Paper-outputting device for printer and its working method

A printer and paper cutting technology, applied in printing devices, typewriters, printing, etc., can solve the problems of printer jamming, pulling printing paper, blocking paper outlets, etc., to achieve simple structure, good reliability, and prevent paper jamming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

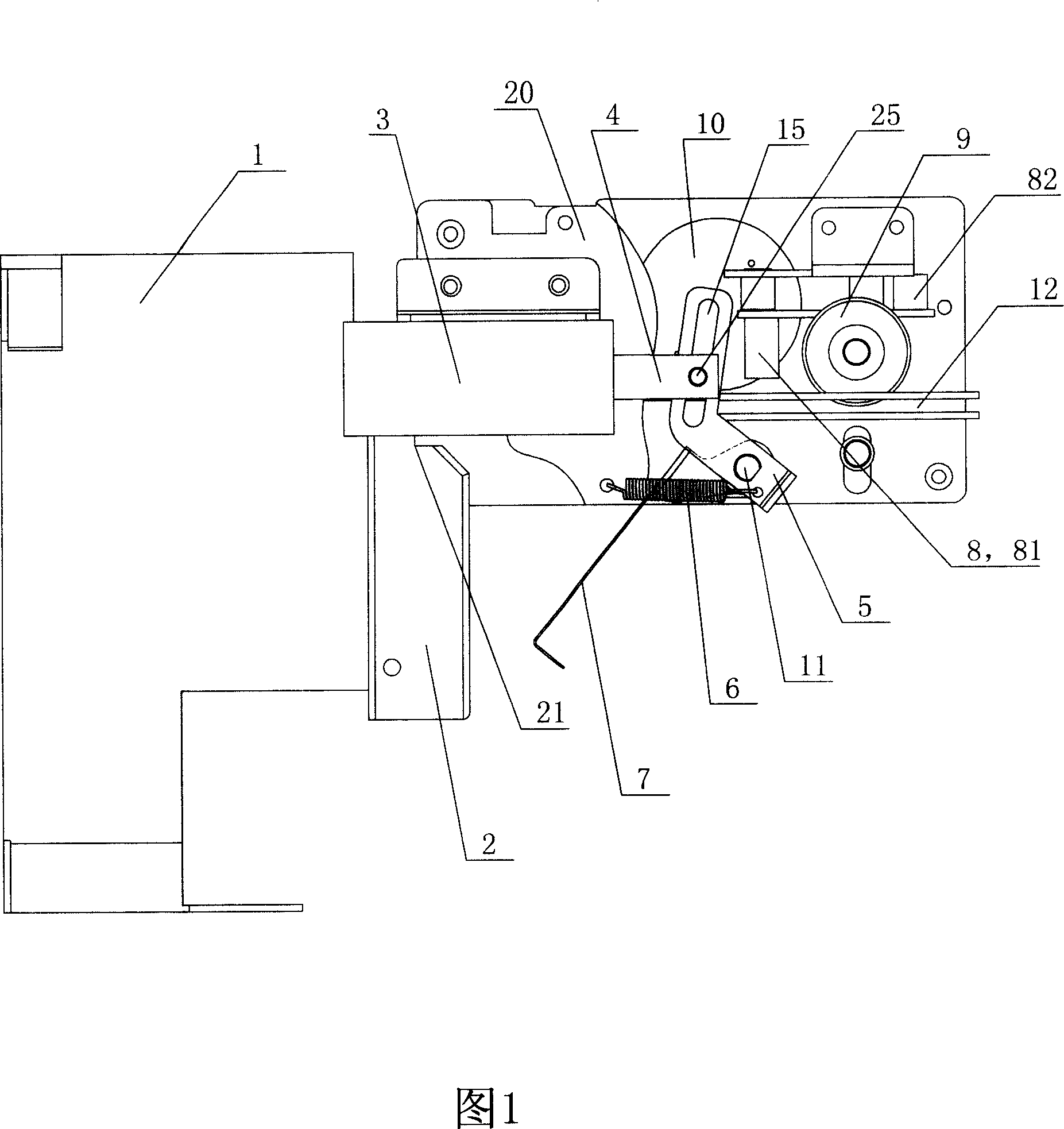

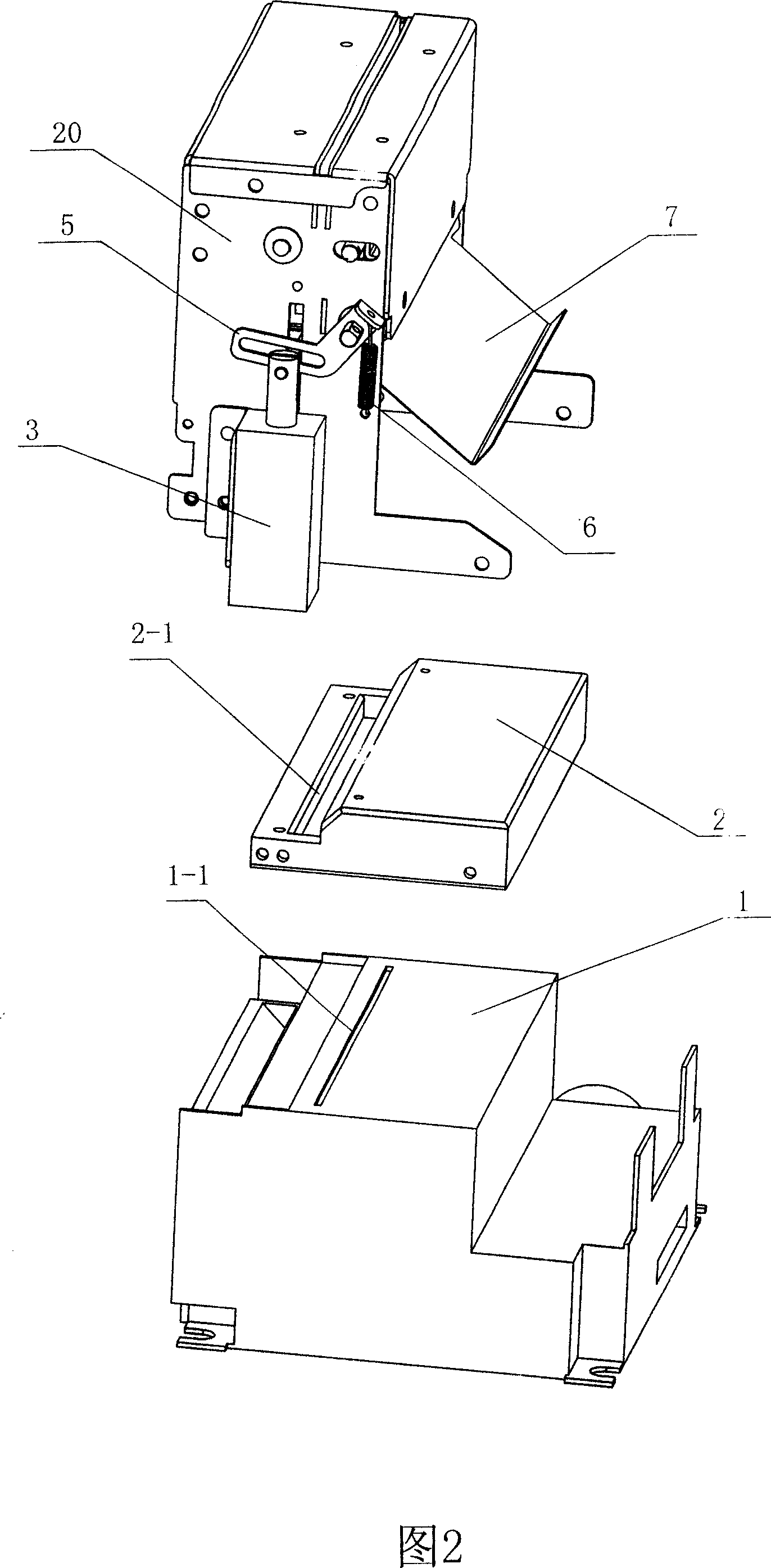

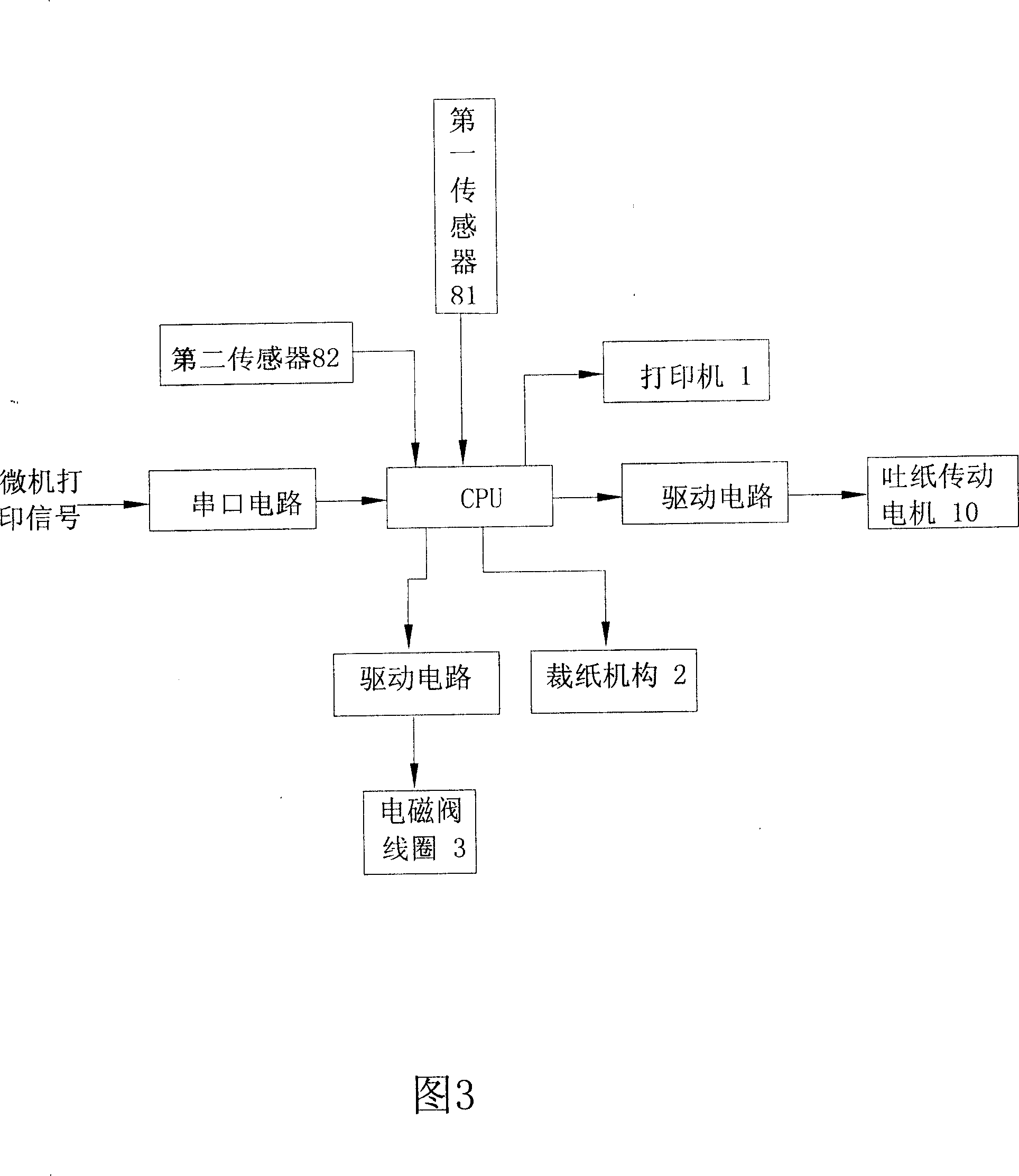

[0025] Referring to Fig. 1-2, the paper ejecting device of the printer in this embodiment includes: a paper ejecting device of the printer, including a paper cutting mechanism 2 arranged at the paper outlet of the printer 1, a paper cutting mechanism 2 arranged at the paper cutting mechanism 2 The paper ejecting mechanism at the outlet 2-1 and the control circuit for connecting with the control end of the printer 1 and the paper cutting mechanism 2; The relative rotating shaft 11 of outlet 2-1, be arranged between the outlet 2-1 of paper-cutting mechanism 2 and rotating shaft 11 and one edge is fixedly arranged on the paper guide plate 7 on rotating shaft 11, the rotating implement that links to each other with rotating shaft 11 Force mechanism, the paper feeding channel 12 arranged on one side of the rotating shaft 11, the sensor 8 arranged at the upper end of the paper feeding channel 12 for detecting the position of the paper, and the paper ejecting transmission combination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com