Method for preparing ceramic particle enhanced steel-base composite material cast by evaporative pattern casting die

A technology of lost foam casting and ceramic particles, which is used in casting molding equipment, molds, mold components, etc., can solve problems such as being unsuitable for large-scale industrial production, easy to form slag inclusions, and poor process controllability, and achieve dense organization. , Improve the bonding strength, the effect of high volume fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

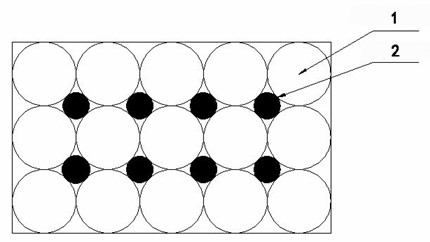

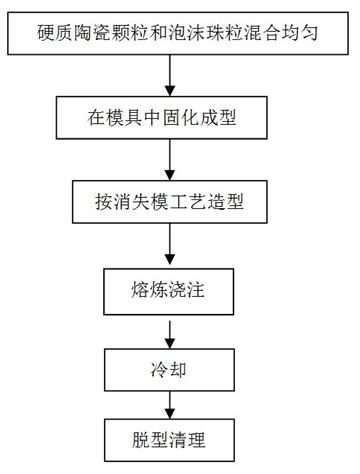

[0025] (1) Alumina particles 2 with a particle size of -40 to +60 mesh and polystyrene (EPS) foam beads 1 with a particle size of -10 to +20 after aging are mixed evenly in a volume ratio greater than 2:8, Then fill the mixture into the curing cavity of the mold for hot water heating and molding to make a foam mold in which the reinforcement (hard ceramic particles) are evenly distributed, such as figure 1 shown;

[0026] (2) Modeling according to the conventional lost foam method, place the foam mold obtained in step (1) in the cavity, and then melt the alloy steel Cr15 high chromium steel to the pouring temperature of 1580°C, pour it into the cavity, cool and solidify at room temperature, After sand cleaning treatment, the ceramic particle reinforced steel matrix composite material (aluminum oxide particles as the dispersed reinforcement phase and Cr15 high chromium steel as the base material) is obtained in which hard ceramic particles are dispersed in the base metal.

Embodiment 2

[0028] (1) Mix silicon carbide and tungsten carbide particles with a particle size of 60 mesh with cured 20 mesh polymethyl methacrylate (PMMA) foam beads in a volume ratio greater than 2:8, and then fill the mixture into the mold In the curing mold cavity, steam cylinder foam molding is performed to make a foam mold in which the reinforcement (hard ceramic particles) are evenly distributed;

[0029] (2) Modeling according to the conventional lost foam method, place the foam mold obtained in step (1) in the cavity, and then melt low carbon steel (ordinary carbon steel) to a pouring temperature of 1580°C, pour it into the cavity, and cool at room temperature After solidification and sand cleaning, the ceramic particle-reinforced iron-based composite material (tungsten carbide and silicon carbide particles are the dispersed reinforcement phase, and low-carbon steel is the base material) is obtained in which hard ceramic particles are dispersed in the base metal.

Embodiment 3

[0031] (1) Mix silicon carbide, tungsten carbide and silicon nitride particles with a particle size of 80 mesh with the cured polymethyl methacrylate (PMMA) foam beads of 20 mesh at a volume ratio of less than 2:8, and then mix the The mixture is filled into the curing cavity of the mold for press foam molding and curing to make a foam mold in which the reinforcement (hard ceramic particles) are evenly distributed, such as figure 1 shown;

[0032](2) Modeling according to the conventional lost foam method, place the foam mold obtained in step (1) in the cavity, and then melt the ductile iron QT500 to the pouring temperature of 1530°C, pour it into the cavity, cool and solidify at room temperature, and clean the sand After treatment, the ceramic particle-reinforced iron-based composite material (tungsten carbide, silicon carbide and silicon nitride particles as the dispersed reinforcement phase, and QT500 as the substrate) is obtained in which hard ceramic particles are dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com