Board grinding device and grinding method

A grinding and plate technology, which is applied in the direction of automatic grinding control devices, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as no specific solutions have been proposed, and achieve precise and efficient grinding Operation and efficient realization of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

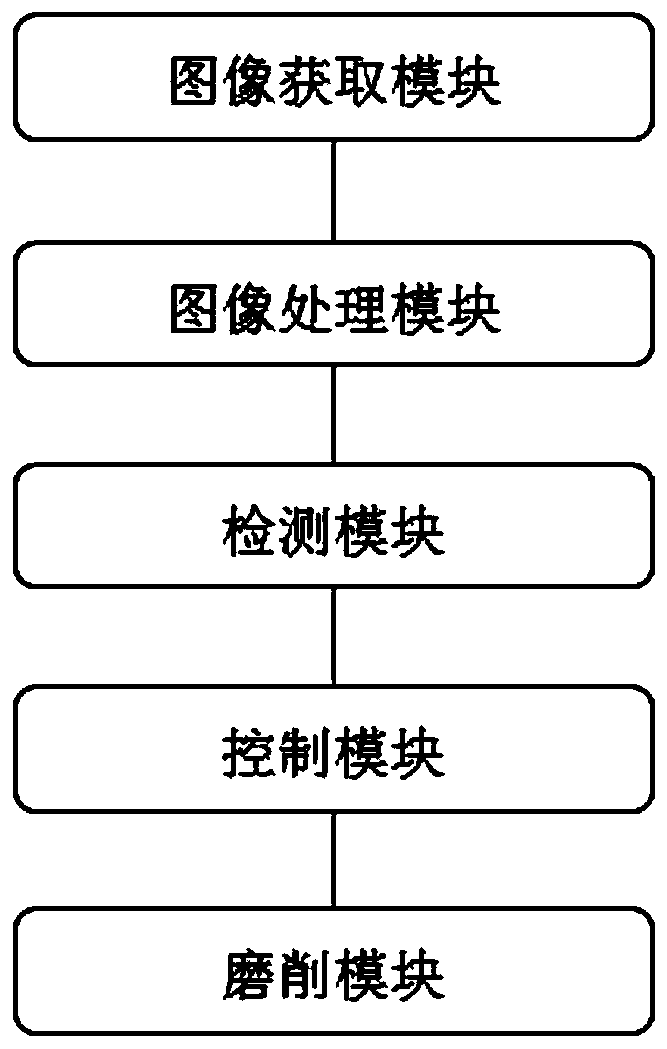

Embodiment 1

[0038]This embodiment provides a plate grinding device, including: a detection module, an image acquisition module, a grinding module, an image processing module and a control module, wherein the image acquisition module is used to acquire an image of the plate surface; the image The processing module is used to perform grayscale processing on the surface image of the board, compare the surface image of the board with the image template in the template database, and call the image template that matches the image, and receive The received image is divided into multiple areas to be ground, attribute detection information and corresponding feature information are obtained, and the feature information is matched with pre-stored feature information; the detection module is used to detect the plate to be ground according to the attribute detection information. The roughness of each area to be ground on the grinding surface, judge whether the roughness is within the preset roughness r...

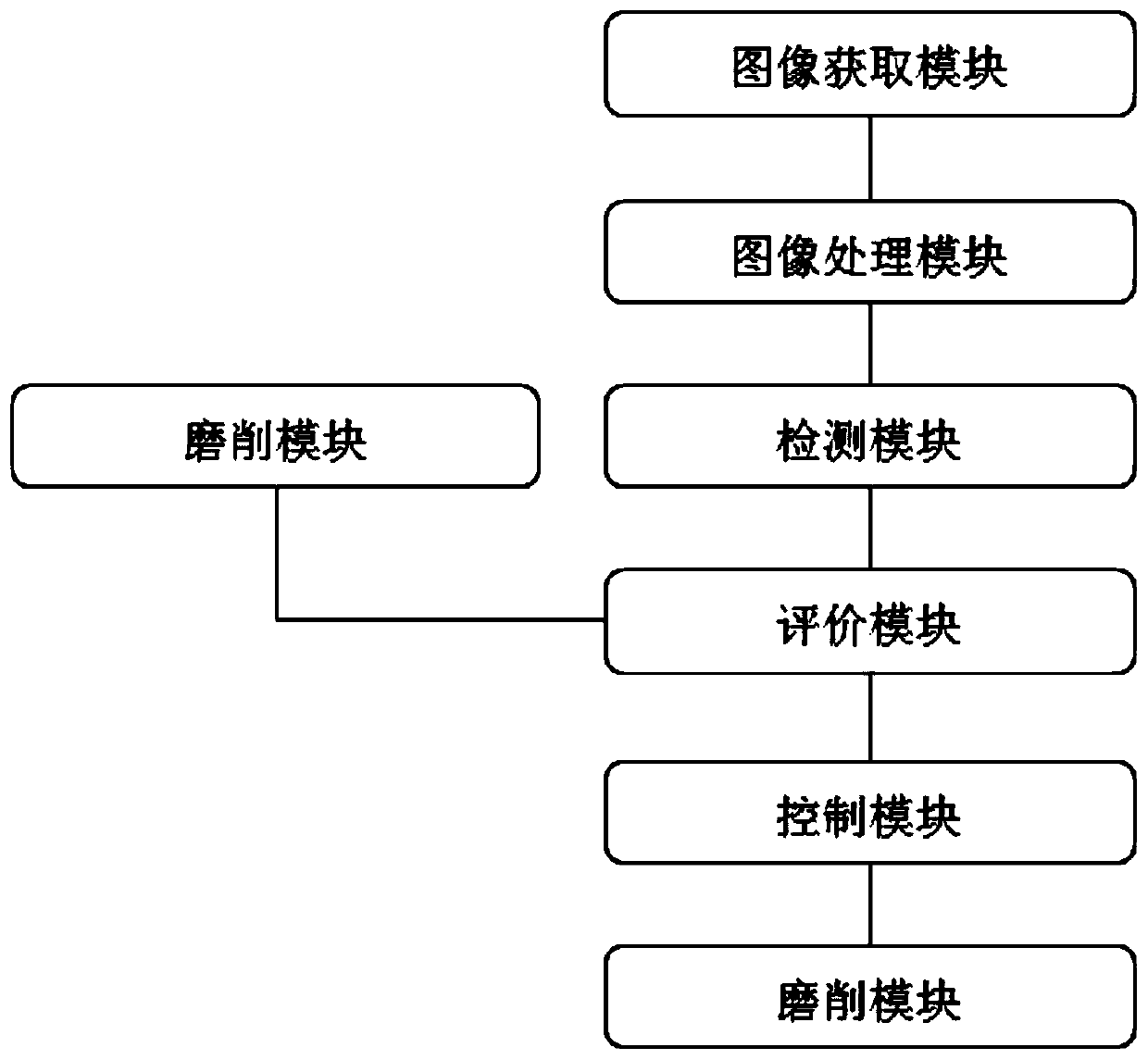

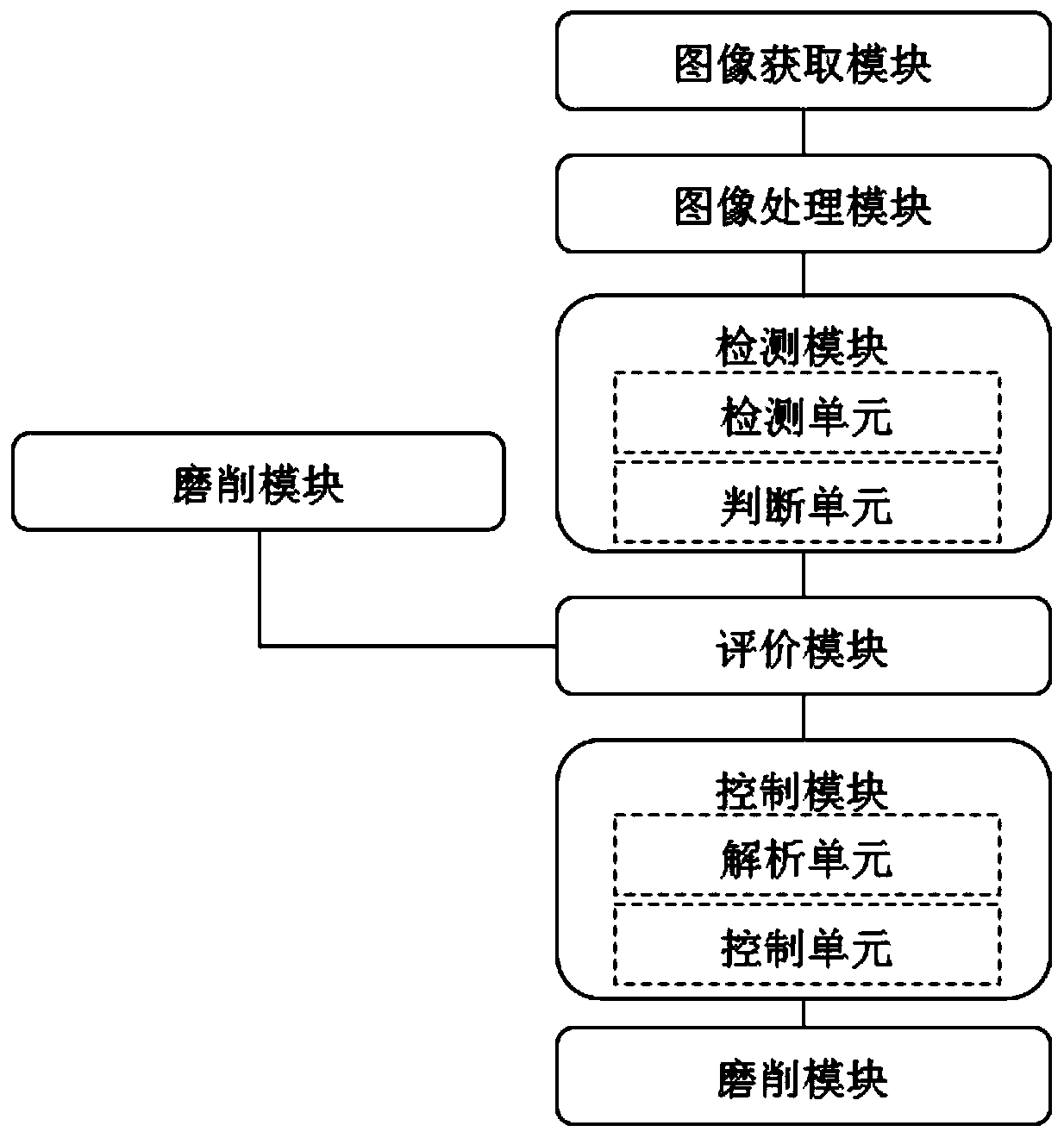

Embodiment 2

[0051] This embodiment provides a plate grinding device, including: a detection module, an image acquisition module, a grinding module, an image processing module and a control module, wherein the image acquisition module is used to acquire an image of the plate surface; the image A processing module, configured to perform grayscale processing on the surface image of the board, compare the surface image of the board with the image template in the template database, and call an image that matches the image and is set according to the distribution including the XY-axis Cartesian coordinate system According to the matching image template, the received image is divided into multiple areas to be ground, and the location information of the area to be ground can be clearly known through the Cartesian coordinate system, and the number information including the area to be ground, The attribute detection information of the size information and the position information and the correspondi...

Embodiment 3

[0065] Based on this embodiment, it is basically the same as Embodiment 2, except that: the plate grinding device also includes a path planning module, which is used to plan the grinding path according to the attribute detection information and the feature matching result, and send it to The control module controls the grinding module to grind the plate according to the path, and because the grinding path is clear, it can effectively avoid the situation that part of the plate surface is not ground , and can effectively improve the processing efficiency without secondary processing of the plate. In addition, the communication connection between the control modules of the adjacent plate grinding devices can realize the cross work of the adjacent grinding modules, thereby reducing the idle situation of the grinding devices.

[0066] In summary, the beneficial technical effects produced by the plate grinding device and grinding method disclosed in the present invention include: 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com