Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

225results about How to "Reduce part cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

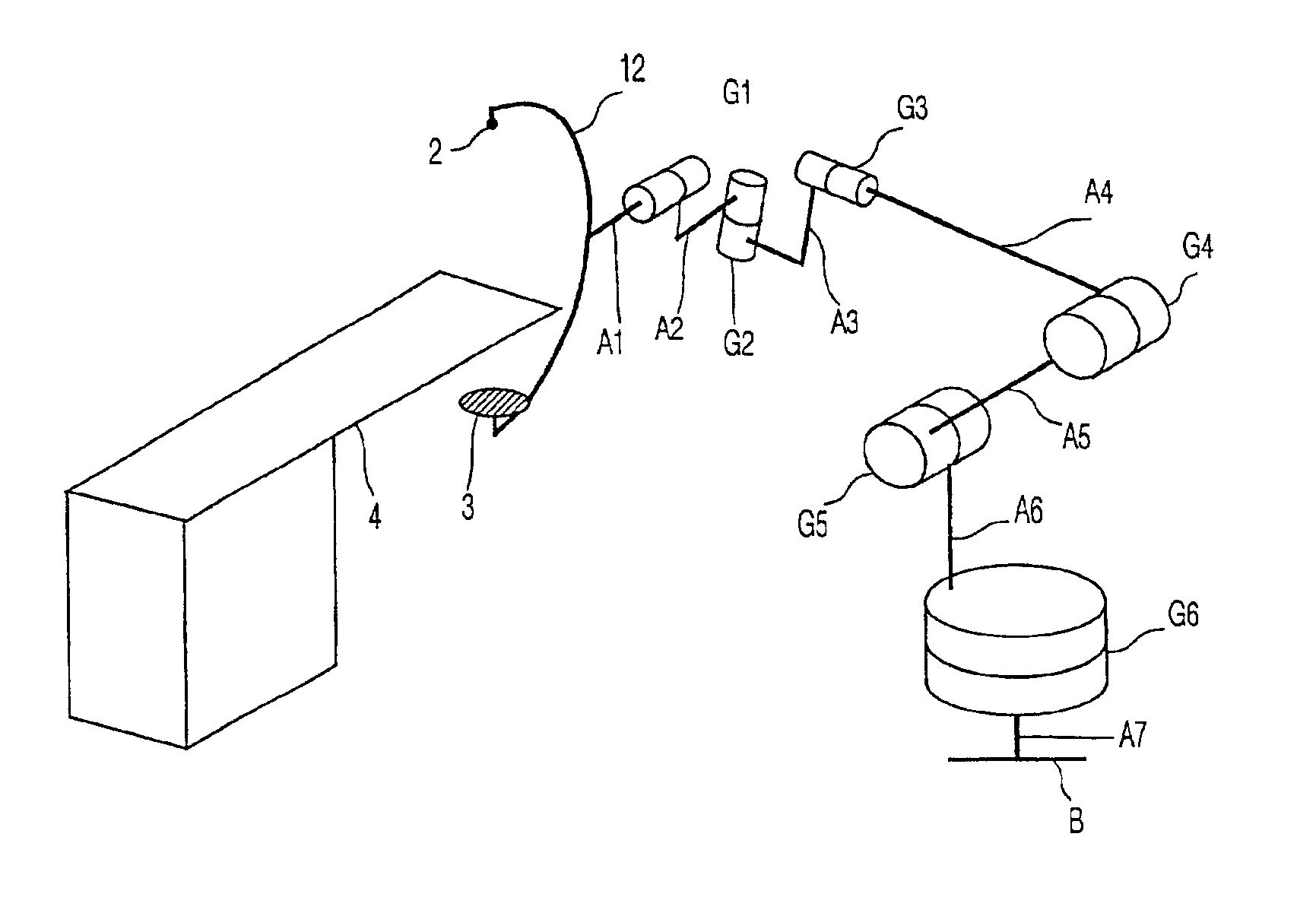

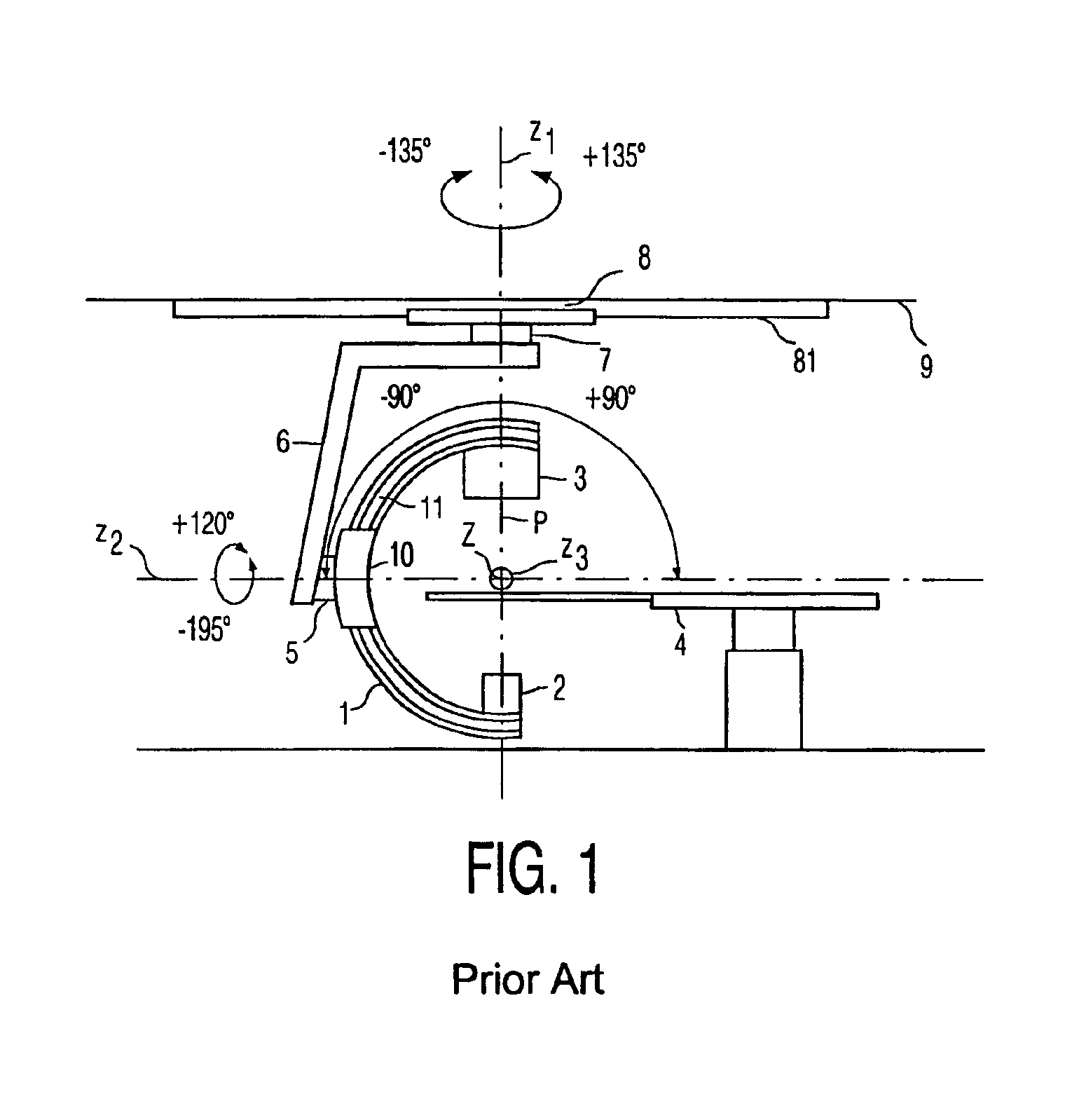

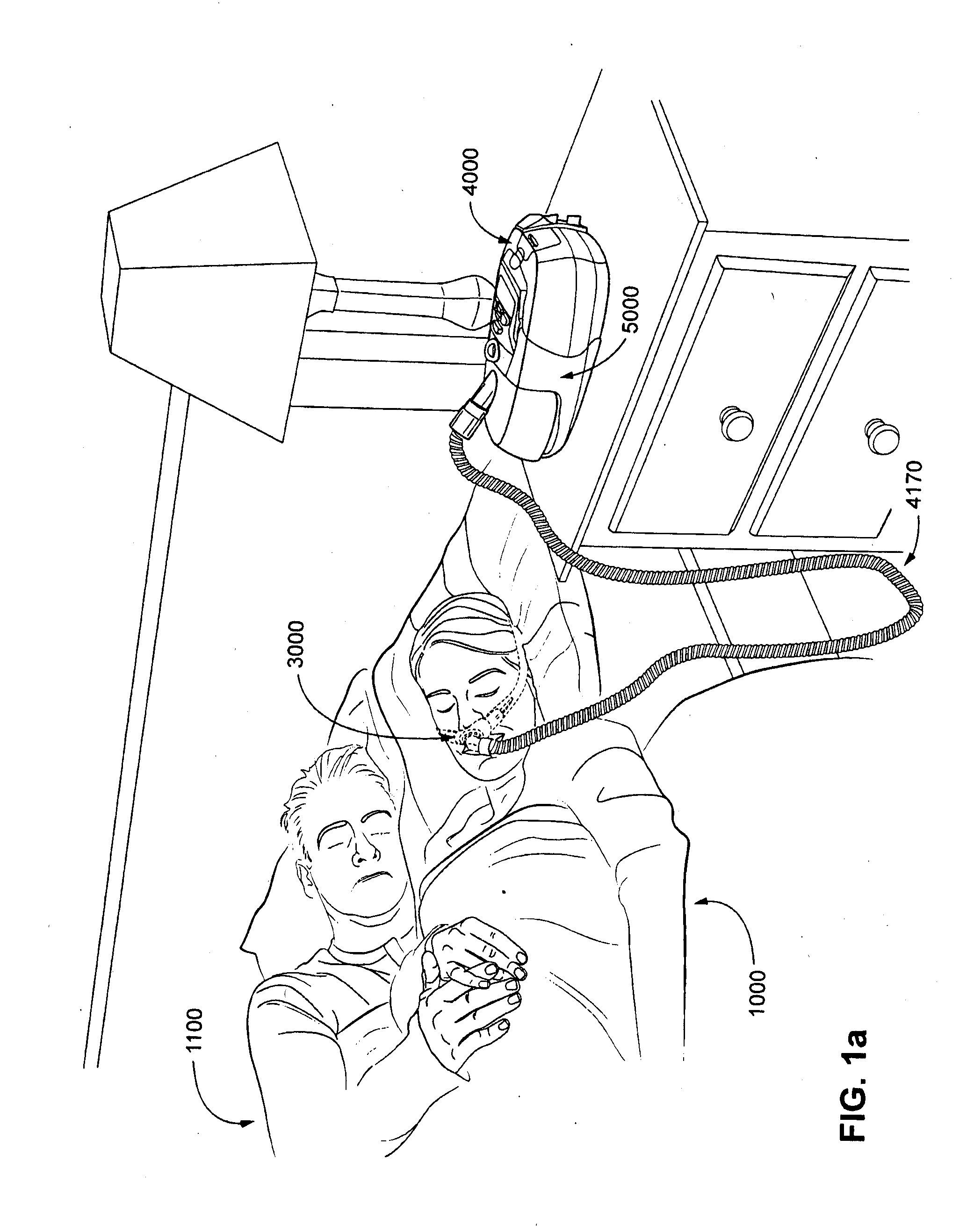

X-ray device provided with a robot arm

InactiveUS6869217B2High positioning accuracyEconomically manufacturedProgramme-controlled manipulatorRadiation safety meansX-rayEngineering

The invention relates to an X-ray device which includes an X-ray source and an X-ray detector which are mounted at a respective end of a common holding device. The holding device being attached to the room by way of a supporting device. In order to realize a more flexible construction of such X-ray devices that are widely used and are usually provided with a holding device in the form of a C-arm and nevertheless maintain a high positioning accuracy. The invention further relates to a supporting device constructed with a plurality of hinged, serially interconnected supporting members. The supporting device is formed notably by a serial manipulator, for example, a conventional robot arm.

Owner:U S PHILIPS CORP

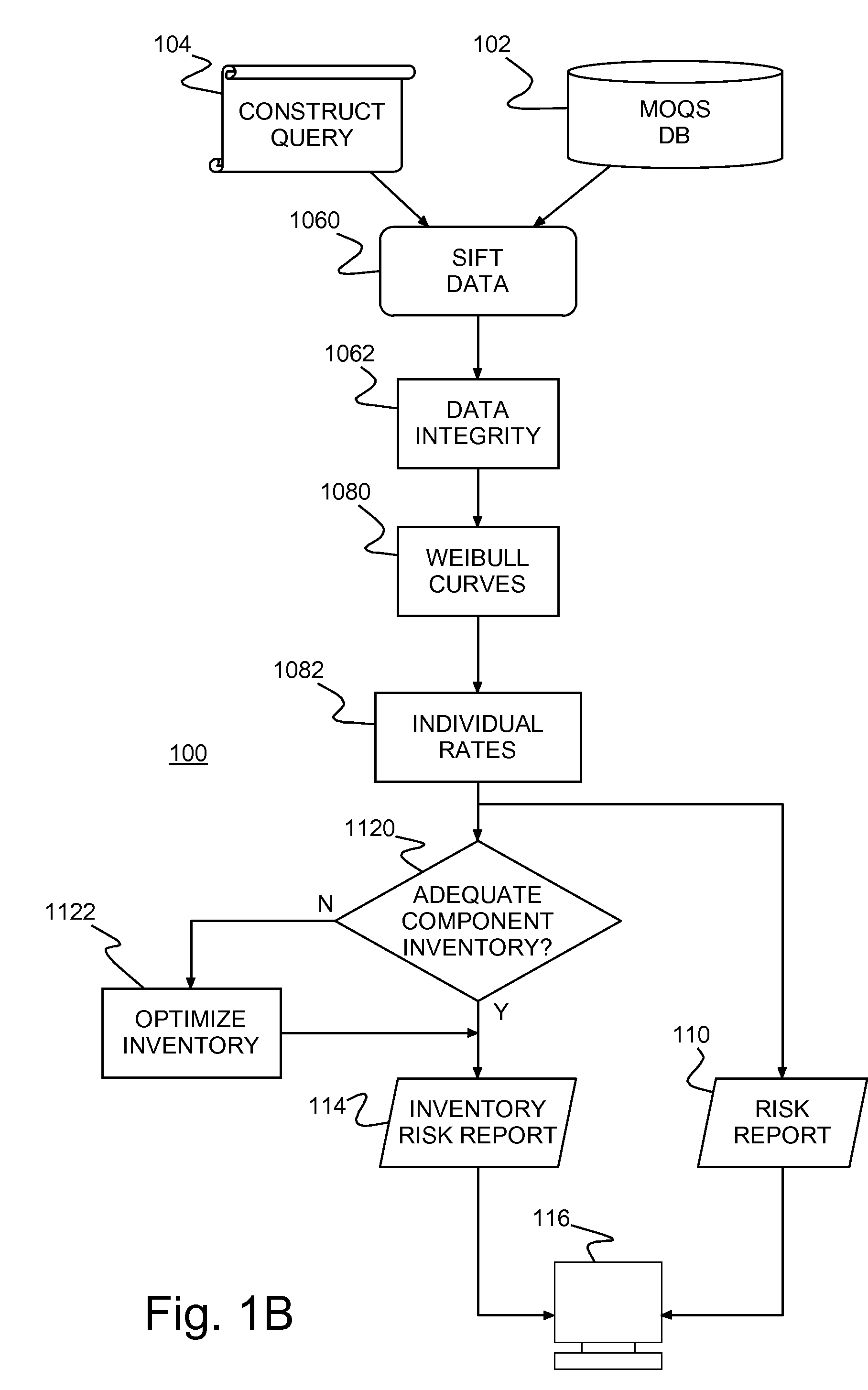

System, method and program product for predicting fleet reliability and maintaining a fleet of vehicles

InactiveUS20080154458A1Accurately predict part-level repair-shop throughputReduce part costVehicle testingRegistering/indicating working of vehiclesSpare partAirplane

A system, method and program product for maintaining fleet performance for a fleet of platforms, especially for a fleet of aircraft. Part removal data is contained in a maintenance database. A query is constructed for extracting part removal data from the maintenance database. Weibull analysis is applied to extracted part removal data. Exposed aircraft with parts being likely to fail within a given time period are identified from the Weibull analysis results. Overall part failure numbers are generated for each failing part. Inventory is checked to determine if sufficient spares are available to repair all expected failures. Any shortfalls may be covered. A risk report is generated for the fleet and for inventory. Each risk report highlights likely problems that may require immediate attention.

Owner:THE BOEING CO

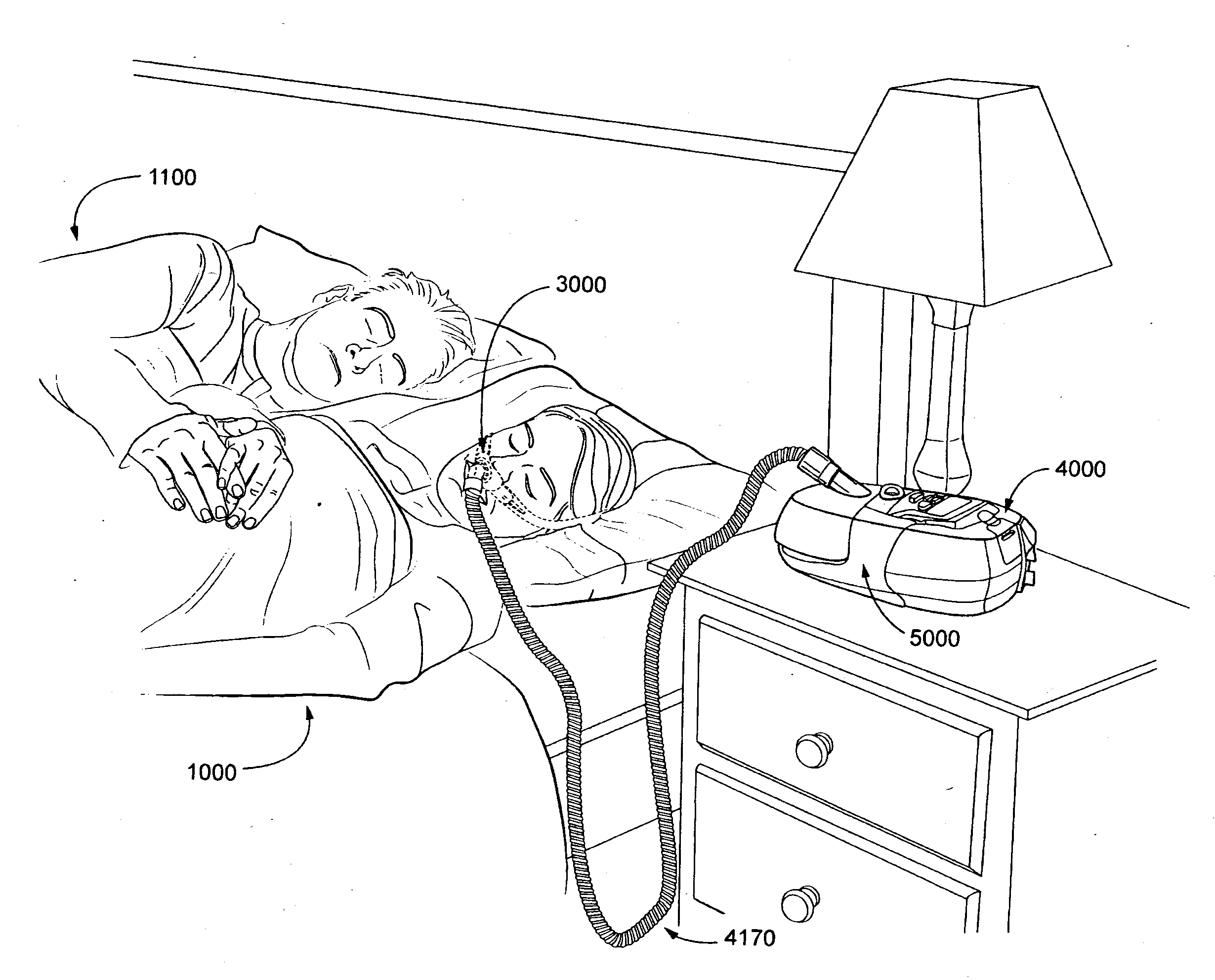

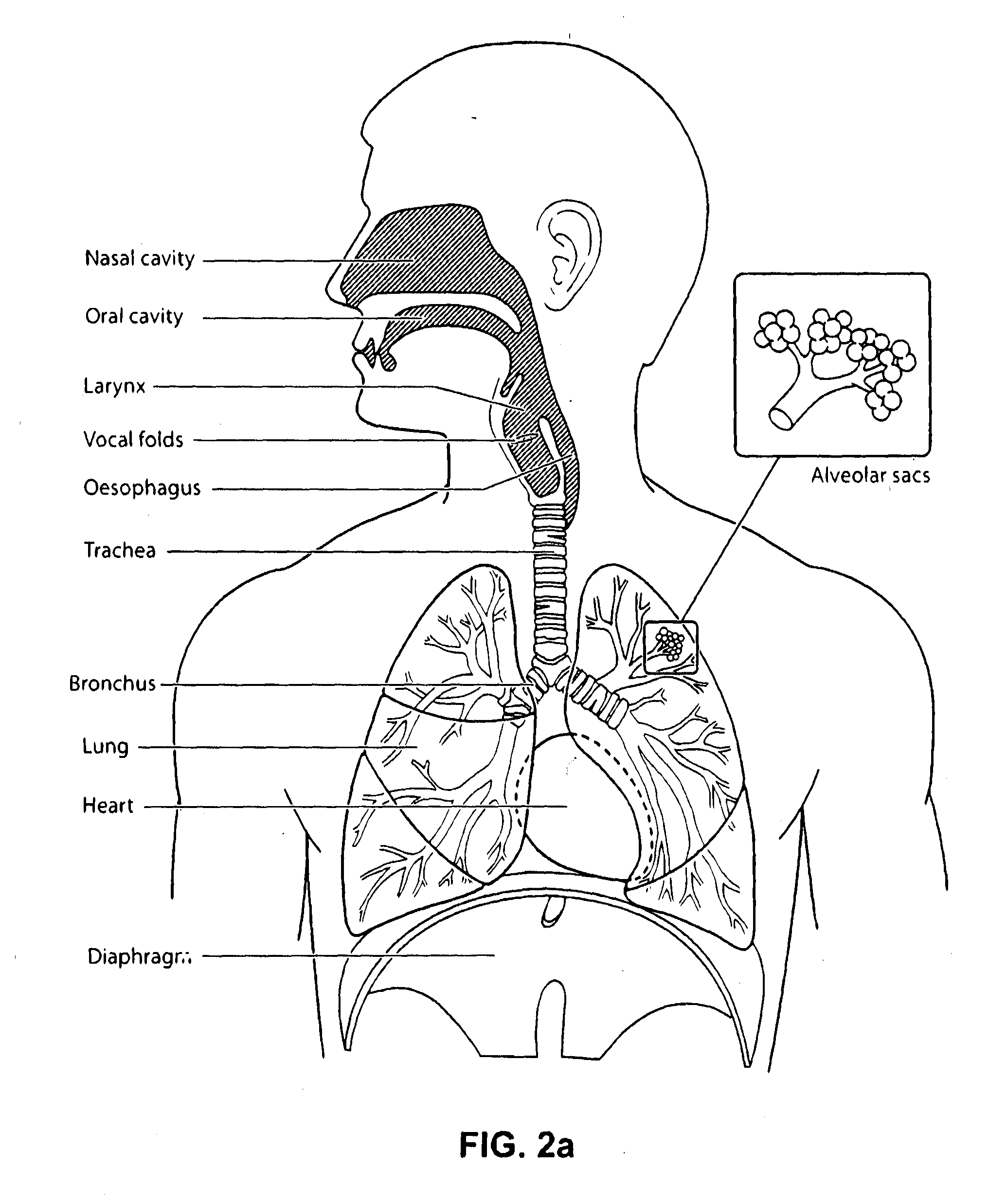

Nasal mask system

ActiveUS20150151071A1Easy to useSuitable for a wide rangeRespiratory masksMedical devicesEngineeringFlange

A swivel elbow and connector assembly for a patient interface system includes a ring (128) configured to be sealingly secured in an aperture of the patient interface system and an elbow (125) swivably secured in the ring (128). The ring (128) includes a first side (128(1)) in an interior of the patient interface system and a second side (128(2)) at an exterior of the patient interface system when the ring (128) is secured in the aperture. The ring (128) comprises a first flange on the first side and a second flange on the second side, the first and second flanges defining a channel (128(3)) that sealingly engages the aperture of the patient interface system. An inner surface (128(4)) of the ring (128) is partially spherical and an outer surface (125(3)) of the elbow (125) is partially spherical and the elbow (125) and the ring (128) form a ball and socket connection.

Owner:RESMED LTD

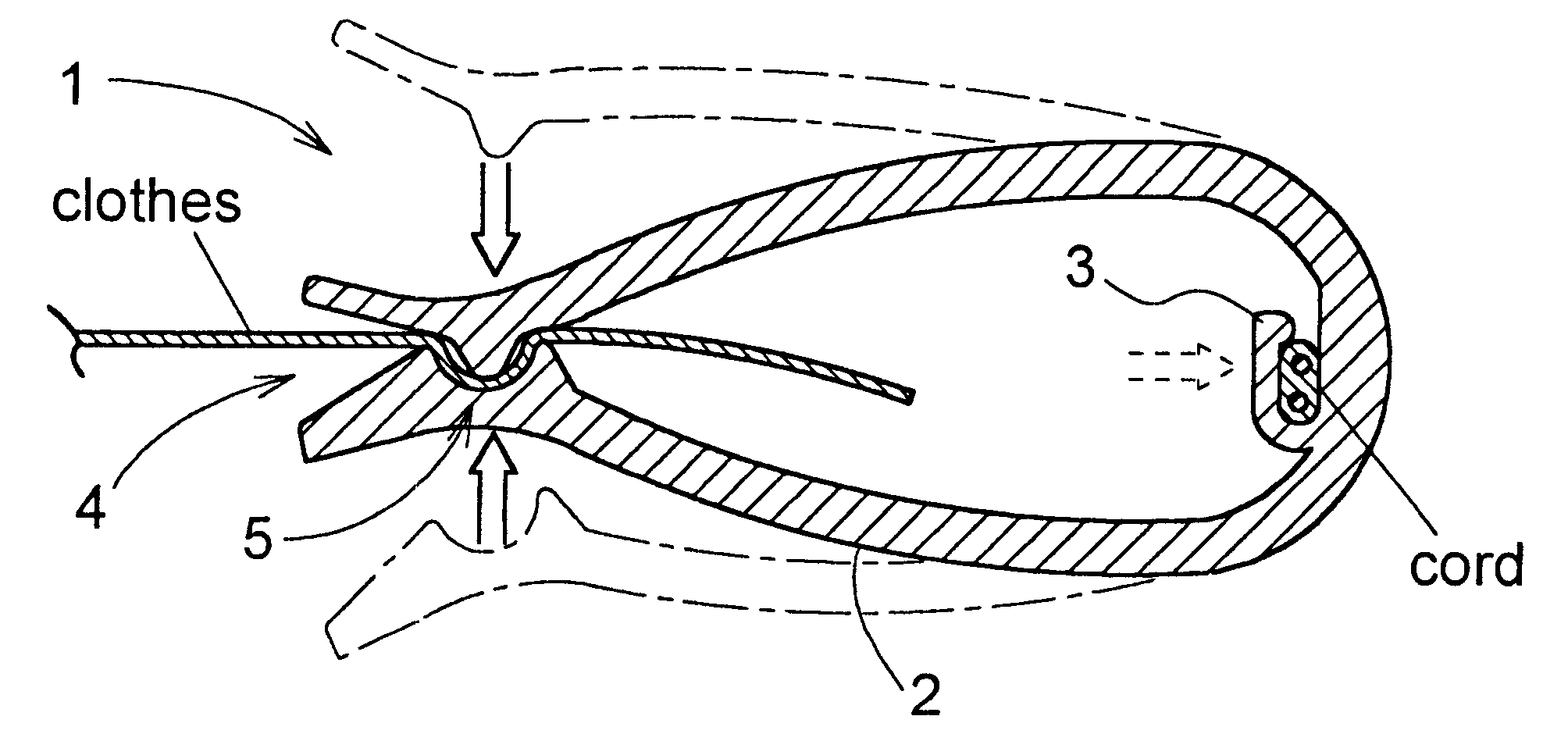

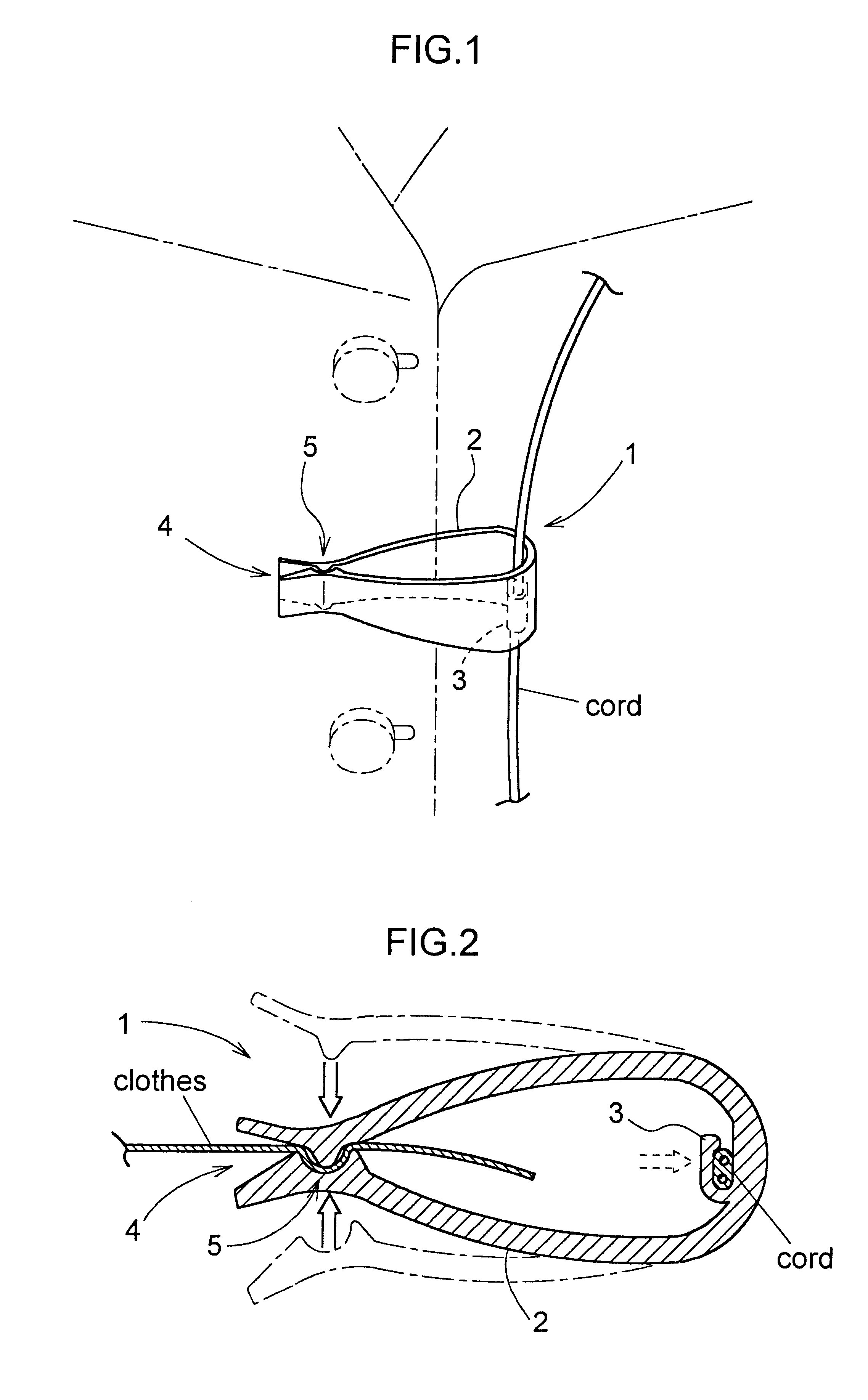

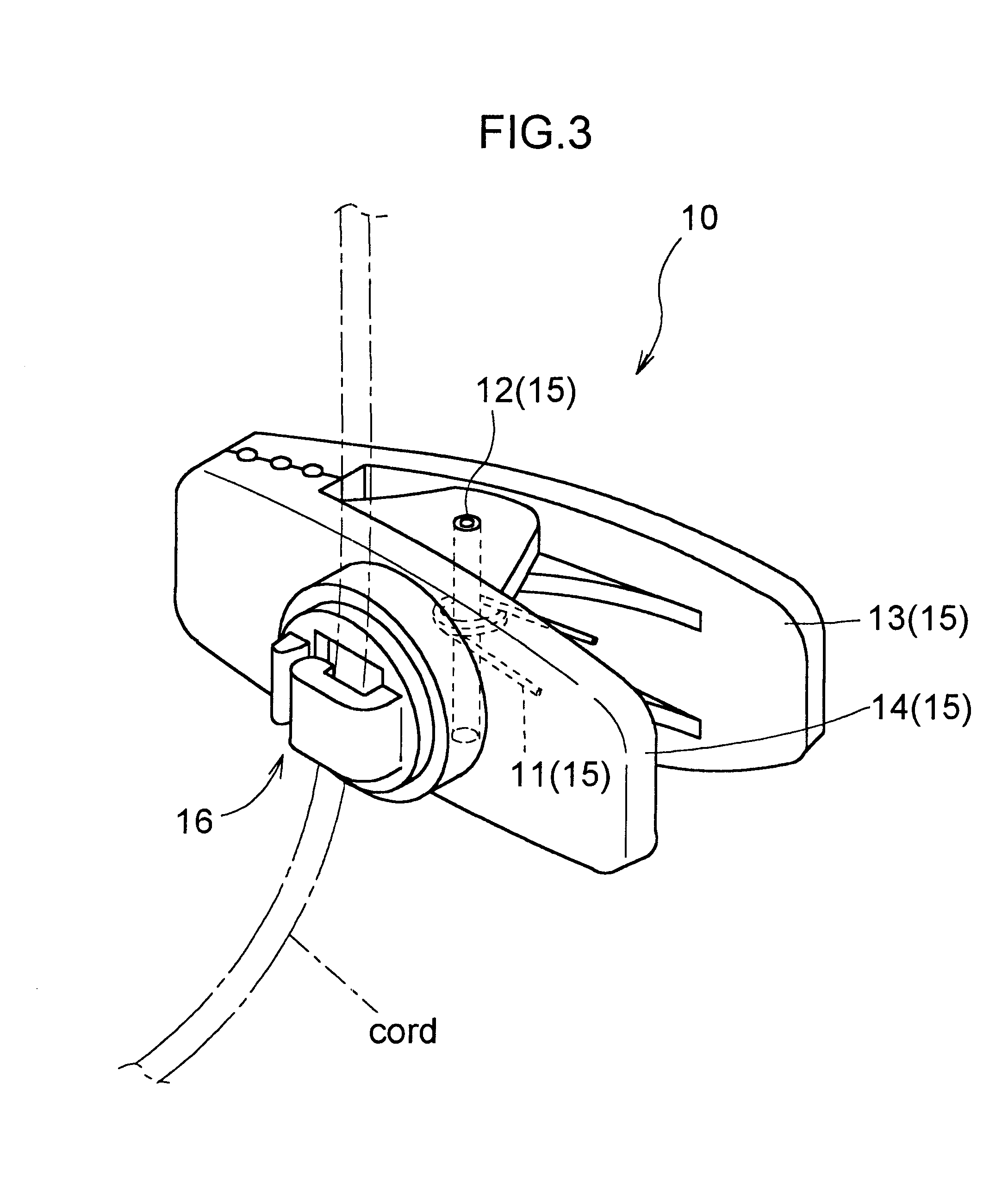

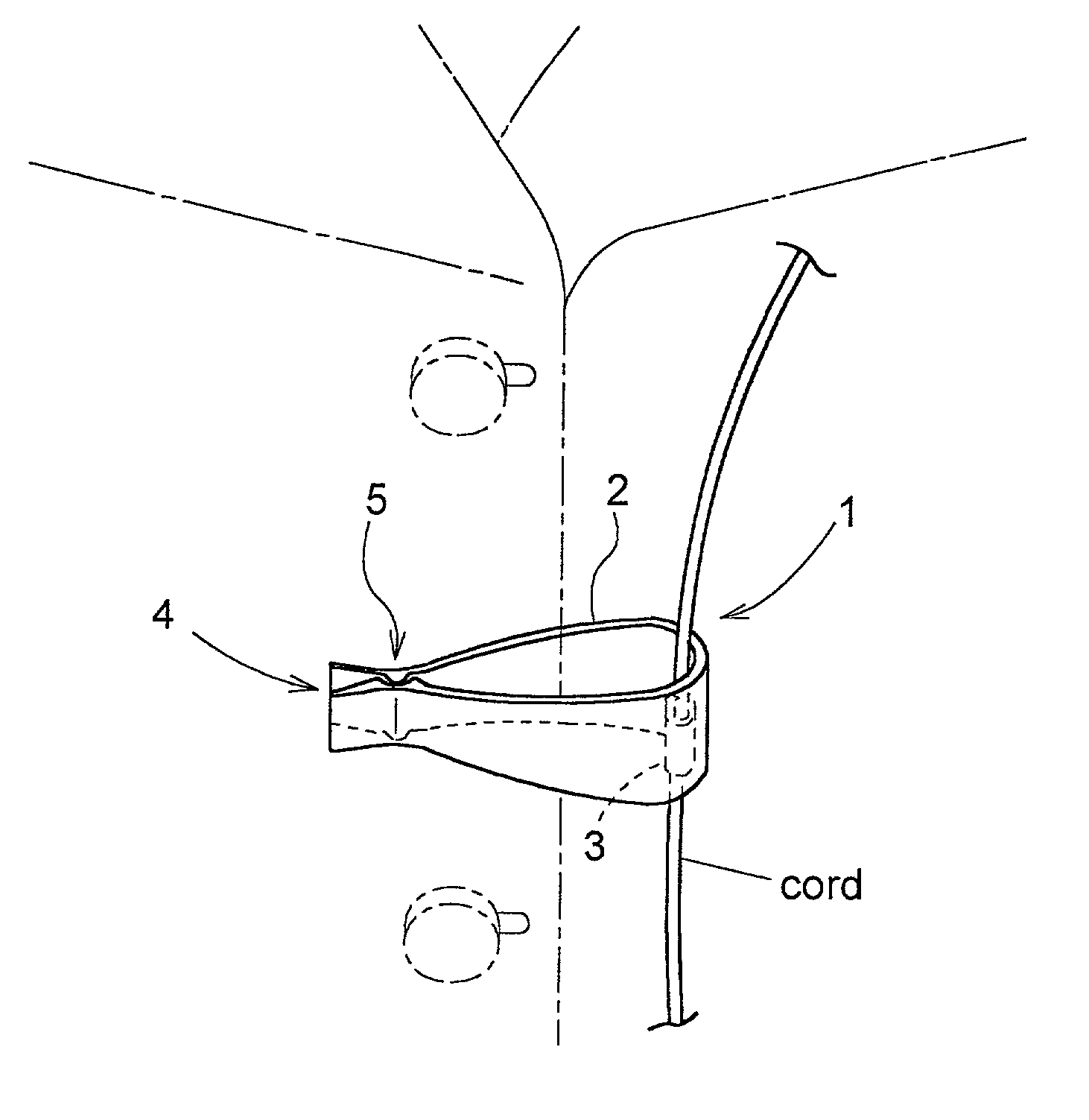

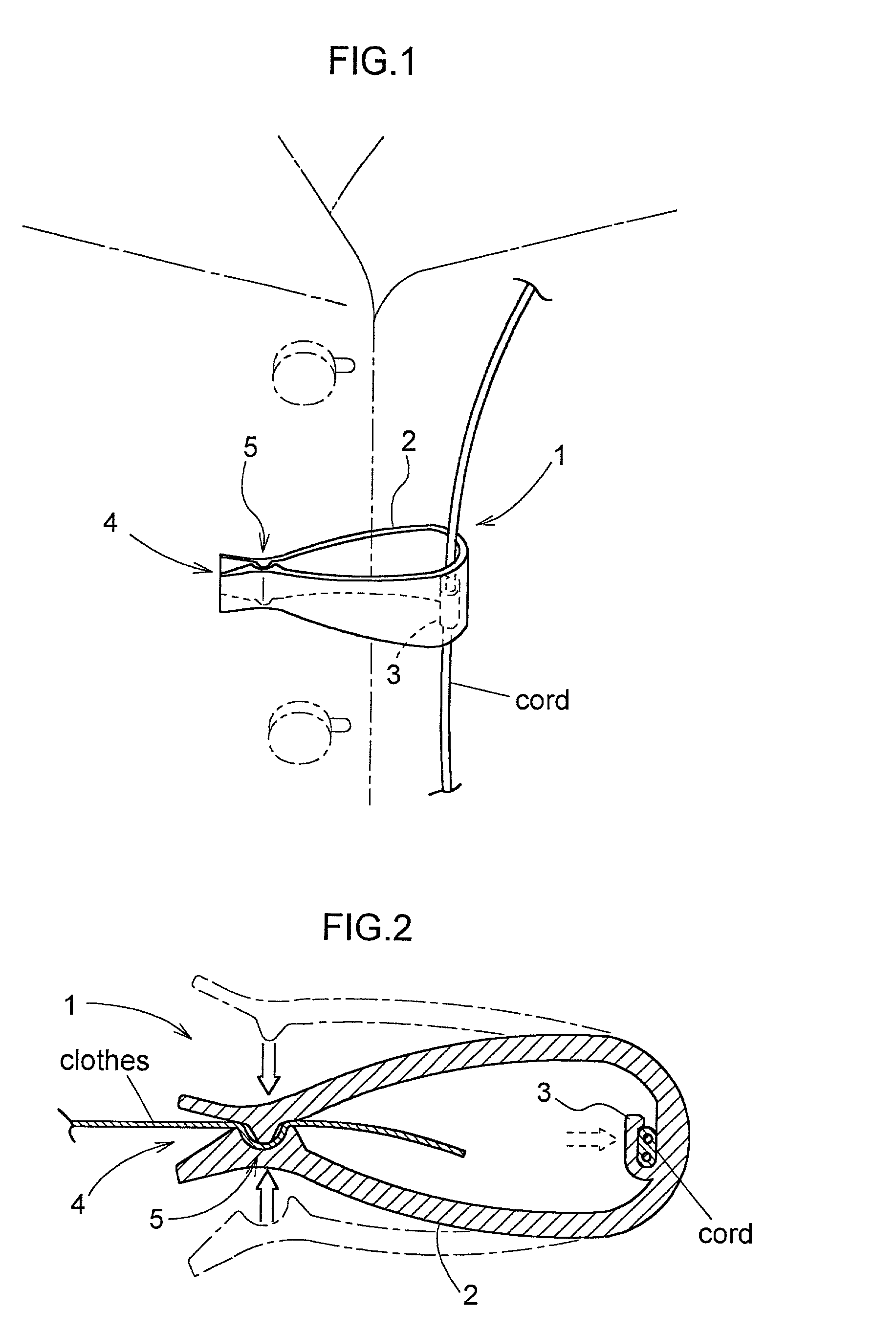

Cord clip

InactiveUS6526635B2Avoid mutual interferenceReduce part costSnap fastenersTravelling carriersEngineeringMechanical engineering

A cord clip for fastening a cord attached to e.g. an earphone to an object such as a clothes is disclosed. The cord clip includes a clipping portion for clamping the object and a cord holding portion for holding the cord. The clipping portion is formed by a first annular portion having a discontinuity at a part thereof. The clipping portion is capable of clamping the object at a clamping portion thereof provided by a narrow gap formed by the discontinuity of the first annular portion by means of an elastic resilient force of the first annular portion. The cord holding portion is formed by a second annular portion having a discontinuity at a part thereof. The cord holding portion is capable of holding the cord therein by means of an elastic resilient force of the second annular portion. This elastic resilient force of the second annular portion is independent of that of the first annular portion. The first annular portion and the second annular portion are formed integrally in a single member.

Owner:HOSIDEN CORP

Apparatus for calculating quantity indicating charged state of on-vehicle battery

ActiveUS20070200567A1Reduce errorsSimple calculationCircuit monitoring/indicationMaterial analysis by electric/magnetic meansInternal resistanceCrankshaft

An apparatus is provided to calculate a quantity indicating a charged state of an on-vehicle battery. The battery powers a starter starting up an on-vehicle engine. In the apparatus, a plurality of pairs of data consisting of current and voltage of the battery are acquired at predetermined sampling intervals during a cranking period of the engine in response to starting up the starter. At intervals, a value of an internal resistance of the battery is calculated based on the plurality of pairs of data of current and voltage. The internal resistance is one kind of the charged-state indicating quantity. An open voltage difference is calculated, which is a difference between a pseudo circuit-open voltage of the battery given before starting up the starter and a pseudo circuit-open voltage of the battery given after the cranking period. The value of the internal resistance is corrected using the open voltage difference.

Owner:DENSO CORP +1

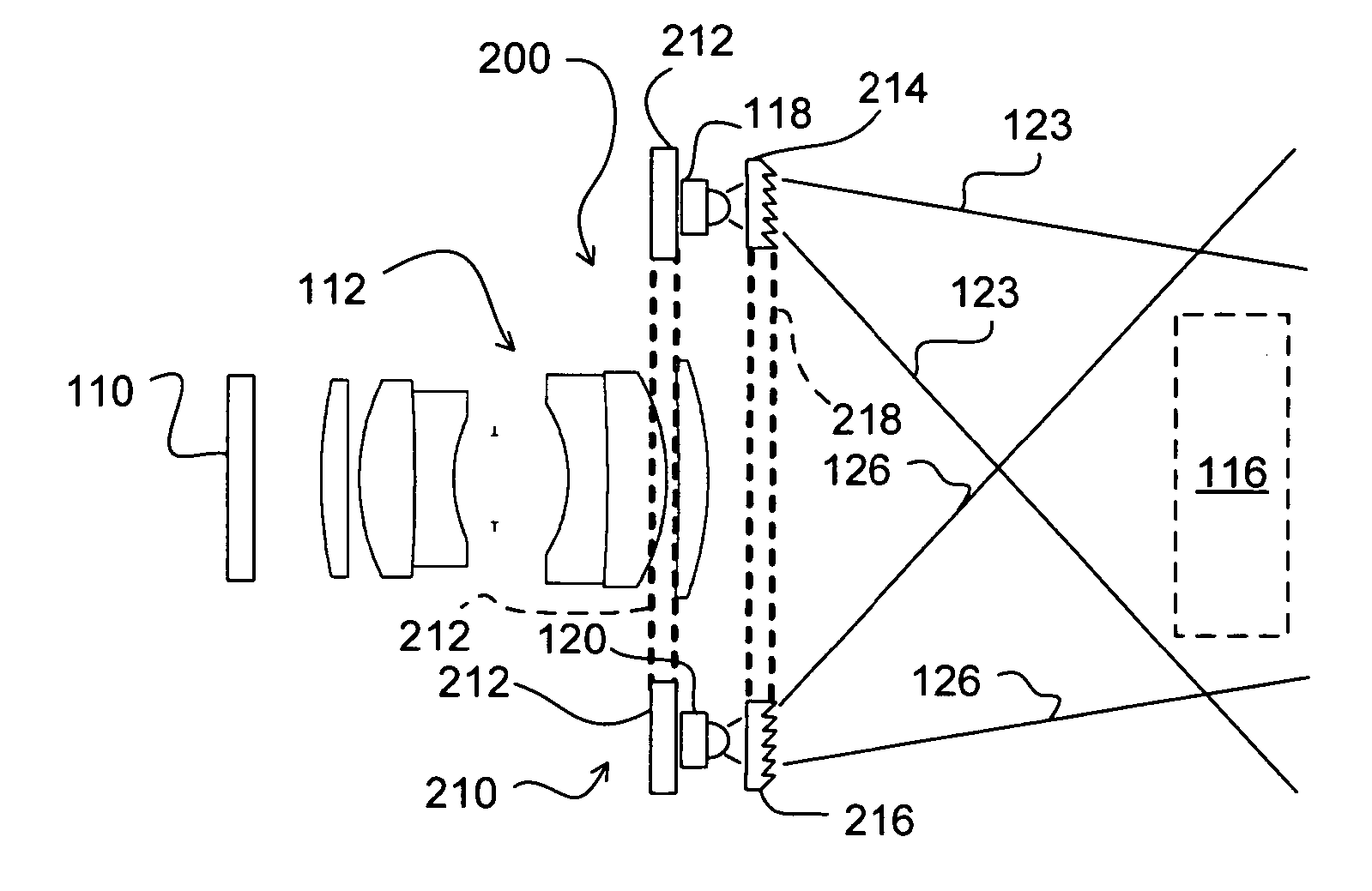

Achieving convergent light rays emitted by planar array of light sources

InactiveUS20070014466A1Shorten assembly timeReduce countScattering properties measurementsCharacter and pattern recognitionImaging lensPrism

Systems and methods are provided for achieving convergent light rays emitted by a planar array of light sources. In one embodiment, an imaging device is provided for inspecting semiconductors or other objects. The imaging device includes one or more imaging lens for imaging light reflected from an object. The imaging device also includes a first light source attached to a planar circuit board and a second light source attached to the planar circuit board. The imaging device further includes a first Fresnel prism for directing light from the first light source toward the object from a first direction and a second Fresnel prism for directing light from the second light source toward the object from a second direction. In one embodiment, the imaging device also includes one or more optical elements for increasing or decreasing the divergence of the light.

Owner:ELECTRO SCI IND INC

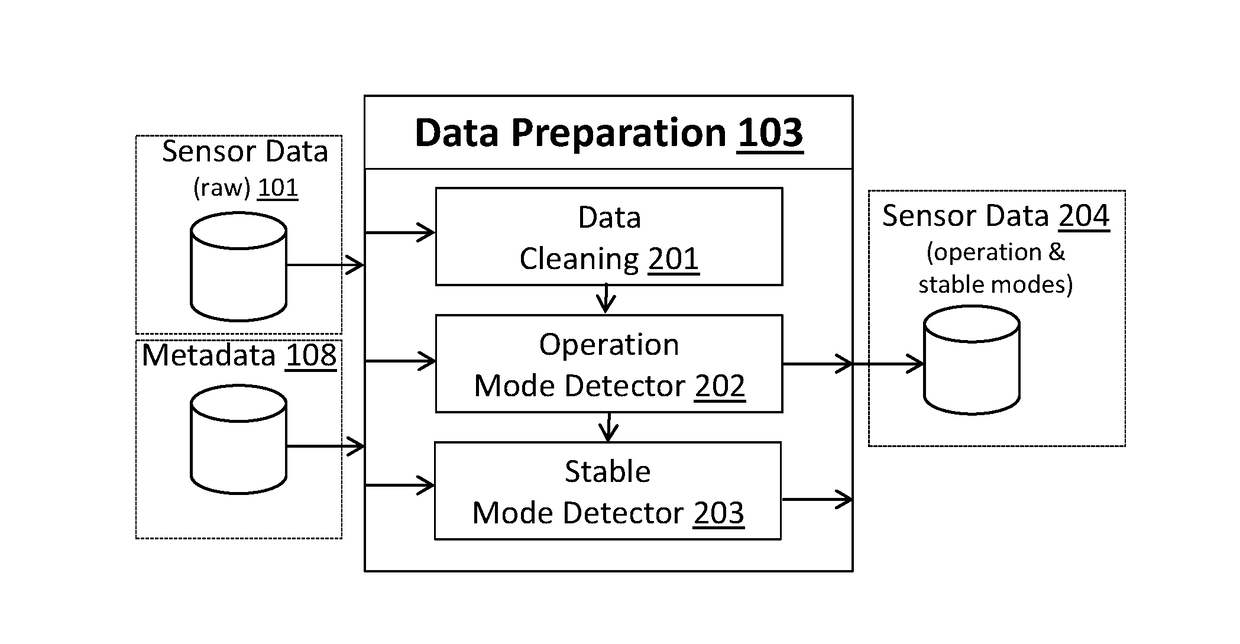

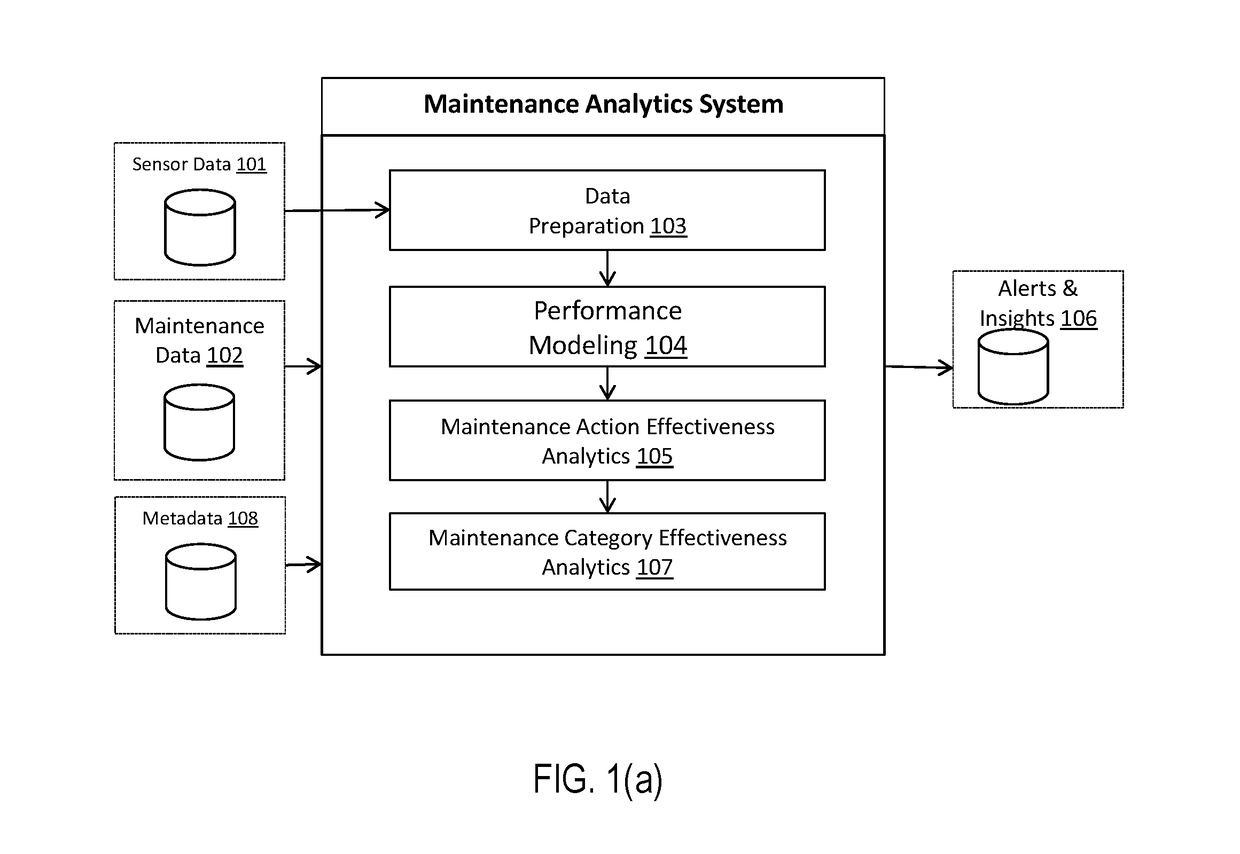

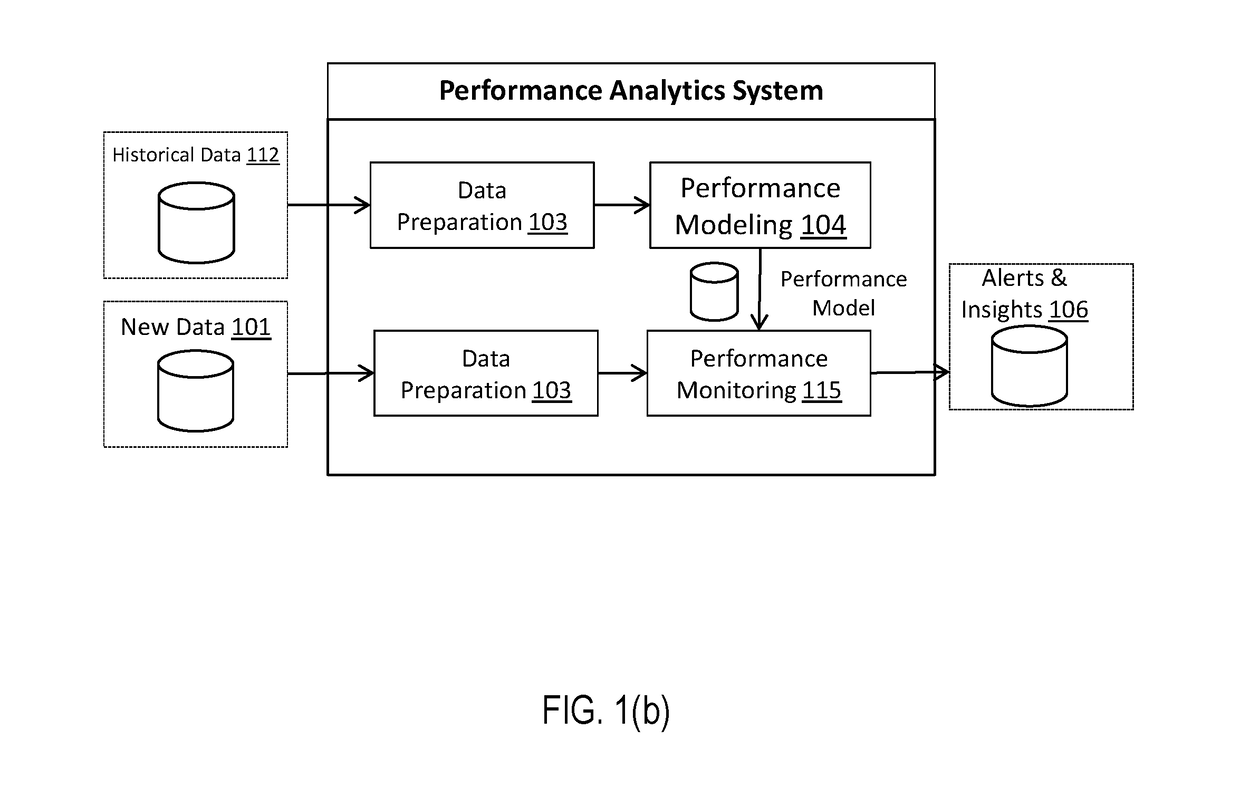

System for maintenance recommendation based on maintenance effectiveness estimation

ActiveUS20170309094A1Labor savingImprove usabilityRegistering/indicating working of vehiclesTesting/monitoring control systemsDecision takingSystem usage

Example implementations described herein are directed to a decision-support system for maintenance recommendation that uses analytics technology to evaluate the effectiveness of a maintenance action or a group of actions in improving the performance of equipment and its components, and provide recommendations on which maintenance actions or a group of maintenance actions should be pursued and which should be avoided.

Owner:HITACHI LTD

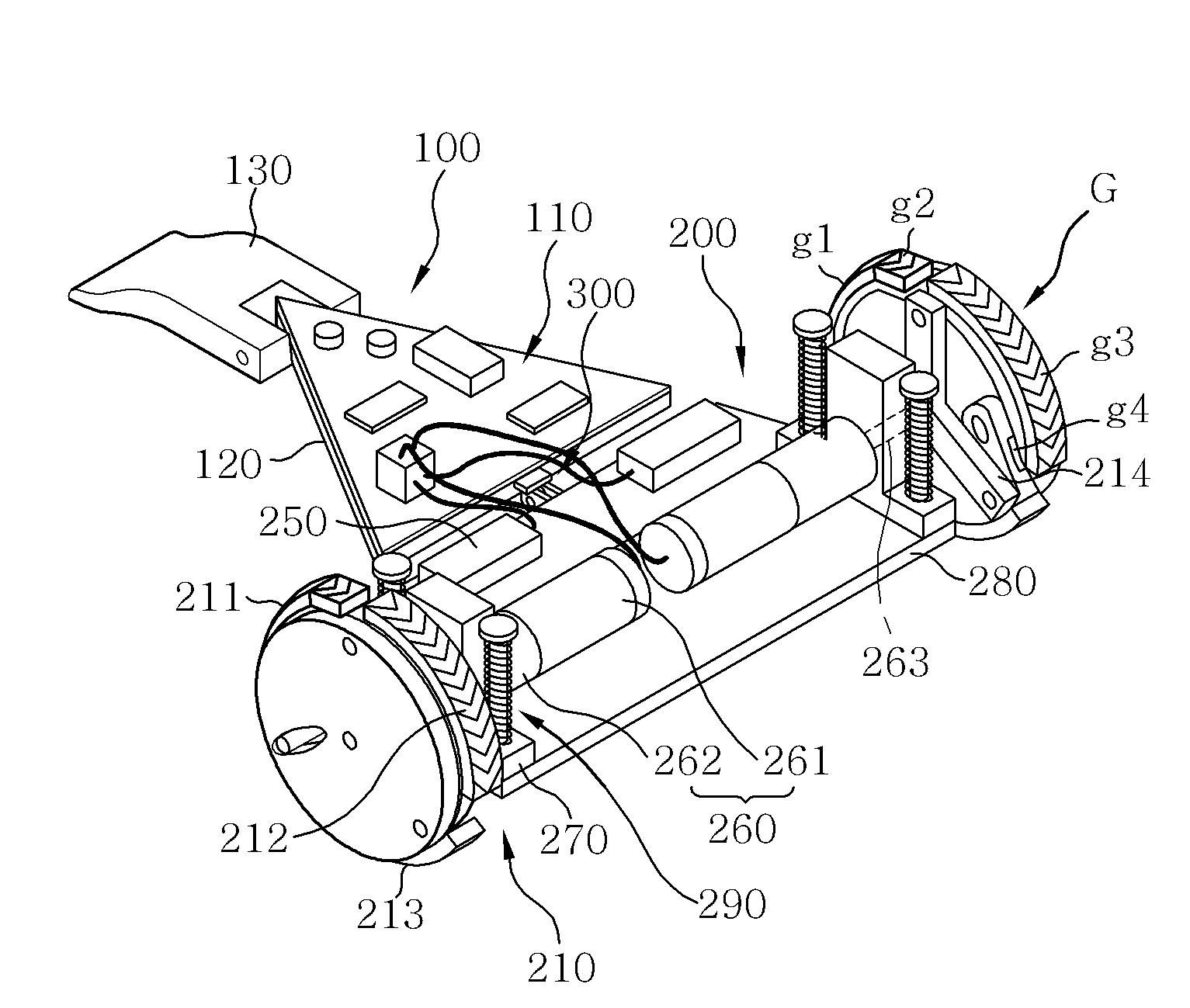

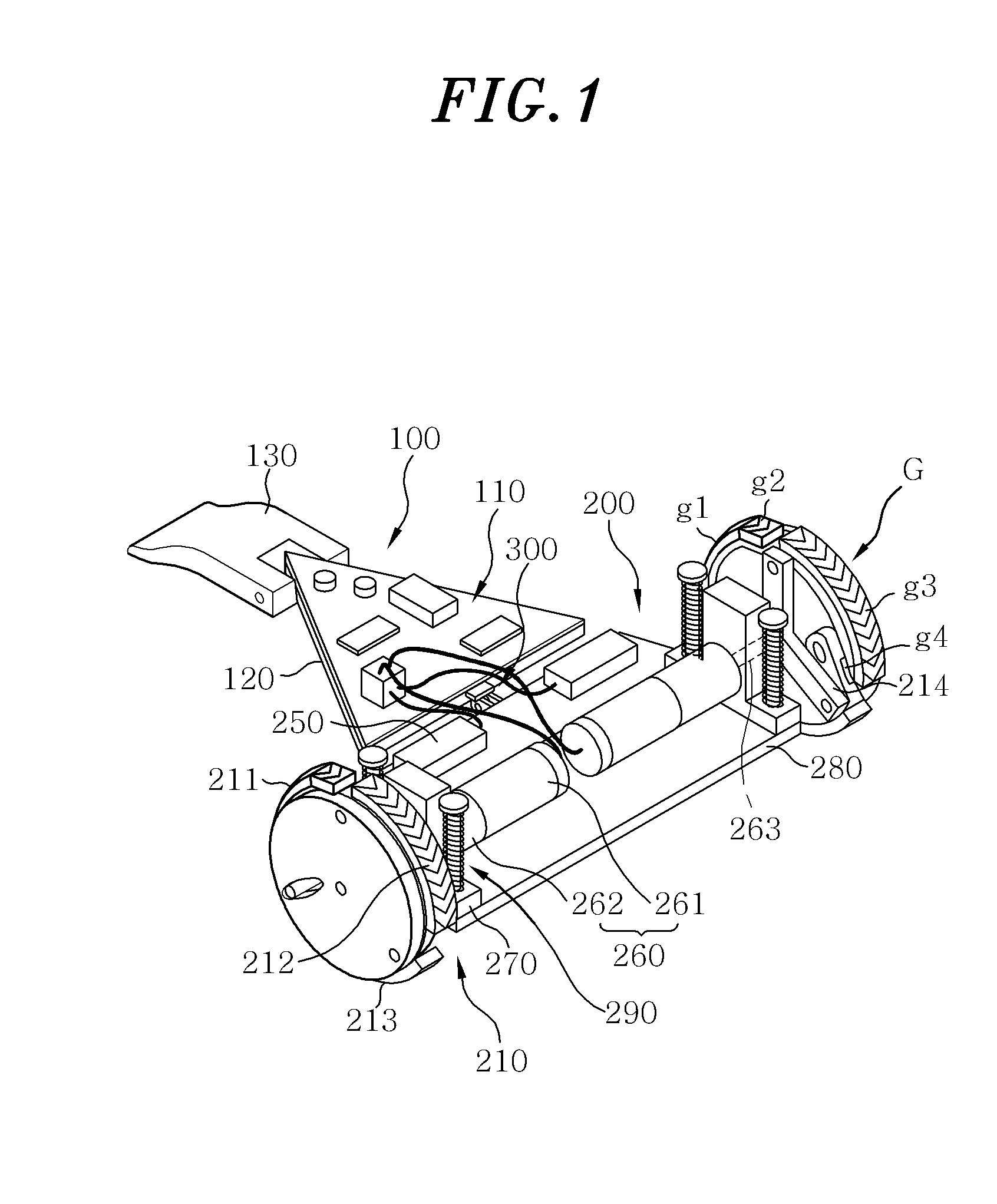

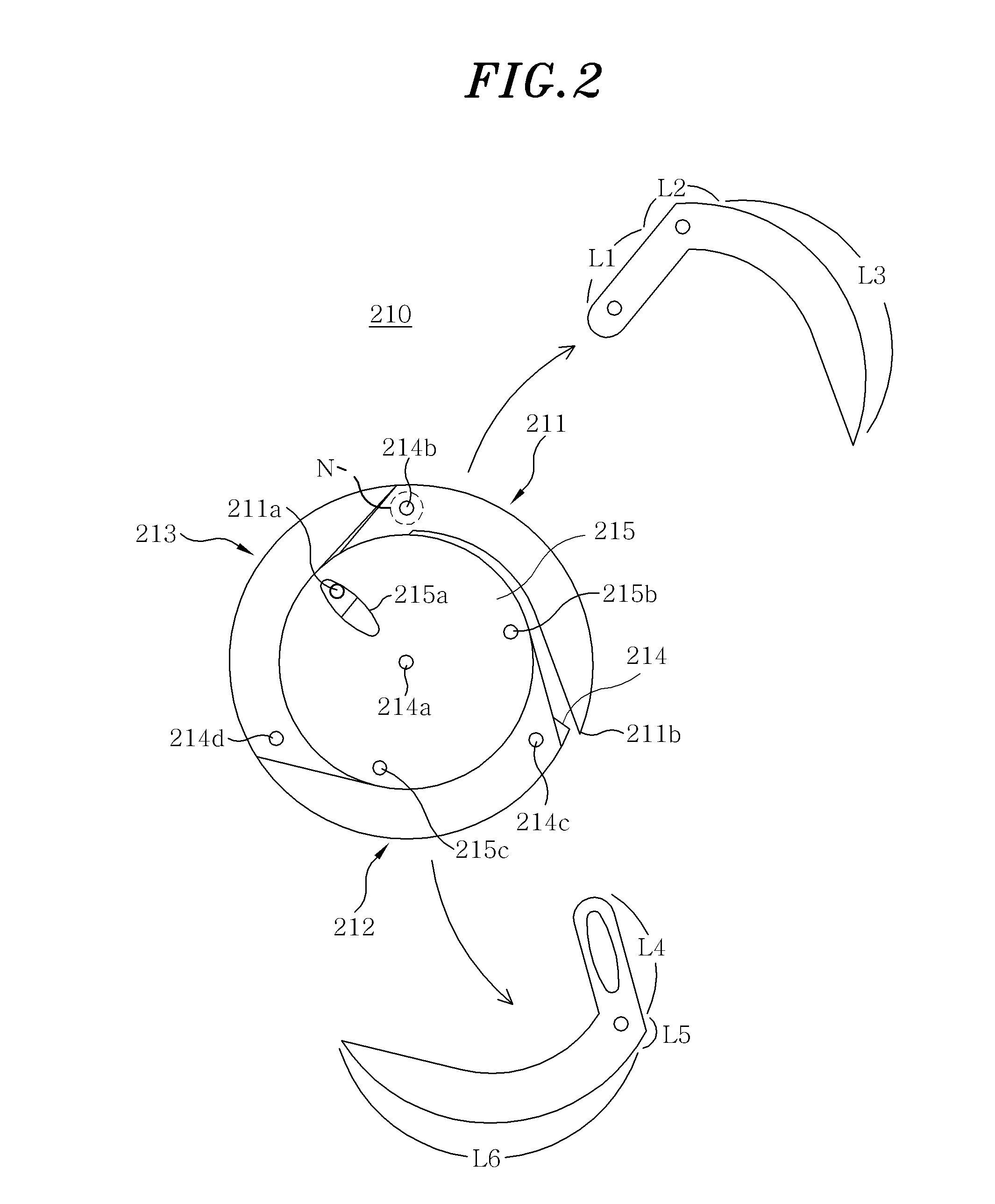

Passive transformable wheel and robot having the wheel

ActiveUS20140158439A1Simple structureReduce manufacturing costCarriage/perambulator accessoriesRimsJoint spacesMechanical engineering

A passively transformable wheel includes a wheel base including a centrally positioned transmitter rotation shaft and one or more passive leg rotation shafts positioned in the outer periphery; a force transmitter rotatably coupled to an end of the transmitter rotation shaft, the force transmitter including a trigger slide and one or more passive leg joints spaced apart from one another; a trigger leg arranged between the wheel base and the force transmitter and rotatably coupled to the trigger leg rotation shaft, the trigger leg including a trigger joint fitted to the trigger slide; andone or more passive legs arranged between the wheel base and the force transmitter so as not to interfere with the trigger leg and rotatably coupled to the passive leg rotation shafts, the passive legs including one or more passive leg slides engaging with the passive leg joints of the force transmitter.

Owner:SEOUL NAT UNIV R&DB FOUND

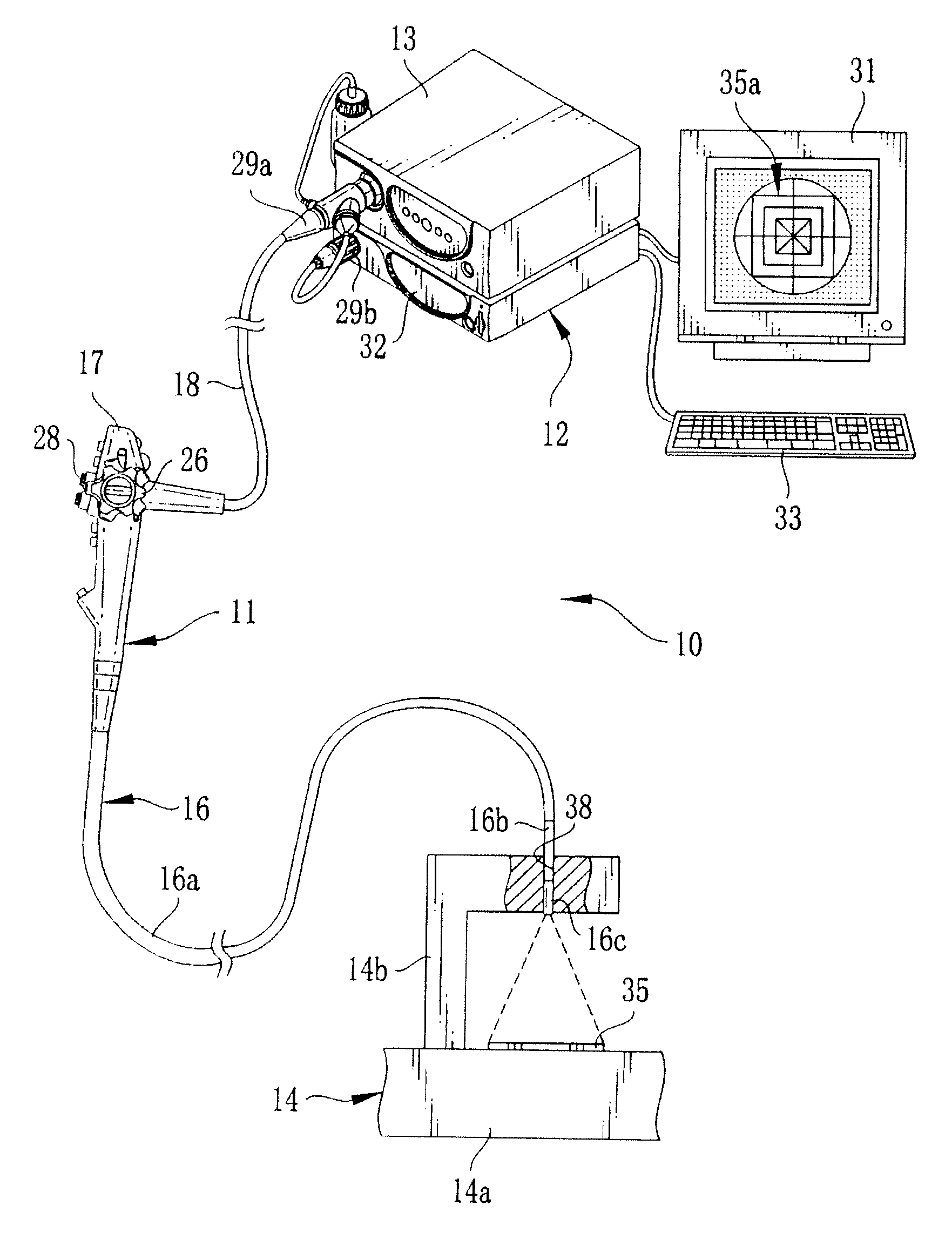

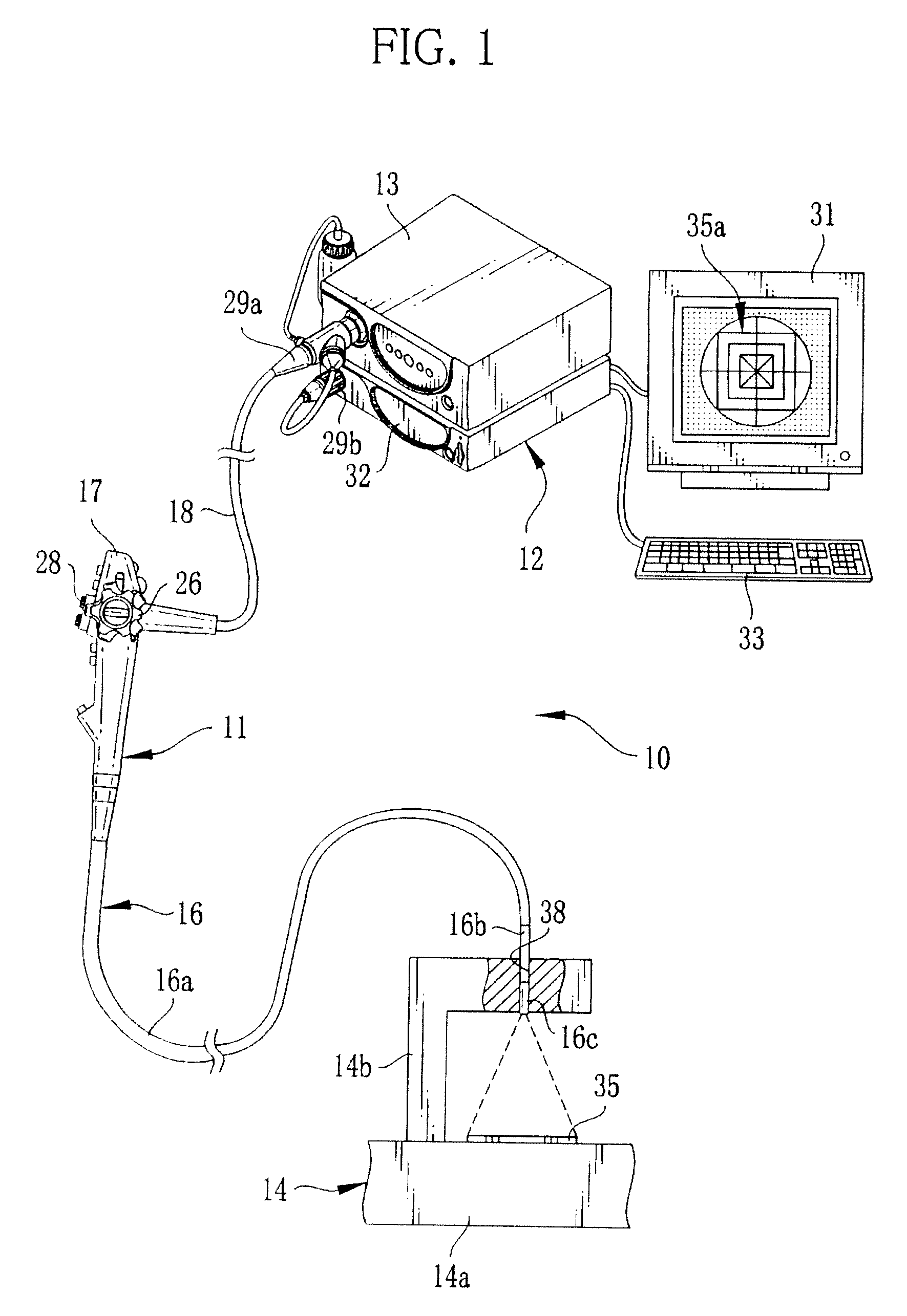

Apparatus and method for measuring displacement amount of endoscope image, electronic endoscope, and image processing device for endoscope

InactiveUS20100048993A1Reduce the burden onShort timeSurgeryEndoscopesImaging processingReference patterns

An image of a test chart having a test pattern is taken with an electronic endoscope. A DSP of a processing device generates a test pattern image from image signals input from the electronic endoscope. An image compositor composites the test pattern image and a test mask image having a predetermined reference pattern and generates a test mask composite image. An inspector visually measures positional and rotational displacement amounts of the test pattern with respect to the reference pattern in the test mask composite image displayed on a monitor, and inputs measurement results as displacement amount information to the processing device. The displacement amount information is stored in an EEPROM of the electronic endoscope. The processing device calibrates an endoscope image of a body cavity based on the displacement amount information input from the electronic endoscope.

Owner:FUJIFILM CORP

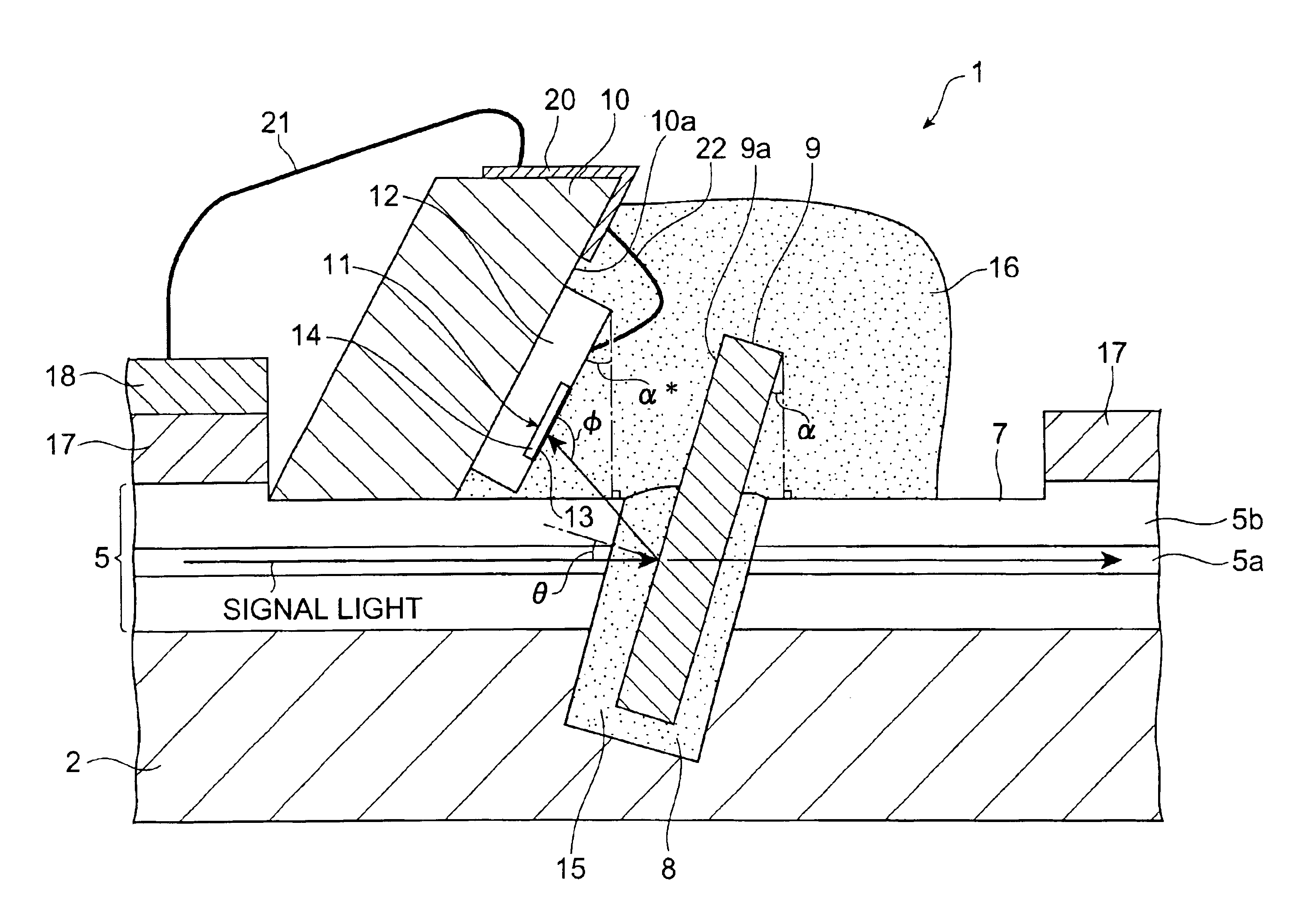

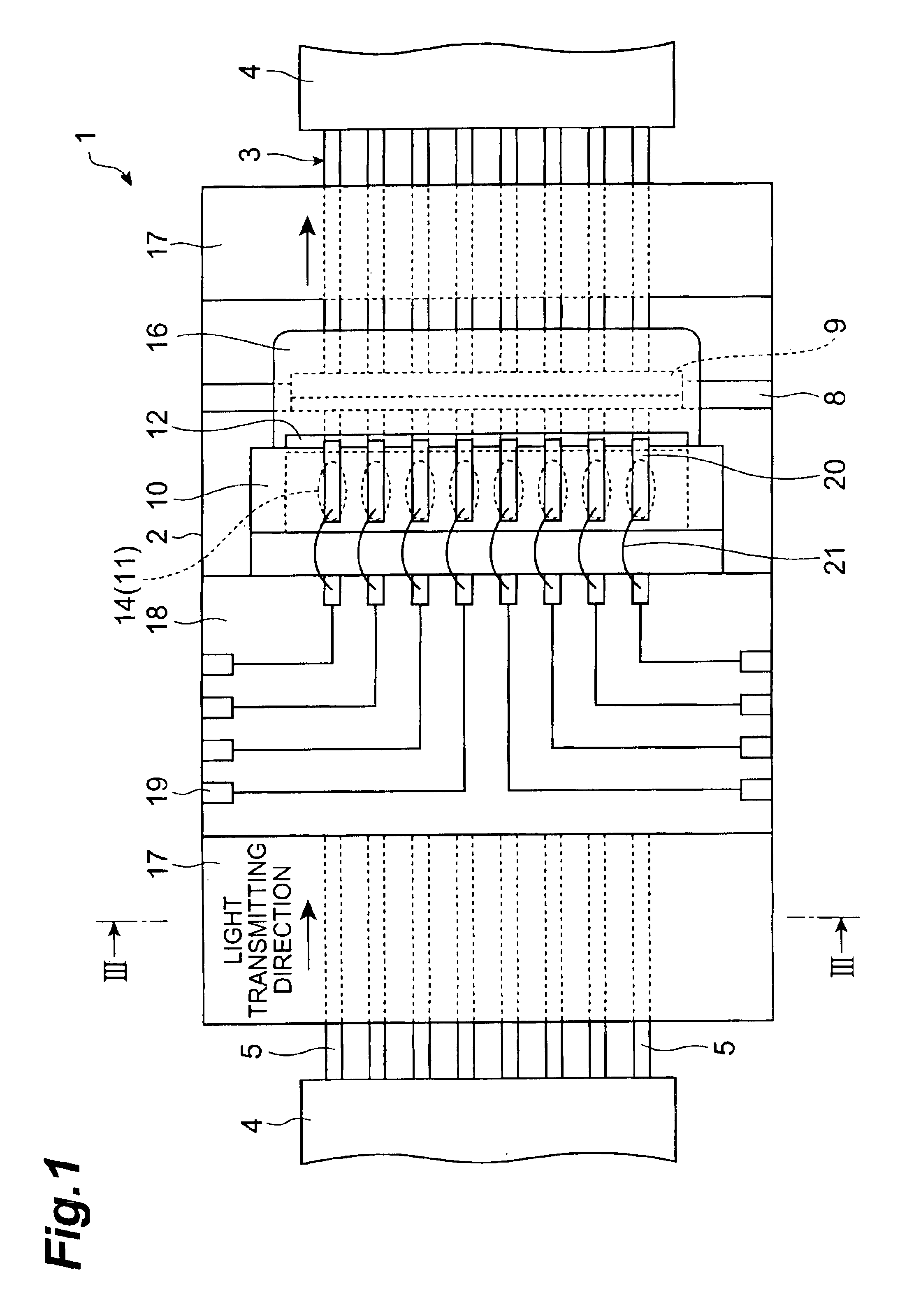

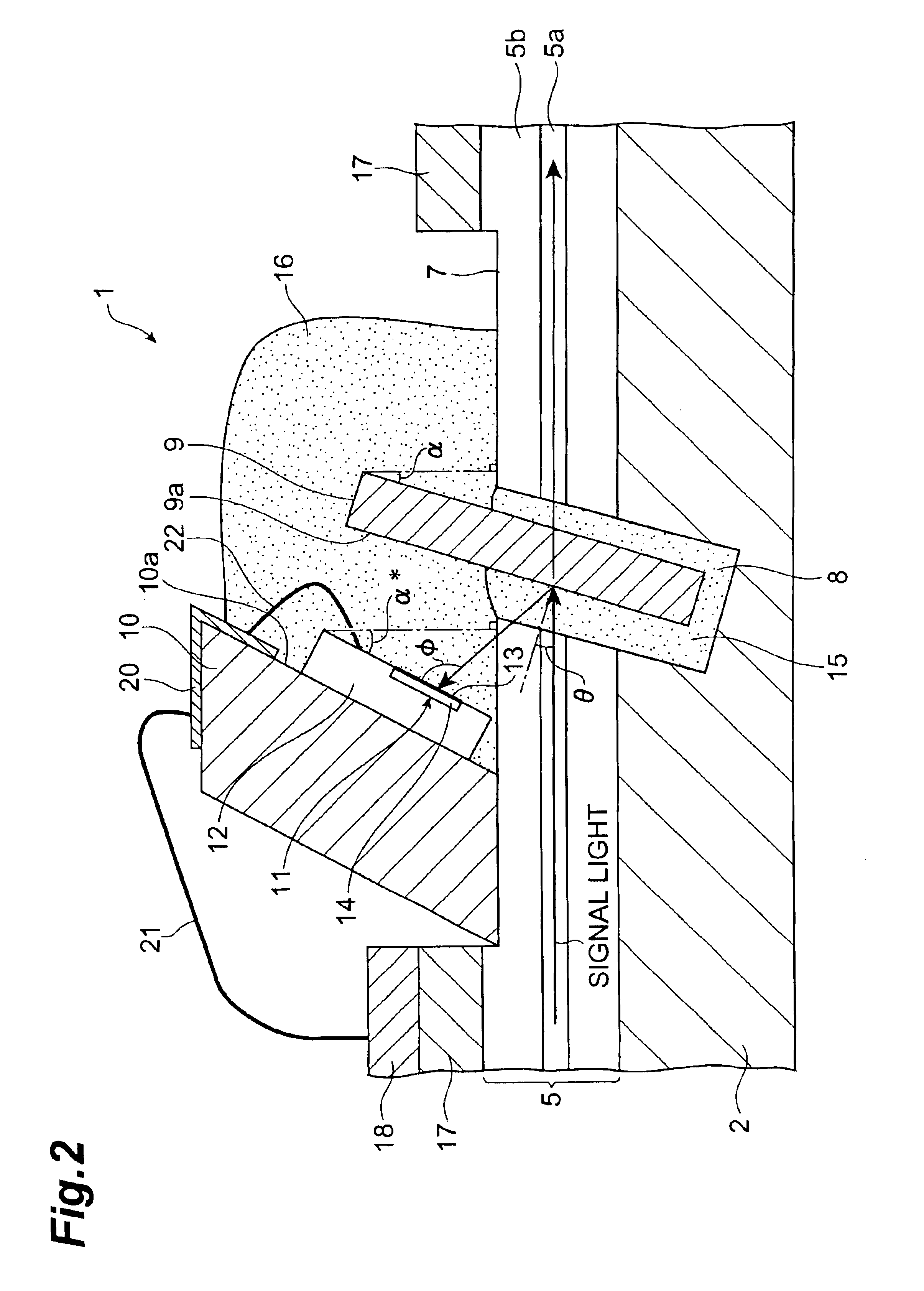

Optical device

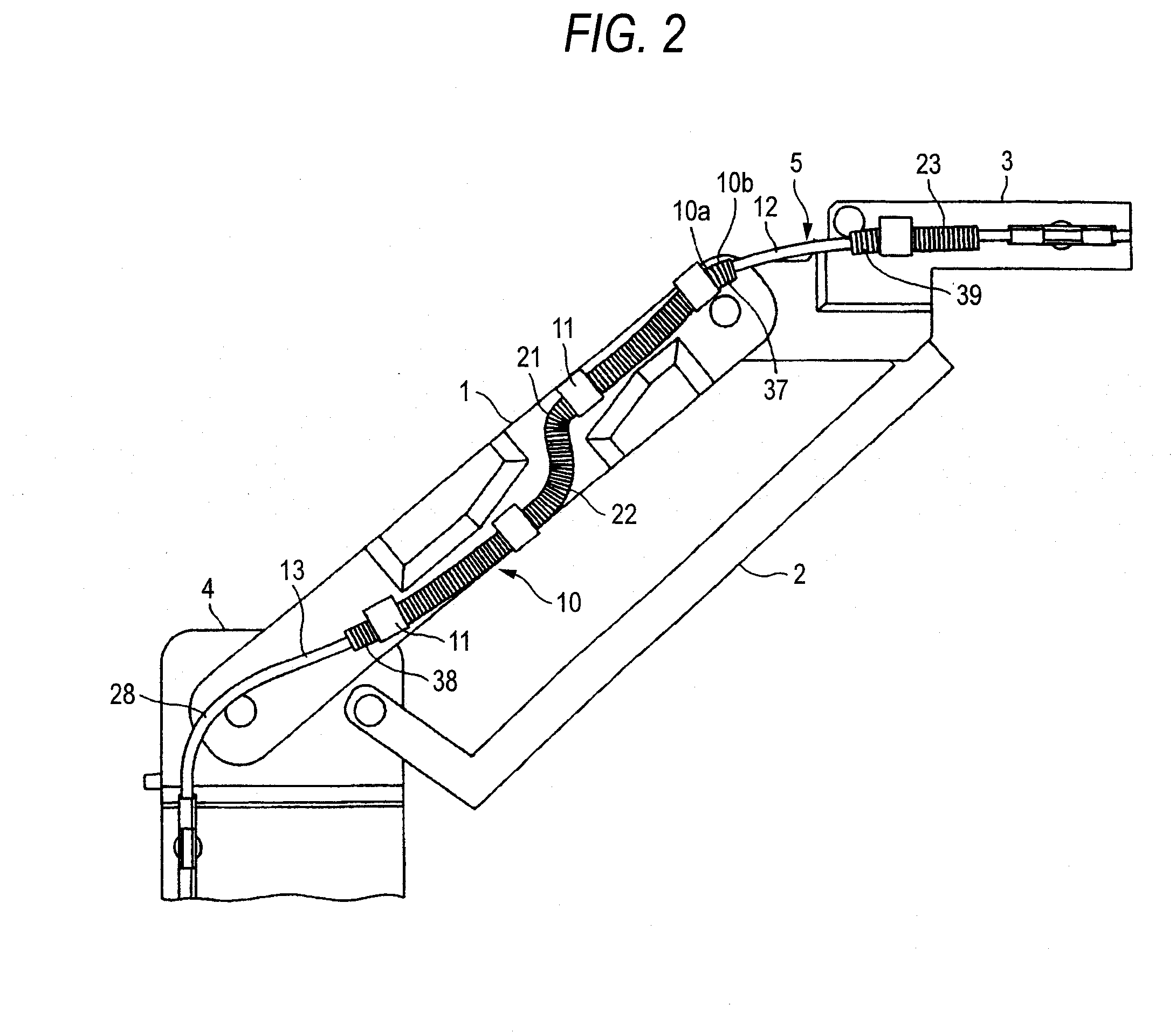

InactiveUS6850674B2Deterioration of characteristicCheap to achieveLaser detailsCoupling light guidesPhotovoltaic detectorsPhotodetector

An optical device 1 has a substrate 2, whereas bare fibers 5 exposed from a coated optical fiber tape 3 by removing a coating 4 from its middle part are secured to the upper face part of the substrate 2. In the substrate 2, a transverse groove 8 is formed obliquely with respect to an axis of the bare fibers 5 so as to traverse core parts 5a of the bare fibers. An optical member 9 for reflecting a part of signal light transmitted through the bare fibers 5 is inserted in the transverse groove 8. A support member 10 is provided on the upper side of the bare fibers 5, whereas a support surface 10a of the support member 10 is provided with photodetectors 11 for detecting light reflected by the optical member 9. The support surface 10a of the support member 10 is inclined with respect to the upper face of the substrate 2, whereby the light entrance surface 13 of each photodetector 11 is inclined by a predetermined angle with respect to the upper face of the substrate 2. Such a configuration realizes an optical device which can lower the polarization dependence of received light in the photodetectors.

Owner:SUMITOMO ELECTRIC IND LTD

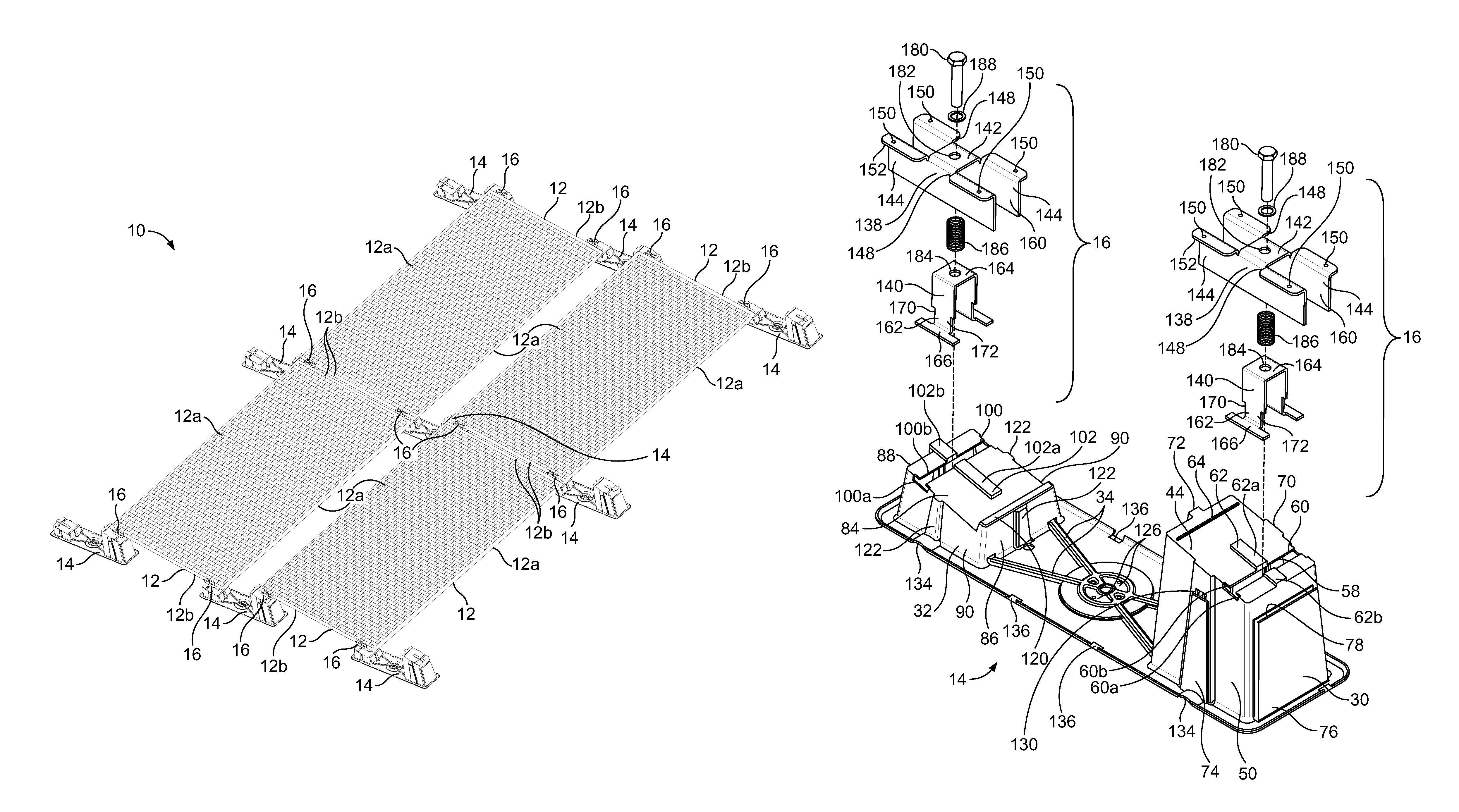

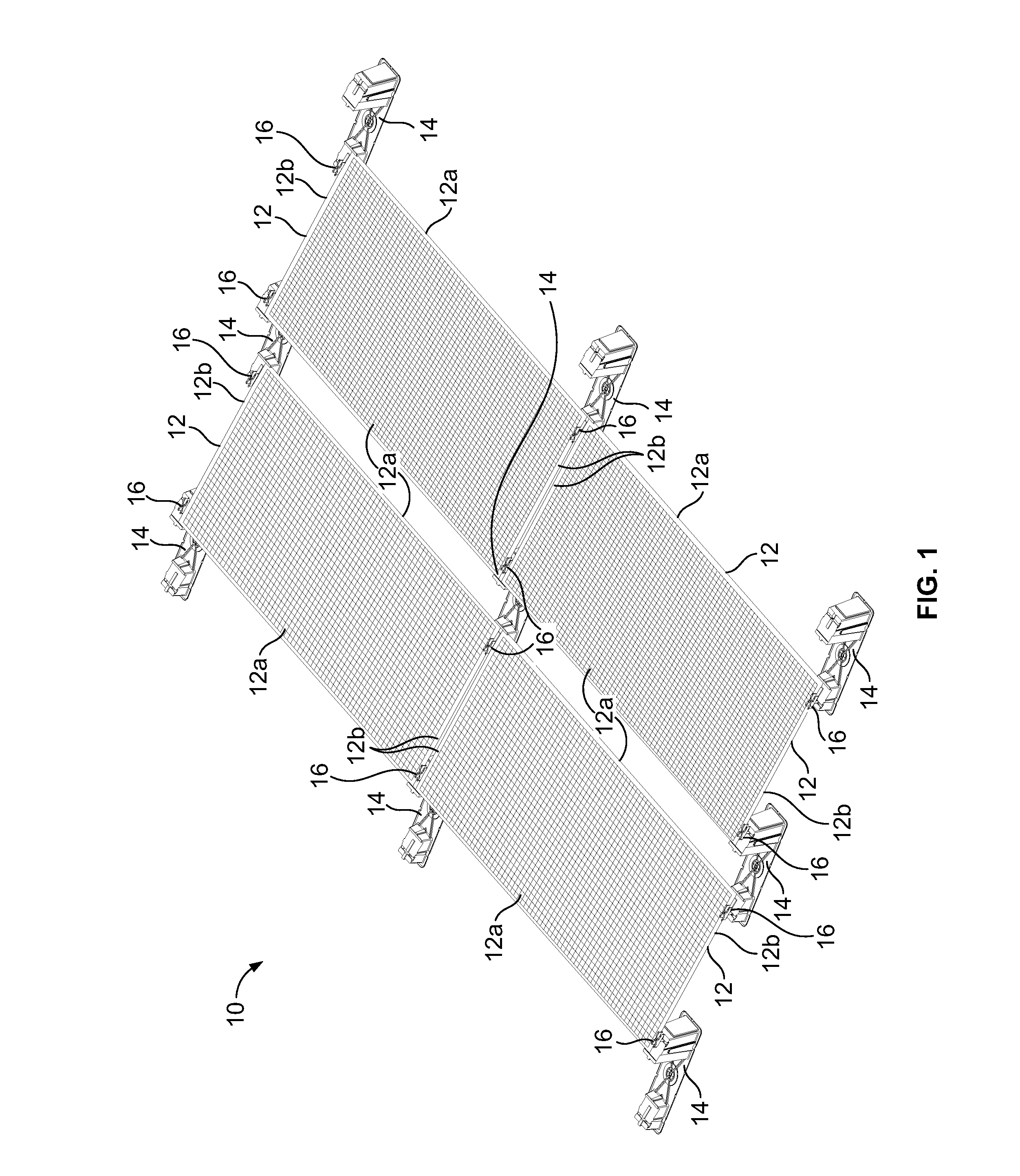

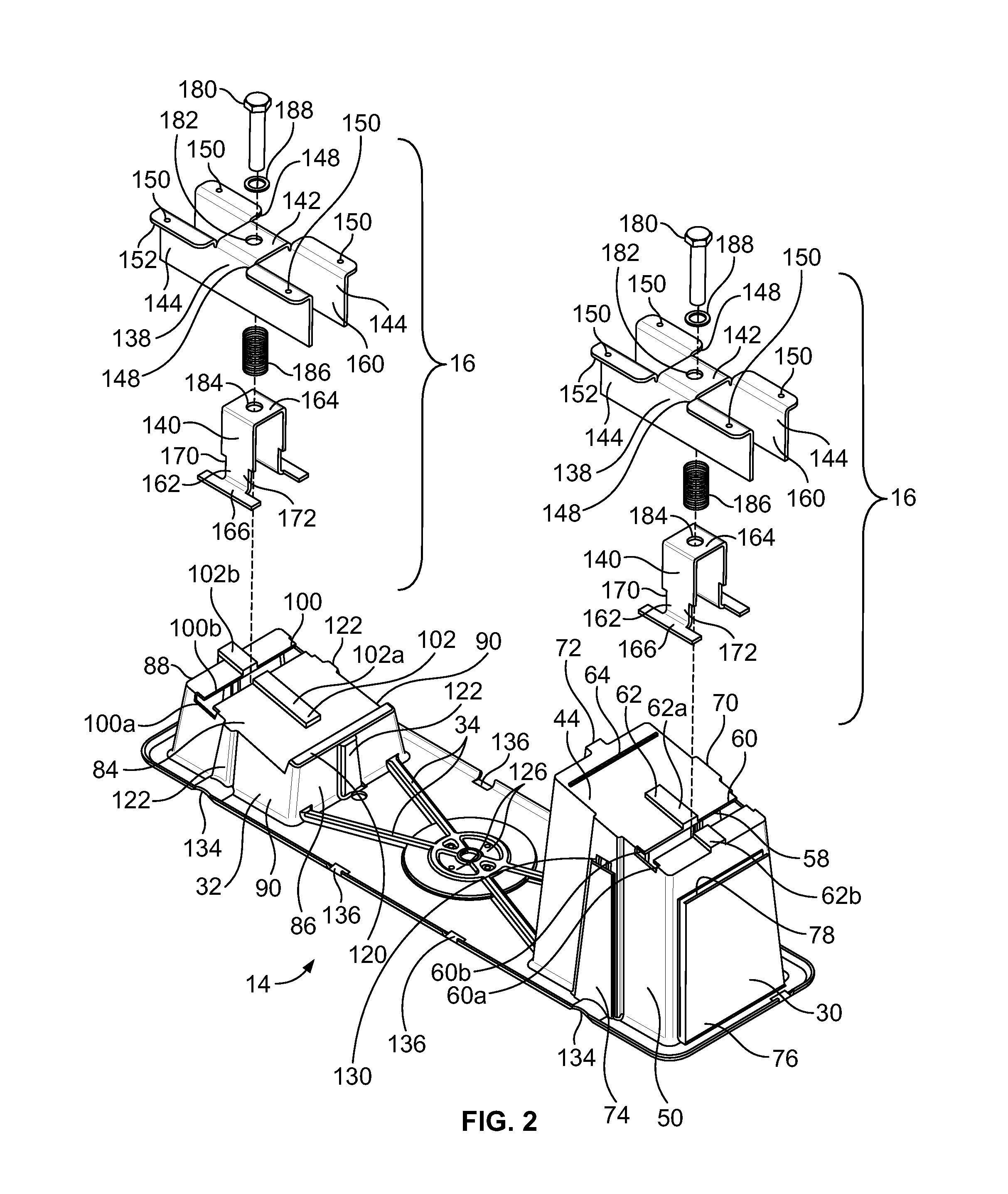

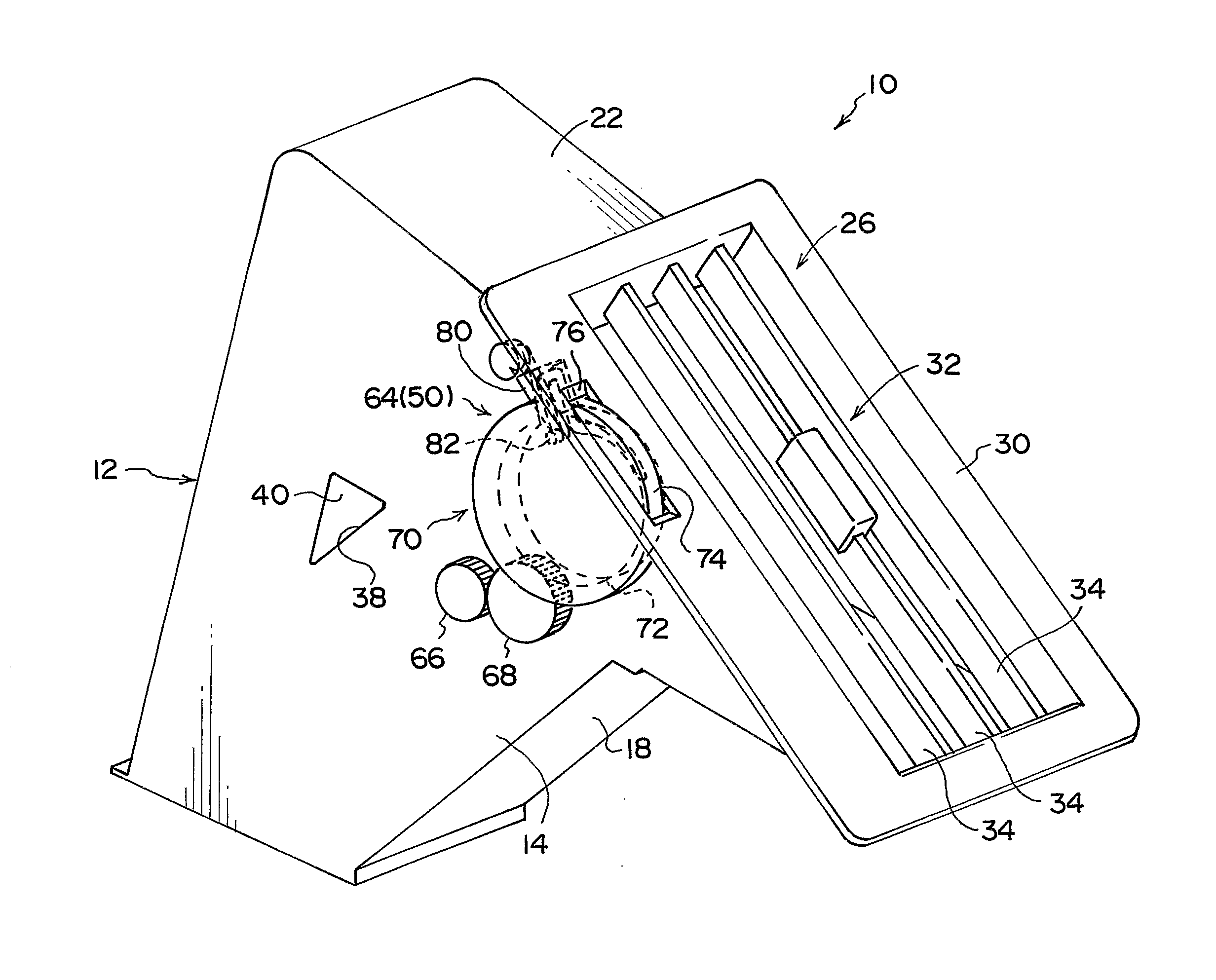

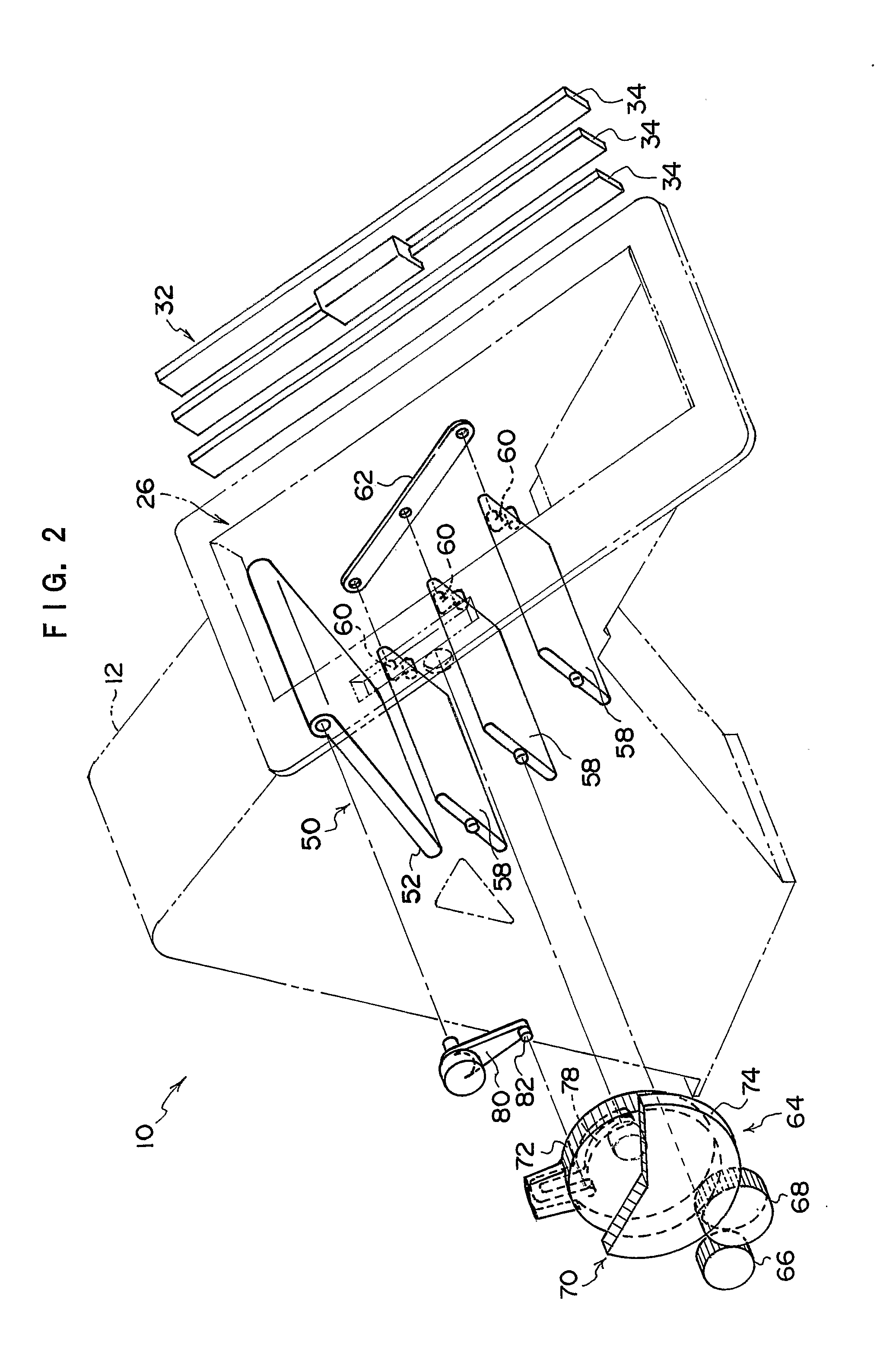

System for mounting solar modules

InactiveUS8875453B2Low costReduce part costPhotovoltaic supportsSolar heating energyComputer moduleEngineering

A system for mounting solar modules comprising a plurality of racks and clamps. Each rack has an inclined upper mounting surface to support one of the solar modules and an inclined lower mounting surface to support one of the other solar modules. Each upper mounting surface and lower mounting surface define a slot. One of the clamps slidably receivable by a slot of one of the upper mounting surfaces and configured to secure the one solar modules to the upper mounting surfaces and an other of the clamps slidably receivable by a slot of one of the lower mounting surfaces and configured to secure said one of the other solar modules to one of the lower mounting surfaces. Each rack has a tray having a first tower supporting the upper mounting surface and a second tower supporting the lower mounting surface.

Owner:KANZO PROD

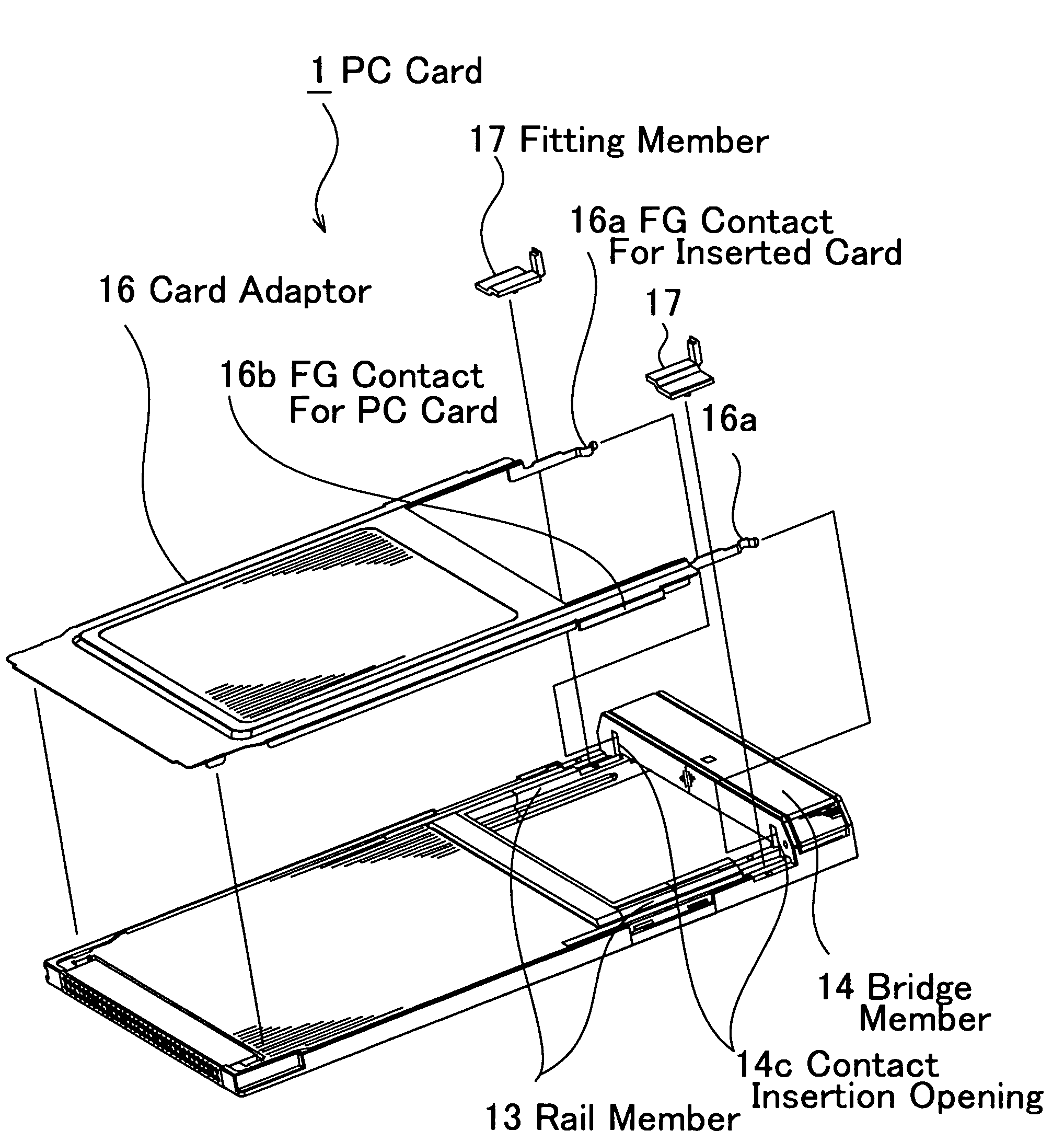

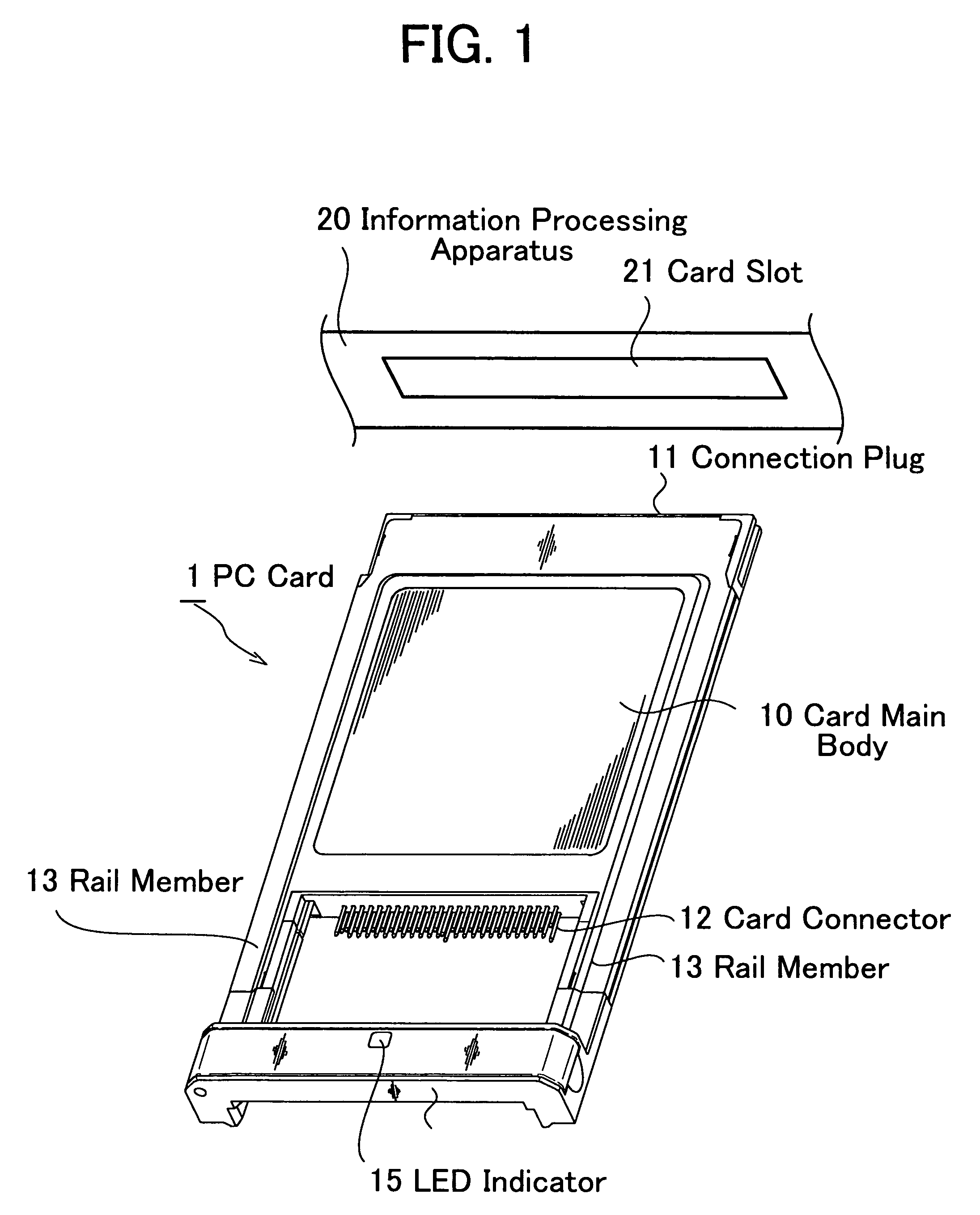

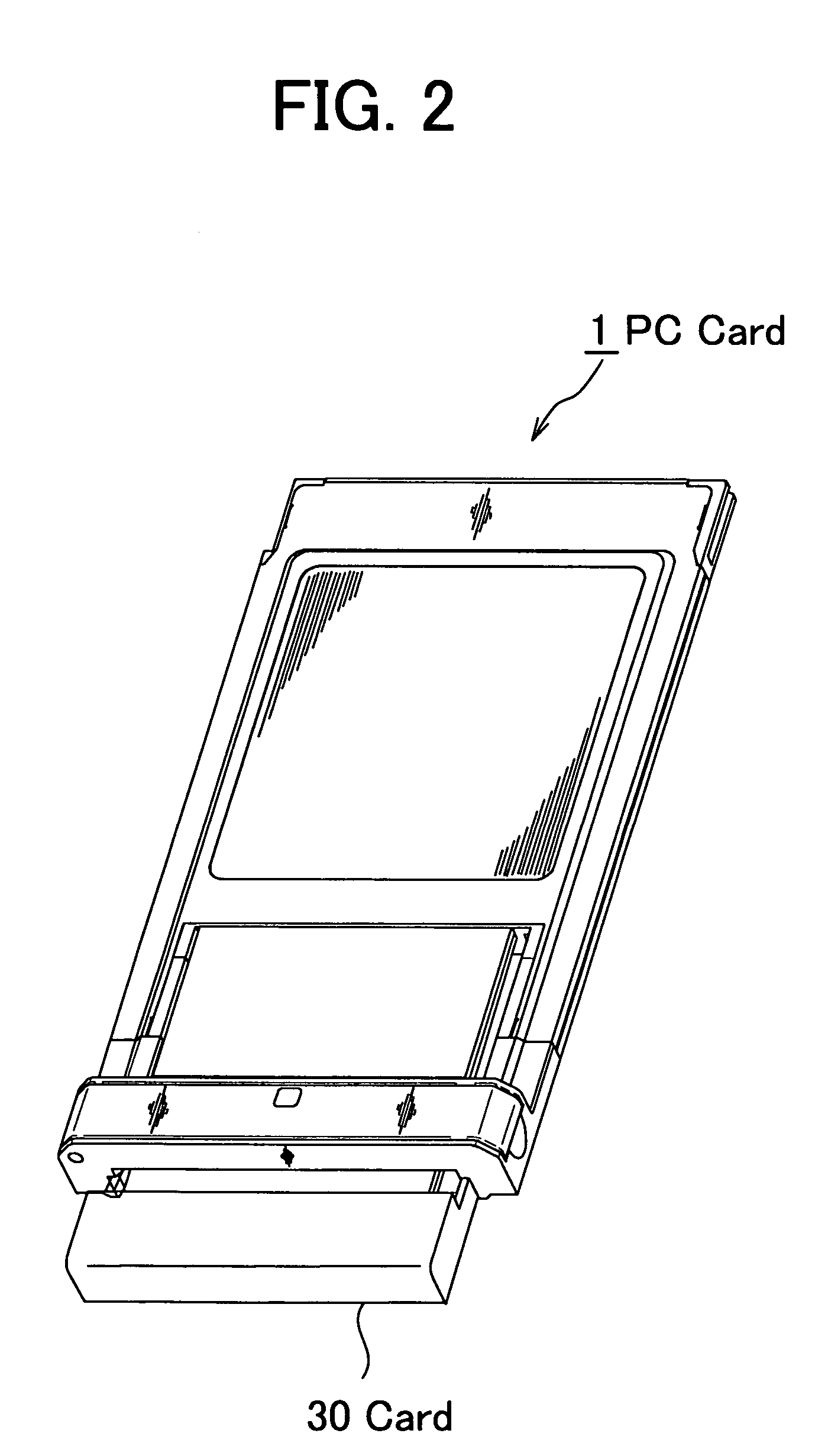

PC card

InactiveUS7265989B2Improve performanceImprove stabilityMagnetic/electric field screeningSensing record carriersInformation processingComputer hardware

Owner:SOFTBANK BB CORP +1

Pressure measurement module

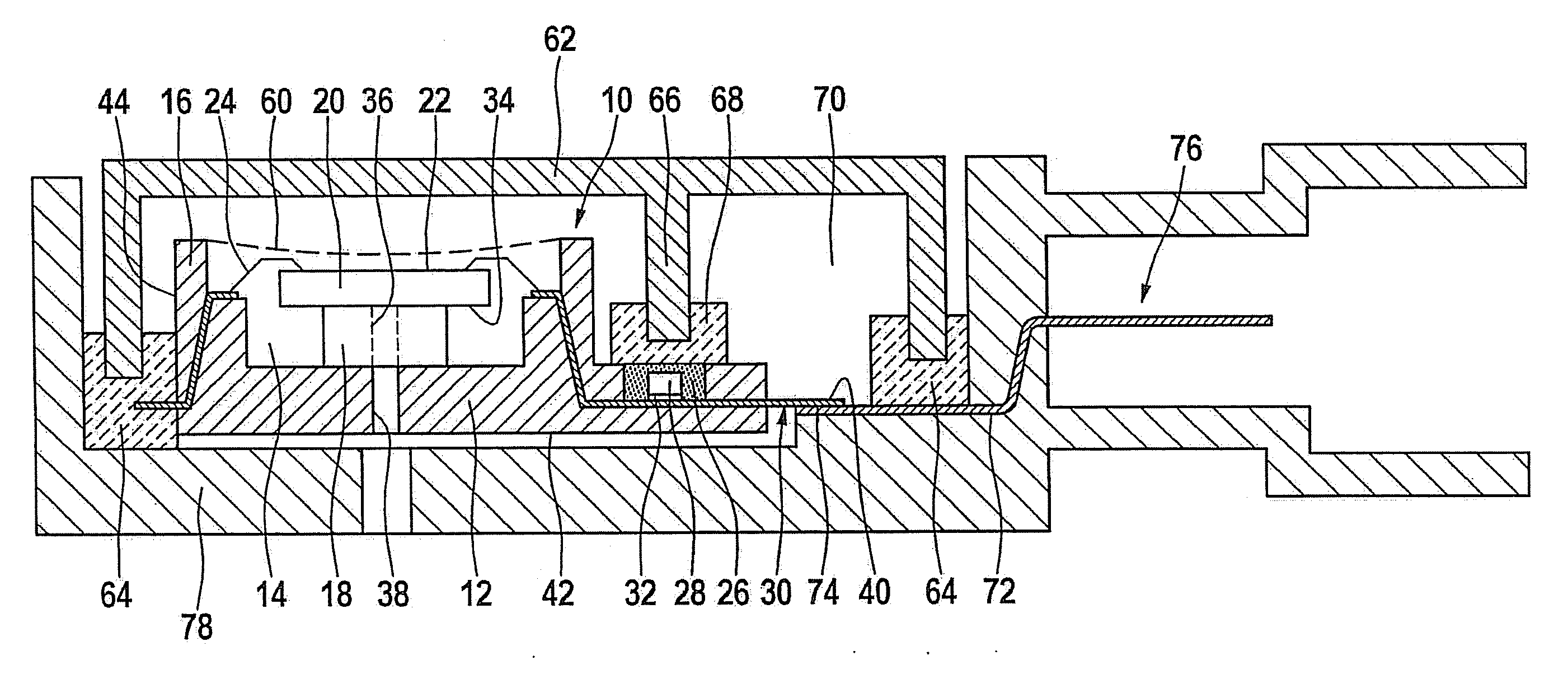

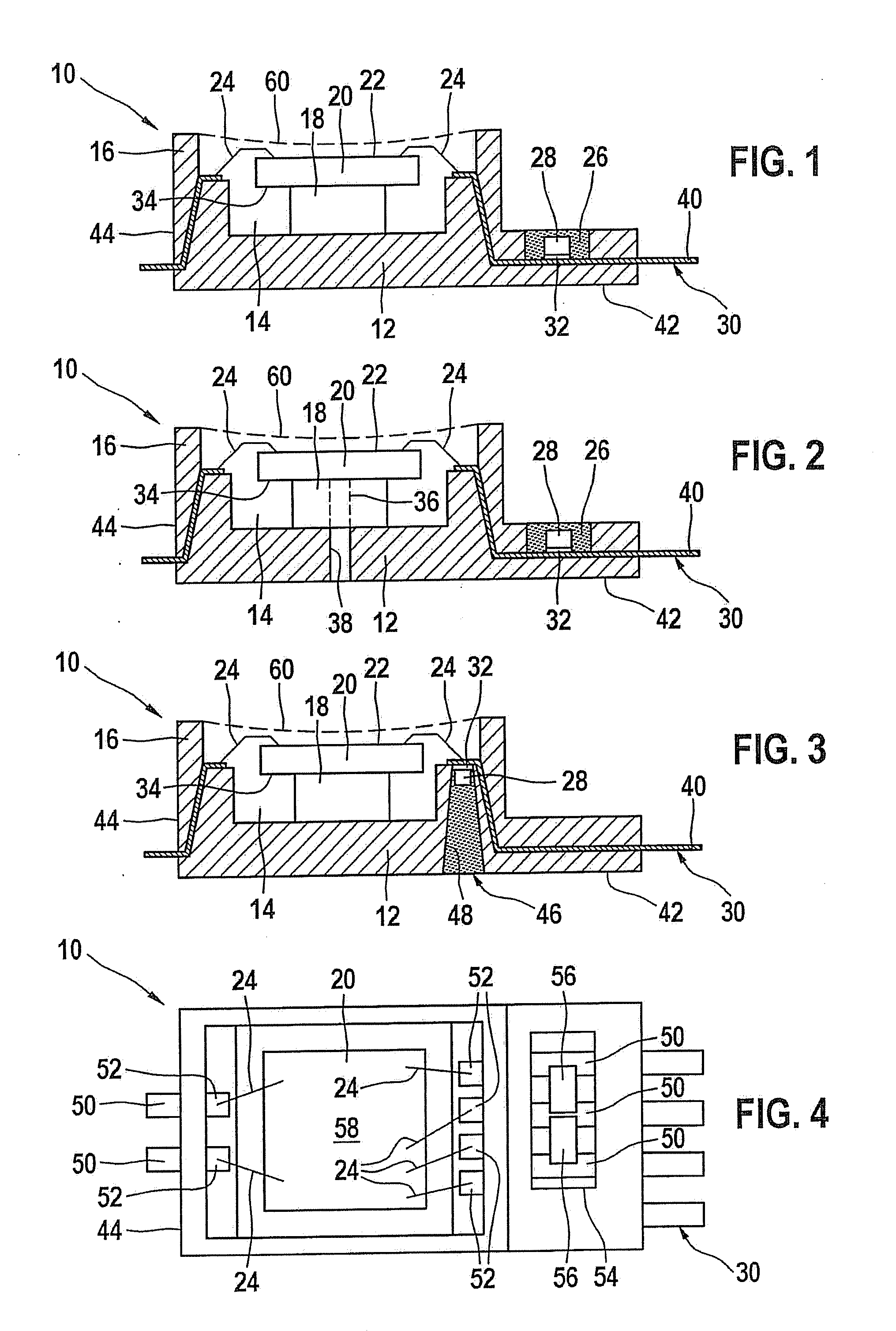

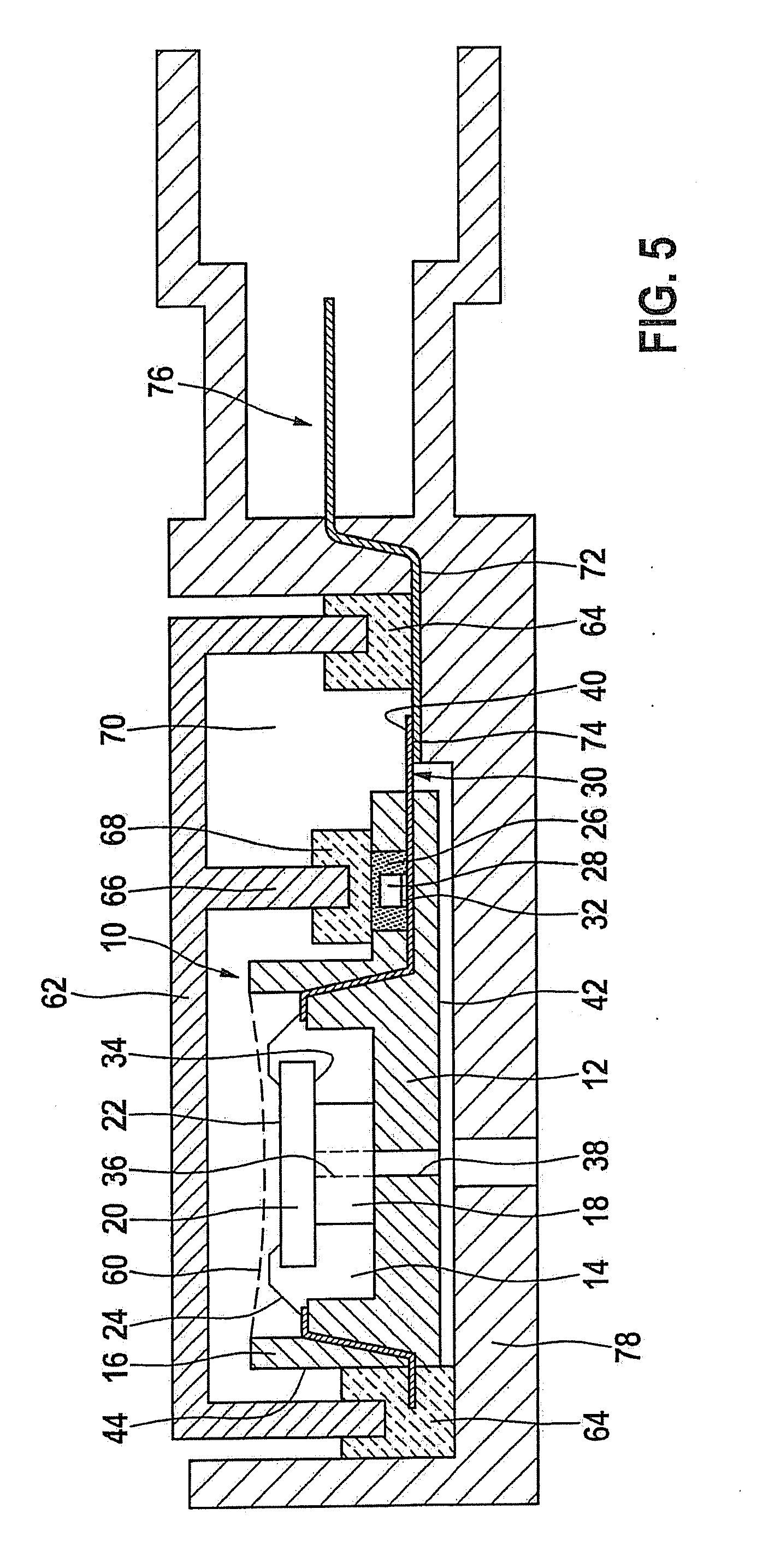

ActiveUS20110016981A1Improve the immunitySimpler and flexibleFluid pressure measurement by electric/magnetic elementsPrinted circuit manufactureElectricityRelative pressure

A pressure measuring module for recording an absolute pressure or a relative pressure. Pressure measuring module includes a housing produced preferably as a premold, in which a pressure measuring chip is accommodated. The latter is contacted electrically either to a lead frame or to at least one printed circuit trace, at least one electronic component being provided, which is connected to a section of the lead frame or of the at least one printed circuit trace, exiting laterally from the housing that is produced as a premold, and is covered by a partition of a cover.

Owner:ROBERT BOSCH GMBH

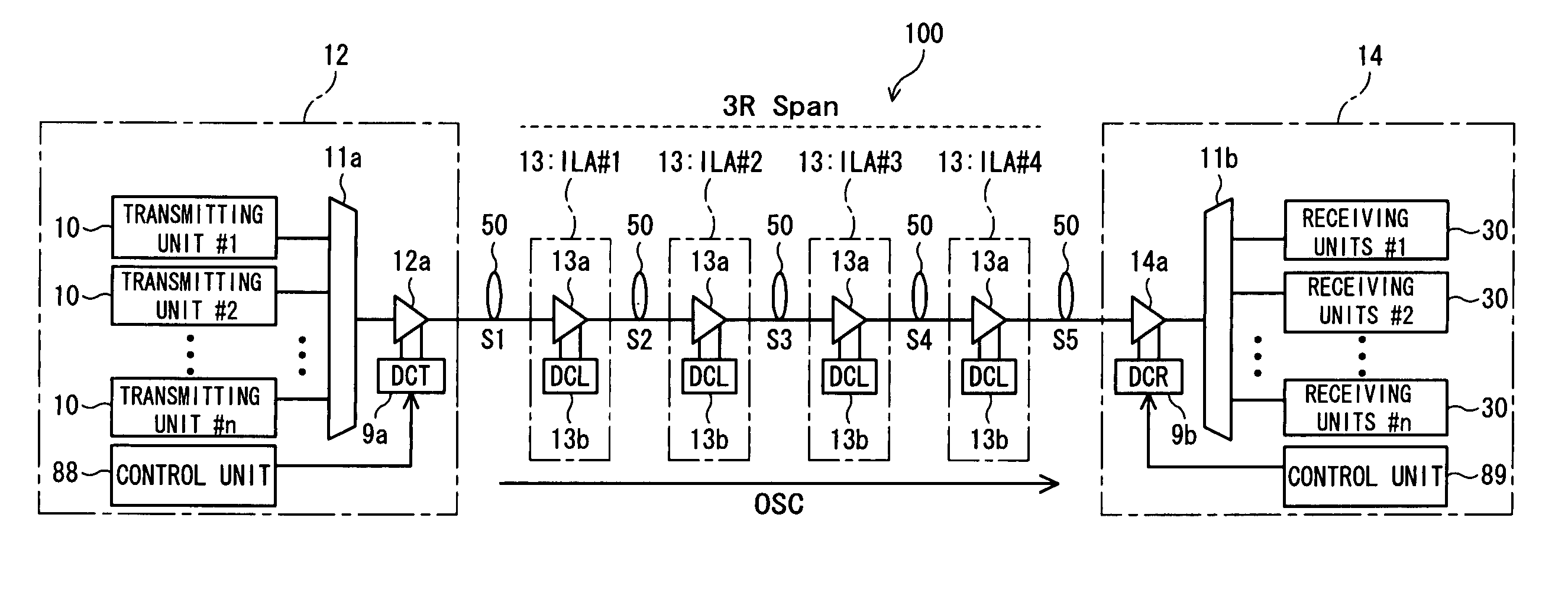

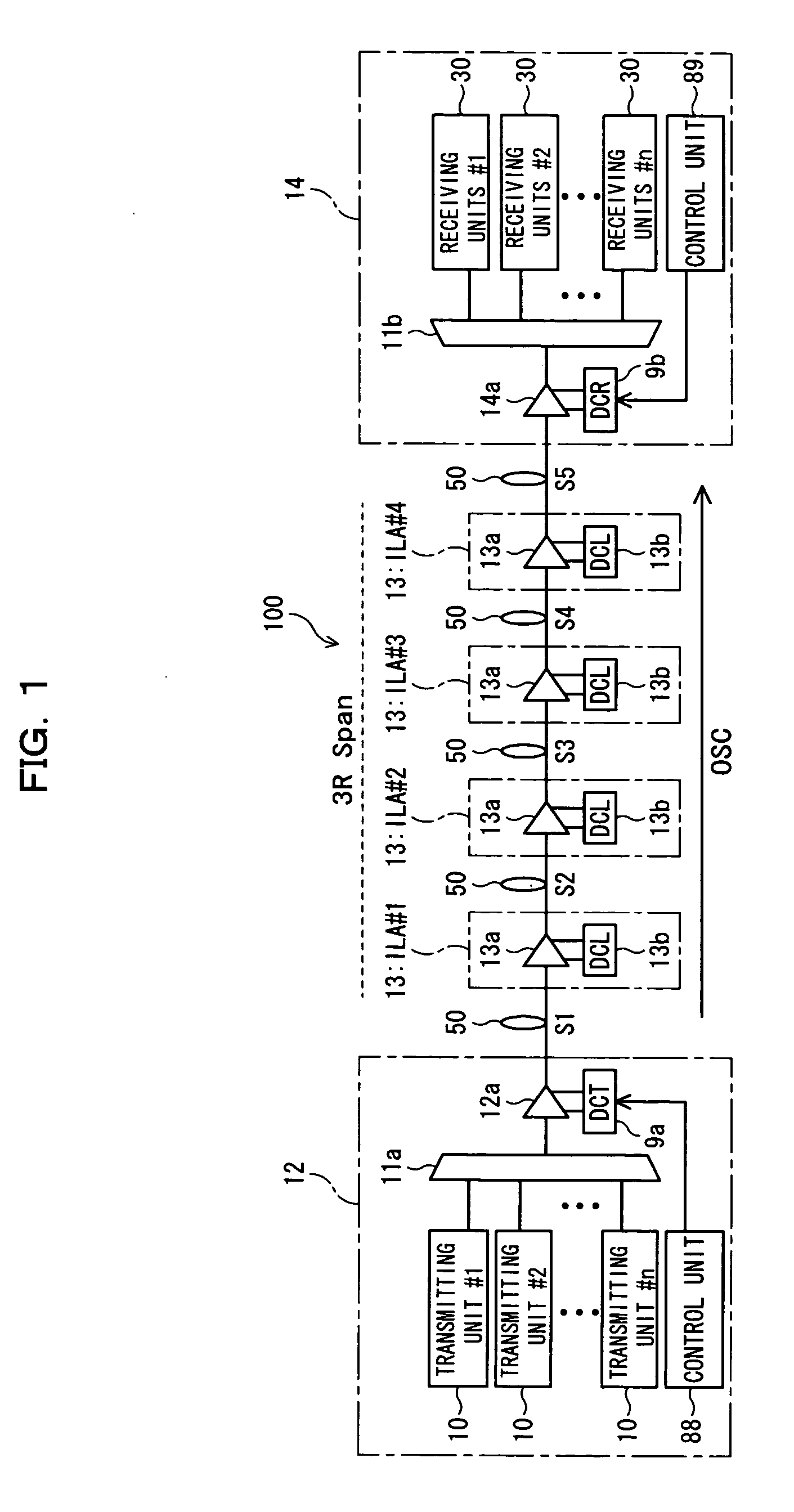

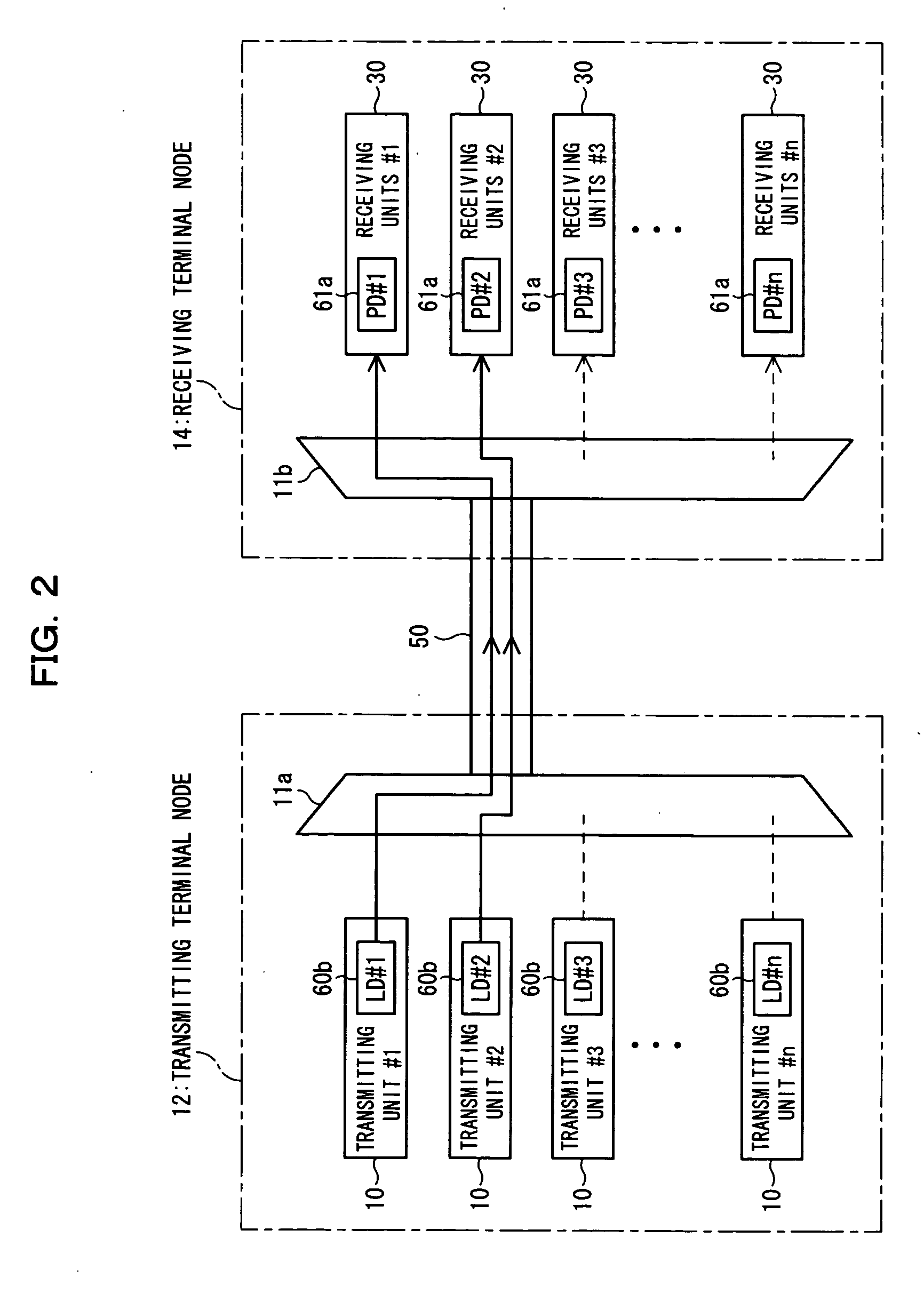

Dispersion compensation quantity setting method, receiving terminal station, and wavelength-multiplexing optical transmission system

InactiveUS20050238362A1Quality improvementImprove reliabilityWavelength-division multiplex systemsDistortion/dispersion eliminationWdm transmission systemsTransport system

In a dispersion compensation quantity setting technique for use in a WDM transmission system, a transmitting terminal node transmits CW light and modulated light obtained by modulation using a modulation pattern signal, while a receiving terminal node detects a physical quantity stemming from cross phase modulation occurring between the transmitting terminal node and the receiving terminal node on the basis of a variation of an intensity of the transmitted CW light and sets a dispersion compensation quantity on the basis of a variation of the detected physical quantity. Moreover, this optimizes the crosstalk, suppresses the output power of transmitted light, eliminates the nonlinear optical effect of the transmitted light, and carries out dispersion compensation superior in cost performance.

Owner:FUJITSU LTD

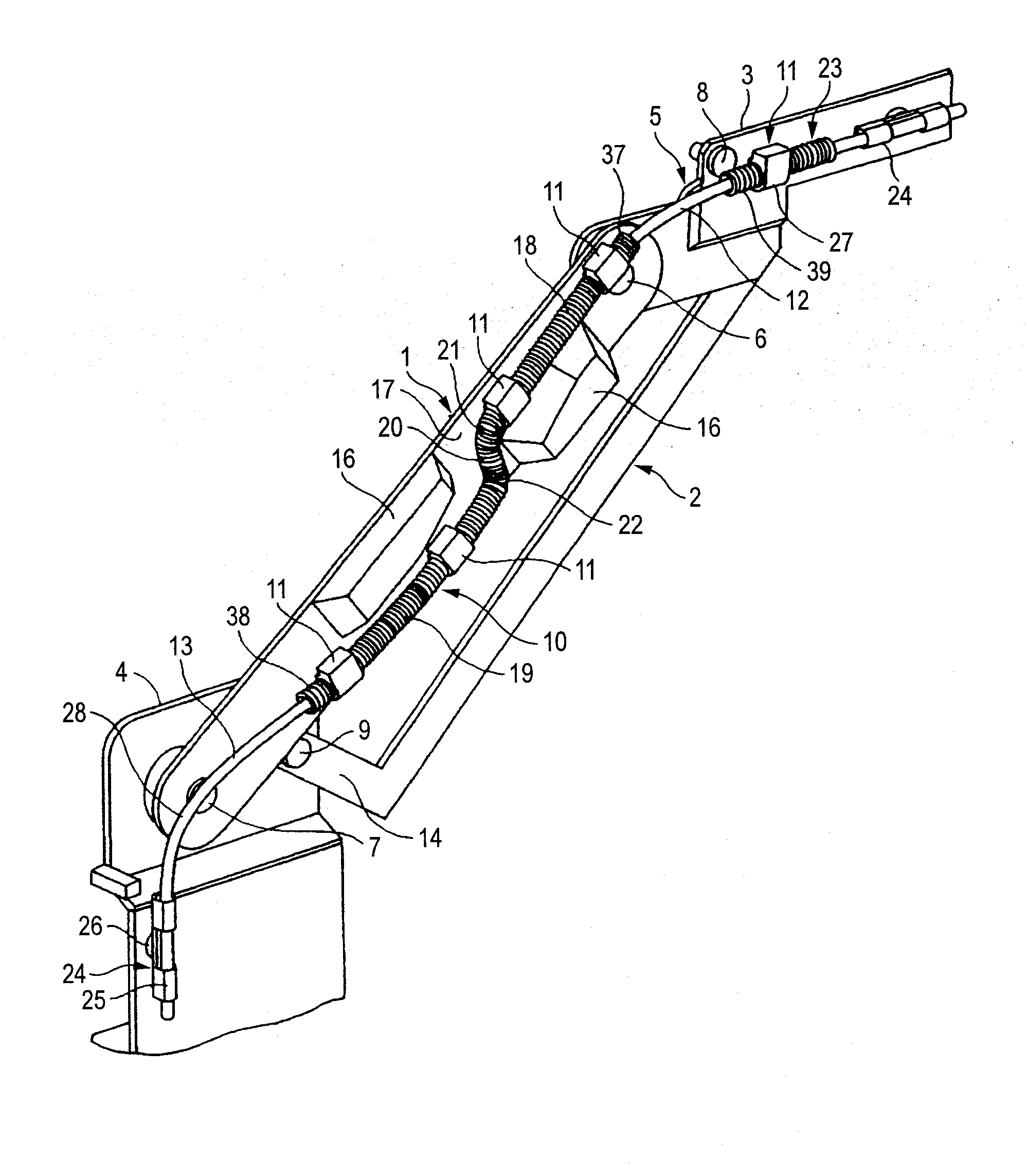

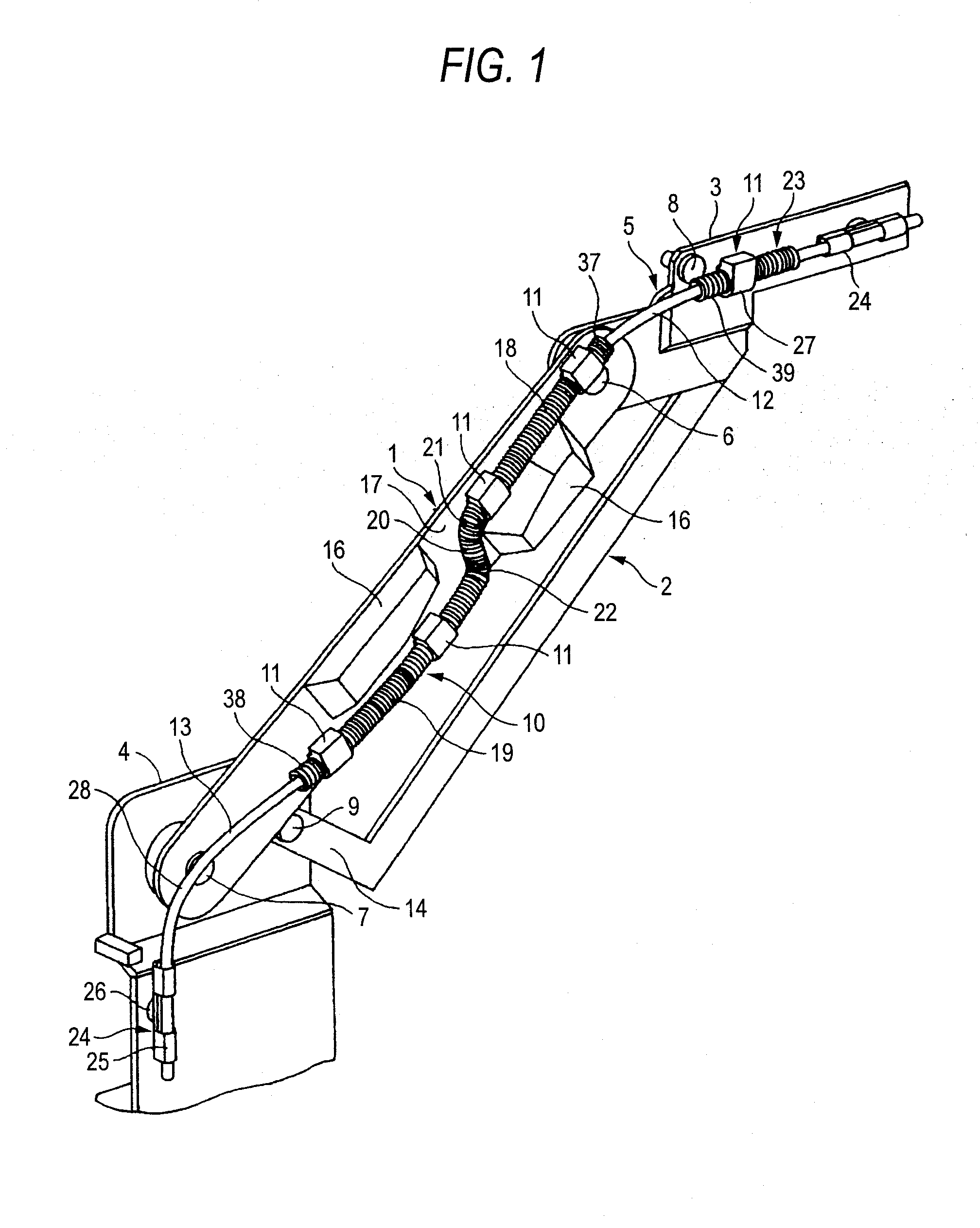

Installing structure of wire harness

ActiveUS20080035800A1Promote absorptionAvoid damagePipe supportsSemiconductor/solid-state device detailsEngineeringMechanical engineering

Owner:YAZAKI CORP

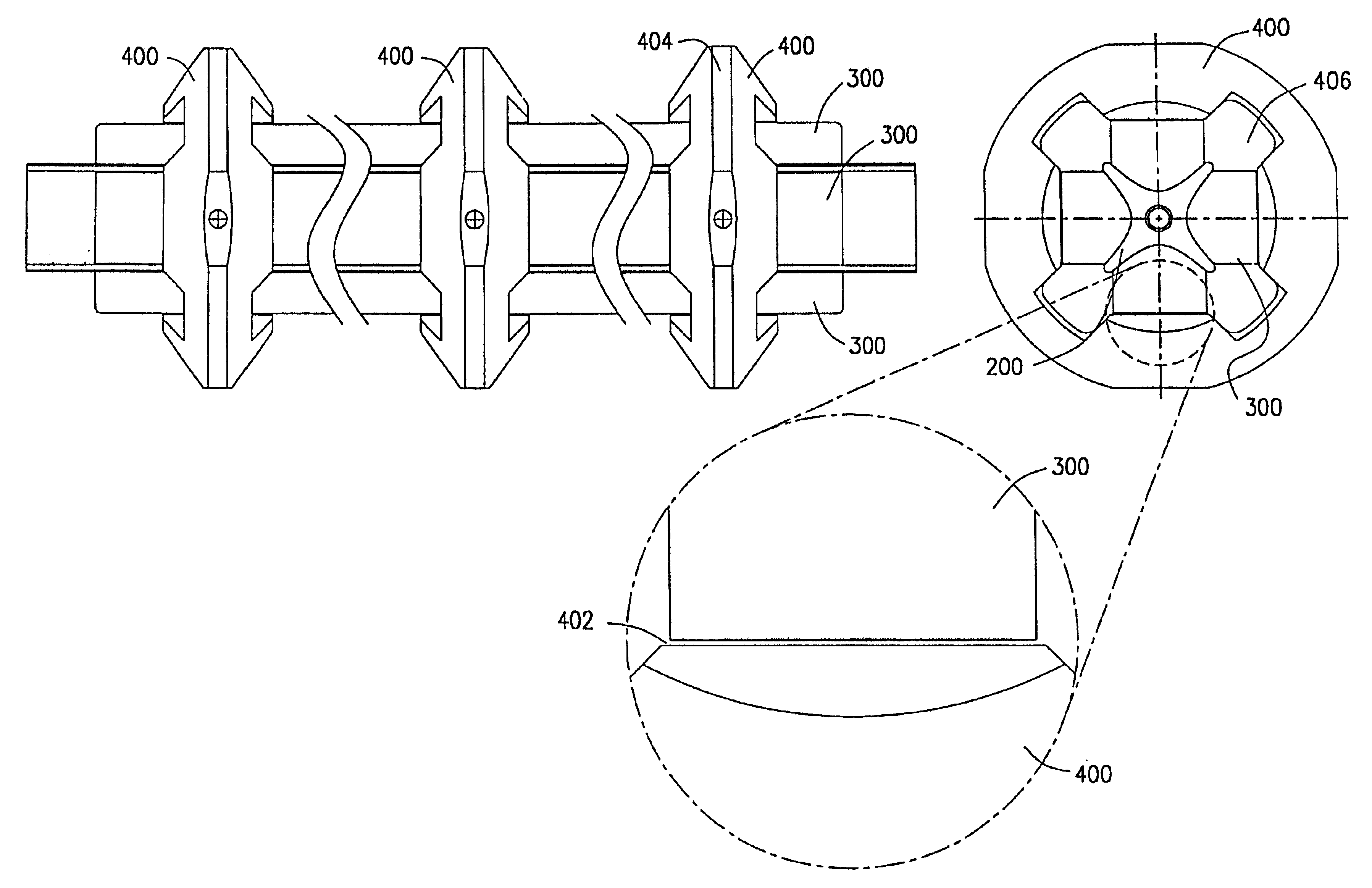

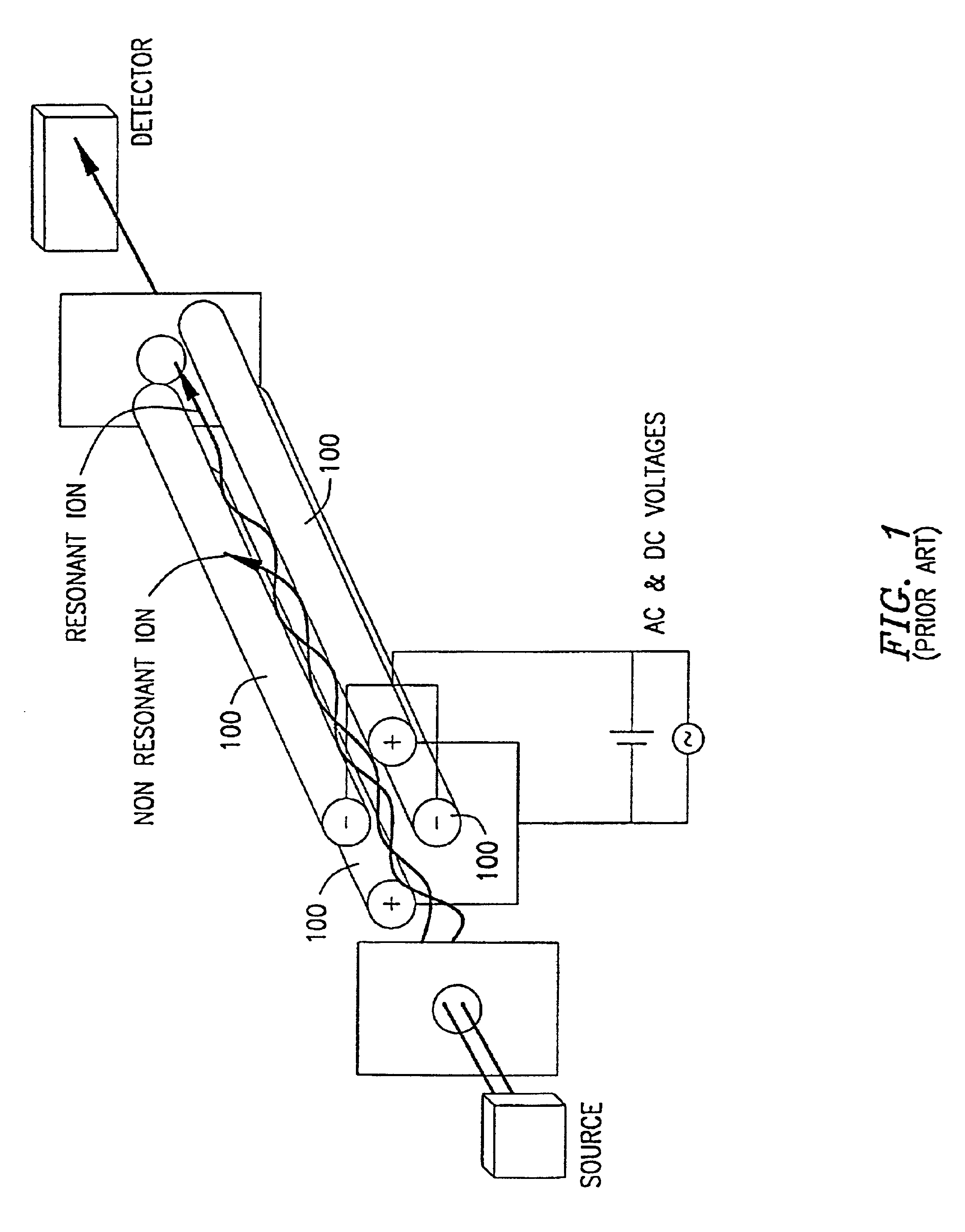

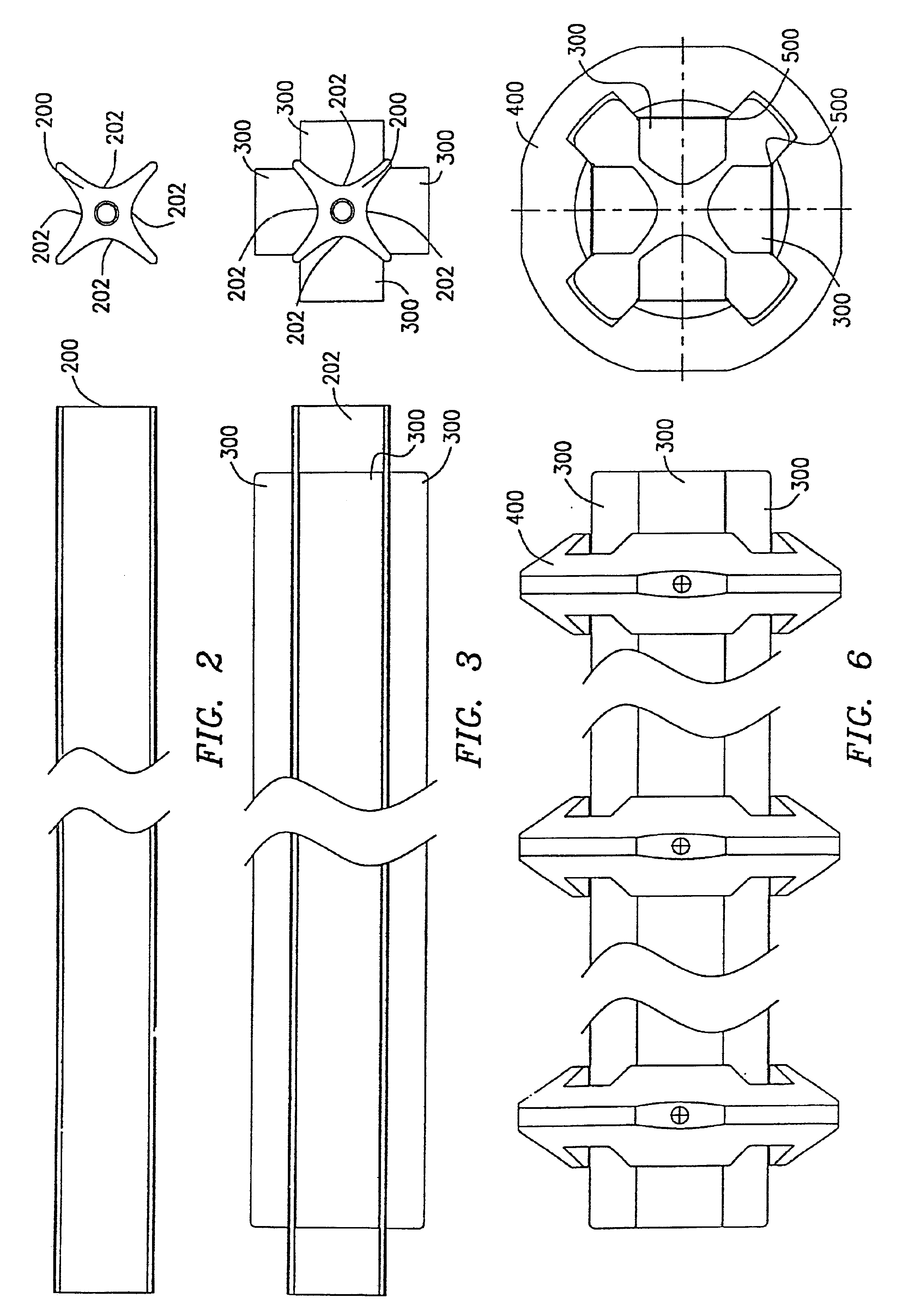

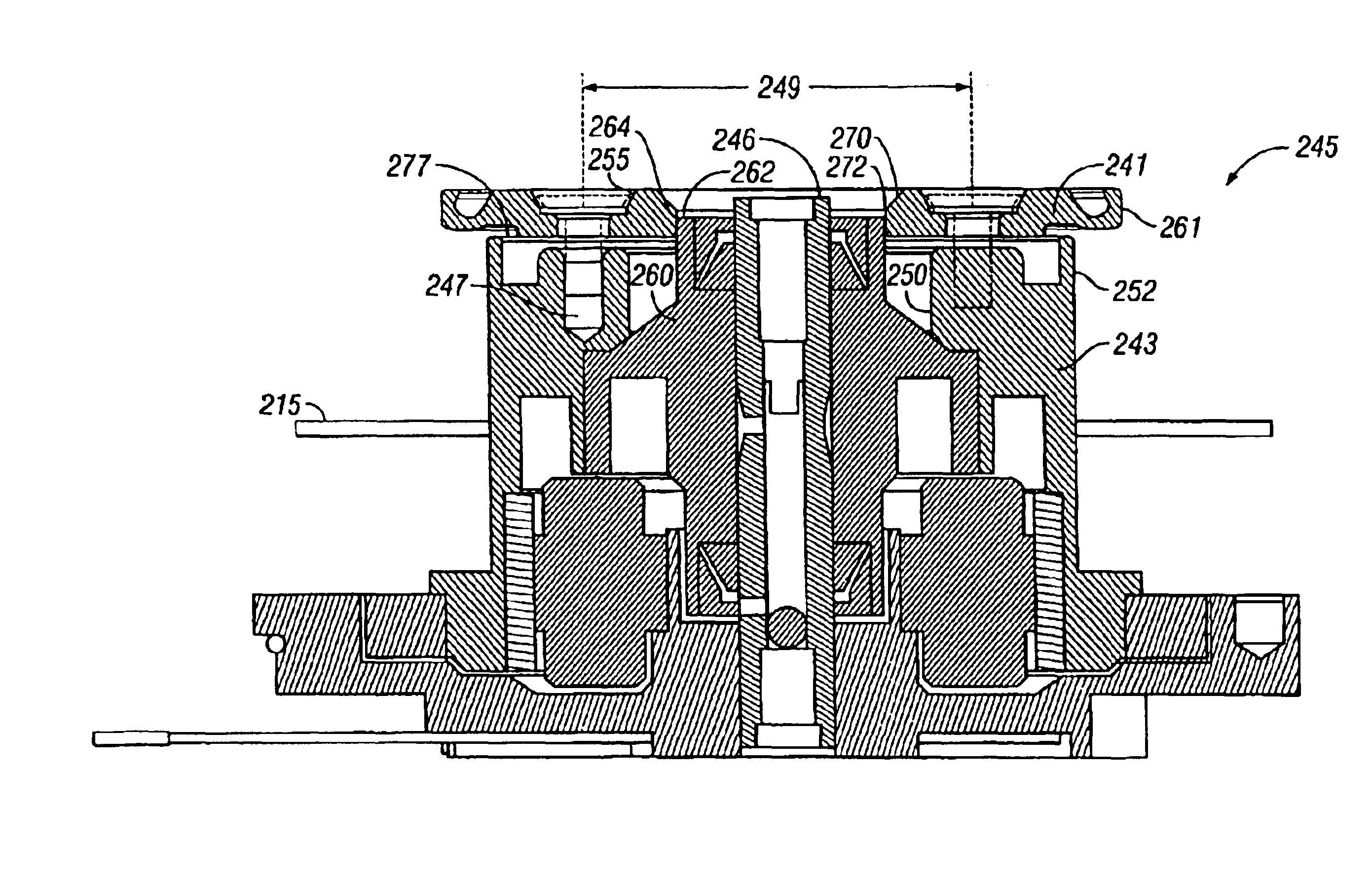

Manufacturing precision multipole guides and filters

InactiveUS6926783B2Precise positioningImprove accuracyAdhesive processesStability-of-path spectrometersResidual gas analyzerParticle beam

A method for manufacturing a multipole assembly for use in mass spectrometers, residual gas analyzers, mass filters, ion containment apparatus and particle beam accelerators. A precision mandrel tool is utilized for positioning a plurality of electrode rods in position during the manufacturing process. The electrode rods are placed on the mandrel. At least one insulator is positioned about the mandrel-rod assembly such that the mandrel-rod assembly psses through the insulator. The rods are tightly clamped to the mandrel and adhesive is placed in a gap established between each rod and the insulator. The adhesive is cured such that it acts both as a rigid bond between the insulator and each rod, as well as a precision spacer for positioning each rod in a precision position after the mandrel is removed from the assembly.

Owner:AGILENT TECH INC

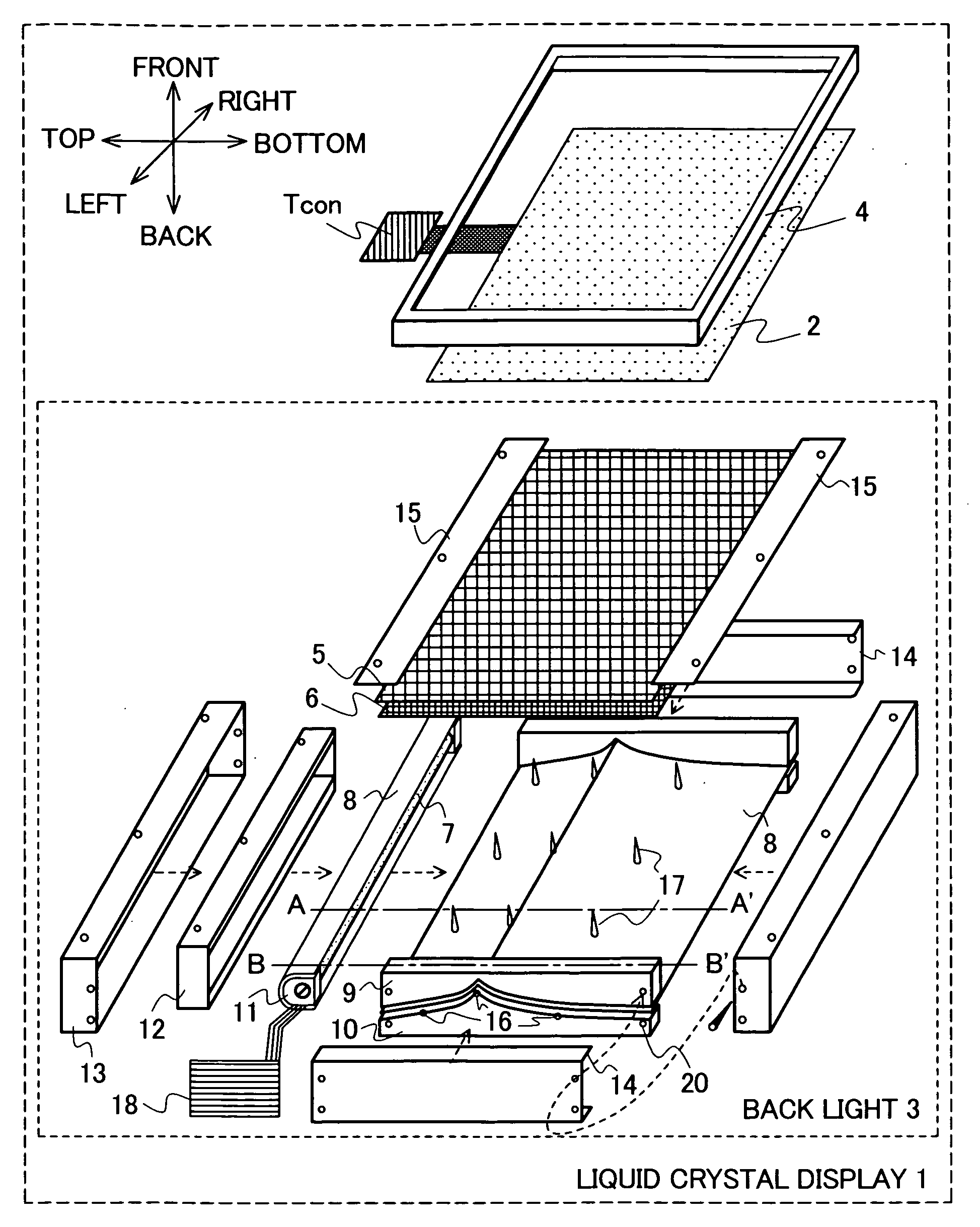

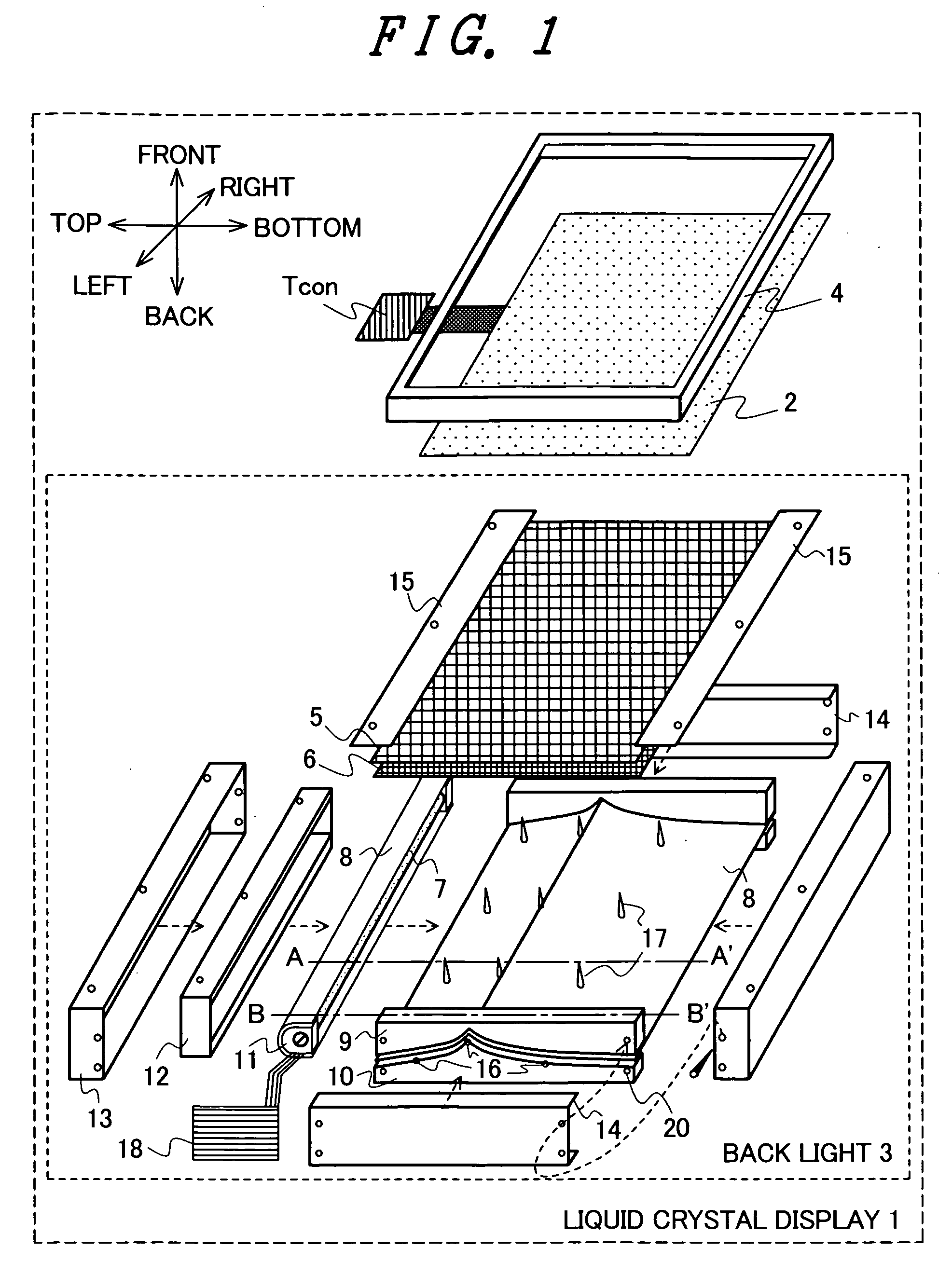

Liquid crystal display device

ActiveUS20080186431A1Simple structureUniform brightnessNon-linear opticsReflectorsLiquid-crystal displayLight guide

The present invention provides a light-weighted backlight capable of ensuring a sufficient light quantity at a low cost. A backlight is arranged below a liquid crystal panel. A light source is arranged in the vertical direction with respect to a screen of the liquid crystal panel so that light from the light source is directed toward the liquid crystal panel by a reflector. Due to such a constitution, the reflector can also function as a back lid of the backlight. Further, the reflector plays a role of directing the light from the light source toward the liquid crystal panel and hence, a light guide plate can be omitted. Due to such a constitution, the present invention can realize the reduction of weight and cost of the backlight or the liquid crystal display panel.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

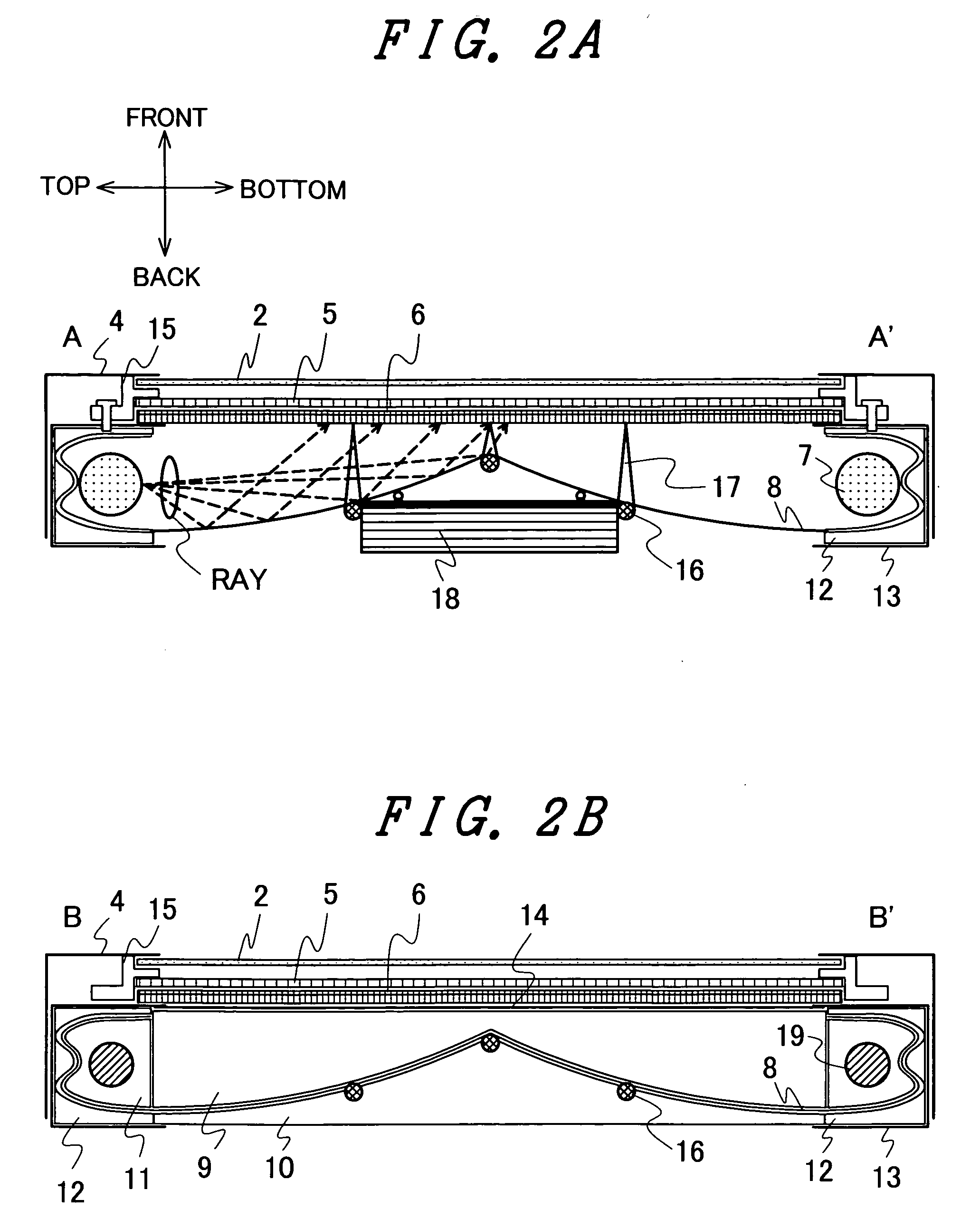

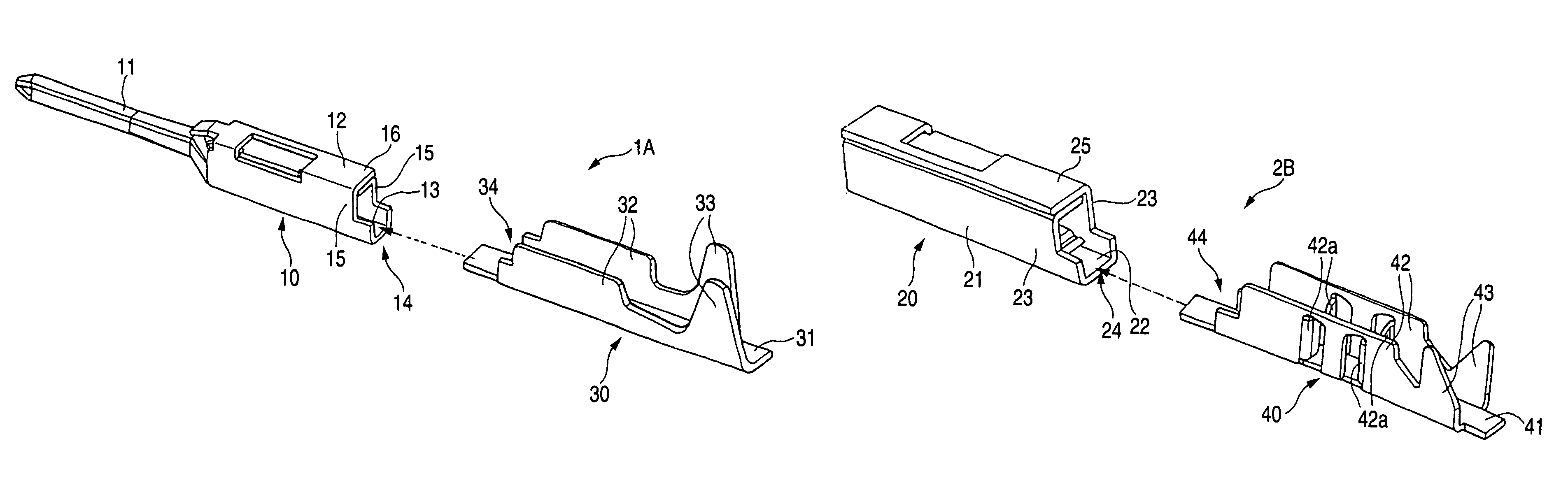

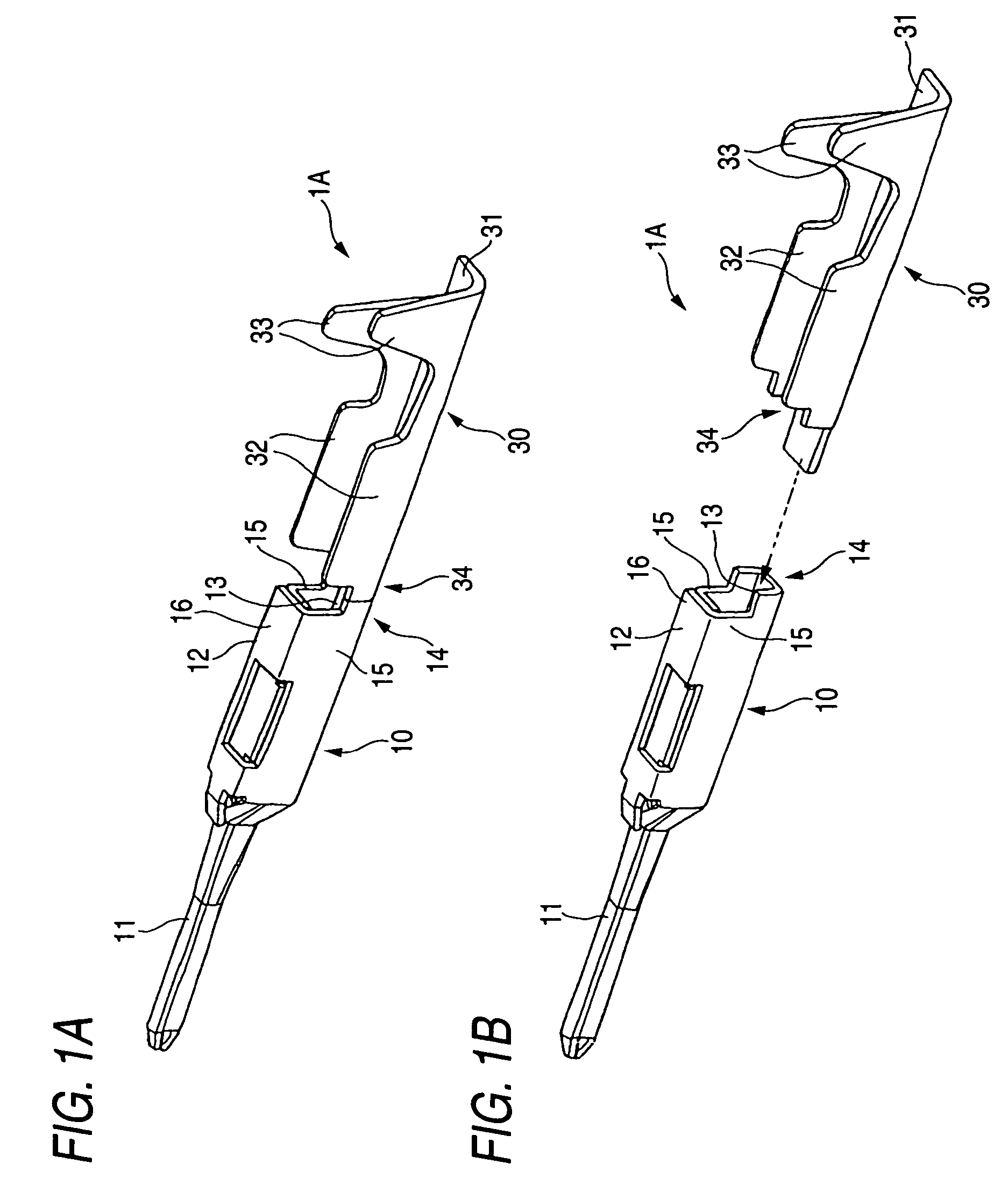

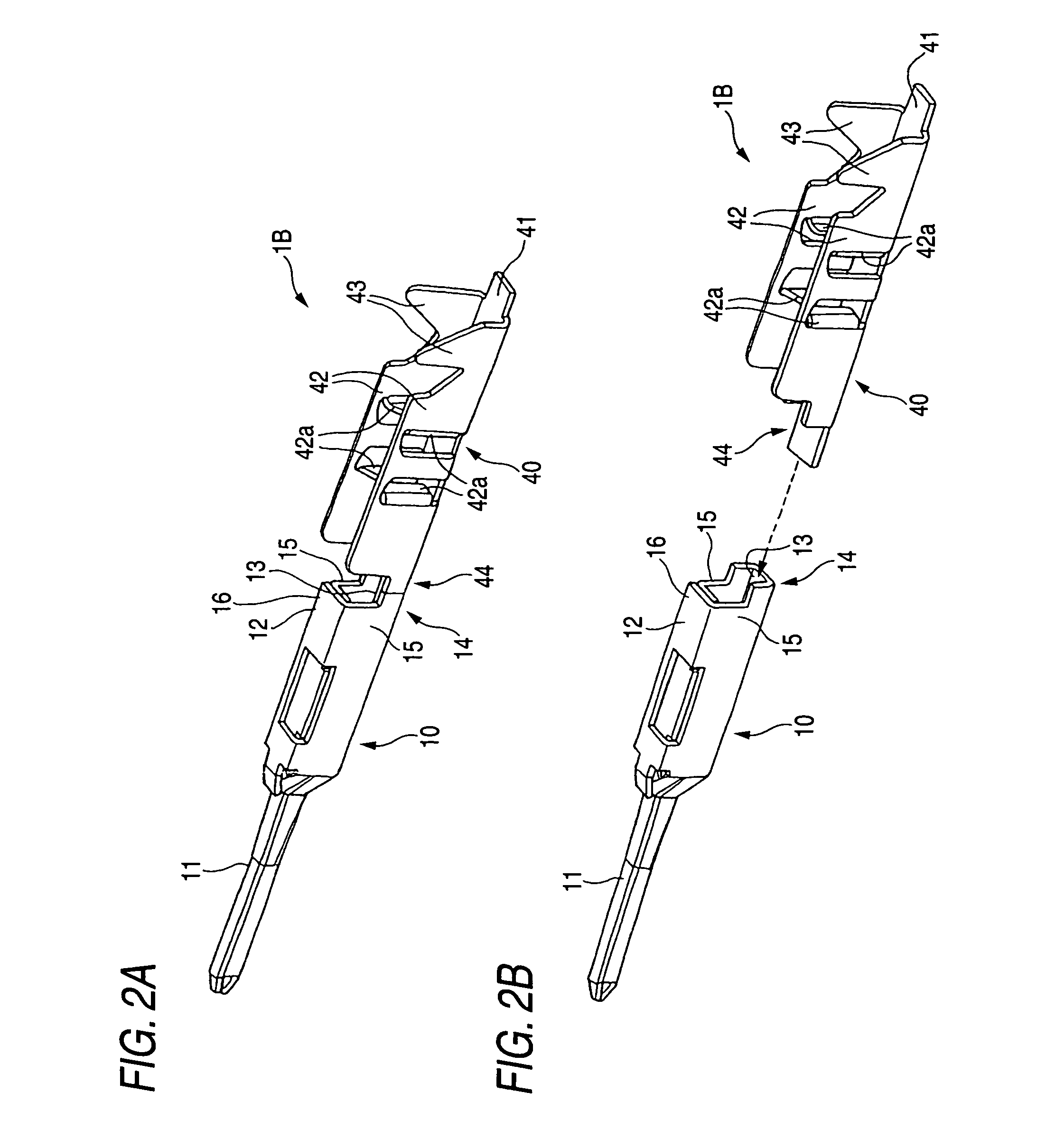

Method for forming a terminal metal and terminal metal formed by the method

ActiveUS7338334B2Free from variationImprove performanceContact member manufacturingConnections effected by permanent deformationEngineeringMetal

A male contact portion, a female contact portion, a clamp portion where an electric wire is clamped for connection, a crimp portion where an electric wire is crimped and a piercing portion where an electric wire is pierced to be crimped are formed separately, whereby one of the male contact portion and the female contact portion is selected according to an application and one of the clamp portion, the crimp portion and the piercing portion is selected according to the application, and a connecting portion of the selected electric contact part and a connecting portion of the selected wire connection part are superposed on each other so as to join the selected electric contact making point and the selected wire connection part together.

Owner:YAZAKI CORP

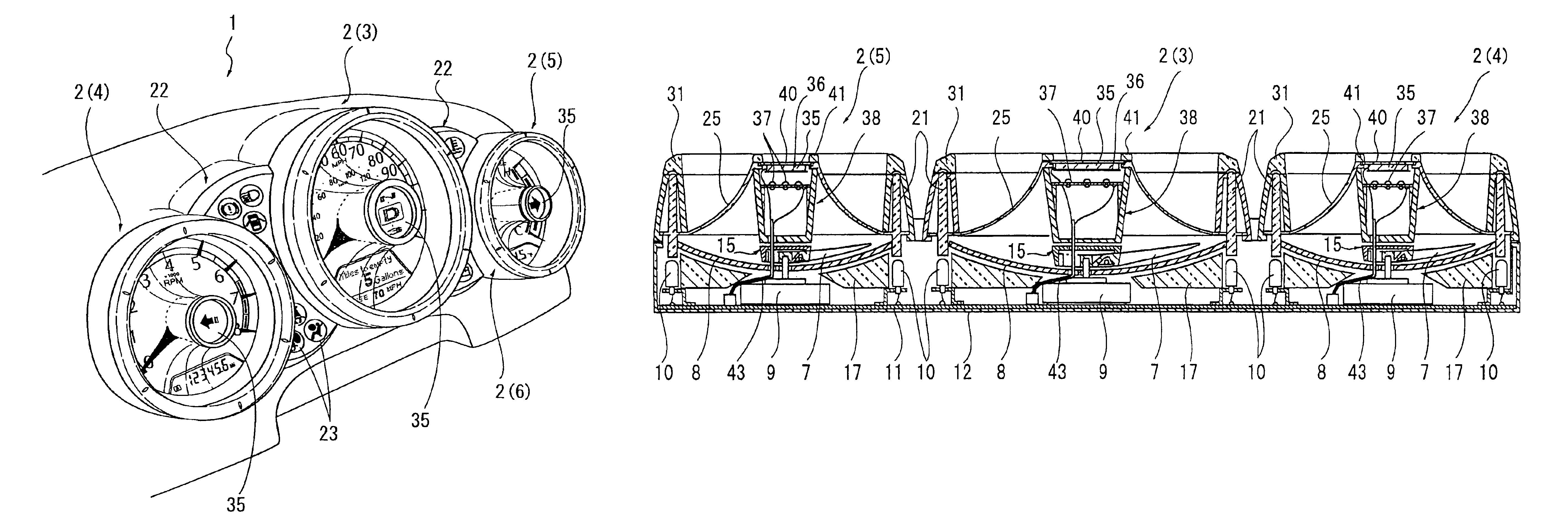

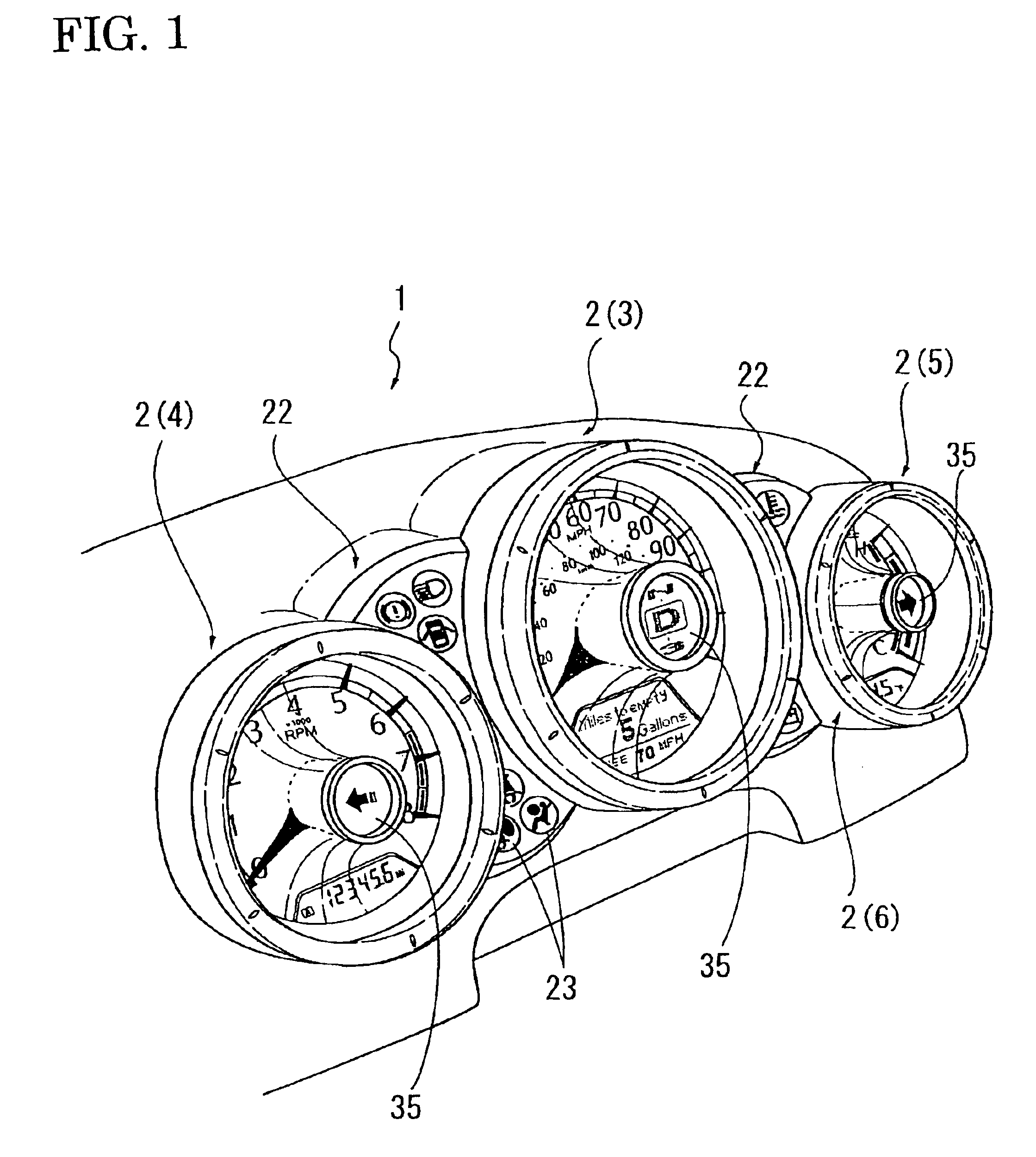

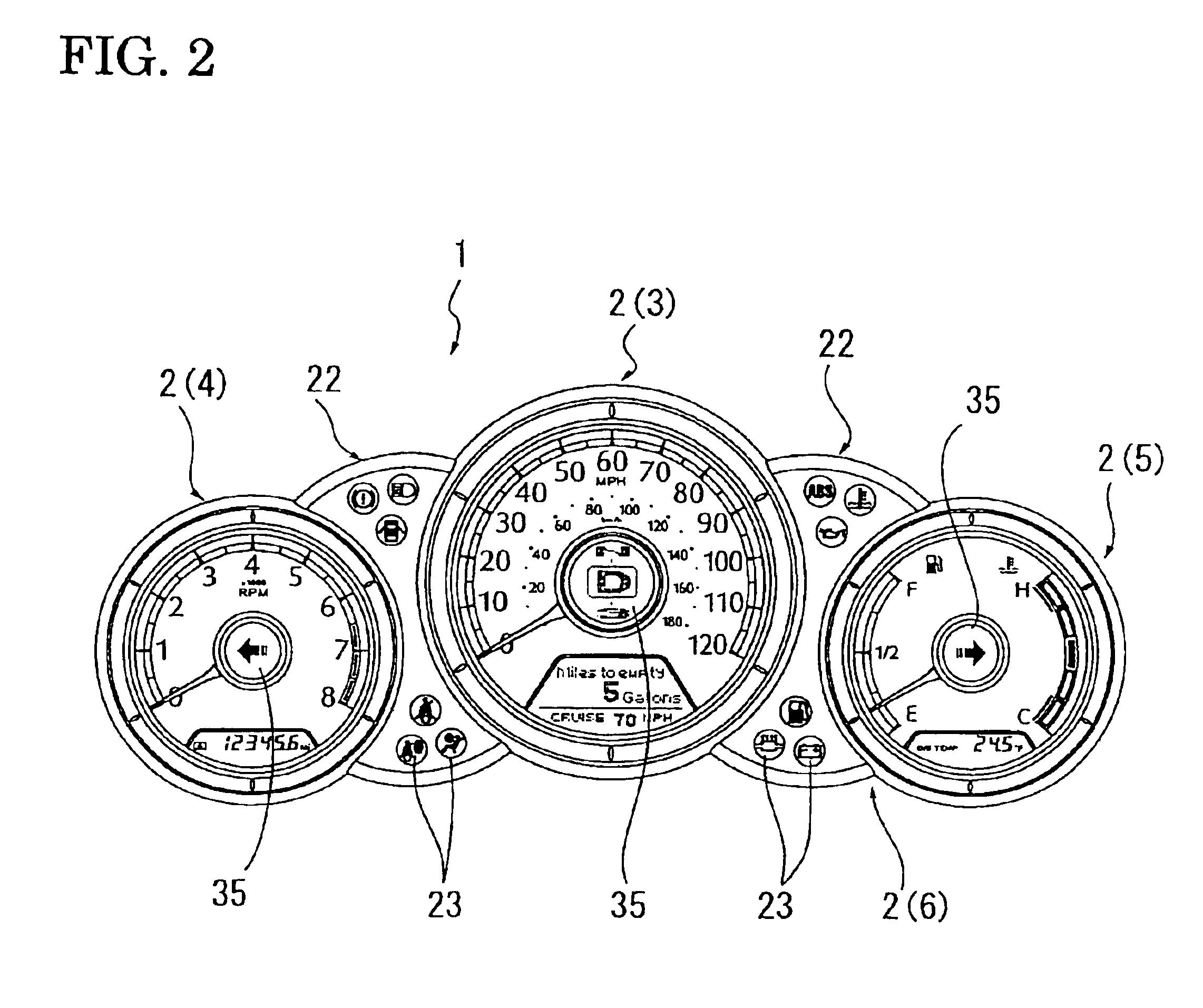

Display device for vehicle

InactiveUS6915758B2Easy to seeGood lookingInstrument arrangements/adaptationsMachines/enginesDisplay deviceMechanical engineering

A display device for a vehicle comprises an instrument for a vehicle (1), which includes a plate having a surface on which characters are provided (8), an indicating needle (7) rotatably disposed along a surface of the plate (8), and a transparent cover (25) disposed in a surface side of the plate (8) separately from the plate (8), and a small display portion (35) is disposed in a portion of the transparent cover (25) to be a floating state to the plate (8), and a new visual effect having a stereoscopic feeling can be obtained because the small display portion (35) can be seen as the floating state to the surface of the plate (8).

Owner:CALSONIC KANSEI CORP

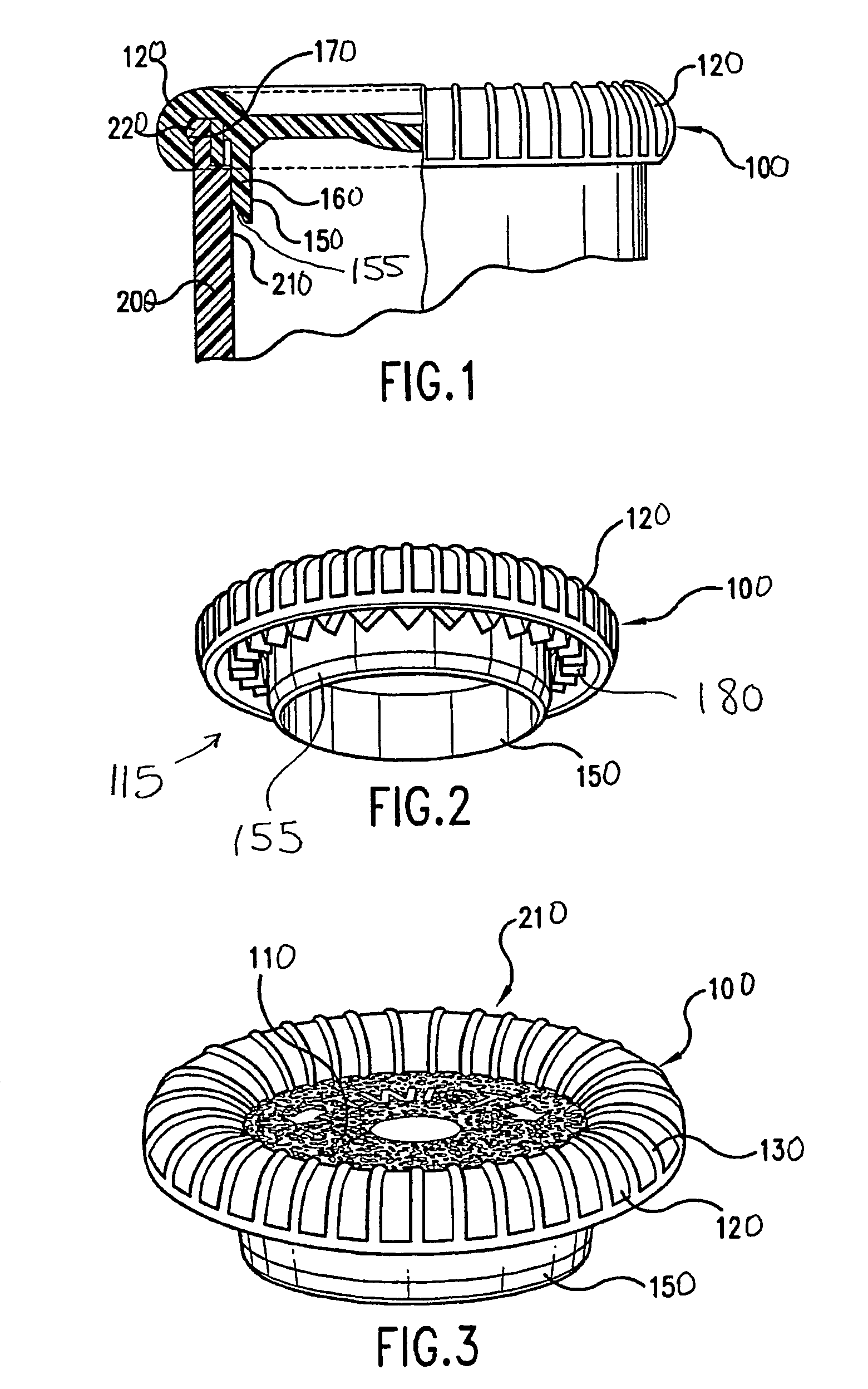

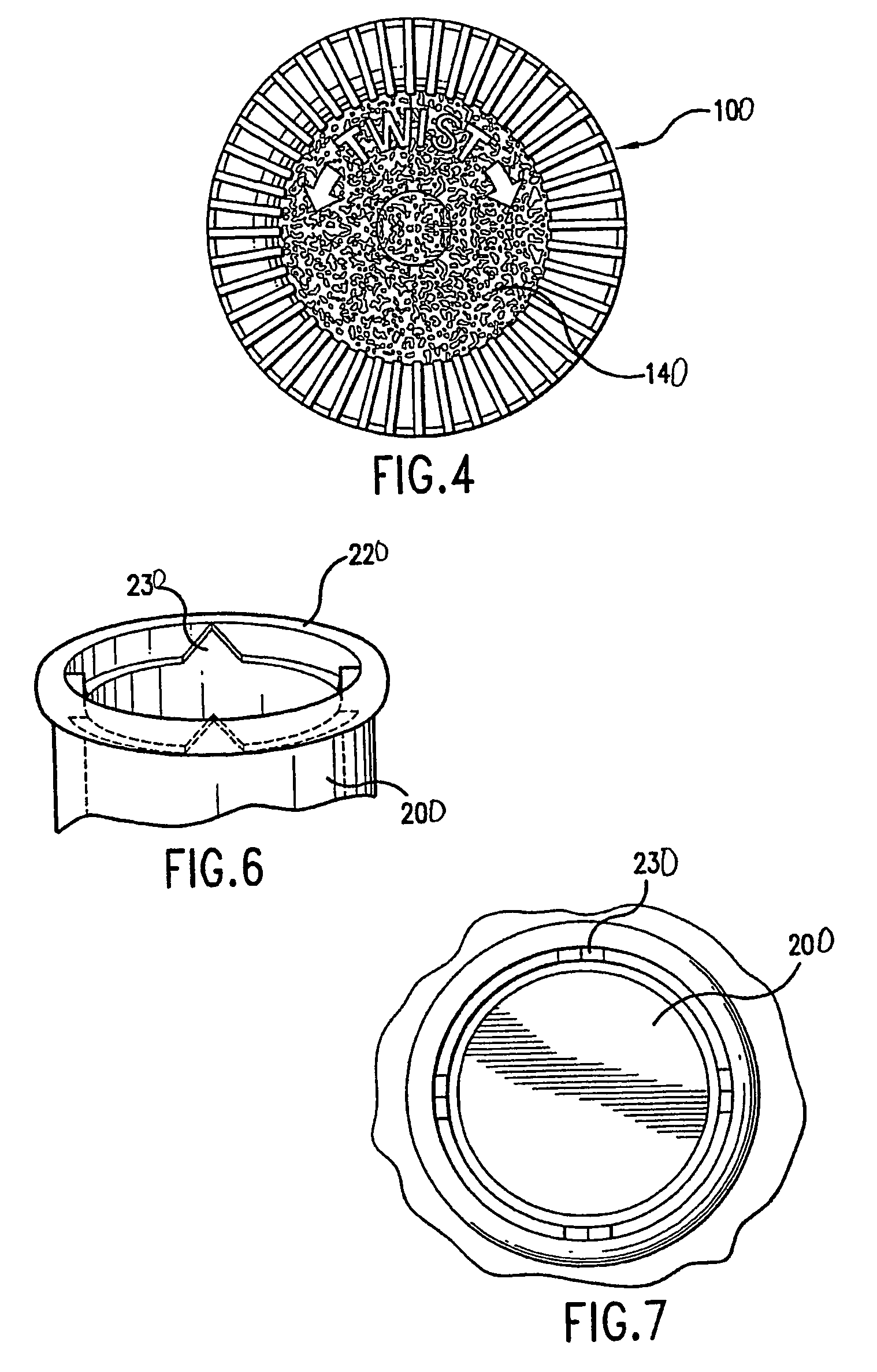

Tamper-evident quick twist closure

InactiveUS7210593B2Save materialReduce part costCapsClosure using stoppersEngineeringMechanical engineering

A cap with a tamper-evident ring is designed to snap engage a container that is provided with an upper and lower bead. A ring of teeth provided along an inside skirt of the cap engage teeth located along an inside wall of the container. When the cap is snapped onto the container, both sets of teeth automatically engage and a plug seal provided on the cap engages the container upper bead. By turning the cap clockwise or counterclockwise, the side angles of the teeth force the cap to disengage upwards over the upper bead and unsnap from the container. When the closure is opened for the first time, the ring breaks away from the cap and slides down the container below the lower bead, which keeps the ring from coming off the container and provides evidence that the cap had been opened.

Owner:MRP NEW JERSEY LLC

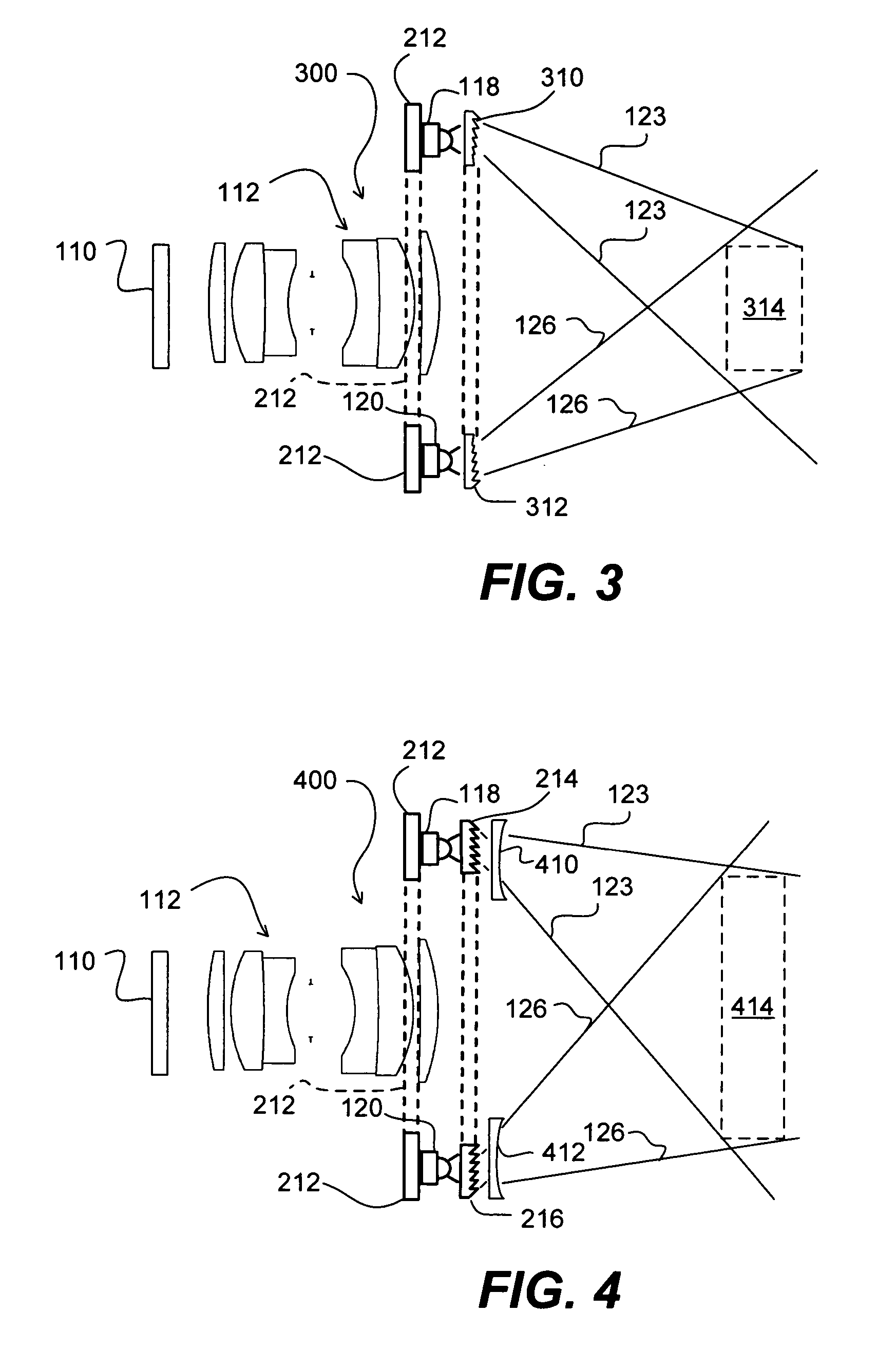

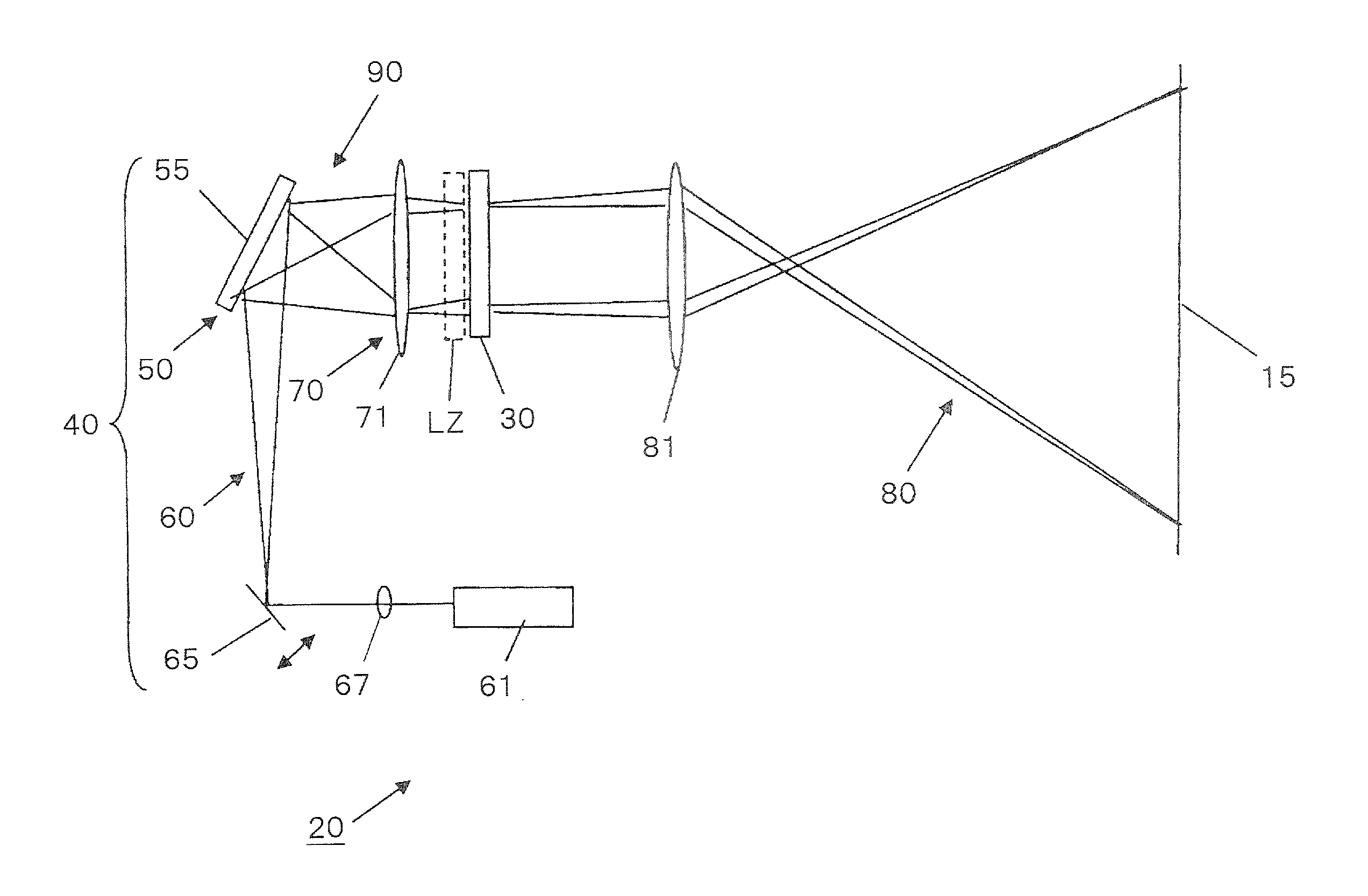

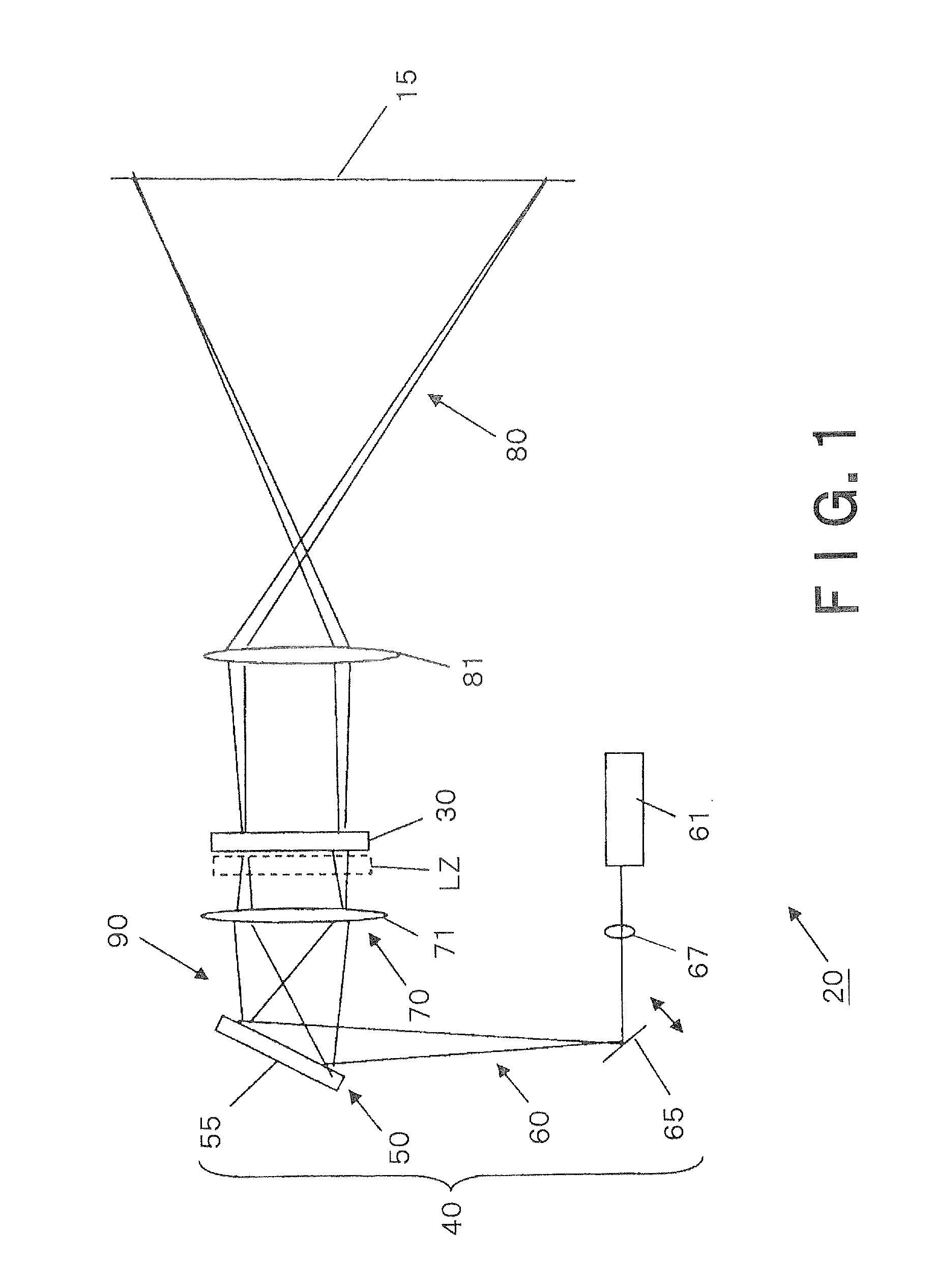

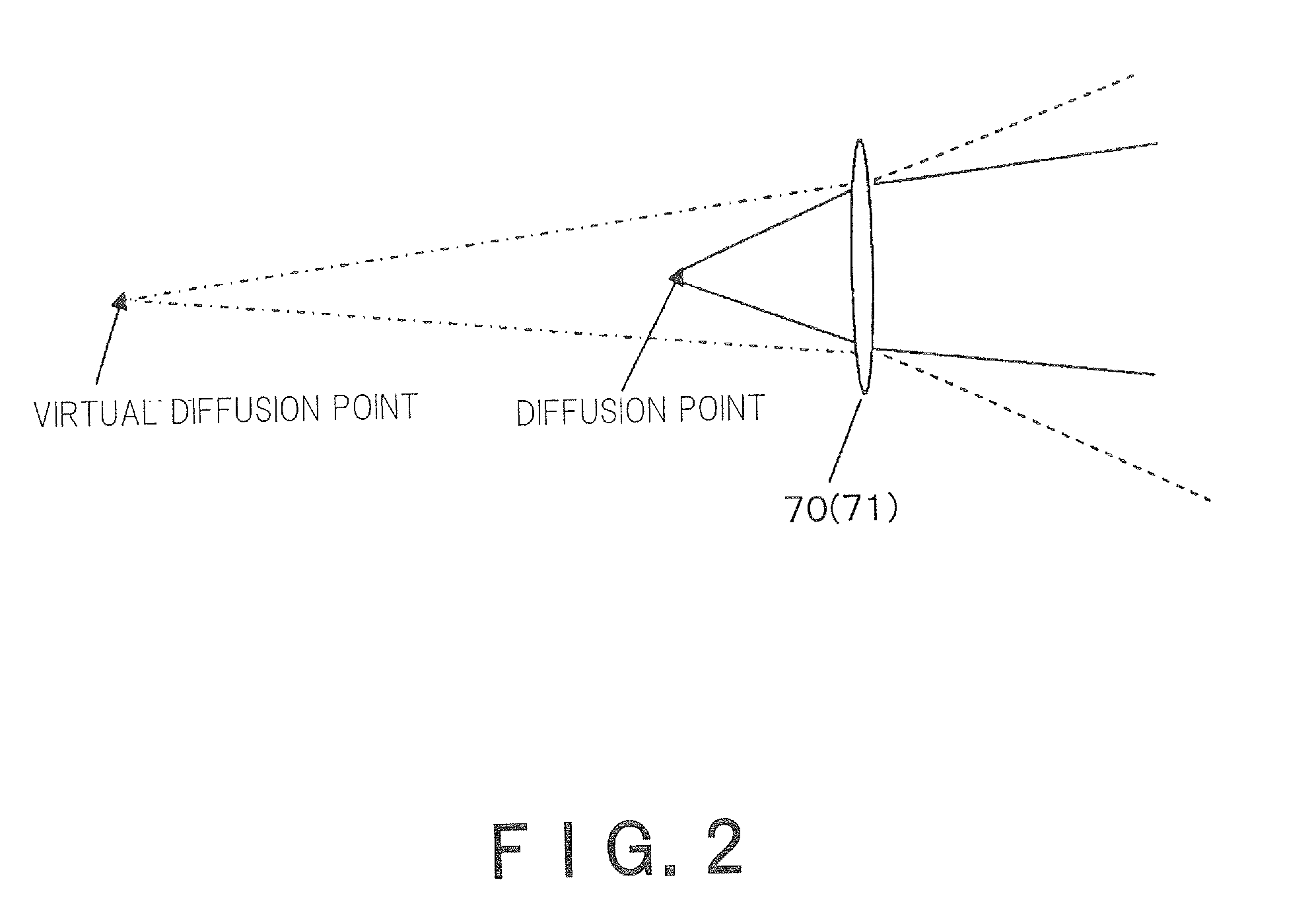

Projection apparatus and projection control apparatus

ActiveUS20140043591A1Efficient preparationInhomogeneous suppressionProjectorsColor television detailsLight beamIrradiation

A projection apparatus has an optical device configured to be capable of diffusing coherent light beams, an irradiation unit configured to irradiate the coherent light beams to the optical device so that the coherent light beams scan the optical device, a light modulator that is illuminated by coherent light beams incident on and diffused at respective points of the optical device from the irradiation unit, a projection optical system configured to project a modulated image generated by the light modulator onto a scattering plane, and an intermediate optical system provided between the optical device and the light modulator, configured to restrict an diffusion angle of coherent light beams diffused by the optical device.

Owner:DAI NIPPON PRINTING CO LTD

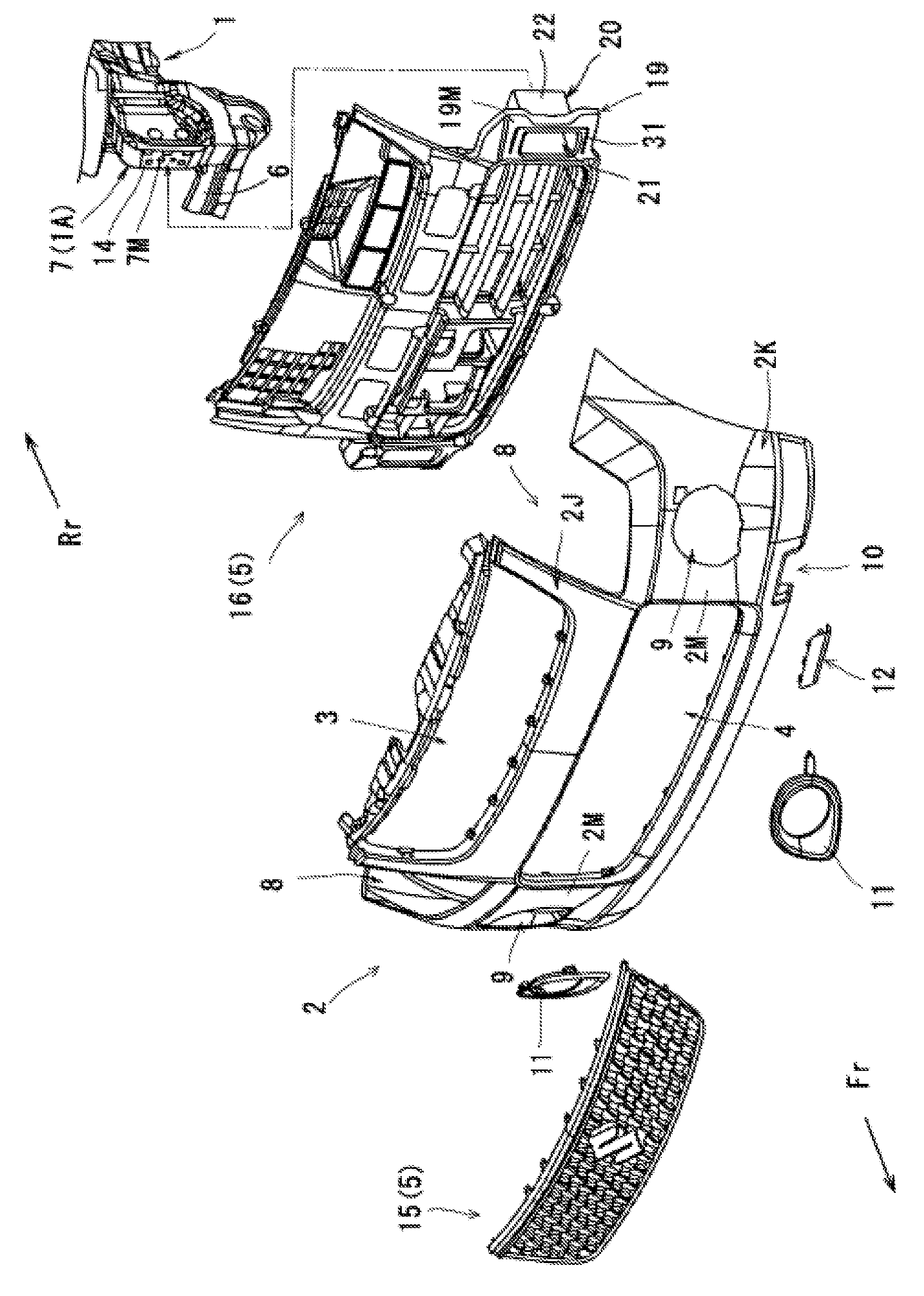

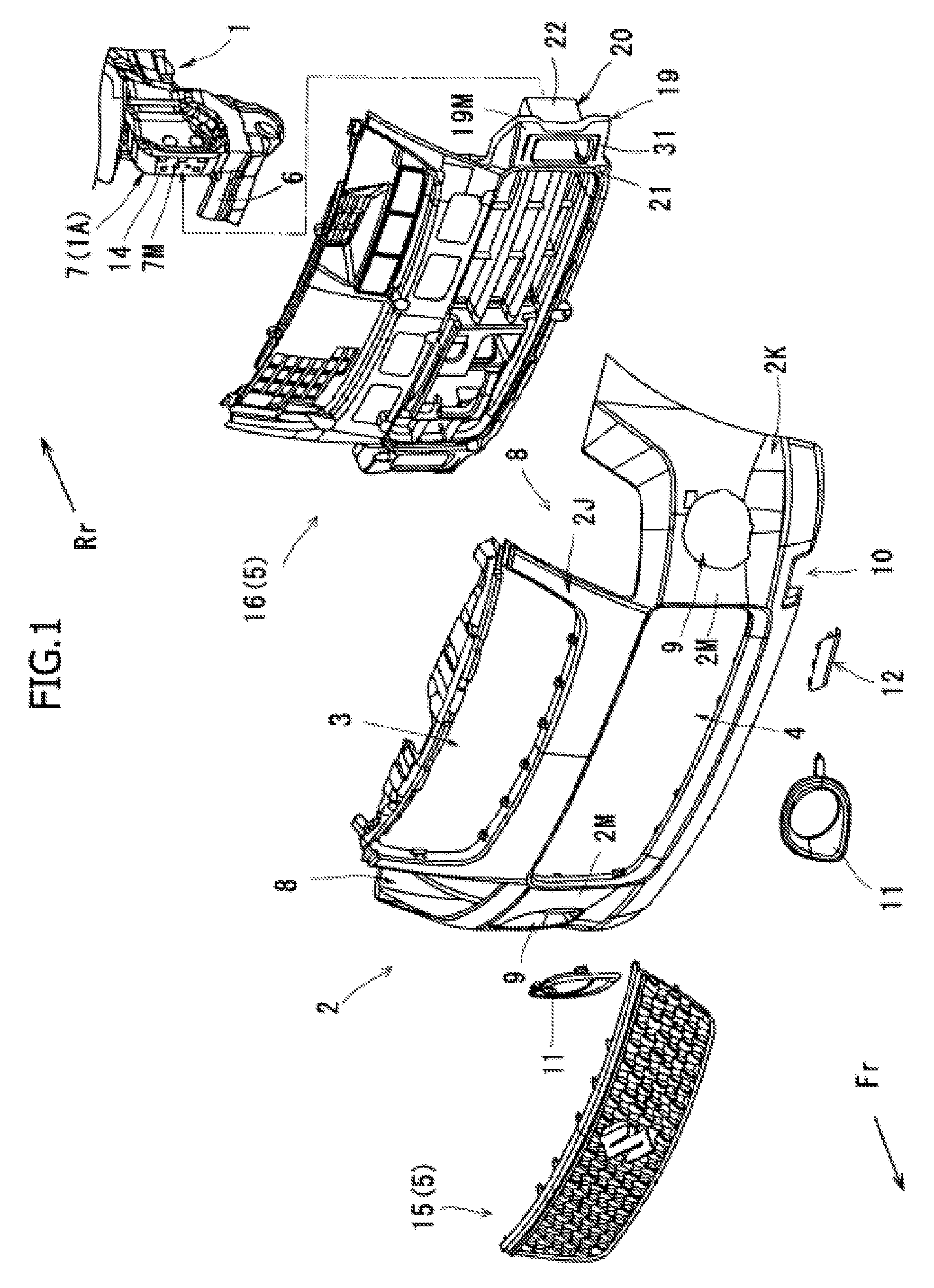

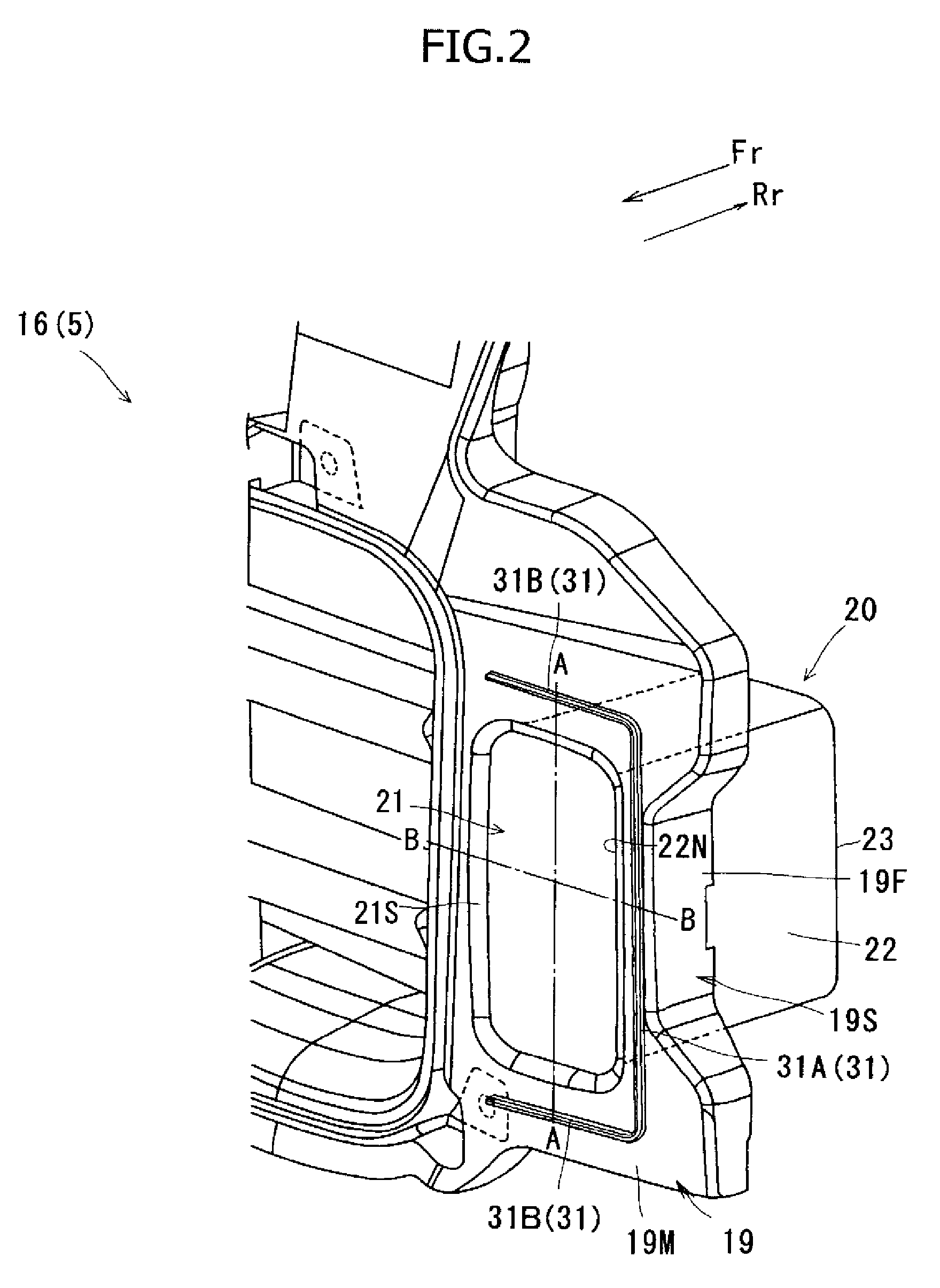

Vehicle Front Structure

Owner:SUZUKI MOTOR CORP

Method for forming a terminal metal and terminal metal formed by the method

ActiveUS20060205289A1Minimize variationPrevent failure and deformationContact member manufacturingConnections effected by permanent deformationEngineeringMetal

A male contact portion, a female contact portion, a clamp portion where an electric wire is clamped for connection, a crimp portion where an electric wire is crimped and a piercing portion where an electric wire is pierced to be crimped are formed separately, whereby one of the male contact portion and the female contact portion is selected according to an application and one of the clamp portion, the crimp portion and the piercing portion is selected according to the application, and a connecting portion of the selected electric contact part and a connecting portion of the selected wire connection part are superposed on each other so as to join the selected electric contact making point and the selected wire connection part together.

Owner:YAZAKI CORP

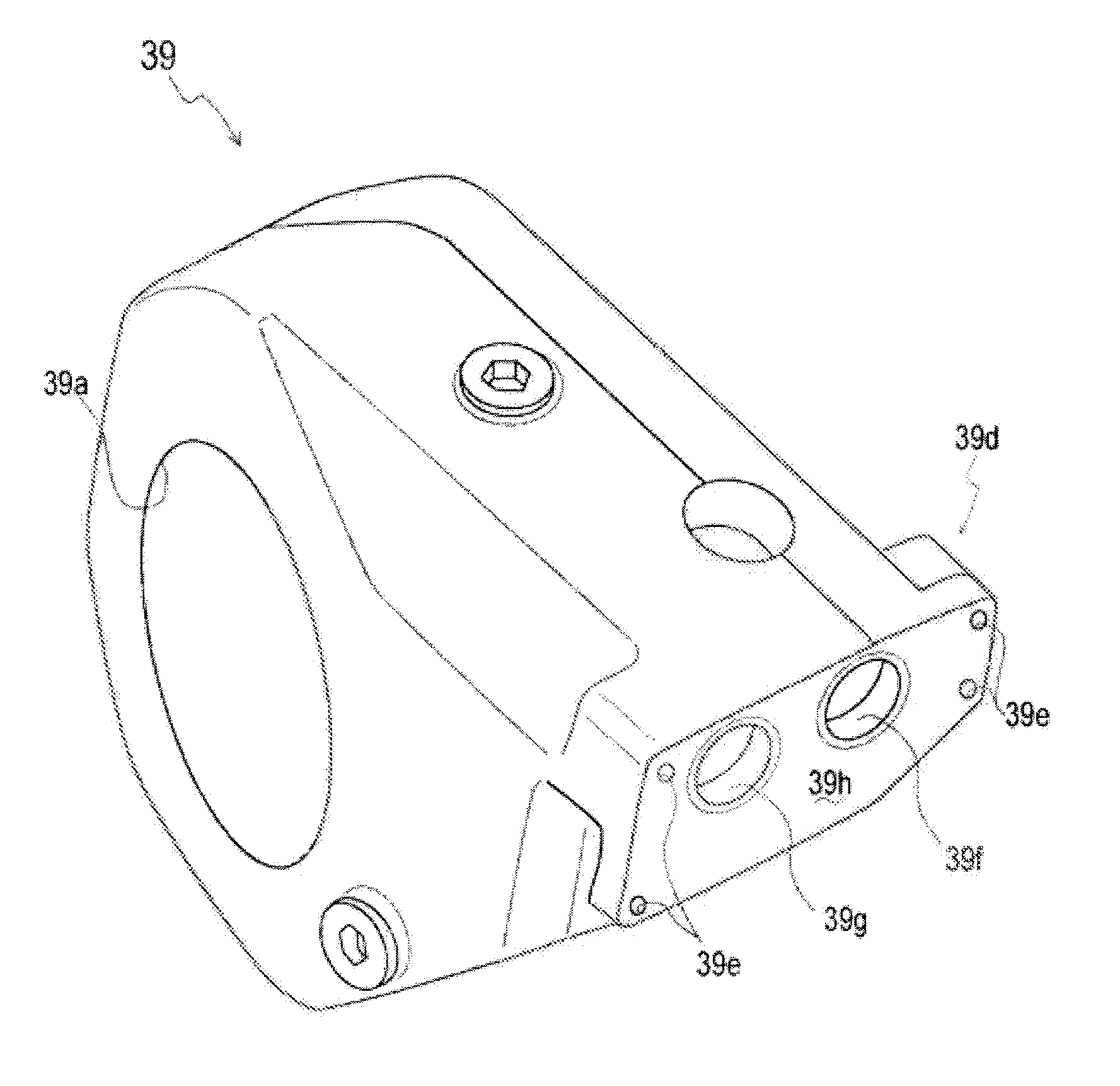

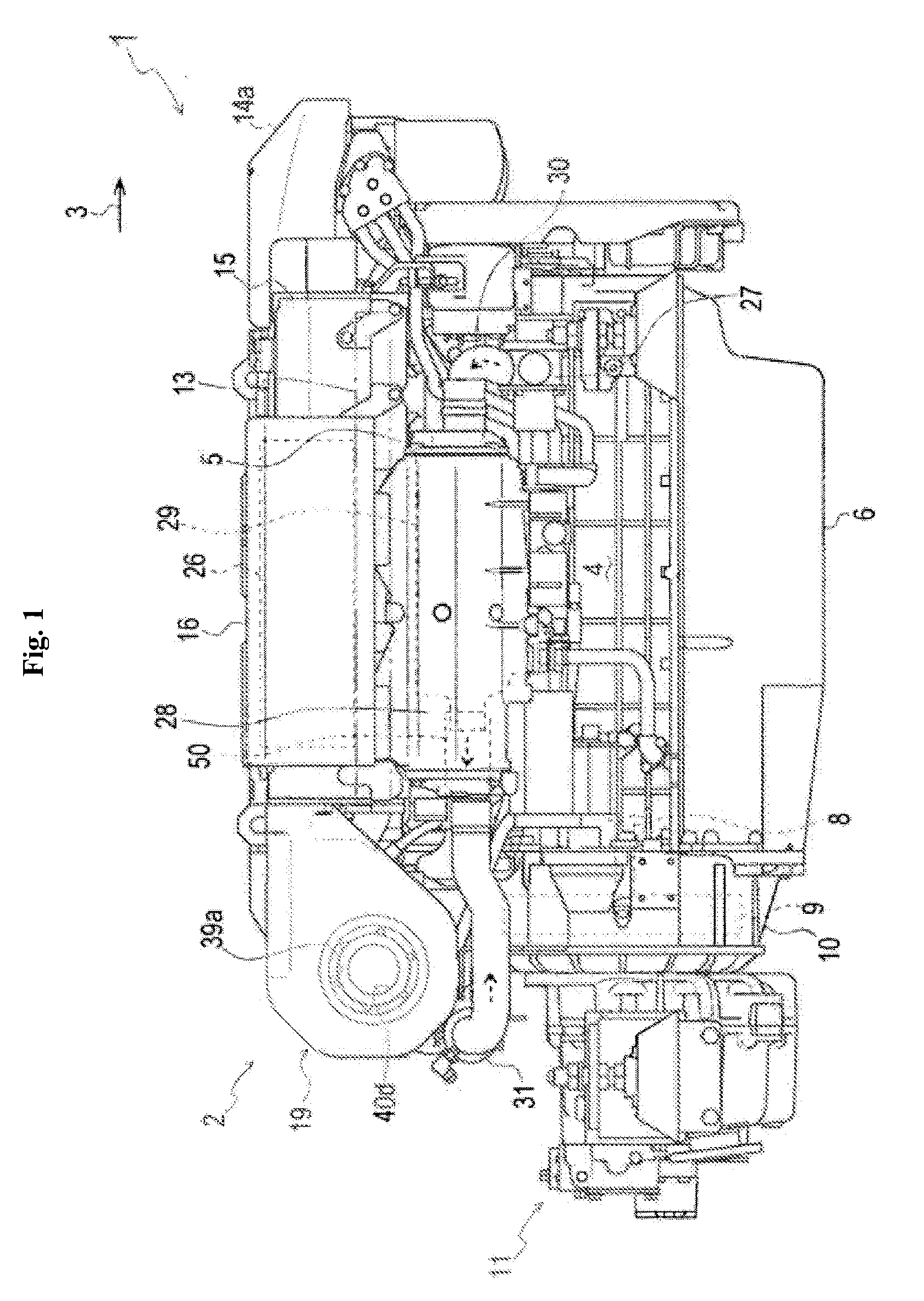

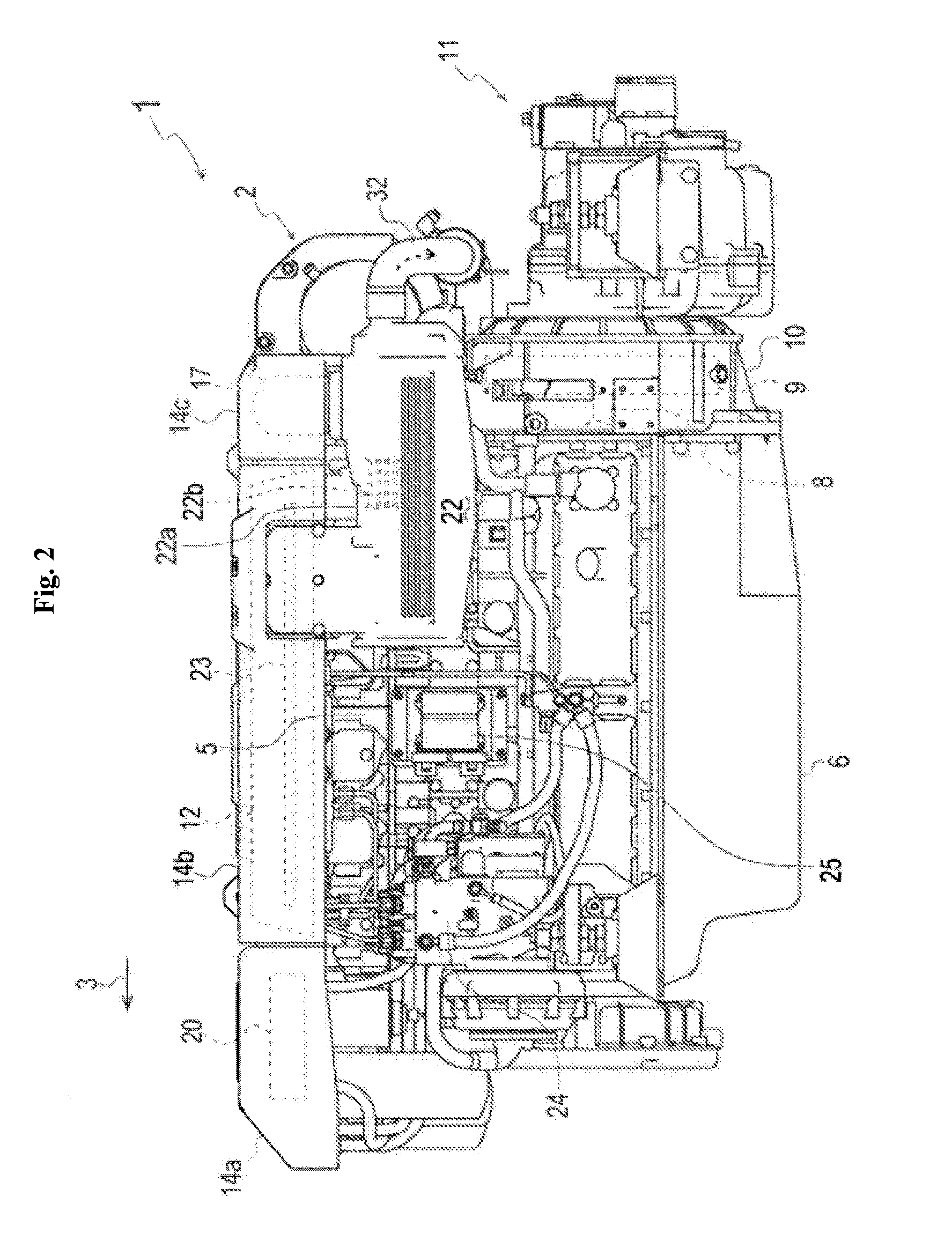

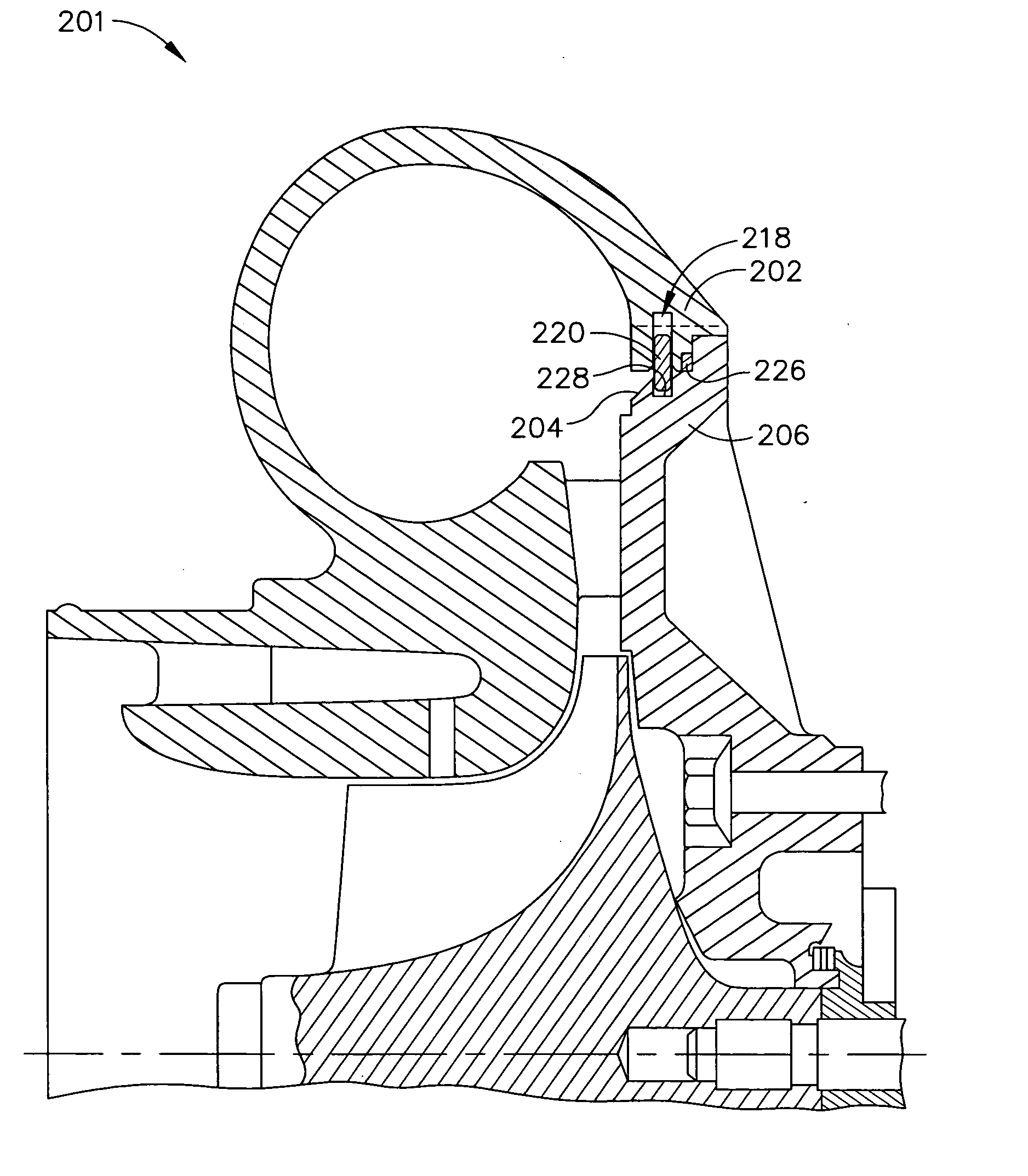

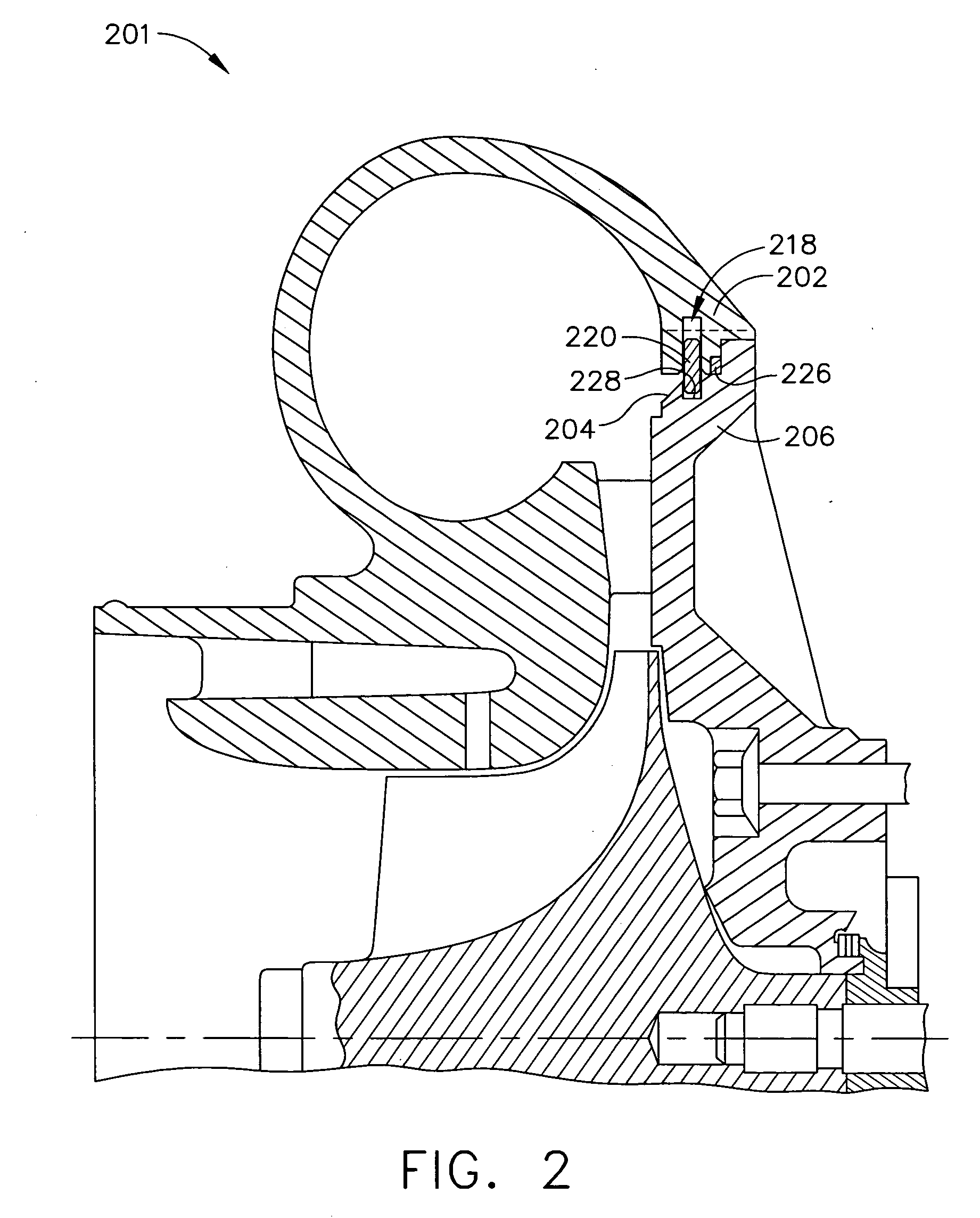

Cooling Structure Of Supercharger

InactiveUS20110154818A1Reduce number of partReduce cost of partLiquid coolingPump componentsThermal insulationExhaust gas

In order to reduce radiation heat from the turbine housing of a supercharger, the turbine housing is conventionally water-cooled or covered with a heat shielding material, but it is required to control heat loss due to excessive water cooling or high temperature on the outer surface of the heat shielding material. On the contrary, a solution by a cooling structure consisting of an inner thermal insulation portion of an air layer and an outer low temperature portion covering the inner thermal insulation portion has an inevitable problem of increasing number of components and upsizing. In a cooling structure of a supercharger (2) equipped with a turbine wheel (35) which rotates with exhaust gas from an engine (1) and provided, on the periphery of a turbine housing (40) for housing the turbine wheel (35), with a cooling structure (47) consisting of an inner thermal insulation portion of an air layer (45) and an outer low temperature portion covering the inner thermal insulation portion, the outer low temperature portion is constituted by integrally forming a circulation passage (46) of fresh water in a turbine cover (39) which covers and protects the turbine housing (40).

Owner:YANMAR POWER TECHNOLOGY CO LTD

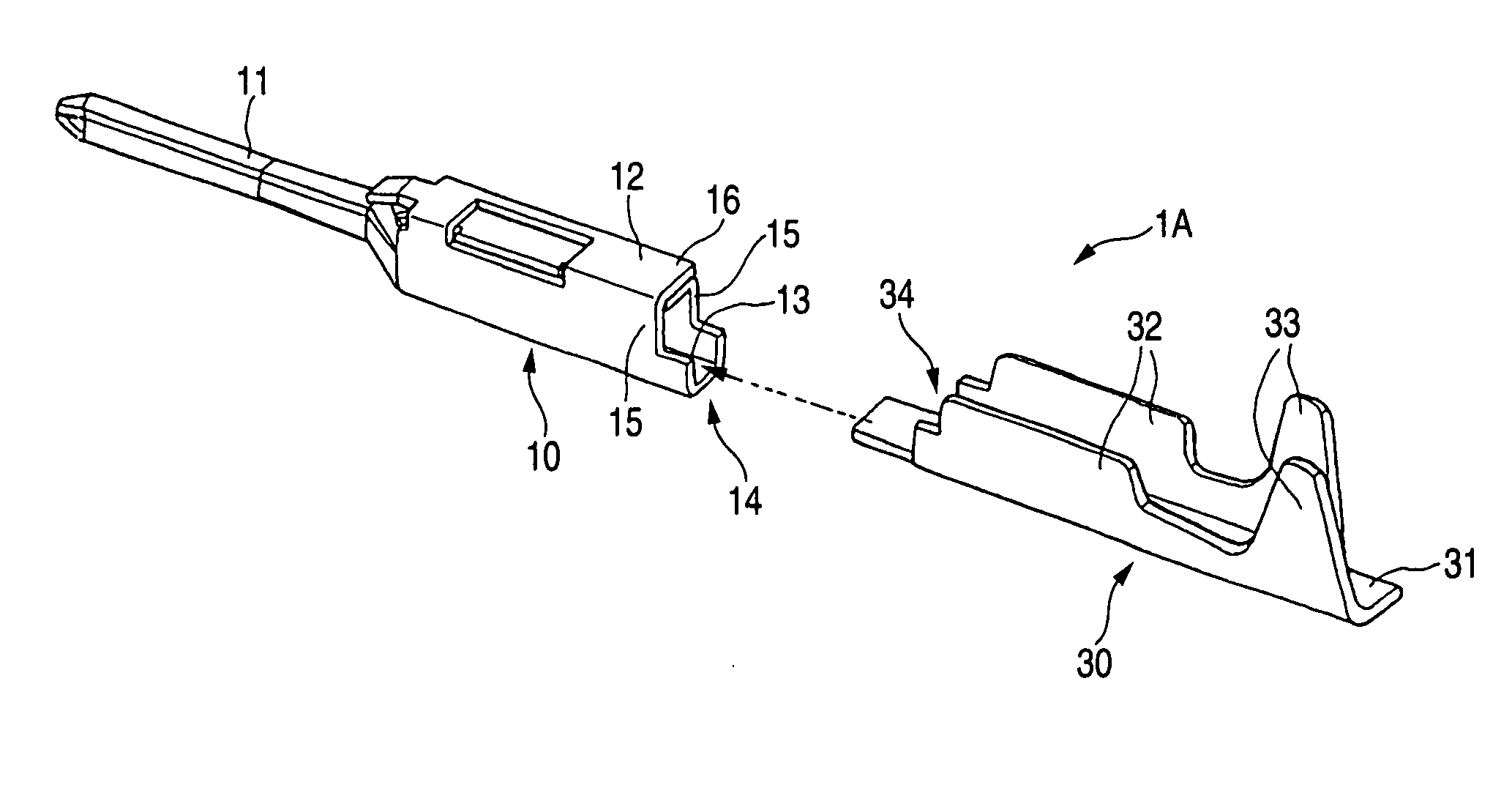

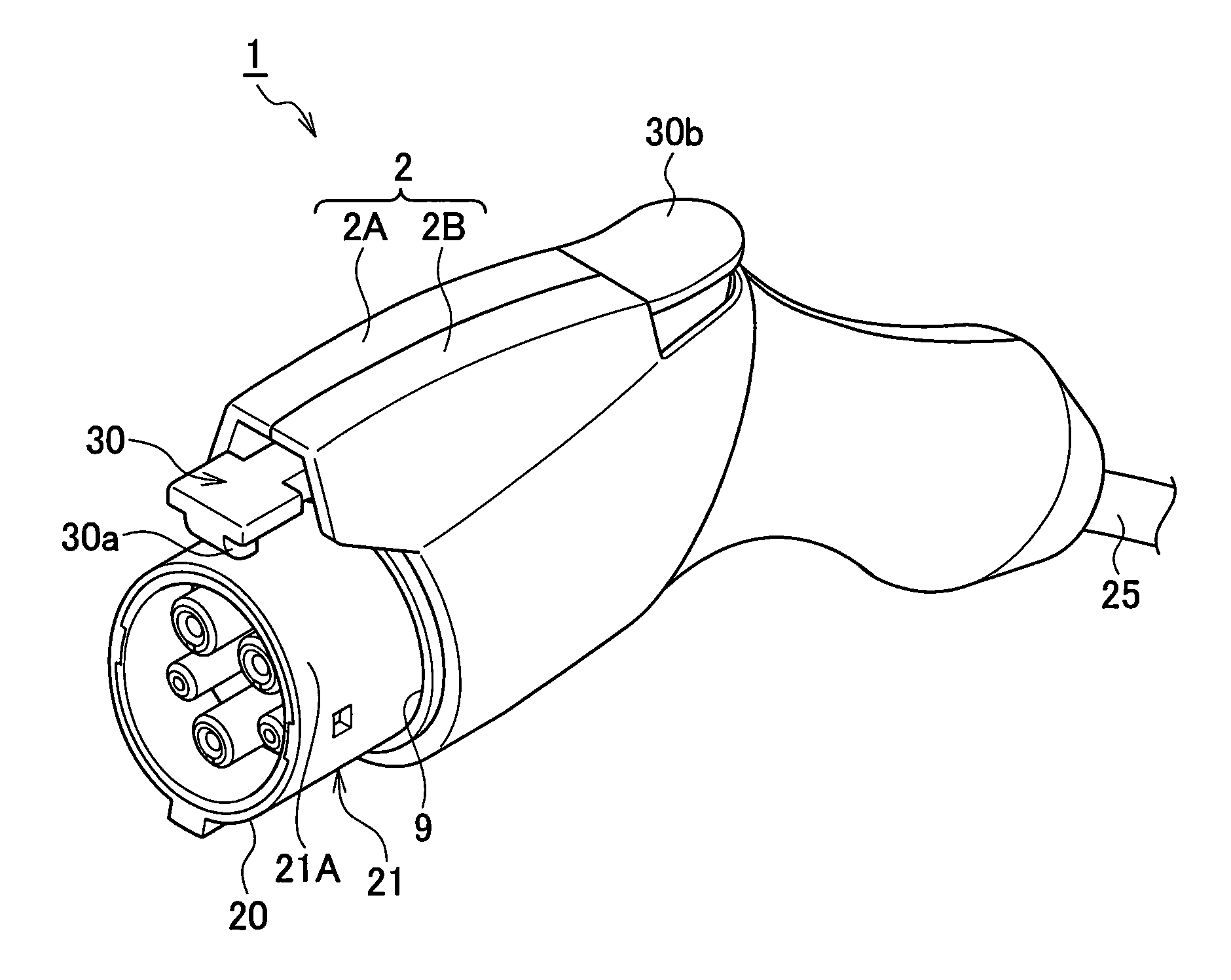

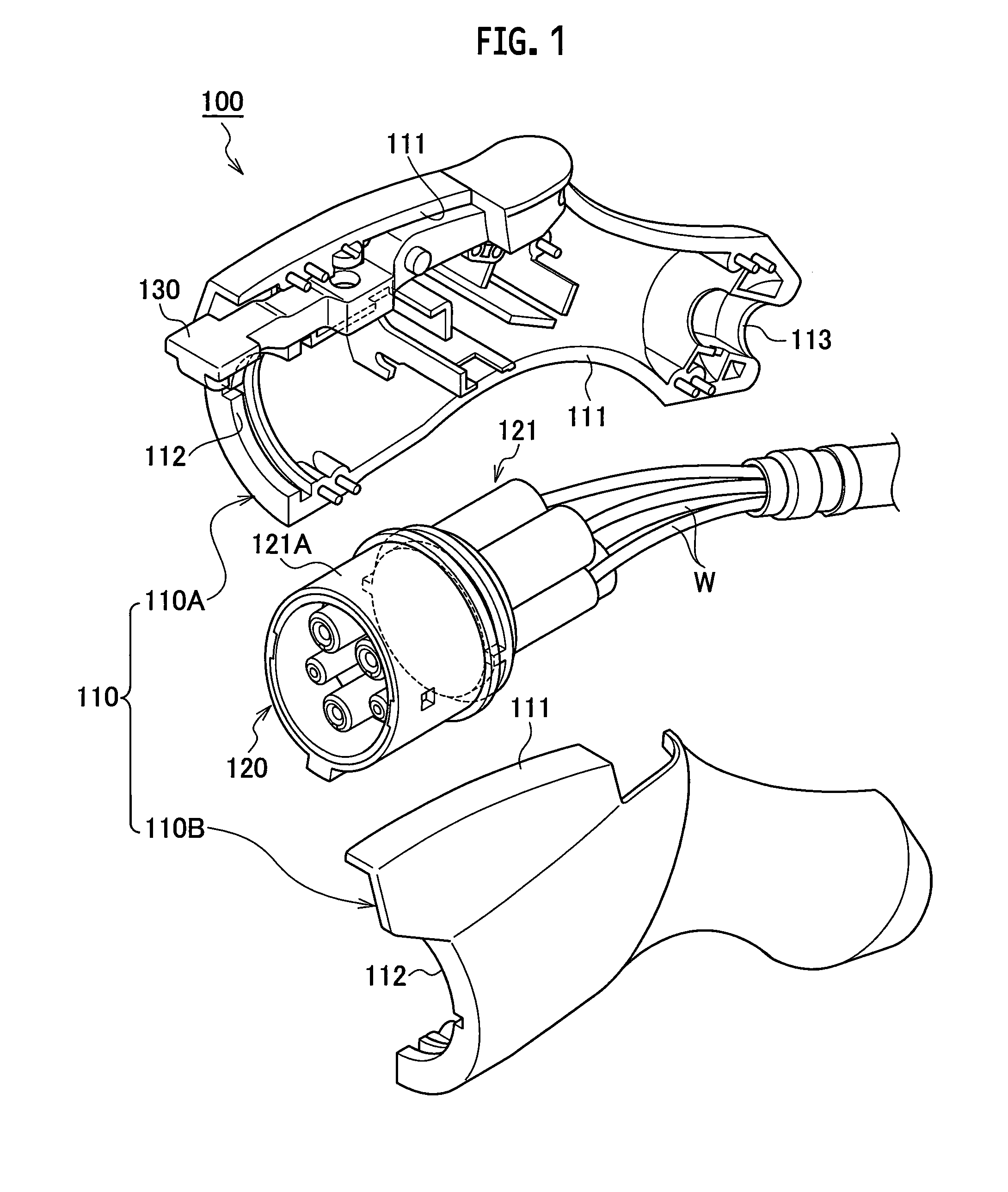

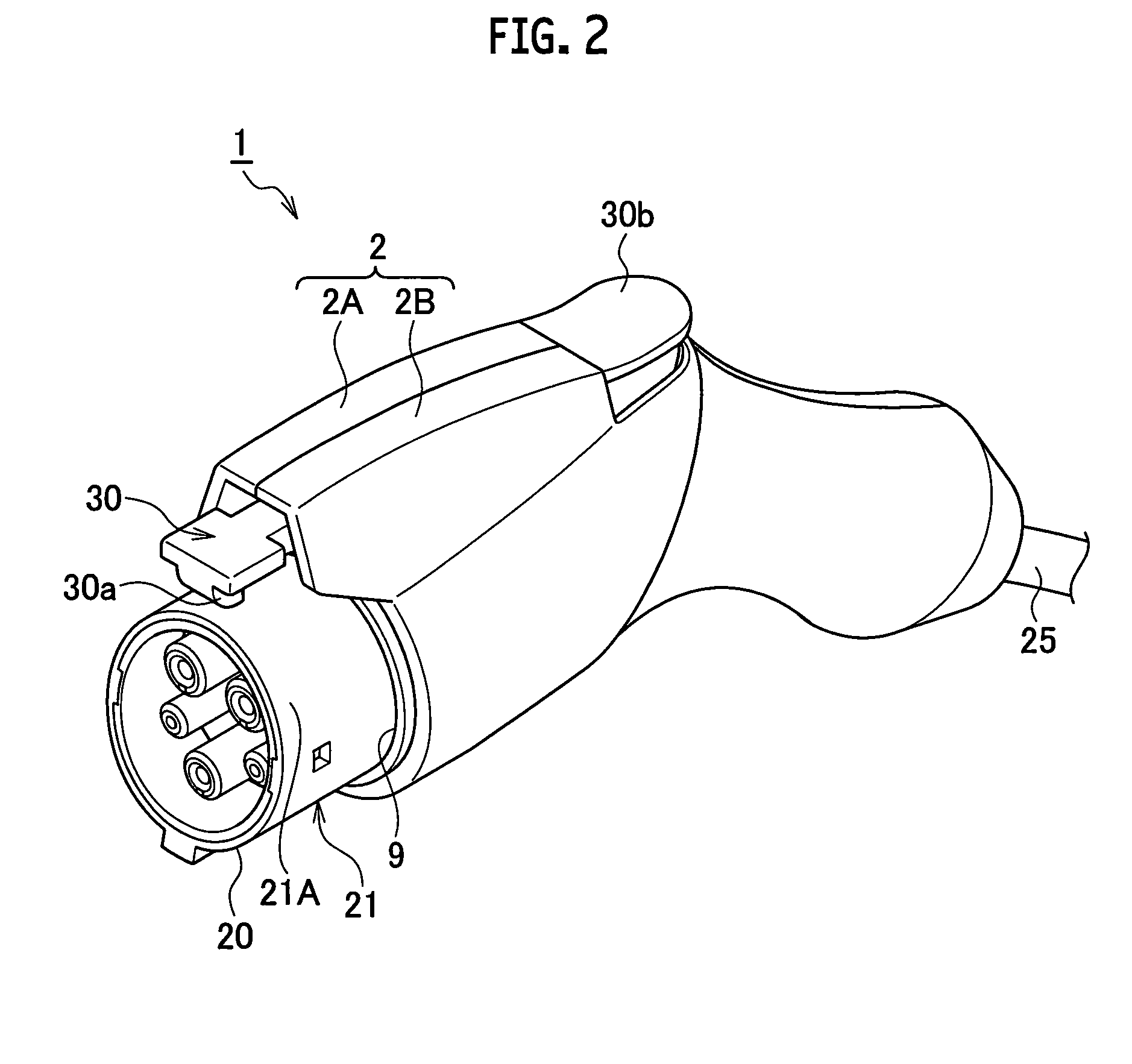

Charging connector

InactiveUS20150295344A1Reduce part costReduce manufacturing costVehicle connectorsCharging stationsEngineeringElectric wire

A seal member (40) is formed of an integral body including a case split surface seal portion (41) arranged along whole circumferences of abutting surfaces (3, 7) surrounding a portion of a connector body (20) housed inside an exterior case (2) and interposed between the abutting surfaces (3, 7) of two case split bodies (2A, 2B), a connector body seal portion (42) arranged along a whole circumference of a connector fitting portion projecting hole (9) and interposed between the exterior case (2) and the connector body (20), and an electric wire seal portion (43) arranged along a whole circumference of an electric wire pullout hole (10) and interposed between the exterior case (2) and an electric wire (W1) pulled out from the connector body (20) and led outside the exterior case (2) through the electric wire pullout hole (10).

Owner:YAZAKI CORP

Air conditioning register

InactiveUS20100263401A1Good lookingImprove rigidityLighting and heating apparatusVehicle heating/cooling devicesEngineeringAir conditioning

There is provided an air conditioning register which can prevent or effectively suppress a reduction in an effective opening surface area at an air-conditioned air blow-out portion, and which has good blow-out efficiency of air-conditioned air. A first flow path 42 and a second flow path 44, whose directions toward a blow-out bezel 26 differ, are formed within a retainer 12 of an air conditioning register 10. A first damper 52 and plural second dampers 58, which are interlocked with one another, are provided at the retainer 12. The first damper 52 opens and closes the first flow path 42, and the second dampers 58 open and close the second flow path 44. The first damper 52 and the second dampers 58 are operated such that either one of the first flow path 42 and the second flow path 44 is opened and the other is closed, and the flow path of the air-conditioned air is switched. In this way, a blow-out direction of the air-conditioned air from the blow-out bezel 26 is controlled, while a reduction in an effective opening surface area at the blow-out bezel 26 is prevented or effectively suppressed.

Owner:TOYOTA JIDOSHA KK

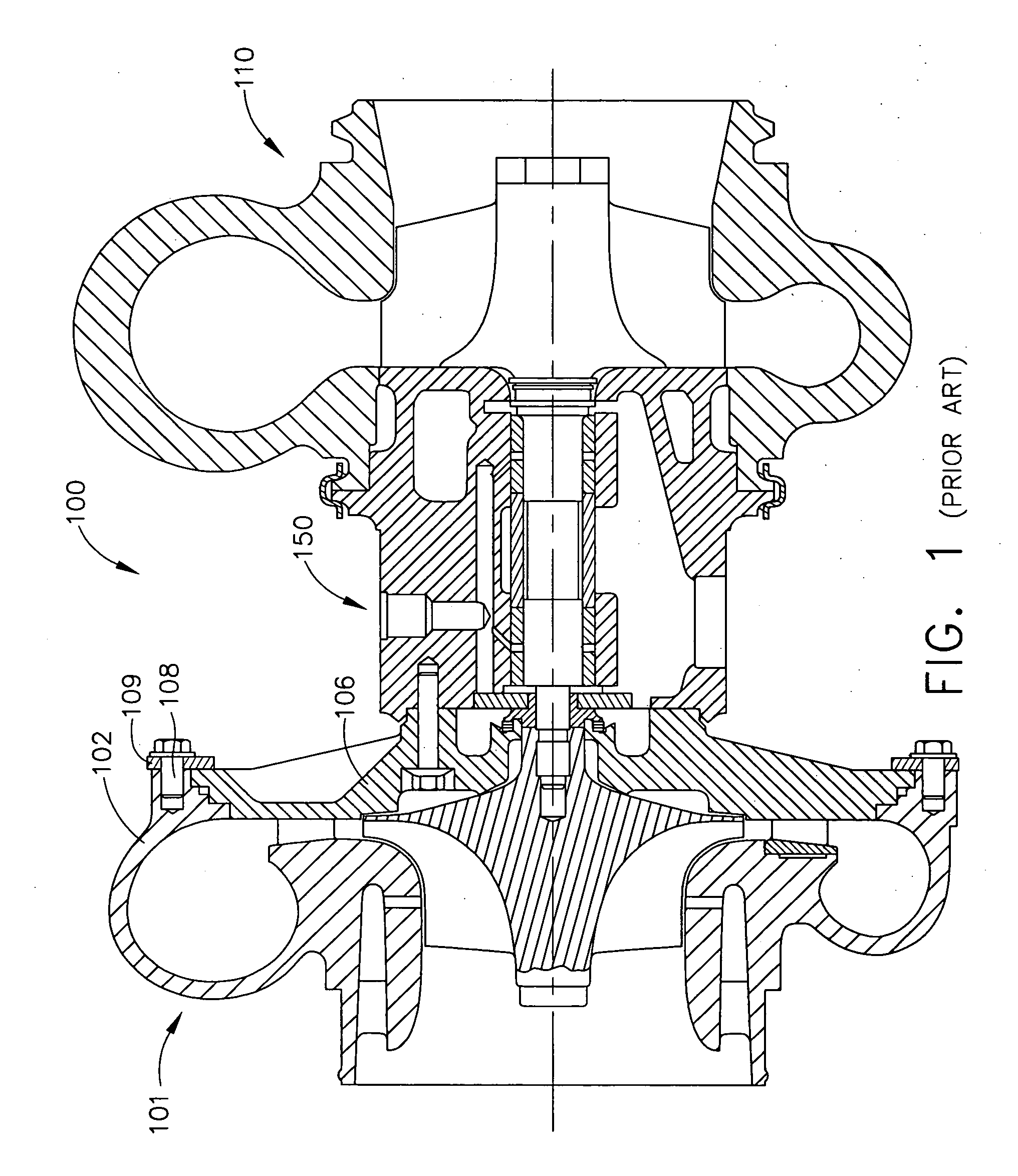

Compressor stage assembly lock

ActiveUS20070256412A1Assembly minimizedReduce part costWind motor controlPump componentsTurbochargerEngineering

The present invention relates to a turbocharger assembly lock comprising a retaining ring partially disposed in a circumferential groove of a first turbocharger stage component and partially in a circumferential groove of a second turbocharger stage component so that the turbocharger stages are securely attached to each other.

Owner:GARRETT TRANSPORATION I INC

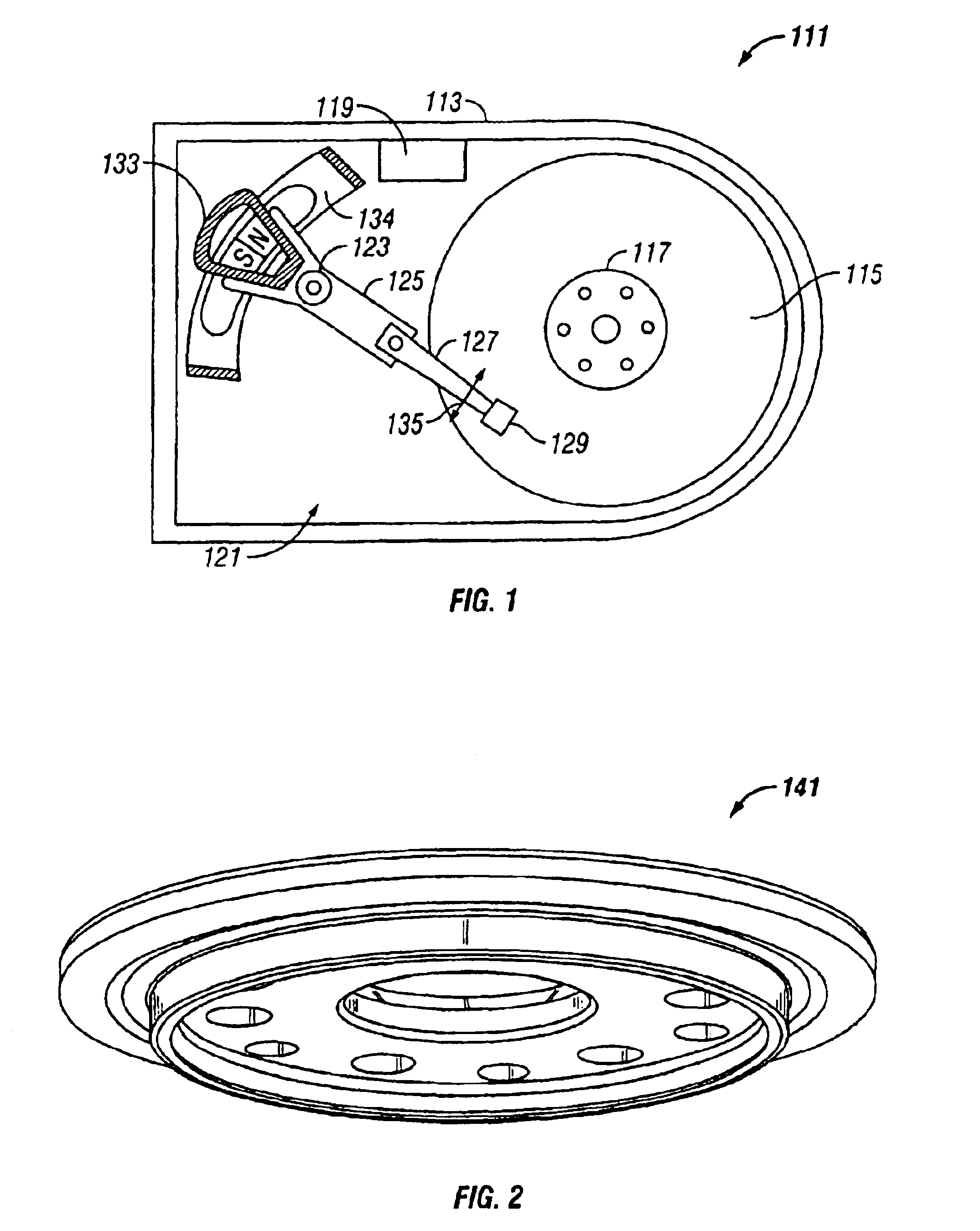

Hard disk drive with disk clamp inner wall engaging bearing sleeve outer wall

InactiveUS6961216B2Reduce complexityAccurate featuresRecord information storageHard disc driveElectric motor

A disk clamp for securing data storage disks to the hub of a spindle motor in a hard disk drive has a circumferential rib protruding from a lower surface of the disk clamp. A complementary recess is formed in the hub of the spindle motor for closely receiving the rib on the disk clamp. The inner diameter of the rib and the outer diameter of the recess are closely toleranced to provide a very precise centering feature for mounting and aligning the disk clamp with respect to the hub and spindle motor. This design reduces the complexity of the tooling and fixtures required to complete the assembly and the overall part cost is reduced.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Cord clip

InactiveUS20020020045A1Avoid mutual interferenceReduce part costSnap fastenersTravelling carriersHeadphonesMechanical engineering

A cord clip for fastening a cord attached to e.g. an earphone to an object such as a clothes is disclosed. The cord clip includes a clipping portion for clamping the object and a cord holding portion for holding the cord. The clipping portion is formed by a first annular portion having a discontinuity at a part thereof. The clipping portion is capable of clamping the object at a clamping portion thereof provided by a narrow gap formed by the discontinuity of the first annular portion by means of an elastic resilient force of the first annular portion. The cord holding portion is formed by a second annular portion having a discontinuity at a part thereof. The cord holding portion is capable of holding the cord therein by means of an elastic resilient force of the second annular portion. This elastic resilient force of the second annular portion is independent of that of the first annular portion. The first annular portion and the second annular portion are formed integrally in a single member.

Owner:HOSIDEN CORP

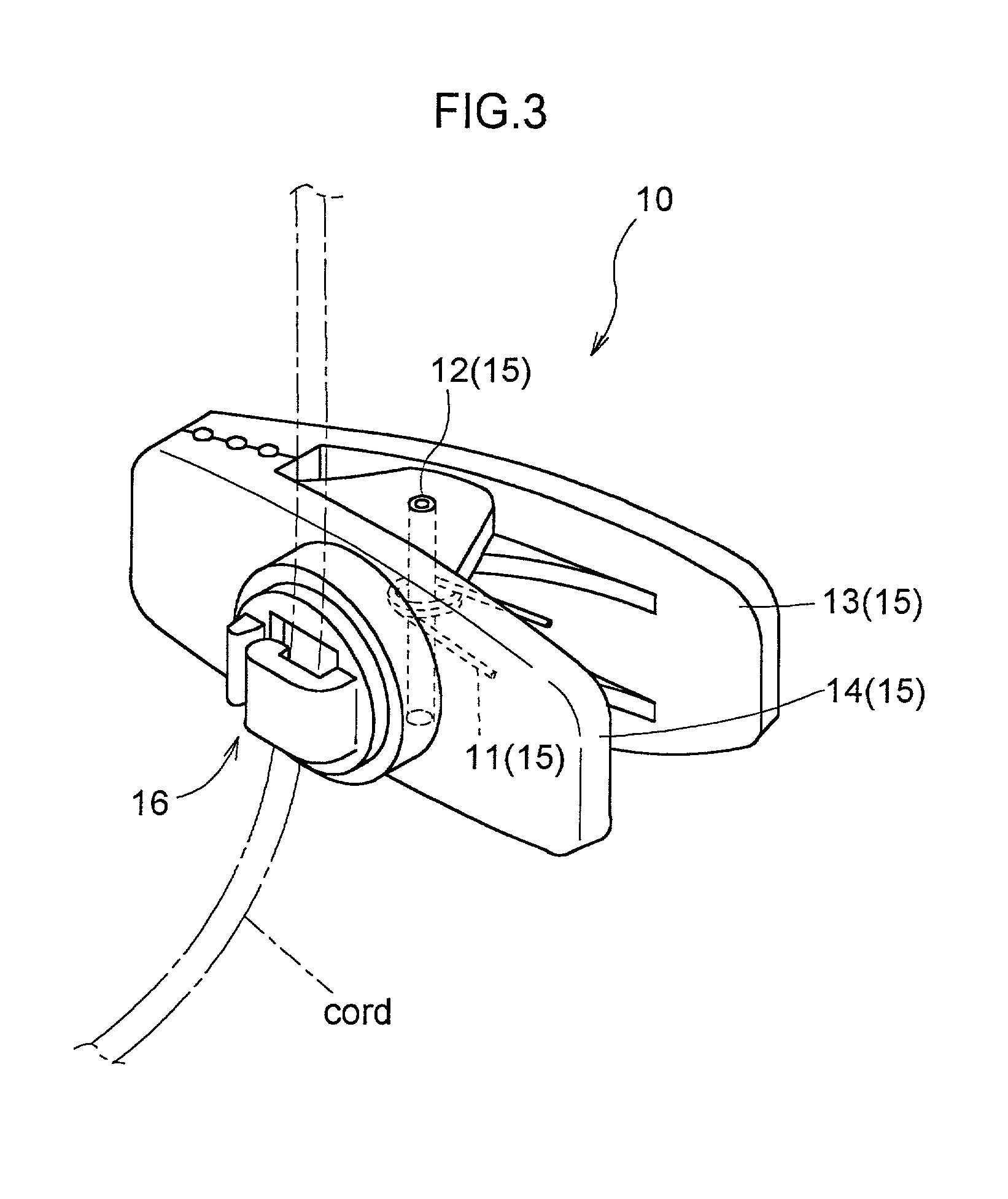

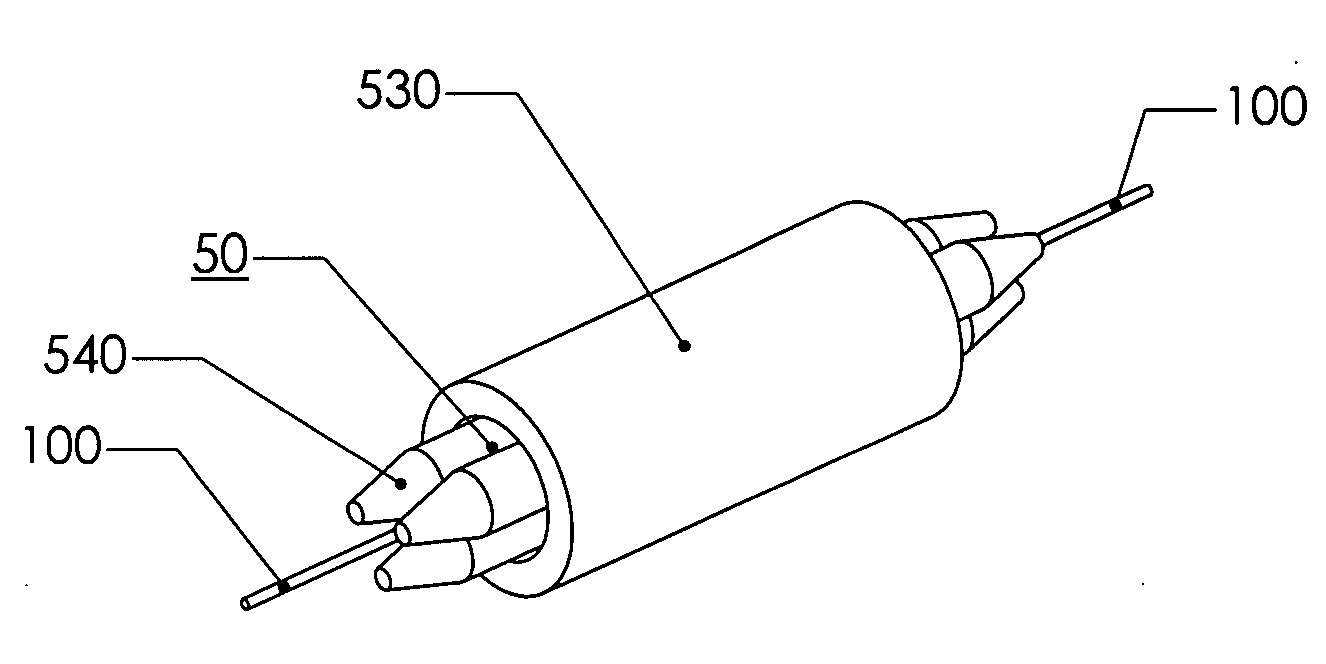

Fiber guiding platform for mechanical splicer, optical connectors, fiber holder and methods

A three rod bundle confined inside a sleeve is constructed as a light guiding fiber mechanical splicing device which is stiff, strong and precise, with no moving parts. The design also applies to splicing fibers to pre-polished optical connectors through a built-in model of this innovative mechanical splicer. Applying the Soddy circles formula and using a bin approach assists in deriving the exact rod sizes needed and sleeve bore size to accommodate the three-rod bundle, so that this apparatus can be properly designed to guide any size of light guide fibers and studs with minimum clearance. Rods of varying diameters are sorted into bins and chosen based upon the aperture desired, thus eliminating the need for tight tolerance of the diameters of the three rods. This unique design allows for construction of a precision virtual hole of very long depth, which enables two optical fiber studs to butt against each other with a core to core misalignment of less than 1 um for single mode fiber optics cables. Unlike prior arts, the sleeve holding the rods eliminates the need for any clamping mechanism to tighten a loose bundle, which induces undesirable mechanical strain. It also eliminates the need to use a fiber clamp to force the fiber studs against dimensionally unstable V or U groove alignment features which also induce undesirable mechanical strain. A fiber holder is also presented to depict the usefulness of this invention on hold fiber in position.

Owner:WANG WEI MIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com