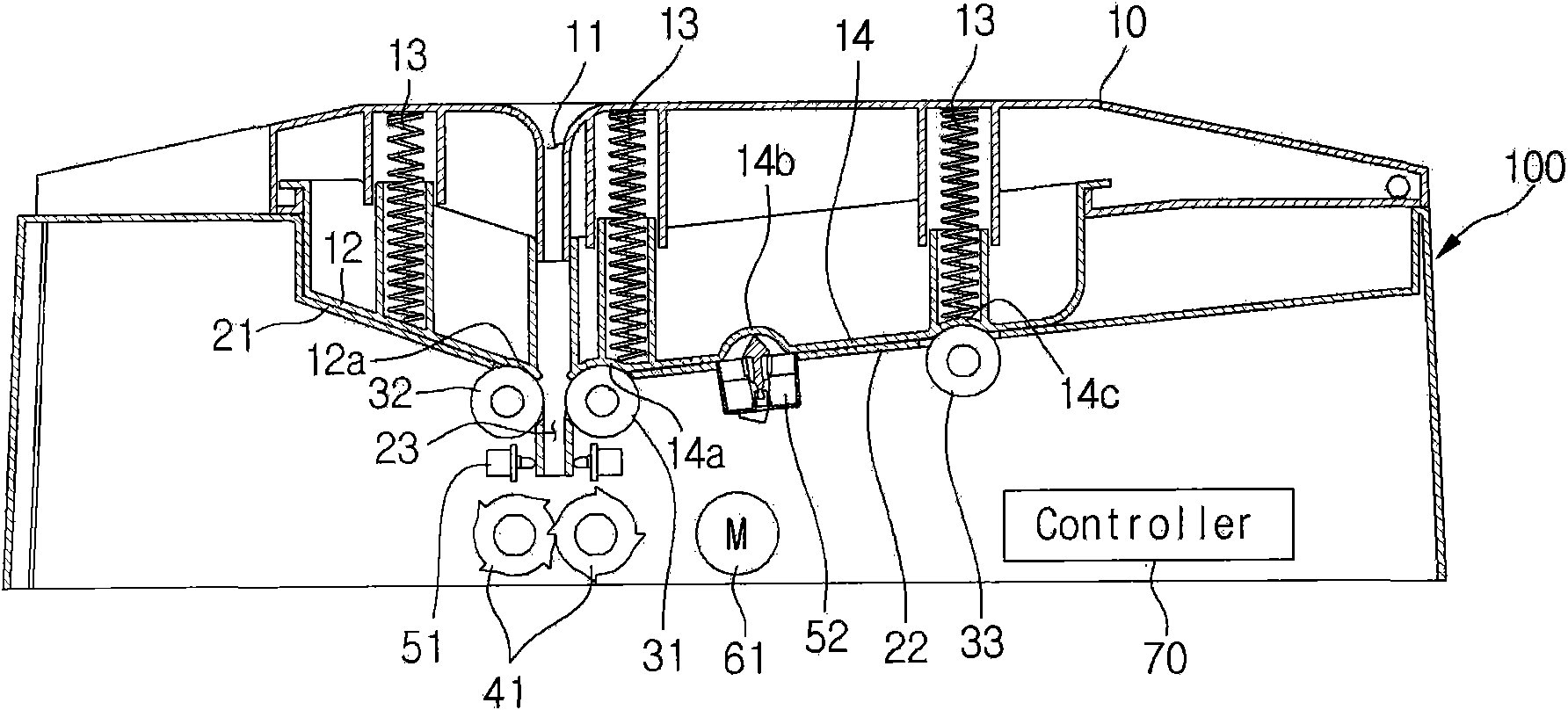

Electric paper shredder

ActiveCN102151598AAdd anytimeControl the amount of paper fedGrain treatmentsCardboardPulp and paper industry

Owner:ROYAL SOVEREIGN QINGDAO

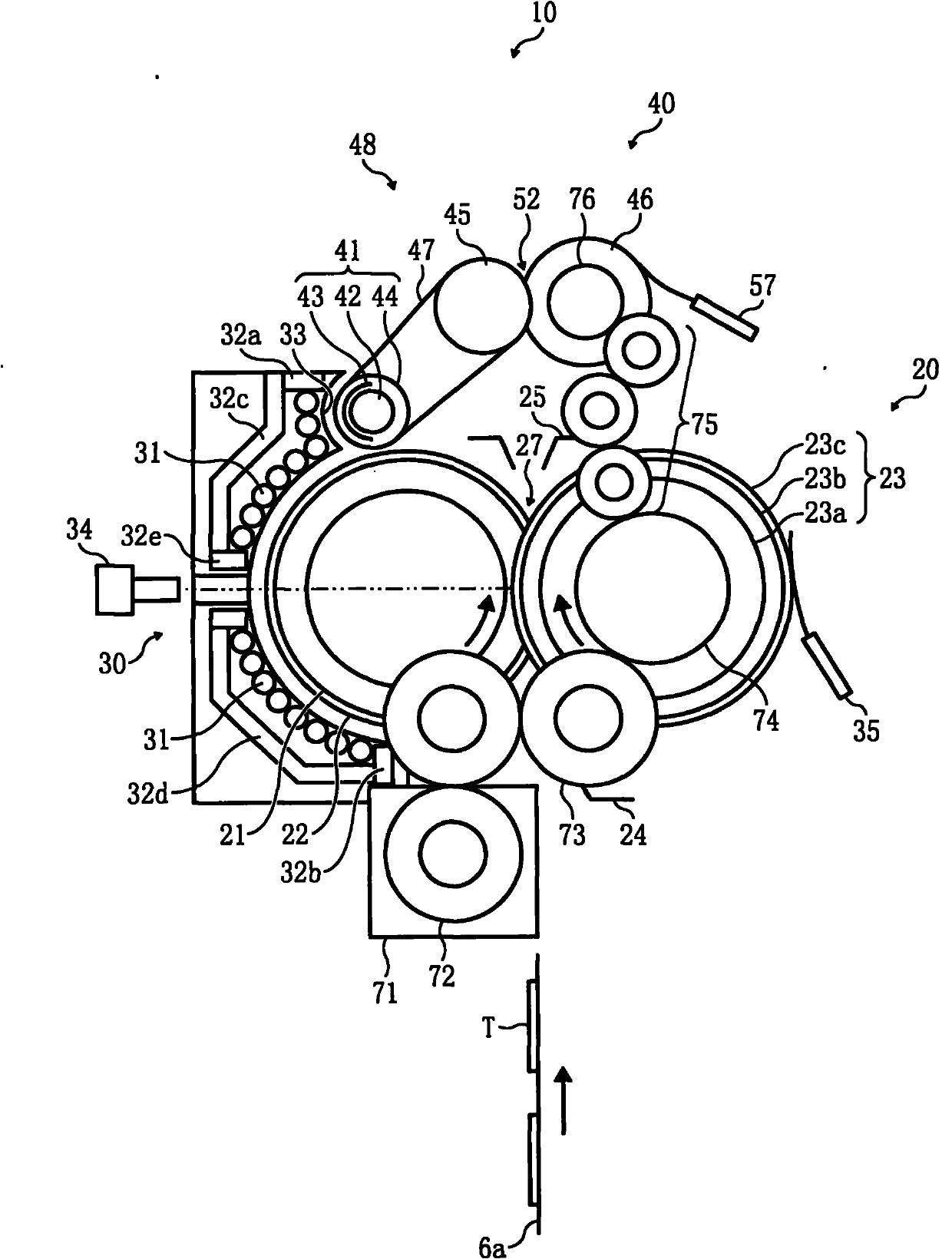

Fixing device and image forming apparatus

ActiveCN102023545ACorrection of curvatureAvoid paper jamsElectrographic process apparatusElectromagnetic inductionRecording media

The present invention provides a fixing device and an image forming apparatus, which prevents paper jam and performs bending correction for the recording medium. The fixing device (10) comprises the following components: a fixing section (20) which heats the toner image placed on a sheet member (6a) and fixes on the sheet member (6a); a correction mechanism (40) which corrects the bending of the sheet member (6a) that passes through the fixing section (20), and comprises an induction fixing section (30) that is provided next to the fixing section (20) and the correction mechanism (40) for generating magnetic beam, while the fixing section (20) comprises a fixing roller (21) that is heated by the electromagnetic induction caused by the magnetic beam generated by the induction fixing section (30); a pressing roller (23) which contacts the fixing roller (21) through pressure, while the correction mechanism comprises a heating roller section (48) which is heated by the electromagnetic induction caused by the magnetic beam generated by the induction fixing section (30); and an elastic roller (46) which contacts the heating roller section (48) through pressure.

Owner:RICOH KK

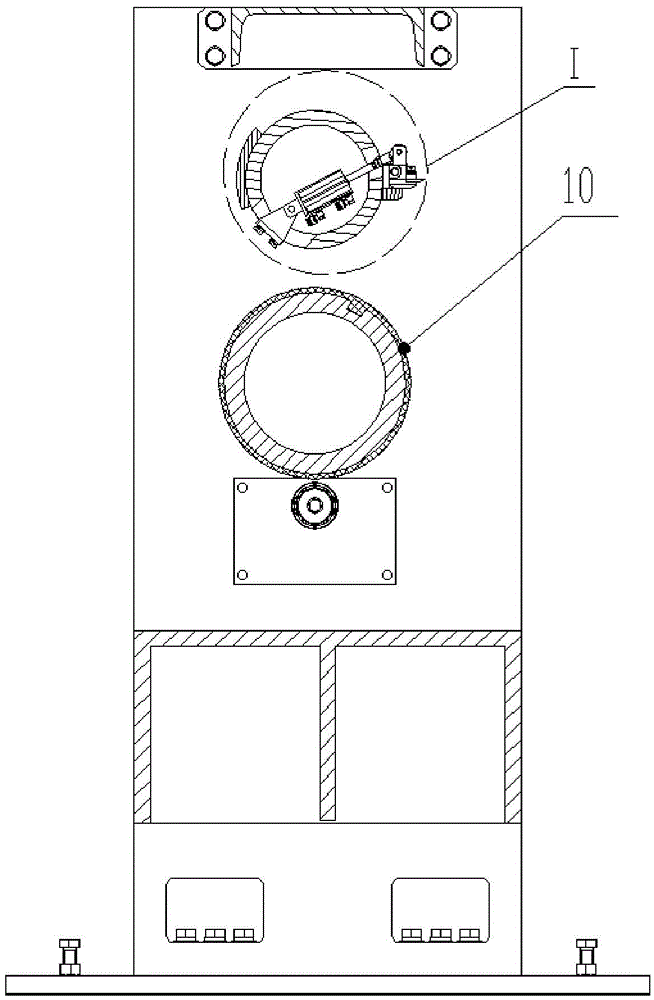

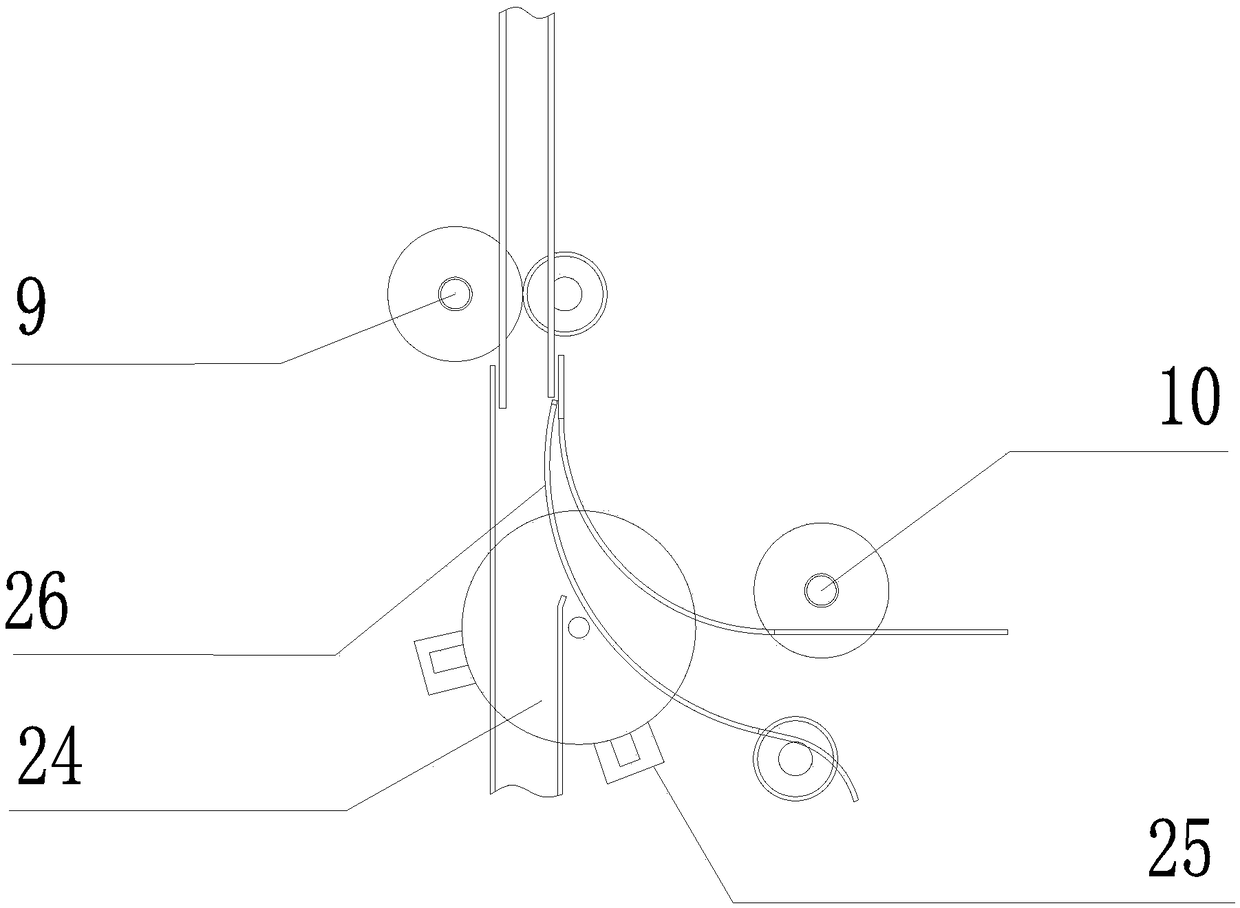

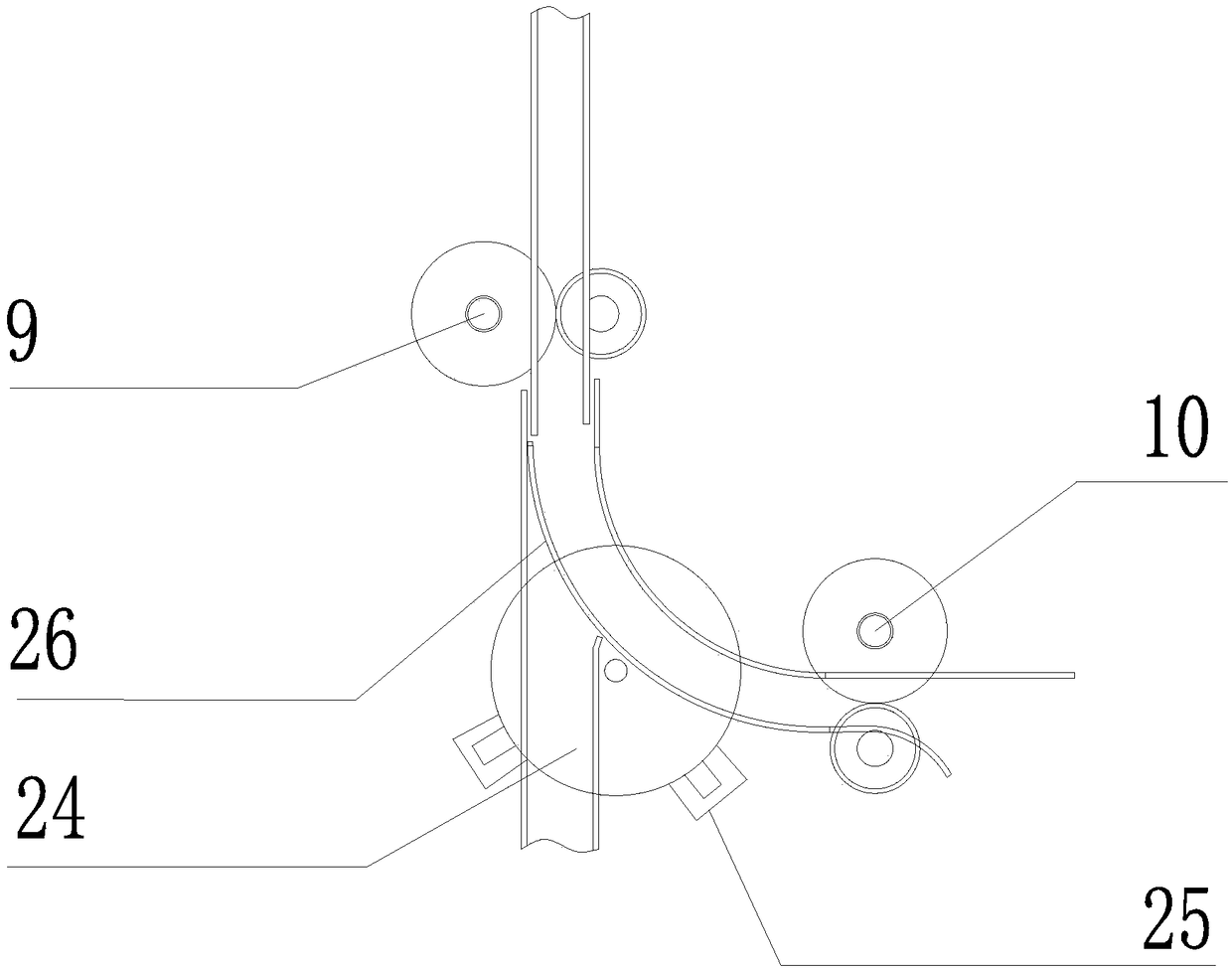

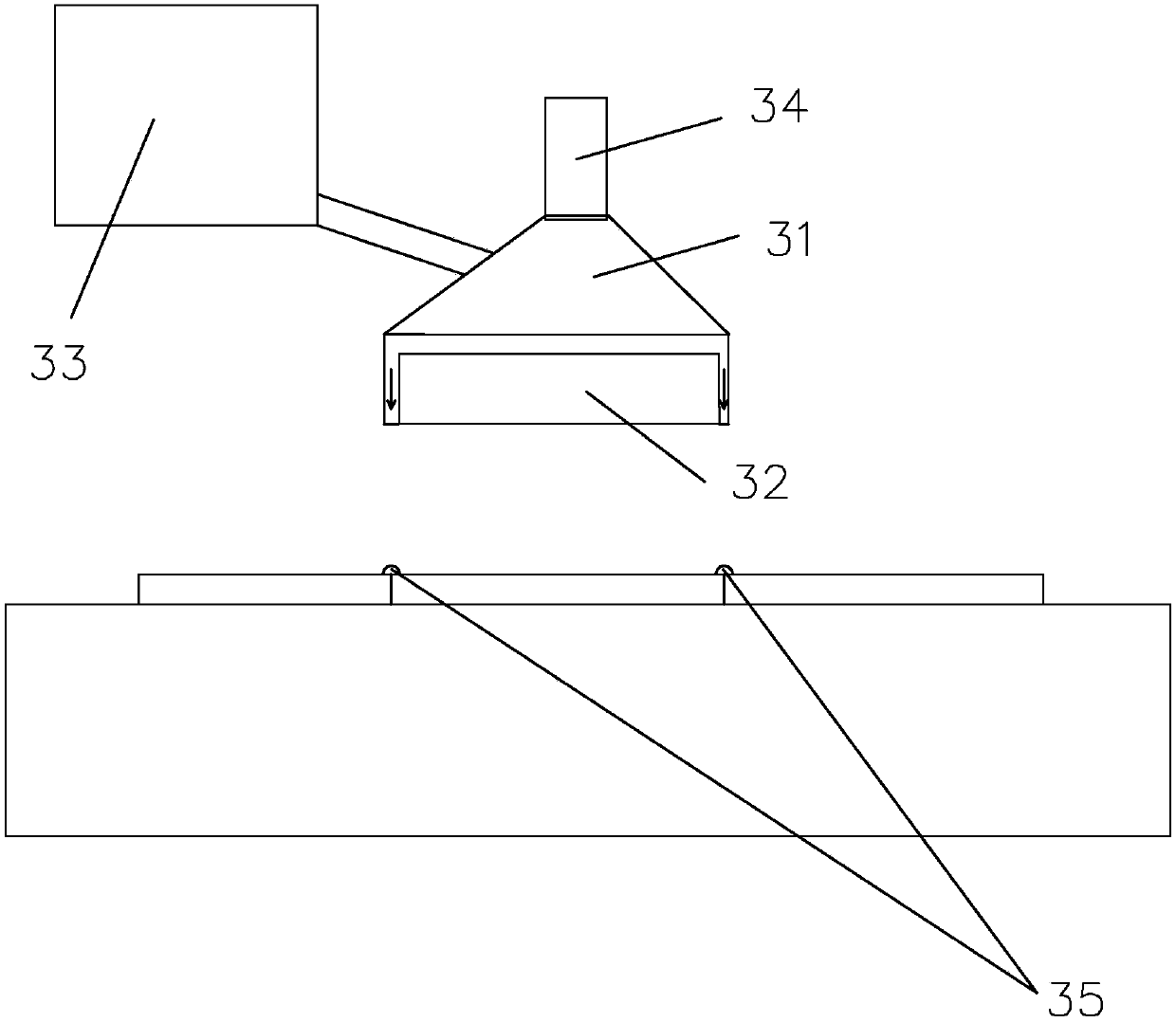

Paper dividing device and paper dividing method

InactiveCN103482382ALower quality requirementsSimple structureArticle separationMotor driveDrive wheel

The invention discloses a paper dividing device and a paper dividing method. The paper dividing device comprises a motor, a synchronized belt, a driving wheel, at least one planet wheel and an air pump; the motor drives the driving wheel to rotate by the synchronized belt; the driving wheel and the at least one planet wheel are arranged in a linkage mode so that when being rotated, the driving wheel can drive the at least one planet wheel to rotate; the planet wheel is provided with a paper sucking tip and branch air suction pipes; the paper sucking tip is provided with an air suction channel of which one end is an air suction port while the other end is of an air inlet; when the paper sucking tip is used for rotating, the air inlet is communicated with the branch air suction pipes; the air suction port is adjacent to an external paper sheet; the air pump is respectively communicated with each branch air suction pipe and is used for sucking air from the branch air suction pipes when being controlled, and negative pressure is formed at the corresponding air suction port to suck the external paper sheet. By adopting the scheme, the paper dividing device is simple in structure, low in cost and convenient to apply, has low quality demands on the paper sheet, is suitable for the paper sheets of different standards, effectively avoids the paper clamping and has better practical value.

Owner:XUCHANG UNIV

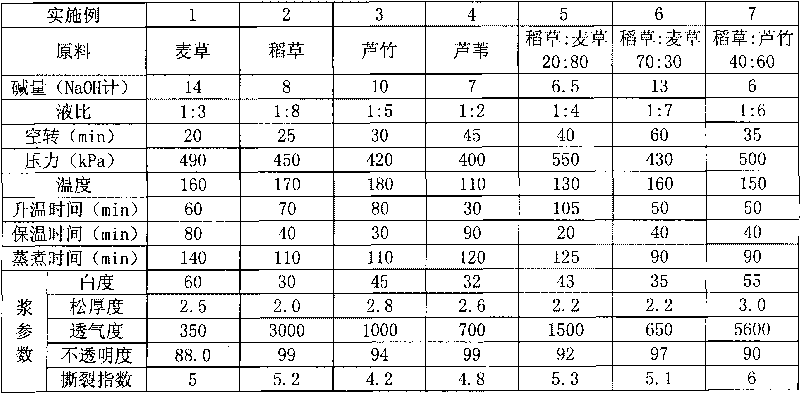

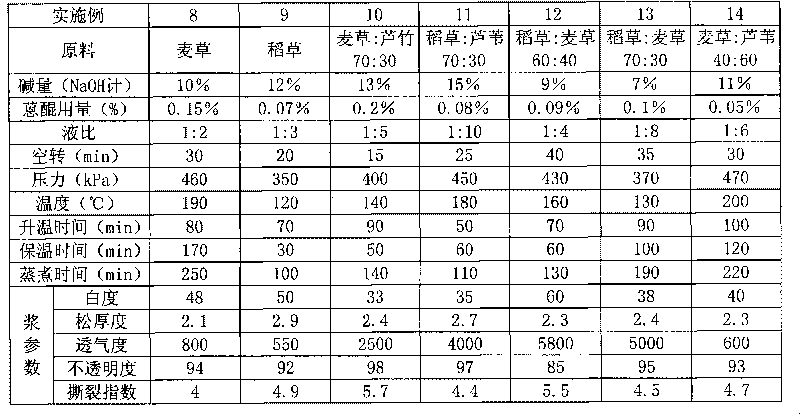

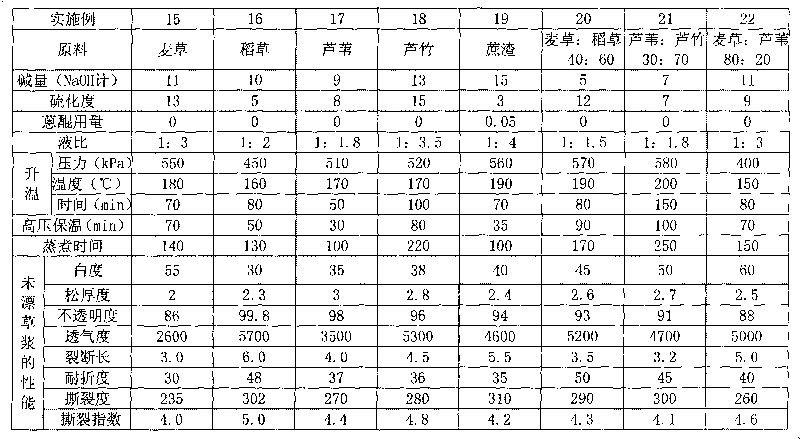

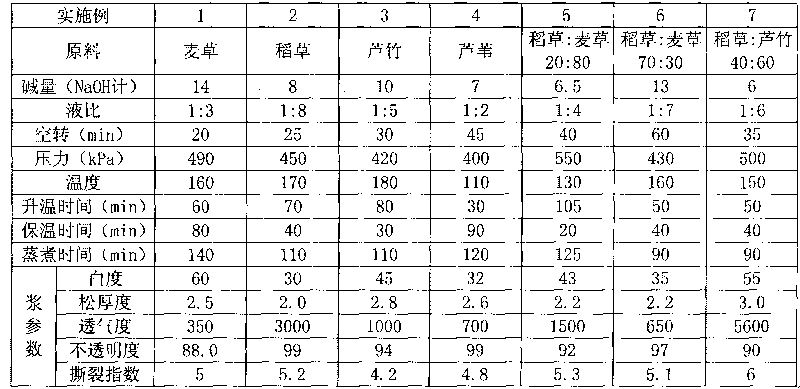

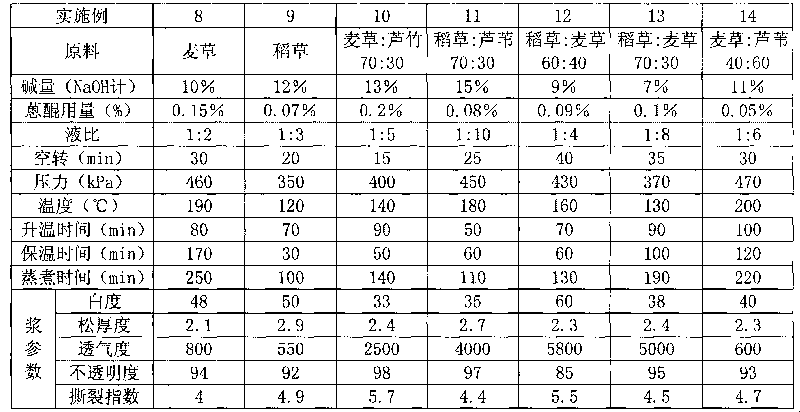

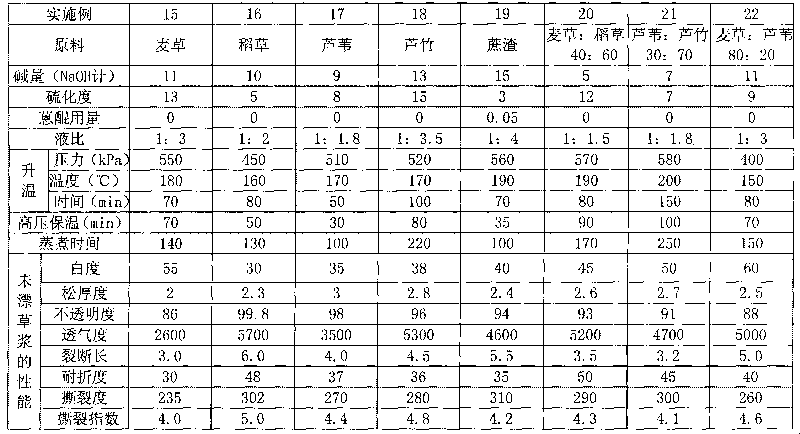

Mixed pulp and paper with the same

ActiveCN101760983AImprove performanceComprehensive performance meets the requirementsNatural cellulose pulp/paperPulping with inorganic basesPapermaking

The invention relates to mixed pulp and paper with the same. The high-performance straw pulp has the loose depth of 2 to 3 cm<3> / g, preferably 2.3 to 2.8 cm<3> / g, and more preferably 2.4 to 2.6 cm<3> / g. The opacity is from 88 percent to 100 percent, preferably 90 to 99 percent, and more preferably 94 to 98 percent. The air permeability is from 300 to 6500 ml / min, preferably 500 to 5500 ml / min, and more preferably 1000 to 5000 ml / min. The mixed pulp provided by the invention has high loose depth, high opacity and high air permeability, so the loose depth, the opacity and the air permeability of the paper with the mixed pulp are improved, the stiffness and the like of the paper is improved, and the papermaking speed is greatly improved because of the improvement of the opacity.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

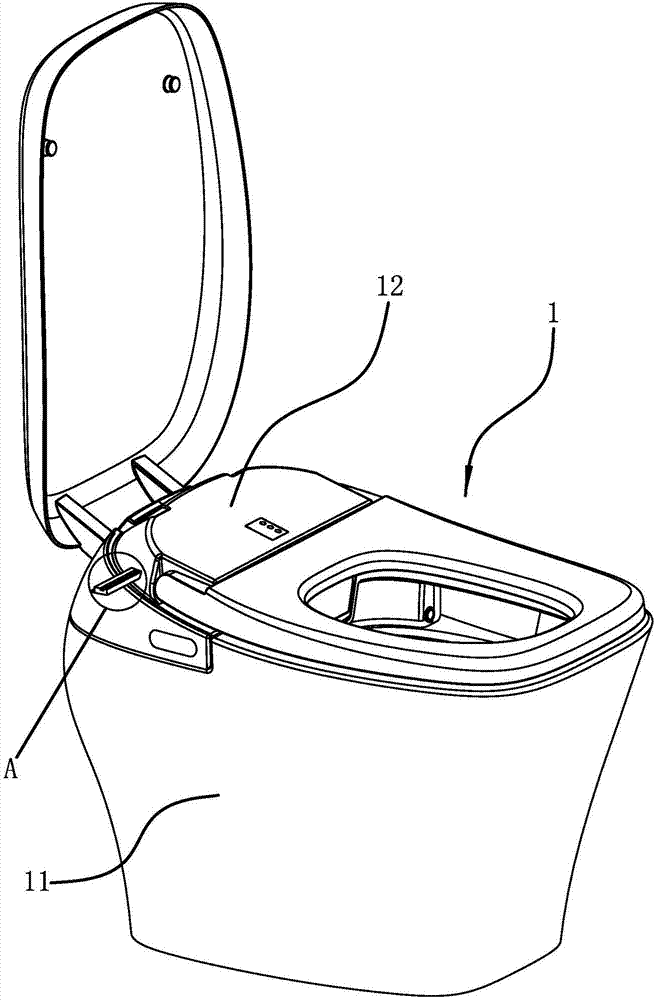

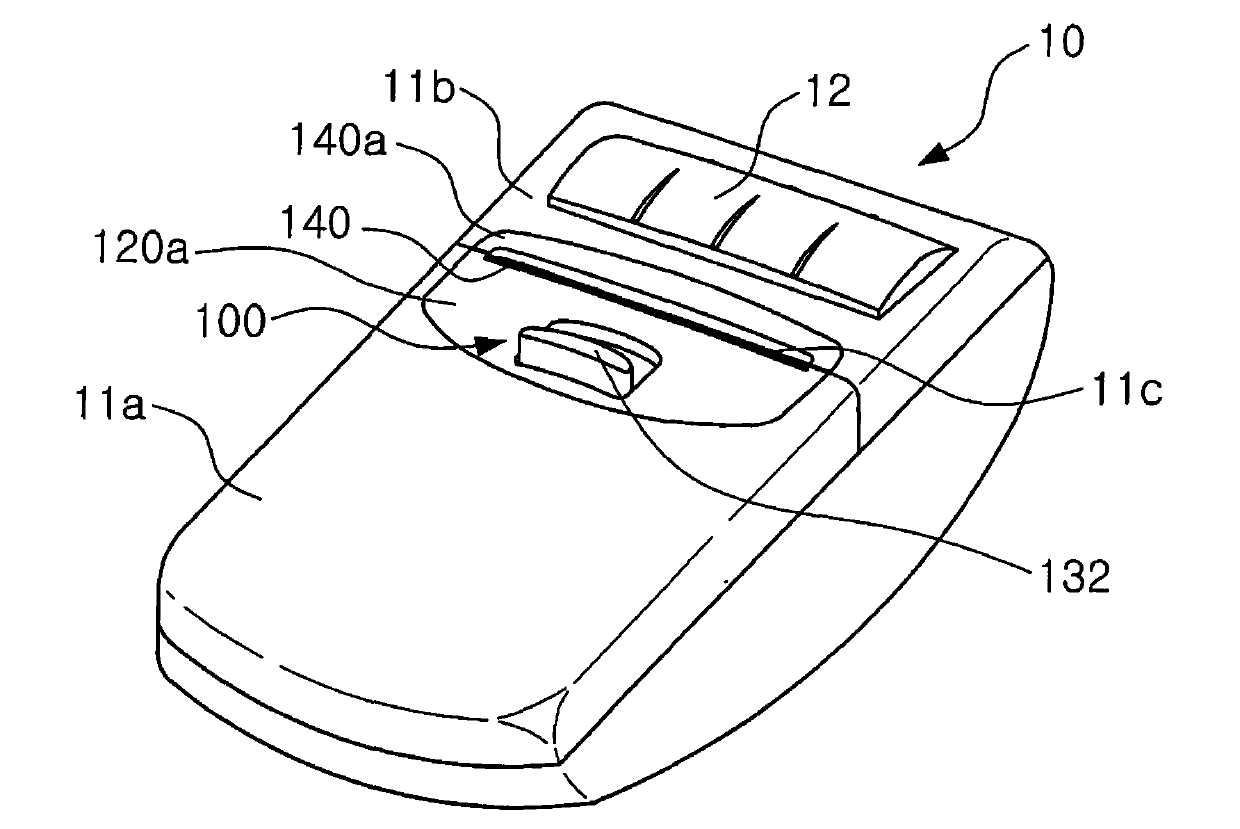

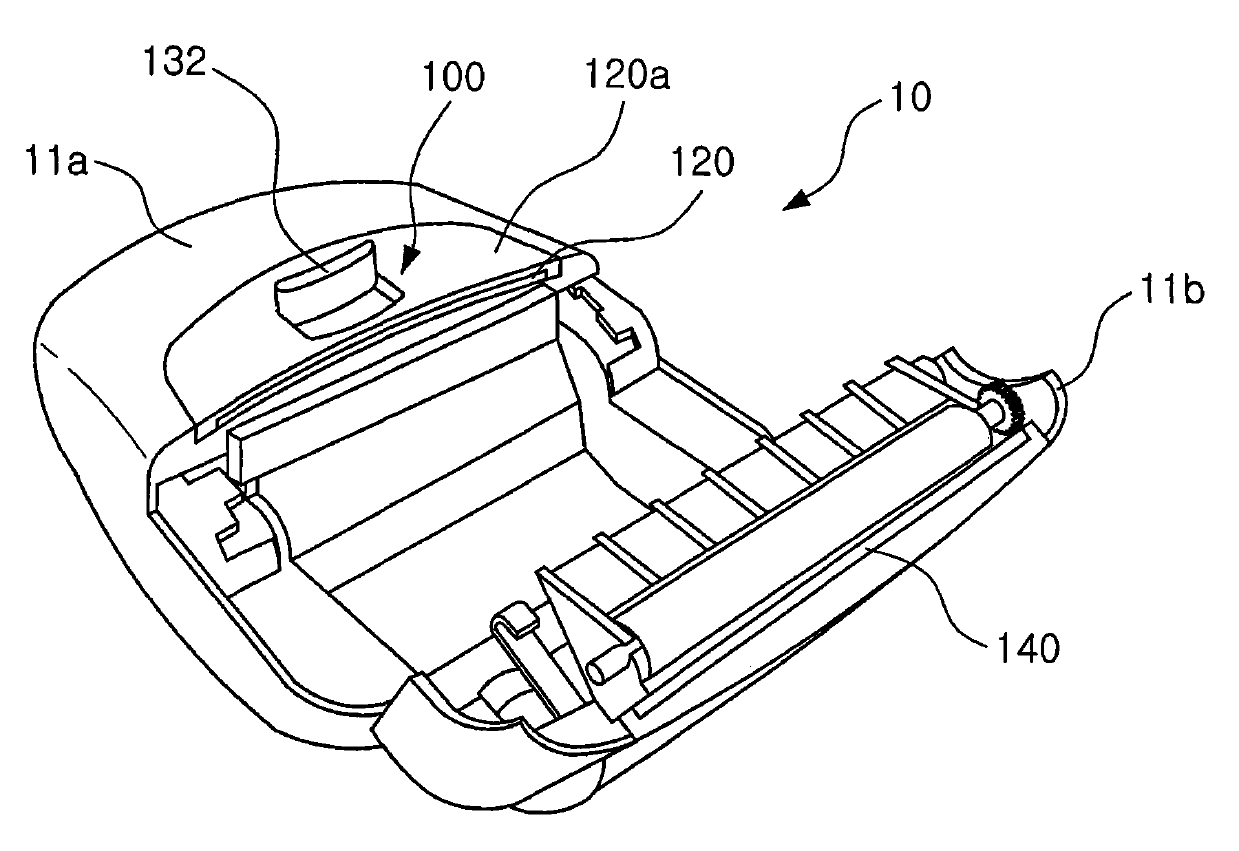

Urine detection device for intelligent closestool and use method of urine detection device

InactiveCN107237380AEasy to moveImprove detection accuracyLavatory sanitoryMaterial analysisPaper basedComputer science

The invention provides a urine detection device for an intelligent closestool and a use method of the urine detection device, and belongs to the technical field of intelligent closestools. By means of the urine detection device, the problems that an existing urine detection device for the intelligent closestool is poor in precision and inconvenient to use are solved. The urine detection device for the intelligent closestool comprises a shell, a urine analysis probe is arranged on the shell, a test paper base is connected with the inside of the shell in a sliding mode, two guide protruding edges are arranged on the test paper base, guide outward edges are arranged on the inner wall of the shell, and the guide outward edges are matched with the guide protruding edges in a sliding and guiding mode. A guide base is arranged on the outer side of the shell, and a limiting structure used for limiting the end of test paper into a test paper groove is arranged in the shell. The use method of the urine detection device for the intelligent closestool comprises the steps of Bluetooth connection, starting up, detection and analysis, result generation and the like. By means of the urine detection device for the intelligent closestool, the detection precision can be improved, and the use method of the urine detection device for the intelligent closestool is simple and convenient in operation.

Owner:ZHEJIANG WANJIE SMART BATHROOM

Mixed pulp with high bulk and paper having same

ActiveCN101760982AImprove performanceComprehensive performance meets the requirementsNon-woody plant/crop pulpCellulose material pulpingPulp and paper industryPaper sheet

The invention relates to mixed pulp with high bulk and paper or paper molded products having the same, which are characterized in that the mixed pulp comprises bulky straw pulp of which the bulk is 2-3cm<3> / g, preferably 2.3-2.8cm<3> / g, more preferably 2.4-2.6cm<3> / g. The bulky straw pulp or unbleached straw pulp provided by the invention has high bulk, so that the paper prepared by the bulky straw pulp or the unbleached straw pulp prepared by the method of the invention has high bulk and non-transparency; the increased bulk improves the stiffness of the paper or the paper molded products so as to avoid the phenomena, such as paper blocking and the like, and the improved non-transparency can prevent the print through of the paper.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

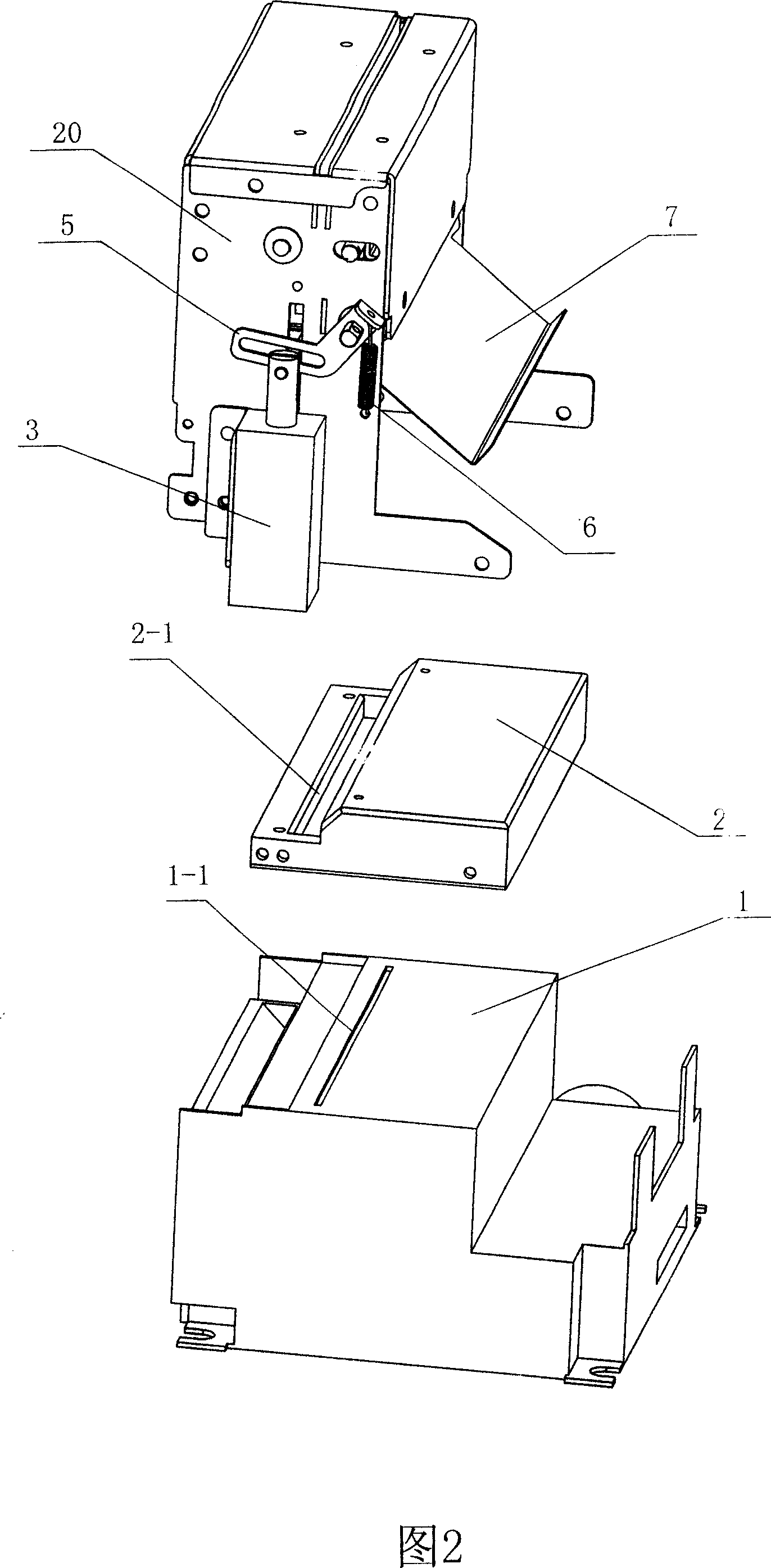

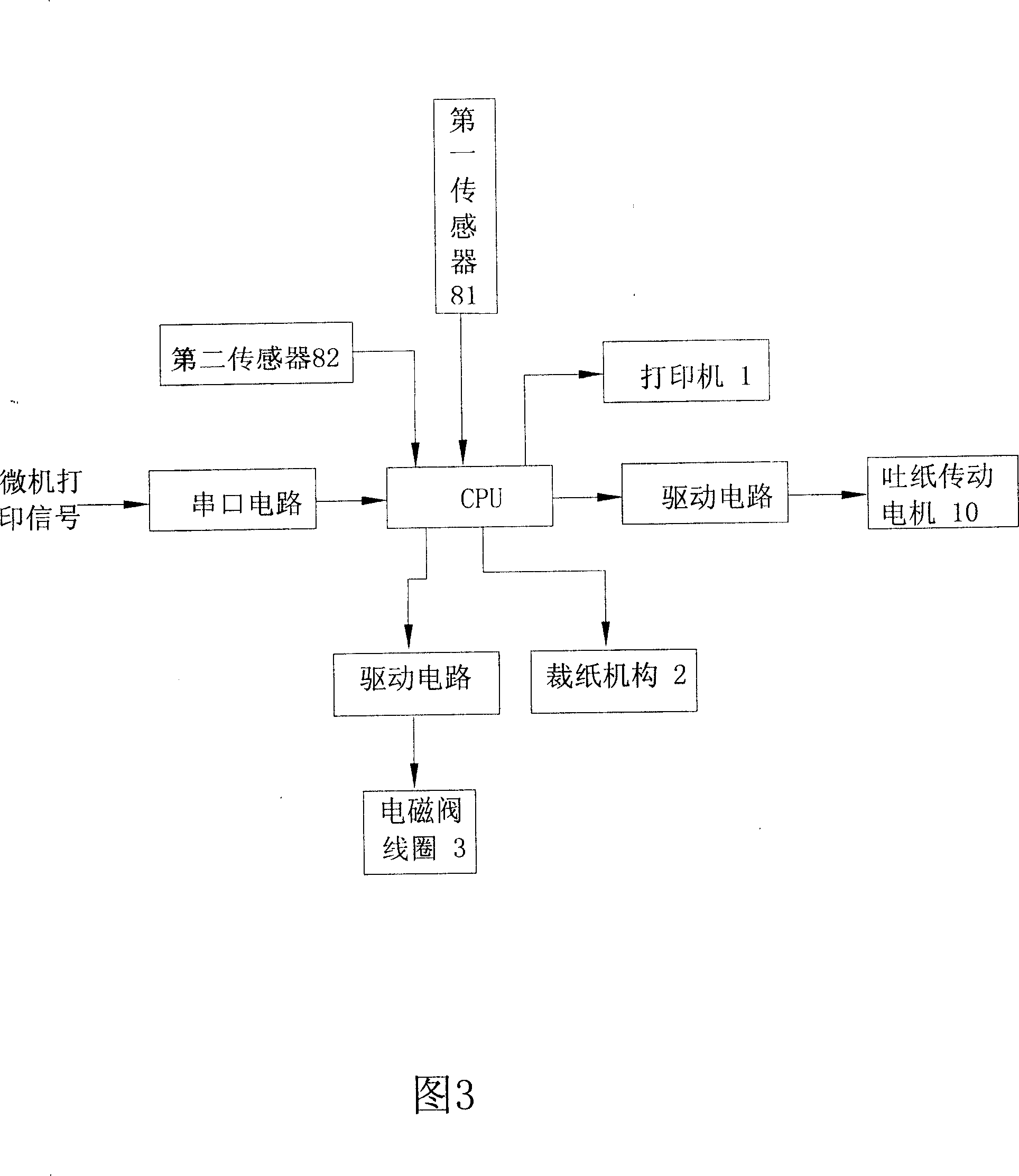

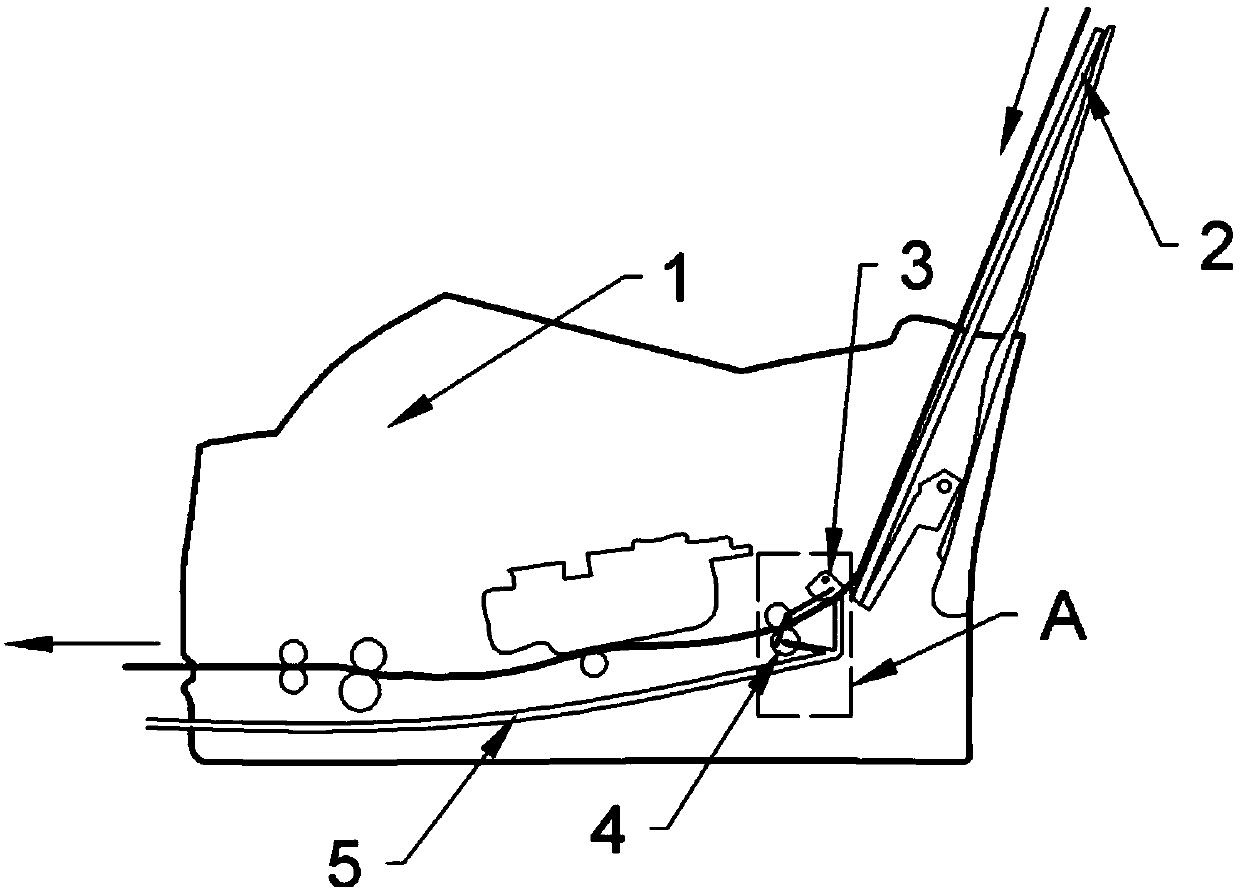

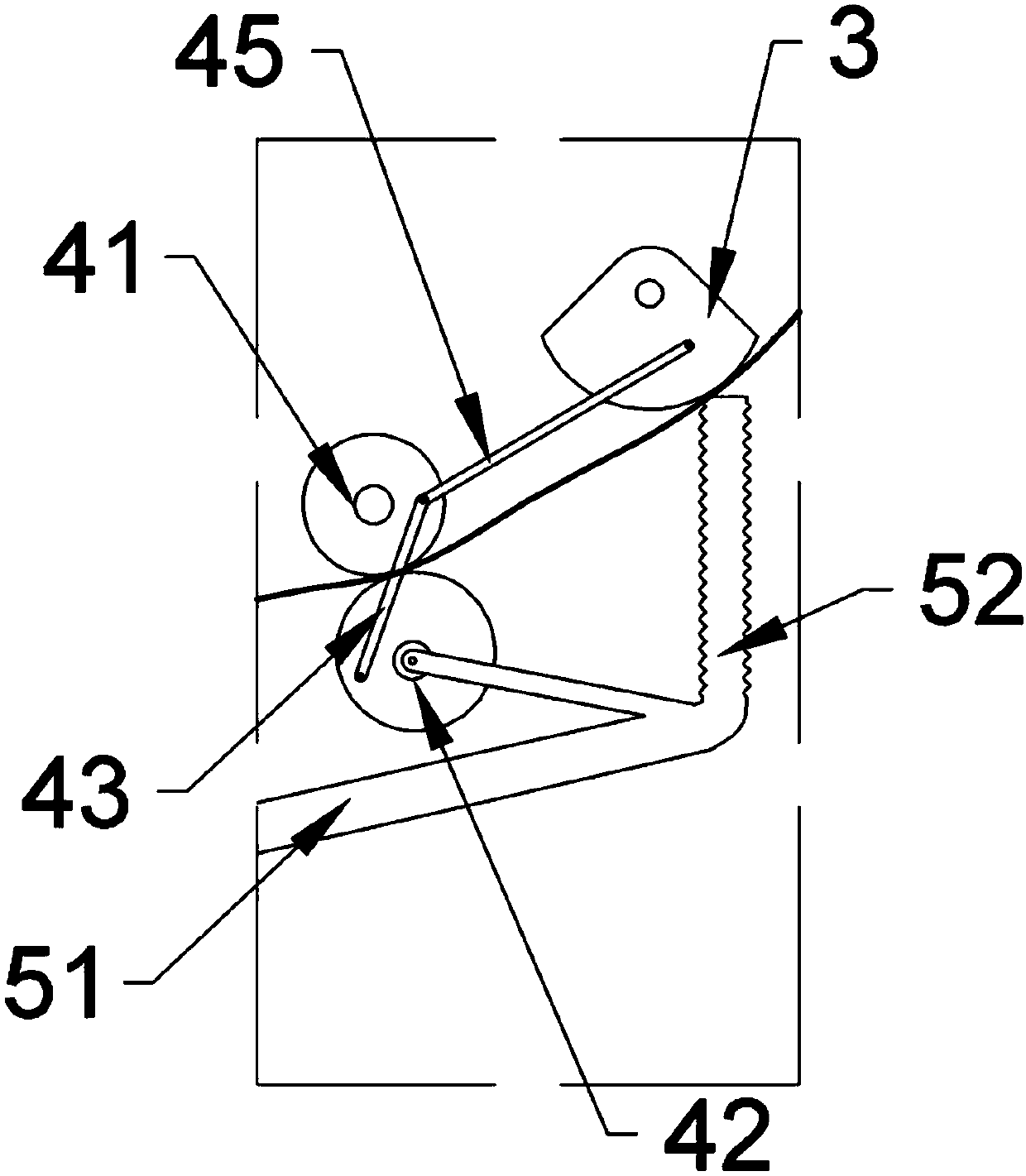

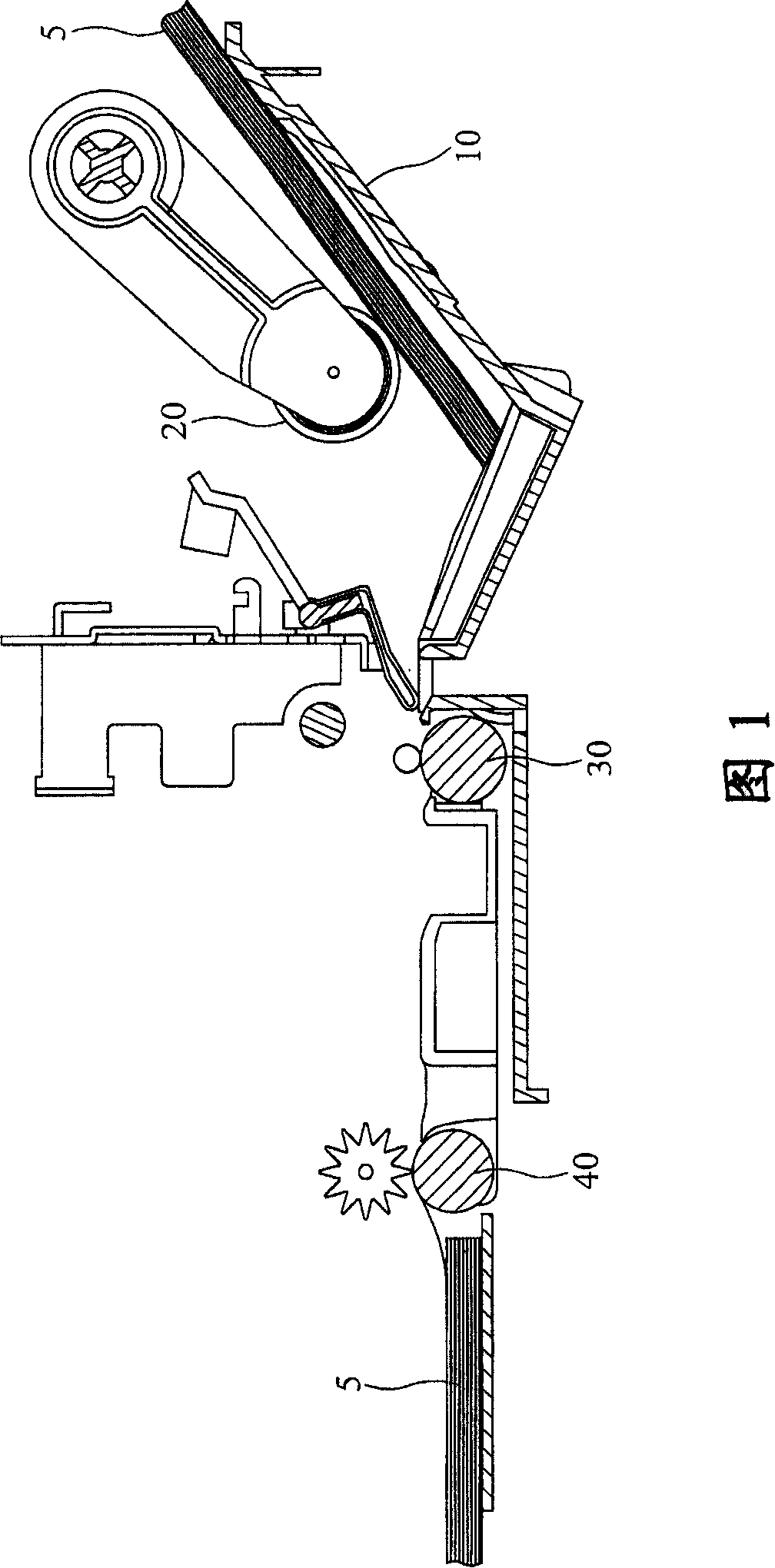

Paper-outputting device for printer and its working method

ActiveCN101125496AAvoid Paper JamsSimple structureTypewritersOther printing apparatusCardboardPulp and paper industry

The present invention relates to a printer paper spitting device and operation method. The device comprises a paper cutting mechanism which is arranged at the paper outlet of the printer, a paper spitting mechanism which is arranged at the exit of the paper cutting mechanism and a control circuit which is connected with the control end of the printer and the control end of the paper cutting mechanism. The paper spitting mechanism comprises a shell, a rotating shaft which is arranged at the bottom of the shell and is opposite to the exit of the paper cutting mechanism, a paper guide plate which is arranged between the exit of the paper cutting mechanism and the rotating shaft with one edge fixed on the rotating shaft, a rotating force mechanism which is connected with the rotating shaft, a paper spitting channel which is arranged at one side of the rotating shaft, a sensor which is arranged on the upper end of the paper feeding channel and is used for measuring the position of the paper and a paper spitting transmission unit. The rotating force mechanism can lead the rotating shaft to rotate so as to ensure the paper guide plate to turn downwards. When the rotating force mechanism is stopped, the paper guide plate and the paper feeding channel are in the same plane. The device can effectively prevent the phenomenon of paper jamming of the printer paper spitting device from happening.

Owner:GUOGUANG ELECTRONICS INFORMATION TECH

Automated paper feeding printing machine

ActiveCN109572247AAvoid Paper JamsPrinting works fineOther printing apparatusCardboardPulp and paper industry

The invention relates to the field of laser printing devices and provides an automated paper feeding printing machine. The phenomenon that paper is prone to being jammed due to the fact that pieces ofpaper enter the printing machine at the same time in the process of automatic paper feeding in an existing printing machine is solved. The automated paper feeding printing machine includes a body, apaper feeding box is mounted at one end of the body, a paper discharging opening is arranged at the other end of the body, the paper feeding box includes a paper feeding plate, wherein the paper feeding box further includes a heating mechanism and a paper feeding mechanism, the feeding mechanism includes a paper feeding cam and paper feeding couple rollers, the paper feeding cam is positioned at the paper discharging end of a paper feeding plate, when the paper feeding cam rotates at the lower half of a circle, the protrusion end of the paper feeding cam contacts with the paper discharging endof the paper feeding plate; and the heating mechanism includes a heat conduction assembly, an air inlet of the heat conduction assembly is positioned at the paper discharging opening, the paper feeding couple rollers and the paper feeding cam are provided with inner cavities, the air outlet of the heat conduction assembly can communicate with the inner cavities and is positioned at the lower endof the paper feeding cam, when the protrusion end of the paper feeding cam rotates at the lower half of the circle, and air is introduced into the inner cavities through the heat conduction assembly.

Owner:宁波隆锐机械制造有限公司

Automatic sorting and finishing machine for accounting documents

ActiveCN110451305AGood effectAvoid paper jamsArticle feedersArticle deliveryInfrared emitterEngineering

The invention discloses an automatic sorting and finishing machine for accounting documents. The automatic sorting and finishing machine includes a machine box and a storage box, the machine box is internally provided with a sorting machine, a finishing machine, a terminal transmission machine and automatic paper blocking rod, a document sorting machine is arranged at the conveying front end of the sorting machine, the sorting machine includes a sorting machine electric drum, a transparent sorting belt and a high-definition camera, the finishing machine includes a finishing machine drum, a chain transmission belt and N electric clamping jaws, and the electric clamping jaws are internally provided with infrared emitters, infrared receivers and electric clamping jaws control modules which communicate with a main controller. According to the automatic sorting and finishing machine, the stacked accounting documents are staggered through the document sorting machine, the sorting machine isused for sorting the accounting documents of bill numbers to be selected, the accounting documents of the bill numbers to be selected and the automatic paper blocking rod are matched and clamped by the electric clamping jaws on the finishing machine, the accounting documents of unselected bill number fall into a terminal transmission belt and are output, then the bill numbers to be selected are sorted, the electric clamping jaws release the sorted accounting documents in turn and the accounting documents are output through the terminal transmission belt, and automatic sorting and finishing ofthe accounting documents are realized.

Owner:XIAN UNIV OF SCI & TECH

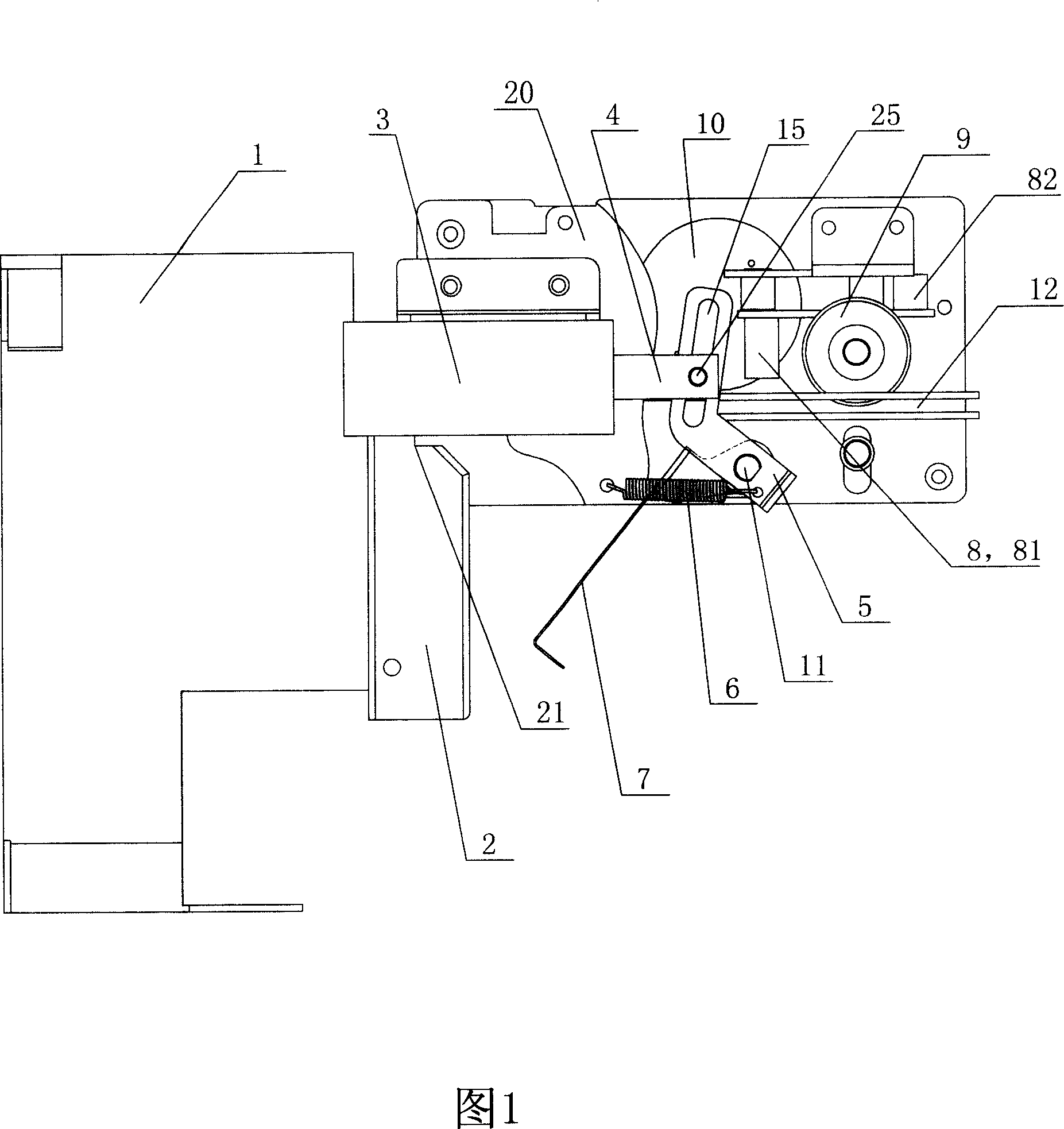

Paper-pulling mechanism of paper-out rolling wheel and printer using the same

The invention provides a paper-forcing mechanism in a paper delivery roller and a printer provided with the paper-forcing mechanism. The paper-forcing mechanism comprises a paper- forcing part, a cam and an elastic component. The invention is characterized in that the paper-forcing mechanism is combined with a shaft, with the rotating of the paper delivery roller, the mechanism moves intermittently toward the paper delivery direction to force the printed paper and enables the paper to depart from the paper delivery roller. The printer comprises a body, a paper delivery roller and at least a paper-forcing mechanism.

Owner:QISDA SUZHOU

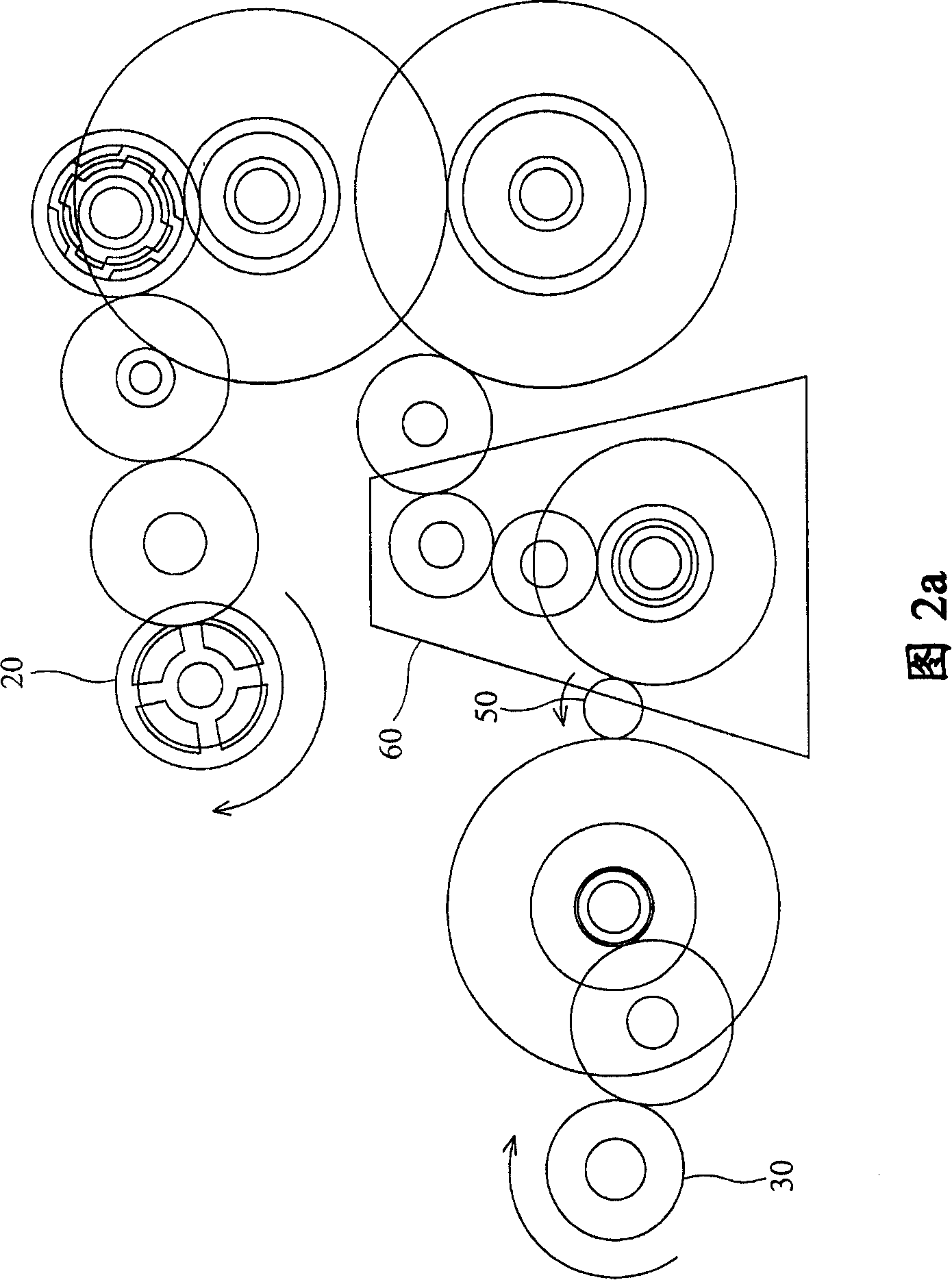

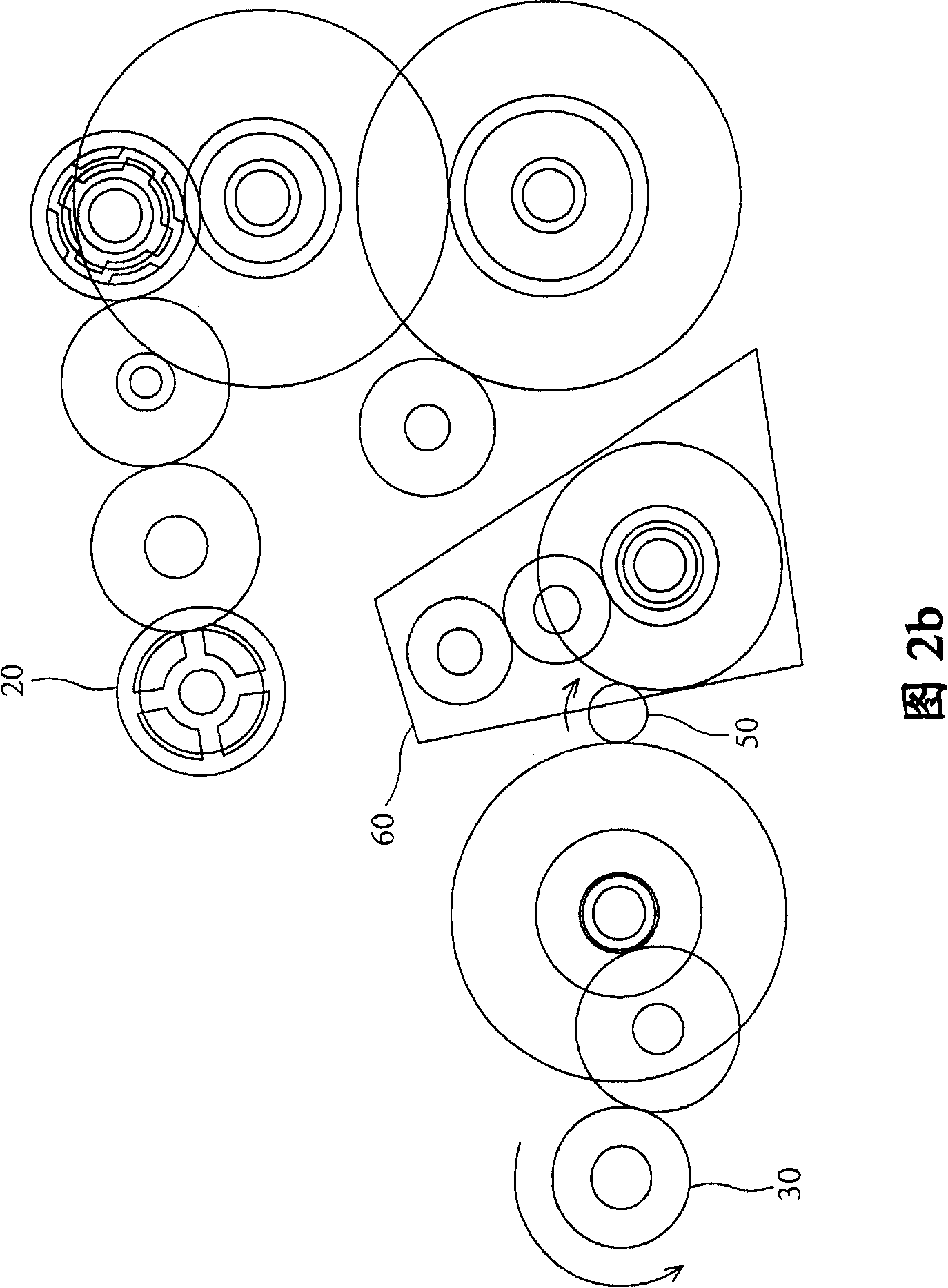

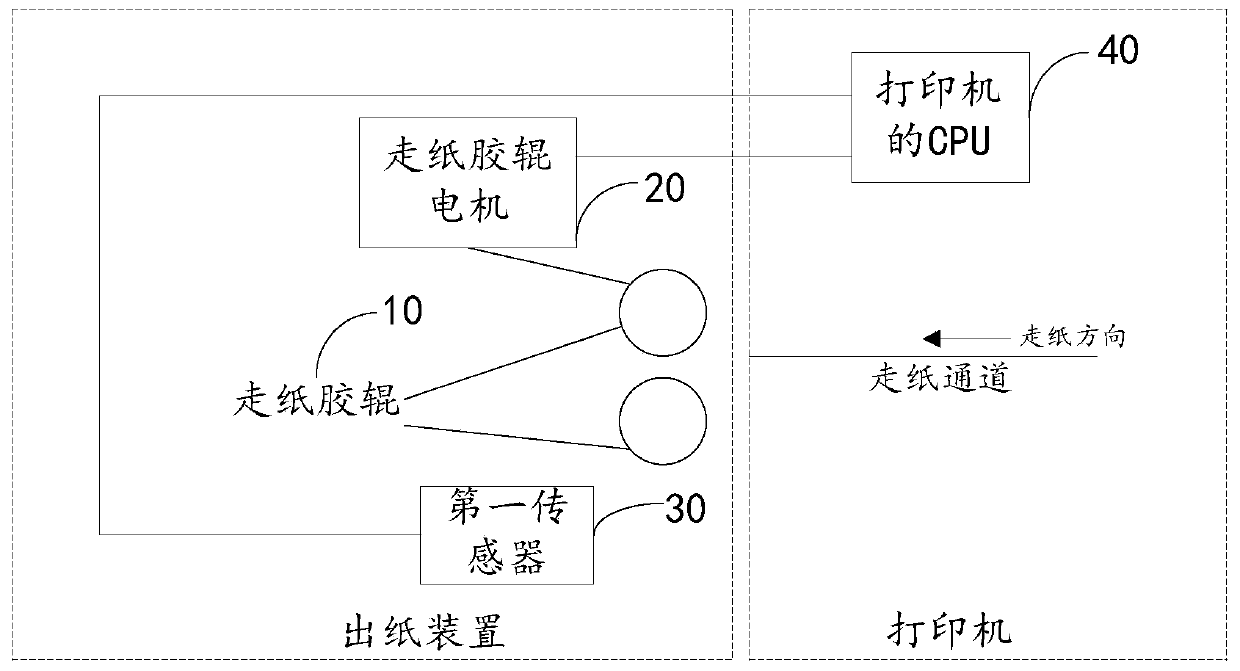

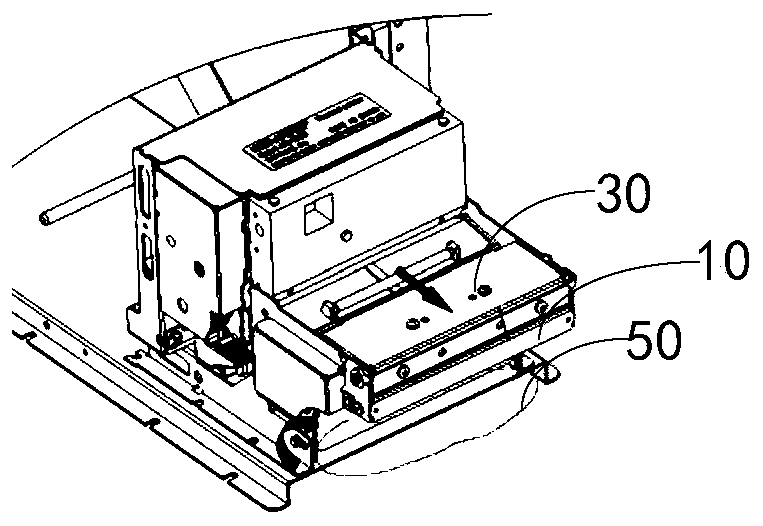

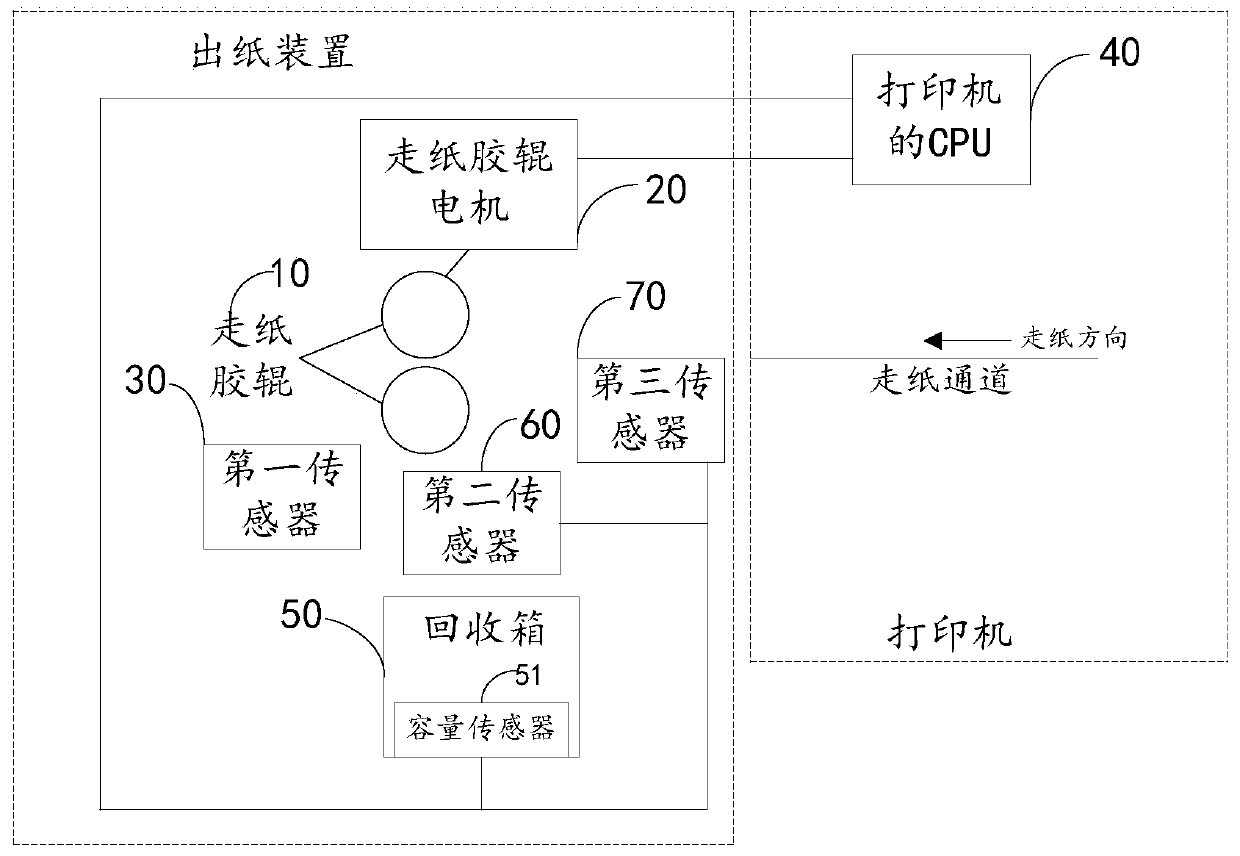

Paper delivery device and printer

PendingCN110228723AAvoid paper jamsPrevent forced pullingFunction indicatorsArticle deliveryPulp and paper industryPaper sheet

The invention provides a paper delivery device and a printer. The paper delivery device is arranged on a paper outlet of a paper feeding channel of the printer; and an inlet part of the paper deliverydevice is connected with the paper outlet of the paper feeding channel of the printer. The paper delivery device comprises a paper feeding rubber roller, a paper feeding rubber roller motor and a first sensor, wherein the paper feeding rubber roller is arranged on an inlet position of the paper delivery device and is connected with a central processing unit (CPU) of the printer; an output shaft of the paper feeding rubber roller motor is in drive connection with the paper feeding rubber roller and is used for driving the paper feeding rubber roller to rotate so as to output printing paper sheets; and the first sensor is connected with the CPU of the printer, is arranged on an outlet part of the paper delivery device, and is used for detecting paper sheet state information of the outlet part of the paper delivery device, generating a feedback signal according to the paper sheet state information, sending the feedback signal to the CPU of the printer so as to enable the CPU of the printer to trigger the paper feeding rubber roller motor to reverse according to the feedback signal to recover the paper sheets on the outlet part of the paper delivery device. The printer is prevented from getting stuck by paper, and the user information is protected, so that the user experience is improved.

Owner:威海新北洋技术服务有限公司

Full-automatic edge-cutting, notching and cutting-off all-in-one machine

ActiveCN105108799AAvoid paper jamsGuaranteed productionMetal working apparatusCardboardProduction line

The invention discloses a full-automatic edge-cutting, notching and cutting-off all-in-one machine. The machine is installed on a corrugated paper board production line and comprises a cutting-off part and a waste discharging part which are installed on a machine frame. The cutting-off part comprises a rubber mat roll transversely installed on the machine frame and a cutting-off cutter shaft located above the rubber mat roll. The whole cutting-off cutter shaft is a cylindrical cutter shaft, and a plurality of cutting-off assemblies are installed on the outer surface of the cutter shaft and provided with blades and independent driving air cylinders used for driving the blades of the cutting-off assemblies to stretch and retract. The cutting-off cutter shaft and the rubber mat roll are driven by a servo motor through a transmission gear. The waste discharging part is installed behind the cutting-off part and mainly composed of a sun gear assembly, a conveying assembly, a paper board beating assembly and a paper pressing assembly. The edge-cutting, notching and cutting-off functions can be achieved by one cutting-off assembly, the working mode is flexible, the notching order exchanging speed is increased to 200 m / min from 130 m / min, and the waste discharging speed is increased to 200 m / min from 150 m / min.

Owner:QINGDAO KAITUO NC EQUIP

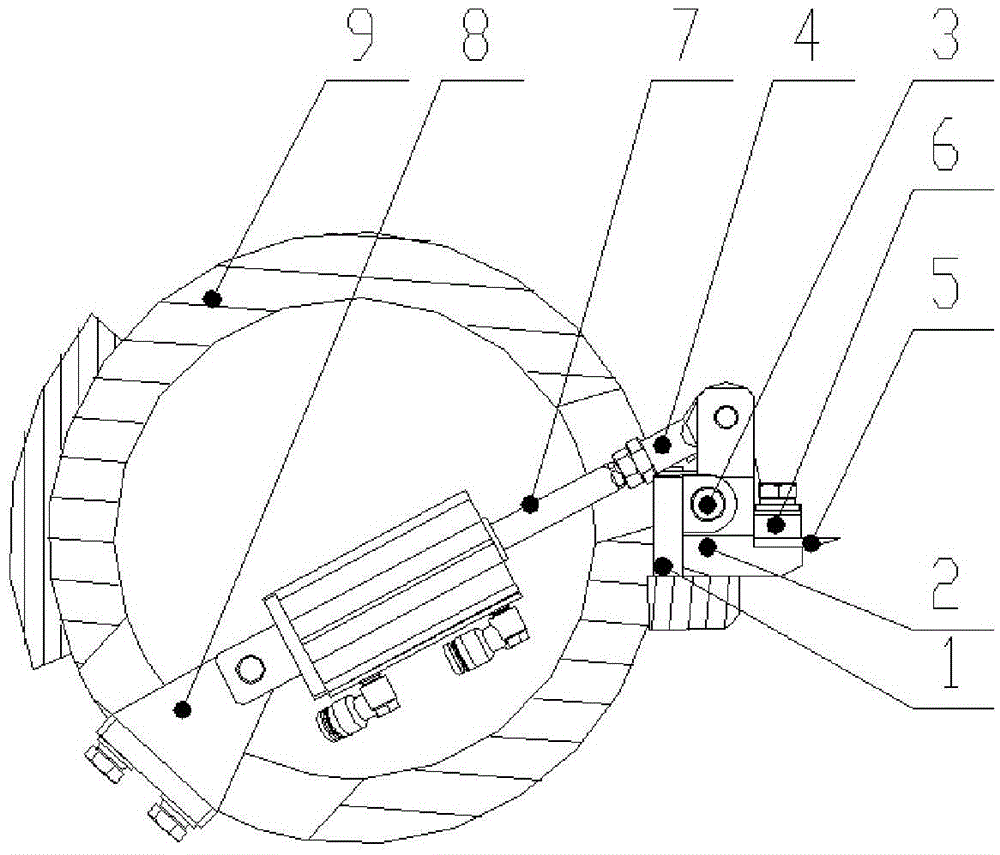

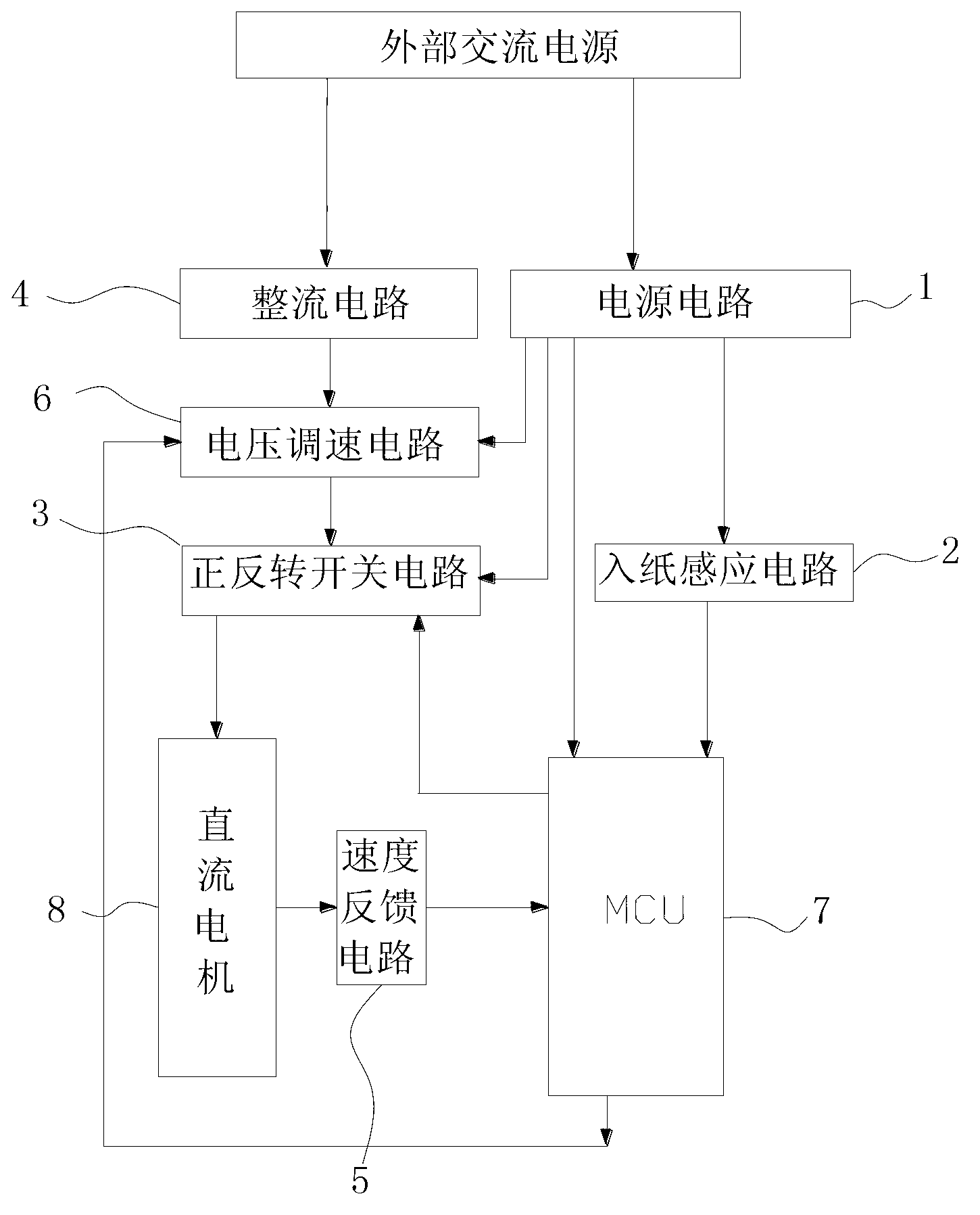

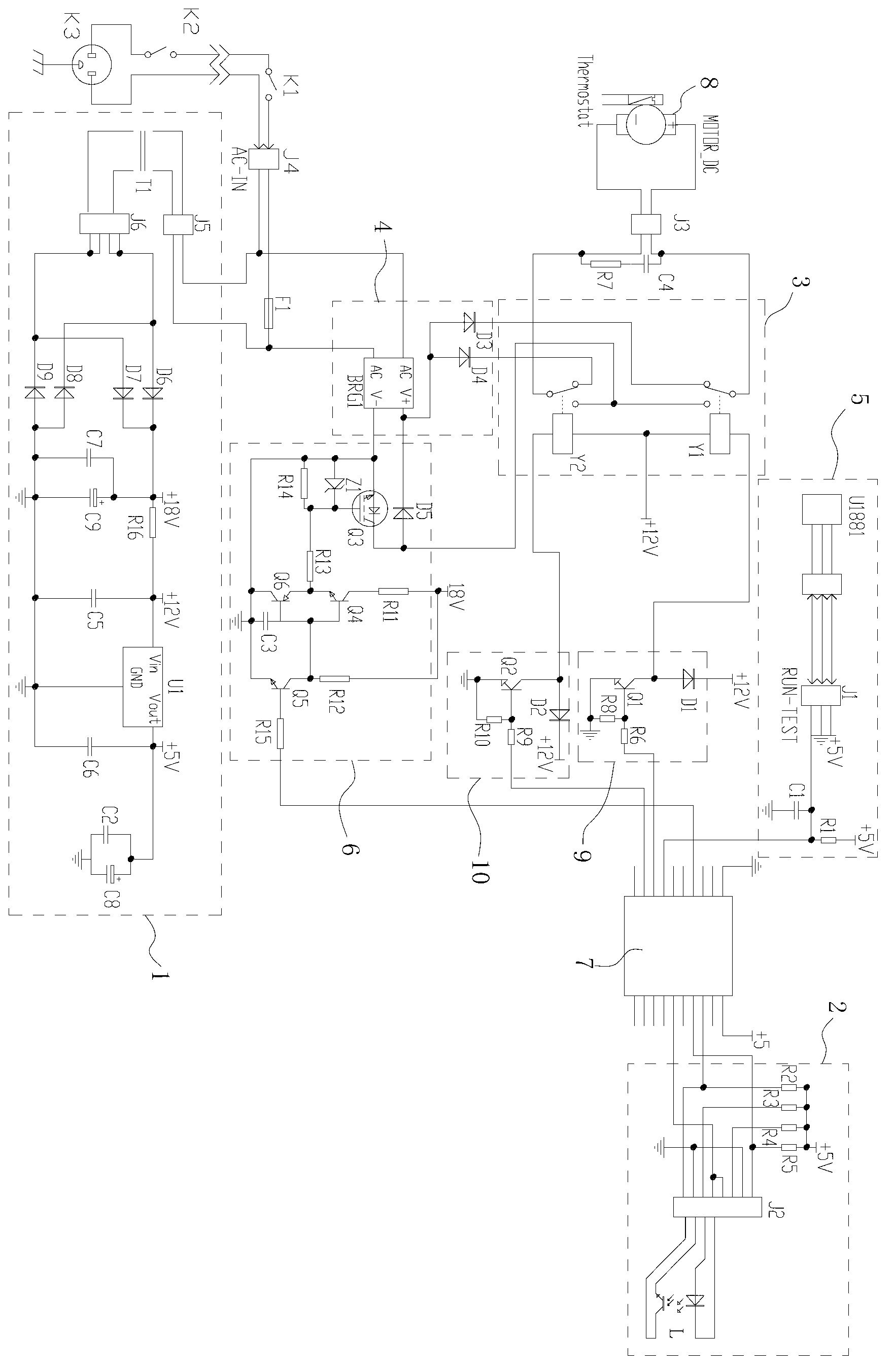

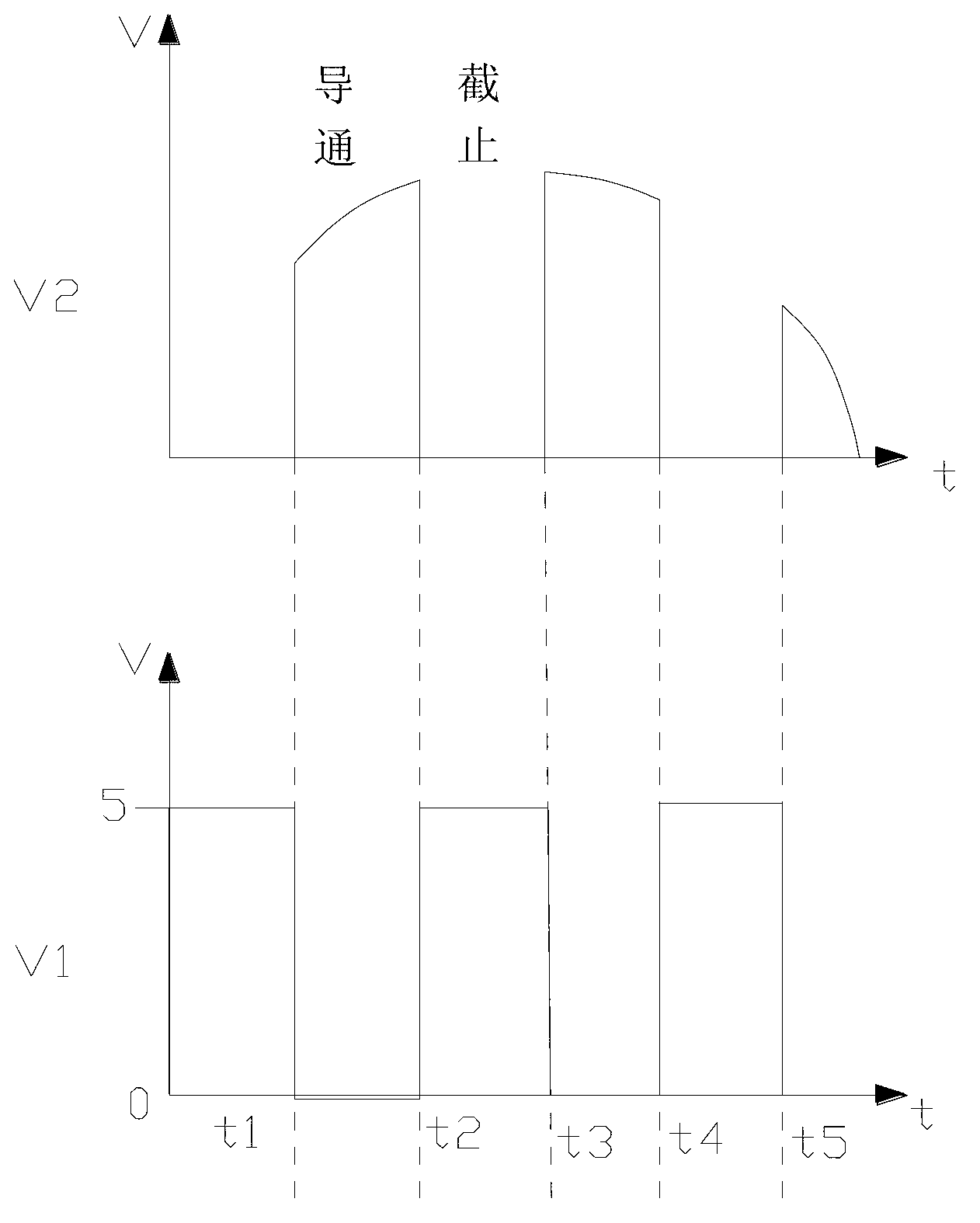

Speed-changing anti-blocking anti-jamming paper shredder circuit and control method of motor thereof

The invention relates to the field of the manufacturing of a paper shredder, and discloses a speed-changing anti-blocking anti-jamming paper shredder circuit which comprises a power supply circuit, a paper feeding sensing circuit, a forward-reversed switching circuit, a rectification circuit, a speed feedback circuit, a voltage speed regulation circuit, an MCU (microprogrammed controller unit) and a motor, wherein the input end of the speed feedback circuit is connected with the motor, the output end of the speed feedback circuit is connected with the MCU, the speed feedback circuit is used for transmitting a square-wave voltage signal representing the rotation speed of the motor to the MCU, the MCU is used for adjusting the voltage of the motor through the voltage speed regulation circuit according to the square-wave voltage signal and controlling the motor to rotate forwards or backwards through the forward-backward switching circuit according to the square-wave voltage signal. By adopting the speed-changing anti-blocking anti-jamming paper shredder, not only is the manufacturing cost low, but also the paper blocking can be prevented, and the working noise of the paper shredder can be lowered.

Owner:GUANGZHOU COMET

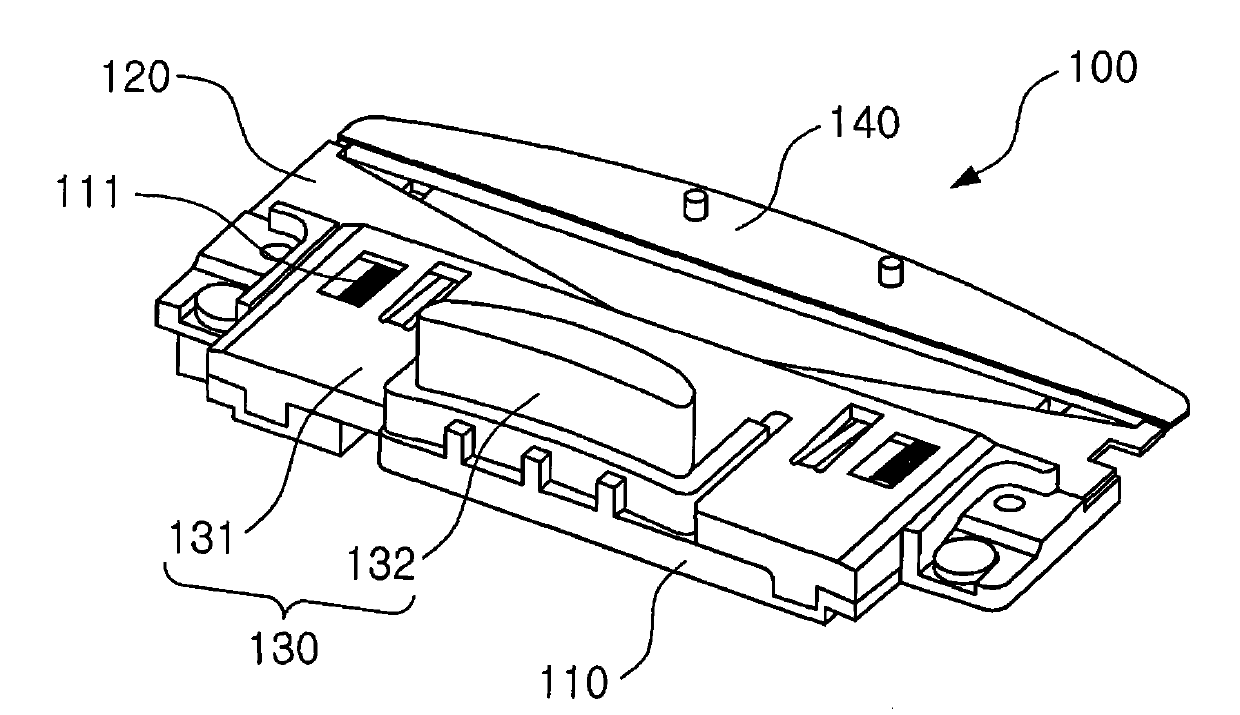

Portable printer equipped with manual cutter

There is provided a portable printer equipped with a manual cutter. The portable printer equipped with a manual cutter may include: a fixed blade disposed at one side of a paper outlet; a movable blade holder disposed adjacent to the paper outlet opposite to the fixed blade; a movable blade slidably mounted in the movable blade holder; an operator slidably mounted in the movable blade holder and connected with the movable blade; and elastic members having ends connected to the movable blade holder and the other ends supporting the movable blade or the sides of the operator, and providing restoring force to return the movable blade or the operator to the initial position. Since the portable printer equipped with a manual cutter does not use a power source to cut paper, it is possible to reduce power consumption for the printer and cut paper with the cut surface smooth. Further, it is possible to improve convenience such that a user can operate the printer worn on the body with one hand, and reduce malfunctions by maximally preventing scraps of paper.

Owner:BIXOLON

High-strength printing paper and preparation method thereof

InactiveCN106120462AHigh tensile strengthImprove antioxidant capacityInorganic fibres/flakesSpecial paperPolyamideOxidation resistant

The invention discloses high-strength printing paper and a preparation method thereof. The high-strength printing paper is prepared from the following raw materials: hardwood pulp fibers, softwood pulp fibers, basalt fibers, polyurethane fibers, ramie fibers, cotton pulp fibers, hydroxyethylcellulose, butadiene-vinylpyridine copolymer latex, polyamide polyurea resin, a surfactant and calcined zinc oxide. Compared with the prior art, the high-strength printing paper has the following advantages that the basalt fibers are added so that the tensile strength and the oxidation resistance of paper sheets can be easily improved; the other raw materials are matched so that the physical properties of the paper sheets are intensified; after the surfactant and the butadiene-vinylpyridine copolymer latex are mixed, a good protection layer is formed on the surface of each paper sheet, so that the oxidization-resisting capability is improved; the whiteness of the printing paper prepared by the invention is 87% and the printing paper does not fade after being stored for long time; the printing paper can also have a certain eye protection effect; and the strength of the paper sheets is high, so that a paper clamping phenomenon in a printing process is avoided and the service life of a printer is prolonged.

Owner:安徽文峰新材料科技股份有限公司

Splitting machine

InactiveCN105538398AEasy to operateSmooth waste dischargeMetal working apparatusEngineeringConveyor belt

The invention discloses a splitting machine. The splitting machine comprises a rack, a splitting mechanism and a paper conveying mechanism. The paper conveying mechanism is arranged behind the splitting mechanism. The paper conveying mechanism comprises an upper conveyor belt and a lower conveyor belt. The splitting machine is characterized in that the paper conveying mechanism is arranged on a movable trolley which is connected with a power source, and the rack is provided with a rail on which the movable trolley moves horizontally; the upper conveyor belt is arranged on an upper transmission wheel, and the lower conveyor belt is arranged on a lower transmission wheel; when the work condition of the splitting mechanism is maintained, the movable trolley drives the paper conveying mechanism to go away from the splitting mechanism, a maintenance space is reserved between the paper conveying mechanism and the splitting mechanism, and operation of a worker is made to be more convenient through the maintenance space, so that the work efficiency is greatly improved.

Owner:ZHEJIANG HAOSHENG PRINTING MACHINERY

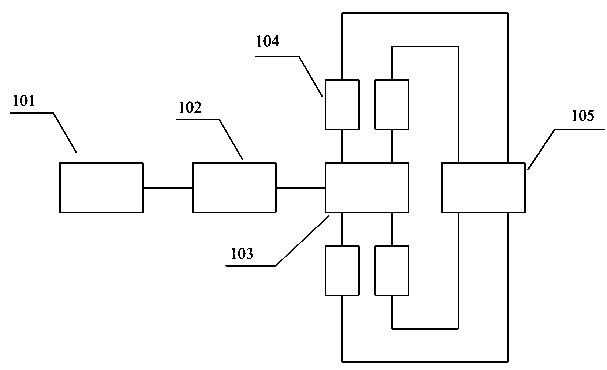

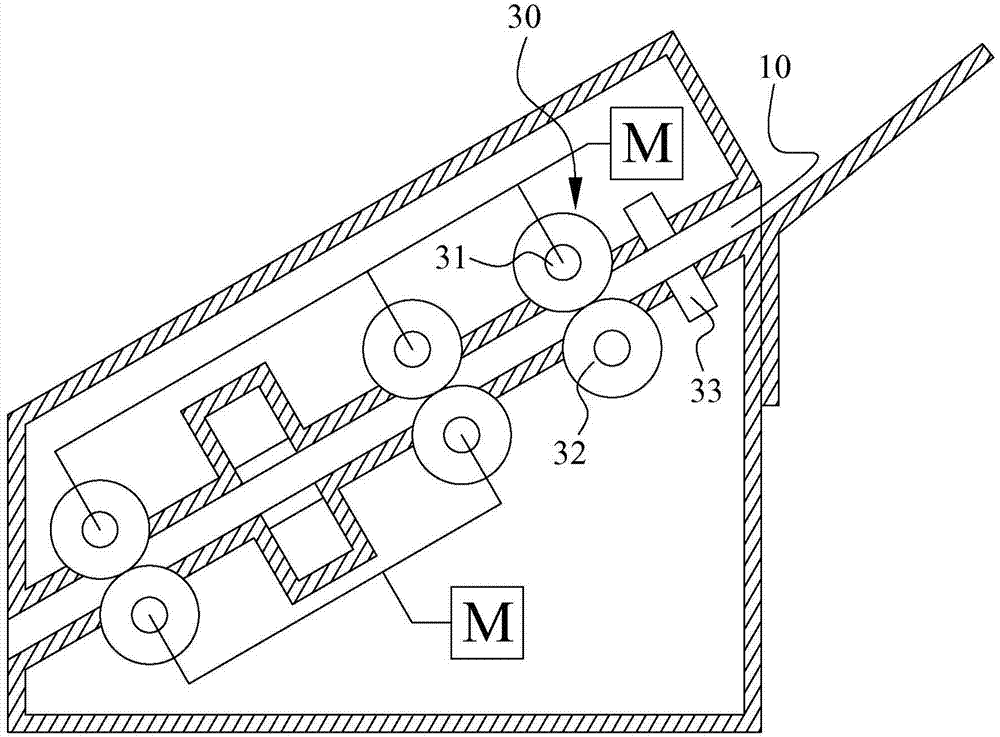

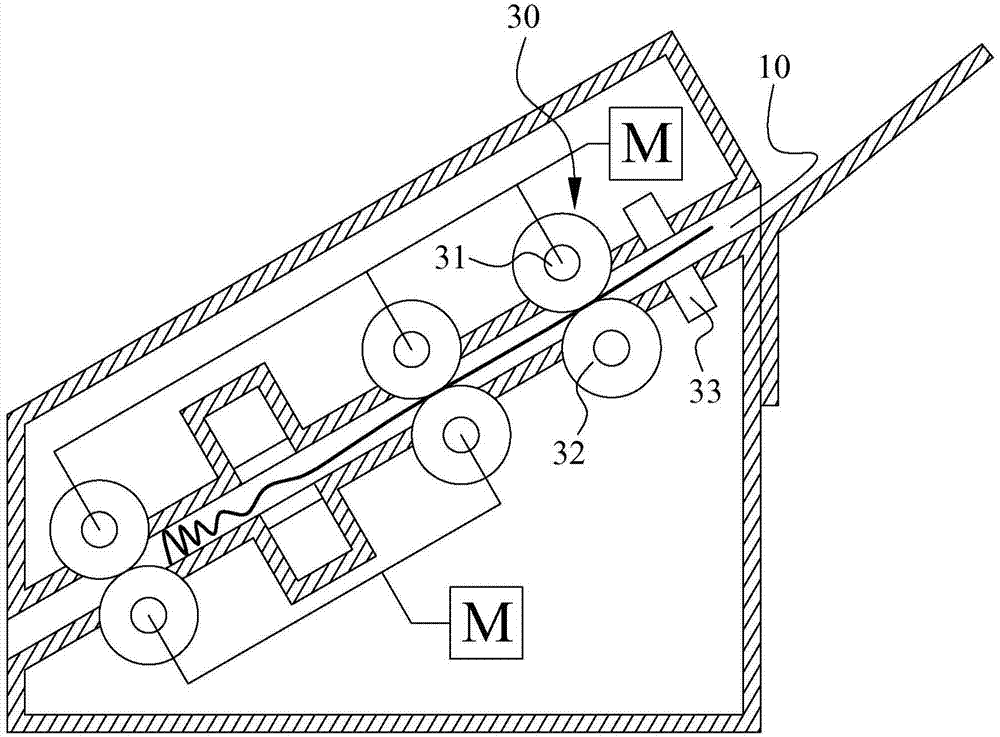

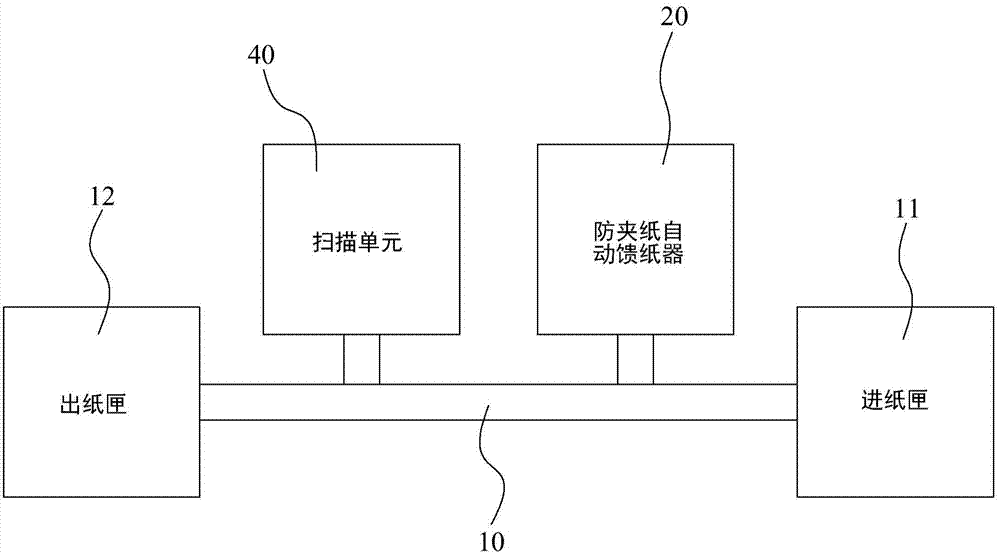

Paper jam-prevention automatic paper feeder

Disclosed is a paper jam-prevention automatic paper feeder. The paper jam-prevention automatic document feeder is mounted on a paper feeding path and comprises a paper fetching device, wherein the paper fetching device is arranged on the upstream of the paper feeding path so as to feed paper in the paper feeding path. The feeder also comprises a set of transport devices, a dynamic measurement module and a control unit, wherein the set of transport devices is arranged on the paper feeding path for transporting paper; the dynamic measurement module is arranged on the paper feeding path and used for measuring information such as the movement speed and the movement direction of paper; and the control unit is connected with the dynamic measurement module and the paper fetching device for monitoring the movement speed and the movement direction of paper and temporarily stopping the paper fetching device when the movement speed or the movement direction is abnormal. The paper jam-prevention automatic paper feeder can rapidly and accurately respond abnormality of the paper transport condition and reduces phenomena of paper damage due to paper jam.

Owner:FOXLINK IMAGE TECH

Multidirectional conveying guider for flaky materials

InactiveCN103879824AReduce the amount of rotationSimple structureArticle deliveryEngineeringMechanical engineering

The invention discloses a multidirectional conveying guider for flaky materials. The multidirectional conveying guider comprises a channel plate assembly and a reversing blade assembly. Multidirectional channels are formed on the channel plate assembly, the different channels on the channel plate assembly can be closed or opened by the reversing blade assembly, the reversing blade assembly is driven by a bidirectional electromagnet, the bidirectional electromagnet is driven by a power motor via a screw, and accordingly an optional channel on the channel plate assembly can be opened. The multidirectional conveying guider has the advantages that the bidirectional electromagnet and the power motor are matched with each other, so that the multidirectional channels can be selected, the multidirectional conveying guider is simple in structure and small in size, the work complexity can be greatly lowered, and the production and maintenance costs can be effectively reduced; the bidirectional electromagnet can work safely and quickly, and accordingly the multidirectional conveying guider is favorable for improving the work efficiency; movement is transmitted via the screw, so that the control precision of the multidirectional conveying guider can be effectively improved, and influence of errors of the motor can be prevented.

Owner:广州智萃电子科技有限公司

Color laser printer with function of preventing paper jamming

InactiveCN107608186AAvoid Paper JamsGuaranteed to proceed normallyElectrographic process apparatusCardboardPulp and paper industry

The invention relates to the technical field of laser printing, and in order to solve the problem of low printing efficiency in the prior art, which is caused by paper jamming in the printing processof a color laser printer due to paper damping, the invention provides a color laser printer with a function of preventing paper jamming. The color laser printer comprises a paper inlet box; the paperinlet box comprises ripping fences at two ends and a supporting plate at the bottom end; two ends of the supporting plate are connected with the ripping fences; a paper feeding structure is arranged on the ripping fences; the paper feeding structure comprises a rotating rod capable of rotating, a paper sucking roller, a lifting cam and a paper lifting plate; the paper sucking roller is mounted onthe rotating rod; the lifting cam is mounted at one end of the rotating rod; the lifting cam is connected with the paper lifting plate by a crank; the lifting cam can drive the paper lifting plate tobe lifted up; the paper lifting plate is positioned above the supporting plate, wherein chutes are formed in corresponding positions on the ripping fences, the insides of the chutes are in sliding connection with a paper ironing plate, the paper ironing plate is positioned above the paper lifting plate, and elastic parts are arranged between the paper ironing plate and the bottoms of the chutes; apressing block is arranged at one end, which is connected with the paper lifting plate, of the crank.

Owner:贵州云侠科技有限公司

Channel for conveying bill or paper

PendingCN109080270AEasy to recycleReduce design sizeTypewritersOther printing apparatusHigh intensityPulp and paper industry

The invention relates to a channel for conveying a bill or paper. The channel comprises a printing paper feeding channel, a scanning paper feeding channel, a connecting channel, a storage box A paperfeeding channel and a storage box B paper feeding channel; one end of each of the printing paper feeding channel and the scanning paper feeding channel is communicated with the top end of the connecting channel which is arranged vertically; one end, far away from the connecting channel, of the printing paper feeding channel is communicated with a printer; one end, far away from the connecting channel, of the scanning paper feeding channel is communicated with a scanner; and after the paper or bill enters the connecting channel, the paper or bill enters the storage box A paper feeding channel or the storage box B paper feeding channel correspondingly according to the set classification and under the action of a paper prodding mechanism, so that the paper or bill is collected in the storagebox A and the storage box B correspondingly. The channel for conveying the bill or paper avoids high-intensity work of manual classification, effectively improves the working efficiency and has greatmarket prospect.

Owner:BEIJING C&W ELECTRONICS GRP

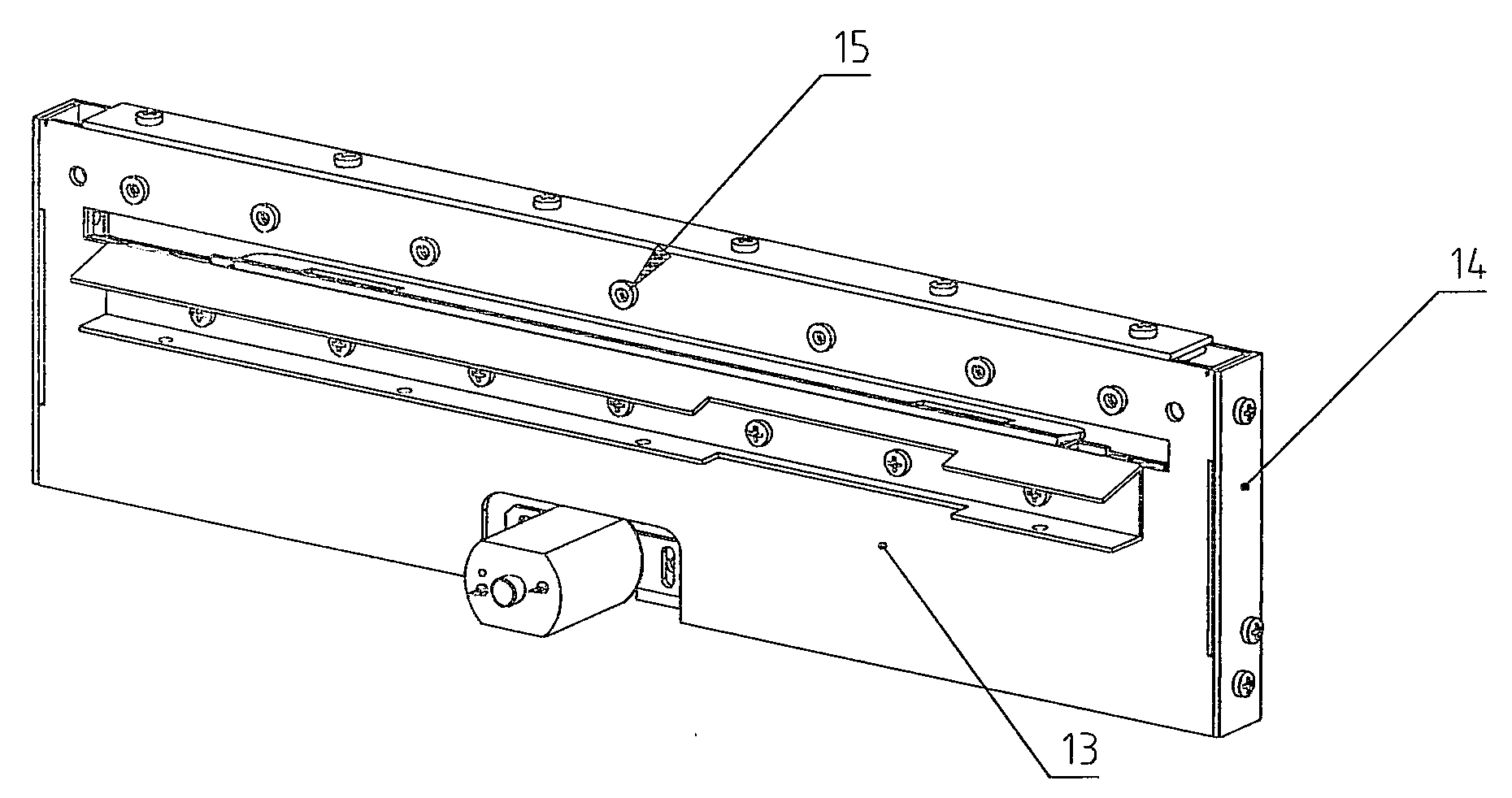

Automatic paper cutting device for multi-piece chain paper bill printer

InactiveCN103158374ASolution to short lifeAvoid burrsOther printing apparatusEdge surfacePulp and paper industry

The invention discloses an automatic paper cutting device for a multi-piece chain paper bill printer. The automatic paper cutting device comprises a fixed knife installation frame, a movable knife installation frame, a fixed knife, a movable knife matched with the fixed knife, a movable limit guide mechanism and a drive transmission mechanism which drives the movable knife to slide on the movable knife installation frame up and down and is matched with the fixed knife to cut paper; the fixed knife installation frame is arranged on the top of the movable knife installation frame; the fixed knife is arranged on the fixed knife installation frame; the movable knife is arranged on the movable knife installation frame; the fixed knife installation frame is provided with a jacking and bending structure which can ensure that the fixed knife has certain curvature and gradually bends toward one side of the movable knife from two sides of the fixed knife to the middle part of the fixed knife; and the movable knife is provided with a knife edge surface of which the middle part is lower than two sides. The automatic paper cutting device avoids phenomena that burrs are easily produced, and paper is wound and jammed during paper cutting, a cut of cut paper is smooth and clean, the paper is cut reliably, and multiple layers of paper can be cut.

Owner:颜炳辉

Full-automatic efficient packing box production line

InactiveCN107756874AEfficient splicingAvoid Paper JamsPaper-makingBox making operationsProduction lineProcess engineering

The invention discloses a full-automatic efficient packaging box production line. The full-automatic efficient packaging box production line comprises a paper feeding device, a gluing device and a bonding device, wherein the paper feeding device, the gluing device and the bonding device are sequentially connected through an annular conveyor belt. The gluing device comprises a vertically-liftable glue gun with a rectangular glue spray opening. The glue gun is connected with a glue pool. The top of the glue gun is connected with a vertical lifting device. By the adoption of the full-automatic efficient packaging box production line, the application range is wide, the requirements of paper with different sizes and thicknesses can be met, the paper jamming phenomenon is avoided effectively, and splicing of a packaging box can be completed efficiently.

Owner:浙江欧影包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com