Method of preparing bacterial cellulose/glass fiber composite material and prepared material

A technology of bacterial cellulose and composite materials, which is applied in the field of a method and the obtained materials, can solve problems such as inability to resist external forces, poor mechanical properties, and complicated processes, achieve good application prospects, improve mechanical properties, and expand application fields Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for bacterial cellulose / glass fiber composite material and the material obtained, the steps are as follows:

[0038] ⑴Fix a 10cm-long glass support on the electrophoresis tank with a height of about 3cm. Arrange the glass fiber filaments evenly between the two glass supports, about 1000 in total, and the arrangement direction is the direction of the vertical electric field line. figure 1 A;

[0039] (2) Take the G.xylinus bacterial liquid stored in a 400uL glycerol tube and put it in a 500uL fermentation medium. The composition of the fermentation medium (g / L): glucose 25, peptone 10, yeast extract powder 7.5, disodium hydrogen phosphate 10, glacial acetic acid to adjust pH to 6.0, pour it into the electrophoresis tank until the liquid level reaches the glass fiber surface, and incubate at 30°C for 24 hours to allow the bacteria to grow fully;

[0040] (3) Turn on the electric field, adjust the voltage to 10 volts, and cultivate for 3 days;

[0041] (4) Soak ...

Embodiment 2

[0044] A method for bacterial cellulose / glass fiber composite material and the material obtained, the steps are as follows:

[0045] ⑴Fix a 10cm-long glass bracket on the electrophoresis tank, about 3cm high, arrange the glass fiber filaments evenly between the two glass brackets, a total of about 1000 pieces, and the arrangement direction is parallel to the direction of the electric field line, showing figure 1 B;

[0046] (2) Take the G.xylinus bacterial liquid preserved in the 400uL glycerol tube and put it in the 500uL fermentation medium, and pour it into the electrophoresis tank until the liquid level reaches the glass fiber surface. Incubate at 30°C for 24 hours to allow the bacteria to grow fully;

[0047] (3) Turn on the electric field, adjust the voltage to 10 volts, and cultivate for 3 days;

[0048] (4) Soak the obtained composite material in 0.1mol / L sodium hydroxide solution overnight until the film is milky white. Rinse with water until the film is neutral. ...

Embodiment 3

[0051] A method for bacterial cellulose / glass fiber composite material and the material obtained, the steps are as follows:

[0052] ⑴Fix a 10cm-long glass bracket on the electrophoresis tank with a height of about 3cm, and arrange the glass fiber filaments evenly between the two glass brackets, about 1000 in total, and the arrangement direction is random, showing figure 1 C;

[0053] (2) Take the G.xylinus bacterial liquid preserved in a 400uL glycerol tube in a 500uL fermentation medium, pour it into the electrophoresis tank until the liquid level reaches the glass fiber surface, and incubate at 30°C for 4 days;

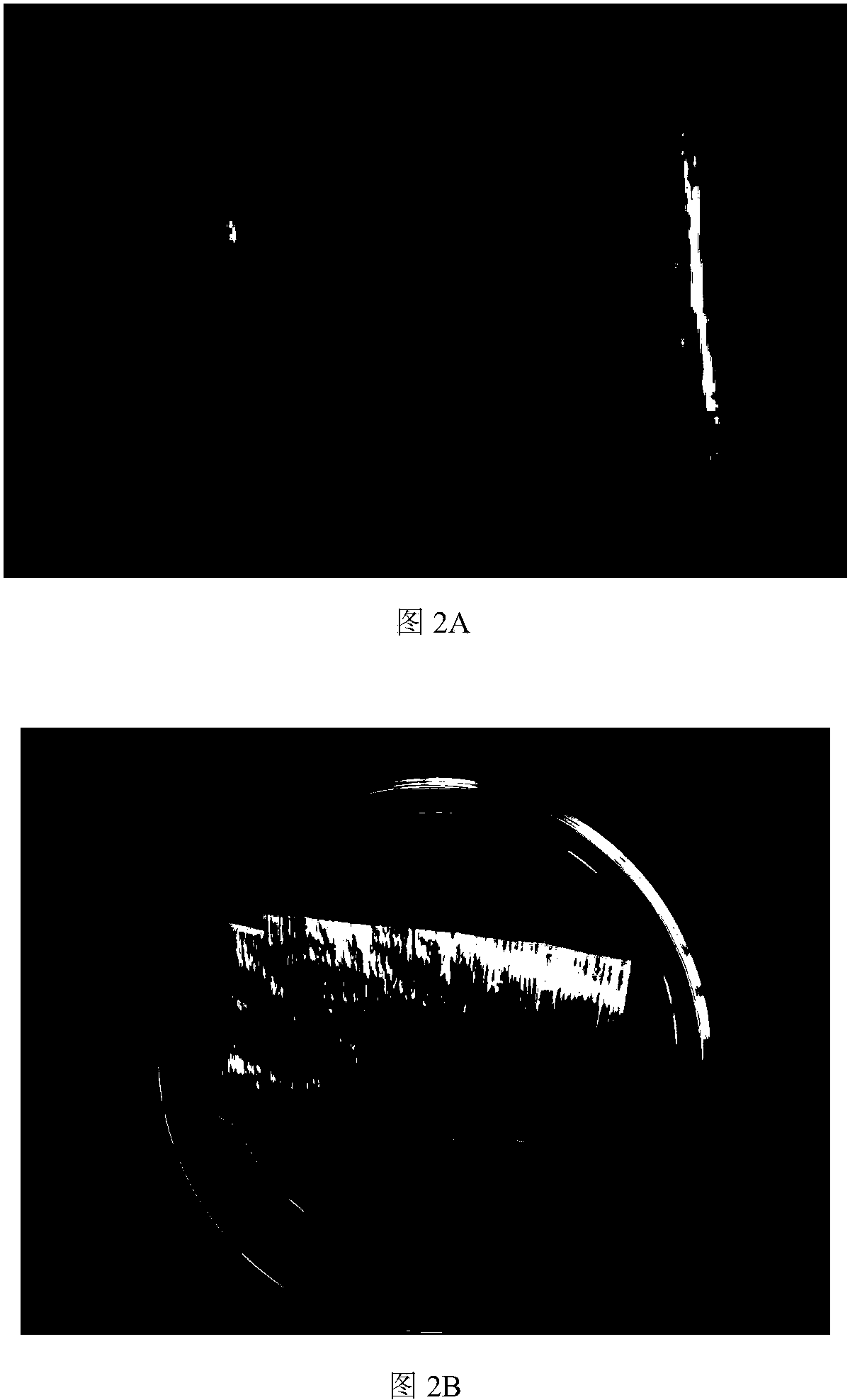

[0054](3) Soak the obtained composite material in 0.1mol / L sodium hydroxide solution overnight until the film is milky white. Rinse with water until the film is neutral. Dry at room temperature to constant weight. Test results: the maximum force along the direction of glass fiber filaments is greater than that of static cultured bacterial cellulose ( figure 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com