Catalyst compsns. for olefin polymerization and catalyst thereof

An olefin polymerization and catalyst technology, applied in the field of catalyst components and catalysts, can solve the problems of low activity, wide particle size distribution, low apparent density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

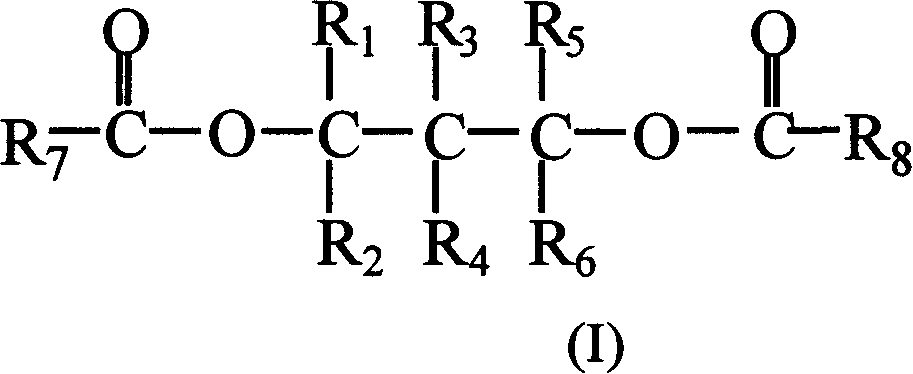

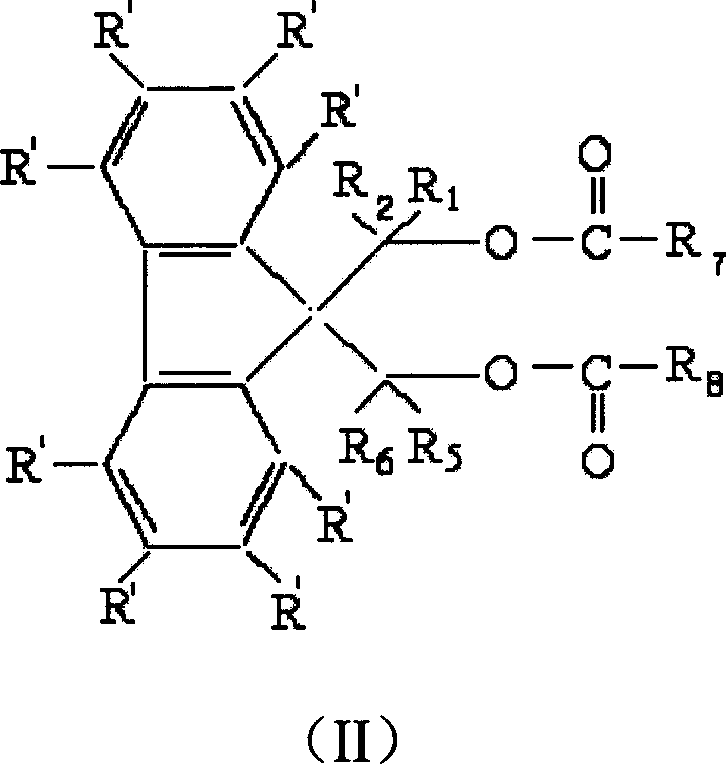

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1. Catalyst synthesis: after high-purity N 2 In the fully replaced glass bottle, add 5.0 g of anhydrous MgCl successively 2 , 120ml of toluene, 8.0ml of epichlorohydrin, and 10.0ml of tributyl phosphate were completely dissolved at 60°C, and the solution was cooled to -25°C, and then 50ml of titanium tetrachloride was dropped into it, at -25°C Stir at low temperature for half an hour, add 3.0 g of silica gel (Davison XPO2485, dry at 600°C for 4 hours before using the silica gel), then slowly raise the temperature to 90°C, add 1.0ml of 9,9-bis(benzylcarboxymethyl)fluorene, It was treated with 40 ml of titanium tetrachloride, filtered, washed twice with toluene and hexane, and dried in vacuo to obtain 10.6 g of a solid catalyst.

[0061] 2. Propylene polymerization: a stainless steel kettle with a volume of 2 liters is heated by N 2 After full replacement, add 11.9 mg of the above solid catalyst, 2.0 mmol of triethylaluminum, 0.1 mmol of cyclohexylmethyldimethoxysilane (C...

Embodiment 2

[0063] 1. Synthesis of catalyst: except that 2,4-pentanediol dibenzoate is used to replace 9,9-bis(benzylcarboxymethyl)fluorene, all the other are the same as in Example 1.

[0064] 2. Polymerization of propylene: same as in Example 1, and the polymerization results are shown in Tables 1 and 2.

Embodiment 3

[0066] 1. Catalyst synthesis: except that 4-methyl-3,5-diheptanol dibenzoate is used to replace 9,9-bis(benzylcarboxymethyl)fluorene, all the other are the same as in Example 1.

[0067] 2. Polymerization of propylene: same as in Example 1, and the polymerization results are shown in Tables 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com