Automated paper feeding printing machine

A technology for printers and paper feeding, applied in printing devices, printing, etc., can solve problems such as paper jams, and achieve the effect of ensuring printing effects and avoiding paper jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further detailed explanation through specific implementation mode below:

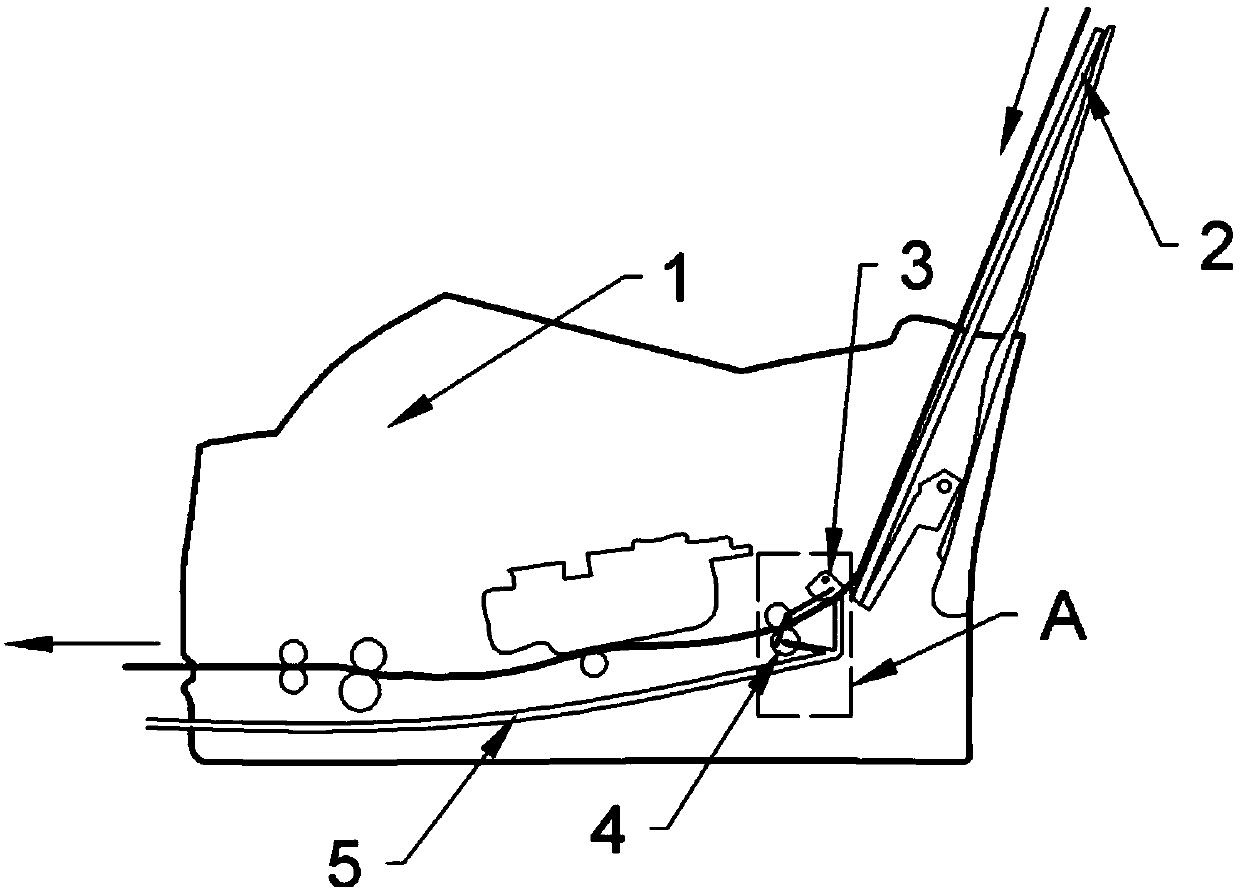

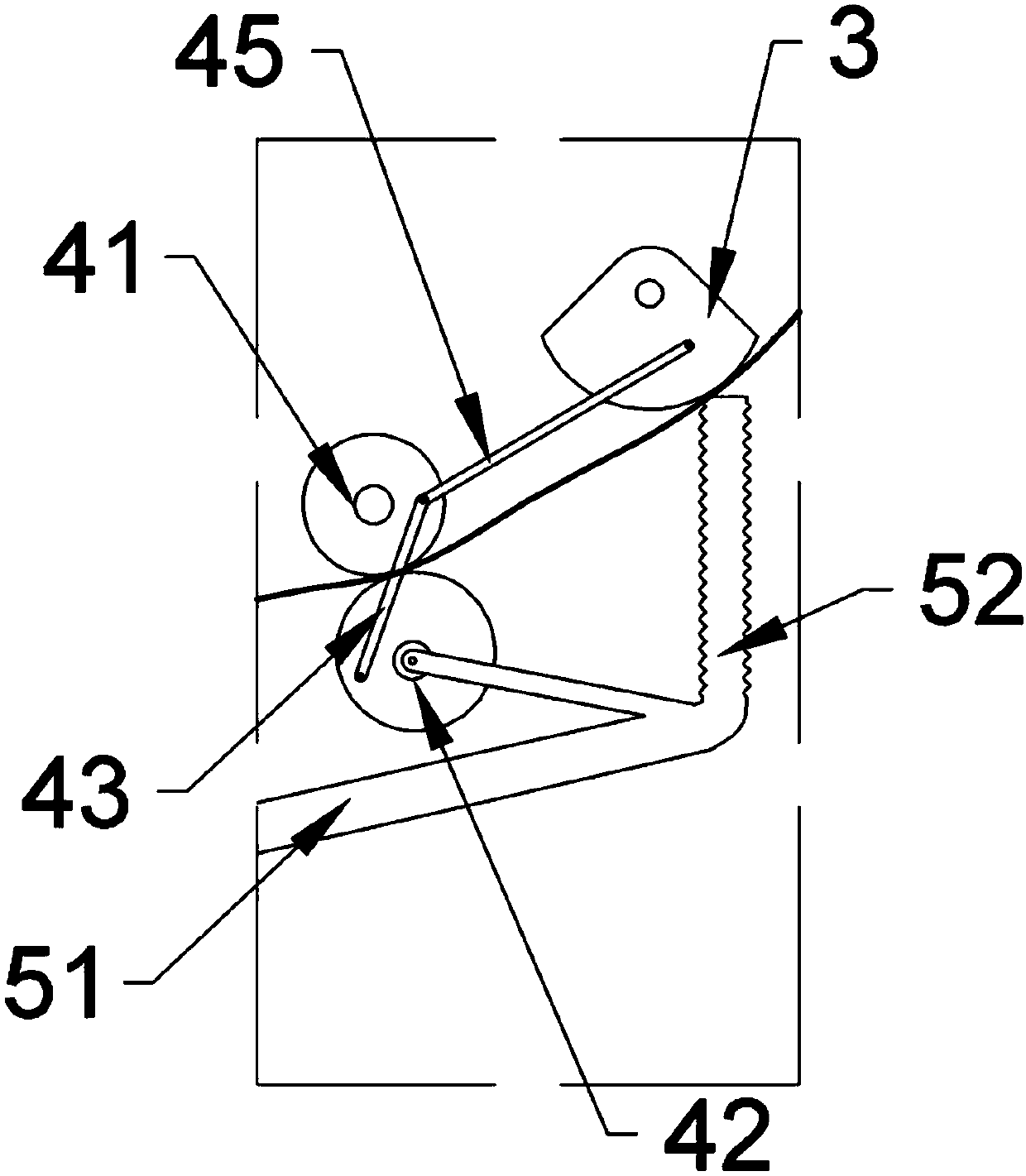

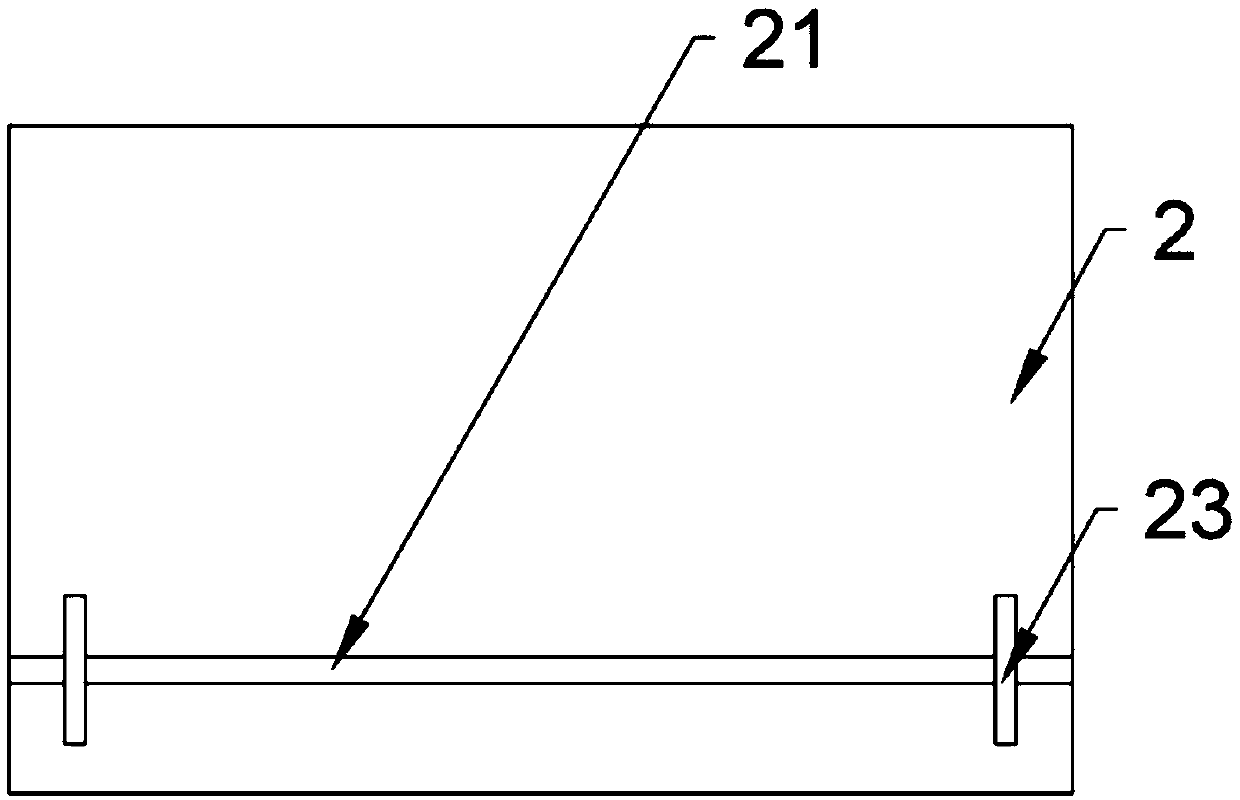

[0023] The reference signs in the drawings of the specification include: body 1, paper feeding board 2, chute 21, limit block 23, paper feeding cam 3, paper feeding pair roller 4, second rotating roller 41, first rotating roller 42, second rotating roller A connecting rod 43 , a second connecting rod 45 , a heat conduction component 5 , an air duct 51 , and a bellows 52 .

[0024] Such as figure 1 The shown automatic paper feeding printer includes a main body 1, a paper feeding box is installed at one end of the main body 1, and a paper outlet is provided at the other end. Specifically, in this embodiment, a paper feeding box is installed at the right end of the main body 1, and a paper feeding box is installed at the left end of the main body 1. The paper outlet, the paper feeding box includes a paper feeding board 2 for putting paper, wherein: the paper feeding box also includes a heating mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com