Automobile handrail reinforced left-and-right support continuous die

An automobile armrest, left and right technology, which is applied in the field of improvement and invention of the continuous die for strengthening the left and right brackets of the automobile armrest, can solve the problems of unfavorable product stamping, low production efficiency, single die structure, etc., and achieves the effect of saving cost and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

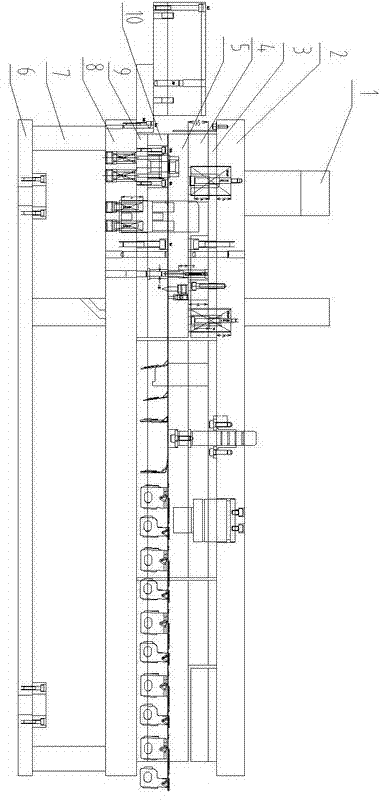

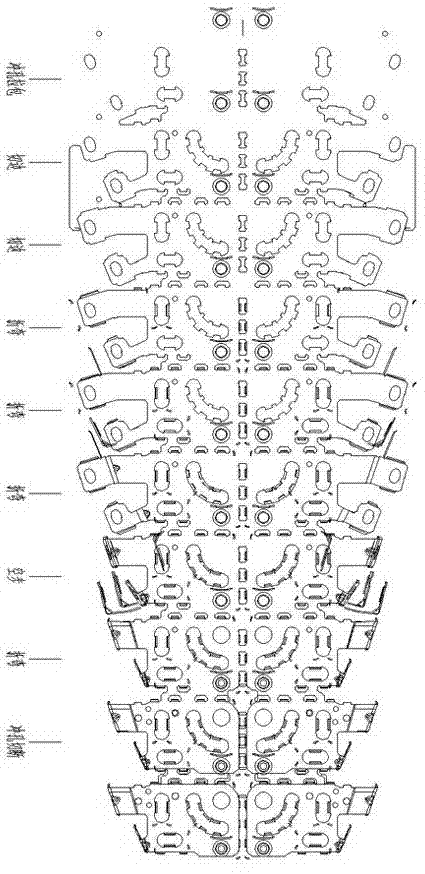

[0010] Accompanying drawing has shown structure of the present invention, further illustrates its relevant details below again in conjunction with accompanying drawing. The continuous mold for strengthening the left and right brackets of the automobile armrest includes an upper mold base of the continuous mold and a lower mold base of the continuous mold for manufacturing the corresponding structure of the left side panel of the backrest of the automobile. Feet 1, upper mold base 2, upper backing plate 3, upper splint 4 and stripper plate 5, the lower mold base of the continuous mold includes a lower supporting plate 6, a lower foot 7, a lower mold base 8, The lower backing plate 9 and the lower template 10; the first punching and bagging station, the second trimming station, the third trimming station, the third Four bending station, the fifth bending station, the sixth bending station, the seventh empty step station, the eighth bending station, the ninth punching and cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com