Full-automatic edge-cutting, notching and cutting-off all-in-one machine

An all-in-one, fully automatic technology, applied in metal processing and other directions, can solve the problems of tail paper deviation, paper head upturning, sharp increase in equipment impact, etc., to ensure production, smooth production, and avoid paper jams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

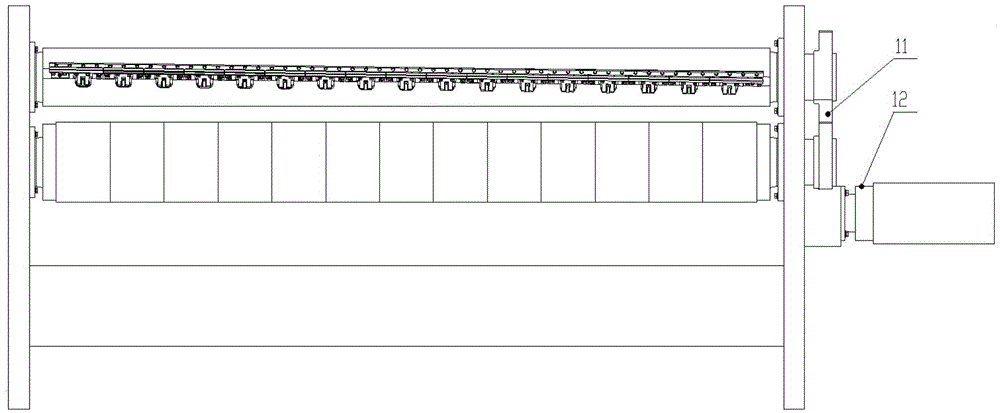

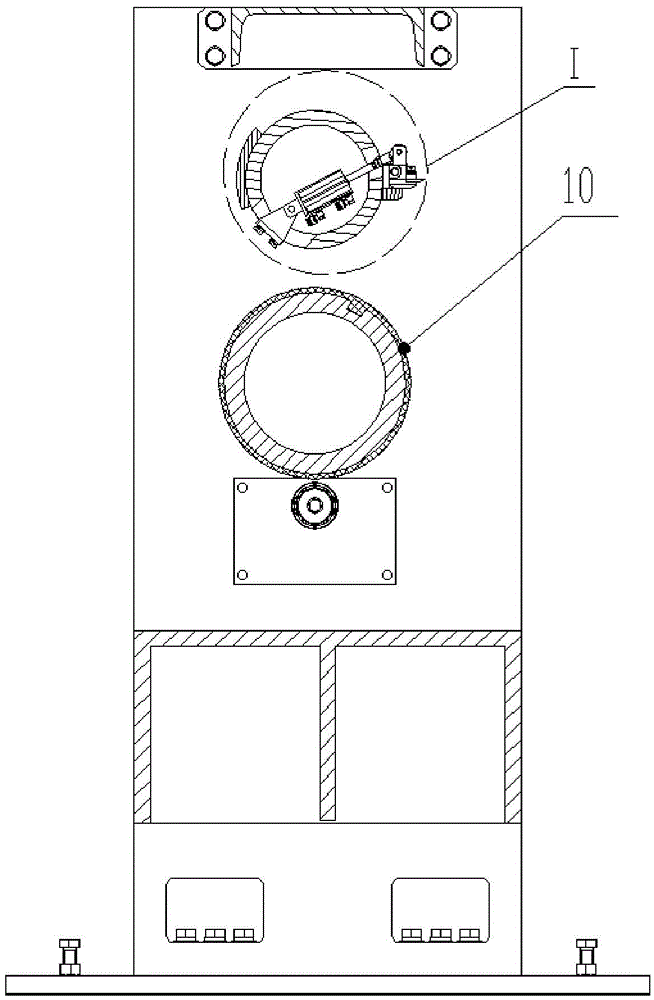

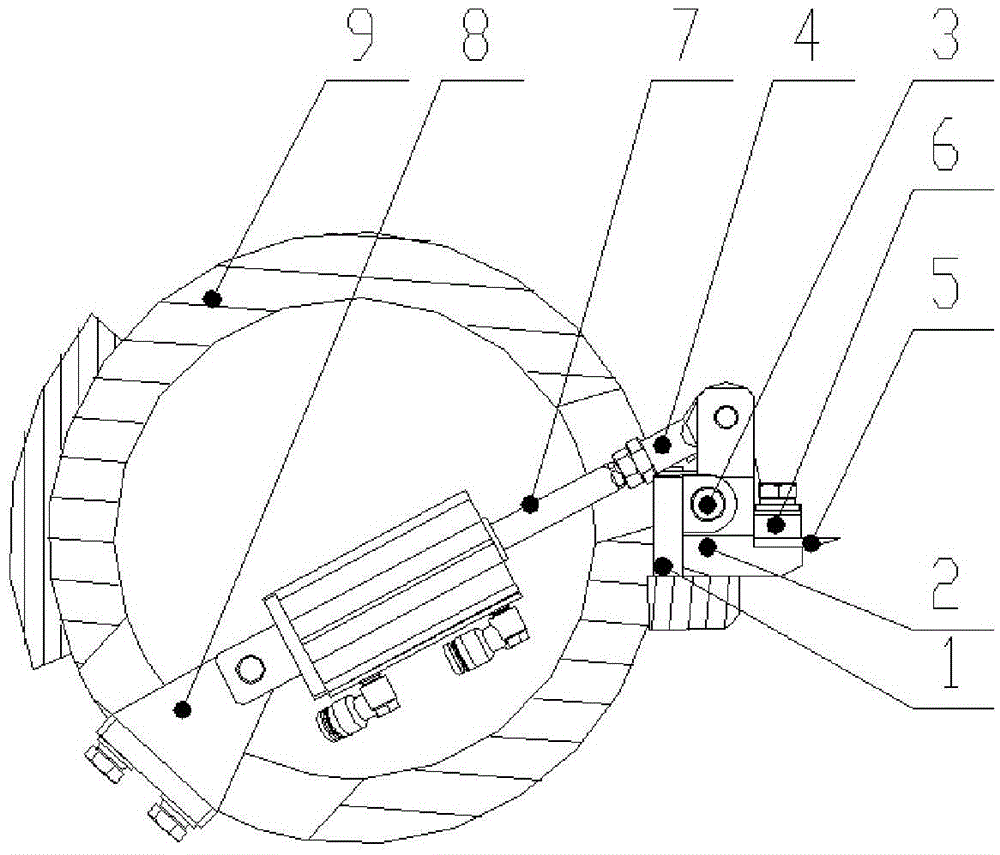

[0023] see Figure 1-Figure 4 , the full-automatic edge trimming and cutting all-in-one machine of the present invention is installed on a corrugated cardboard production line, and includes a cutting part and a waste discharge part installed on the frame, and the cutting part includes a rubber pad roller 10 and a rubber pad horizontally installed on the frame The cutting knife shaft above the roller 10;

[0024] The cutting cutter shaft is a cylindrical cutter shaft 9 as a whole, and several cutting assemblies are installed on the outer surface of the cutter shaft 9. The cutting assemblies have blades, and each cutting assembly has a separate drive cylinder 7, which drives the blades of the cutting assemblies to expand and contract;

[0025] The cutting knife shaft and rubber pad roller 10 are driven to rotate by a servo motor 12 at one end through a transmission gear 11;

[0026] The waste discharge part is installed behind the cutting part along the cardboard conveying dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com