Preparation mold of composite material in ceramic-base corrugated sandwich structure

A sandwich structure and composite material technology, which is applied in the field of manufacturing molds with corrugated core structures, can solve the problems of low temperature, inability to ensure the accuracy of the size of the test piece, and easy deformation, etc., to achieve convenient and quick use, simple structure, and guaranteed Effect of Dimensional Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

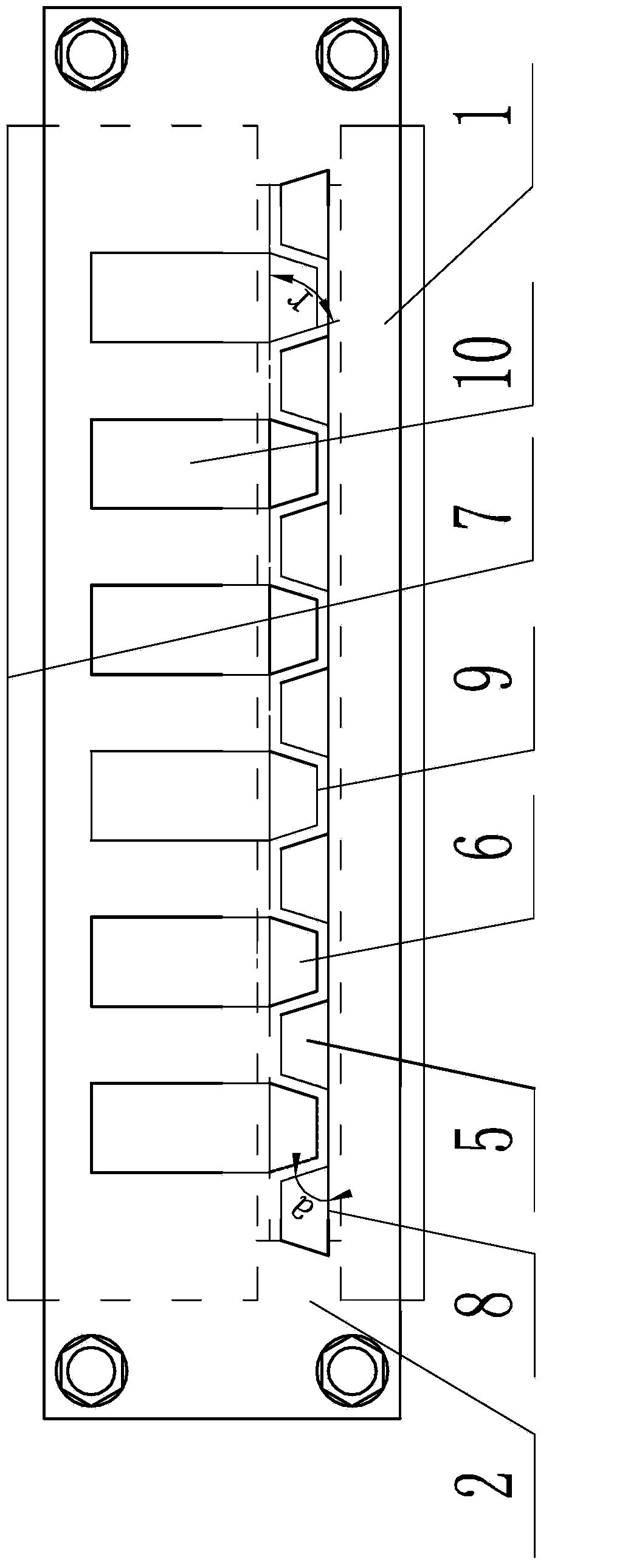

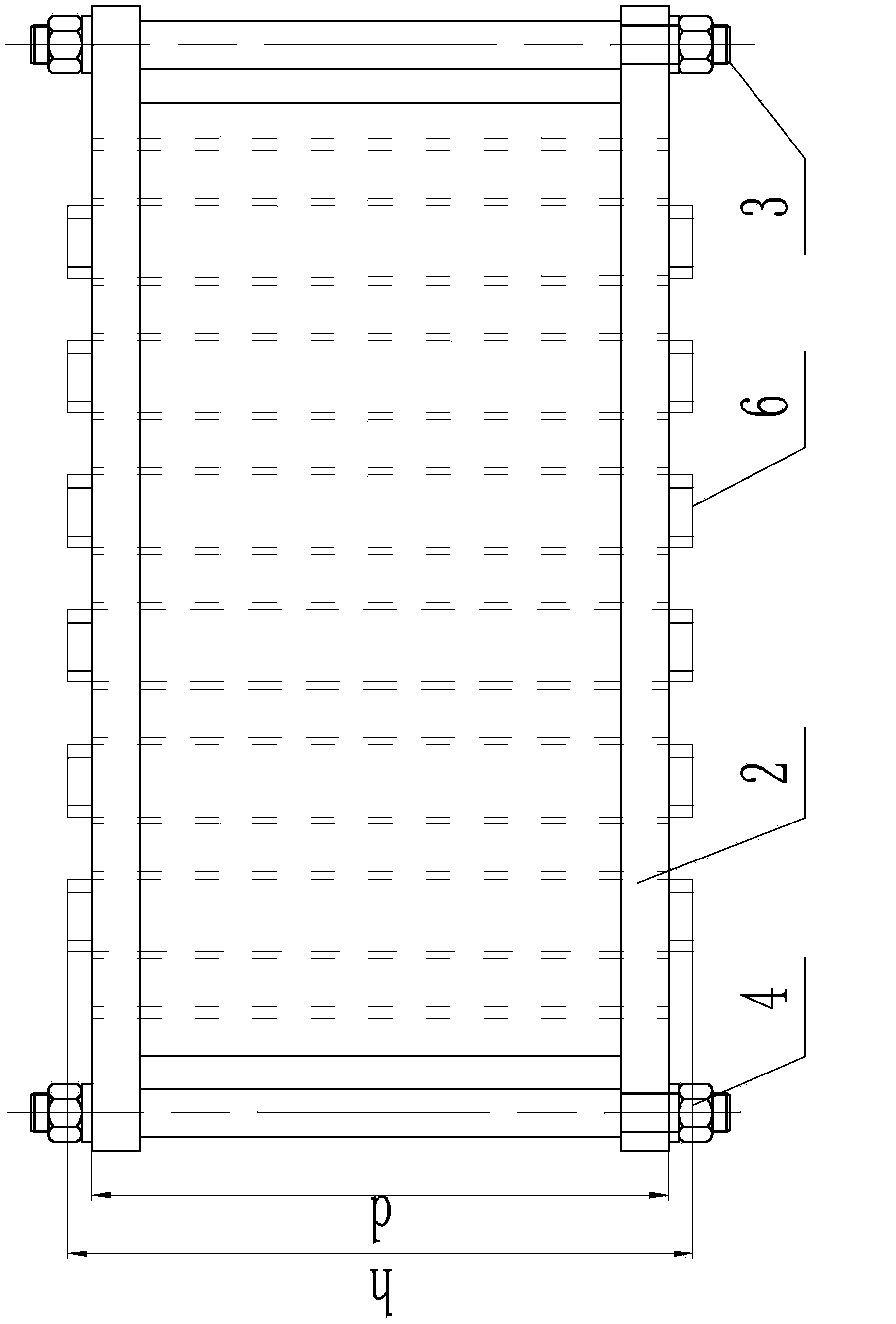

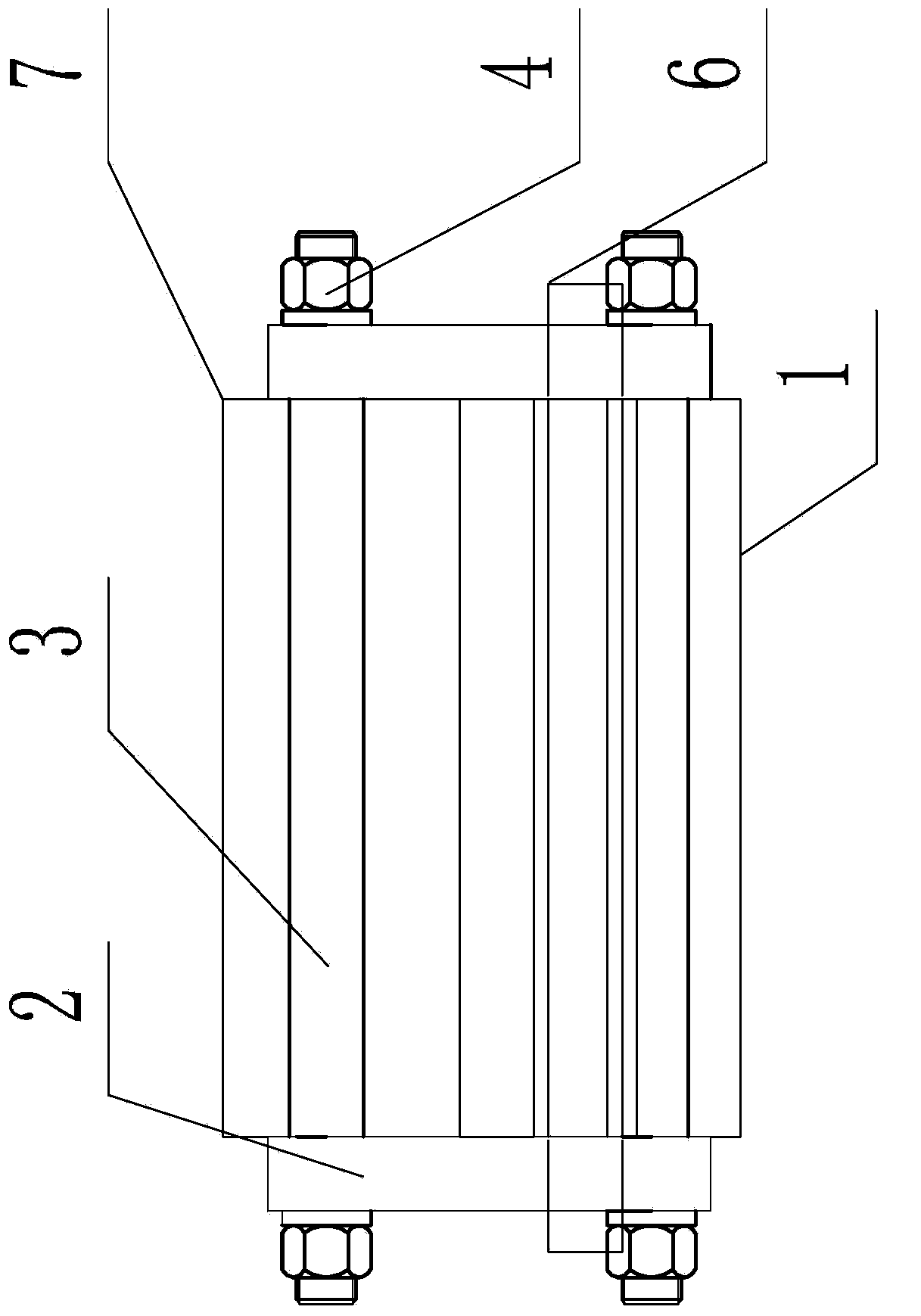

[0007] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, the preparation mold of a ceramic-based corrugated sandwich structure composite material described in this embodiment, the preparation mold includes a backing plate 1, a pressure plate 7, two slide rail plates 2, four cylindrical connectors 3, N+1 trapezoidal fixed sliders 5 and N trapezoidal movable sliders 6, the slide rail plate 2 is a rectangular slide rail plate, and the bottom of each slide rail plate 2 is evenly distributed along the horizontal direction with N+1 upright etc. N inverted isosceles trapezoidal through holes 8 are evenly distributed along the horizontal direction near each upright isosceles trapezoidal through hole 8, and N+1 upright isosceles trapezoidal through holes 8 and N inverted isosceles trapezoidal through holes 9 are relatively staggered, 2≤N≤10, and N is an integer, each inverted isosceles trapezoidal through hole 9 is vertically processed with a rectan...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Figure 1-Figure 3 Describe this embodiment, the preparation mold of a ceramic-based corrugated sandwich structure composite material described in this embodiment, the backing plate 1 is a backing plate 1 made of low-carbon steel material, and the slide rail plate 2 is made of low-carbon The slide rail plate 2 made of steel material, the cylindrical connector 3 is a cylindrical connector 3 made of low-carbon steel, the trapezoidal fixed slider 5 is a trapezoidal fixed slider 5 made of low-carbon steel, and the trapezoidal movable The slider 6 is a trapezoidal movable slider 6 made of low-carbon steel material, and the pressing plate 7 is a pressing plate 7 made of low-carbon steel material. Others are the same as the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination Figure 1-Figure 3 Describe this embodiment, the preparation mold of a ceramic-based corrugated sandwich structure composite material described in this embodiment, the preparation mold also includes four nuts 4, and the two ends of each cylindrical connector 3 are respectively processed with external threads, The external threads at both ends of the cylindrical connecting piece 3 pass through the two slide rail plates 2 respectively, and each end of the two cylindrical connecting pieces 3 is respectively provided with a nut 4 , and the others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com