Paper-pulling mechanism of paper-out rolling wheel and printer using the same

A technology of printers and rollers, which is applied in the directions of sending objects, handling thin materials, transportation and packaging, and can solve problems such as paper jams and paper rewinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

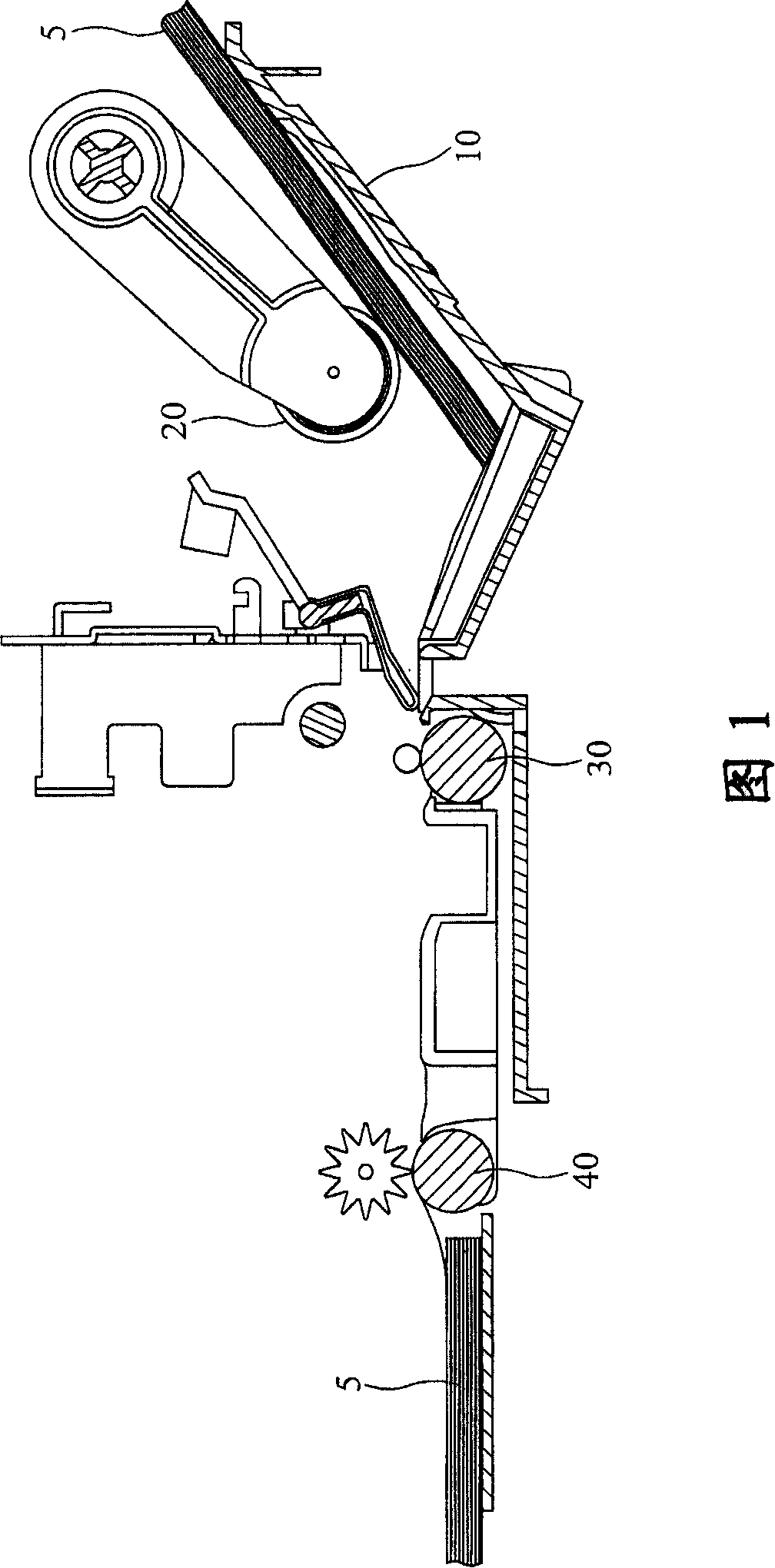

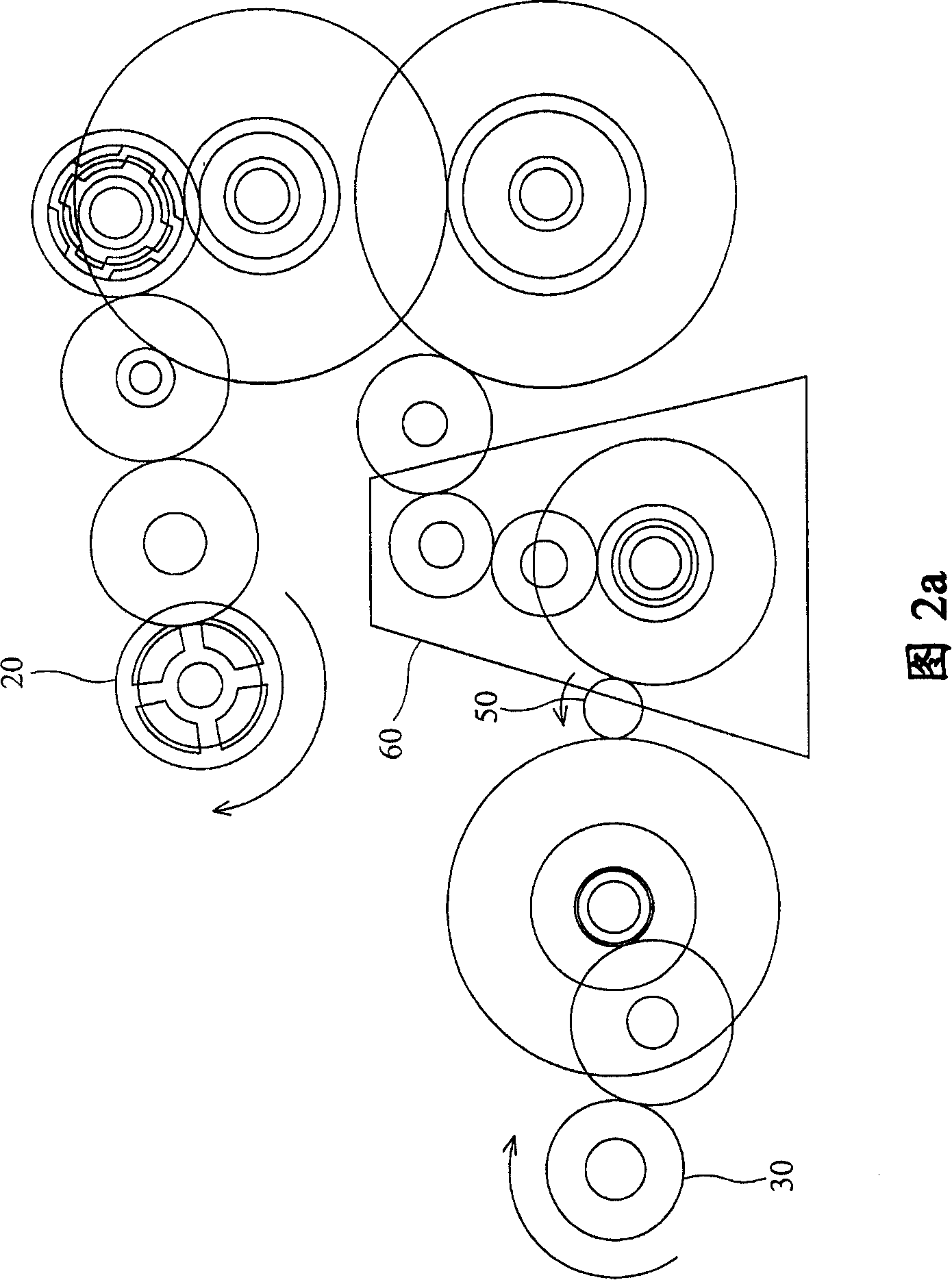

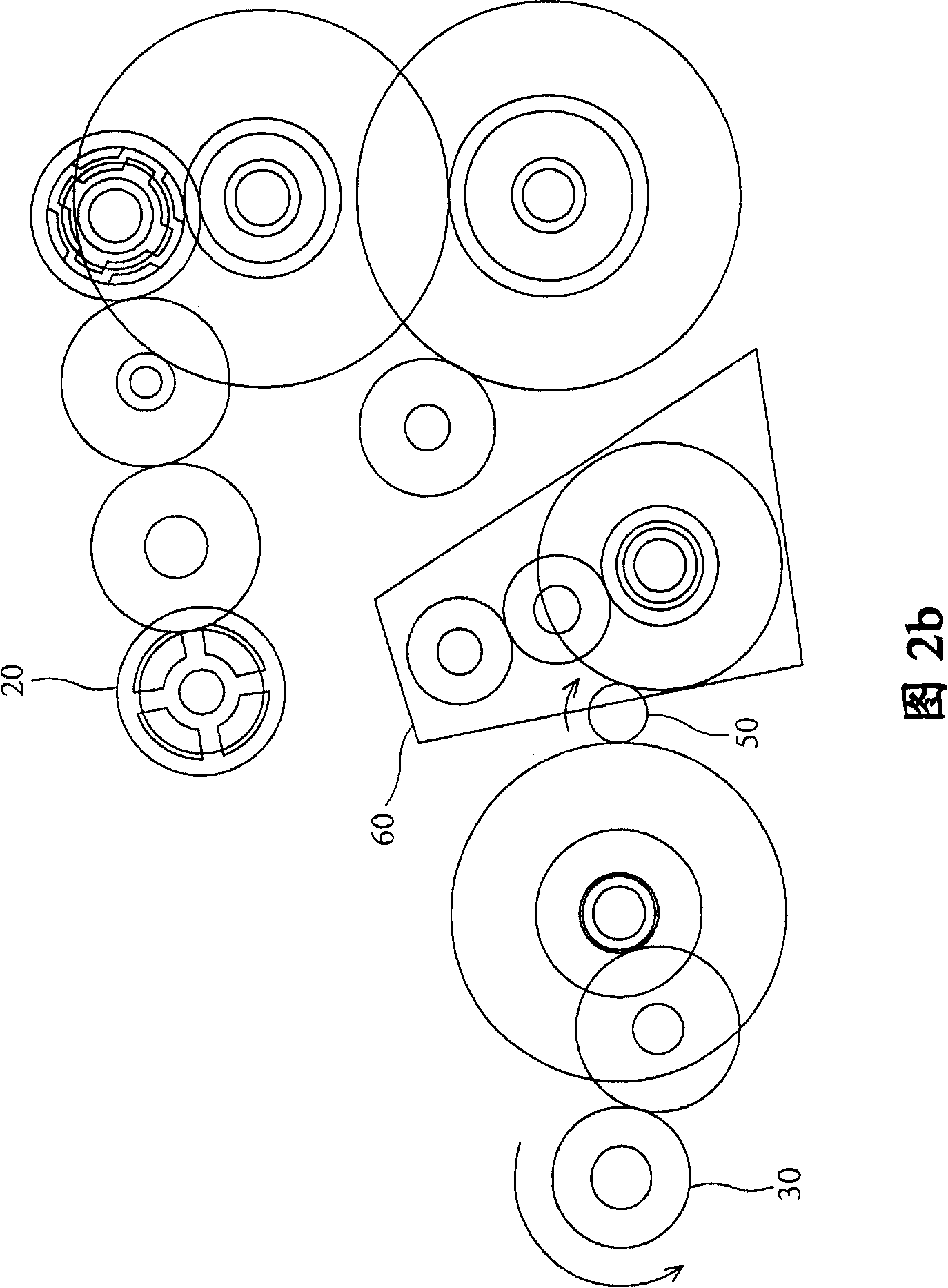

[0023] Fig. 3a is a perspective view of the paper output mechanism of the printer of the present invention, and Fig. 3b is an enlarged view of part A in Fig. 3a. Figure 4 is an exploded view of Figure 3a. The printer 1000 of the present invention includes a body 100, a paper discharge roller 200, and a paper pushing mechanism 300. When the paper discharge roller 200 rotates, paper (not shown) leaves the body from the body 100 in the paper discharge direction shown by arrow D 100.

[0024] As shown in FIG. 4 , the paper output roller 200 includes a shaft portion 210 and a roller portion 220 . The shaft part 210 is rotatably arranged on the body 100, and the roller part 220 is a cylinder with a larger diameter than the shaft part 210. It is arranged on the periphery of the shaft part 210 and is coaxial with the shaft part 210. , the roller part 220 will also rotate to push the paper toward the paper output direction D.

[0025] In order to ensure that the paper can be pushed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com