Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Good internal pore structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry powder of active powder concrete and use method of dry powder

The invention relates to dry powder of active powder concrete and a use method of the dry powder. The dry powder comprises the following components by weight percent: 25%-55% of concrete, 5%-20% of blending stock, 30%-60% of fine aggregate, 5%-20% of micro powder, 2-5% of super plasticizing agent powder, 1-3% of air entraining agent powder, 0.2-1% of defoamer powder, and 0%-25% of fibers. According to the invention, through industrial production, water, of which the weight is 5%-10% of the weight of the dry powder, is added into the products on site, a conventional stirring technology and equipment are used for uniformly stirring, and a mixture meets a certain fluidity of construction performance and is used for easily preparing an active powder concrete prefabricated part or meets the requirement of cast in situ. The dry powder of active powder concrete and the use method of the dry powder have the advantages of stable and reliable quality, small air-entraining volume, excellent homogeneity and convenience in construction, can be widely applied to the engineering fields, such as petroleum, railway, nuclear power, municipal administration, ocean, military facilities and the like, and have excellent economic benefits.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

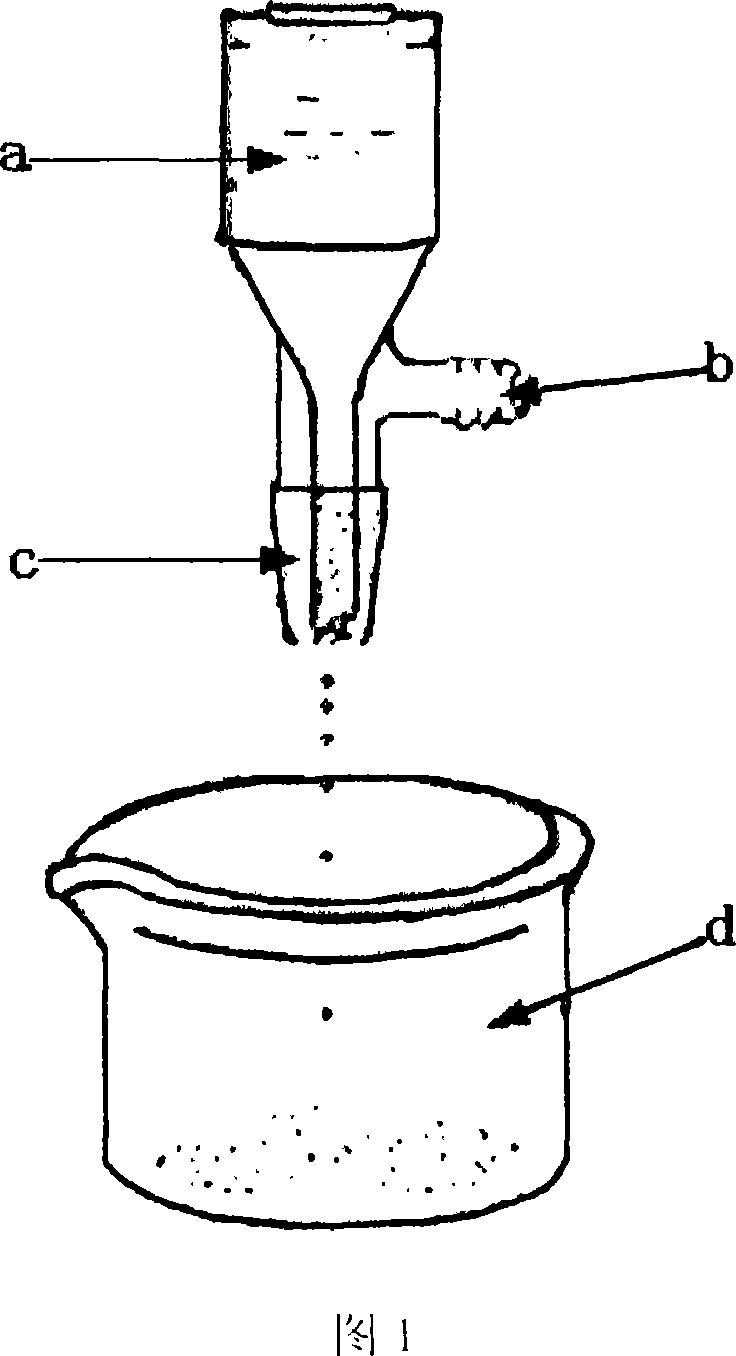

Freeze forming prepn process of ternary lithium ceramic microphere

The freeze forming preparation process of ternary lithium ceramic microsphere includes the following steps: mixing the material for ternary lithium ceramic microsphere, high molecular adhesive and solvent, mixing in a ball mill to form suspension slurry and defoaming; dropping the slurry into cooling medium to form microsphere in a microsphere forming unit, and low temperature vacuum drying in a freezing drier to form ceramic microsphere precursor; roasting, calcining and sintering; and programmed heat treatment to obtain ternary lithium ceramic microsphere. The ternary lithium ceramic microsphere has high sphericity, controllable size, high size dispersivity, high apparent density, high phase purity, high strength and other features.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Dry-mixed mortar prepared from industrial solid waste

The invention provides dry-mixed mortar prepared from industrial solid waste. The dry-mixed mortar is characterized by being prepared from materials in parts by weight as follows: 100 parts of cement, 300-400 parts of river sand, 50-100 parts of steel slag, 0-50 parts of iron mine tailings, 0-50 parts of glass powder, 1-2 parts of an interface reinforcing agent, 1-2 parts of an exciting agent, 0.1-0.5 parts of a water retaining agent, 1-2 parts of a water reducing agent and 0.1-0.3 parts of reinforcing fibers. According to the dry-mixed mortar, the industrial solid waste is fully utilized as aggregate to replace natural river sand, environmental protection is facilitated, resource recycling is realized, and meanwhile, performance such as the freezing resistance, the permeability resistance and the like of the dry-mixed mortar is improved through addition of the industrial solid waste.

Owner:四川震强建筑材料有限责任公司

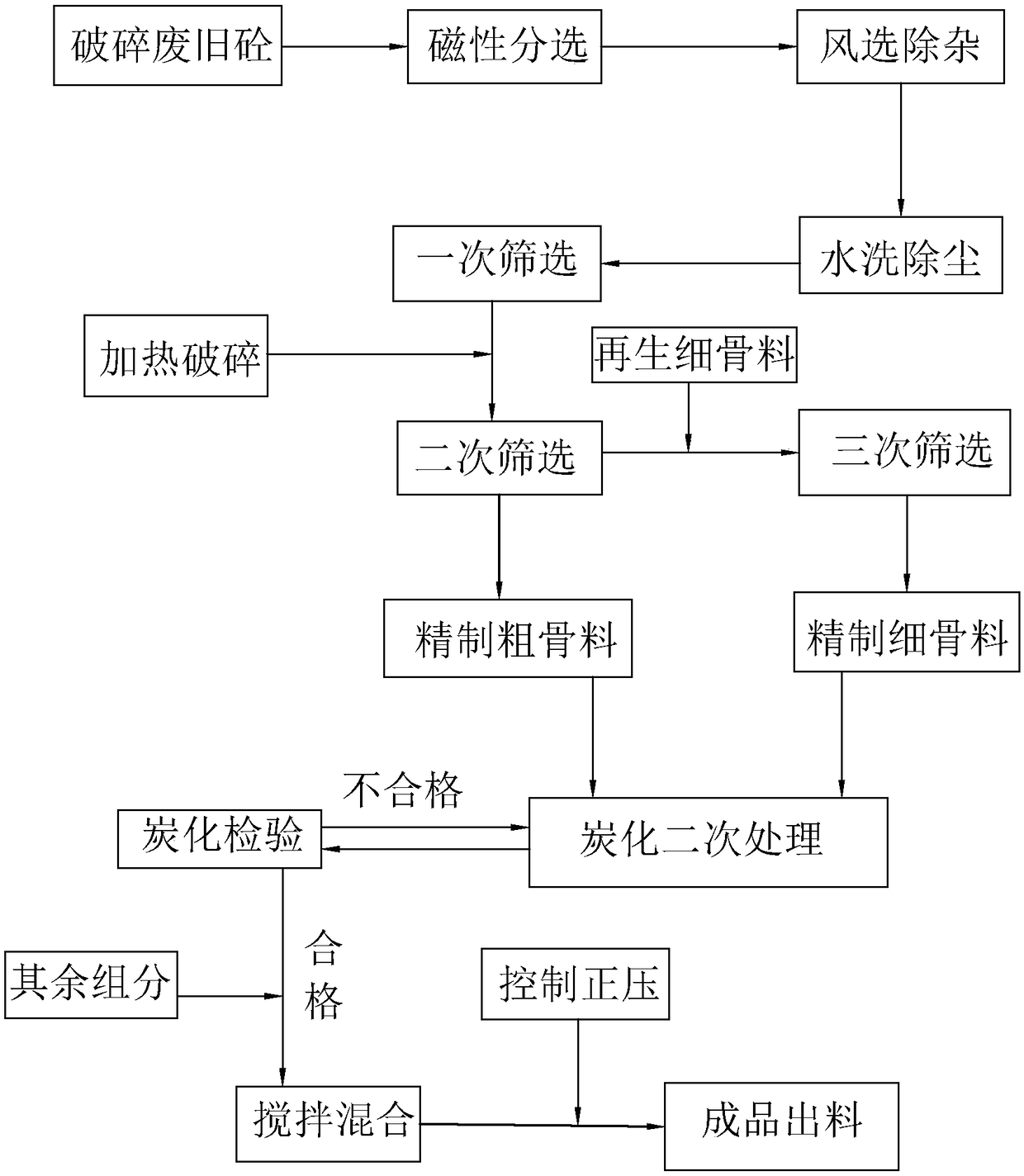

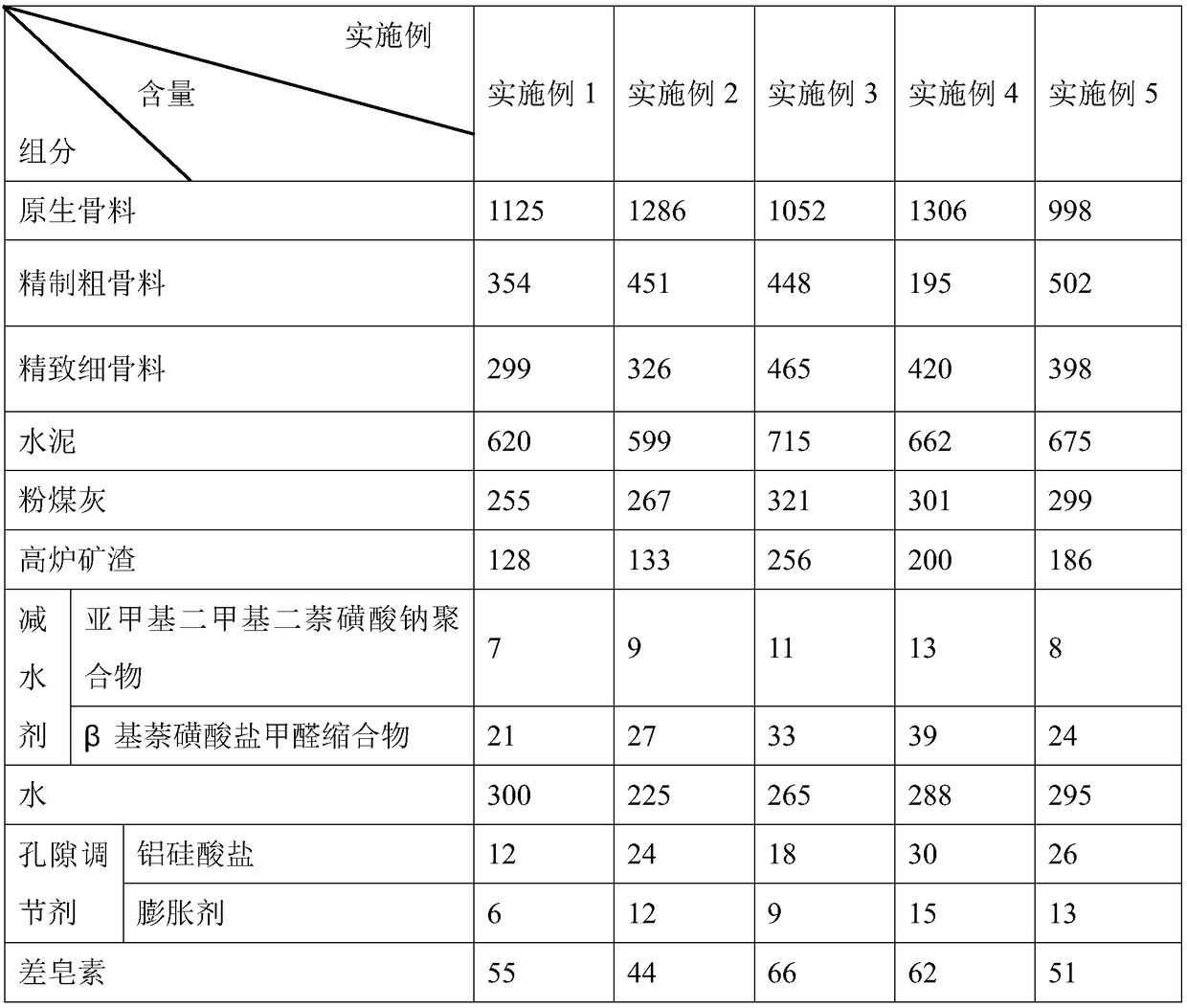

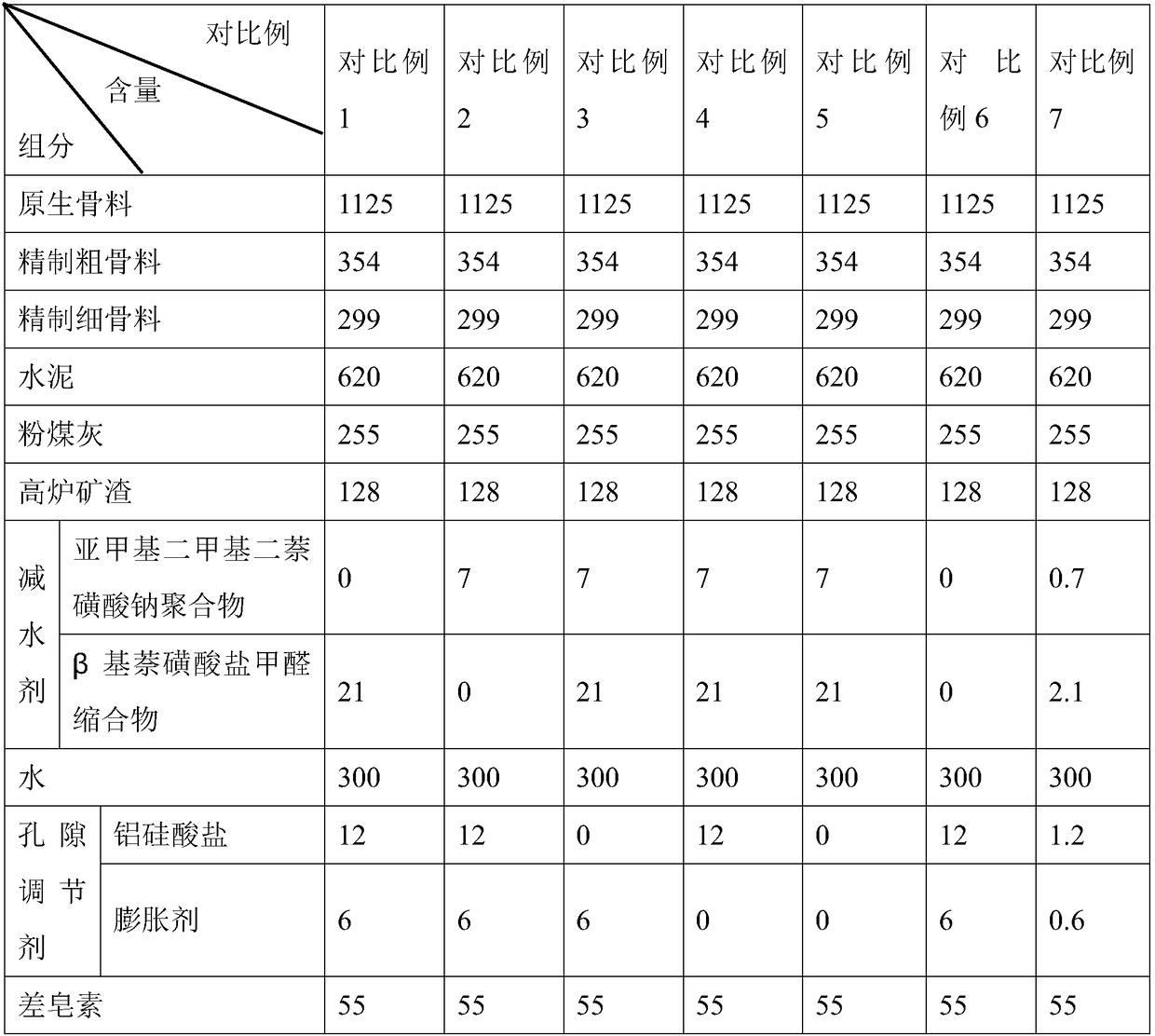

Regenerated concrete production technology

InactiveCN108975815AImprove mechanical propertiesGood internal pore structureSolid waste managementMechanical propertyRelative humidity

The invention discloses a regenerated concrete production technology. The regenerated concrete production technology comprises the following steps: crushing waste concrete, carrying out primary sieving and washing to obtain regenerated coarse aggregate and regenerated fine aggregate; heating the regenerated coarse aggregate and the regenerated fine aggregate to 300 to 400 DEG C; crushing again; carrying out secondary sieving after crushing, so as to obtain refined coarse aggregate and regenerated fine aggregate; putting the refined coarse aggregate and the regenerated fine aggregate into a sealed container and carbonizing; controlling the relative humidity to be 40 to 85 percent and the CO2 concentration to be 30 to 75 percent until the weight of non-carbonized regenerated aggregate is less than or equal to 5 percent; S4, preparing regenerated concrete; stirring and mixing the regenerated aggregate treated by S3 with raw aggregate, an adhering material, filler and an additive, so as toobtain a finished product. With the adoption of the regenerated concrete production technology, waste concrete is subjected to multi-level treatment to obtain relatively qualified regenerated aggregate, and mechanical properties are also greatly improved; meanwhile, the effect of slowly releasing carbon dioxide is realized after the concrete is carbonized, drying shrinkage and creep in the laterperiod can be relieved and the stress and anti-permeability capability of the regenerated aggregate are improved and the service life of the regenerated aggregate is prolonged.

Owner:武汉华强新型建筑材料有限公司

Artificial steel slag aggregate and preparation method and application thereof

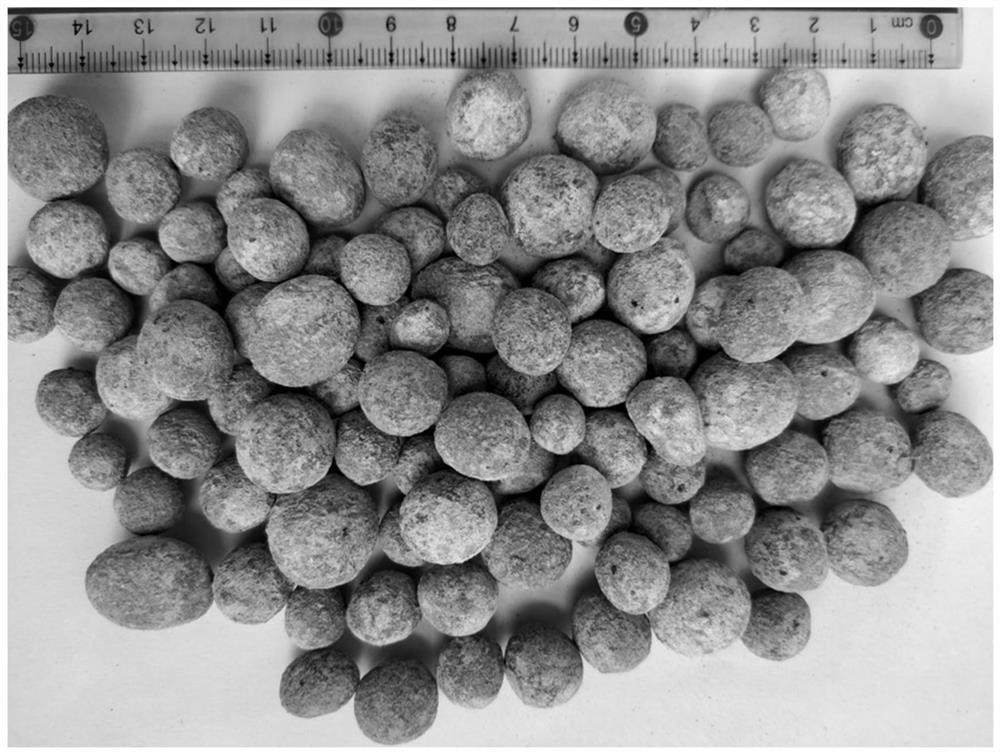

PendingCN112266193AGood performanceAchieve permanent storageSolid waste managementBall millSilicate Cement

The invention discloses an artificial steel slag aggregate and a preparation method and application thereof. The preparation method comprises the following steps: step 1, grinding steelmaking tailingsby using a ball mill to obtain uniform steel slag powder; 2, weighing Portland cement, an admixture fine powder and steel slag powder, and conducting uniform mixing to obtain an aggregate raw material; 3, preparing an additive aqueous solution; 4, putting the aggregate raw material into a ball forming mill, and uniformly spraying the additive aqueous solution prepared in the step 3 to form balls,so as to obtain spherical artificial steel slag aggregate; step 5, putting the pelletized aggregate into a closed environment or a natural environment for pre-curing; and step 6, putting the pre-cured aggregate into a carbonization device for carbonization treatment to finally prepare the artificial steel slag aggregate. The artificial steel slag aggregate prepared by the method can achieve the goals of safety and high strength, the crushing index of the aggregate can reach 9.26% and reach the I-grade aggregate use standard, the production process is simple, the solid waste is recycled, the carbon dioxide is absorbed and cured, and the artificial steel slag aggregate is free of burning, low-carbon and environment-friendly.

Owner:NANJING UNIV OF TECH

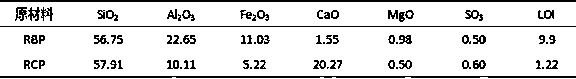

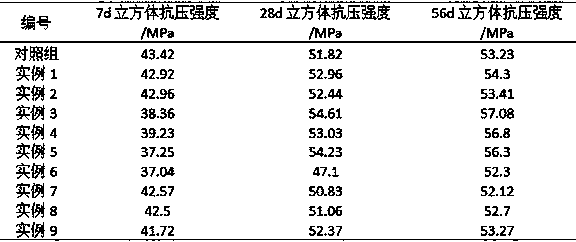

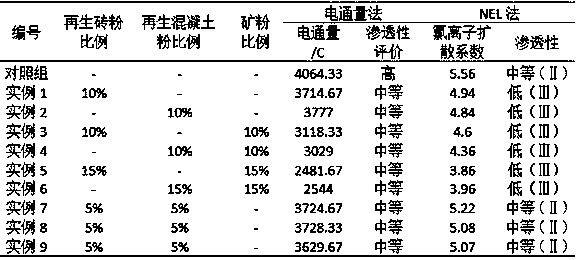

Regenerated powder concrete with good durability, and preparation method thereof

The invention particularly relates to a preparation method of recycled concrete for improving chlorine ion resistance by utilizing regenerated powder. The method comprises: respectively grinding powders in waste concrete and waste clay brick breaking processes to prepare regenerated powder, partially replacing cement with the regenerated powder, and stirring to prepare the recycled concrete by adopting a neat paste stone-wrapping method. According to the invention, the prepared recycled concrete can fully utilize the construction waste and reduce the cement consumption, has good chlorine ion penetration resistance, and further has remarkable economic benefits, social benefits and environmental benefits.

Owner:FUZHOU UNIVERSITY

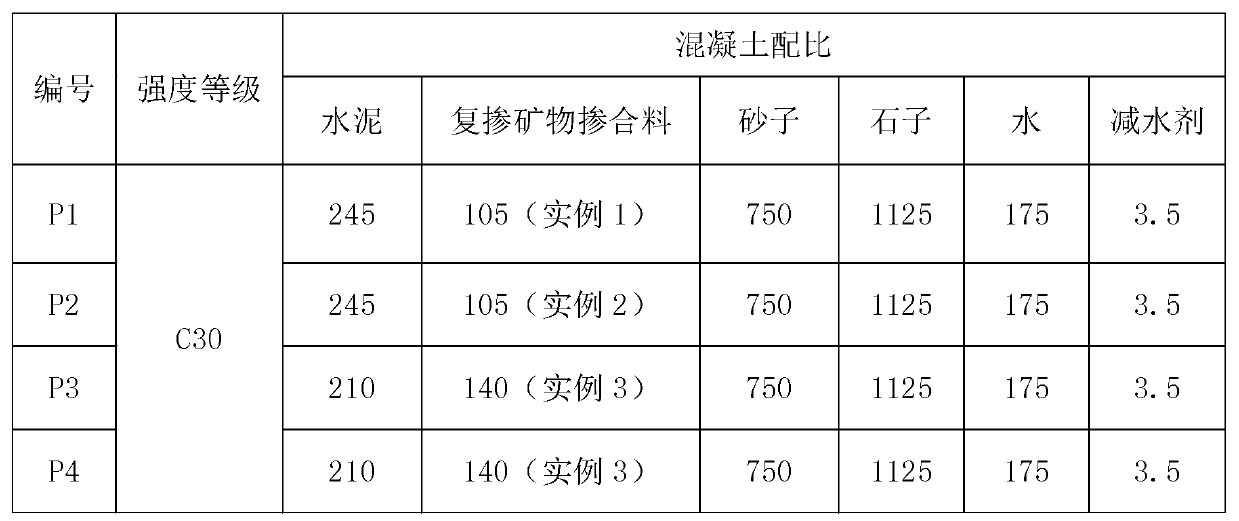

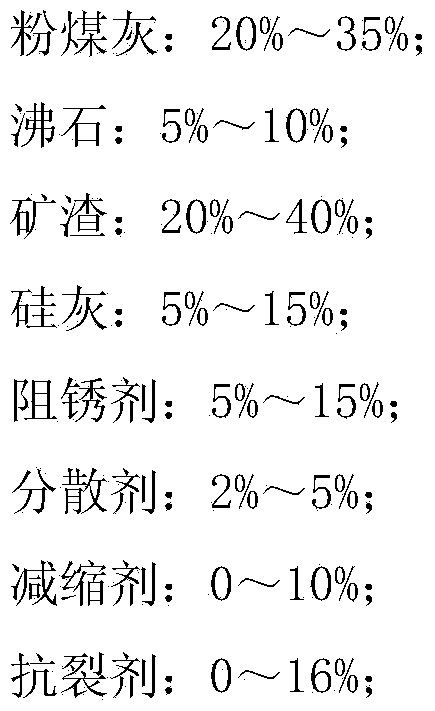

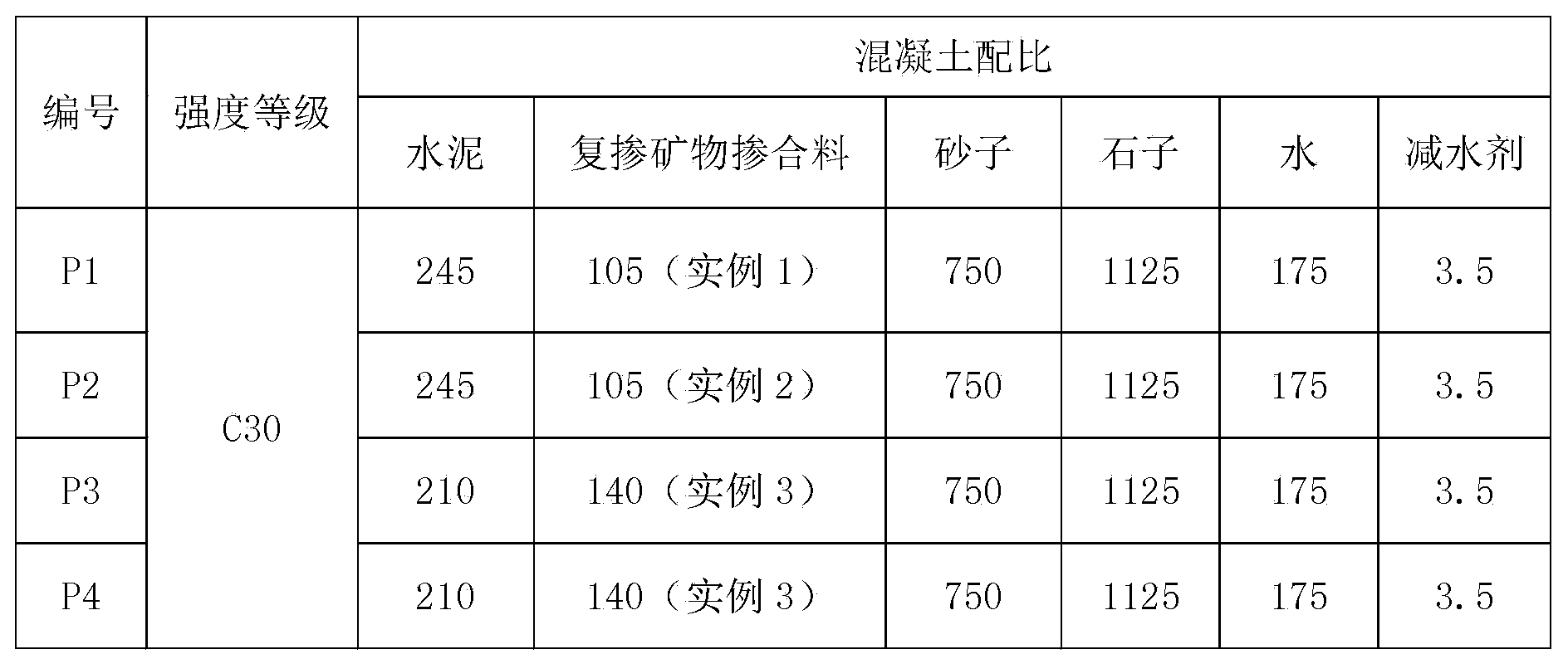

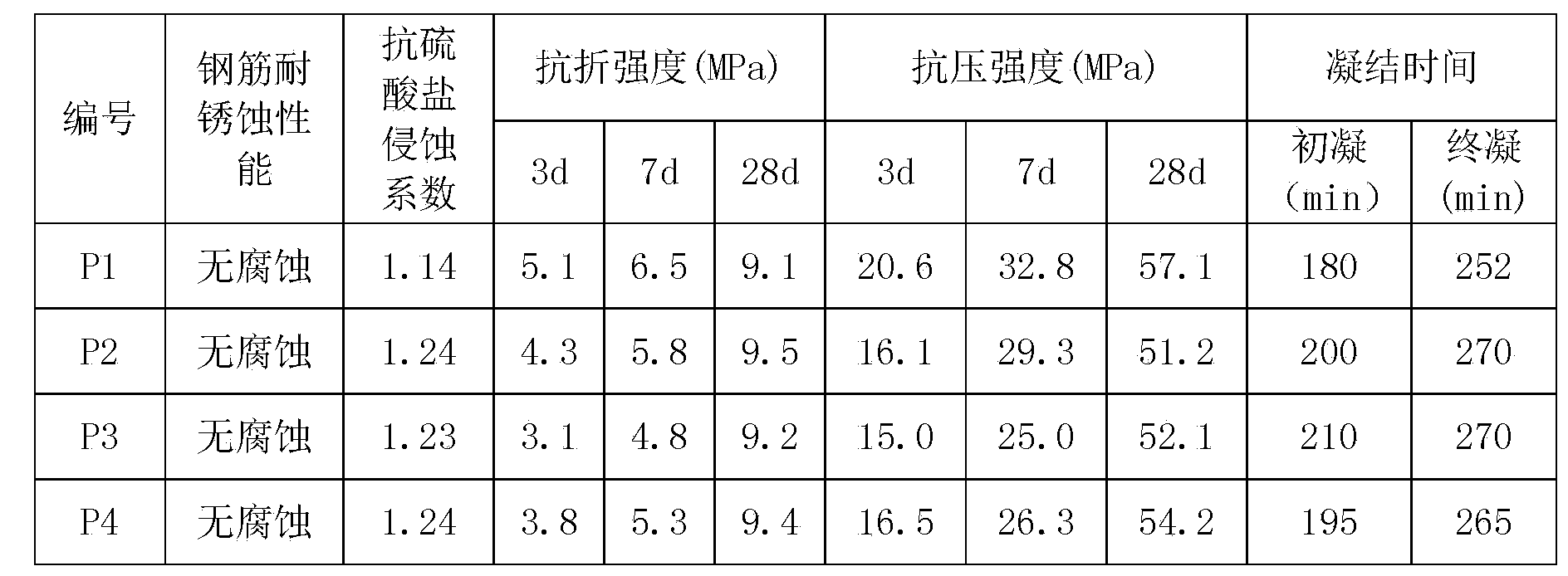

Compound-doped mineral admixture for reinforced concrete structure of oceanographic engineering

The invention relates to the field of concrete additives for oceanographic engineering, and aims at providing a compound-doped mineral admixture for a reinforced concrete structure of the oceanographic engineering. The compound-doped mineral admixture comprises the following components in percentage by mass: 20 to 35% of coal ash, 5 to 10% of zeolite, 20 to 40% of slag, 5 to 15% of silica fume, 5 to 15% of corrosion inhibitor, 2 to 5% of dispersing agent, 0 to 10% of shrinkage reducing agent, and 0 to 16% of antimitotic agent. According to the compound-doped mineral admixture, multi-component design is adopted, the functions of all the components are combined and coordinated, and thus the crack resistance and rust resistance of the structure are optimized, and the wear resistance of the oceanographic engineering can be improved; and a plurality of functional components are compounded into the admixture, so that the functional components can be uniformly dispersed in the concrete, and the effects of stably resisting crack and resisting rust can be realized. The compound-doped mineral admixture can reduce the concrete agitating conditions and reduce the usage cost of an enterprise, and is convenient for massive popularization and application.

Owner:浙江合力海科新材料股份有限公司

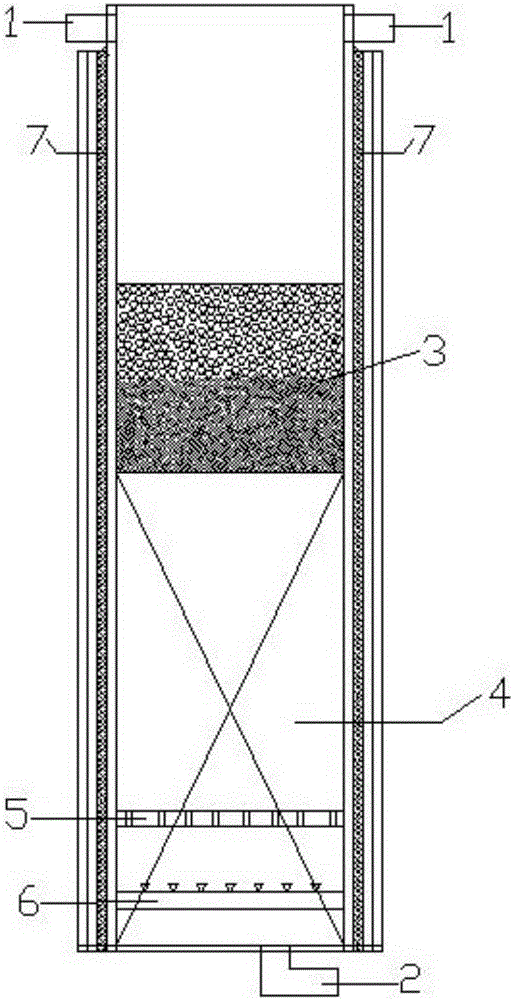

Biological aerated filter system with alkaline leaching excess sludge as filler, operating method of biological aerated filter system and preparing method of filler

InactiveCN106082428ARealize the harmless utilization of resourcesLarge emissionsWater treatment parameter controlTreatment using aerobic processesSludgeGlass wool

The invention discloses a biological aerated filter system with alkaline leaching excess sludge as filler, an operating method of the biological aerated filter system and a preparing method of the filler, and belongs to the technical field of sewage disposal. The biological aerated filter system comprises a water inlet and a water outlet, and further comprises a filter layer, the filler, a microporous aeration device and a backwash device. The biological aerated filter system is provided with the filter layer, the microporous aeration device and the backwash device in sequence from top to bottom, the space between the filter layer and the microporous aeration device in the biological aerated filter system is filled with the filler, the water inlet is located in the top of the biological aerated filter system, the water outlet is located in the bottom of the biological aerated filter system, the space between an inner column layer and an outer column layer of the biological aerated filter system is sealed to be vacuum, and the outer surface of the inner column layer is closely wrapped with a heat insulation glass wool layer. Due to the heat insulation arrangement, the biological aerated filter system still has high ammonia nitrogen and phosphorus removing efficiency in cold winter. By the adoption of the up-to-bottom water inlet mode, the problem that filler is likely to cause blockage is relieved; meanwhile, the purpose of recycling the industrial waste alkaline leaching excess sludge is achieved.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Preparation method of recycled concrete

PendingCN113149564AImprove performanceQuality improvementSolid waste managementPre treatmentUltimate tensile strength

The invention discloses a preparation method of recycled concrete, and the method comprises the following steps: pretreating: cleaning waste concrete blocks, performing hammering, removing impurities, performing primary crushing treatment, performing primary crushing and screening on the pretreated concrete blocks, screening the concrete subjected to primary crushing treatment, and obtaining concrete particles with the particle size of less than 30mm after screening; secondary crushing treatment: carrying out secondary crushing treatment and grading treatment on the concrete particles with the particle size larger than 30 mm after primary screening, separating and grading the concrete particles with the particle size smaller than 30 mm, removing micro powder with the particle size smaller than 1 mm, and mixing the materials. The preparation method of the recycled concrete can improve the performance of recycled aggregate and improve the quality of the recycled concrete; during use, the recycled concrete does not have a large number of cracks, the internal pore structure is improved, the strength is increased, and the performance is good.

Owner:河南多利克生态环保科技有限公司

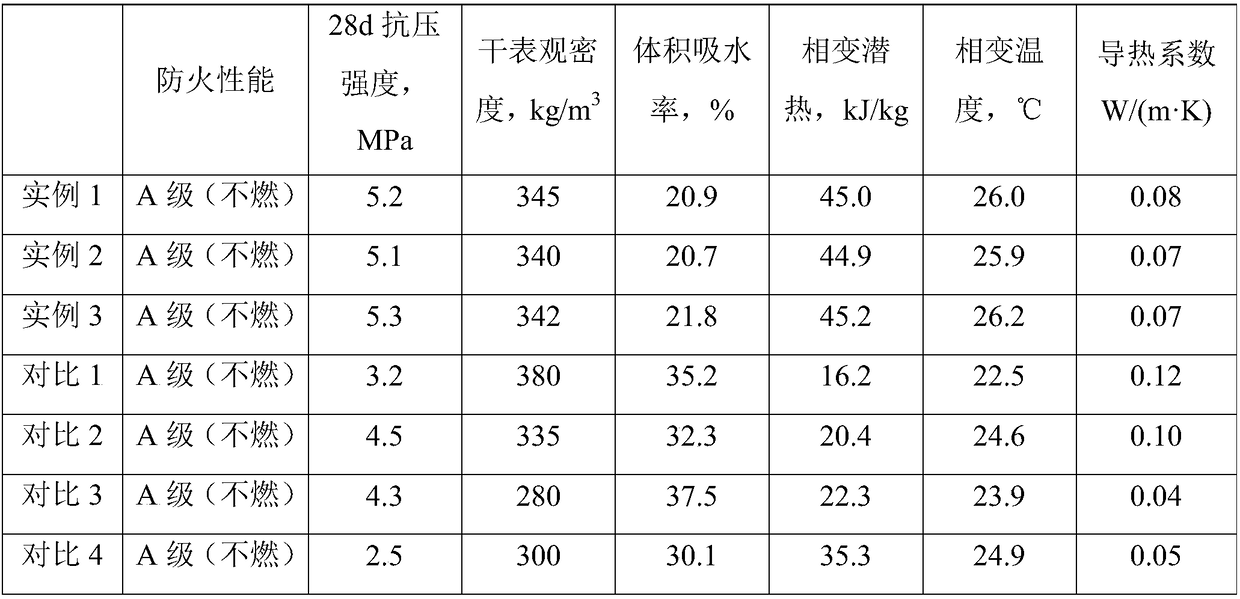

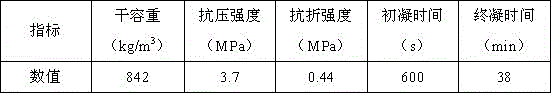

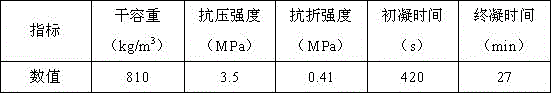

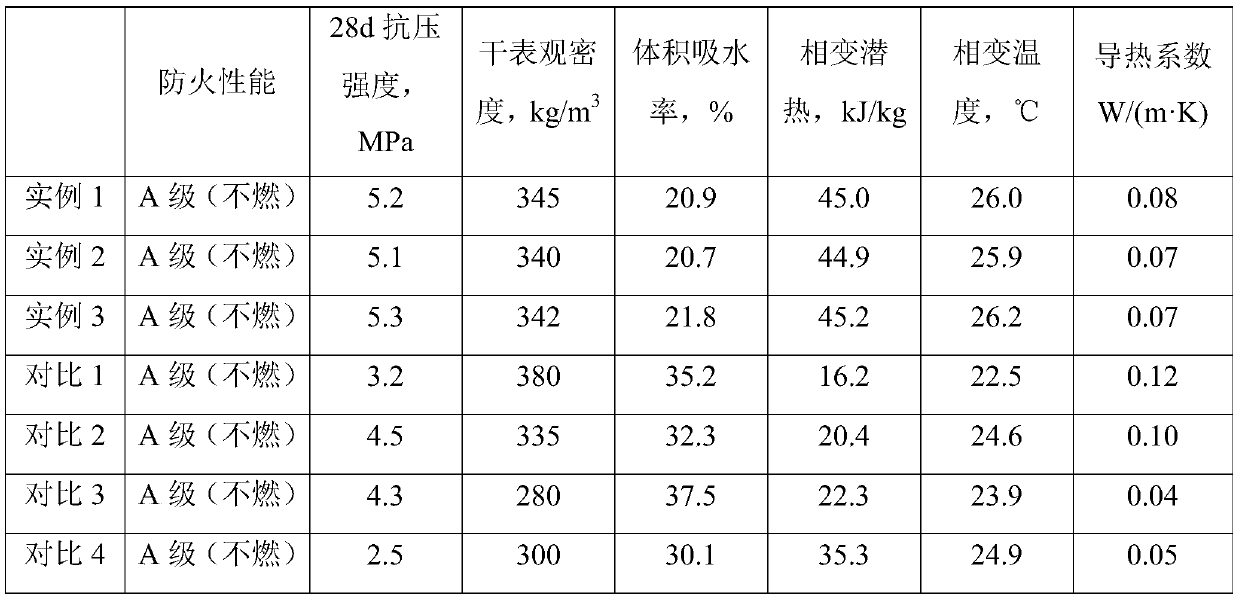

Lightweight foam cement composite thermal insulation material, and preparation method thereof

The invention discloses a lightweight foam cement composite thermal insulation material, and a preparation method thereof, and belongs to the technical field of building material. The lightweight foamcement composite thermal insulation material is composed of 60 to 90 parts of sulphate aluminium cement, 10 to 15 parts of modified foam phenolic aldehyde powder, 15 to 20 parts of fly ash, 1 to 2 parts of nanometer silicon oxide powder, 3 to 7 parts of hydrogen peroxide, 0.5 to 1.5 parts of calcium formate, 0.2 to 1 part of polypropylene fiber, 0.5 to 1.5 parts of calcium stearate, and 0.01 to 0.1 part of lithium carbonate. The lightweight foam cement composite thermal insulation material is an inorganic material, is excellent in flame resistance, belongs to A grade non-combustible materials, and is long in service life; and the service life is as long as that of buildings.

Owner:UNIV OF JINAN

Accelerant for accelerating anaerobic digestion of excess sludge as well as preparation method and application thereof

ActiveCN108975647ASpeed up digestionPromote dissolutionWaste based fuelBiological sludge treatmentEthylene diamineActivated carbon

The invention discloses an accelerant for accelerating anaerobic digestion of excess sludge as well as a preparation method and application thereof, and belongs to the field of solid waste reclamation. According to the accelerant as well as a preparation method and application thereof, the problems that in existing iron treatment excess sludge, pretreatment needs to be enhanced, the iron dissolution rate is low, the efficiency is low, and the sludge reduction and reclamation degree is low can be solved, the excess sludge is used as a raw material, a series of steps are carried out so as to obtain sludge activated carbon which is highly activated, then the sludge activated carbon, iron powder, common activated carbon and a binder are mixed according to a specific ratio and are pressed intoballs, sintering is carried out, then sodium ethylene diamine tetracetate is added, pressing forming is carried out, and drying is carried out so as to obtain the accelerant for accelerating anaerobicdigestion of the excess sludge; and an iron-carbon micro-electrolysis principle is utilized, the dissolution of iron is accelerated, due to the existence of ethylene diamine tetraacetic acid and Mn,the pH range of the accelerant in the sludge treatment is widened, the pH of the sludge does not need to be adjusted, the sludge can be treated by directly using the accelerant obtained through the method, and the cost is lowered.

Owner:NANJING UNIV

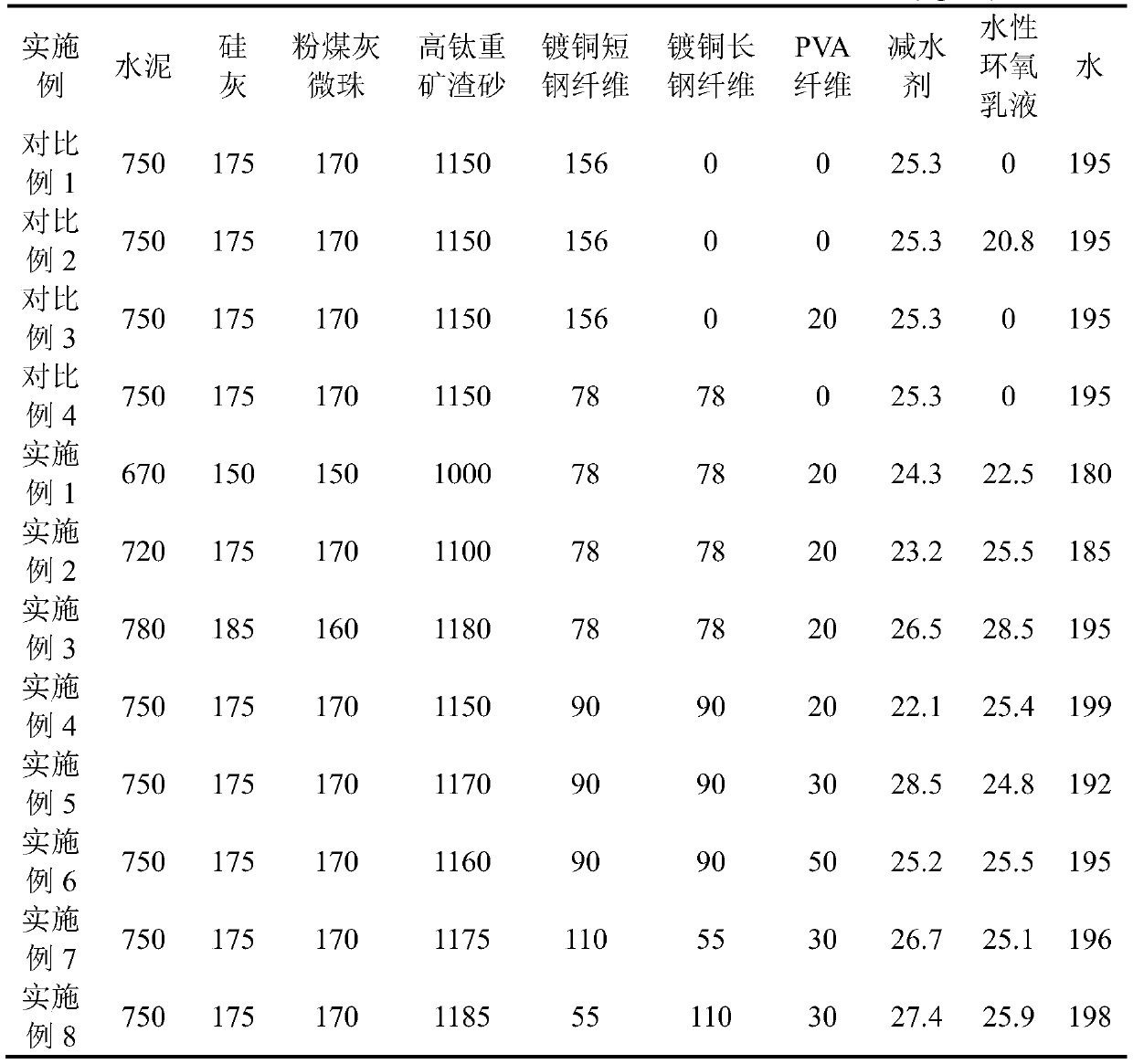

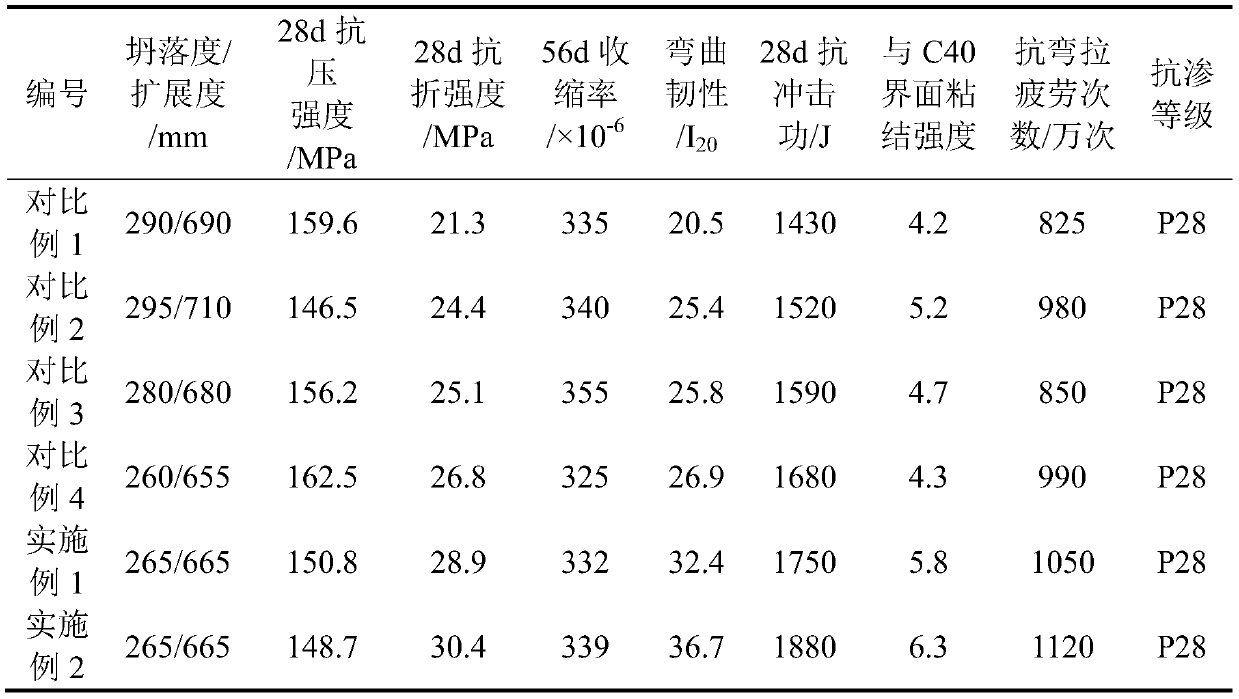

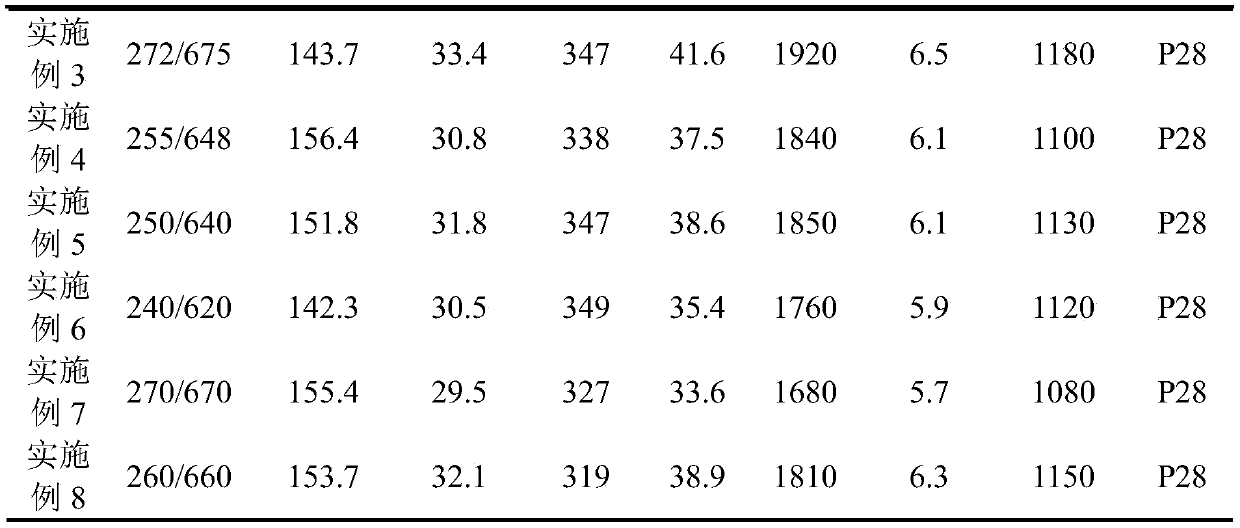

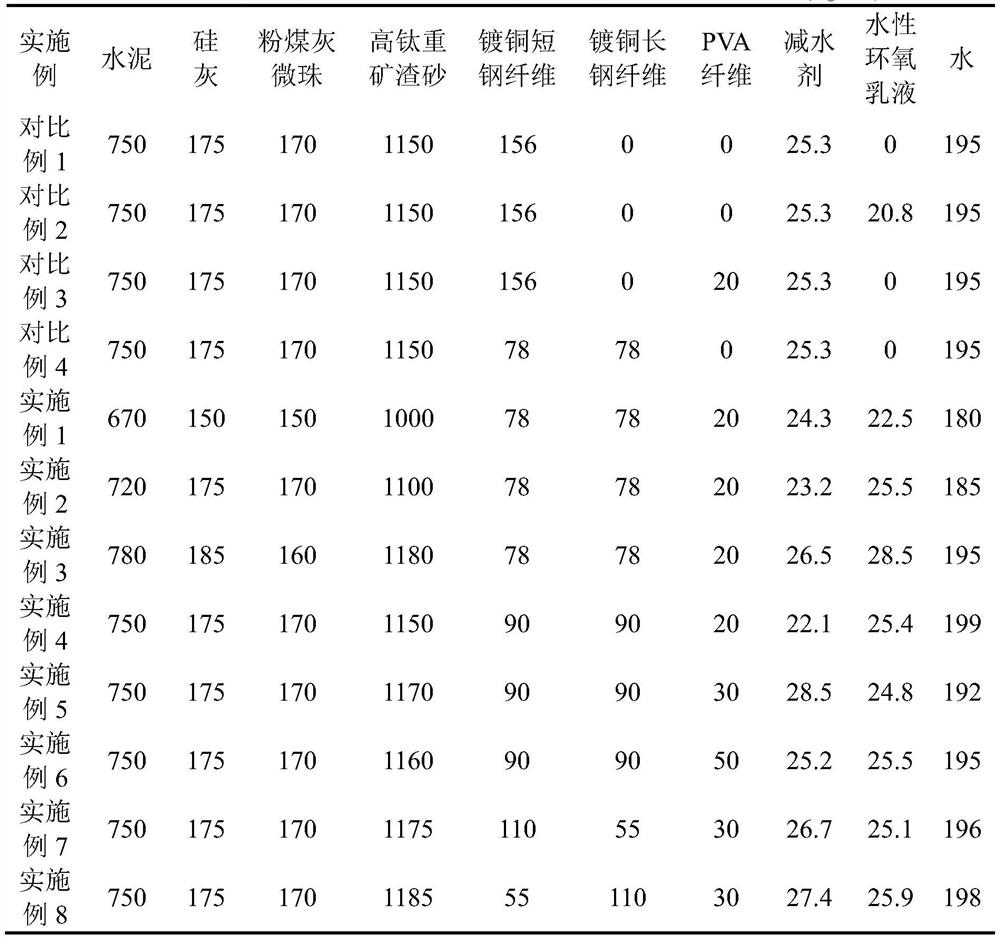

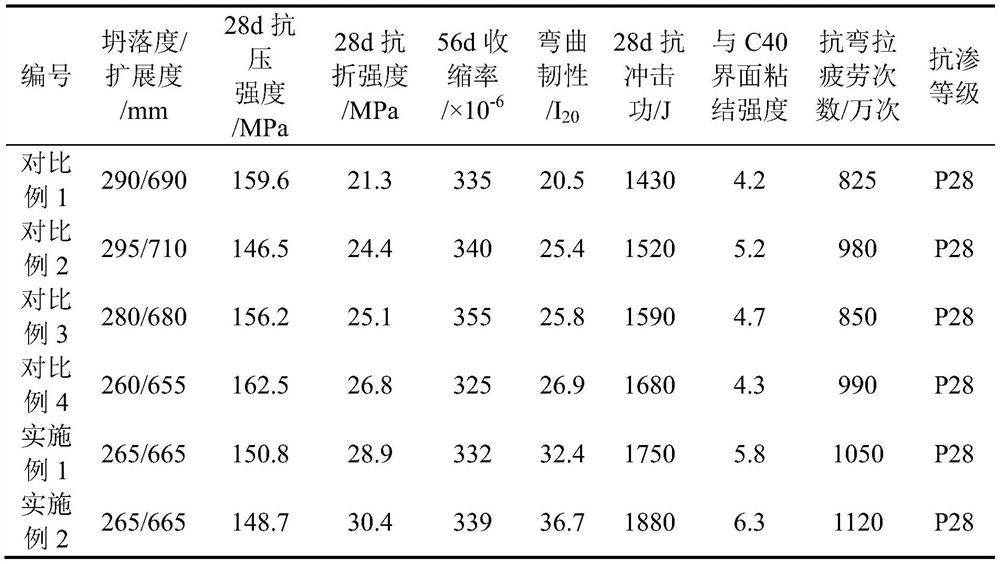

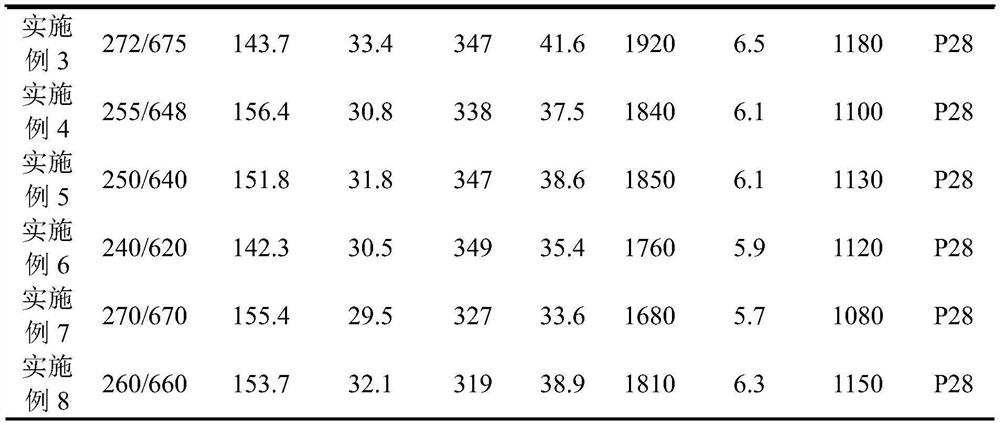

Ultra-high performance concrete for expansion joint transition area and preparation method thereof

The invention discloses an ultra-high performance concrete for an expansion joint transition area. The ultra-high performance concrete is prepared from the following main raw materials: cement, fly ash microbeads, silica fume, high-titanium heavy slag sand, organic-inorganic hybrid fiber, a waterborne epoxy emulsion, a water reducing agent and water. According to the invention, the high-titanium heavy slag sand is used as aggregate, the internal curing and pin effects of the aggregate are utilized to improve the volume stability, anti-permeability and cracking resistance, and mechanical properties of the concrete; an organic-inorganic fiber composite toughening technology is adopted to enhance the bending toughness and impact resistance; the water reducing agent and fly ash microbeads areadded to improve the working performance and compactness; and the obtained ultra-high performance concrete has the advantages of high flow state, low shrinkage, high toughness, high adhesion, high impact performance, fatigue resistance and the like, can fundamentally solve the problems of repeated repairing, repeated damage and the like of concrete in expansion joint transition areas, and has important practical application value.

Owner:WUHAN UNIV OF TECH

Rapid hardening early strength type foam concrete and preparation method thereof

The invention discloses rapid hardening early strength type foam concrete and a preparation method thereof. The rapid hardening early strength type foam concrete comprises components with percentage by mass: 20%-40% of composite cement, 15%-25% of water, 5%-10% of b-hemihydrated gypsum, 10%-20% of first-grade fly ash, 5%-15% of S105 activated mineral powder, 3%-5% of condensed silica fume, 5%-15% of polymer emulsion, 0.05%-0.2% of polypropylene fibers, 0.3%-0.5% of polycarboxylate superplasticizer, 0.05%-0.1% of cellulose ethers and 0.05%-0.15% of foaming agents which are mixed and stirred. The rapid hardening early strength type foam concrete is small in contraction, large in flexibility and excellent in subsidence resistance, greatly reduces setting time of foam concrete binding materials, reduces number of foams losing stability along with time, and optimizes structures of inner holes.

Owner:SOUTHEAST UNIV +1

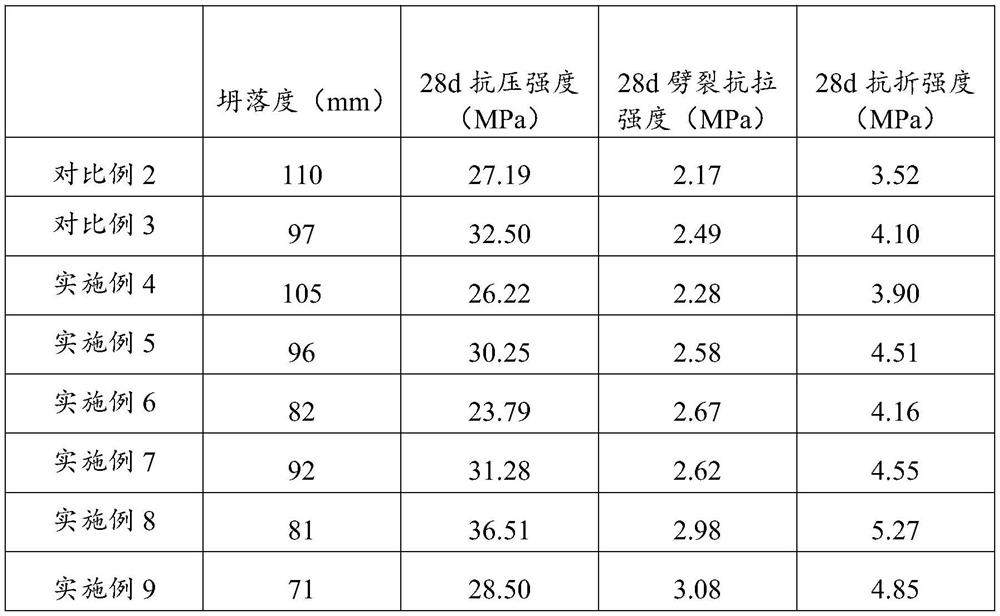

Nano silicon dioxide and basalt fiber synergistically enhanced recycled concrete and preparation method thereof

The invention discloses a nano silicon dioxide and basalt fiber synergistically enhanced recycled concrete and a preparation method thereof.The mass ratio of cement to water to modified recycled coarse aggregate to natural fine aggregate to basalt fiber to polycarboxylic acid high-performance water reducing agent in the recycled concrete is 1: (0.48-0.52): (2.72-2.76): (1.45-1.49): (0.006-0.018): (0.006-0.012), the compressive strength of the recycled concrete reaches 36.51 MPa, the splitting tensile strength reaches 2.98 MPa, and the tensile strength of the recycled concrete reaches 36.51 MPa. And the breaking strength reaches 5.27 Mpa. Besides, nano silicon dioxide which is not completely reacted and exists on the surface of the recycled coarse aggregate can react with a cement hydration product Ca (OH) 2 to generate C-S-H gel, so that mortar attached to the surface of the recycled coarse aggregate is strengthened, and the strength of an interface transition area of the recycled concrete is improved; the distribution of the basalt fibers is facilitated by the rough surfaces of the nano silicon dioxide and the recycled aggregate, so that the toughening and anti-cracking effects of the fibers are fully exerted, and the mechanical property and the durability of the recycled concrete are remarkably improved by the synergistic effect of the nano silicon dioxide and the basalt fibers.

Owner:ZHENGZHOU UNIV +1

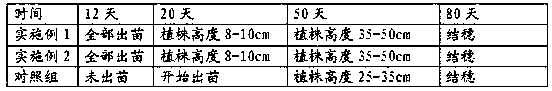

Saline-alkali soil improvement fertilizer and preparation method thereof

InactiveCN111170794AImprove growth performanceImprove water absorption and retention capacitySuperphosphatesFertilizer mixturesMicroorganismAlkali soil

The invention discloses a saline-alkali soil improvement fertilizer and a preparation method thereof. The improvement fertilizer comprises the following components in parts by weight: 15-25 parts of nutrient substances, 50-65 parts of an organic filler, 8-15 parts of an inorganic filler, 15-50 parts of acidic mellow soil and 5-15 parts of water retention resin. The saline-alkali soil improvement fertilizer mainly comprises the nutrient substances, the organic filler, the inorganic filler, the acidic mellow soil and the water retention resin. When the saline-alkali soil improvement fertilizer is prepared, the inorganic filler and the nutrient substances are used as main raw materials and a polyglutamic acid aqueous solution is used as an adhesive for granulation to obtain granules which have good water retention property and can provide nutrients for growth of microorganisms and plants, and then a water retention layer is formed on the surfaces of the granules through the water retention resin, so that the land condition of the saline-alkali land can be effectively improved, and the growth effect of the plants is improved.

Owner:东营市农业科学研究院

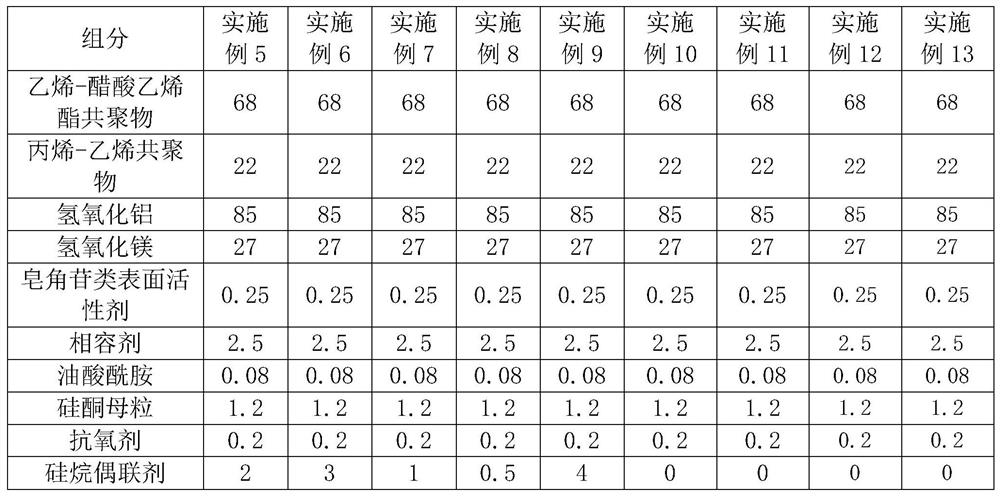

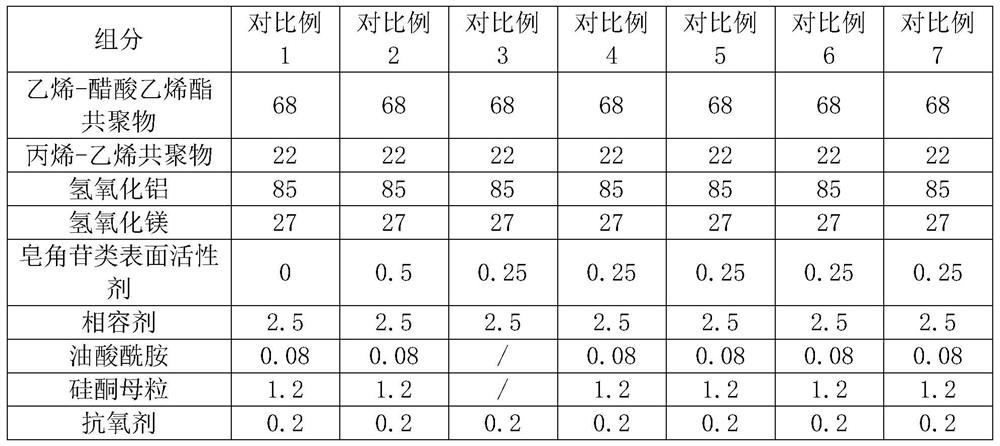

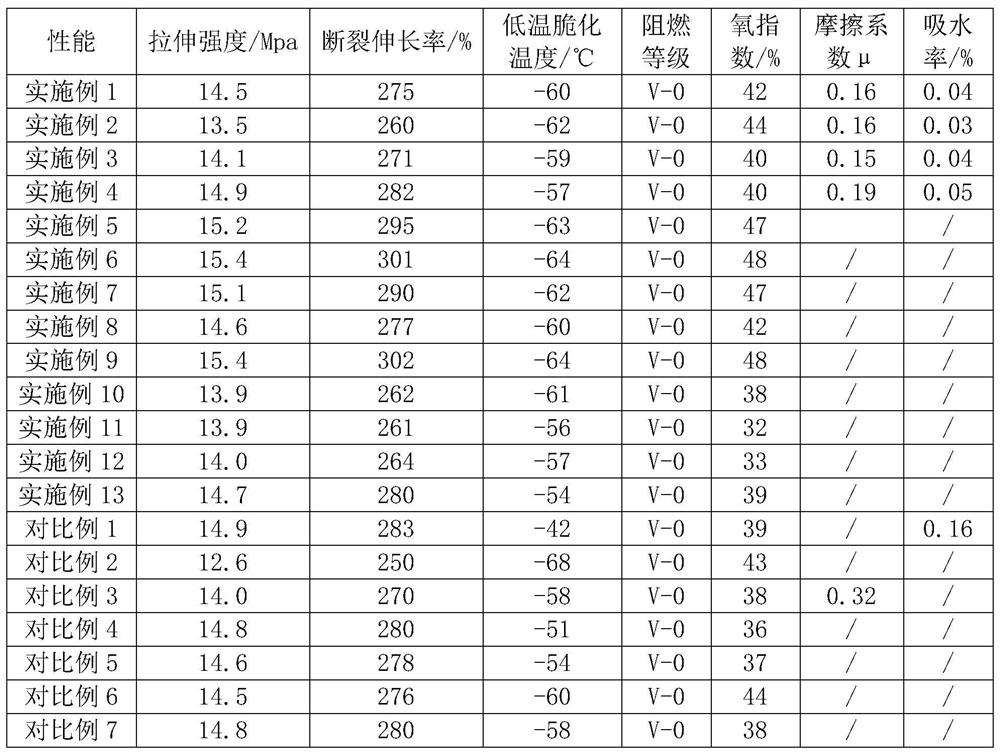

Low-friction low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

InactiveCN111690201AHarm reductionLow smoke productionPlastic/resin/waxes insulatorsPolymer sciencePolyolefin

The invention discloses a low-friction low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof, and relates to the technical field of cable materials. Raw materials of the cable material comprise: matrix resin, a flame-retardant filler, a hydrophobic surfactant, a compatilizer, a slipping agent and an antioxidant; wherein the matrix resin comprises an ethylene-vinyl acetate copolymer and a propylene-ethylene copolymer; the flame-retardant filler comprises aluminum hydroxide and magnesium hydroxide; and the slipping agent comprises oleamide and siliconemaster batch. The cable material has excellent low-temperature flexibility. The preparation method comprises the following steps of: heating the ethylene-vinyl acetate copolymer to a molten state, and spraying a hydrophobic surfactant aqueous solution while stirring to obtain a first mixture; adding the flame-retardant filler, the slipping agent, the compatilizer and the antioxidant into the first mixture, and mixing the substances uniformly to obtain a second mixture, and performing high-pressure banburying; subjecting the first mixture, the second mixture and the propylene-ethylene copolymer to mixing granulation so as to obtain a final product. The prepared product is uniform and stable in quality.

Owner:上海方之德新材料有限公司

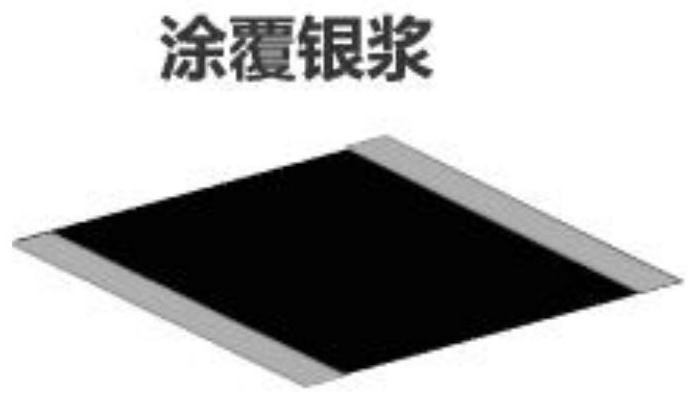

Liquid sensor, and preparation method and application thereof

ActiveCN110068595AExcellent cycle characteristicsLow mobilityMaterial resistanceElectrical resistance and conductanceOrganic solvent

The invention belongs to the technical field of liquid detection, and in particular to a liquid sensor, and a preparation method and application thereof. The liquid sensor provided by the invention comprises graphene paper and silver coating, and the silver coating is coated on the surfaces of two opposite ends of the graphene paper; and the specific surface area of the graphene paper is 60-200 m2 / g. The liquid sensor provided by the invention has various advantages of realizing the micro-detection of organic solvents, having excellent cycle stability characteristic, and being capable of combining vapor pressures of different solvents to identify the components of trace amount of organic solvents. The results of embodiments show that when acetone is detected by the liquid sensor provided by the invention, the minimum detection amount can reach 0.3 mu L, and the resistance response change amount is 0.1%.

Owner:BEIHANG UNIV

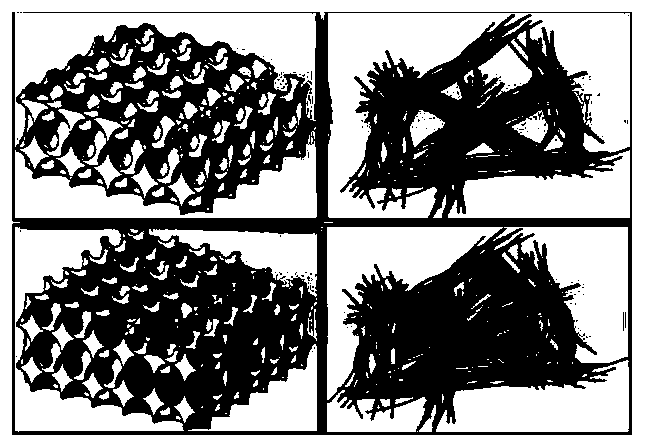

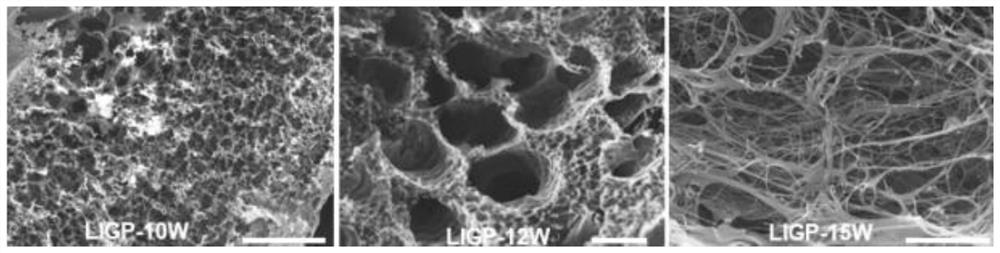

Preparation method of nitrogen-doped porous biochar and method for preparing electrode material

PendingCN114212790AImprove surface microstructureImprove electrochemical performanceCarbon compoundsHybrid capacitor electrodesCarbonizationBiochar

The invention relates to the technical field of capacitor electrode production, in particular to a preparation method of nitrogen-doped porous biochar and a method for preparing an electrode material, and the method comprises the following steps: (1) raw material pretreatment: mixing and pretreating algae biomass and terrestrial biomass; (2) adding an activating agent: mixing the pretreated raw materials with the activating agent; and (3) carbonizing and pickling: carbonizing the mixture obtained in the step (2) under the protection of inert gas, pickling the obtained biochar until the biochar is neutral after the reaction is finished, and drying to obtain the nitrogen-doped porous biochar.

Owner:JIANGSU TAIHU BOILER

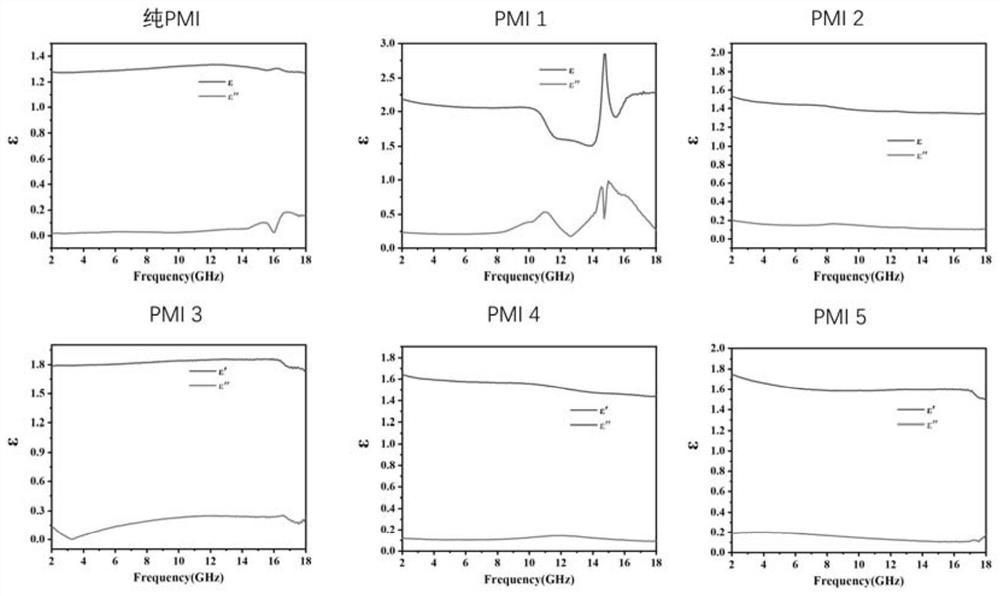

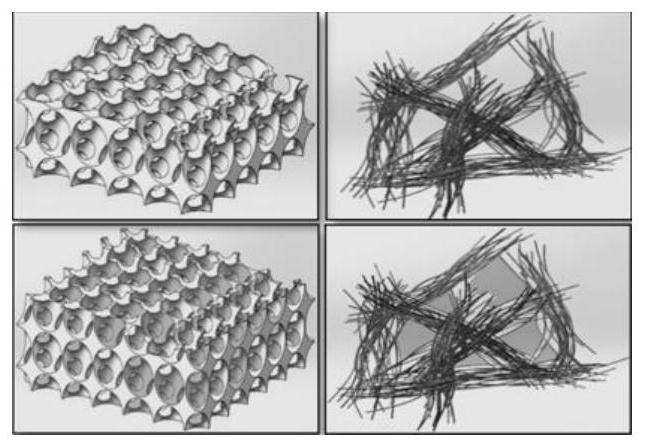

Wave-absorbing/lightweight structure integrated foam material and preparation method and application thereof

ActiveCN114806052ALow densityExcellent thermomechanical propertiesMagnetic/electric field screeningFoaming agentCross linker

The invention provides a wave-absorbing / lightweight structure integrated foam material as well as a preparation method and application thereof, and belongs to the technical field of advanced materials. The foam material is prepared from the following raw materials in parts by weight: 100 parts of a matrix resin monomer, 1-30 parts of a foaming agent, 0.05-15 parts of an initiator, 0-10 parts of a cross-linking agent, 0.5-50 parts of a tackifier and 1-100 parts of a wave absorbing agent. After a wave-absorbing agent is added into the foam material, a good foaming effect can still be achieved, and the wave-absorbing foam material with a uniform foam structure is obtained. The foam material is excellent in mechanical property, thermal mechanical property and wave absorbing property, and light and adjustable in functional weight. The foam material disclosed by the invention can be used as a light wave-absorbing structure and function integrated material with excellent performance, is used for preparing a structure / stealth integrated broadband wave-absorbing material with high strength, heat resistance and corrosion resistance, and has a wide application prospect.

Owner:SICHUAN UNIV

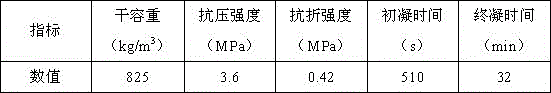

Additive for dry reactive powder concrete powder and usage thereof

InactiveCN102557510AMeet the needs of preparing active powder concrete dry powderGood dispersionMetallurgySuperplasticizer

The invention relates to an additive for dry reactive powder concrete powder and usage thereof. In percentage by weight, the materials of the additive are as follows: 5 to 55 percent of superplasticizer powder; 2 to 15 percent of air-entraining agent powder; 1 to 20 percent of defoamer powder; and 30 to 70 percent of coal ash. The invention organically integrates inorganic materials and organic materials together, and solves the problem of compatibility between the additive and the inorganic materials as well as the organic materials by way of modification. All the main property indexes of reactive powder concrete coordinate with, constrain and affect one another. By means of the additive, various properties of the reactive powder concrete are modified, such as the air-entraining effect and the shrinkage-reducing effect, consequently, after the dry reactive powder concrete powder is mixed with water, all the components are added to one another and affect one another, and thereby the main property indexes of the reactive powder concrete can meet the requirements of construction and designs.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

A kind of ultra-high performance concrete in the transition zone of expansion joints and its preparation method

The invention discloses an ultra-high performance concrete for an expansion joint transition area. The ultra-high performance concrete is prepared from the following main raw materials: cement, fly ash microbeads, silica fume, high-titanium heavy slag sand, organic-inorganic hybrid fiber, a waterborne epoxy emulsion, a water reducing agent and water. According to the invention, the high-titanium heavy slag sand is used as aggregate, the internal curing and pin effects of the aggregate are utilized to improve the volume stability, anti-permeability and cracking resistance, and mechanical properties of the concrete; an organic-inorganic fiber composite toughening technology is adopted to enhance the bending toughness and impact resistance; the water reducing agent and fly ash microbeads areadded to improve the working performance and compactness; and the obtained ultra-high performance concrete has the advantages of high flow state, low shrinkage, high toughness, high adhesion, high impact performance, fatigue resistance and the like, can fundamentally solve the problems of repeated repairing, repeated damage and the like of concrete in expansion joint transition areas, and has important practical application value.

Owner:WUHAN UNIV OF TECH

A kind of lightweight foamed cement composite thermal insulation material and preparation method thereof

The invention discloses a lightweight foam cement composite thermal insulation material, and a preparation method thereof, and belongs to the technical field of building material. The lightweight foamcement composite thermal insulation material is composed of 60 to 90 parts of sulphate aluminium cement, 10 to 15 parts of modified foam phenolic aldehyde powder, 15 to 20 parts of fly ash, 1 to 2 parts of nanometer silicon oxide powder, 3 to 7 parts of hydrogen peroxide, 0.5 to 1.5 parts of calcium formate, 0.2 to 1 part of polypropylene fiber, 0.5 to 1.5 parts of calcium stearate, and 0.01 to 0.1 part of lithium carbonate. The lightweight foam cement composite thermal insulation material is an inorganic material, is excellent in flame resistance, belongs to A grade non-combustible materials, and is long in service life; and the service life is as long as that of buildings.

Owner:UNIV OF JINAN

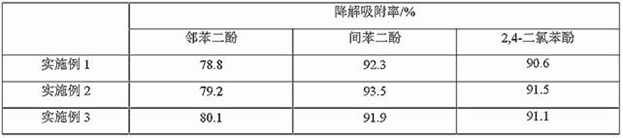

Method for immobilizing laccase by ionic liquid modified composite material

ActiveCN113980921AGood degradation and adsorption effectLarge specific surface areaOxidoreductasesOn/in organic carrierAdsorption effectIonic liquid

The invention discloses a method for immobilizing laccase by an ionic liquid modified composite material, the ionic liquid modified composite material is used for immobilization of laccase, and the preparation comprises three main steps of preparation of the composite material, acidification of the composite material and modification of the ionic liquid. In the preparation process, firstly, rectorite is used as a raw material, and the rectorite composite material is prepared through calcination; then, abundant hydroxyl and amino are formed on the surface of the rectorite composite material through acidification and coupling agent modification, and finally, the hydroxyl and the amino are combined with the ionic liquid, so that the carrier is further modified by the ionic liquid. The immobilization amount of the obtained immobilized enzyme is close to 120mg / g; the immobilized enzyme has good degradation and adsorption effects on common phenolic substances such as 2, 4-dichlorophenol, catechol and resorcinol, the degradation and adsorption rate of the resorcinol and the 2, 4-dichlorophenol exceeds 90%, the degradation and adsorption rate of the catechol is close to 80%, and wide application prospects are realized.

Owner:JIANGSU YINONG BIOLOGY CO LTD

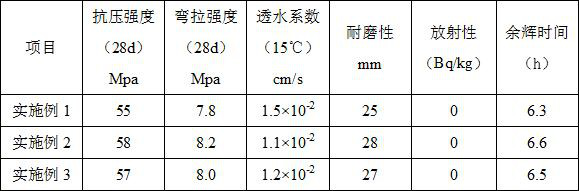

Recycled aggregate energy-storage light-emitting water permeable brick and preparation method thereof

ActiveCN114751696AImprove physical and chemical propertiesImprove water absorptionSolid waste managementBrickPortland cement

The invention provides a recycled aggregate energy-storage luminous water permeable brick, which comprises a water permeable brick main material layer and an energy-storage luminous water permeable brick material layer, the water permeable brick main material layer comprises the following components by weight: 20-30 parts of reinforced recycled aggregate, 10-15 parts of natural fine aggregate, 20-30 parts of Portland cement, 5-10 parts of a water reducer, and 2-5 parts of a slurry viscosity regulator; the energy-storage light-emitting water-permeable brick material layer comprises, by weight, 10-15 parts of red mud, 5-10 parts of fly ash, 2-5 parts of an exciting agent and 5-10 parts of water, and the energy-storage light-emitting water-permeable brick material layer further comprises, by weight, 3-5 parts of rare earth long-acting noctilucent powder, 5-10 parts of silica fume and 2-3 parts of water on the basis of the water-permeable brick main material layer. The production cost of the water-permeable brick is reduced, the application range of the water-permeable brick is expanded, and the ecological problem caused by surface hardening is solved.

Owner:玺大建设工程有限公司

A kind of liquid sensor and its preparation method and application

The invention belongs to the technical field of liquid detection, and in particular relates to a liquid sensor and its preparation method and application. The liquid sensor provided by the invention comprises graphene paper and silver coating, and the silver coating is coated on the surfaces of opposite ends of the graphene paper; the specific surface area of the graphene paper is 60-200m 2 / g. The liquid sensor provided by the invention has the advantages of being able to realize trace detection of organic solvents, having excellent cycle stability characteristics, and being able to identify components of trace organic solvents in combination with vapor pressures of different solvents. The results of the examples show that when the liquid sensor provided by the present invention is used to detect acetone, the minimum detection amount can reach 0.3 μL, and the variation of the resistance response is 0.1%.

Owner:BEIHANG UNIV

Composite material for outdoor table tennis table

The invention relates to a composite material for an outdoor table tennis table. The composite material comprises the following raw materials in parts by weight: 90-110 parts of cement, 55-65 parts of river sand, 0.5-0.8 part of redispersible latex powder, 0.3-0.6 part of polypropylene fiber, 4-8 parts of fly ash, 3-6 parts of bagasse ash, 0.3-0.8 part of lignocellulose, 0.2-0.4 part of a reducing agent, 1-3 parts of metakaolin loaded zirconium dioxide, 36-48 parts of water, 5-10 parts of epoxy resin, 1-2 parts of a curing agent and 0.4-1 part of an auxiliary agent. The problems that an existing wooden table tennis table top is not suitable for outdoor use, not resistant to corrosion and prone to aging are solved.

Owner:QUANZHOU SHUNTONG CRAFTS

Dilute nitric acid solution dipping and calcination process for regenerating waste active alumina

InactiveCN100357181CGood internal pore structureReduce processing costsAluminium oxides/hydroxidesFree coolingRoom temperature

The process of regenerating waste active alumina includes the following steps: washing waste active alumina in water and stoving; dipping waste active alumina inside 8-20 % dilute nitric acid solution in a pond for 5-25 min; washing dipped waste active alumina in water and stoving; calcining in a kiln the 500-800 deg.c for 2-6 hr, and naturally cooling to room temperature to obtain regenerated active alumina. The process can improve the inner pore structure of active alumina and raise activity to reach the aim of regeneration, and the regenerated active alumina has high activity, low processing cost and environment friendship.

Owner:FUZHOU UNIV

Recycled concrete capable of reducing porosity and preparation method thereof

PendingCN114230281AImprove mobilityImprove filling strengthSolid waste managementPre treatmentSilicate Cement

The invention discloses recycled concrete capable of reducing porosity and a preparation method of the recycled concrete. The preparation method comprises the following steps: step 1, carrying out pretreatment such as collection, cleaning, beating and impurity removal on waste concrete; 2, the pretreated concrete blocks are subjected to crushing, screening and grading treatment; step 3, mixing the treated concrete particles with raw materials in a corresponding proportion to form concrete recycled aggregate; and 4, treating the recycled aggregate to form mortar, and pouring and vibrating to form new recycled concrete. According to the recycled concrete capable of reducing the porosity and the preparation method, gaps among slurry can be filled by adding the water reducing agent, the nano silicon dioxide, the reinforcing filler and the acid solution, so that the porosity is reduced, and meanwhile, the swelling agent, the Portland cement, the mineral powder, the anti-cracking agent, the reinforcing filler and the curing filler are added, so that the porosity is reduced. The performances of deformation resistance, impact resistance, compression resistance, permeation resistance and the like of the concrete can be enhanced.

Owner:THE THIRD ENG CO LTD OF CCCC SECOND HIGHWAY ENG BUREAU

A compound mineral admixture for marine engineering reinforced concrete structure

Owner:浙江合力海科新材料股份有限公司

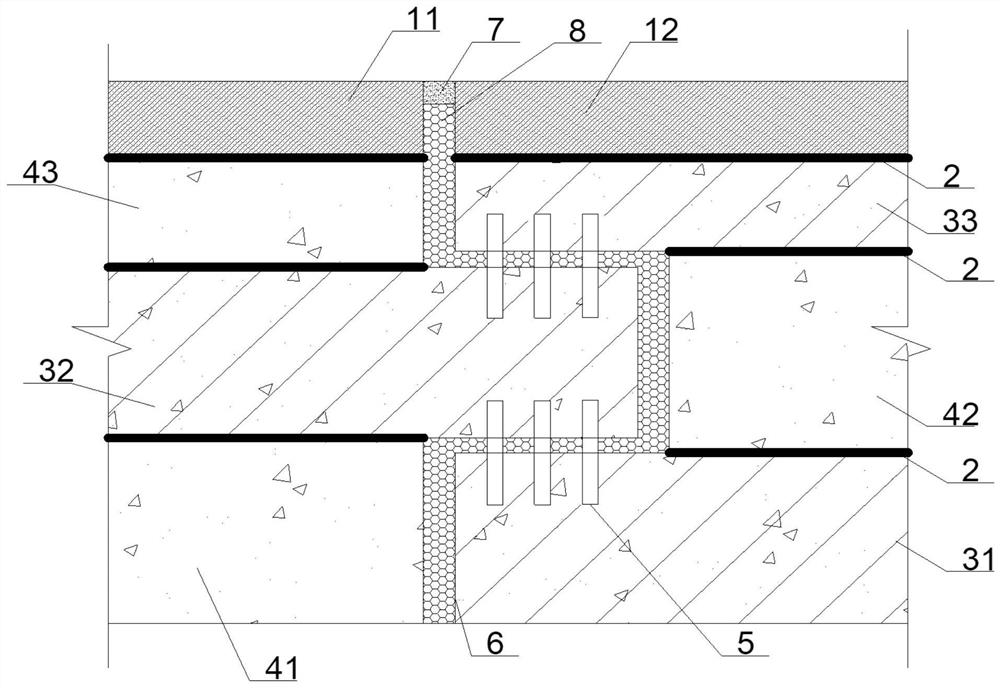

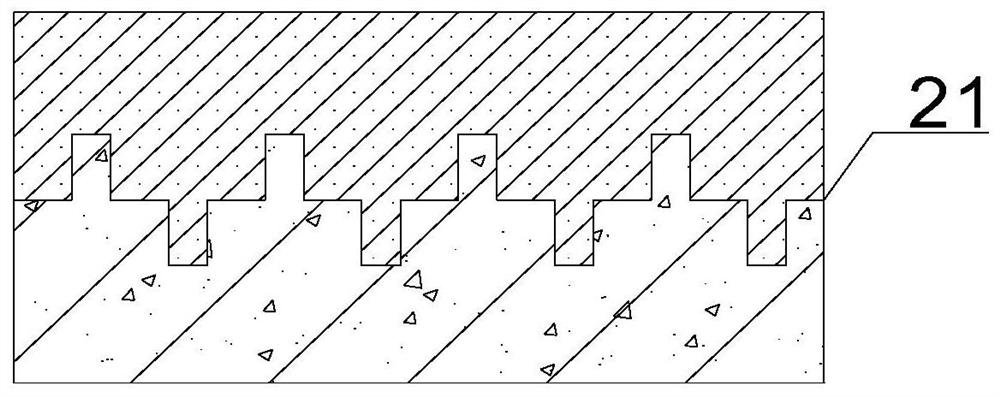

Functionally graded deformation joint structure and manufacturing method

PendingCN111677135AImprove waterproof performanceAchieve waterproofBuilding constructionsFlat jointArchitectural engineering

The invention belongs to the field of civil engineering, and particularly relates to a functionally graded deformation joint structure and a manufacturing method. The deformation joint is a tongue-and-groove joint, different concrete layers are arranged on the two sides of the tongue-and-groove joint in different thickness directions to construct a functionally graded concrete layer, the portion,close to an upstream face concrete layer, of the functionally graded concrete layer is a high-impermeability anti-crack concrete layer, and a sealing material is arranged in the portion, at the high-impermeability anti-crack concrete layer, of the tongue-and-groove joint. The functionally graded deformation joint structure has the advantages that a tongue-and-groove joint is better in waterproof performance compared with a common flat joint, but the integrity of concrete structures protruding out of the two sides of the tongue-and-groove joint is weak, under the influence of earthquakes or other factors, the tongue-and-groove joint is prone to breakage and deformation joint blockage, for the functionally graded deformation joint structure, the functionally gradient concrete layer is constructed on the two sides of the tongue-and-groove joint, and the upstream face of the tongue-and-groove joint is sealed by adopting the sealing material, so that the waterproofness is better realized under the condition of ensuring the strength.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com