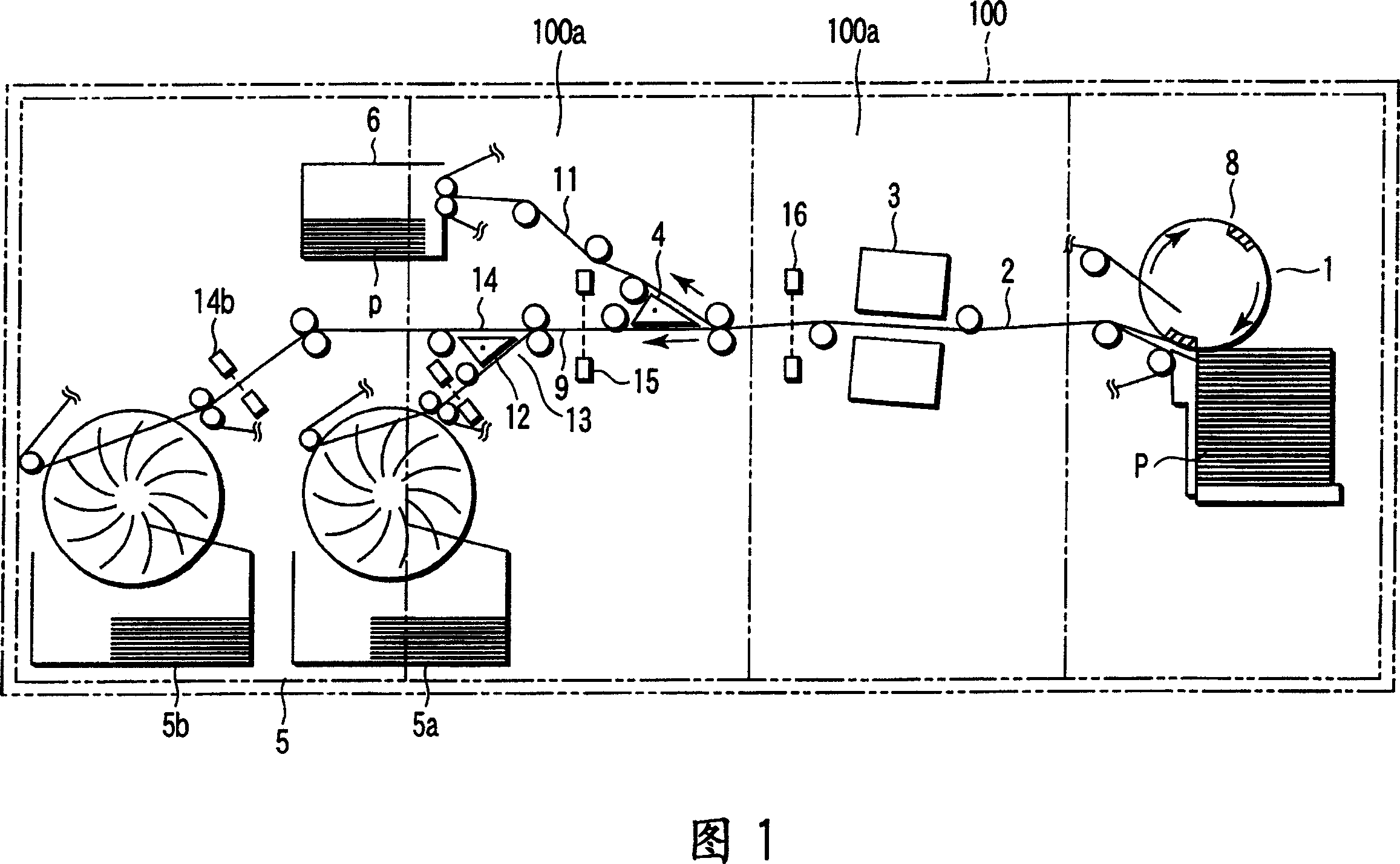

Paper sheet conveying apparatus

A technology for conveying equipment and paper, applied in the direction of thin material handling, transportation and packaging, object supply, etc., can solve the problem that the operator cannot easily remove paper jams, and achieve the effect of preventing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

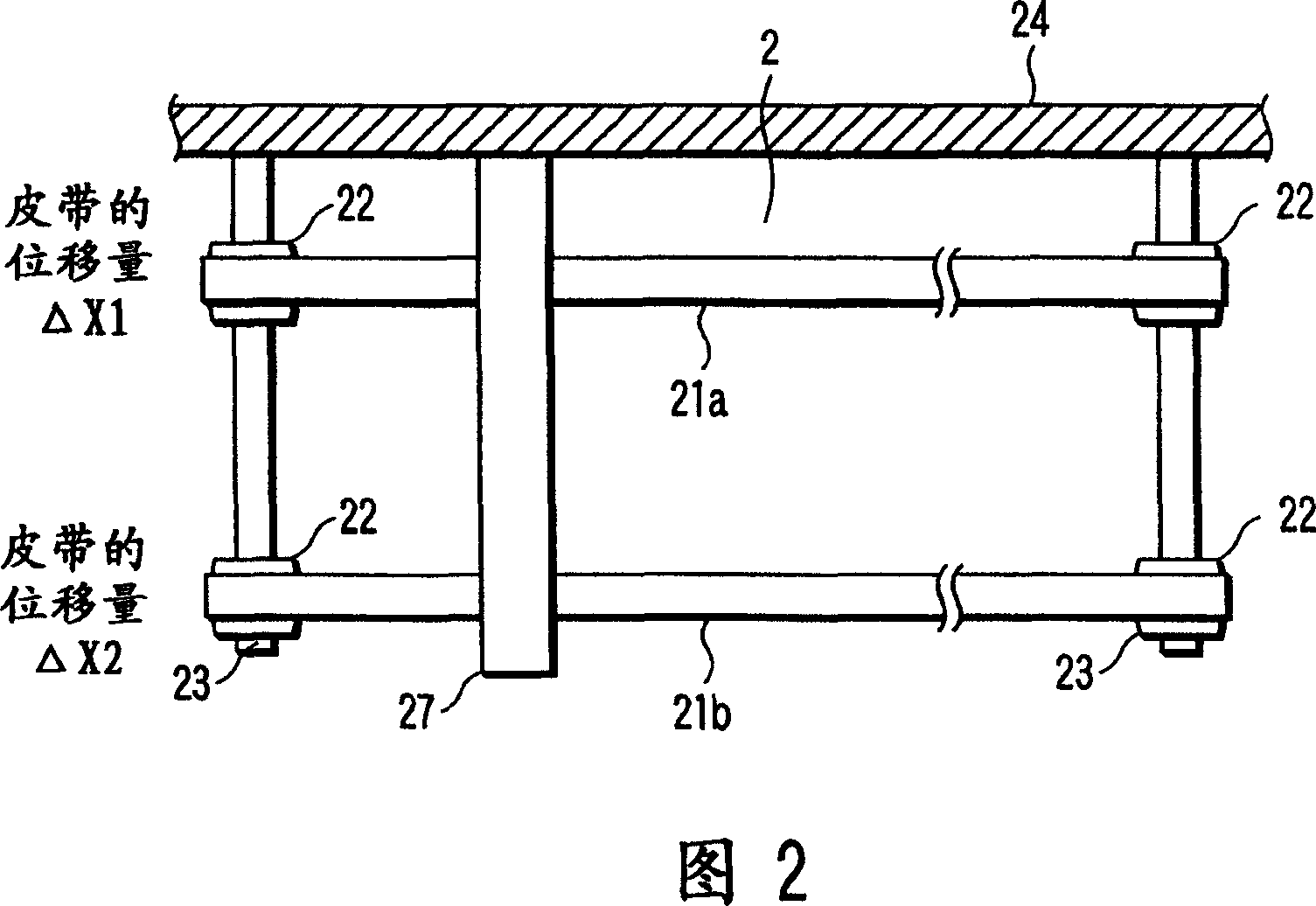

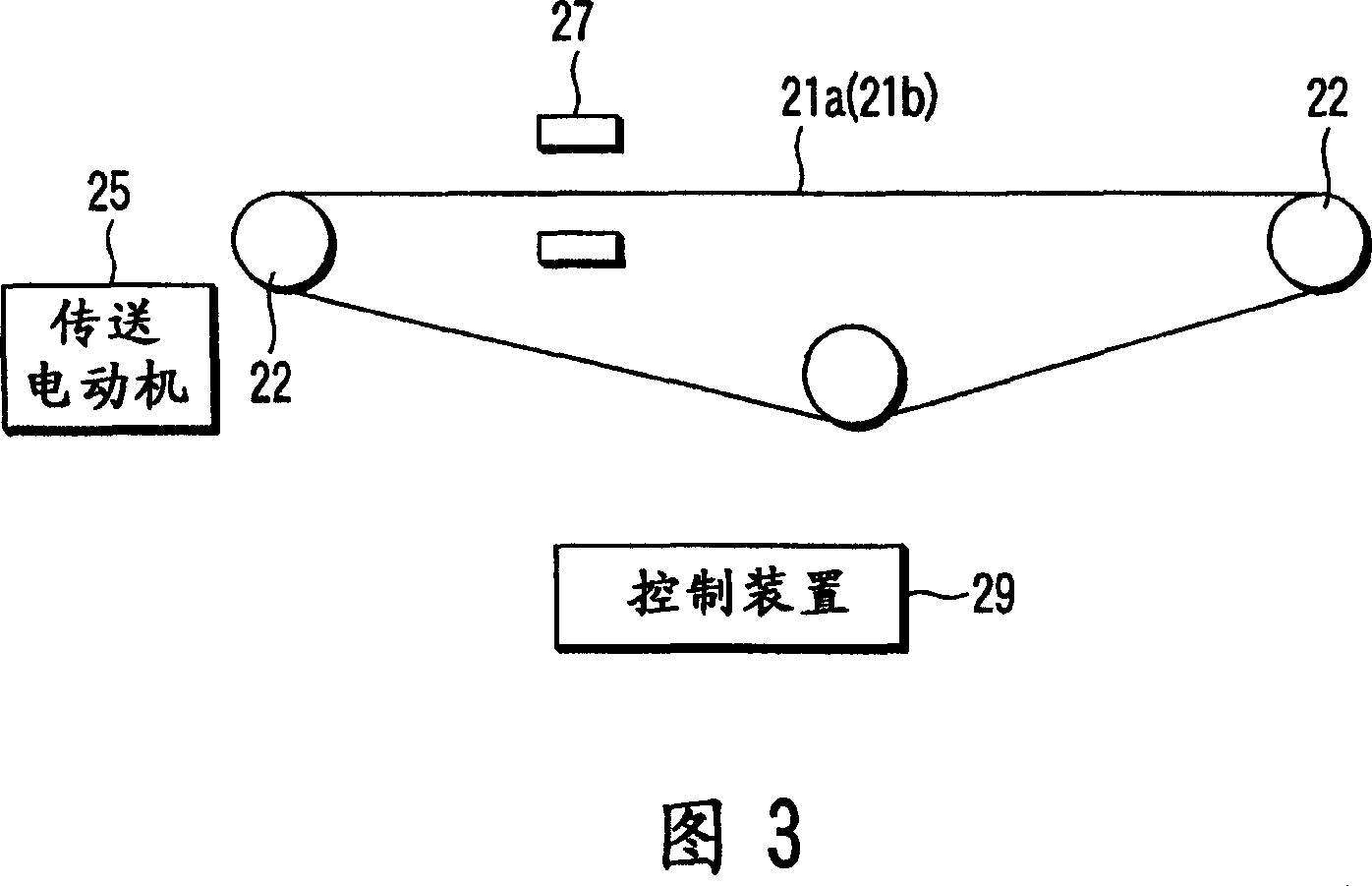

Method used

Image

Examples

no. 2 example

[0071] According to the second embodiment, when the conveying system has not been operated for a certain period of time, the system automatically runs at a low speed as a test run, and gradually increases the speed of the motor, thereby preventing the conveying belt from shifting or falling off, and preventing paper jams.

[0072] When the usage period of the conveyor belt is near the end, it is notified to the third notification means 35, and the conveyor belt can be replaced before the usage period expires, thereby preventing paper jams.

[0073] Fig. 14 is a block diagram showing a drive control system of a conveyor belt according to a third embodiment.

[0074] Components that are the same as those in the first embodiment are given the same reference numerals, and detailed descriptions of these components will be omitted.

[0075] In the third embodiment, a paper jam detection sensor 37 is provided as paper jam detection means to detect a paper jam, and a display part 39 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com