Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

243results about How to "No secondary processing required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

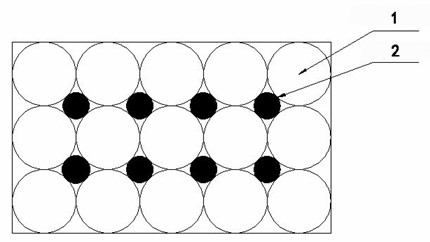

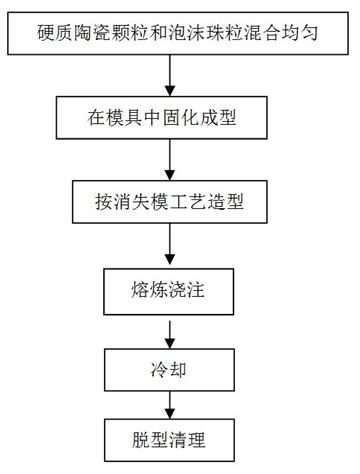

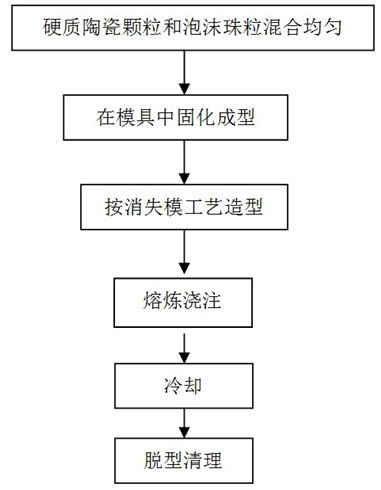

Method for preparing ceramic particle enhanced steel-base composite material cast by evaporative pattern casting die

InactiveCN102489686AHigh bonding strengthImproved dimensional accuracy and surface qualityFoundry mouldsFoundry coresCoalCeramic particle

The invention provides a method for preparing a ceramic particle enhanced steel-base composite material cast by an evaporative pattern casting die. The method comprises the following steps of: uniformly mixing hard ceramic particles and aged foam beads according to any proportion, and filling the mixture into a curing die cavity of the die for curing to manufacture a foam die in which enhancement bodies are uniformly distributed; and then shaping according to the conventional evaporative pattern casting method, putting the obtained foam die into the cavity, smelting a base metal material to pouring temperature, pouring the base metal material into the cavity, cooling and solidifying the base metal material at room temperature, and clearing sand away from the base metal material to obtain the ceramic particle enhanced steel-base composite material, of which the hard ceramic particles are dispersed in the base metal. The preparation method is easy to operate, high in whole performance and high in yield rate; furthermore, in spite of whole enhancement and partial enhancement, various metal-base composite material parts can be directly made without secondary processing; the method is suitable for large-scale industrial production, and can be widely applied to anti-abrasion fields, such as mines, power, metallurgy, coals, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

Heat-conducting plastic and preparation method thereof

ActiveCN102746560AImprove thermal conductivityEasy injection moldingHeat conductingDegrees of freedom

The invention discloses a heat-conducting plastic and a preparation method thereof, wherein the heat-conducting plastic comprises, by weight, 25% to 80% of matrix resins, 5% to 40% of heat-conducting fillers, 5% to 10% of coupling agents and 5% to 30% of halogen-free flame retardants. According to the heat-conducting plastic, the coefficient of heat conductivity is high, the injection molding is convenient, the cost is low, heat dissipation is even, hot spots can be avoided, local deformation of parts caused by the high temperature is reduced, the weight is light and lighter than the weight of aluminum materials by 40% to 50%, the molding processing is convenient, secondary processing is not needed, and the product design degree of freedom is high.

Owner:SHENZHEN FRD SCI & TECH

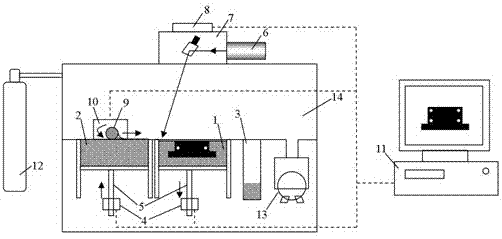

Forming device and method of aluminum-based silicon carbide particle reinforced composite material and member thereof

ActiveCN103695681ASimple molding processDense and uniform internal tissueCarbide siliconControl system

The invention provides a forming device and method of an aluminum-based silicon carbide particle reinforced composite material and a member thereof. The forming device comprises a laser system, a powder spreading system, an inert atmosphere system and a control system. By using the forming device, quick formation of the aluminum-based silicon carbide particle reinforced composite material and the member thereof can be realized. The forming method provided by the invention is simple, and adopts digitized manufacturing. The formed product is compact and uniform in texture, and any complicated members can be directly manufactured without being secondarily processed.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

Photo-curable 3D (three-dimensional) printing aluminum-base ceramic slurry and method for preparing ceramic mold cores

ActiveCN108083777AImprove liquidityEvenly dispersedAdditive manufacturing apparatusFoundry mouldsSlurryViscosity

The invention discloses photo-curable 3D (three-dimensional) printing aluminum-base ceramic slurry and a method for preparing ceramic mold cores. The photo-curable 3D printing aluminum-base ceramic slurry comprises ceramic formula powder, photo-curable resin systems and additives. The photo-curable 3D printing aluminum-base ceramic slurry and the method have the advantages that the photo-curable 3D printing aluminum-base ceramic slurry is high in solid phase content, low in viscosity and applicable to photo-curable 3D printing photo-polymerization, the problems of high viscosity and poor flowability of existing slurry for photo-curable 3D printing ceramics, easiness in agglomerating ceramic particles in the existing slurry, uneven dispersion of the ceramic particles, low solid phase contents and the like can be solved, and application of photo-curable 3D printing to ceramic precision components can be expanded.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Semitransparent fluorescent powder/glass composite luminescent ceramic wafer and preparation method thereof

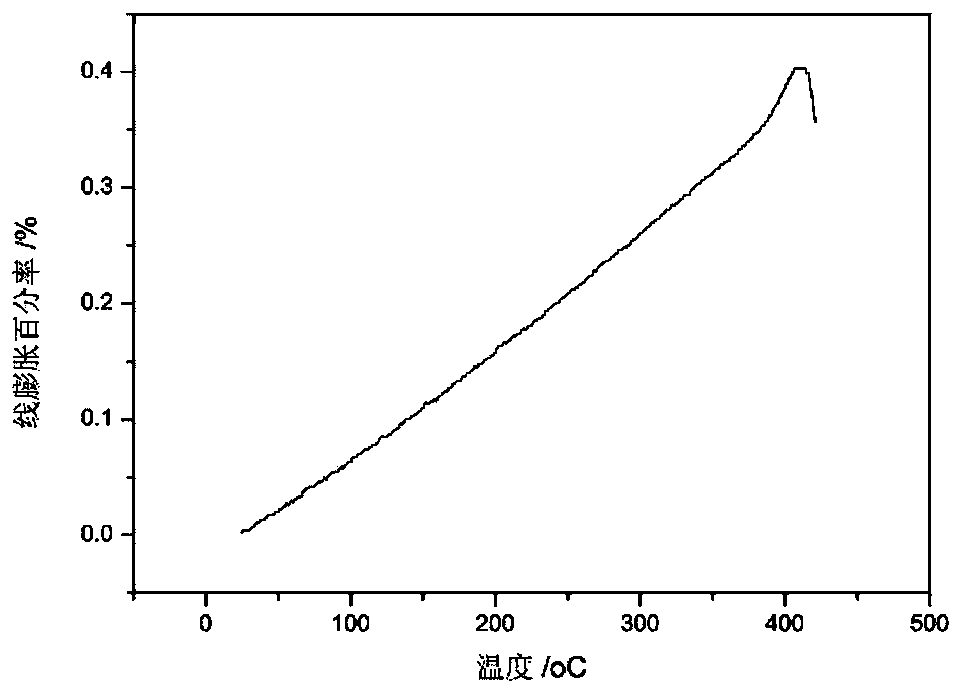

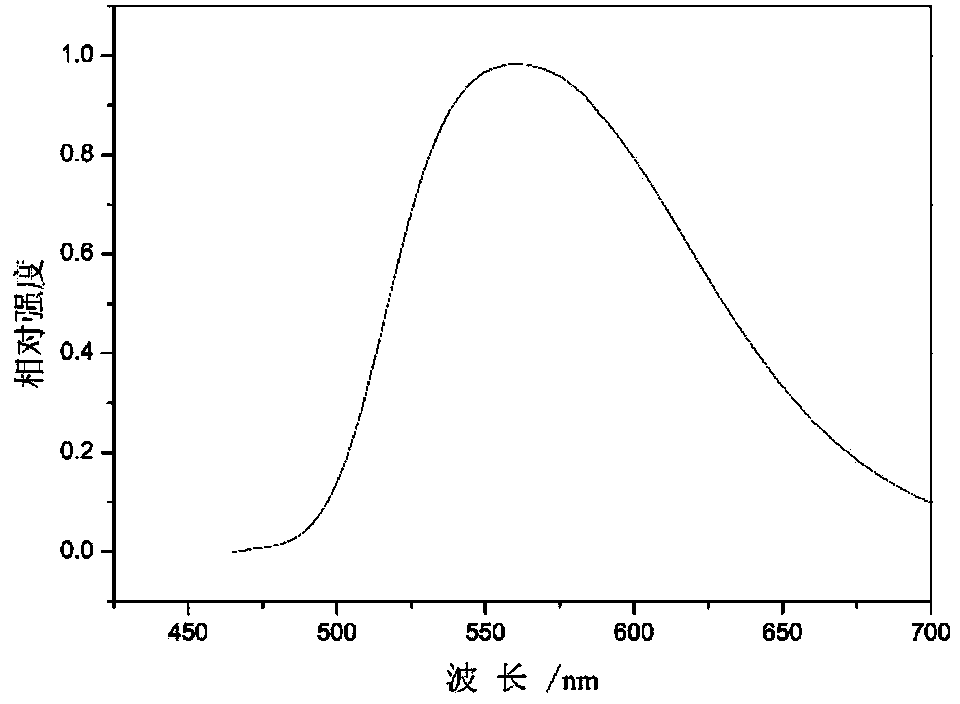

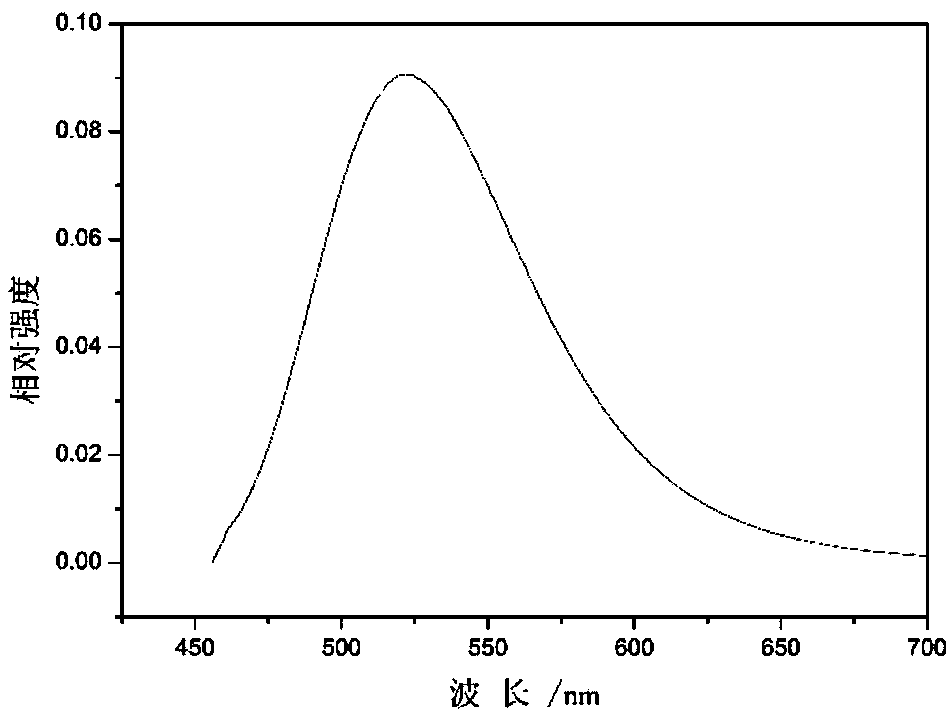

The invention relates to a semitransparent fluorescent powder / glass composite luminescent ceramic wafer and a preparation method thereof. The semitransparent fluorescent powder / glass composite luminescent ceramic wafer is obtained by carrying out 'pelletizing, compression moulding and sintering' on fluorescent powder and low-melting-point glass powder, wherein content of the fluorescent powder is 30-85wt%, and the content of the low-melting-point glass powder is 70-15wt%. The preparation method of the semitransparent fluorescent powder / glass composite luminescent ceramic wafer comprises the following steps: firstly, uniformly mixing fluorescent powder with glass powder in certain proportion, and adding a binding agent required by pelletizing and demoulding, so that pelletized powder of 60-100 meshes is obtained; secondly, carrying out compression moulding on the obtained pelletized powder by virtue of a mould, so that a green body of a certain shape is obtained; thirdly, carrying out heat treatment, namely carrying out glue drainage on the green body for 2-4 hours at the temperature of 300-395 DEG C, and sintering for 1-2 hours at the temperature of 395-410 DEG C, wherein the whole heat treatment process is carried out in the air atmosphere; and finally the fluorescent powder / glass composite luminescent ceramic wafer is obtained.

Owner:厦门百嘉祥微晶材料科技股份有限公司

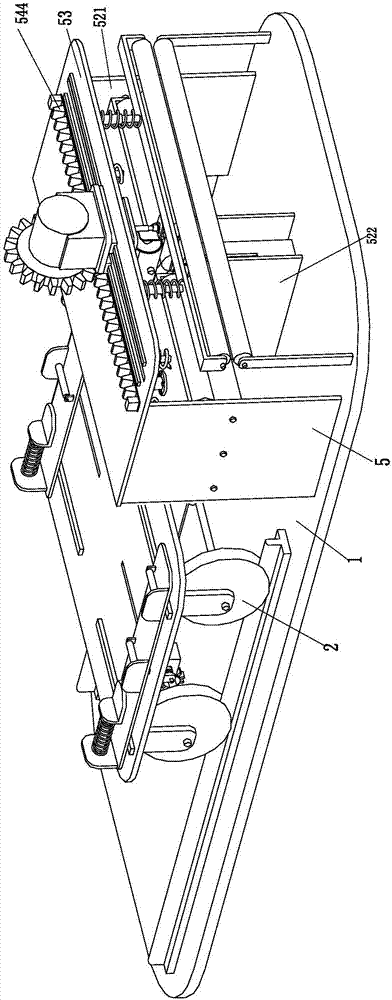

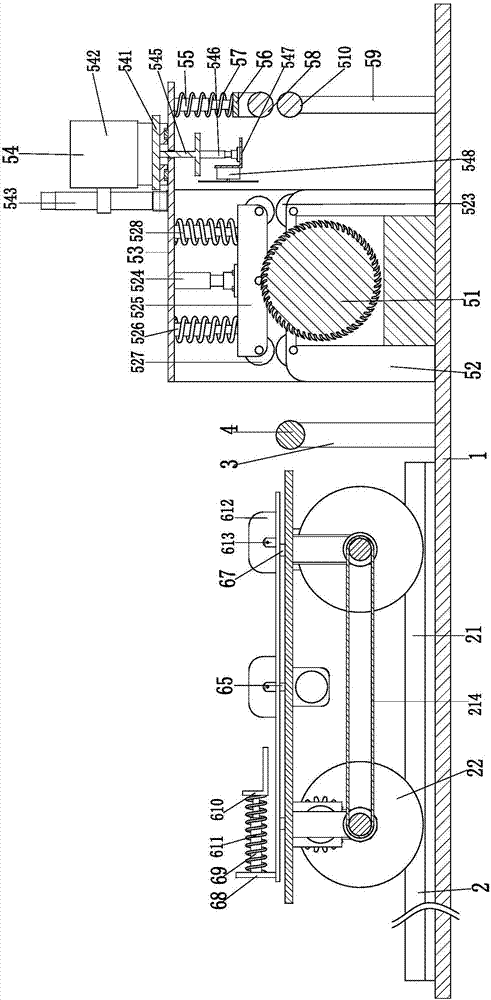

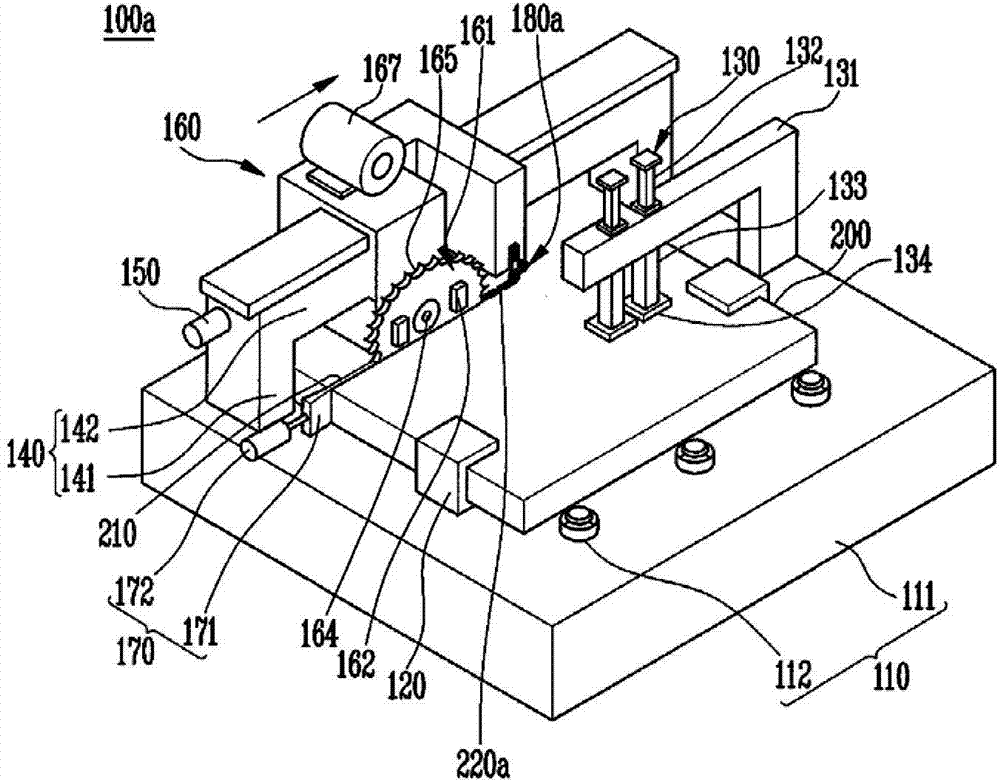

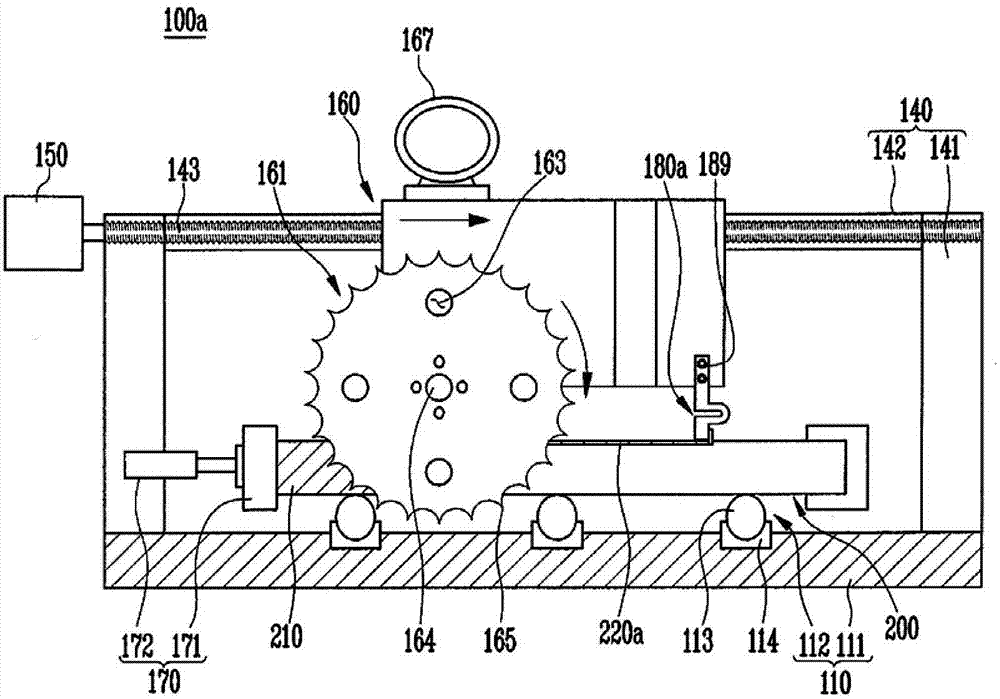

Automatic cutting machine for artificial wood fiber board

InactiveCN107127827ARealize the function of automatic cuttingReduce labor intensityGuide fencesGripping devicesFiberEngineering

The invention relates to an automatic cutting machine for an artificial wood fiber board. The automatic cutting machine for the artificial wood fiber board comprises a base board, a movable pushing device is mounted at the rear end of the base board, two supporting boards are symmetrically mounted in the middle of the base board, a first supporting roller is mounted between the inner walls of the upper ends of the two supporting boards through a bearing, a cutting device is mounted at the front end of the base board, and the movable pushing device and the cutting device cooperate with each other to complete the automatic processing technology of boards. The automatic cutting machine can solve the problems that workers need to use clamps to push the boards and use a disk saw to cut the boards when using a traditional cutting method to conduct cutting processing in small-sized board processing factories, the cutting precision is low, clamps need to be replaced manually according to needs of different board widths, the labor intensity is high, the traditional board cutting method can only conduct cutting in one direction, the boards need to be processed for a second time, and the working efficiency is low; and the automatic cutting machine can achieve the function that the boards are cut automatically.

Owner:广西鹿寨通用人造板有限公司

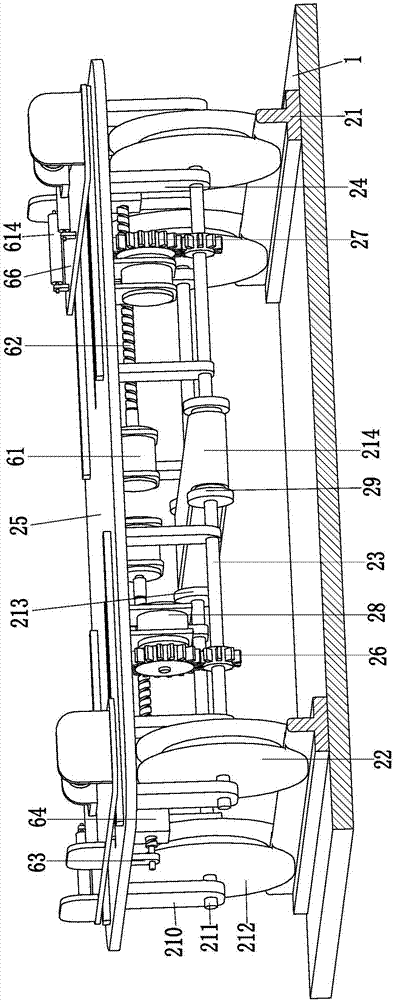

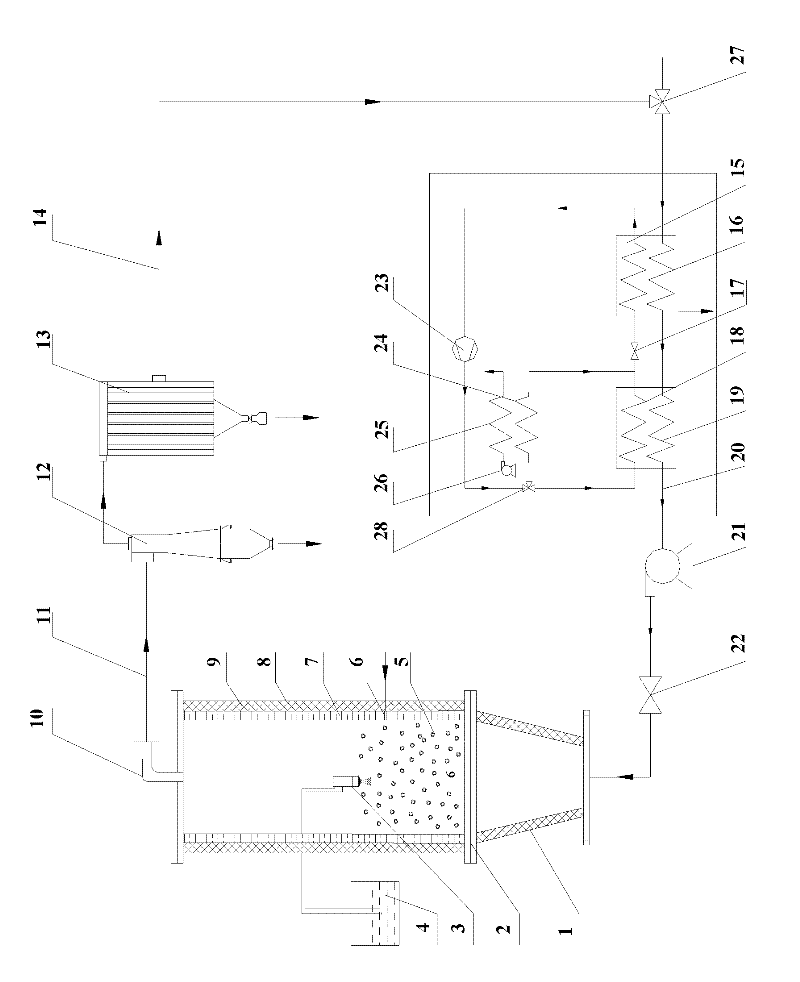

Equipment and method for carrying out spray freezing and drying on inert particles

ActiveCN102226629AFreezing helpsIncrease heat transfer rateDrying solid materials with heatHearth type furnacesFreeze-dryingSpray coating

The invention relates to equipment for carrying out spray freezing and drying on inert particles, comprising a fluidizing system, an atomizing system, a freezing system and a heat exchange system, wherein the heat exchange system is connected to the fluidizing system by virtue of a gas pipeline. The invention also relates to a method for carrying out spray freezing and drying on the inert particles, comprising the following steps of: (1) adding an inert particle group; (2) introducing a refrigerant; (3) introducing low-temperature low-humidity fluidizing gas; (4) freezing and spray coating; (5) freezing and drying; and (6) separating powder. The equipment and process for carrying out spray freezing and drying on inert particles in the invention couple processes such as fluidizing, cold spray coating, drying and separating, thus atomizing, freezing, drying and separating can be completed in one equipment, enclosed action and continuous operation are realized, no pollution is produced to the environment, dried feed liquid foods and medicines can be dried into powder finished products in one step, and no secondary processing is required; and besides, the structure is simple, the operation is convenient, and the manufacturing cost of equipment is reduced.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

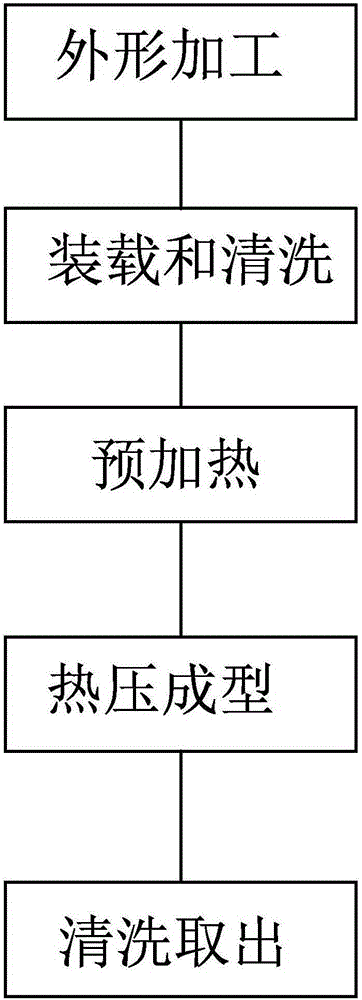

Processing method for three-dimensional glass panel for wearable intelligent devices

InactiveCN105174698AGood smoothnessImprove yield rateGlass reforming apparatusSurface plateHot pressing

The invention provides a processing method for a three-dimensional glass panel for wearable intelligent devices, and belongs to the technical field of glass panel processing techniques. The processing method solves the technical problem of conventional processing methods that surfaces are rough after processing. The processing method comprises the steps of shape machining, loading and cleaning, preheating, hot pressing and cleaning and removal. The processing method can process the high-quality three-dimensional glass panel for one time.

Owner:ZHEJIANG XINGXING TECH CO LTD

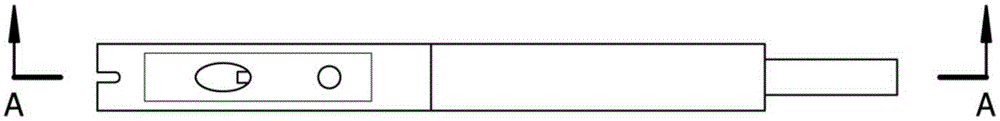

Punching and flanging machine

The invention provides a punching and flanging machine. The punching and flanging machine comprises a rack and a punching mechanism and a front feeding car which are arranged on the rack. The punching and flanging machine is characterized in that the working end of the punching mechanism is provided with a punching pin of which the cross section is in an elliptic shape, and the rack is further sequentially provided with outer mold clamping blocks, a mold core, a back feeding car, a hollow mold core connecting rod, a cone tongue rod connecting rod, a mold core connecting rod fixing seat and a flanging drive oil cylinder; the mold core comprises a hollow outer mold core body, a mold core insert inserted into the top of the outer mold core body, a flanging punch and a cone tongue rod, wherein the flanging punch and the cone tongue rod are arranged in an inner cavity of the outer mold core body, the flanging punch is arranged on the cone tongue rod in a sleeving mode, the cone tongue rod is connected to the flanging drive oil cylinder through the cone tongue rod connecting rod, and the cone tongue rod is moved to push the flanging punch to perform hole flanging machining. The punching and flanging machine is few in process, high in hole flanging efficiency, little in mold wear, durable, low in machining cost and capable of machining thin-wall and thick-wall pipes and machining a same pipe fitting in the different directions.

Owner:王向阳 +1

Recycling process of tin-removing waste liquid

InactiveCN104894599APrecipitation will notWill not cause secondary pollutionPhotography auxillary processesProcess efficiency improvementTin dioxideLiquid waste

The invention discloses a recycling process of tin-removing waste liquid. The method includes the steps of S1, feeding the tin-removing waste liquid into a distilling device, and performing pressure reduction distillation under the temperature of 65-80 DEG C and the pressure of (0.2-0.5)*1.03*10<5>Pa to recycle nitric acid; S2, feeding distillation residual liquid into an electrolytic tank with an ion exchange membrane for electrolysis, controlling current density and cathode potential to recycle copper in the residual liquid through electrolysis, acquiring tin dioxide at the anode of the electrolytic tank, and acquiring metal copper at the cathode of the electrolytic tank; S3, controlling current density to be unchanged after metal copper is recycled, and changing cathode potential to recycle tin through electrolysis, constantly adding sulfuric acid solution in a cathode chamber during the electrolysis process until the electrolysis is ended, acquiring the tin dioxide at the anode of the electrolytic tank, and acquiring metal tin at the cathode of the electrolytic tank, wherein the current density is 100-200A / m<2>. The recycling process has the advantages that no chemical reagent is added, and secondary pollution is avoided.

Owner:CHENGDU HONGHUA ENVIRONMENTAL SCI & TECH CO LTD

Method for preparing corn starch

The invention provides a method for preparing corn starch, which comprises the following steps of: a) soaking corn, coarsely crushing the corn, and separating germs to obtain coarse starch milk; b) finely crushing the coarse starch milk, and separating proteins and fibers to obtain starch milk; c) adding aqueous alkali into the starch milk to form starch solution with the temperature of between 40 and 60 DEG C; and d) filtering the starch solution to obtain amylose starch and amylopectin. In the method, after the corn starch milk is prepared by directly separating germs and proteins, the amylose starch and the amylopectin are filtered and separated by utilizing the different solution natures of the amylose starch and the amylopectin in hot water that the amylose starch is dissolved in the aqueous alkali and the amylopectin is insoluble. The amylose starch and the amylopectin are directly separated in the technological process of preparing the corn starch without secondary processing, so the method has the advantages of simple process and lower cost.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

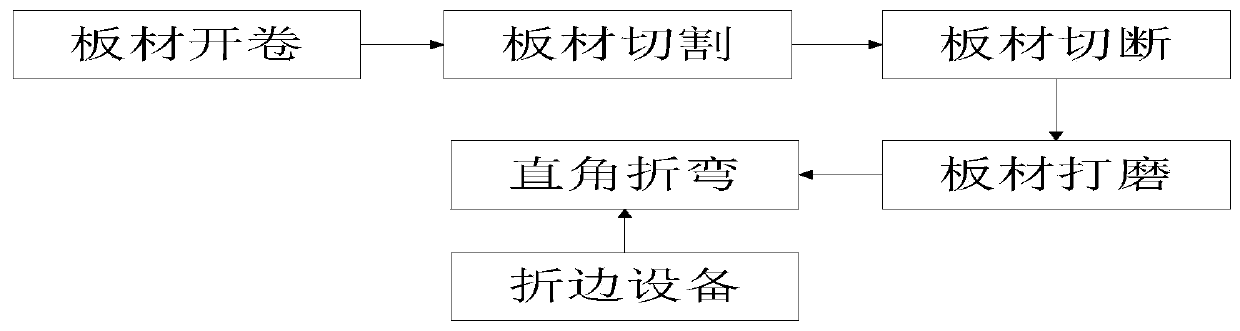

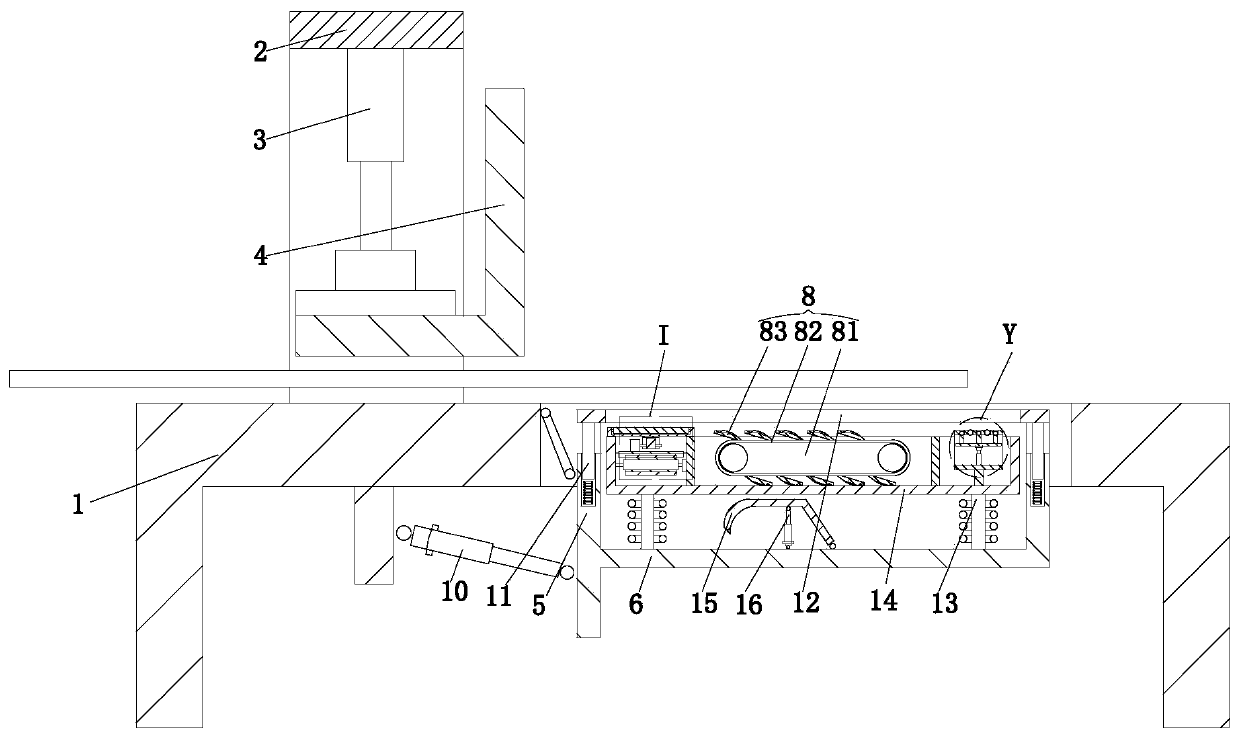

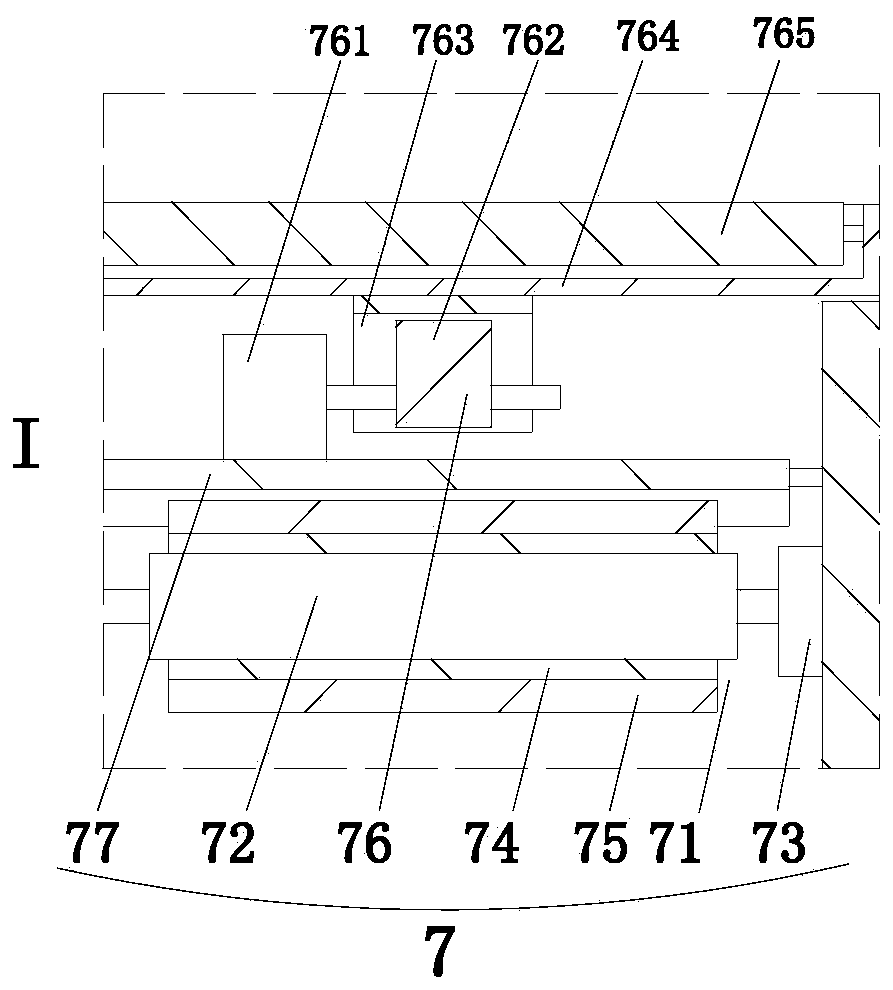

Sheet metal part cold stamping method

ActiveCN110252862AWill not deformGuaranteed accuracyEdge grinding machinesMetal-working feeding devicesPosition angleMetal sheet

The invention relates to a sheet metal part cold stamping method. The method comprises the following steps of 1, uncoiling a sheet; 2, cutting the sheet; 3, cutting off the sheet; 4, polishing the sheet; and 5, folding right angles, wherein an edge folding device used in the step 5 comprises an edge folding support; a fixing support is arranged at the left end of the edge folding support; a lifting air cylinder is arranged on the inner wall of the fixing support; and the lower end of the lifting air cylinder is arranged on a right-angled edge folding frame. According to the method, the following problems when an existing metal sheet is subjected to cold stamping bending operation can be solved: a, an error exists at a corner position angle of the bent sheet, the bending precision is poor, and the bent metal sheet needs secondary processing; and b, when the metal sheet is in angle bending, the metal sheet is prone to deformation under the action of external force, and the sheet needs to be repaired by stretching. By means of the method, the function of accurate and efficient operation of the cold stamping bending operation of the metal sheet can be achieved.

Owner:张亚勤

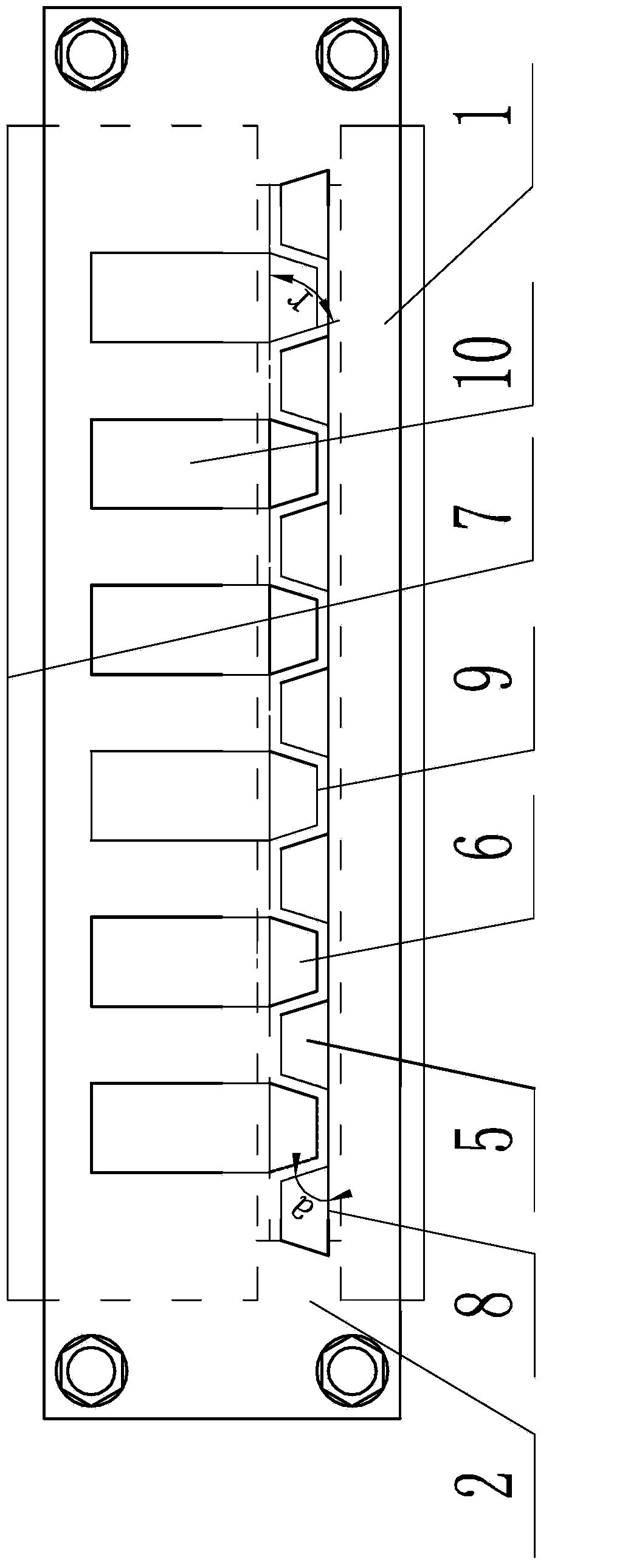

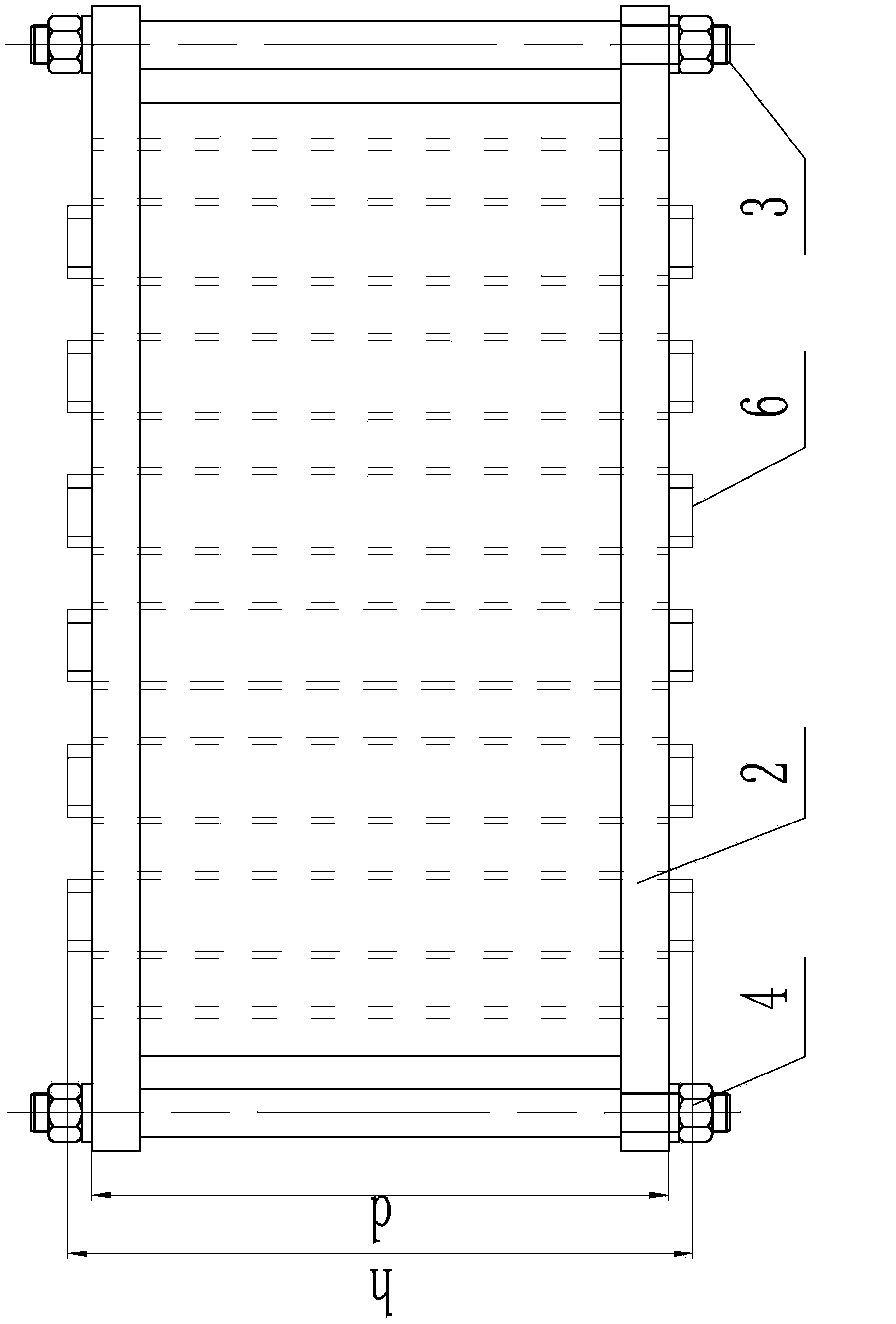

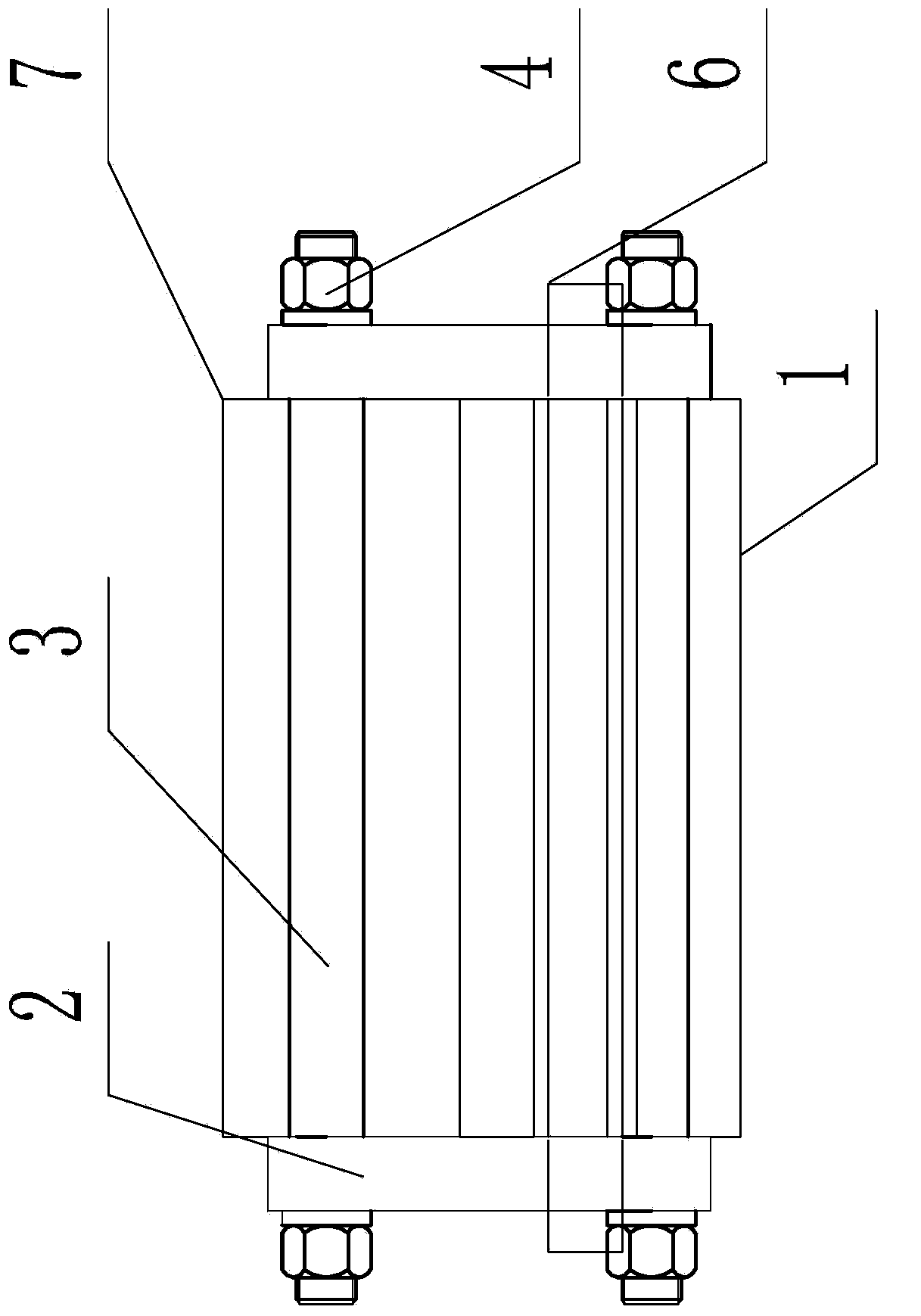

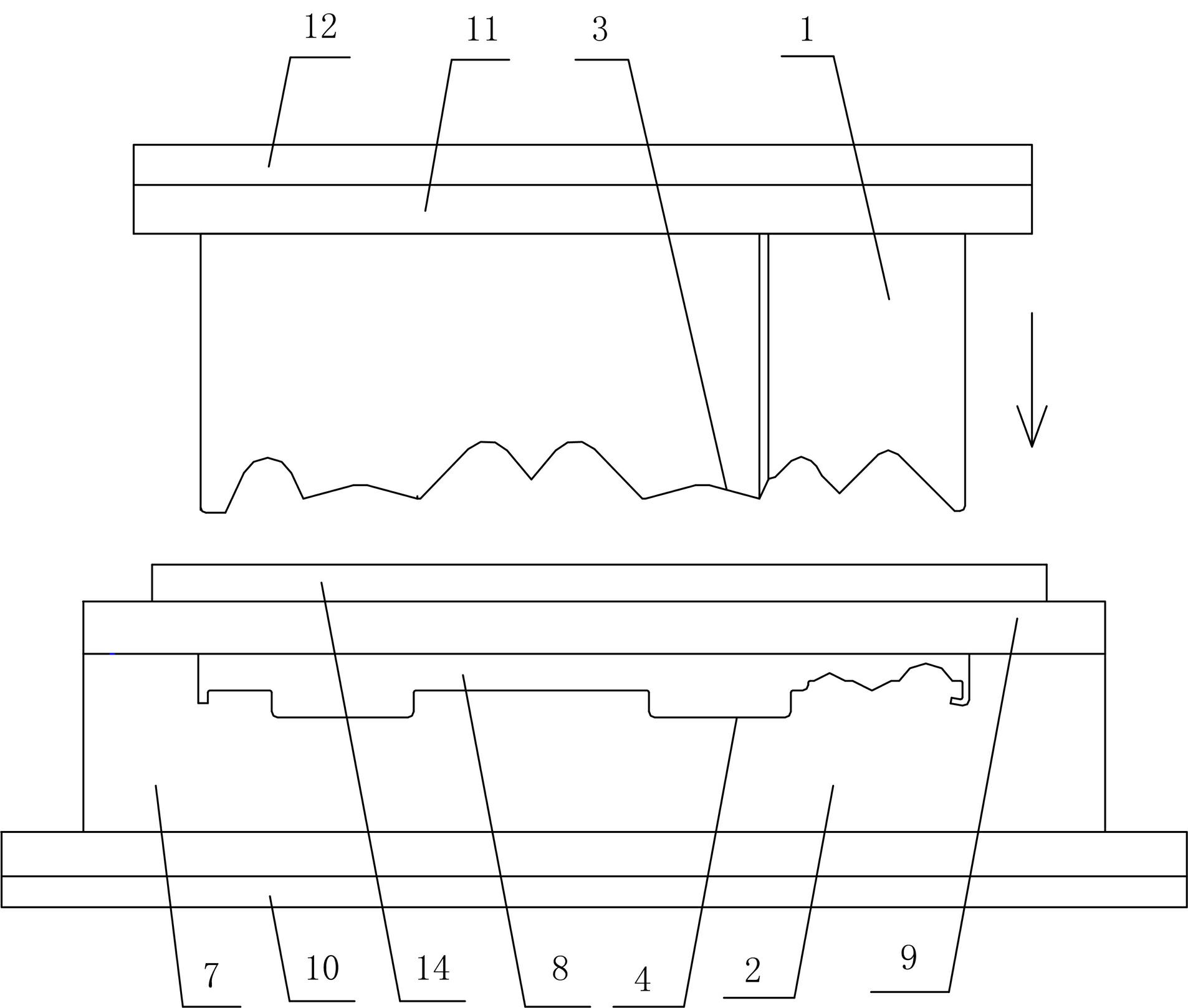

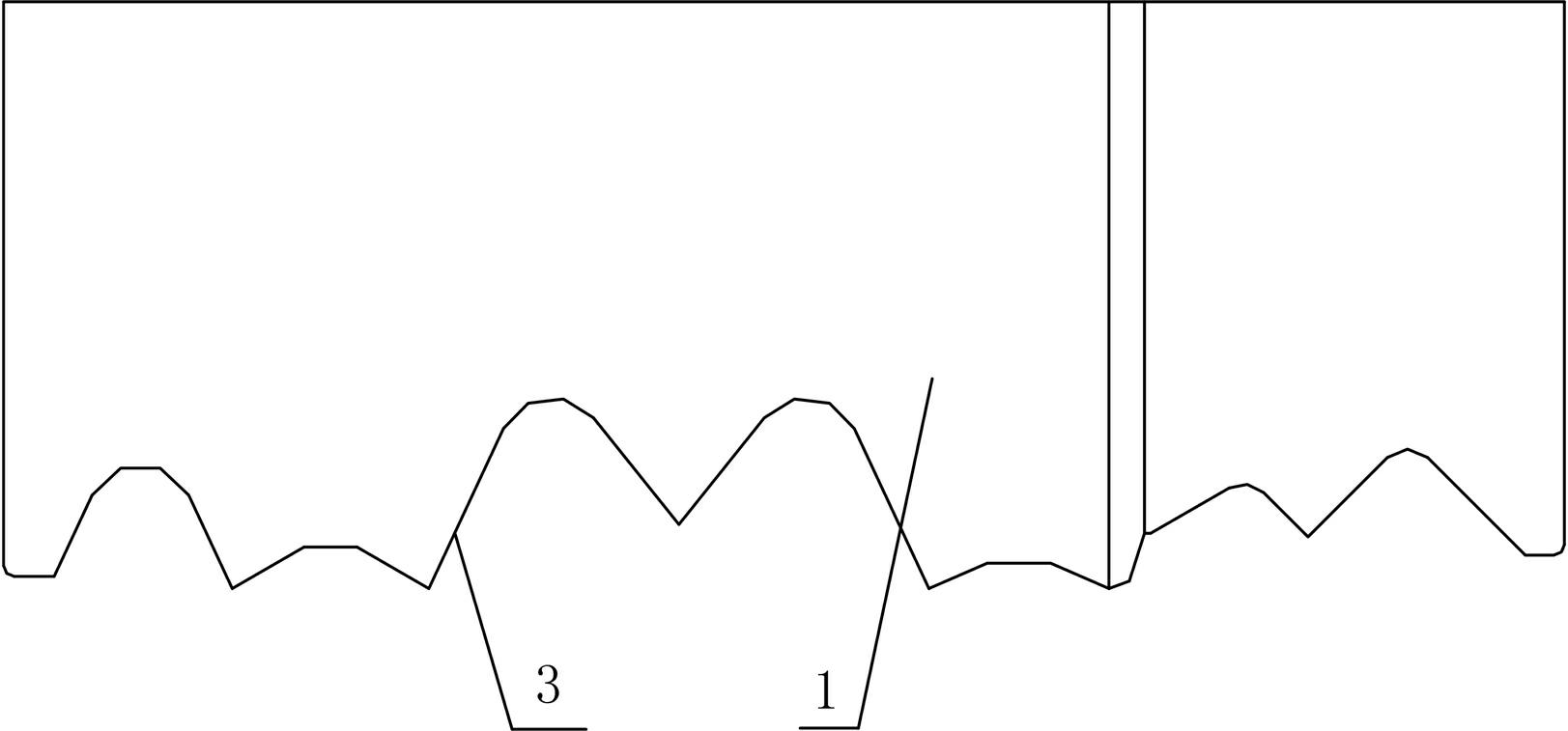

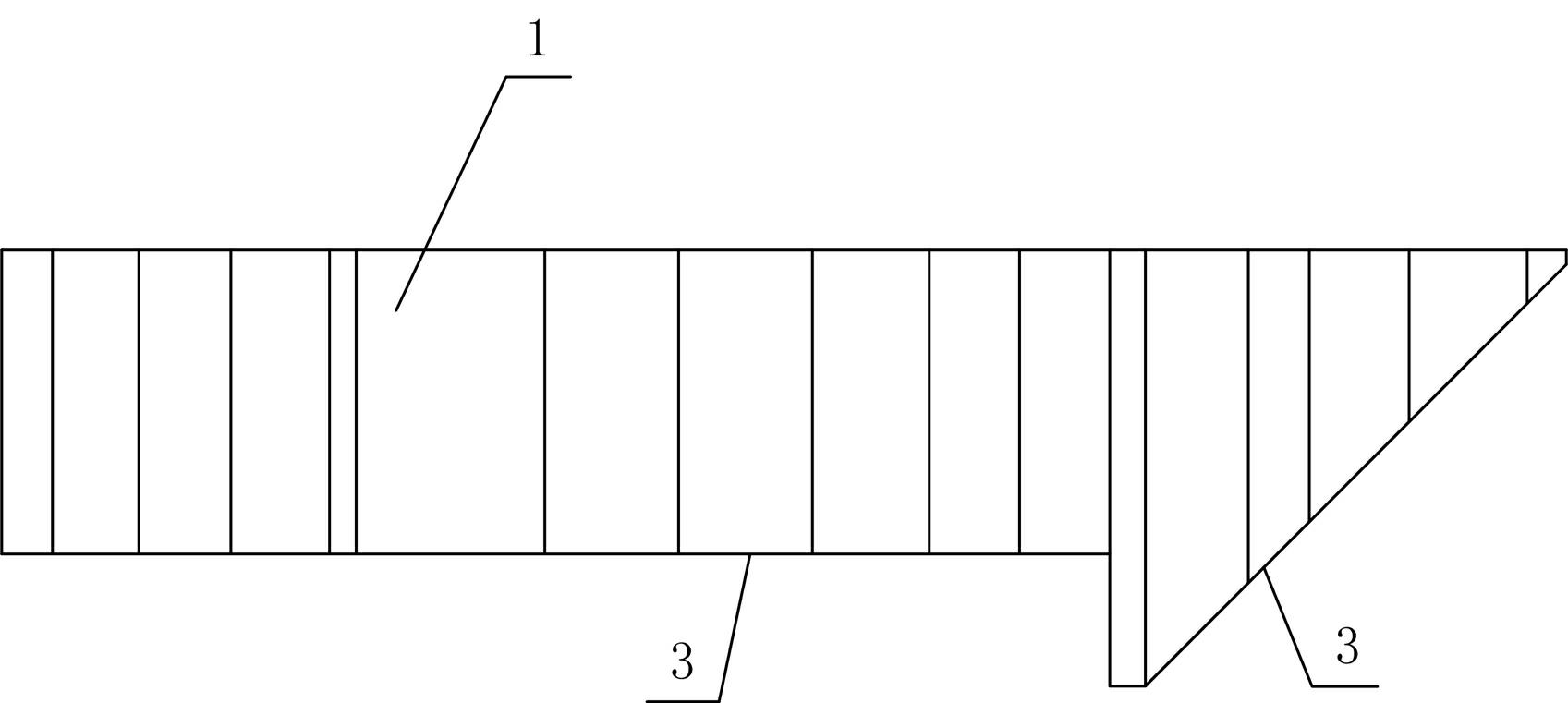

Preparation mold of composite material in ceramic-base corrugated sandwich structure

ActiveCN103831979AGuaranteed dimensional accuracyGuaranteed one-time moldingIsosceles trapezoidState of art

The invention relates to a preparation mold of a composite material in a ceramic-base corrugated sandwich structure and solves the problems that as the borne temperature of the preparation mold of the corrugated sandwich structure is low in a machining process of a component in the corrugated sandwich structure in the prior art, the preparation mold cannot bear sufficient stress, is easy to deform, cannot guarantee the dimensional precision of a test piece and needs to carry out secondary machining. The preparation mold comprises a base plate, a pressing plate, two slide rail plates, four cylindrical connecting pieces, N+1 trapezoidal fixed sliding blocks and N trapezoidal movable sliding blocks, wherein the slide rail plates are rectangular slide rail plates, N+1 erected isosceles-trapezoid-like through holes are uniformly formed in the bottom of each slide rail plate along the horizontal direction, and N inverted isosceles-trapezoid-like through holes are uniformly formed close to each erected isosceles-trapezoid-like through hole along the horizontal direction. The preparation mold is used for manufacturing the ceramic-base corrugated sandwich structure.

Owner:HARBIN UNIV OF SCI & TECH

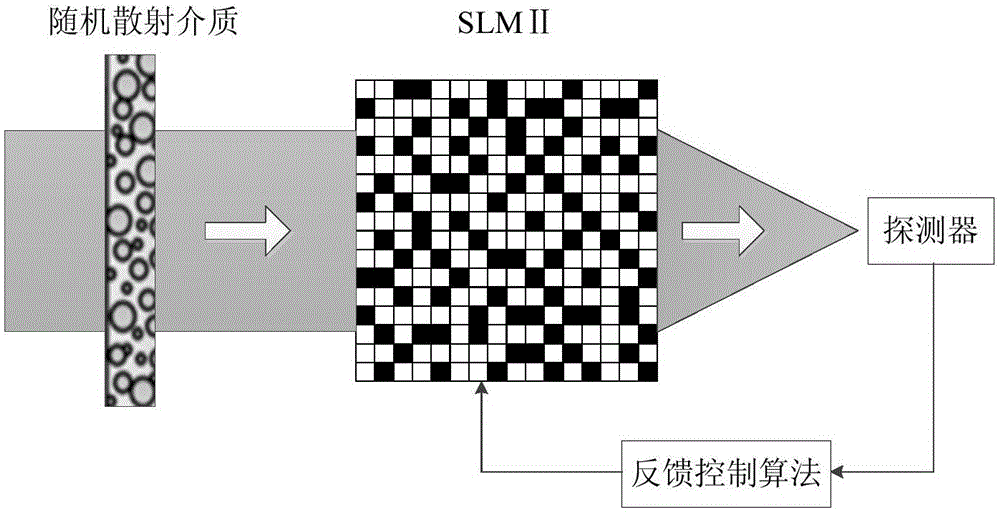

Random scattering medium based controllable sub-wavelength maskless photoetching system and method

ActiveCN106200276AEnabling subwavelength lithographyNo secondary processing requiredPhotomechanical exposure apparatusMicrolithography exposure apparatusWavelengthPhotolithography

The invention proposes a random scattering medium based controllable sub-wavelength maskless photoetching system and method, which is used for solving the technical problem of high cost, low time efficiency and low resolution of a photoetching technology. A spatial light modulator I is used for generating a target pattern, a light wave passes through the spatial light modulator I and then is incident to a surface of a random scattering medium, the random scattering medium is used for random coding of light, a spatial light modulator II is used for compensating phase distortion generated by the random scattering medium, and finally, sub-wavelength imaging through the scattering medium is achieved, an arbitrary controllable sub-wavelength digital mask is formed for projection exposure. By the system and the method, the fabrication of a mask is avoided, and the photoetching cost is greatly reduced; with the combination of random coding of the random scattering medium and phase compensation of the spatial light modulation, the photoetching resolution is improved; and only one time of phase calibration process is required, the photoetching time efficiency is improved, and thus, the maskless photoetching of a controllable sub-wavelength pattern is achieved.

Owner:XIDIAN UNIV

Female die for stamping of automobile parts and machining method thereof

InactiveCN103521621AAccurate dimensional accuracyReduce product scrap rateShaping toolsEngineeringDimensional precision

The invention discloses a female die for stamping of automobile parts. The female die comprises a female die body. The female die body comprises a female die first part, a female die second part and a female die third part, wherein the female die first part, the female die second part and the female die third part are coaxially arranged in sequence from left to right. The outer diameter of the female die first part is larger than that of the female die second part, and the outer diameter of the female die second part is larger than that of the female die third part. A first middle hole is formed in the center of the female die first part, and the depth of the first middle hole is larger than the axial thickness of the female die first part. A second middle hole which is coaxial with the first middle hole and communicated with the first middle hole is formed in the center of the female die third part, and the diameter of the first middle hole is larger that that of the second middle hole. The female die has high dimensional precision, and can be used repeatedly and guarantee manufacturing precision and assembly precision of the automobile parts which are manufactured through the female die. The invention further discloses a machining method of the female die. By means of the machining method, the dimensional precision of the female die in a stamping die is high, the female die can be qualified at a time through the production process, and the product rejection rate is low.

Owner:昆山精创模具有限公司

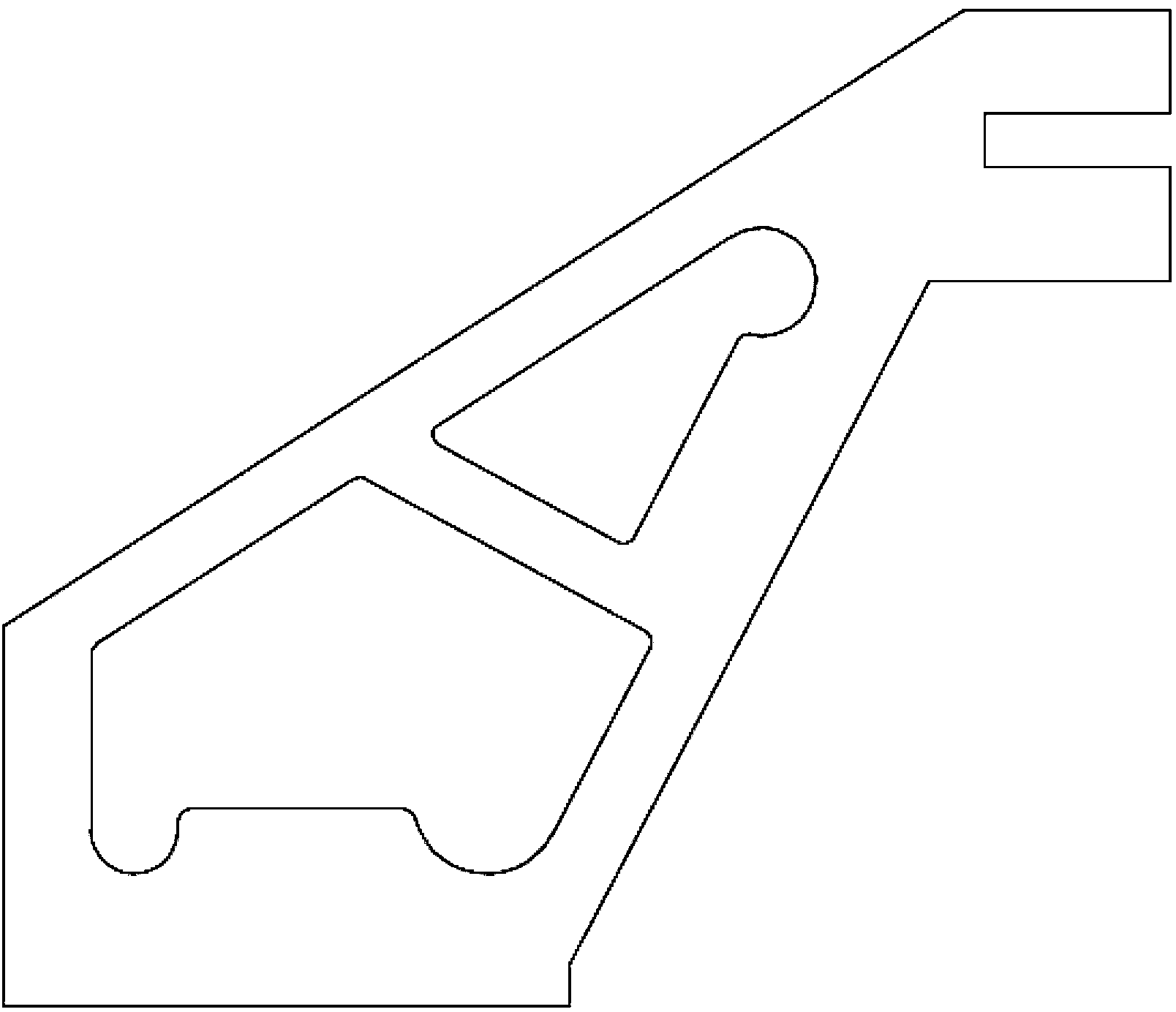

45-degree corner cutting and punching mould for doorframe semi-finished product

The invention provides a 45-degree corner cutting and punching mould for a doorframe semi-finished product, comprising a male mould and a female mould, wherein a 45-degree corner cutting upper cutting edge is arranged at the lower end of the male mould, a 45-degree corner cutting lower cutting edge is arranged on the upper end of the female mould, wherein the shape of the 45-degree corner cutting lower cutting edge is coincident with that of the 45-degree corner cutting upper cutting edge, the upper surface of the 45-degree corner cutting lower cutting edge is in a curve shape coincident with the cross-section shape of the doorframe semi-finished product, the lower surface of the 45-degree corner cutting upper cutting edge is in a sectional incremental shear curve shape, and the 45-degree corner cutting upper cutting edge is arranged corresponding to the 45-degree corner cutting lower cutting edge, and forms a sectional incremental shear structure for the doorframe semi-finished product with the 45-degree corner cutting lower cutting edge. The 45-degree corner cutting punching mould for the doorframe semi-finished product has the beneficial effects that: the lower surface of the 45-degree corner cutting upper cutting edge is in the sectional incremental shear curve shape, and forms the sectional incremental shear structure for the doorframe semi-finished product with the 45-degree corner cutting lower cutting edge, therefore, the punched doorframe cannot generate edge deformation, has little burrs, dispenses with secondary processing and is orderly and attractive.

Owner:ZHUMADIAN ZHAYASHAN DOOR IND

Cast welding device for lead-acid storage battery and cast welding method of cast welding device

The invention discloses a cast welding device for a lead-acid storage battery and a cast welding method of the cast welding device. The cast welding device of the lead-acid storage battery comprises a lifting track arranged at the upper part of a lead furnace, a workbench arranged at one side of the lead furnace, a fixed track arranged on the workbench and a water spraying mechanism, wherein the water spraying mechanism is arranged on the workbench and located outside the fixed track; a busbar die is arranged on the fixed track and the lifting track in a sliding manner and can move back and forth between the fixed track and the lifting track; a lifting support plate is arranged on the workbench and at the upper position of the fixed track; a battery bottom box with a plurality of plate groups is inversely fixed on the lifting support plate; and the busbar die is driven to be immersed into the lead furnace for lead immersion through the lifting track, the busbar die is moved to the fixed track, tabs of the plurality of plate groups are driven to be inserted into a lead liquid in a mold cavity of the busbar die for cast welding by using downward movement of the lifting support plate. According to the cast welding device, the service life of the busbar die can be prolonged and the production safety is ensured.

Owner:ZHUZHOU YINGDING AUTOMATION EQUIP TECH

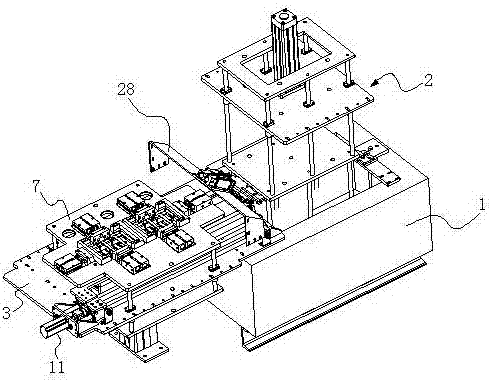

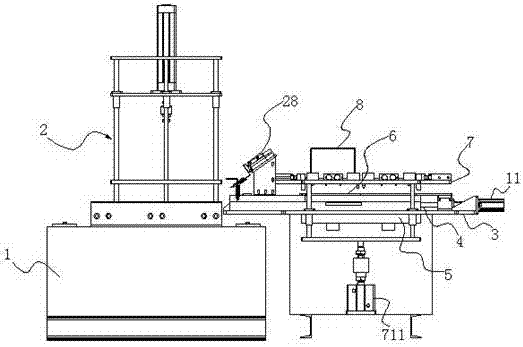

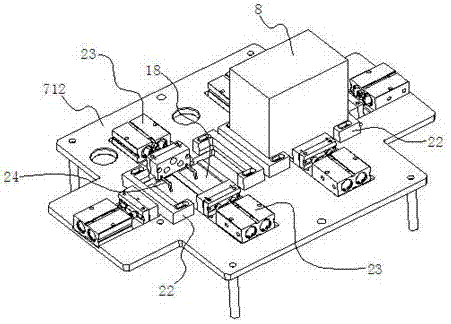

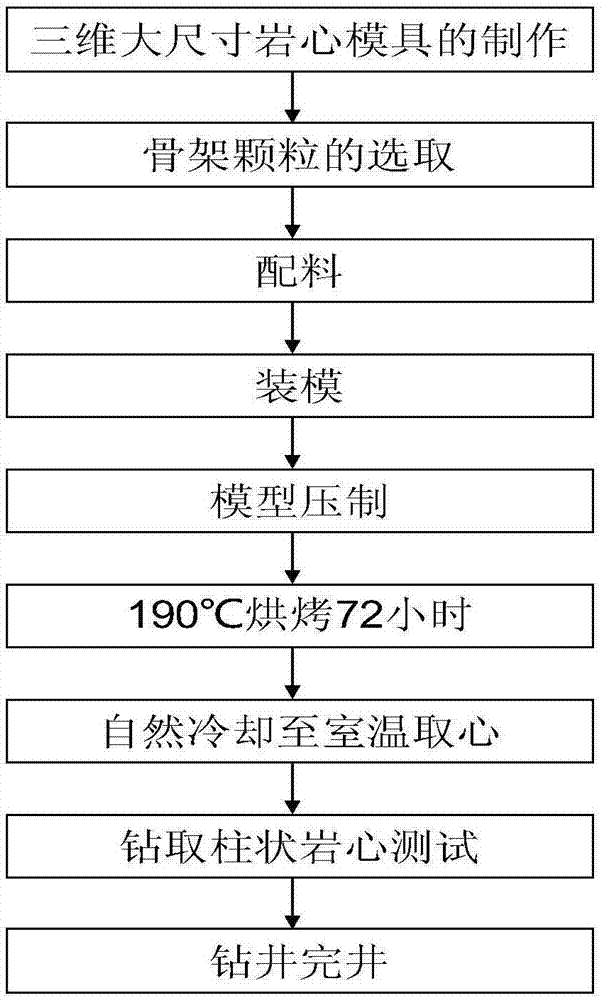

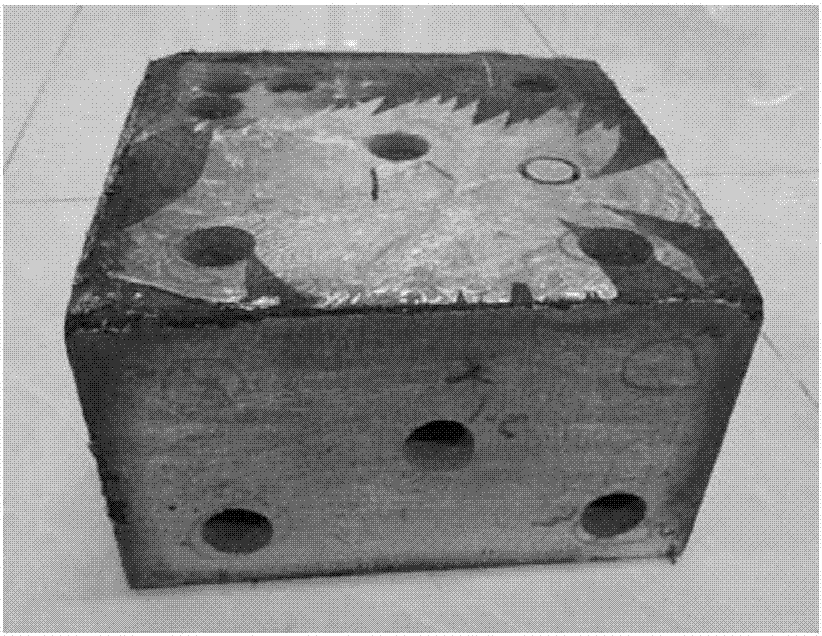

Manufacturing method of three-dimensional large-sized artificial rock core

ActiveCN107063826ARealize one-time moldingNo secondary processing requiredPreparing sample for investigationPorosityExperimental research

The invention discloses a manufacturing method of a three-dimensional large-sized artificial rock core. The manufacturing method comprises the following steps: (1) producing a mold according to a size of a prefabricated three-dimensional large-sized artificial rock core; (2) filling the mold with a mixture of skeleton particles, formation water and a cementing agent, wherein the granularity distribution of the skeleton particles is consistent with that of the natural rock core; (3) pressing the mixture in the mold; and (4) roasting the pressed mold, and shaping. The granularity distribution, porosity, permeability, cementing degree and pore throat characteristics, mechanical properties and the like of the rock core are approximate to the natural rock core; and the manufactured rock core can substitute a reservoir core to perform the macro experimental research. The rock core manufactured by the invention can simulate a sedimentary rhythm and structural configuration of a real reservoir. The rock core manufactured by the invention can simulate different completion conditions and well pattern modes and can realize the indoor experiment under the high pressure condition.

Owner:CHINA NAT OFFSHORE OIL CORP +1

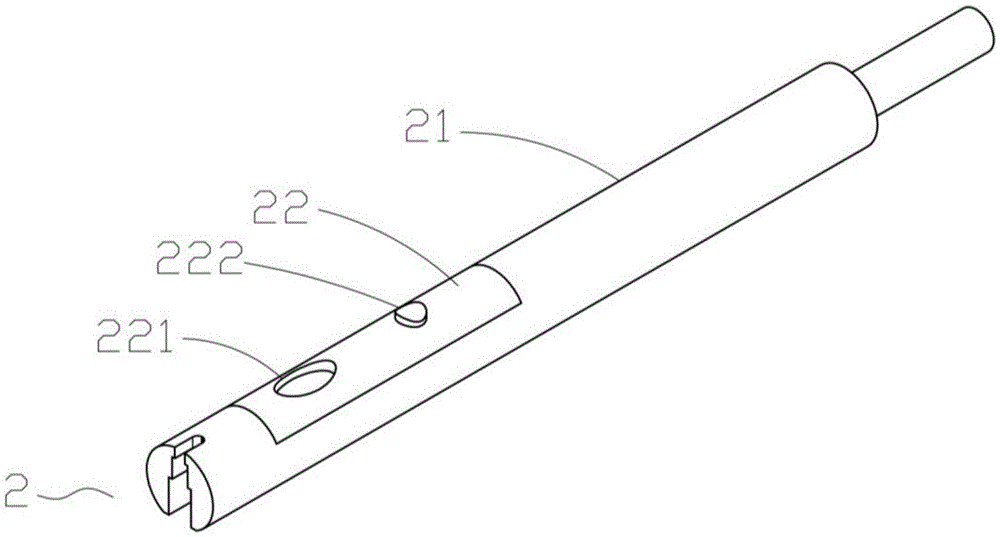

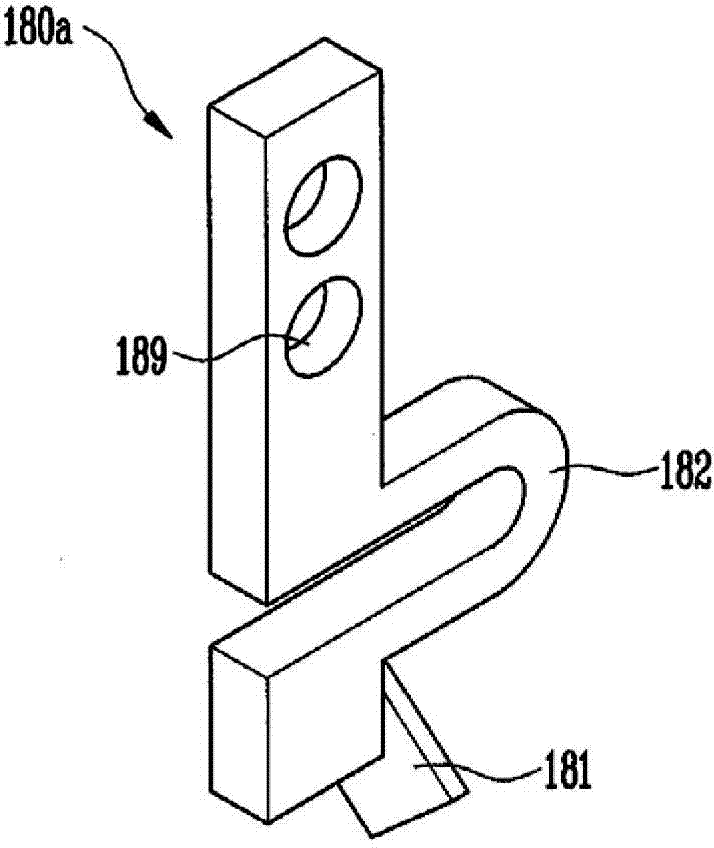

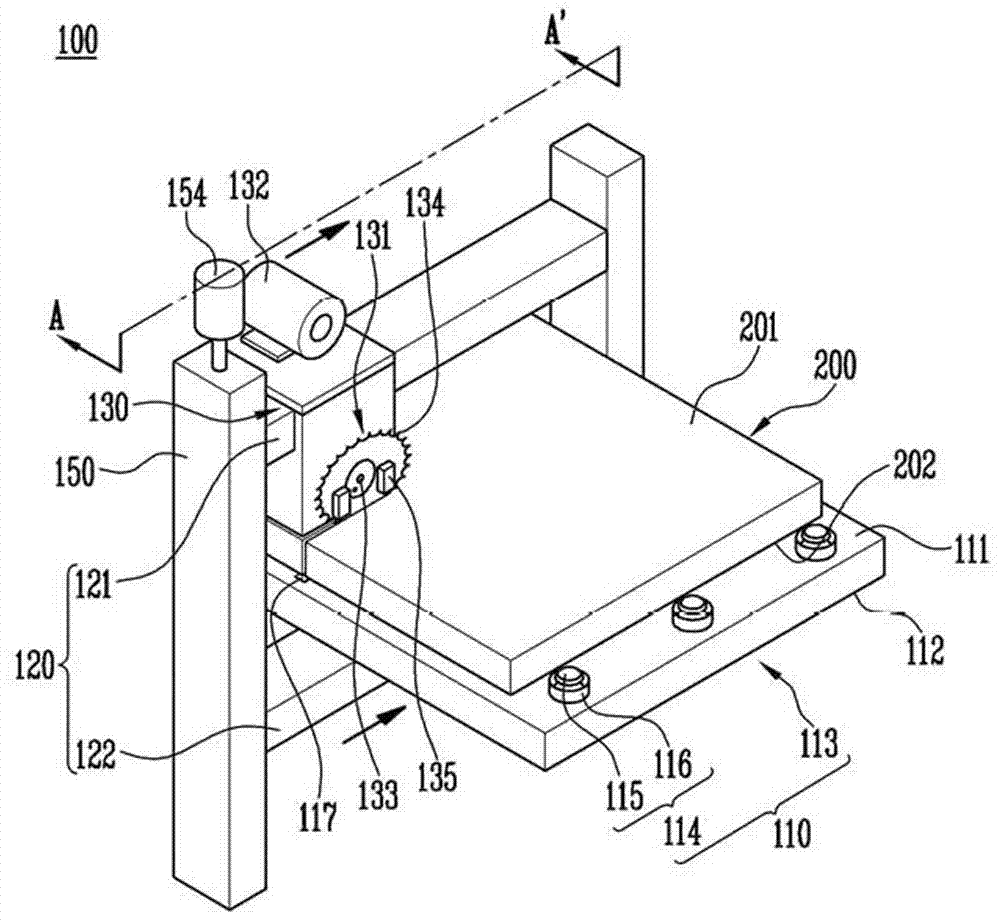

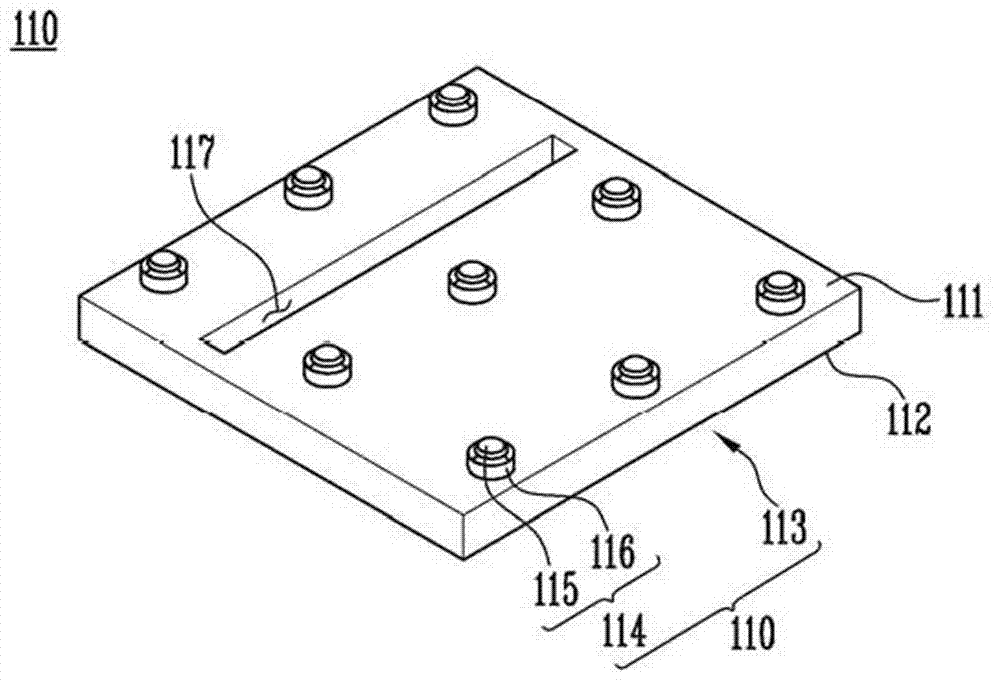

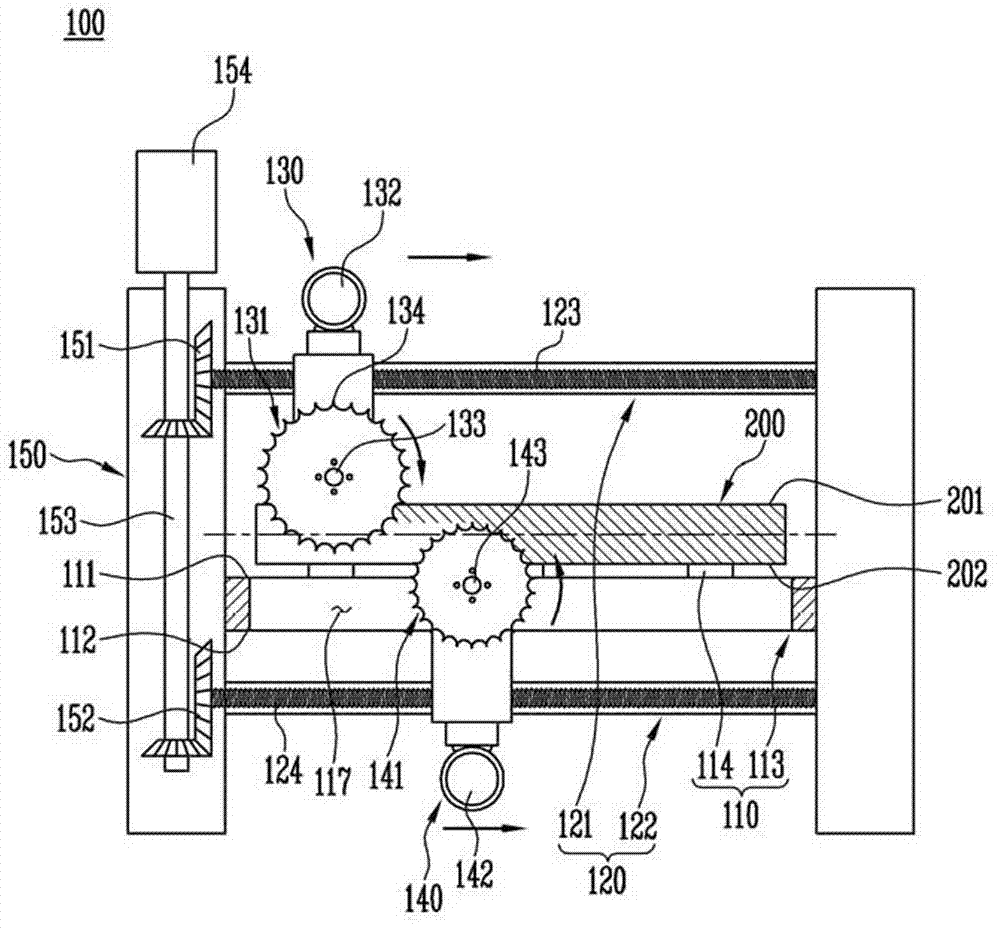

Online automatic pipe cutting device

InactiveCN105436598AHigh degree of automationGood precisionTube shearing machinesShearing machine accessoriesProduction linePinion

The invention provides an online automatic pipe cutting device. The online automatic pipe cutting device comprises a box; a guide disc is arranged in the box; a turntable is arranged on one side of the guide disc; a through hole penetrates through the box, the guide disc and the turntable in sequence, and the through hole is concentric with the turntable; multiple cutters are arranged on the outer side of the through hole, and are uniformly distributed about the axis of the through hole; the cutters include cutter bits and rotating shafts mutually connected; a Lelo polygonal slide way is formed in a guide piece; the rotating shafts are arranged in the slide way after penetrating through the box and the turntable; the cutter bits are positioned on the outer side of the box; deflection pinions are arranged on the rotating shafts; an inner gear ring is arranged on the box, and is concentrically arranged with the through hole; and the pinions and the inner gear ring are matched in an engaged manner. The online automatic pipe cutting device is simple in structure and strong in practicability, adopts an annular cutting method to cut steel pipes to obtain tidy incisions, can be applied to a steel pipe production line, is high in automation degree and excellent in precision, prevents the material waste, needs no secondary processing, reduces the cost, and is high in efficiency.

Owner:TIANJIN SHANGJI HYDRAULIC PRESSURE EQUIP

Device for cutting metal plate

InactiveCN104722832AImproved cutting surface qualityImprove qualityMetal sawing devicesEngineeringMechanical engineering

The present invention relates to a device for cutting a metal plate which comprises: a support part where a metal plate is located on an upper surface; a frame part supported by the support part; and a cutting part movable along the frame part. The cutting part includes a saw blade part rotated to cut the metal plate, and a guide part forming grooves on the metal plate and guiding the saw blade part to be moved along the grooves. The device for cutting a metal plate has no occurrence of burr on a cut surface of the metal plate, and does not require a secondary process.

Owner:POHANG IRON & STEEL CO LTD +1

Device for cutting metal plate

ActiveCN104722833AImproved cutting surface qualityImprove qualityMetal sawing devicesEngineeringMechanical engineering

The present invention relates to a device for cutting a metal plate, comprising: a support part on which a metal plate is placed; first and second transfer frame parts positioned above and under the support part, respectively; a first cutting part which moves along the first transfer frame part and which includes a first saw blade part for cutting at least a part of the metal plate including the top of the metal plate by rotating; and a second cutting part which moves along the second transfer frame part and which includes a second saw blade part for cutting at least a part of the metal plate including the bottom of the metal plate by rotating. The present invention provides a device for cutting a metal plate, capable of cutting a metal plate without generating burrs on the cutting plane and without requiring secondary processing.

Owner:浦项股份有限公司 +1

3D bent glass cover plate production technology

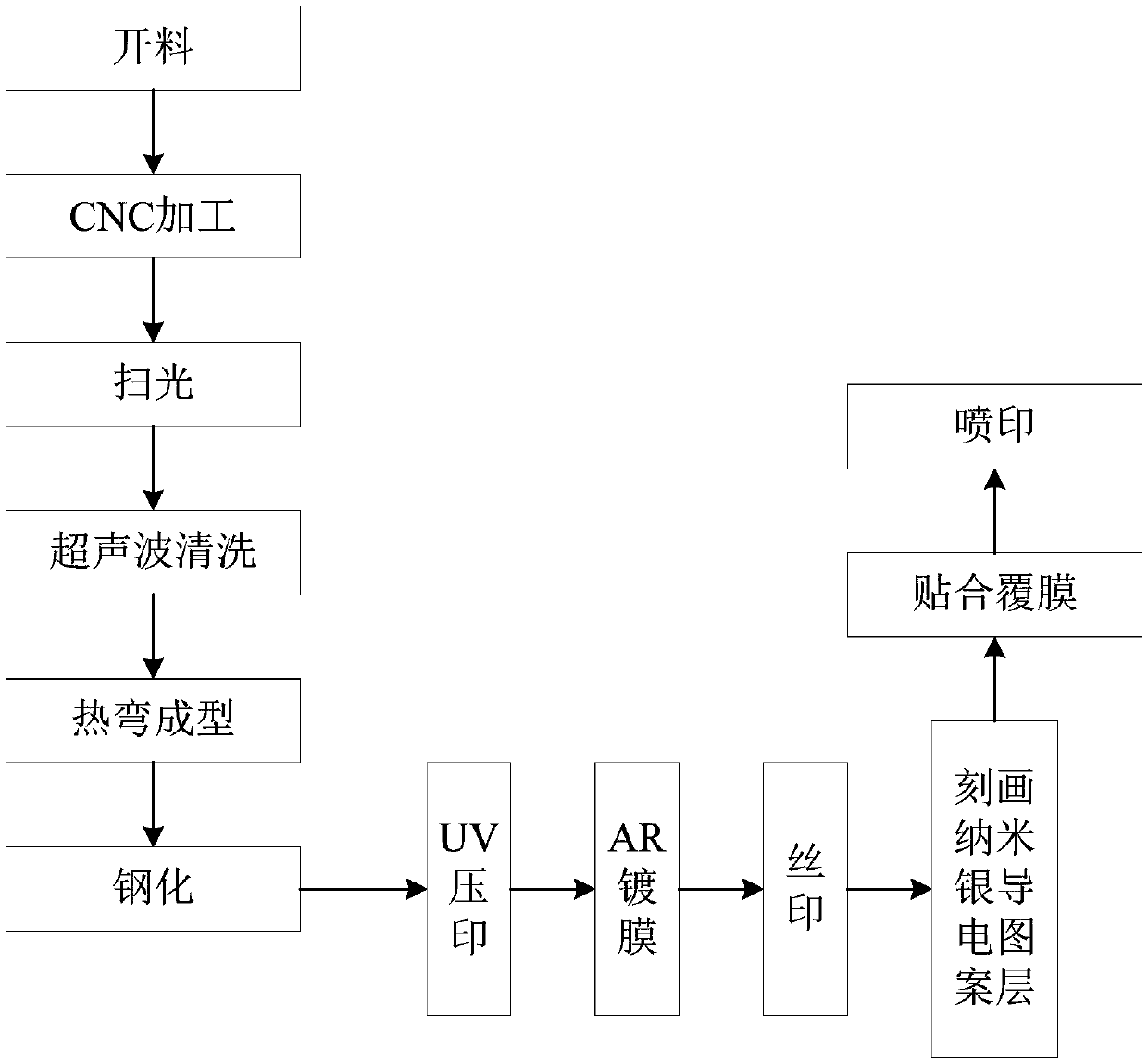

InactiveCN109590843AImprove plasticityImprove smoothnessOptical surface grinding machinesLayered productsElectricityGlass cover

The invention is applicable to a glass cover plate production technology and provides a 3D bent glass cover plate production technology. The production technology comprises the steps of rough shape cutting, CNC machining, thorough sweeping, ultrasonic wave washing, hot bending forming, tempering, UV coining, AR film plating, silk screening, engraving of a nanometer silver electricity conduction pattern layer, fitting laminating and jet printing. A 3D bent glass cover plate manufactured through the technology is novel in appearance and good in vision effect, meets the requirement of people forthe high-quality appearance of the glass cover plate, is low in manufacturing cost, can be produced in batch, and has a wide application prospect. The problems that a glass cover plate in the prior art is a planar or 2.5 D basically, homogenization is severe, novelty is lacked, and the requirement of people for the high-quality appearance of the product cannot be met easily are solved.

Owner:仙游县元生智汇科技有限公司

A ceramic aluminum-clad substrate and its preparation method

ActiveCN102756515BImprove bindingNo secondary processing requiredVacuum evaporation coatingSputtering coatingAluminum substrateAluminum foil

The invention provides a manufacturing method for a ceramic aluminum-coated base plate. The manufacturing method comprises the following steps: coating an aluminum membrane, namely, coating a layer of aluminum membrane on at least one surface of ceramic wafers by a physical vapor deposition method; and connecting aluminum foils in a compressing way, namely, stacking aluminum base brazing filler metal sheets and the aluminum foils on the aluminum membranes in sequence, and sintering to obtain the ceramic aluminum-coated base plate. The invention further provides the ceramic aluminum-coated base plate manufactured by the manufacturing method. The ceramic aluminum-coated base plate comprises the ceramic wafers and the aluminum foils arranged on the at least one surface of the ceramic wafers, and aluminum membrane layers and aluminum base brazing filler metal layers are formed between the ceramic wafers and the aluminum foils in sequence. The manufactured ceramic aluminum-coated base plate is good in bonding force, strong in cold and hot impact resistance, and simple in manufacturing process, does not need secondary processing and is low in cost.

Owner:BYD CO LTD

Magnesium alloy for textile machinery and preparation method of profile thereof

The invention belongs to the technical field of synthesis processing of light-weight metal materials, and particularly relates to a magnesium alloy for textile machinery and a preparation method of a profile thereof. On the basis of the commercial magnesium alloy, the contents of part of alloy elements are strictly controlled, and extrusion pretreatment and extrusion technique are used for regulation and cooperation to obtain the novel magnesium alloy profile for textile machinery; and the magnesium alloy profile for textile machinery has the advantages of stable dimension, high precision and reliable properties, does not need secondary processing for appearance dimensions, and can completely eliminate residual stress. When being used in textile machinery, the magnesium alloy profile extruded by the preparation method has active effects on reducing the energy consumption and lowering the cost.

Owner:WUXI FUMEI LIGHT ALLOY TECH

Method of preparing bacterial cellulose/glass fiber composite material and prepared material

InactiveCN103613776AImprove mechanical propertiesNo secondary processing requiredMicroorganism based processesFermentationFiber bundleBacterial strain

The invention relates to a method of preparing a bacterial cellulose / glass fiber composite material and a prepared material. The method comprises the following steps: (1), flatly spreading glass fiber filaments in an electric filed generating device; (2), pouring a fermentation culture medium containing a bacterial cellulose production bacterial strain into the electric field generating device; (3), culturing and fermenting; and (4), obtaining the composite material after culturing is ended, and dehydrating and drying the composite material after post-treatment. The method disclosed by the invention is simple in process, and greatly improves mechanical performances of the material by compounding glass fibers; moreover, bacterial fiber bundles can be arranged in a directed manner by weak direct-current electric fields, so that the material can generate directional difference; and besides, application field of the bacterial cellulose is expanded, and application prospect is good.

Owner:TIANJIN UNIV OF SCI & TECH

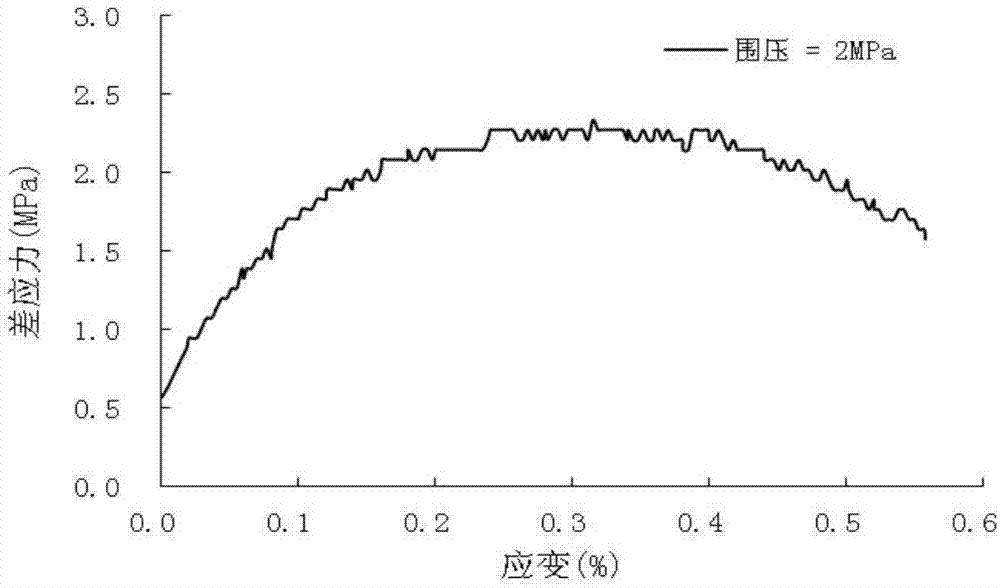

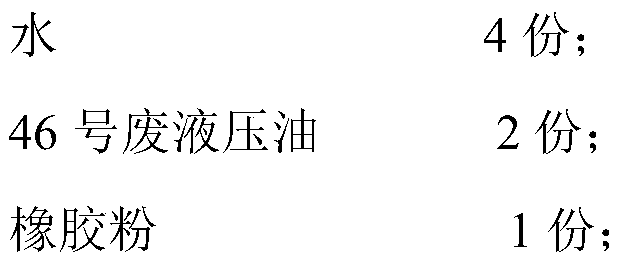

Rock similar material for geomechanics physical model test and preparation method thereof

The invention relates to the field of geological research, in particular to a rock similar material for a geomechanics physical model test and a preparation method thereof. The material is prepared from, by weight, 45-50 parts of barite, 1.5-3.9 parts of cement, 2.4-4.5 parts of water, 1-5 parts of 46# waste hydraulic oil and 0.5-1.5 parts of rubber powder. The barite and the rubber powder are evenly mixed, and then dried and dewatered, the mixture is taken out and cooled to room temperature, the cement is added to continue to be stirred to be uniform, the 46# waste hydraulic oil is added to the mixture to be stirred to be uniform, then the water is added to be stirred to be uniform, and the material is obtained. The preparation process of the method is simple, mixing is carried out at normal temperature in the preparation process, and therefore energy consumption is low, preparation efficiency is high, and cost is low.

Owner:CHINA THREE GORGES UNIV

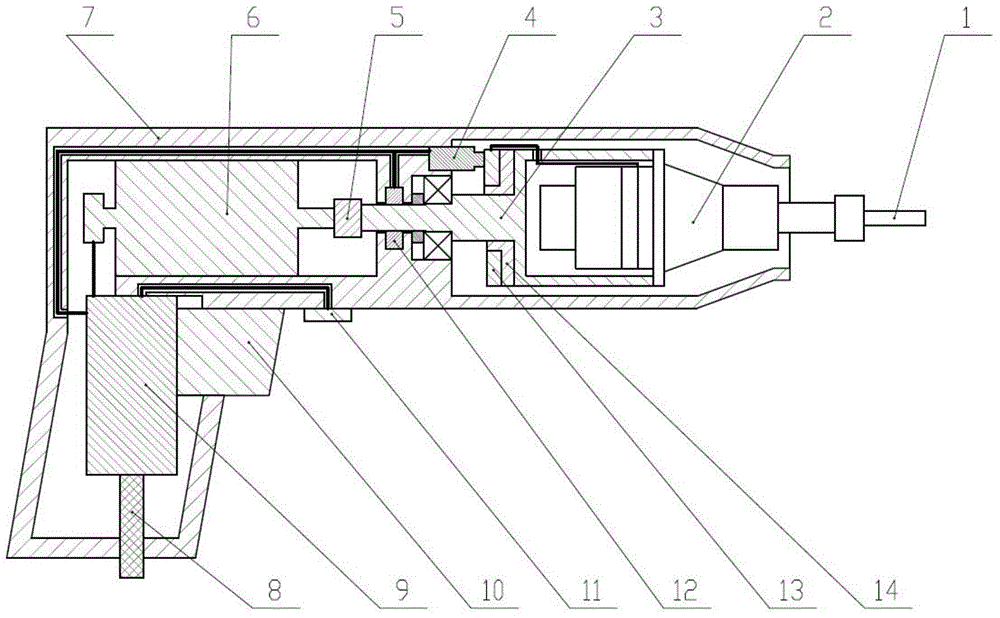

Handheld type ultrasonic electric drill

ActiveCN104400063AReduce labor intensityReduce wearMechanical vibrations separationPortable drilling machinesElectricityCoupling

The invention discloses a handheld type ultrasonic electric drill, which comprises a drill bit, an ultrasonic vibrator, an output shaft, a carbon brush, an insulated coupling, a motor, an outer casing, a power transmission cable, an electric drill controller, a motor rotation speed control trigger, an ultrasonic switch pushbutton, a fixing ring, an electric collector ring, an insulation ring and an ultrasonic power source, wherein the output end of the output shaft is connected with a flange disc of the ultrasonic vibrator, the drill bit is arranged at the output end of the ultrasonic vibrator, and the electric energy input end of the ultrasonic electric drill controller is electrically connected with the ultrasonic power source by the power transmission cable. The handheld type ultrasonic electric drill has the advantages that the ultrasonic vibration is realized, the ultrasonic vibration frequency reaches 20kHz, the drilling force in the drilling process is obviously reduced, an operator can use smaller force to drill material, the labor intensity of the operator is decreased, the drilling efficiency is improved, the abrasion of the drill bit is reduced, the drilling quality is high, the flashes and burrs are fewer, the damage to surrounding material is avoided, and the secondary processing on the surfaces with higher quality requirement is not needed.

Owner:DALIAN UNIV OF TECH

Water purifier purifying system with water way integrated board

InactiveCN106115969ANo secondary processing requiredImprove integrityTreatment involving filtrationMultistage water/sewage treatmentActivated carbonEngineering

The invention relates to a water purifier purifying system with a water way integrated board. The purifying system is characterized by comprising a water way board body, wherein a first water inlet, a first water outlet, a second water inlet, a second water outlet, a third water inlet, a third water outlet, a waste water outlet, a fourth water inlet and a fourth water outlet are sequentially formed below the body, a fixed hole, a first water inlet insertion hole, a first water outlet insertion hole, a second water inlet insertion hole, a second water outlet insertion hole, a third water inlet insertion hole, a third water outlet insertion hole, a waste water insertion hole, a fourth water inlet insertion hole and a fourth water outlet insertion hole are formed in one side of the body, a one-way valve water inlet insertion hole, a one-way valve water outlet insertion hole, an electromagnetic valve water inlet insertion hole and an electromagnetic valve water outlet insertion hole are formed in the other side of the body, and a PP cotton filter core, a water inlet electromagnetic valve, a front activated carbon filter core, a water pump, an RO membrane filter core, a high-voltage switch one-way valve, a pressure barrel, a waste water electromagnetic valve and a rear activated carbon filter core are arranged on the body.

Owner:ZHEJIANG GUANGYUE ENVIRONMENTAL POLYTRON TECH INC

Manufacturing method of sour-sweet lotus rhizome-strip can

InactiveCN102640791AWide range of consumersStay crispFruit and vegetables preservationSodium hypochlorite solutionRhizome

The invention relates to a manufacturing method of a sour-sweet lotus rhizome-strip can. The method comprises the following steps: cleaning lotus rhizome strips, removing head parts and tail parts of the lotus rhizome strips, cutting into lotus rhizome strip sections, soaking in a sodium hypochlorite solution, performing sterilization processing, soaking in a mixed solution of citric acid and ascorbic acid, performing color protection processing, draining the color protection solution, adding the drained lotus rhizome strip sections in a packaging container, soaking in edible white vinegar and sucralose soup with the soup level higher than the lotus rhizome strip sections, sealing under a vacuum condition, and packaging to obtain the product. The product manufactured by the invention is sour-sweet and tasty, and is suitable for extensive consumer population; the original brittleness, shape and color of the lotus rhizome strips are basically maintained; the shelf-life is up to 12 months, and the product can be supplied to the market all the year round; the product can be eaten immediately after opening the can, and no secondary processing is needed.

Owner:洪湖市五湖水产品有限公司

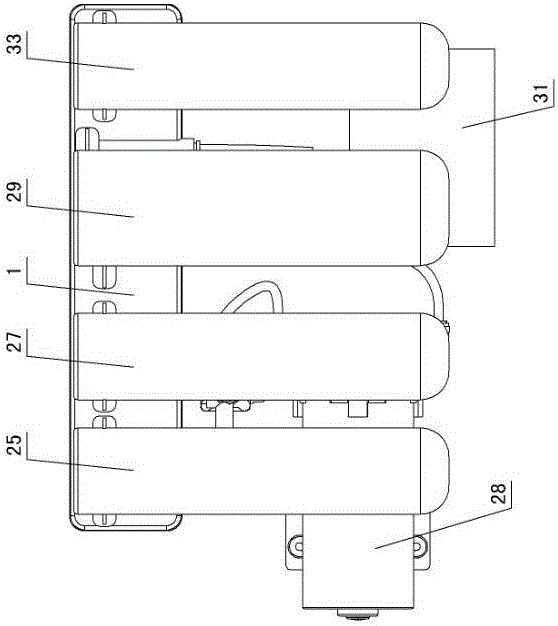

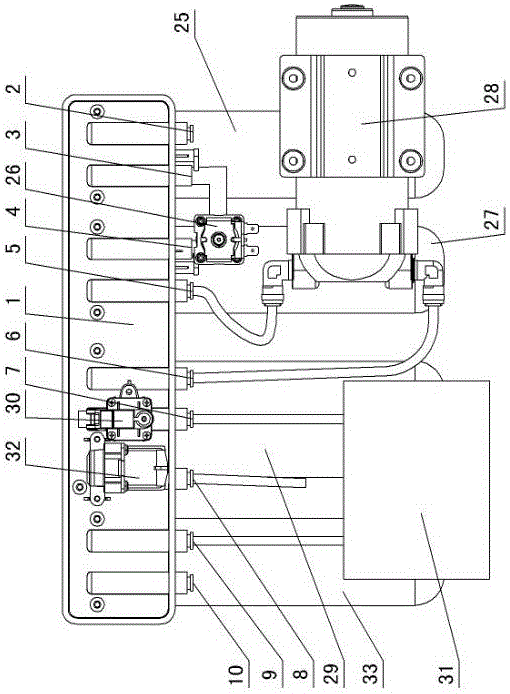

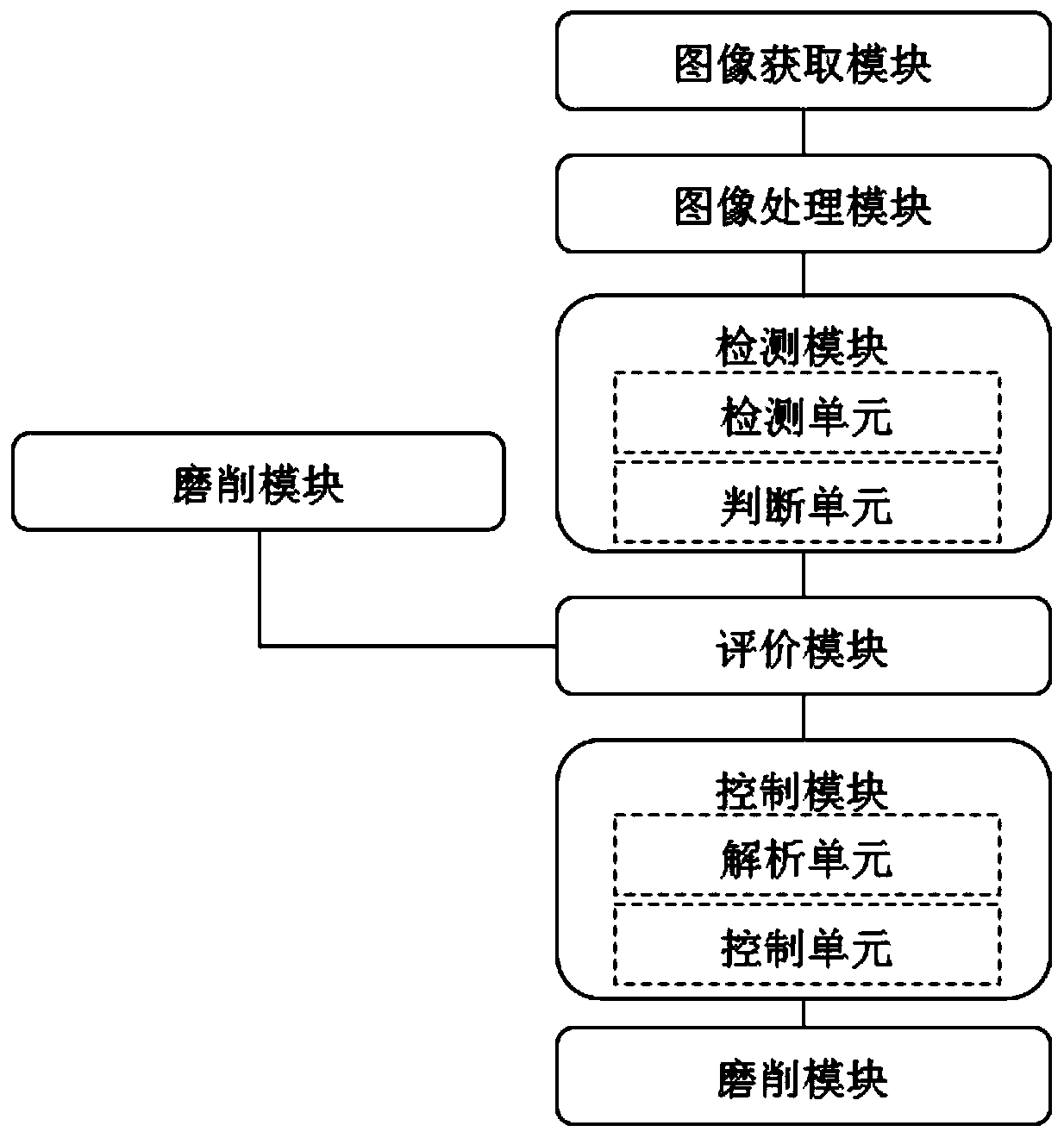

Board grinding device and grinding method

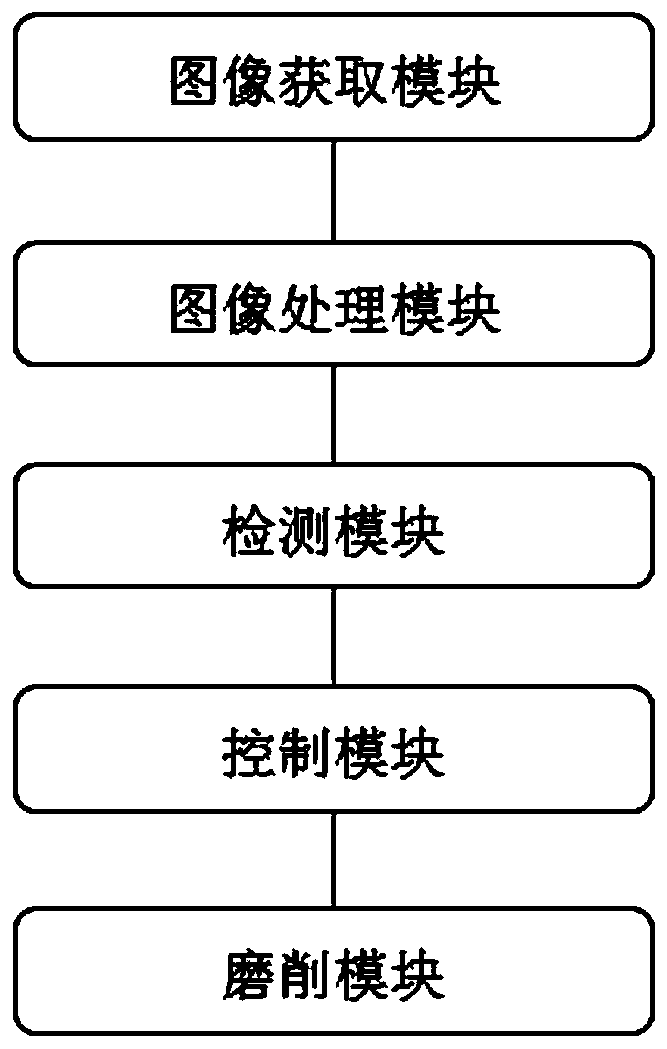

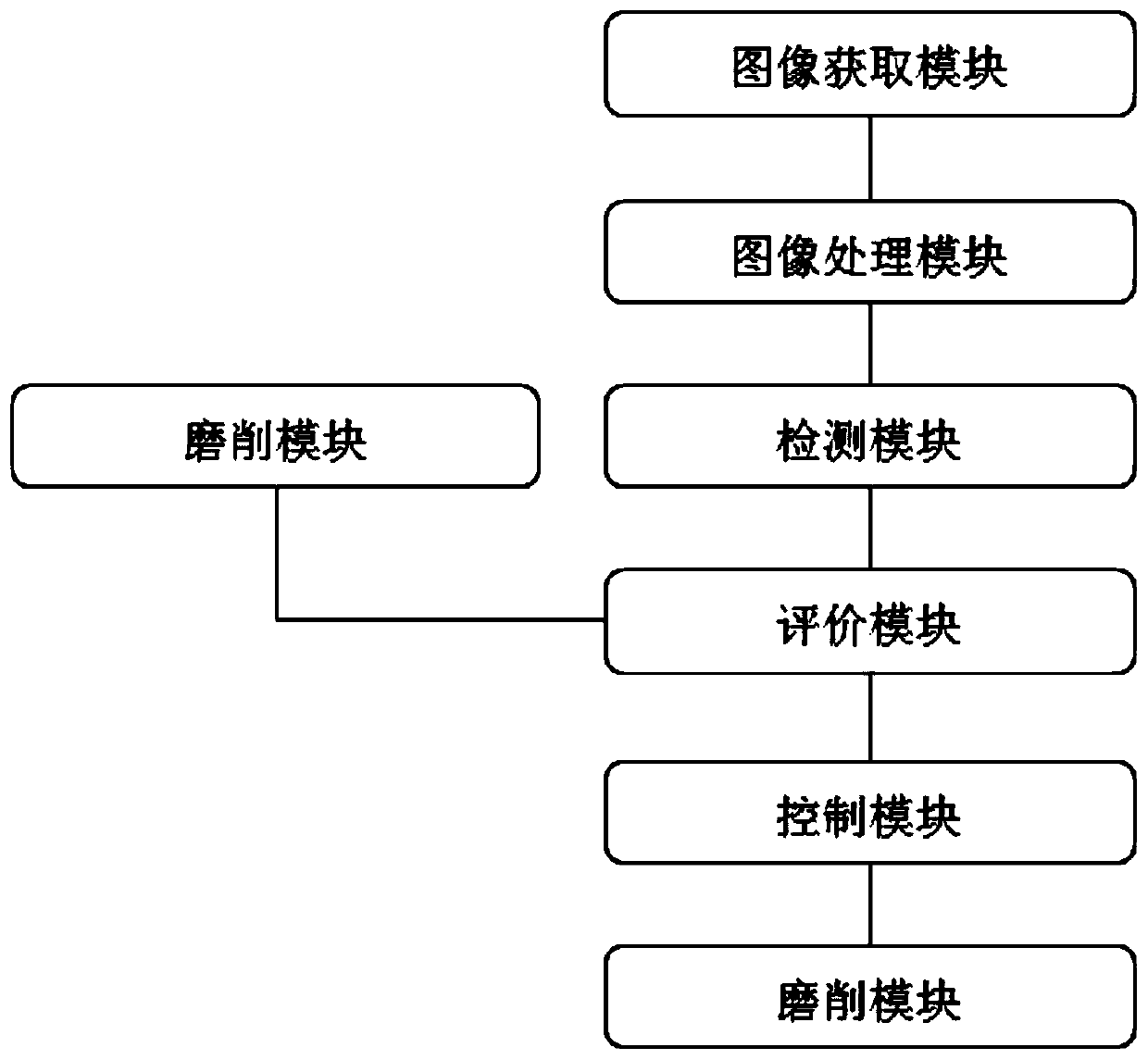

ActiveCN110216530AImprove grinding efficiencyPrecision grindingAutomatic grinding controlImaging processingComputer module

The invention provides a board grinding device. The device comprises an image obtaining module, an image processing module, a detection module, an a control module; the image obtaining module is usedfor obtaining a board surface image; the image processing module is used for carrying out gray-scale processing on the board surface image, and obtaining an image template matched with the image, according to the matched image template, the received image is divided into multiple areas to be ground, attribute detection information and corresponding characteristic information are obtained, and thecharacteristic information and pre-stored characteristic information are subjected to matching operation; the detection module is used for detecting roughness of the areas to be ground in the face tobe ground of a board according to the attribute detection information, judging whether the roughness is within the preset roughness range or not and sending information including the judging result, and the attribute detection information to the control module; and the control module is used for controlling the grinding module to grind the board surface. The device can greatly improve the board grinding efficiency and enables grinding to be more accurate and stable.

Owner:广东金石建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com