Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

230 results about "Green component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

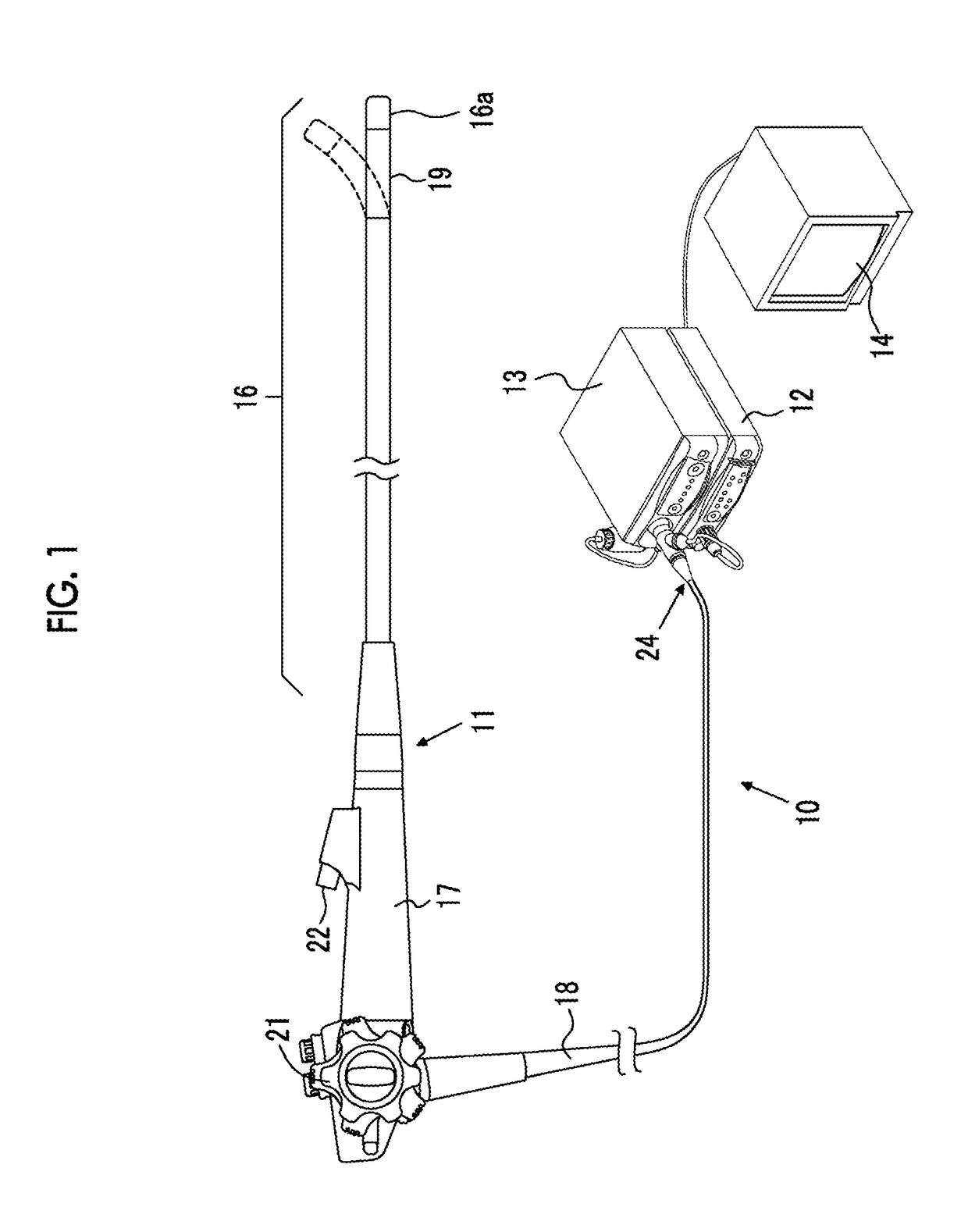

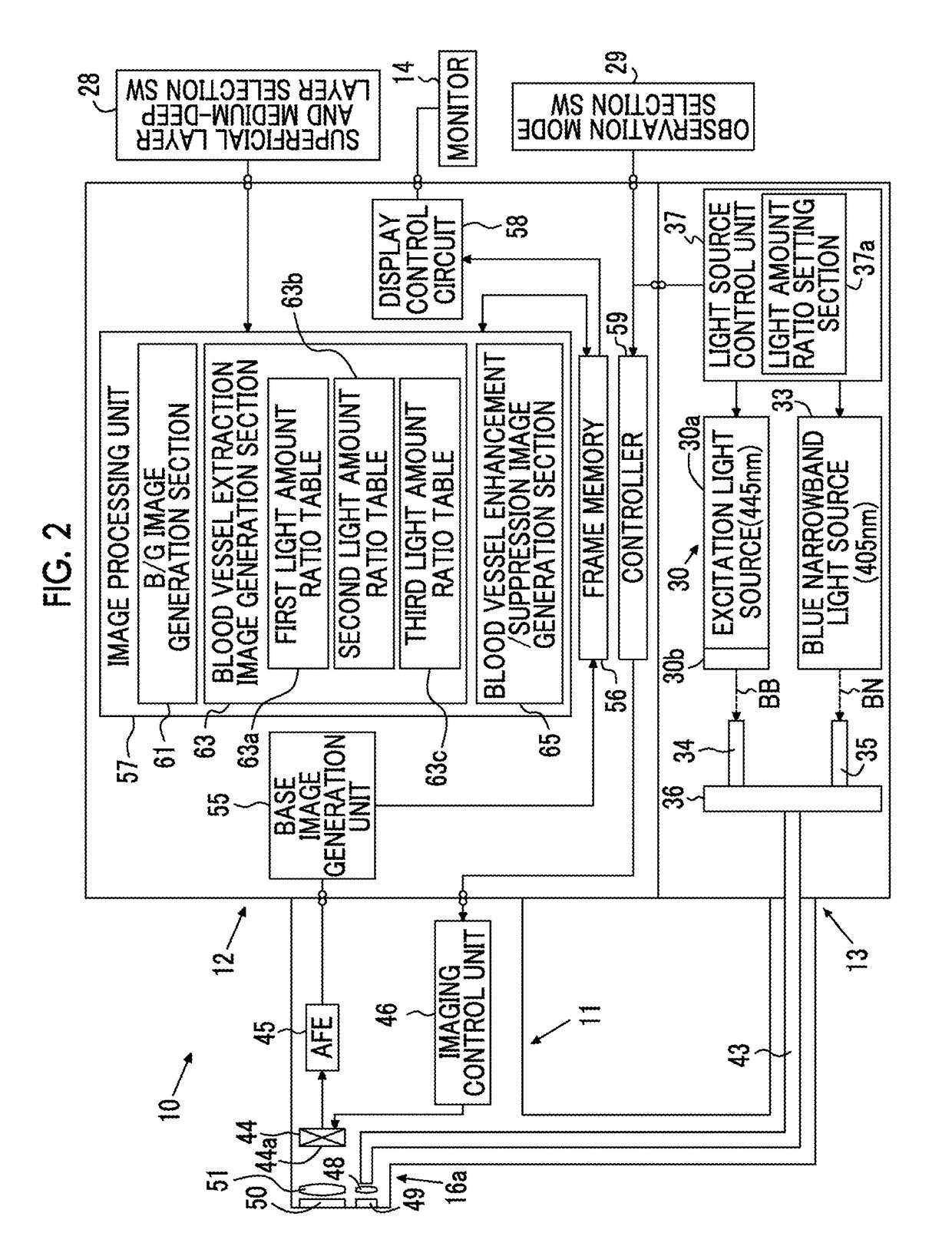

Endoscope system, processor device of endoscope system, and image processing method

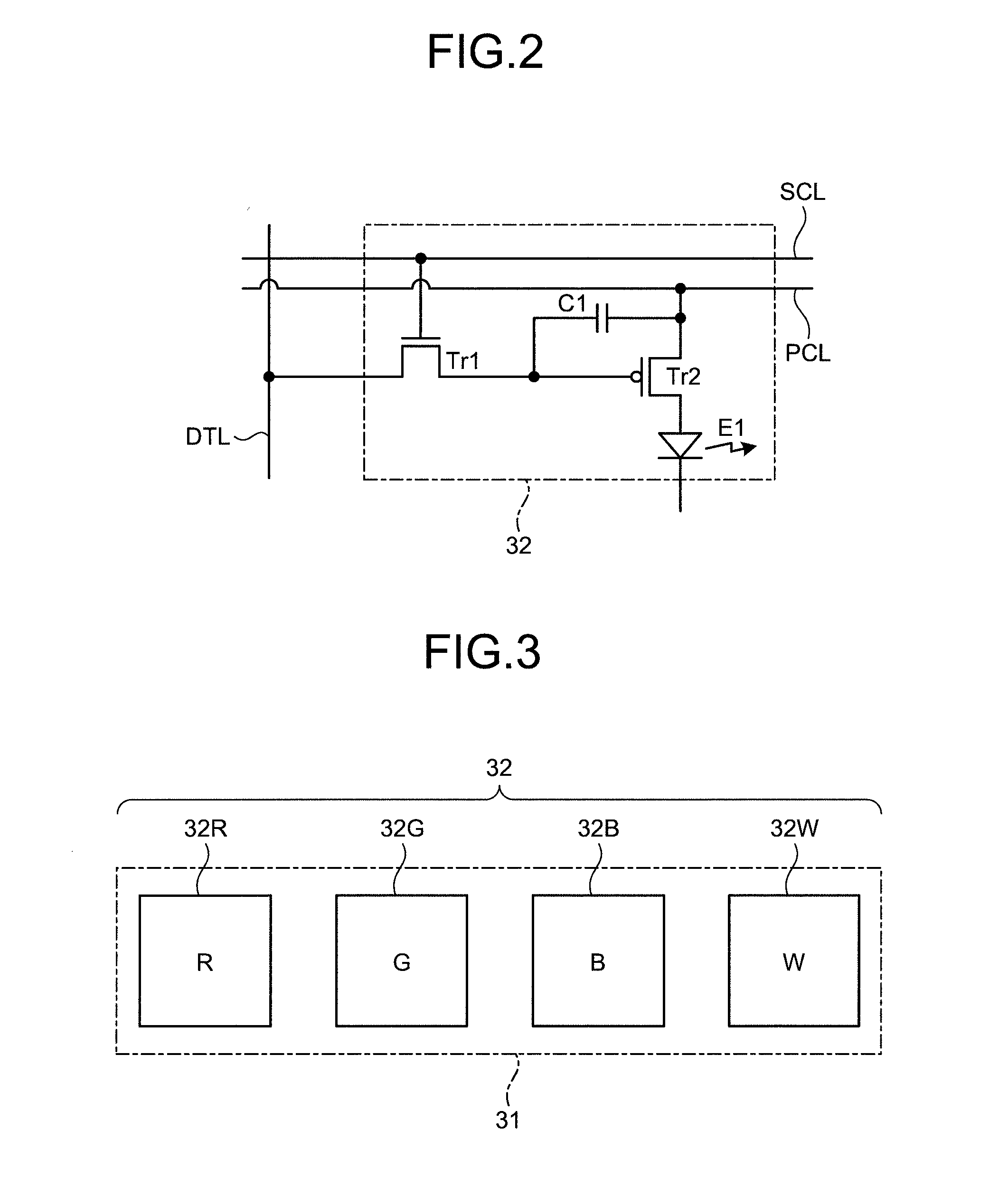

ActiveUS9943230B2Reliably extract a plurality of types of blood vesselsImage enhancementImage analysisImaging processingBoundary values

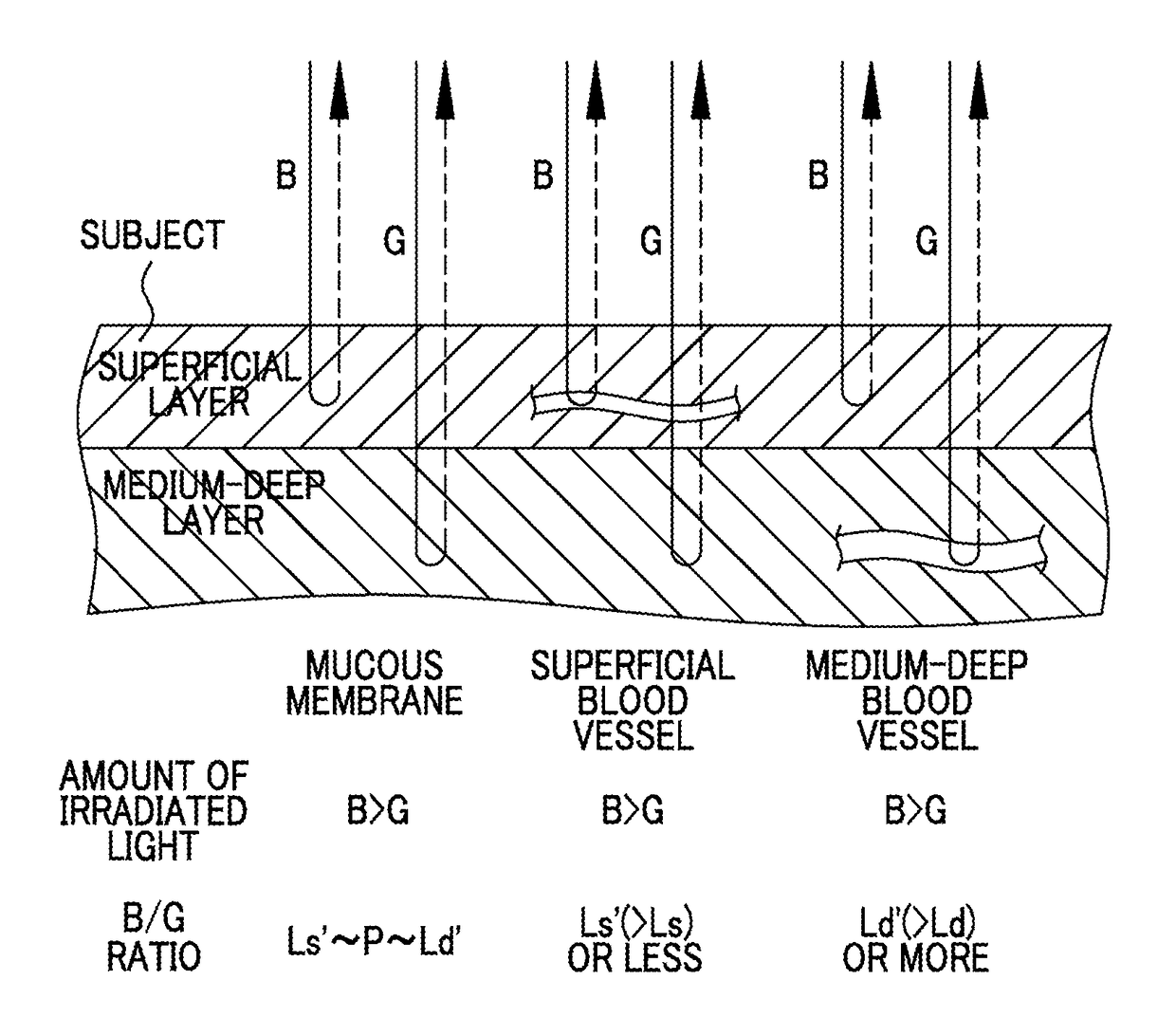

Even if the ratio between blue and green components of illumination light is changed, a plurality of types of blood vessels at different depths are reliably distinguished. A blue signal B, a green signal G, a red signal R is obtained by imaging the subject using a color CCD 44. A B / G image having a B / G ratio is generated. A superficial blood vessel extraction image is obtained by extracting a pixel, in which the B / G ratio is equal to or less than a boundary value Ls between the mucous membrane and the superficial blood vessel, from the B / G image. A medium-deep blood vessel extraction image is obtained by extracting a pixel, in which the B / G ratio is equal to or greater than a boundary value Ld between the mucous membrane and the medium-deep blood vessel. The boundary values Ls and Ld differ depending on the light amount ratio.

Owner:FUJIFILM CORP

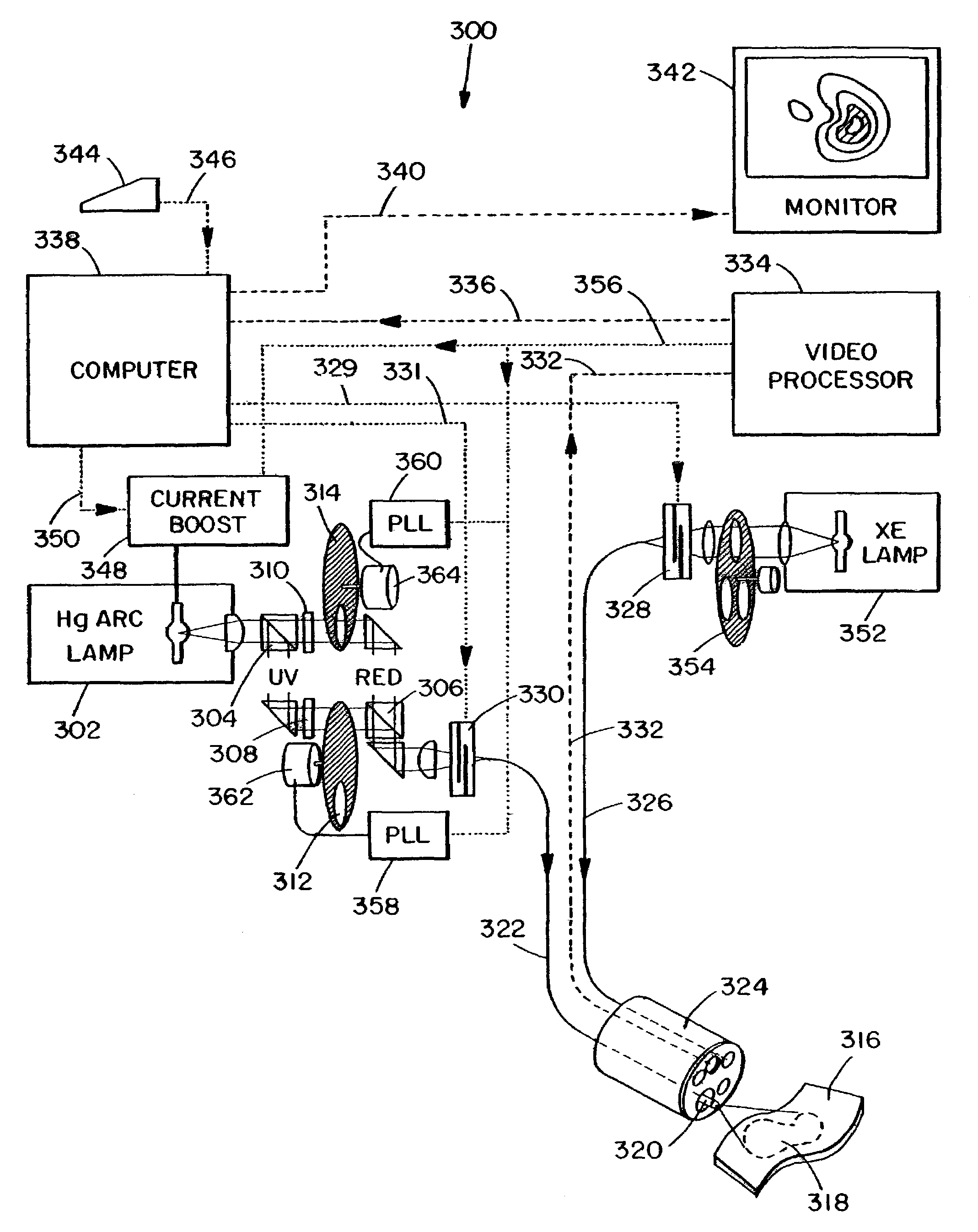

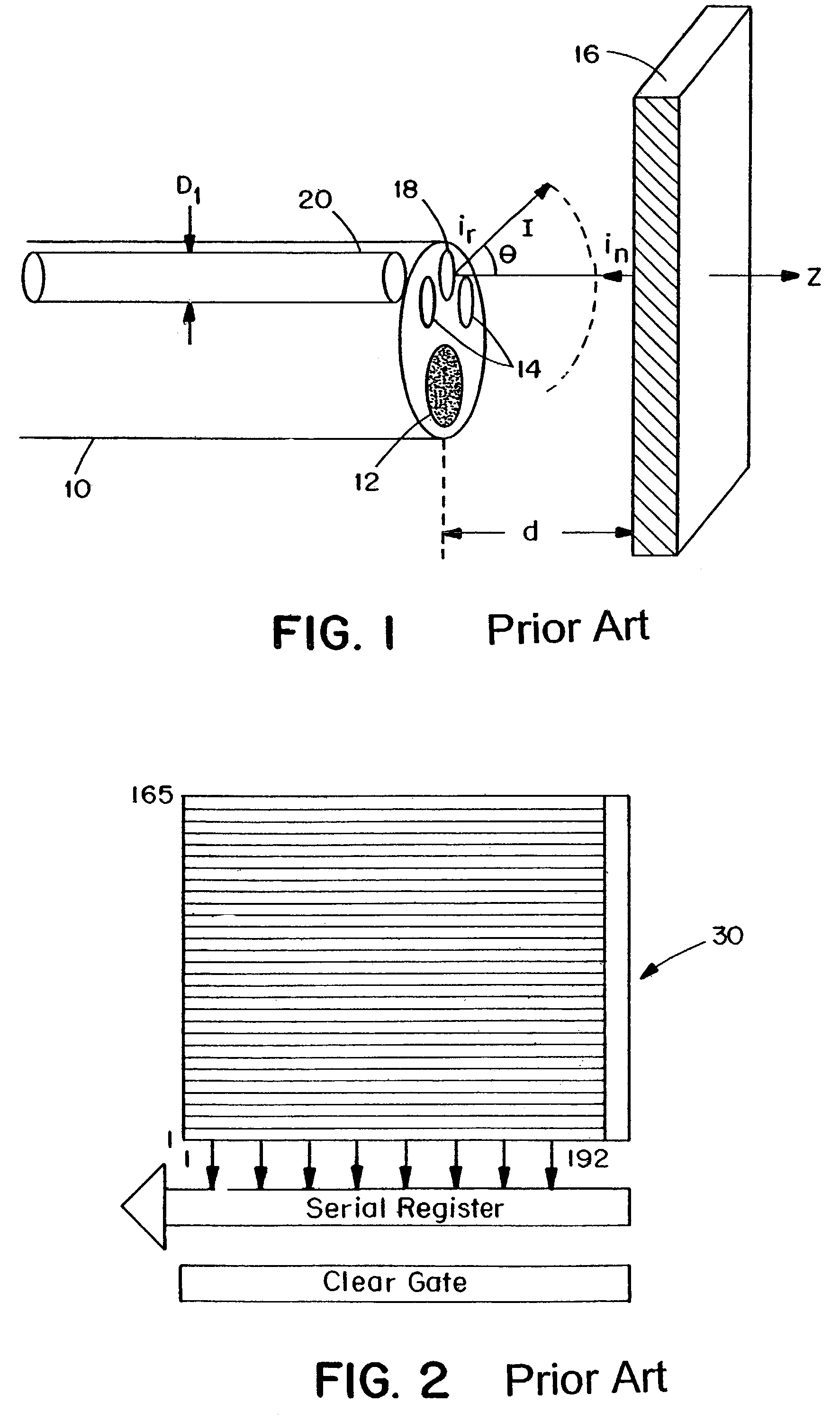

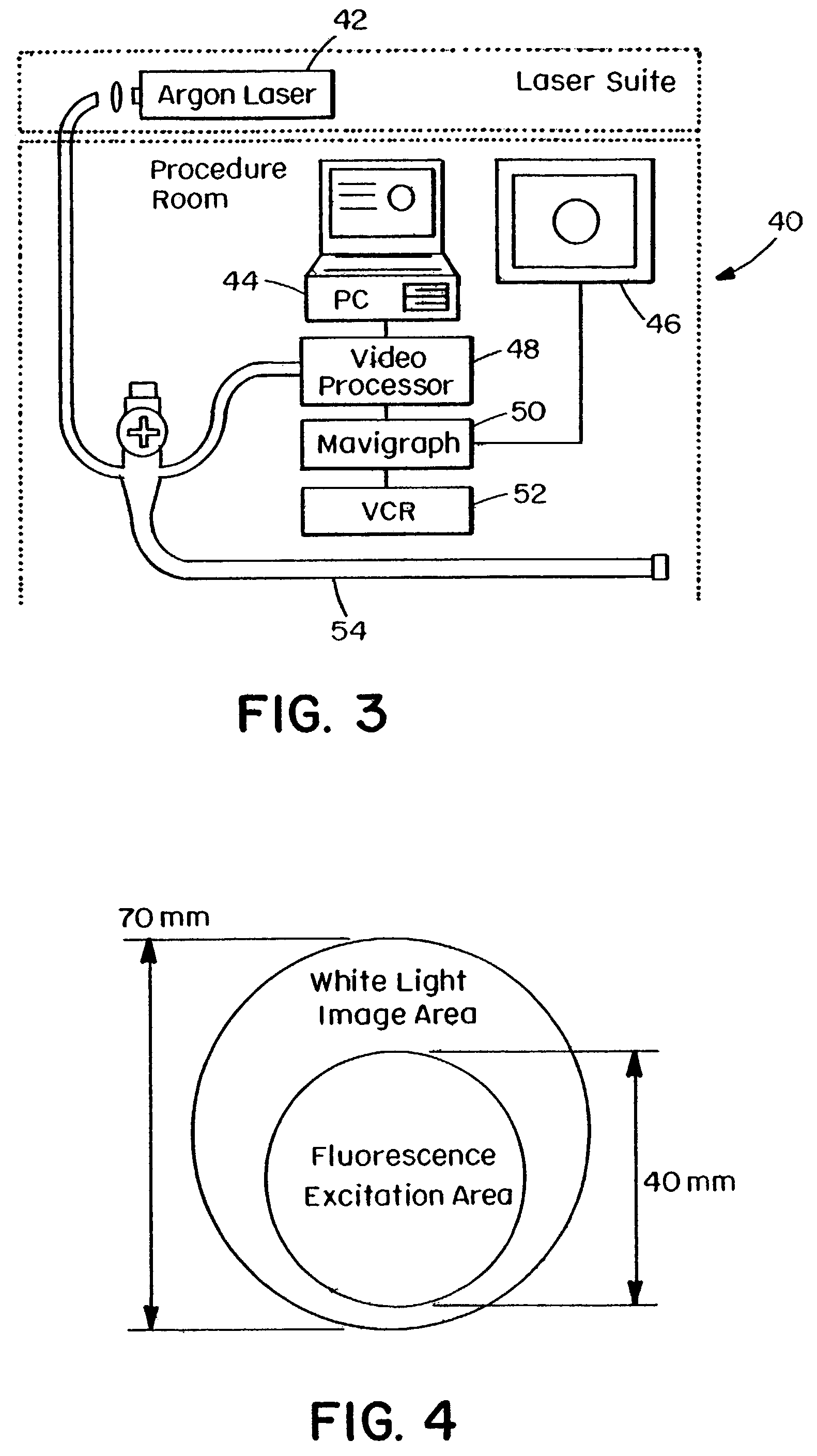

Fluorescence imaging endoscope

InactiveUS7235045B2Simplify System DesignConvenient registrationRaman/scattering spectroscopySurgeryLaser lightReflectivity

An endoscope having an optical guide that is optically coupled to a first broadband light source and a second laser light source that emits light at a wavelength in a range of 350 nm to 420 nm. The endoscope has an image sensor at a distal end and collects a reflectance image including red, green and blue components with the image sensor in response to illumination by said broadband light source. The image sensor also collects an autofluorescence image having a blue component, a green component and a red component. A processor processes the fluorescence image by determining a ratio of the fluorescence image and the reflectance image to provide a processed fluorescence image.

Owner:MASSACHUSETTS INST OF TECH +1

Image processing Method

InactiveUS20090284627A1Image obtainedResolution is sacrificedImage enhancementTelevision system detailsImaging processingImaging data

An image processing method includes photographing an object by a camera via a filter, separating image data, which is obtained by photographing by the camera, into a red component, a green component and a blue component, determining a relationship of correspondency between pixels in the red component, the green component and the blue component, with reference to departure of pixel values in the red component, the green component and the blue component from a linear color model in a three-dimensional color space, and finding a depth of each of the pixels in the image data in accordance with positional displacement amounts of the corresponding pixels of the red component, the green component and the blue component. The image processing method further includes processing the image data in accordance with the depth.

Owner:KK TOSHIBA

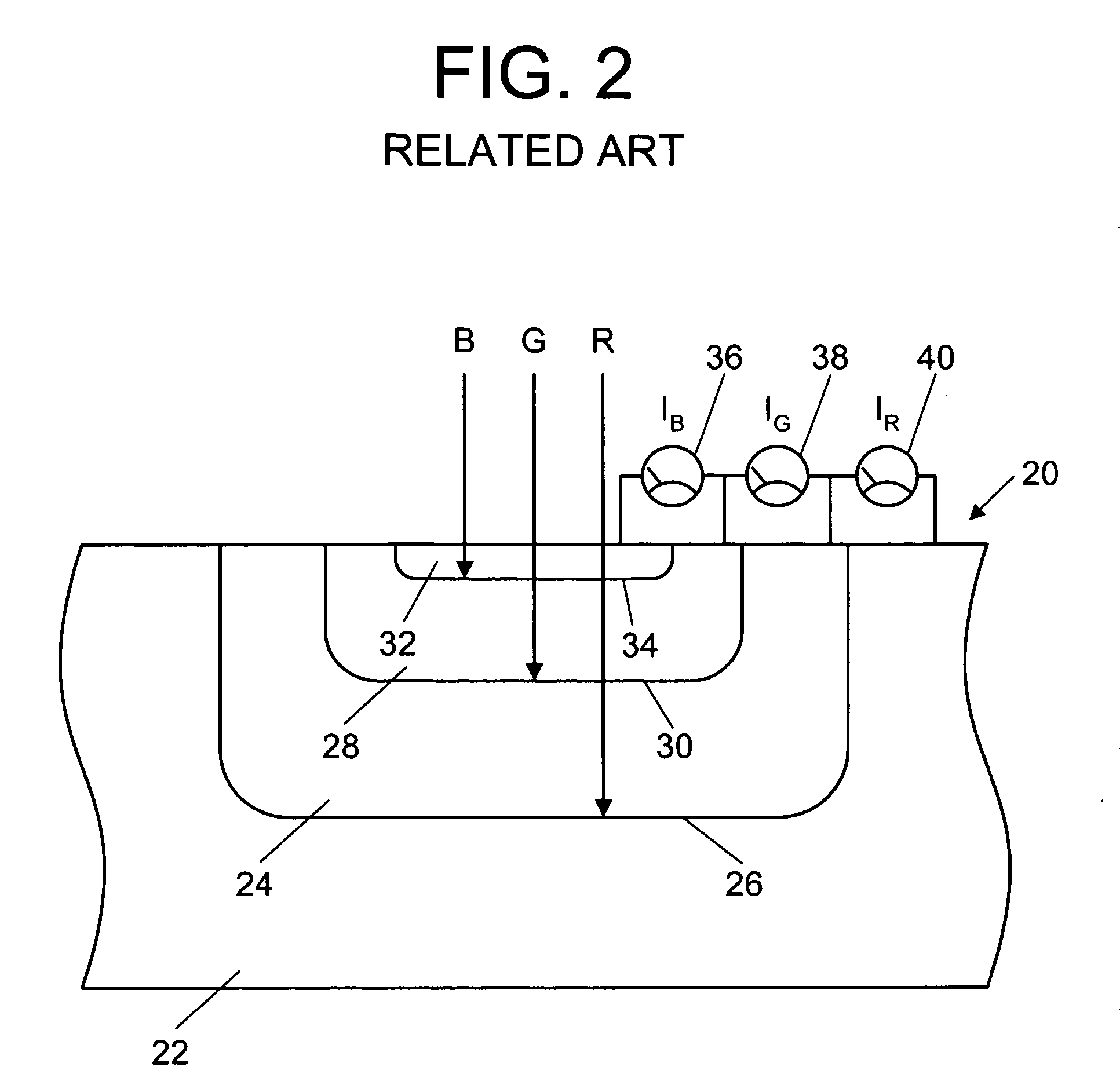

Vertical tri-color sensor

InactiveUS20070200940A1Television system detailsTelevision system scanning detailsSurface plasmonOptoelectronics

A vertical tri-color sensor having vertically stacked blue, green, and red pixels detects at least blue and green components of incident light by converting the blue and green components to surface plasmons.

Owner:APTINA IMAGING CORP

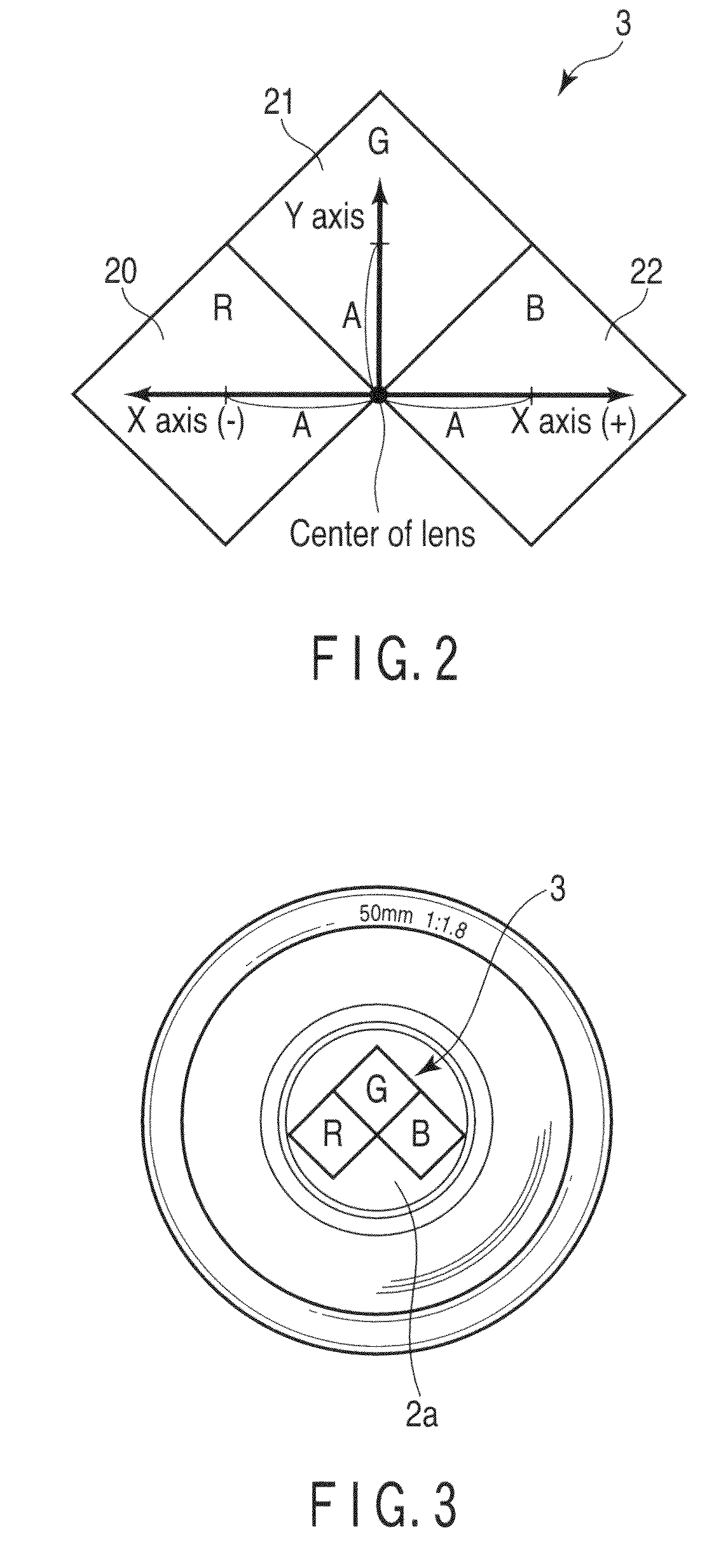

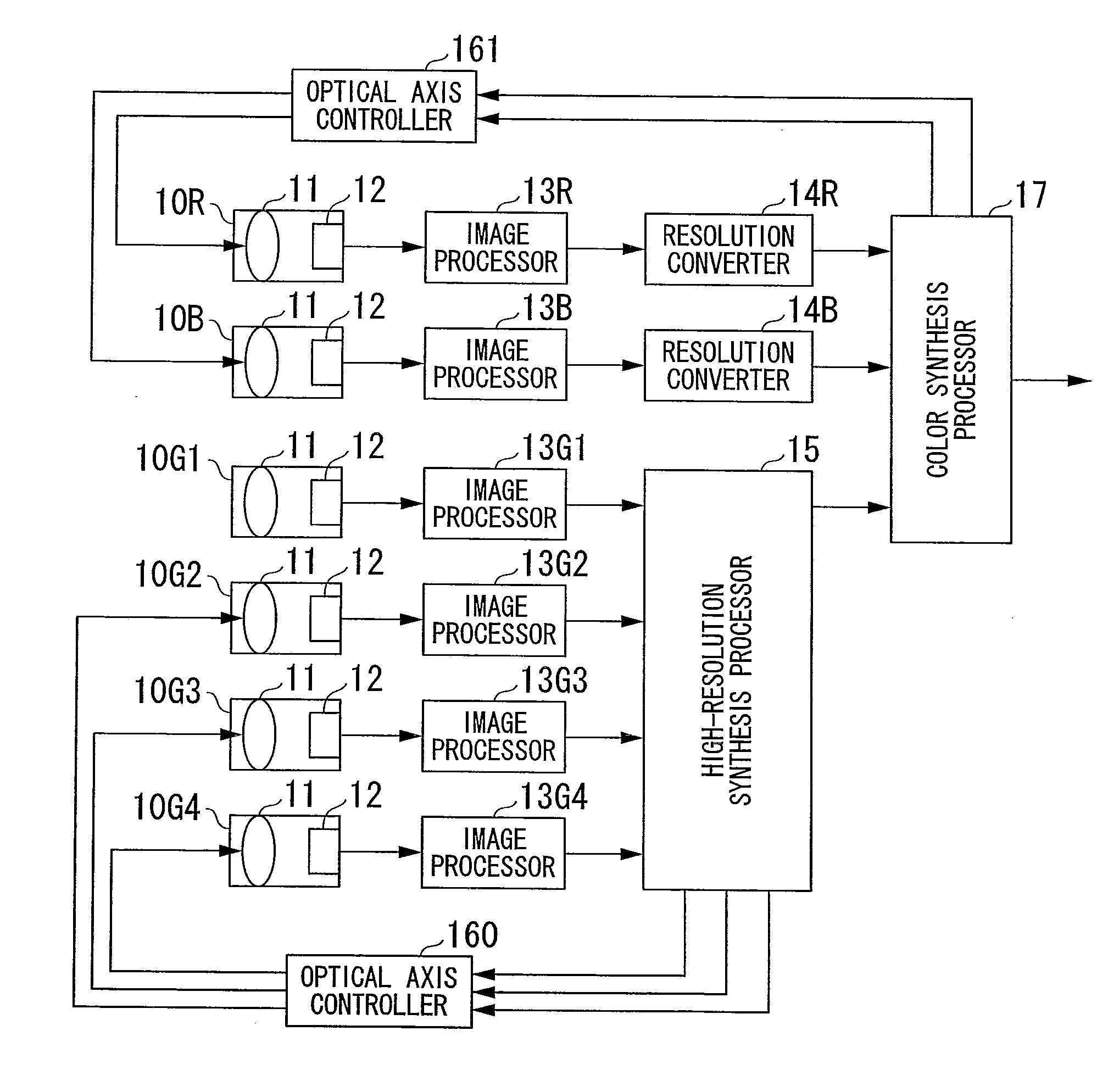

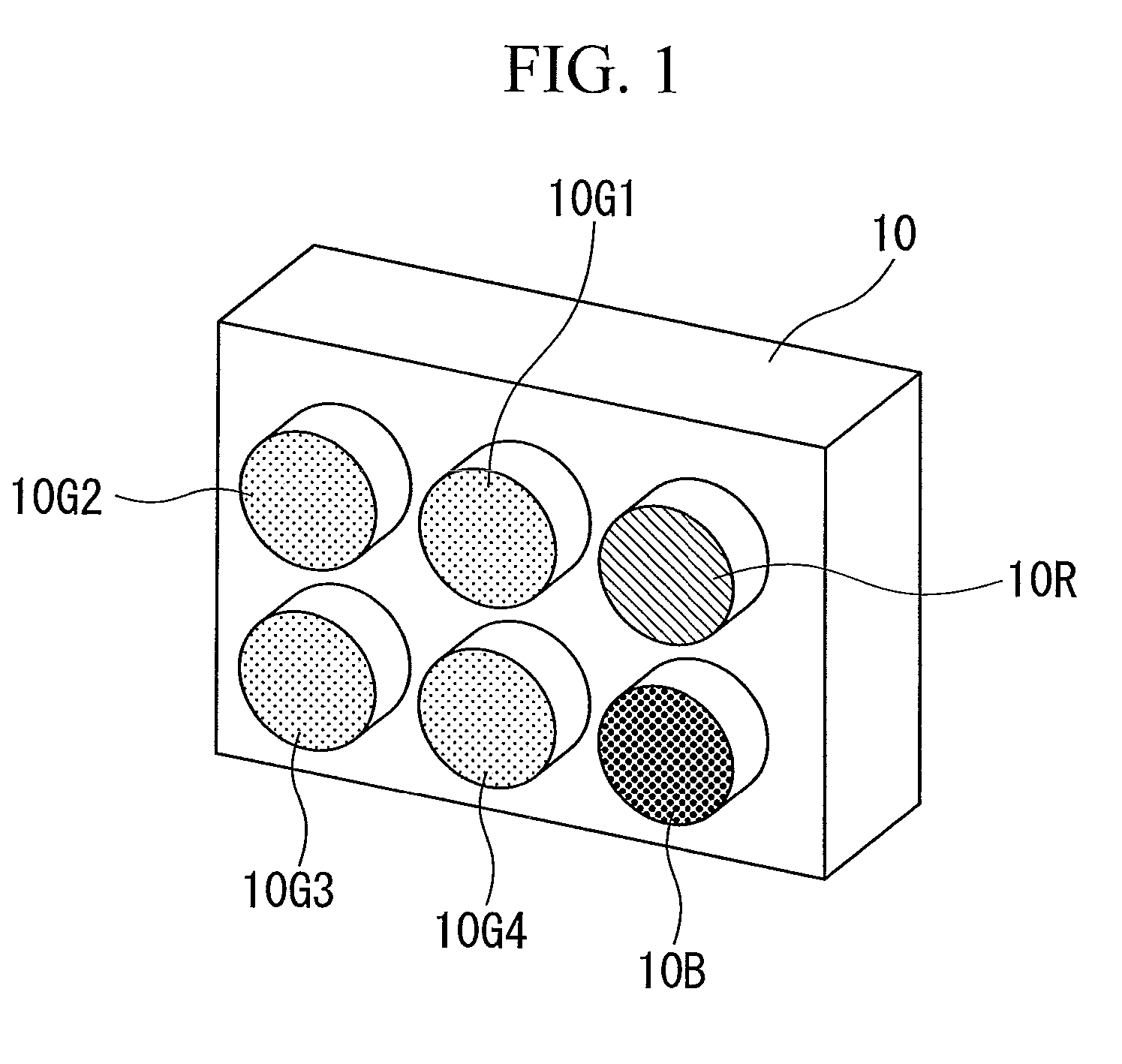

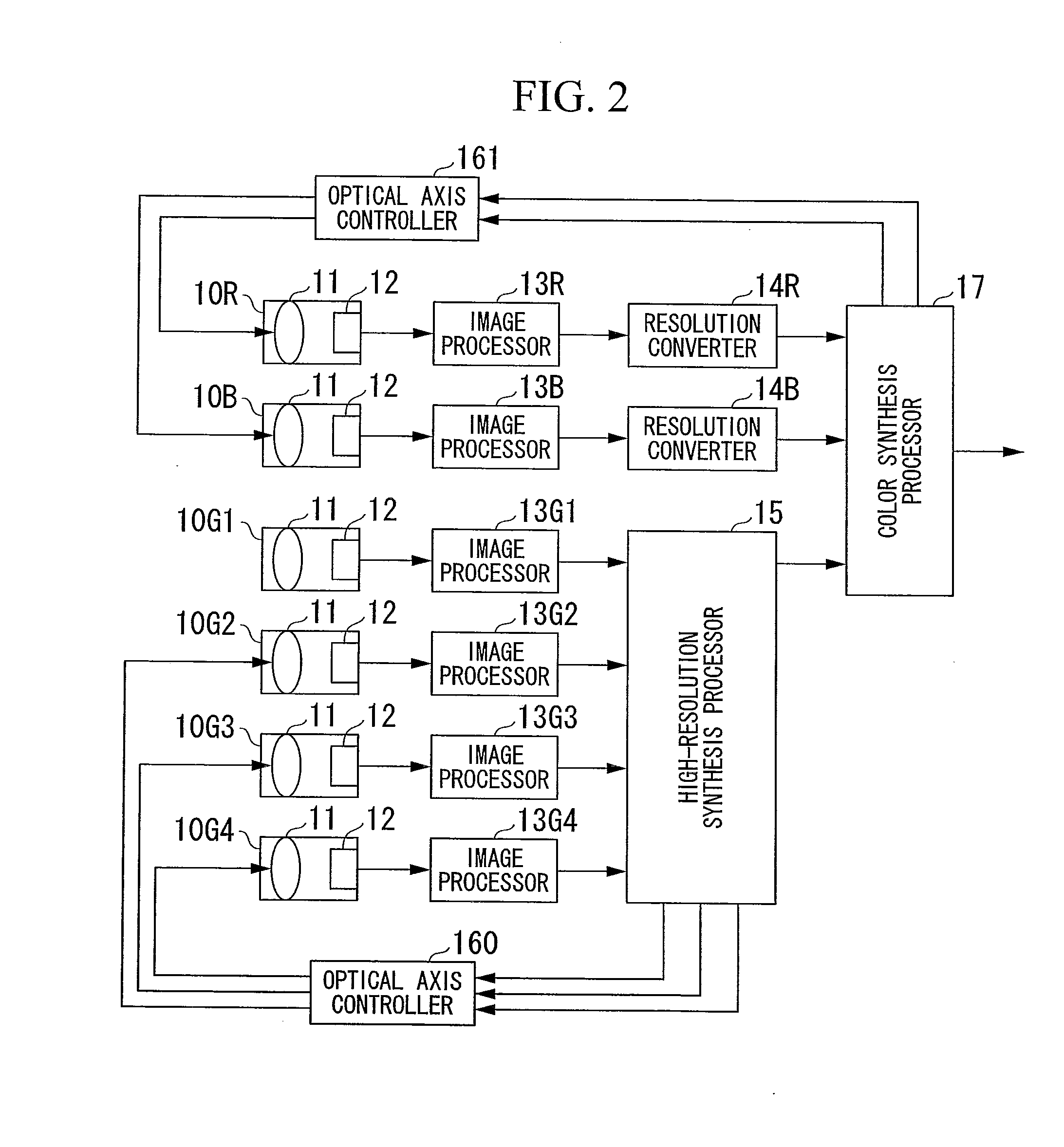

Imaging device and optical axis control method

InactiveUS20110025905A1Television system detailsSignal generator with multiple pick-up deviceColor imageOptical axis

To create a high-resolution color image, an imaging device includes: a plurality of green image pickup units picking up images of green components; a red image pickup unit picking up an image of a red component; a blue image pickup unit picking up an image of a blue component; a high-definition synthesis processor adjusting an optical axis of light incident to the green image pickup units, so that the resolution of a green image obtained by synthesizing a plurality of images picked up by the plurality of green image pickup units becomes a predetermined resolution, and synthesizing the plurality of images to obtain a high-resolution green image; and a color synthesis processor adjusting an optical axis of light incident to each of the red image pickup unit and the blue image pickup unit, and synthesizing the green image, the red image and the blue image to obtain a color image.

Owner:SHARP KK

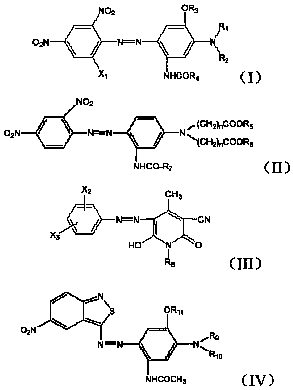

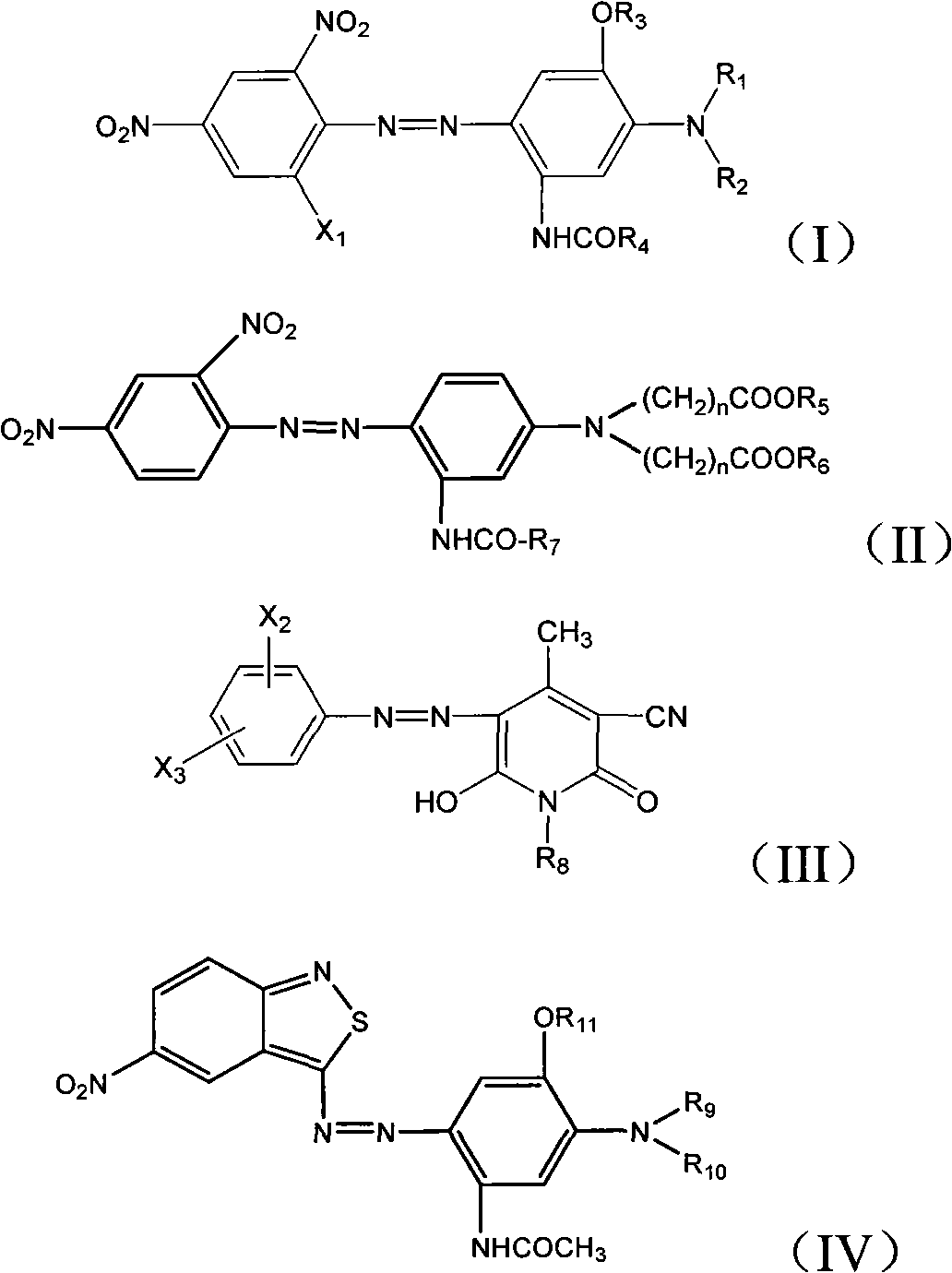

Black disperse dye composition

The invention provides a black disperse dye composition, which mainly comprises: one or more blue components A of which the structure is shown as a formula (I), one or more red components B of which the structure is shown as a formula (II), one or more yellow components C of which the structure is shown as a formula (III) and one or more green components D of which the structure is shown as a formula (IV). Based on the components A, components B, components C and components D, the mass fraction of the components A is 35-85%, the mass fraction of the components B is 1-25%, the mass fraction of the components C is 5-45% and the mass fraction of the components D is 1-35%. When the hydrophobic fiber material is dyed by using the dye prepared from the black disperse dye composition, black fabric with excellent color fastness especially excellent washing fastness after heat treatment can be obtained by adjusting the proportion of different components.

Owner:SHANGYU JINGUAN CHEM IND +2

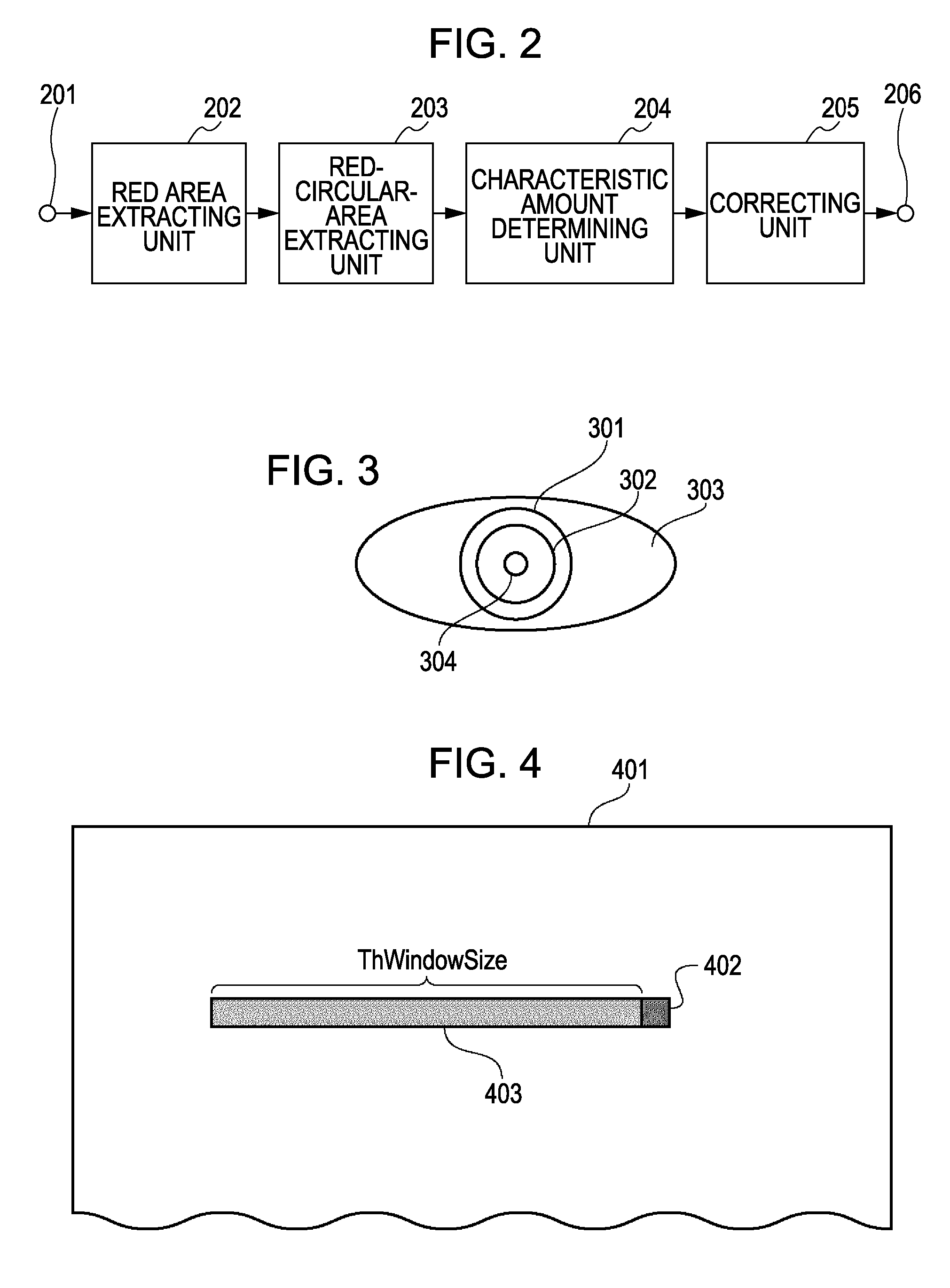

Image processing apparatus, image processing method, computer program, and storage medium

ActiveUS20060280362A1Accurate detectionPoor color toneImage enhancementImage analysisPattern recognitionImaging processing

An image processing apparatus includes a calculating unit configured to calculate an evaluation amount of poor color tone for every pixel in an image and an extracting unit configured to extract a candidate pixel having the poor color tone on the basis of the evaluation amount. The evaluation amount is calculated from red and green components of the image.

Owner:CANON KK

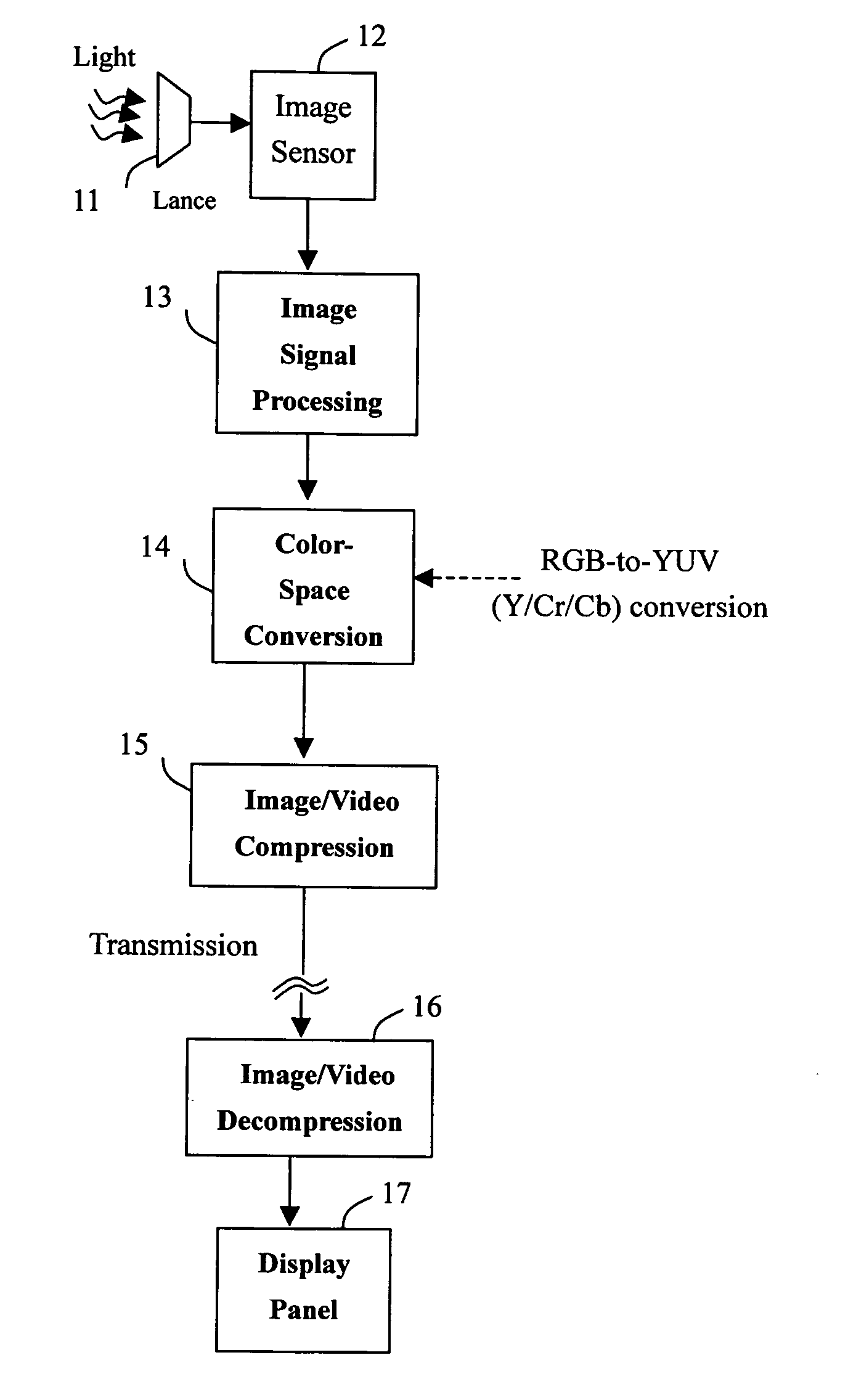

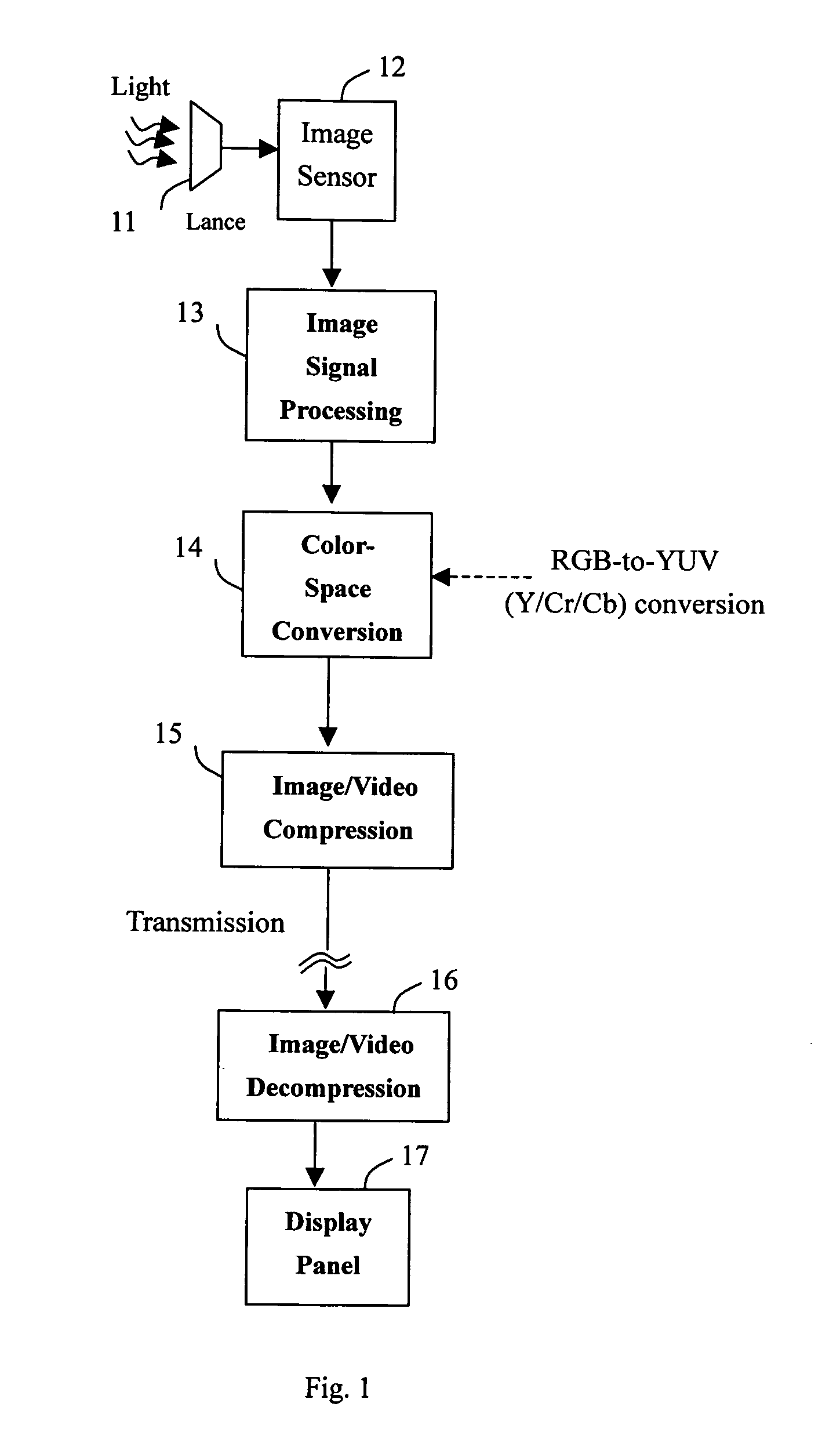

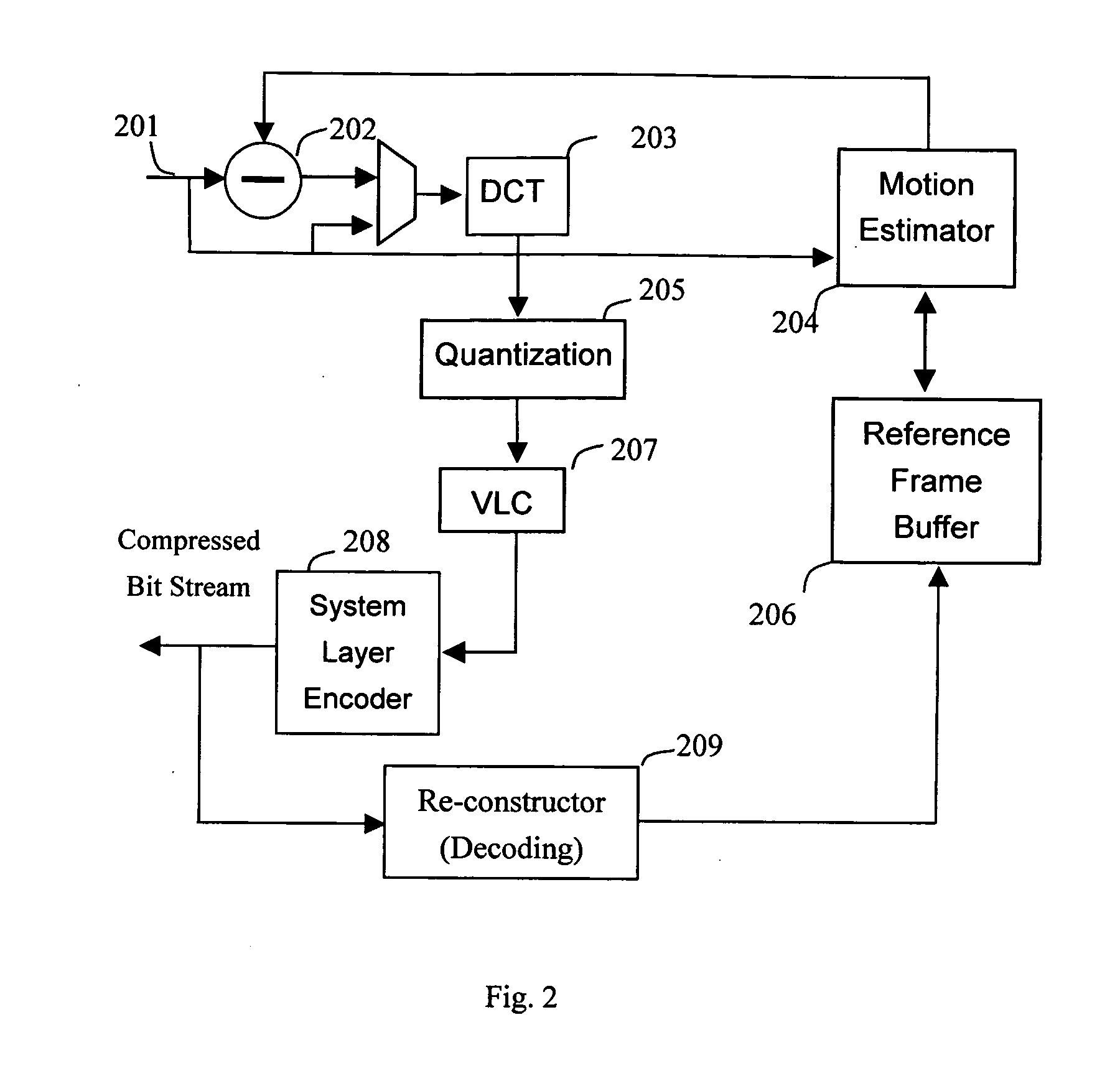

Method and apparatus of bayer pattern direct video compression

ActiveUS20090174811A1Lower requirementImprove efficiencyColor television with pulse code modulationColor television with bandwidth reductionInter frameImage signal

Applying a mechanism of image signal processing and color-space-conversion to convert the captured Green components to be Y, luminance components for only those pixels having raw Green data without interpolation, and to convert the Blue components to be U, chrominance components for only those pixels having raw Blue data, and Red components to be V, chrominance components for only those pixels having raw Red data. These converted YUV components are input to a predetermined video compression codec for reducing the intra- and inter-frame redundant information.

Owner:TAIWAN IMAGINGTEK

Image processing apparatus, endoscope, and computer readable medium

ActiveUS20080079807A1Increase contrastHigh color reproductionTelevision system detailsImage enhancementColor imageImaging processing

An image processing apparatus includes a color image data generation section 54 that generates color image data from an image pickup signal of a red component, an image pickup signal of a green component, and an image pickup signal of a blue component which are output from an image pickup device 100; an infrared image data generation section 53 that generates infrared image data from an image pickup signal of an infrared component output from the image pickup device 100; and a high-contrast infrared image data generation section 55 that generates high-contrast infrared image data using the color image data and the infrared image data. Contrast of the high-contrast infrared image data is more enhanced than that of the infrared image data.

Owner:FUJIFILM CORP

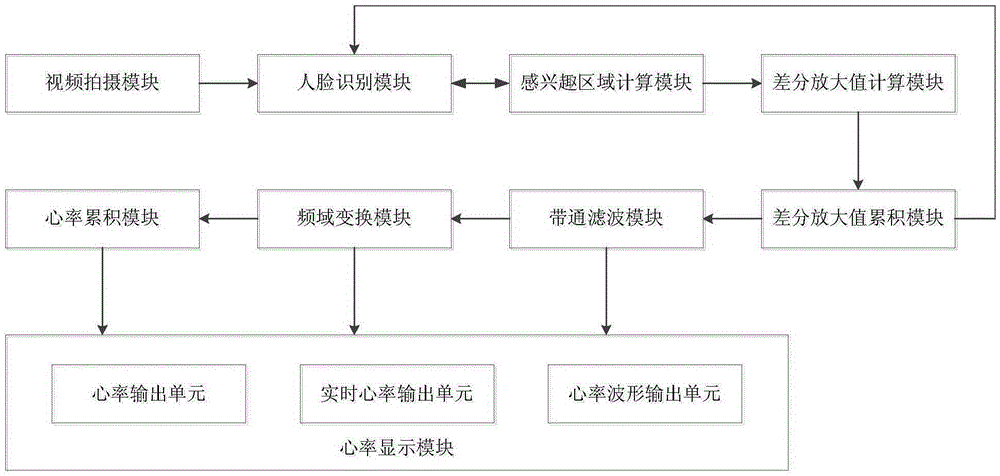

Non-contact type heart rate detection method and system

ActiveCN105266787AImprove robustnessStrong resistance to ambient lightMeasuring/recording heart/pulse ratePattern recognitionVision based

The present invention relates to a non-contact type heart rate detection method and system. The method comprises the steps of (a) obtaining the face video image data of a detected people, identifying the face in the image data, and calculating the interest area image of the face, (b) calculating the red and green component difference value of the interest area image through a time domain difference color change amplification model, calculating the difference amplification value of the interest area image, and calculating the time domain change waveform according to the difference amplification value, (c) carrying out Fourier transform on the time domain change waveform, calculating a frequency domain response maximum value, and calculating the heart rate value of the detected people according to the frequency value corresponding to the frequency domain response maximum value. According to the method and the system, the influence of environment light on a non-contact type heart rate calculation method based on vision can be effectively avoided, and thus a robust and accurate non-contact type heart rate detection result is obtained.

Owner:中科创星科技投资有限公司

Rear projection display device

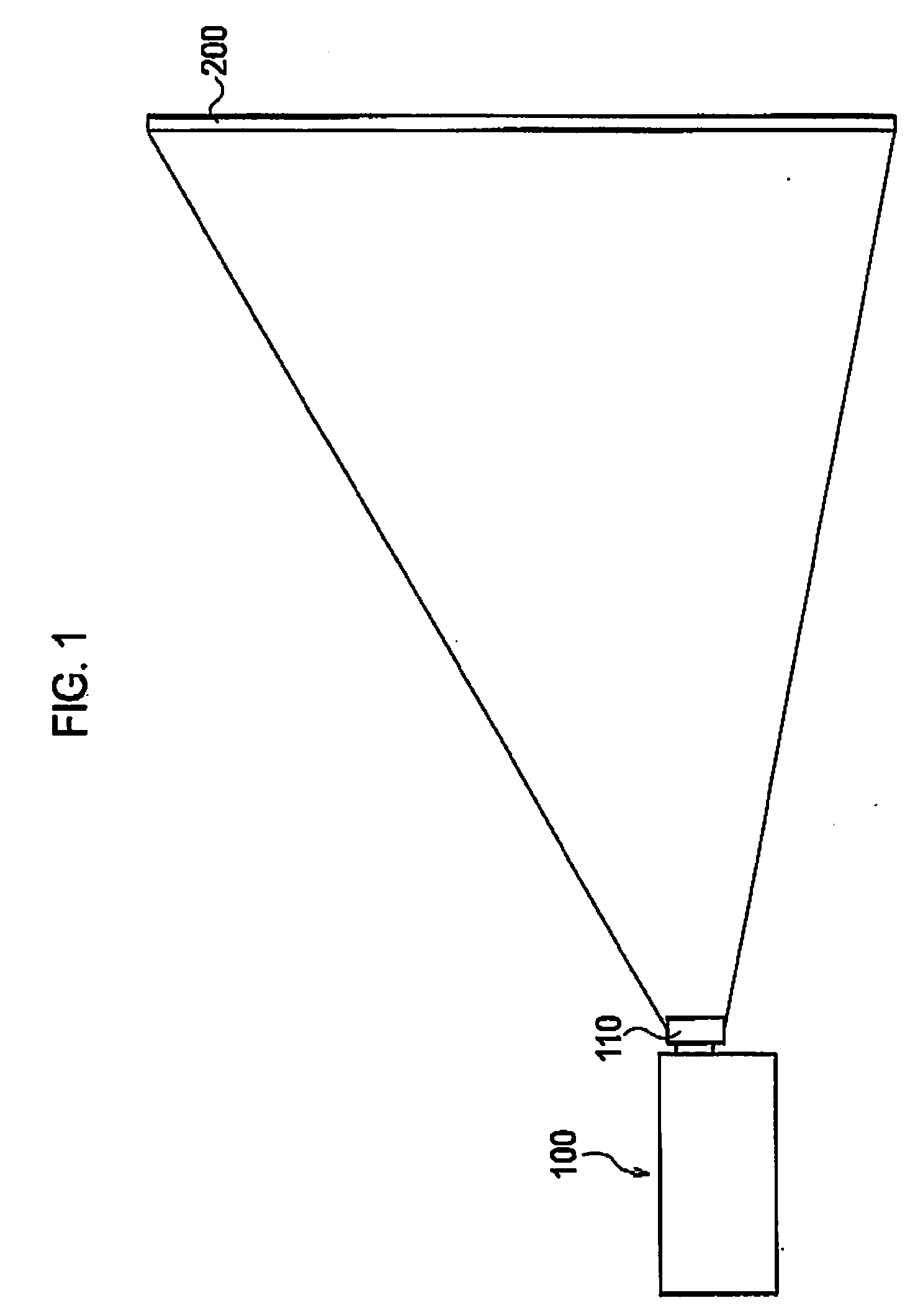

InactiveUS6981771B1Increase brightnessEnhance the imageBuilt-on/built-in screen projectorsNon-linear opticsBrightness perceptionLightness

A rear projection display device improves the brightness by improving the utilization efficiency of image light projected to a screen from slantly below. At least a green component of the image light is P-polarized to the screen (7). Therefore, reflection of light on the screen (7) is reduced.

Owner:SANYO ELECTRIC CO LTD

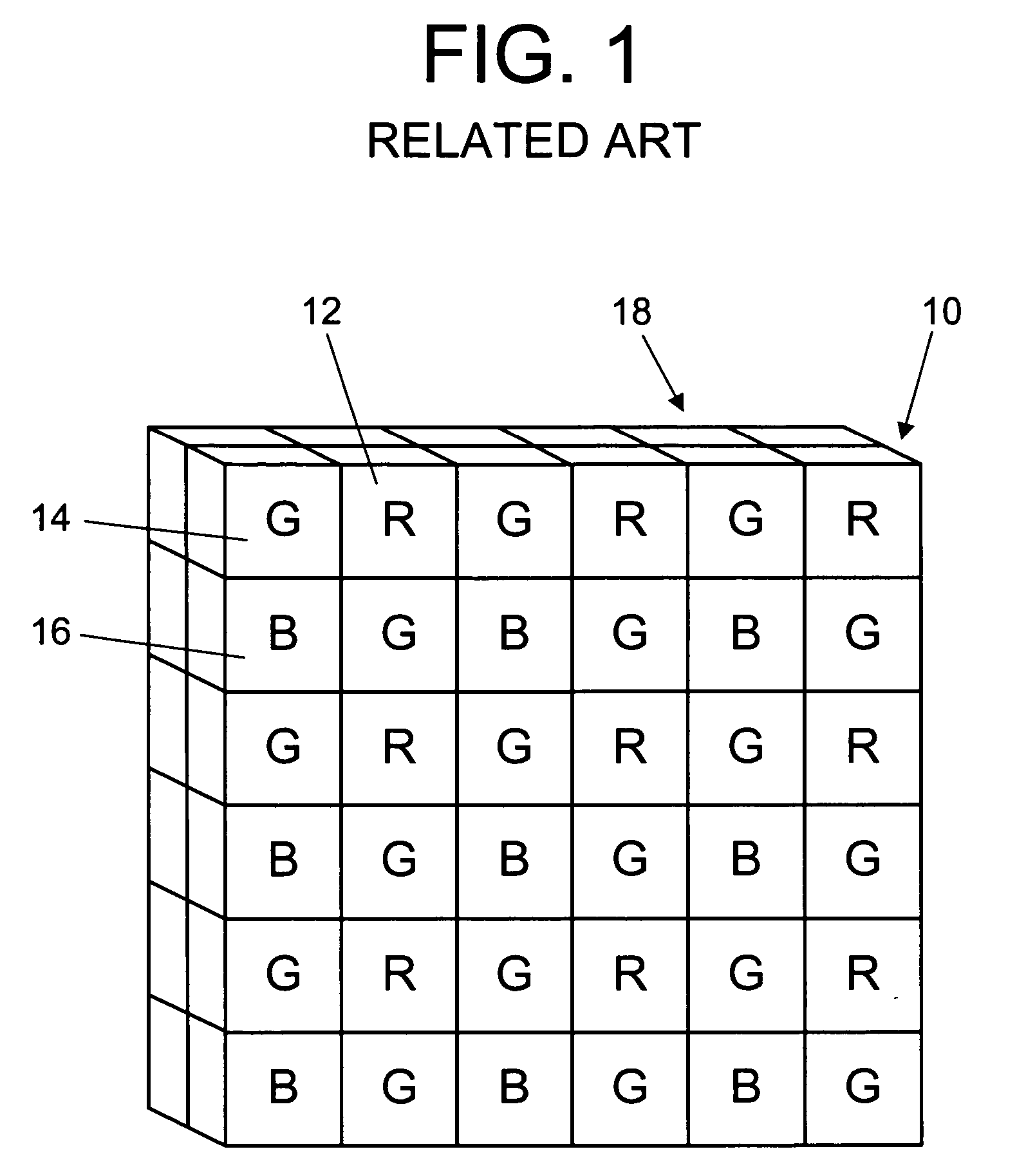

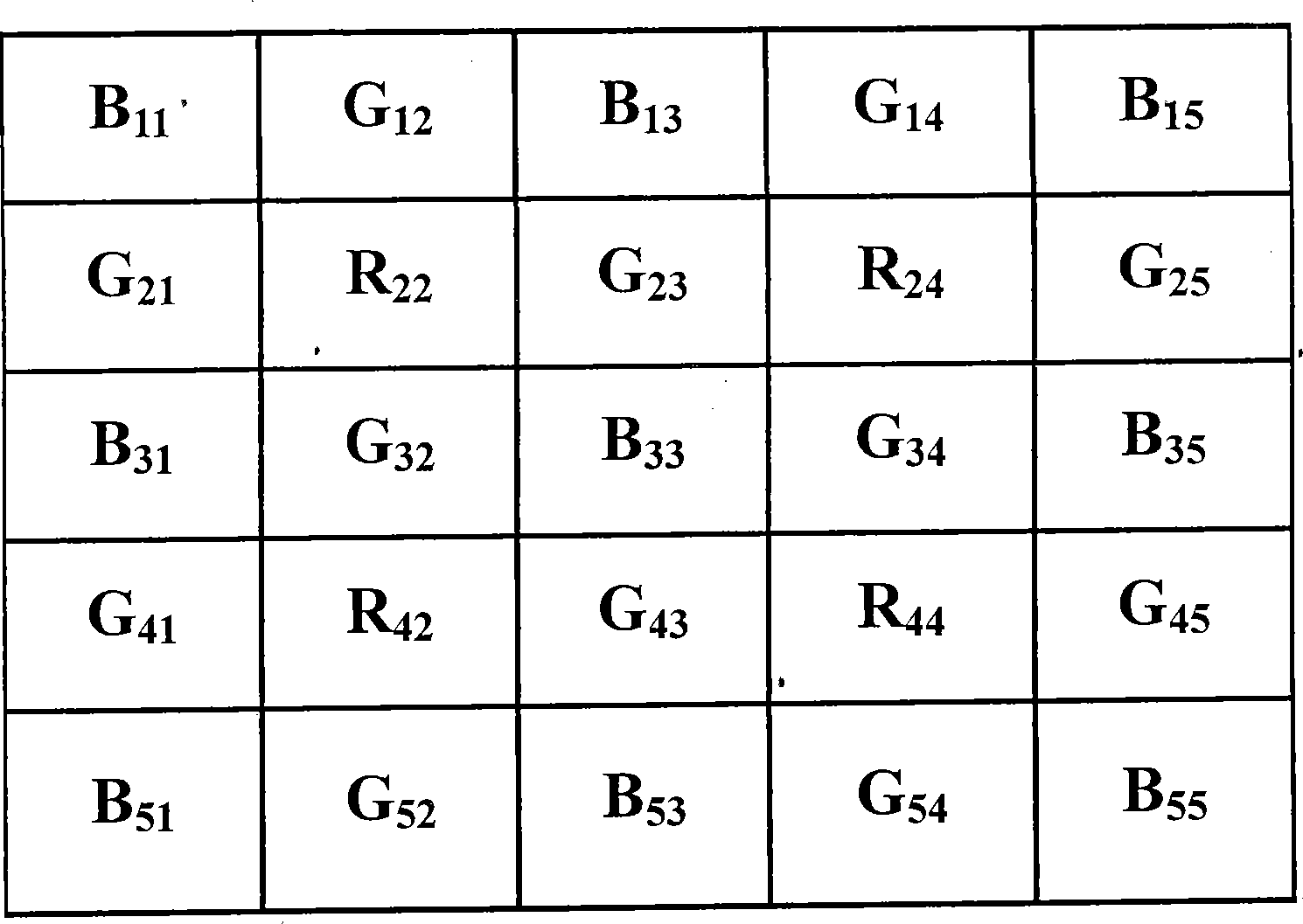

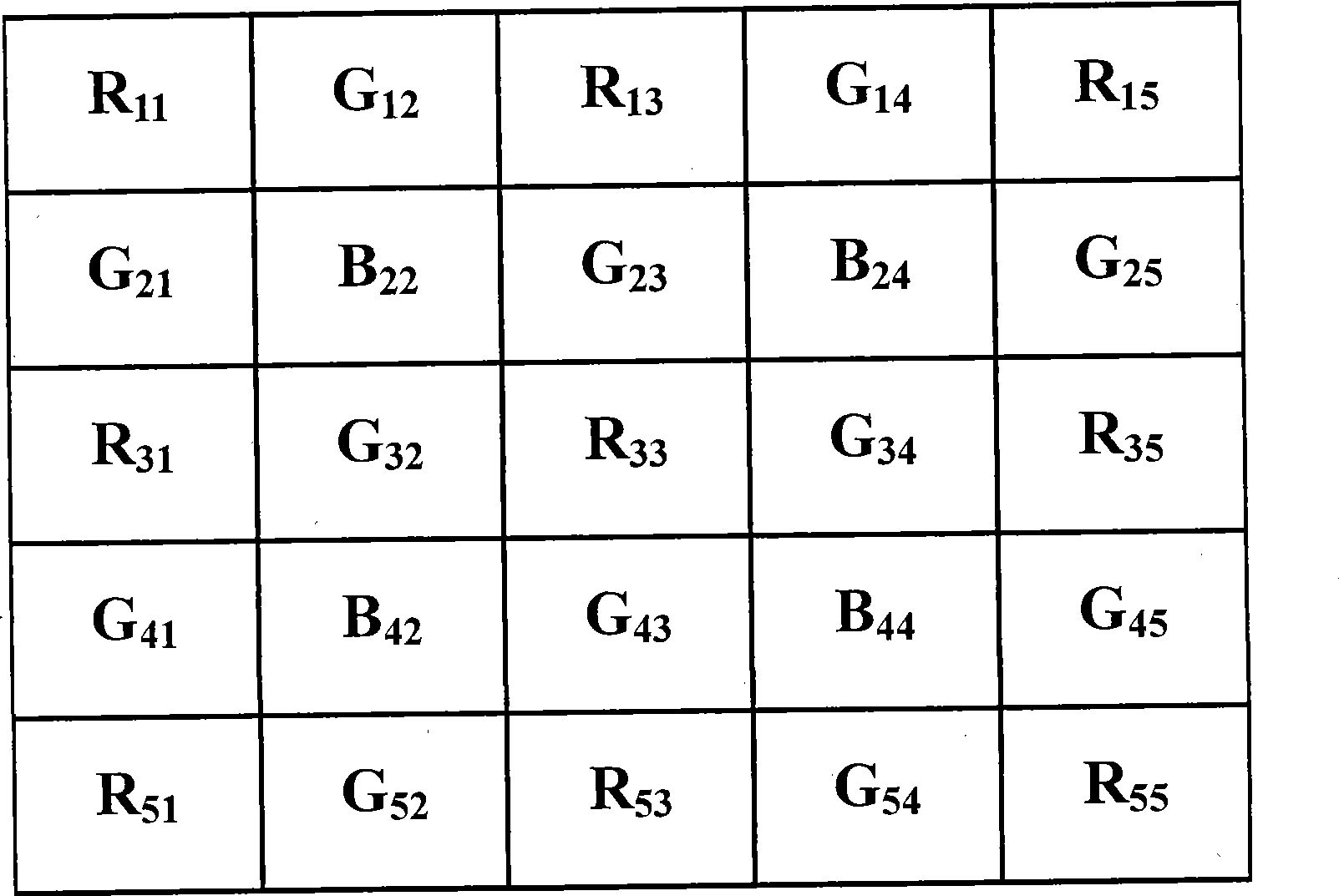

Green component and color difference space-based Bayer format color interpolation method

InactiveCN101917629AReduce operational complexityImprove peak signal-to-noise ratioBrightness and chrominance signal processing circuitsPicture signal generatorsJaggiesImage resolution

The invention relates to a green component and color difference space-based Bayer format color interpolation method. Two main errors which are jaggies and pseudo colors respectively exist in the conventional color interpolation methods. In the method, in a full-color image recovery process, color recovery is realized by adopting a combined way of interpolating green components, red components and blue components in steps; and the method comprises the reconstruction of the full-resolution green components G, the calculation of pixel point color differences R-G or B-G comprising the red or blue components, the reconstruction of full-resolution color difference images R-G and B-G, and the recovery of the red components R and the blue components B by the addition of the reconstructed full-resolution green components and the reconstructed color difference images. The method of the invention has the advantages of effectively solving the problem that the images have blurry edges and unsharp detail textures, reducing the color distortion of the images, preventing color mutation and improving color smoothness.

Owner:ZHEJIANG UNIV

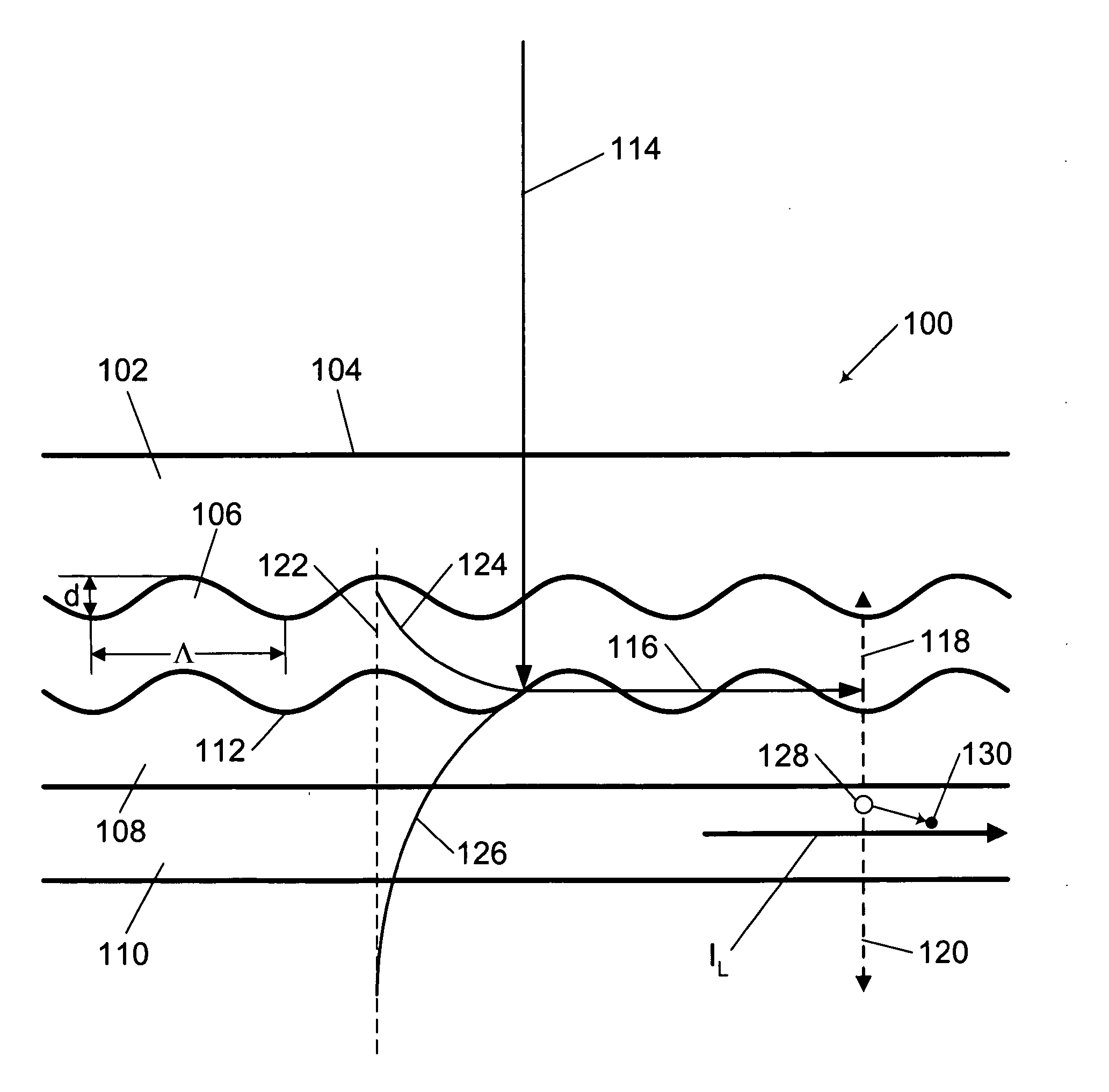

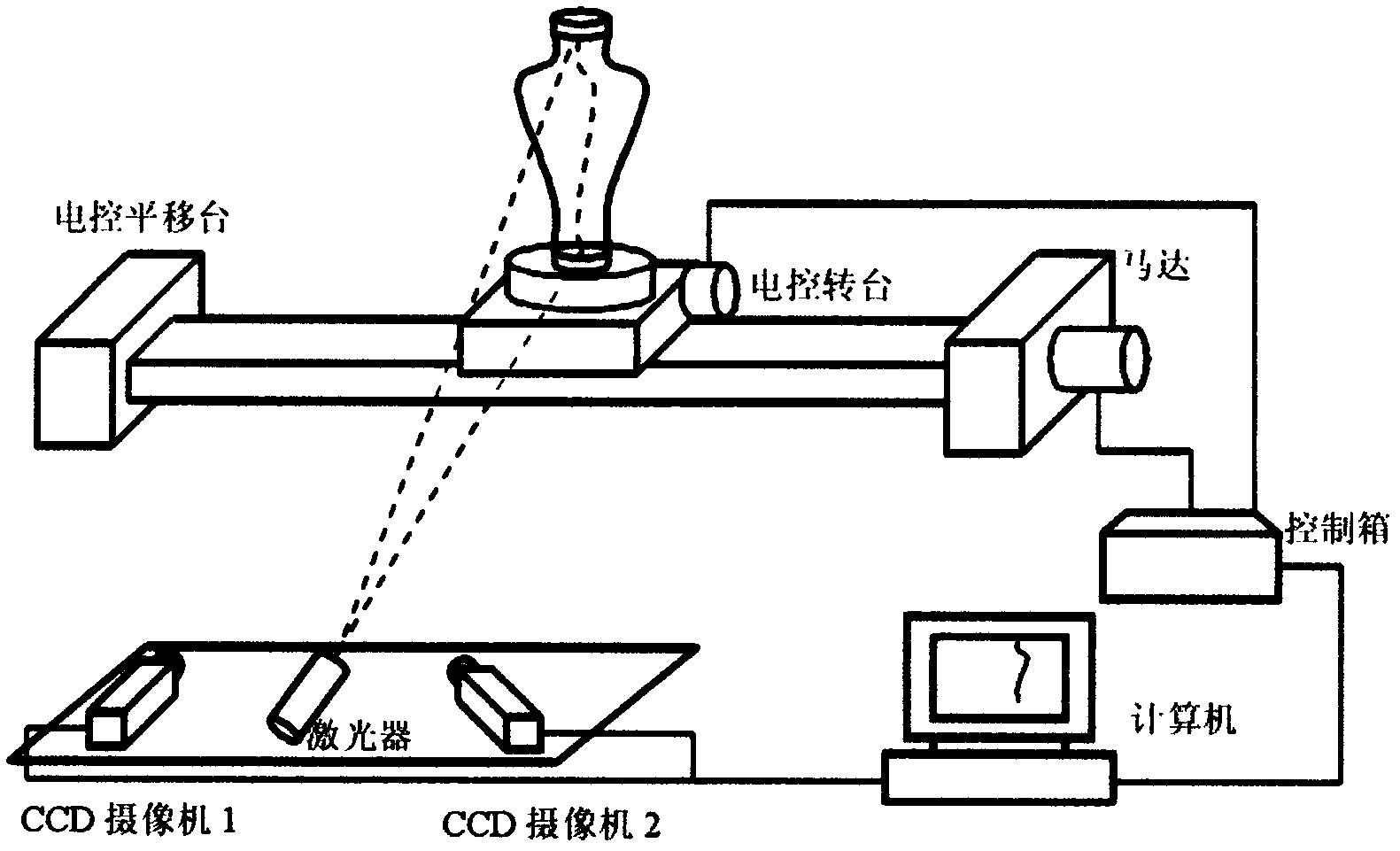

Three-dimensional coordinate measuring method based on single-camera two-color linear structured light

The invention relates to a three-dimensional coordinate measuring method based on single-camera two-color linear structured light, which comprises the steps of calibration of a camera, calibration of a light plane and solution of a three-dimensional coordinate, wherein the calibration of the camera is that: a corresponding relation between a pixel coordinate on an image and a space line forming an image point is established to obtain a continuous mapping inside an entire measuring space; the calibration of the light plane is that: in order to obtain a red-blue linear structured light three-dimensional space equation, a pixel coordinate of a red-blue linear structured light image is obtained on two calibrated images and is converted to a corresponding space three-dimensional coordinate; and the solution of the three-dimensional coordinate is that: a central pixel coordinate of the red-blue linear structured light is searched on a photographed color image, and a space linear equation is established and solved to obtain the space three-dimensional coordinate. Compared with a traditional three-dimensional measuring method, the three-dimensional coordinate measuring method has the advantages of large data collection amount, low cost, small data transmission amount, no need of registration of the data collected by multiple cameras, and capability of eliminating the background interference by a green component in the image so that the measurement is not sensitive to ambient light.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

Improved bilinear Bayer format color interpolation method

InactiveCN102665030AImprove peak signal-to-noise ratioEnhance the imageColor signal processing circuitsPicture signal generatorsSpatial correlationSignal-to-noise ratio (imaging)

The invention discloses an improved bilinear Bayer format color interpolation method. The conventional method is large in calculation amount for chromatic aberration, high in complexity and long in delay, and the imaging speed of a digital camera is remarkably influenced. In a full-color image reconstruction process, color recovery is realized in a combination way of stepwise interpolating a green component and red and blue components. The method comprises the following steps of: strictly distinguishing an image edge by utilizing the spatial correlation of an image, and reconstructing the green component under full resolution; and reconstructing the red and blue components under the full resolution by using an improved bilinear interpolation algorithm and the correction and compensation of a recovered green component. Compared with the conventional interpolation algorithm, the method has the advantages that the peak signal to noise ratio of a recovered full-color image color signal is high, and an ideal interpolated image effect can be achieved under the condition of no increase of computational complexity of the algorithm.

Owner:ZHEJIANG UNIV

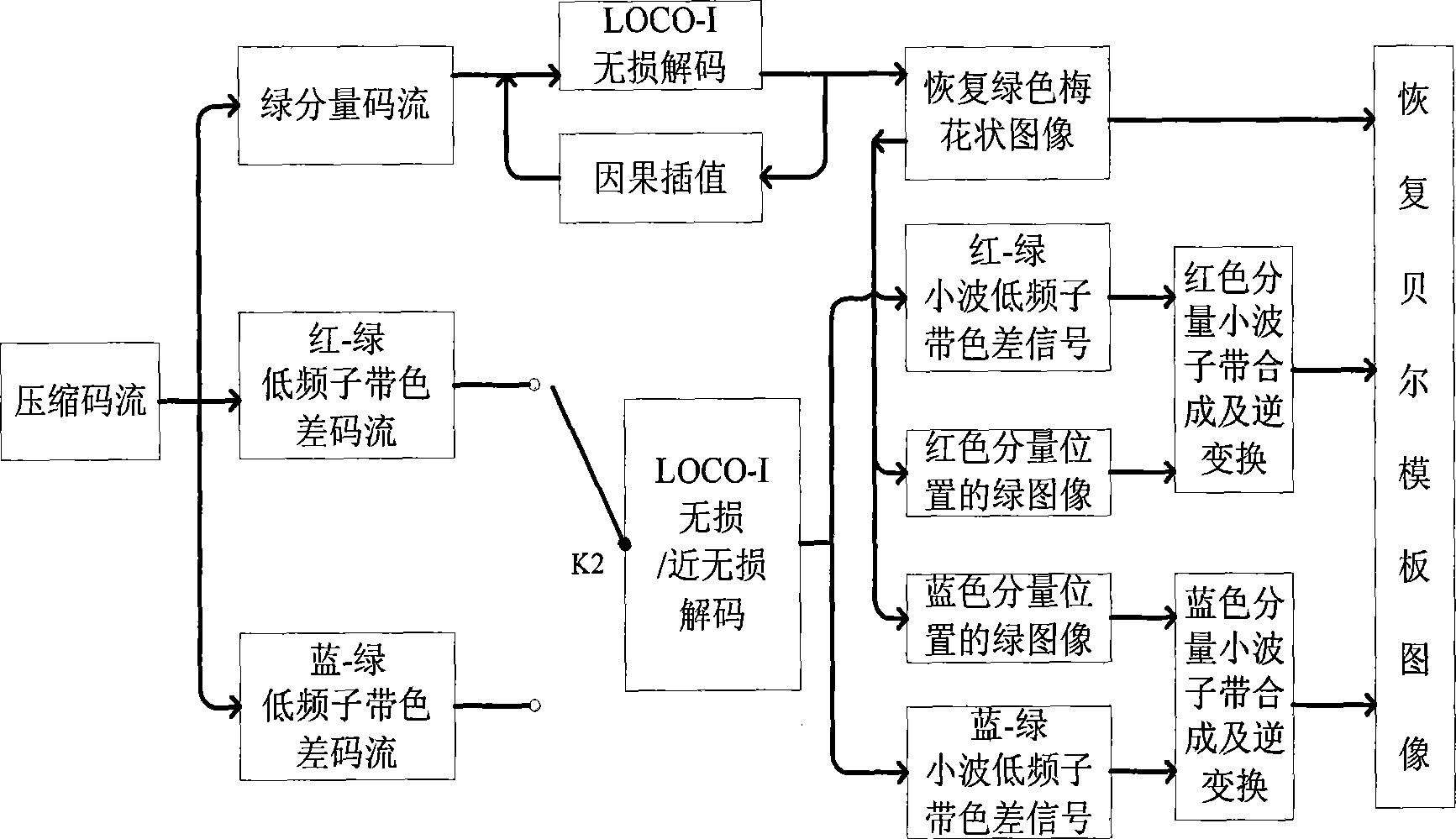

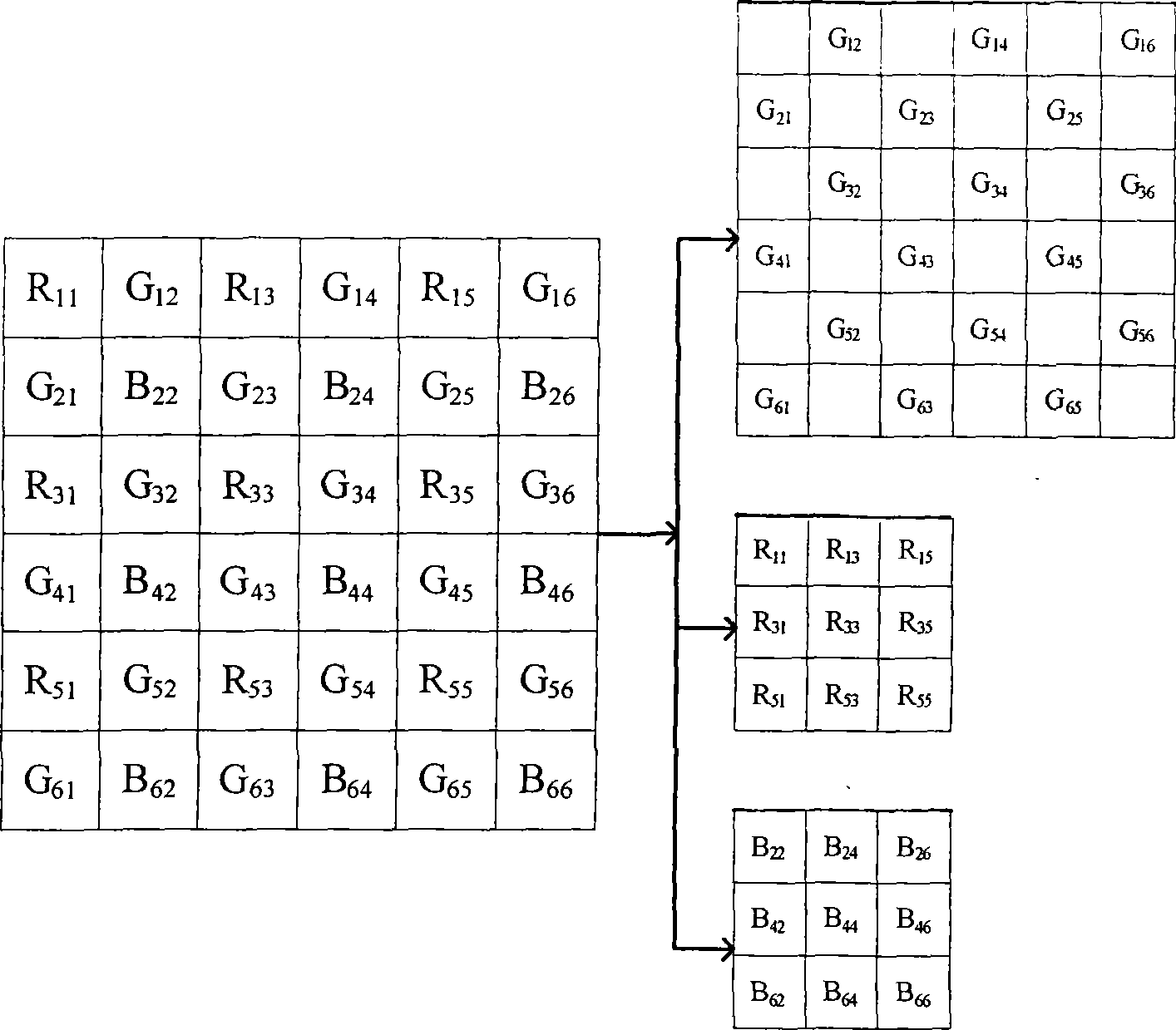

Method for encoding and decoding Bell formwork image

InactiveCN101442673AReduce complexitySimple structureColor television with bandwidth reductionTelevision systemsColor imageDigital image compression

The invention relates to digital image compression technology, in particular to a method for encoding and decoding Bayer patter images, and aims to solve the problem of the difficult establishment of good balance between compression ratio, quality and complexity of restructured color images in the prior method which compresses Bayer pattern image data directly. The invention uses LOCO-I technology to perform lossless encoding for a green component; and through estimation of the green component on the site of a red-blue component by a gradient interpolation method, a color difference signal between the small-wave low-frequency subband of the red-blue component and the low-frequency subband of the estimated green component can be acquired, and can undergo lossless or nearly lossless compression by the LOCO-I technology. At the decoding end, the lossless green component should be obtained firstly, then the green component on the site of the red-blue component is estimated through an process identical to the encoding process; the small-wave high-frequency subband of the estimated green component can replace the corresponding small-wave high-frequency subband of the red-blue component, and the rest part is a reverse process of encoding. The method is characterized by high efficiency and low complexity.

Owner:TAIYUAN UNIV OF TECH

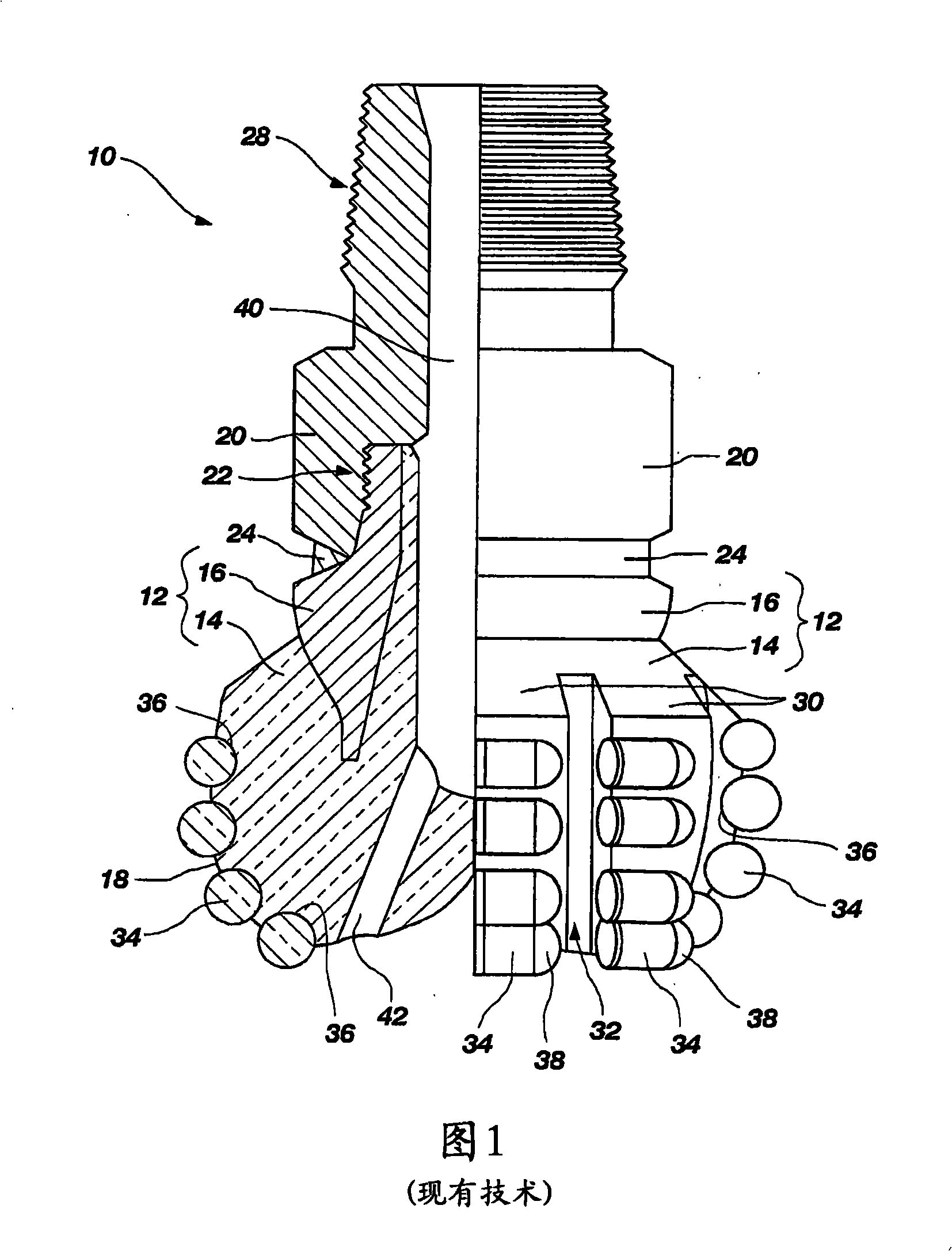

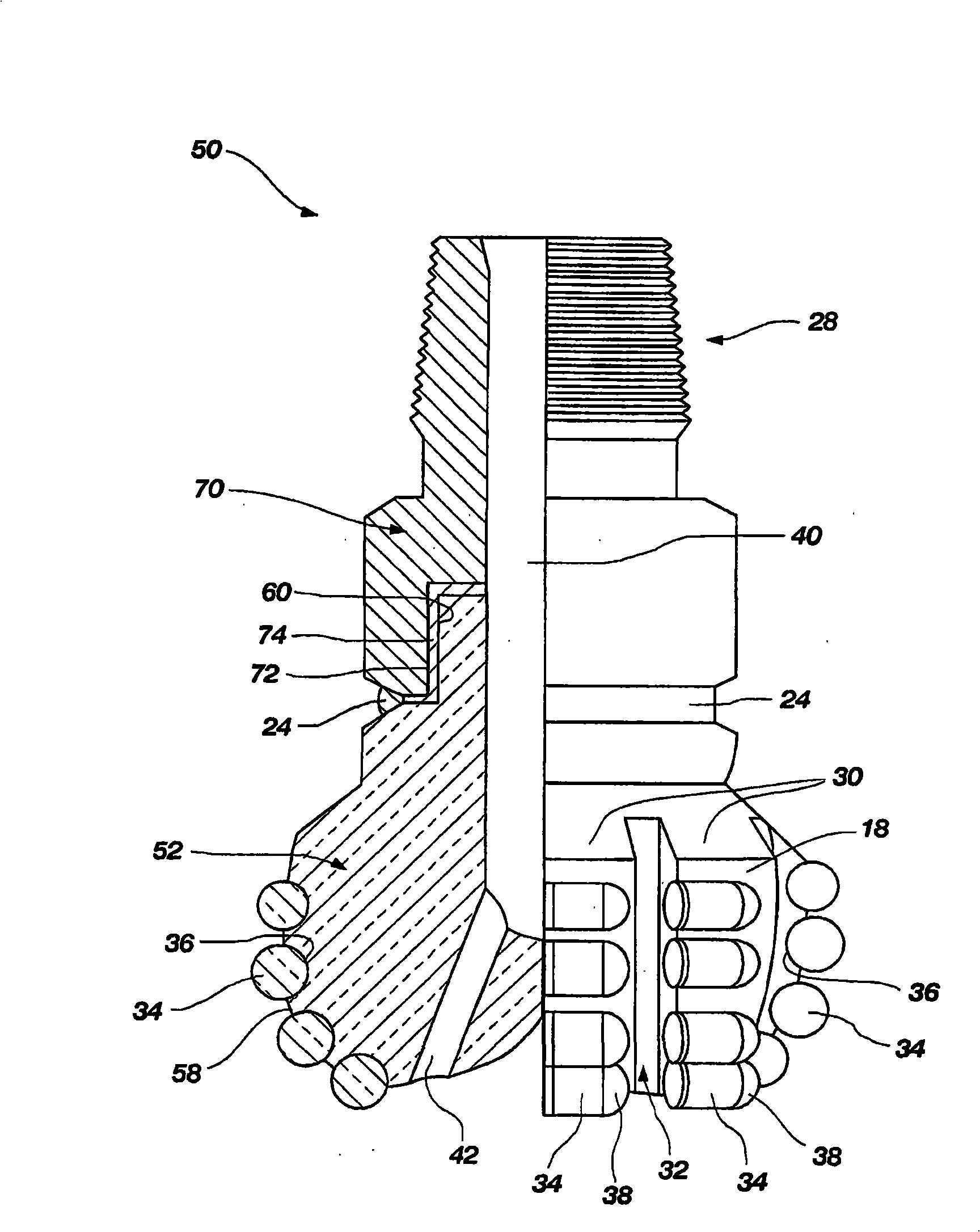

Earth-boring rotary drill bits and methods of manufacturing earth-boring rotary drill bits having particle-matrix composite bit bodies

InactiveCN101356031ADrill bitsOther manufacturing equipments/toolsVolumetric Mass DensityGreen component

Methods of forming bit bodies for earth-boring bits include assembling green components, brown components, or fully sintered components, and sintering the assembled components. Other methods include isostatically pressing a powder to form a green body substantially composed of a particle-matrix composite material, and sintering the green body to provide a bit body having a desired final density. Methods of forming earth-boring bits include providing a bit body substantially formed of a particle-matrix composite material and attaching a shank to the body. The body is provided by pressing a powder to form a green body and sintering the green body. Earth boring Earth-boring bits include a unitary structure substantially formed of a particle-matrix composite material. The unitary structure includes a first region configured to carry cutters and a second region that includes a threaded pin. Earth-boring bits include a shank attached directly to a body substantially formed of a particle-matrix composite material.

Owner:BAKER HUGHES INC

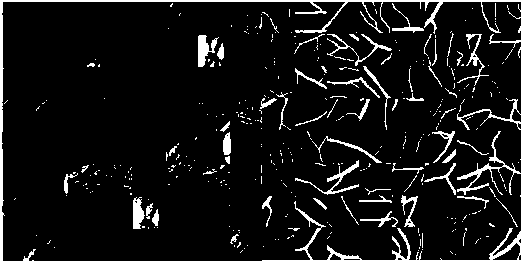

Fundus image blood vessel segmentation method based on Frangi enhancement and attention mechanism UNet

ActiveCN110473188AThe segmentation result is accurateIncrease contrastImage enhancementImage analysisImage extractionThree vessels

The invention relates to a fundus image blood vessel segmentation method based on Frangi enhancement and an attention mechanism UNet, and the method comprises the steps: firstly extracting a green component from an input image, and carrying out the contrast adjustment on the basis of the extracted green component through a contrast-limited histogram equalization method; calculating a Hessian matrix of each pixel point in the image after the contrast ratio is adjusted; constructing a Frangi vascular similarity function by utilizing the characteristic value of the Hessian matrix under the condition of a scale factor, and obtaining the maximum response; respectively subtracting the product of the maximum response value and the enhancement factor factor factor from the pixel values of the RGBthree same channels of each pixel point of the input image; then, carrying out gray scale transformation on the image after frangi enhancement, and carrying out zero mean normalization operation on each pixel value to be between [0, 1]; and finally, inputting the obtained training image blocks and label image blocks into an attention mechanism UNet network for training; and obtaining a segmentation result through testing. According to the invention, the generalization ability of the model is improved.

Owner:FUZHOU UNIV

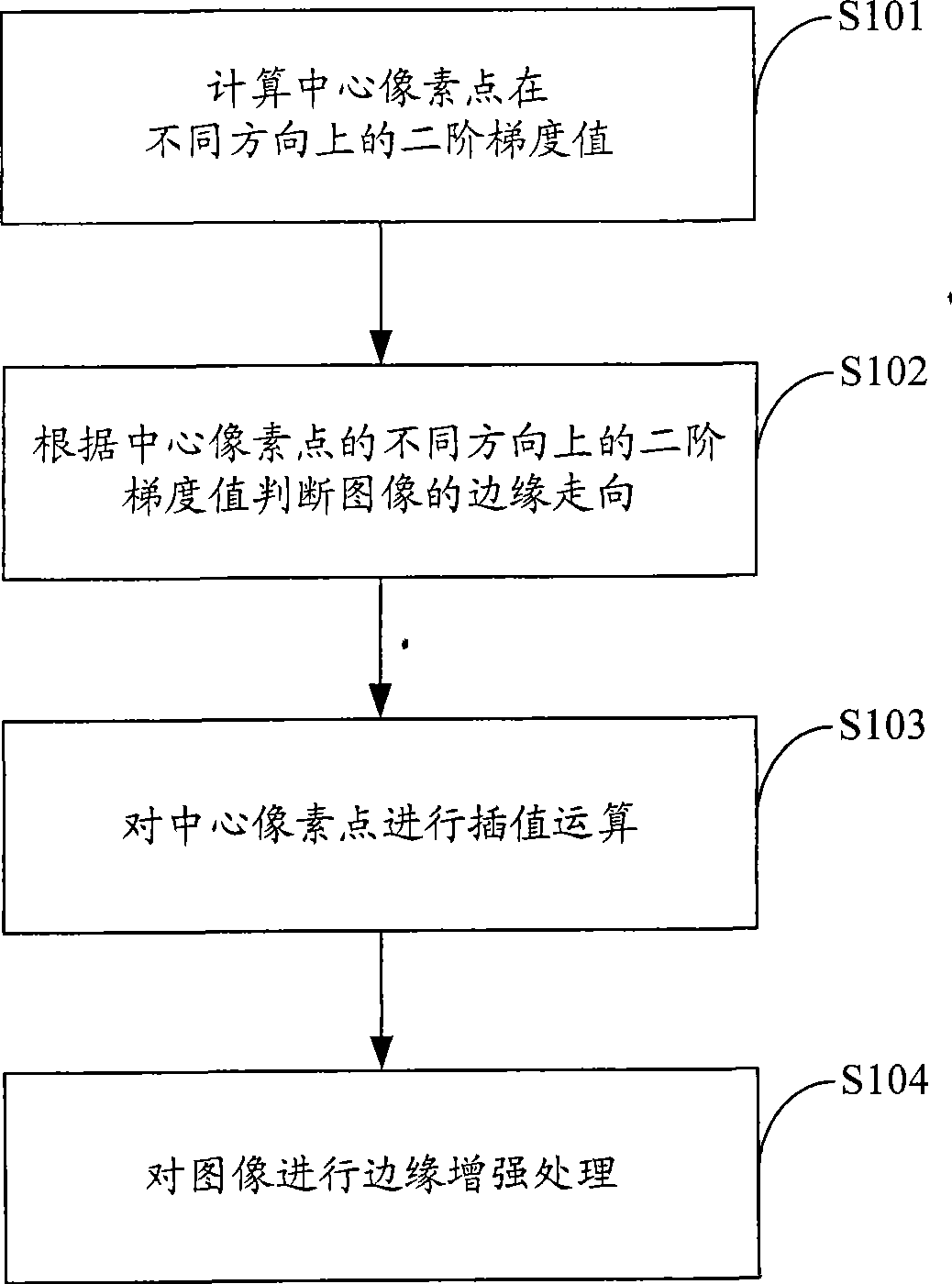

Image edge enhancing method

The invention is applicable to the field of digital image processing and provides an image edge enhancing method. The method comprises: according to the two-step gradients of central pixel point in different directions, judging the edge orientation of an image; carrying out the interpolation of the central pixel point and calculating the lost color component of pixel points; and on the basis of Bayer data, enhancing the edge of the image in an interpolation template according to the color of the original component of the central pixel point and the edge orientation of the image. The embodiment of the invention takes the influences of green component values of different pixel points around the central pixel point into full consideration while carrying out edge enhancement of the image, adopts an adaptive edge enhancement algorithm, eliminates the possible influences of noises on the edge, achieves uniform image edge and helps the processed images to achieve good effect. Meanwhile, due to the edge enhancement processing in the interpolation template on the basis of Bayer data, the method saves SRAM required by single edge enhancement processing, as well as saves large areas of elements and costs.

Owner:BYD SEMICON CO LTD

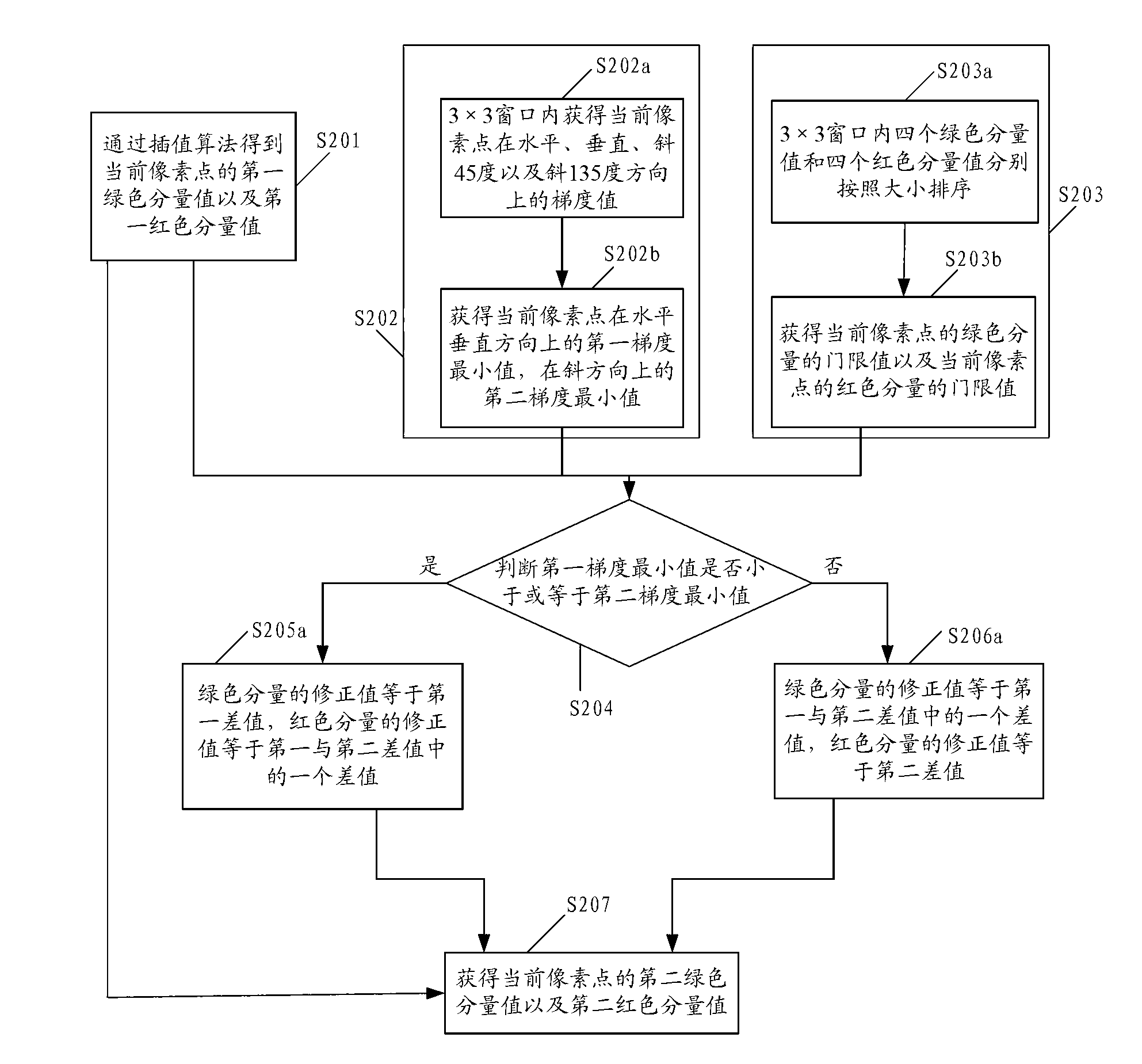

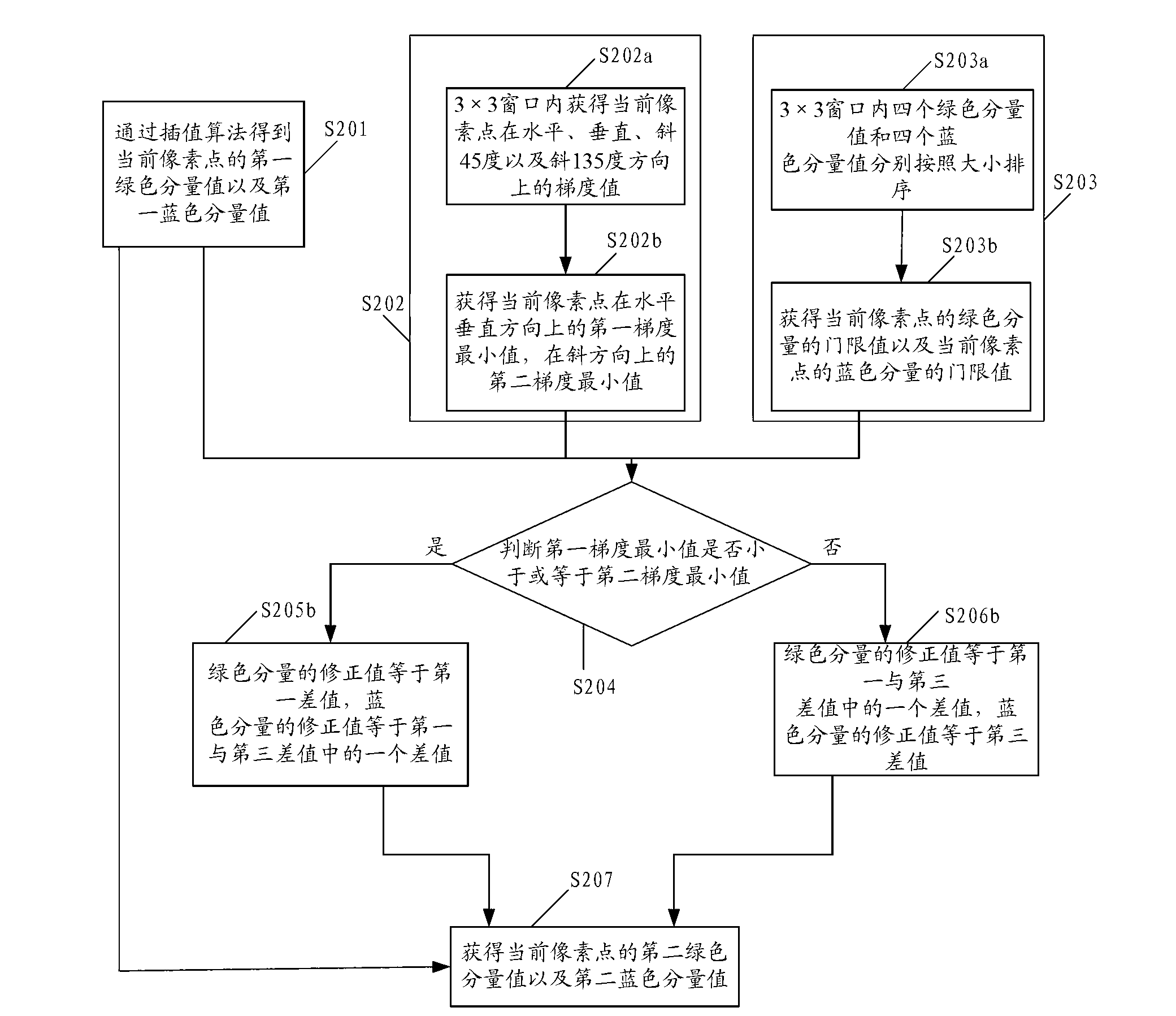

Image processing method, image processing device and imaging device

InactiveCN102938843AReduce crosstalkImage enhancementImage analysisImaging processingGreen component

The invention discloses an image processing method, an image processing device and an imaging device. The image processing method comprises the following steps of: acquiring a first green component value and a first red component value or a first blue component value, a first minimum gradient value in the horizontal vertical direction, a second minimum gradient value in the oblique direction, a threshold value of the green component and threshold values of the red component or the blue component of the current pixel point by using an interpolation algorithm; acquiring a modification value of the green component of the current pixel point and a modification value of the red component or the blue component; and acquiring a second green component value and a second red component value or a second blue component value of the current pixel point. According to the method, the crosstalk on other two interpolated color components by the color component in which the current pixel point is located can be reduced.

Owner:HUAWEI TECH CO LTD

Green pork piglet feed for stimulating appetite and assisting in digestion

InactiveCN103621827AIncrease appetitePromote growth and developmentAnimal feeding stuffBiotechnologySlag

The invention relates to the technical field of livestock breeding and in particular relates to a green pork piglet feed for stimulating the appetite and assisting in digestion. The feed is prepared from the following raw materials in parts by weight: 50-60 parts of corn meal, 20-22 parts of broken rice, 10-12 parts of chaff, 12-15 parts of rye bran, 10-12 parts of corn sugar slag, 8-10 parts of dry vinegar residues, 15-18 parts of rapeseed meal, 3-4 parts of fried white sesame powder, 1-2 parts of flos caryophylli, 2-3 parts of dry phyllanthus emblica powder, 5-8 parts of suaeda salsa, 3-4 parts of fish gut powder, 2-3 parts of fine shell powder, 6-8 parts of sweet potato seedlings, a proper amount of locust leaves, a proper amount of edible salt and 4-5 parts of a phagostimulant. The feed aims at the physiological features of piglets, and the raw materials such as the fried white sesame powder, the flos caryophylli and the dry phyllanthus emblica powder are specially added to stimulate the appetites of the piglets and promote digestion of intestinal tracts to the food; furthermore, the nutrition is balanced and complete; the growth of the piglets can be accelerated; after the piglets are fed on the feed, the daily weight gain is increased; moreover, all the raw materials are pure natural green components, so that the problem of drug residues is solved.

Owner:凤台县古店乡李杰养殖场

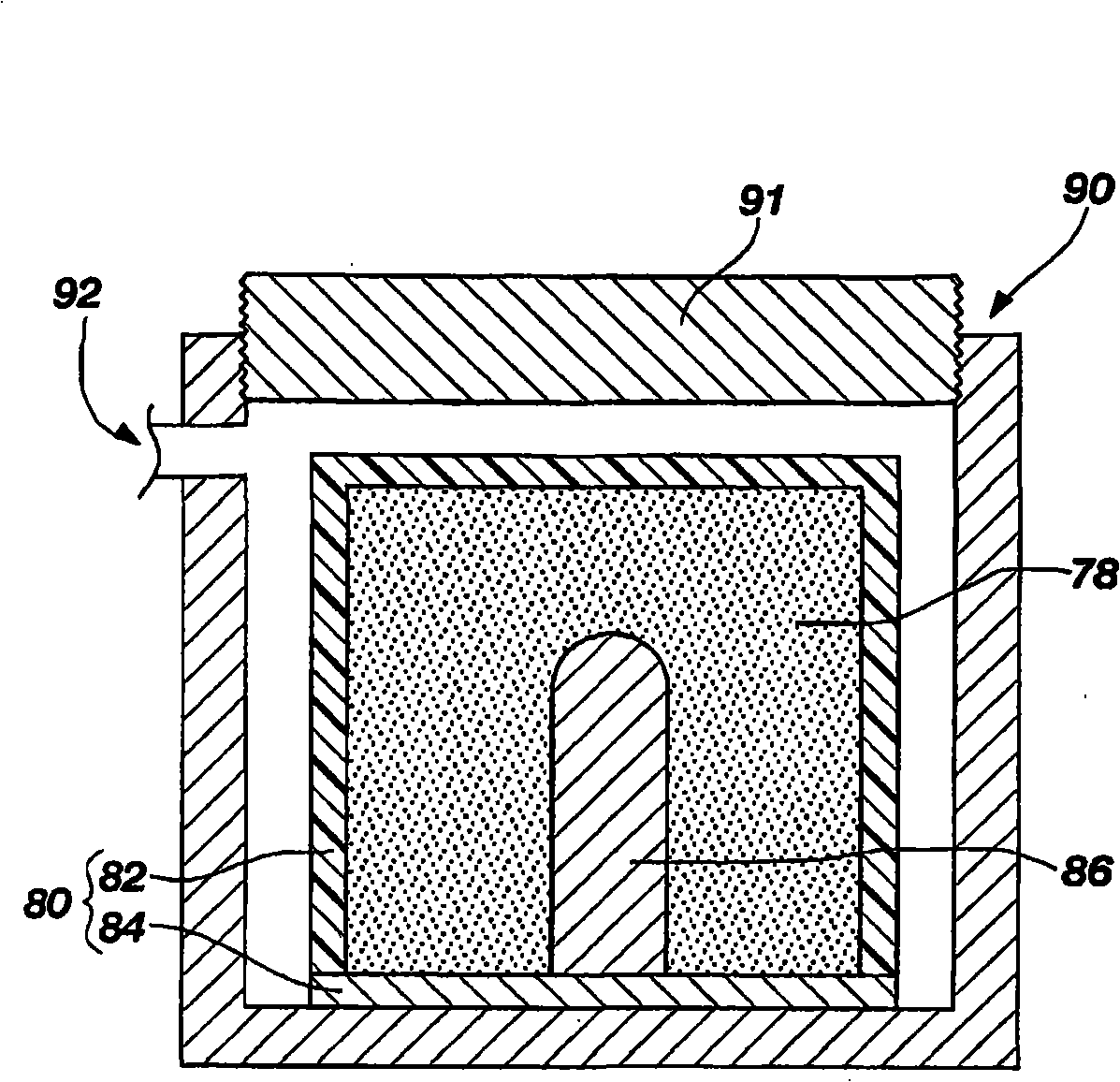

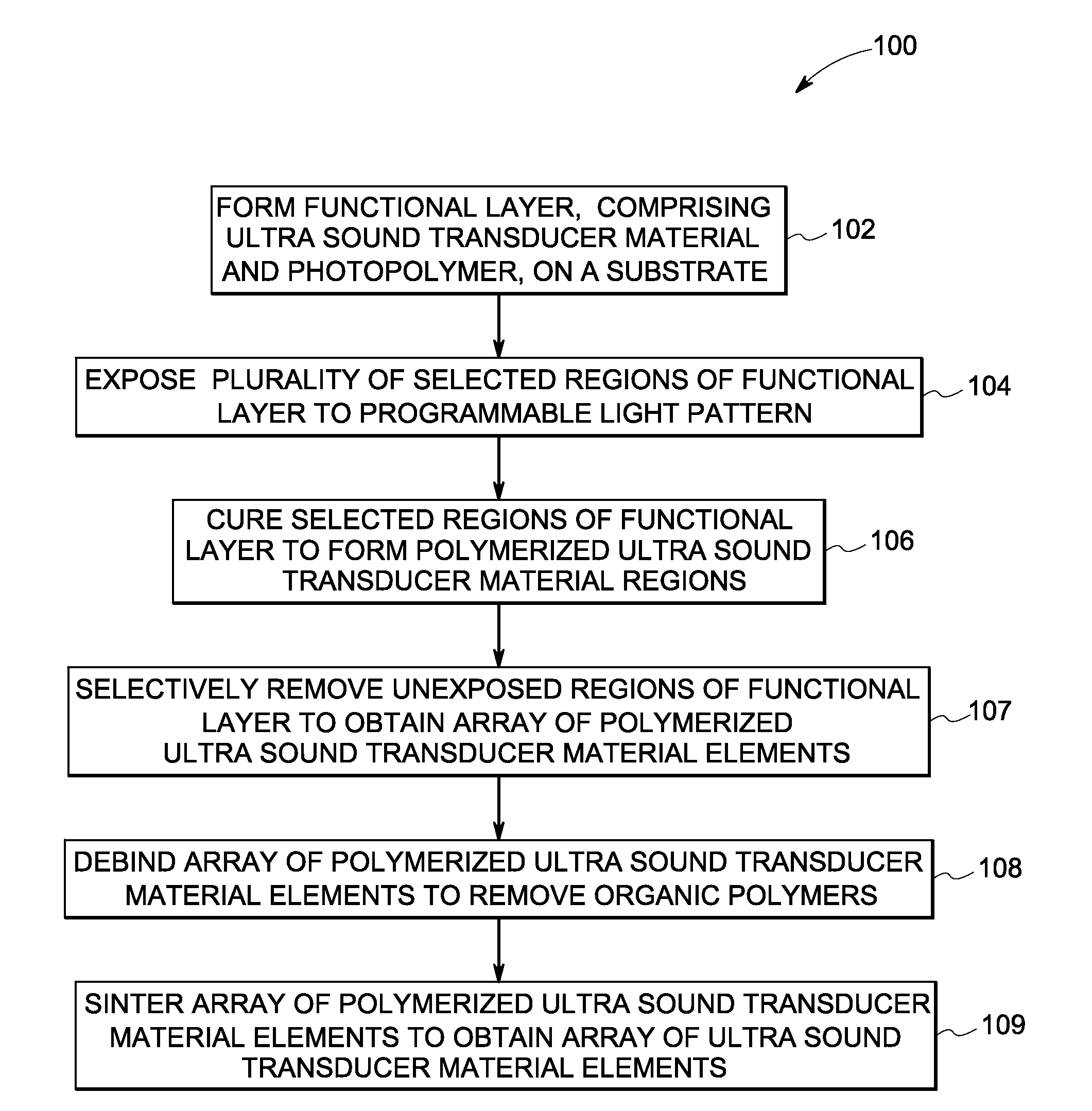

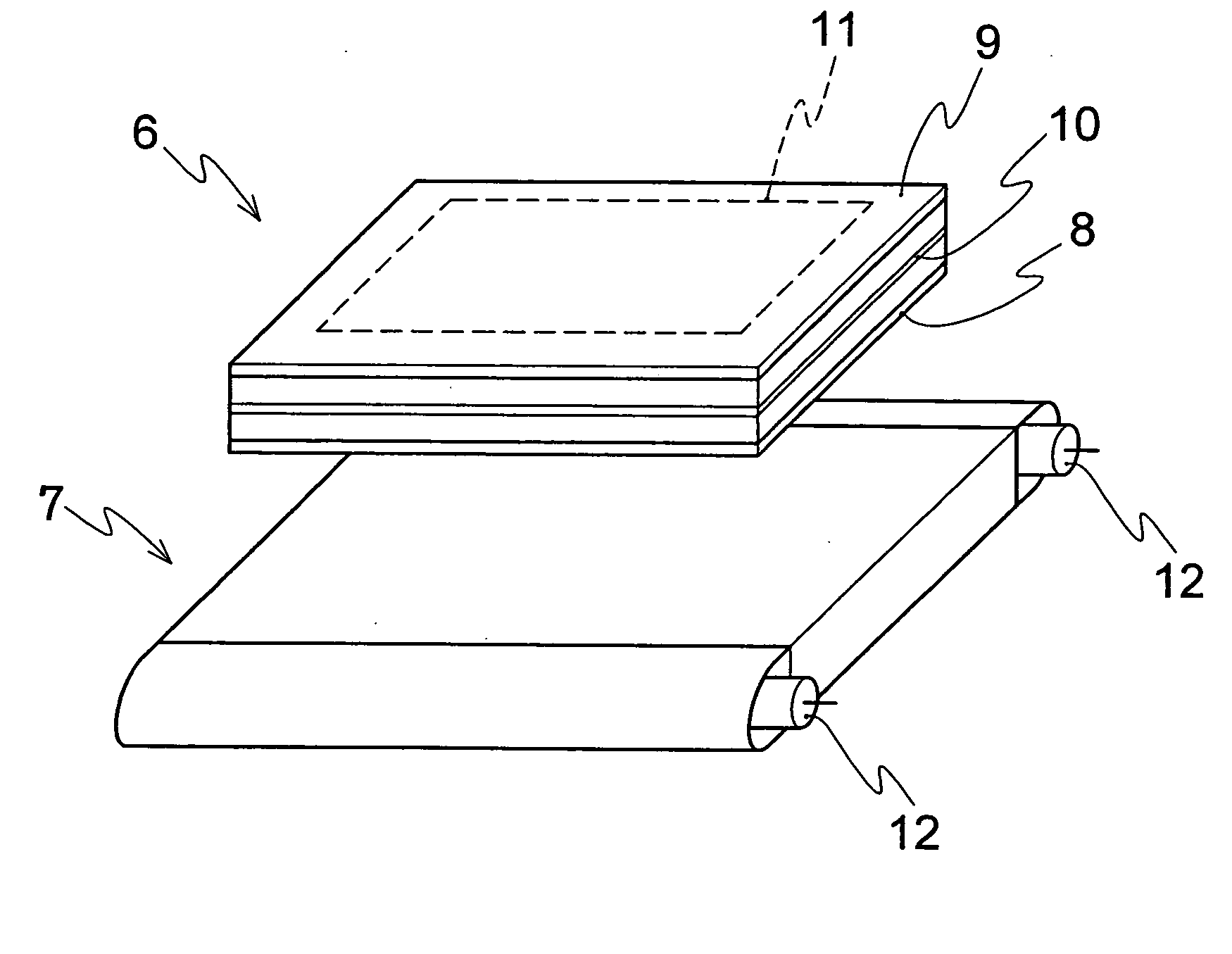

Ultrasound transducer probes and system and method of manufacture

InactiveUS20090199392A1Easy to understandPiezoelectric/electrostrictive device manufacture/assemblyElectrical transducersUltrasonic sensorTransducer

A method for fabricating an ultrasound transducer structure is disclosed. The method includes performing the steps of forming a functional layer, including an ultrasound transducer material and a photopolymer, and exposing a plurality of selected regions of the functional layer to a programmable light pattern to cure the selected regions of the functional layer to form polymerized ultrasound transducer material regions, repeatedly. The method further includes selectively removing unexposed regions of the functional layer to obtain a green component, and sintering the green component to obtain the sensing structure. A system for making at least one piezoelectric element is also disclosed.

Owner:GENERAL ELECTRIC CO

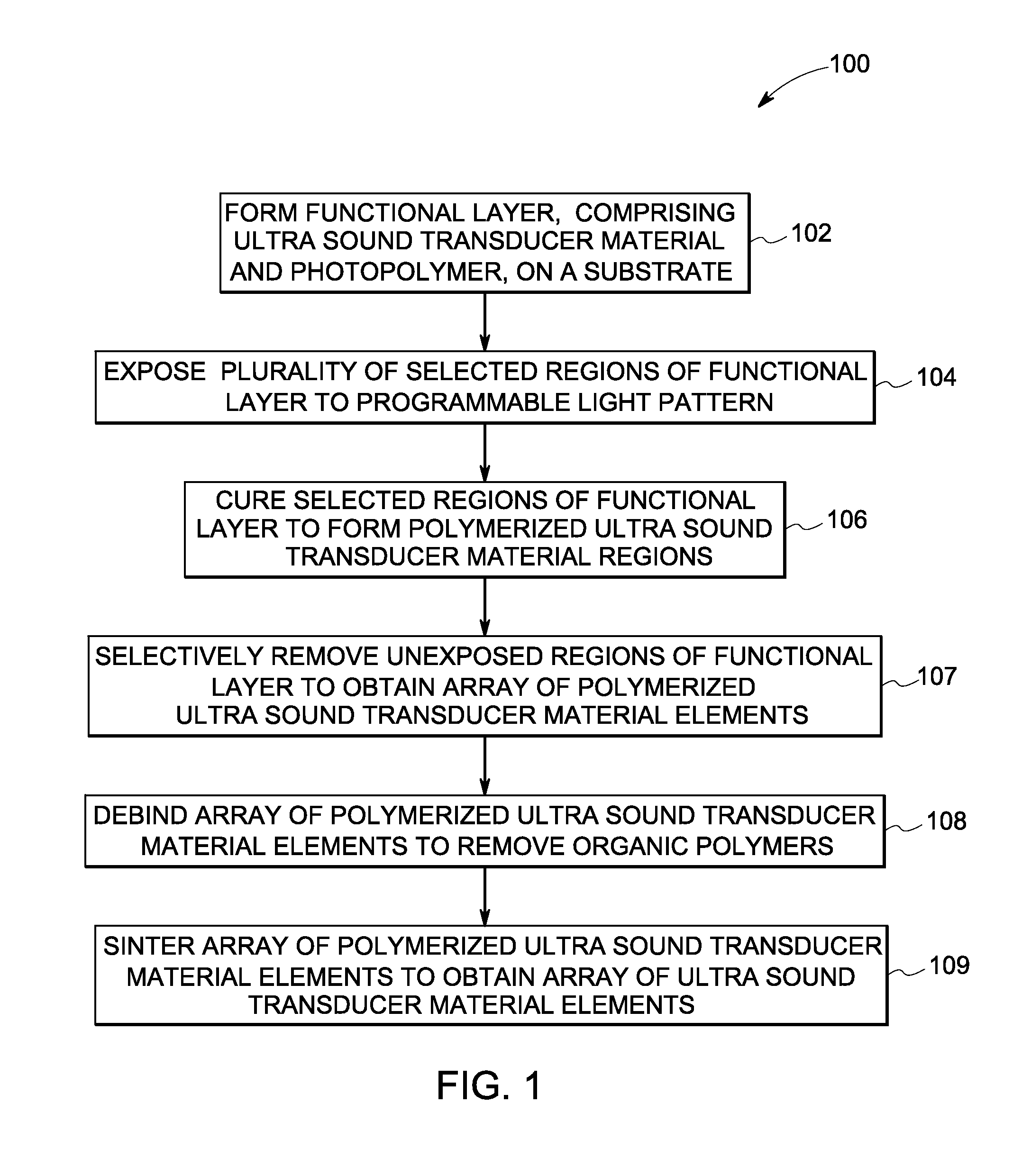

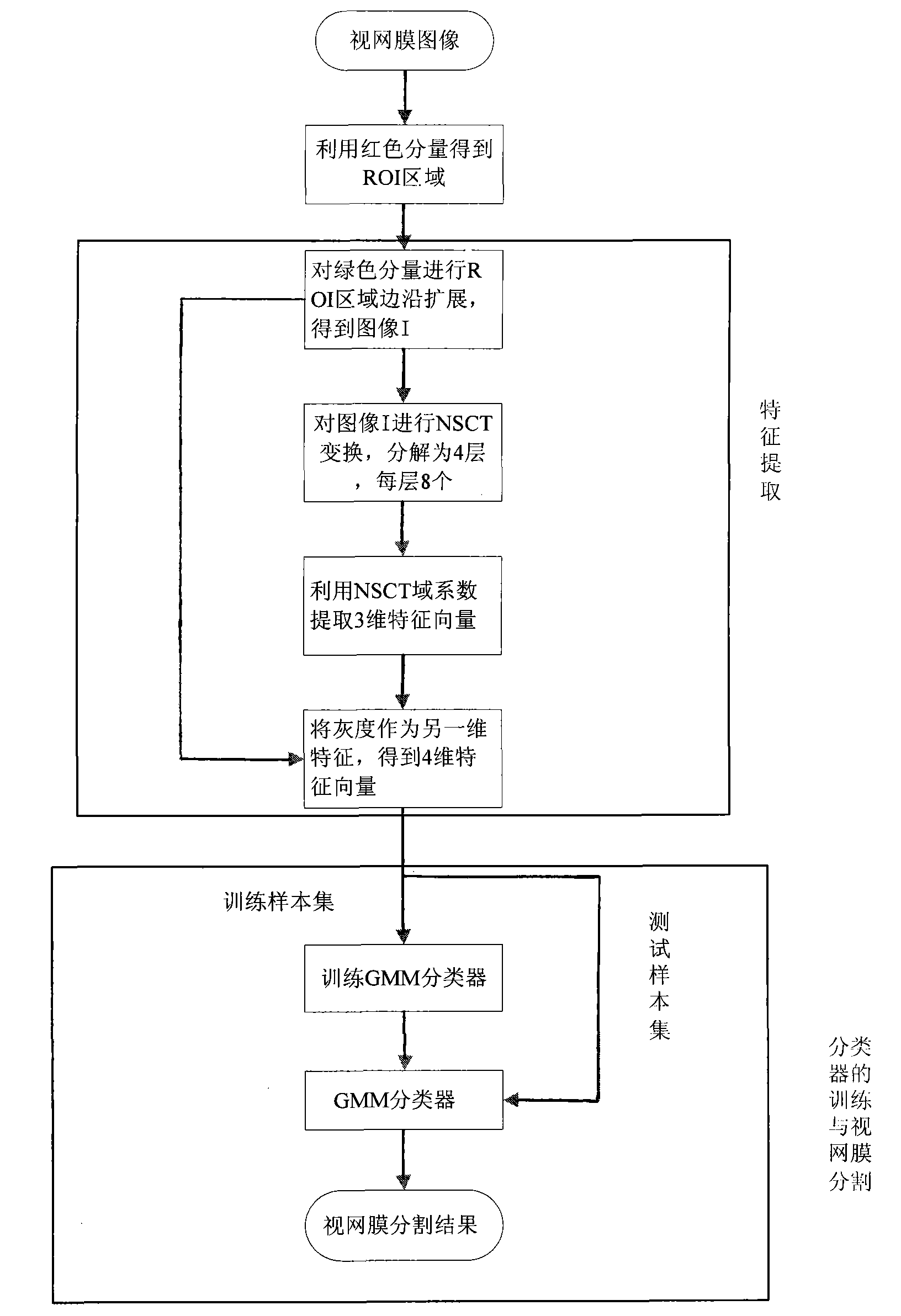

Retinal image segmentation method based on NSCT feature extraction and supervised classification

InactiveCN101667289AReduce mistakesAccurate segmentationImage analysisCharacter and pattern recognitionFeature vectorImaging processing

The invention discloses a retinal image segmentation method based on NSCT feature extraction and supervised classification, which relates to medical image processing. The method comprises the following steps: (1) obtaining interest regions of a retinal training image and a retinal image to be segmented by utilizing red components of the retinal training image and the retinal image to be segmented;(2) respectively carrying out edge iterative expansion of the regions of interest on green components of the retinal training image and the retinal image to be segmented; (3) respectively carrying out NSCT transformation on the expanded images to decompose the images into i layers; (4) extracting a one-dimensional features by utilizing sub-band coefficients in j directions of each layer, extracting the features layer by layer to form feature vectors and normalizing the feature vectors; (5) establishing a training sample of the feature vectors of the normalized retinal training image; (6) selecting a classifier, training the classifier by utilizing the training sample and inputting the feature vectors of the normalized retinal image to be segmented into the classifier so as to segment theretinal image to be segmented. The invention has the advantages of clear image segmentation edge and high precision and is used for medical image retina segmentation.

Owner:XIDIAN UNIV

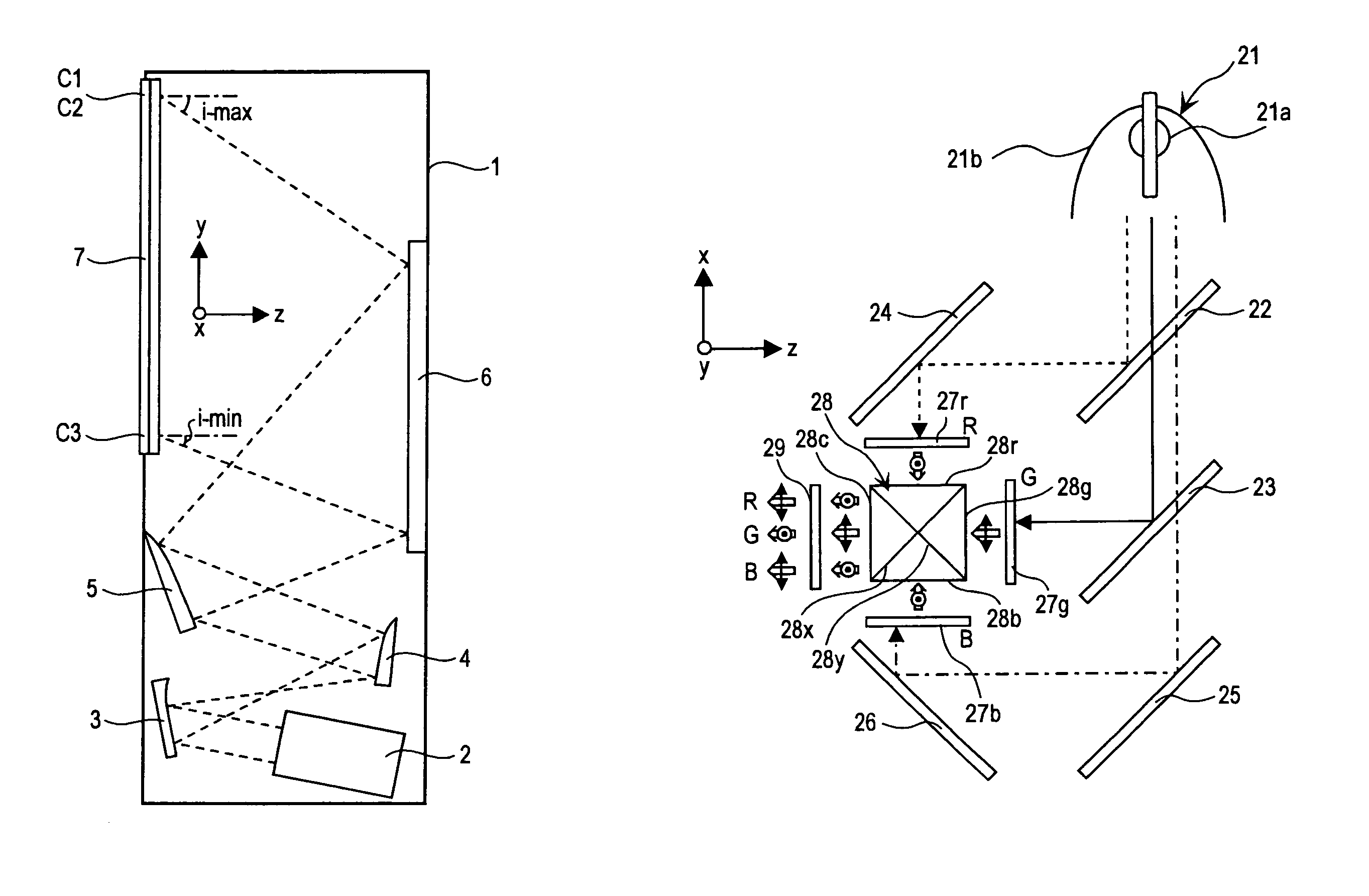

Illumination apparatus and projection display device

ActiveUS20080100804A1Reduce manufacturing costIncrease image brightnessProjectorsColor photographyGreen-lightOptical polarization

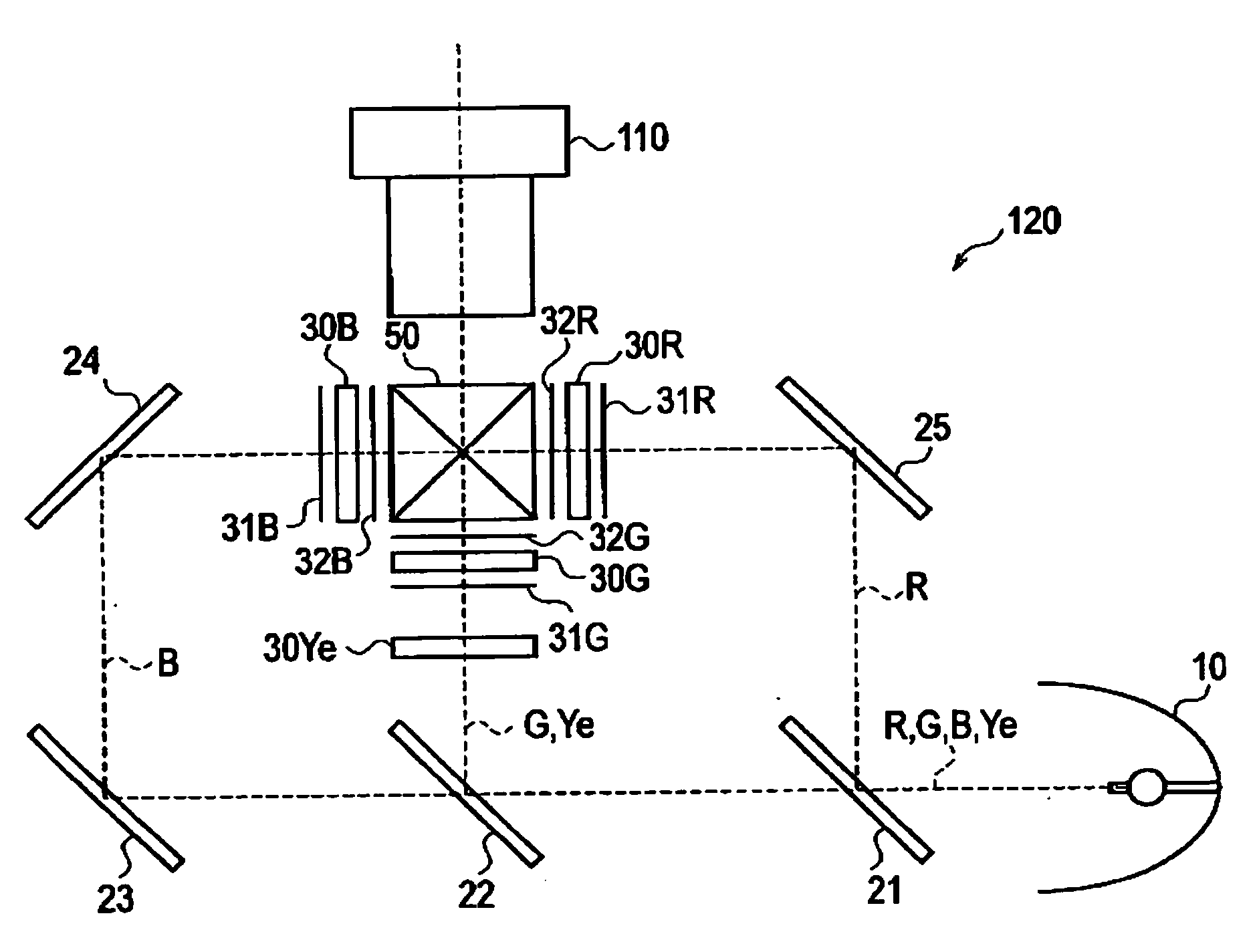

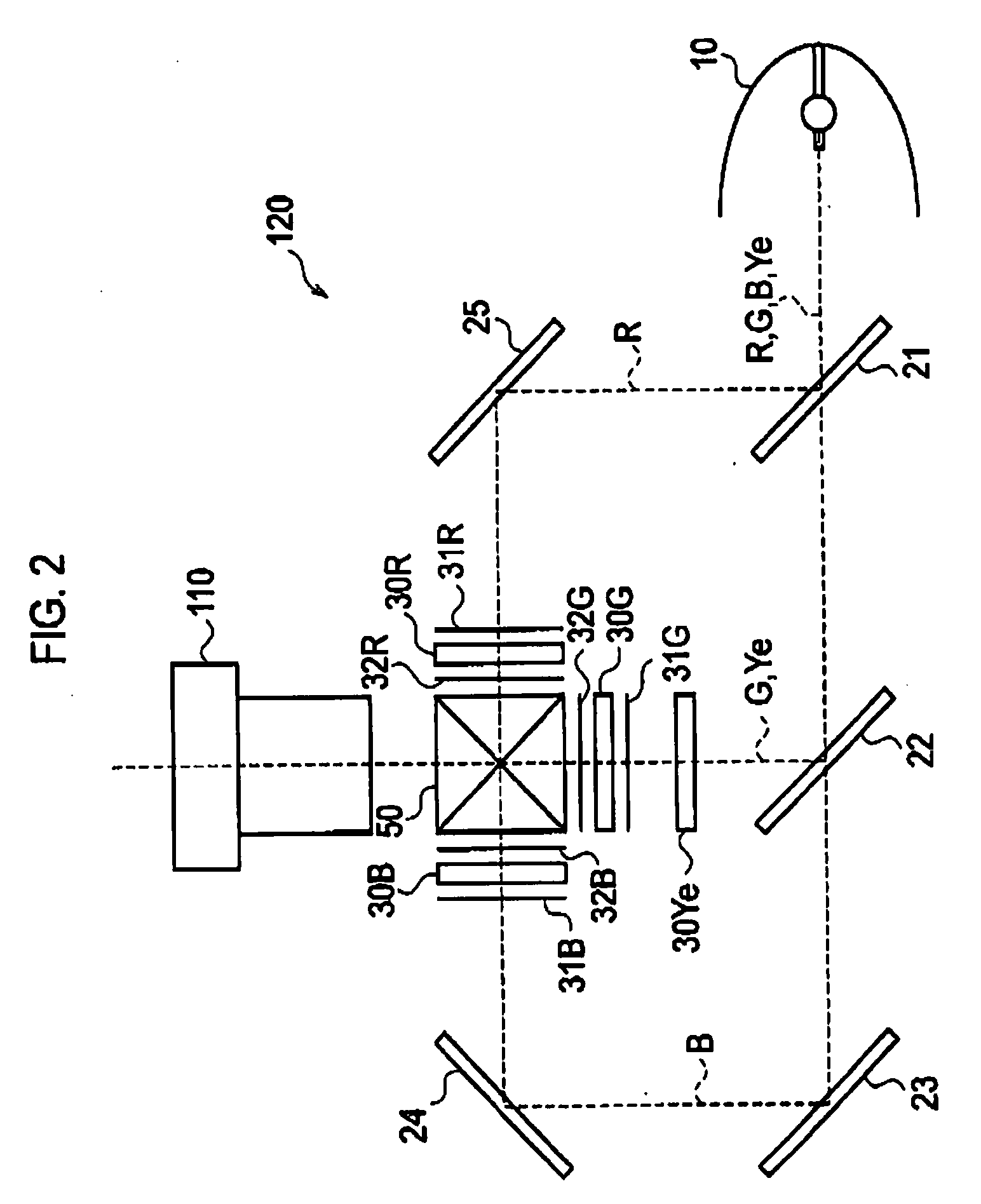

An illumination apparatus includes a red light valve, a green light valve, a blue light valve, a polarization adjustment element, and a color combiner. The polarization adjustment element adjusts polarization of fourth color component light. The color combiner combines light emitted from the red light valve, the green light valve and the blue light valve. Superimposed component light which is any one of a red component light, a green component light and a blue component light enters the polarization adjustment element together with a fourth color component light. The polarization adjustment element transmits the superimposed component light without adjusting the polarization, and transmits the fourth color component light with adjusting the polarization. The superimposed component light and the fourth color component light emitted from the polarization adjustment element enter a specific light valve corresponding to the superimposed component light, among the red light valve, the green light valve and the blue light valve.

Owner:SANYO ELECTRIC CO LTD

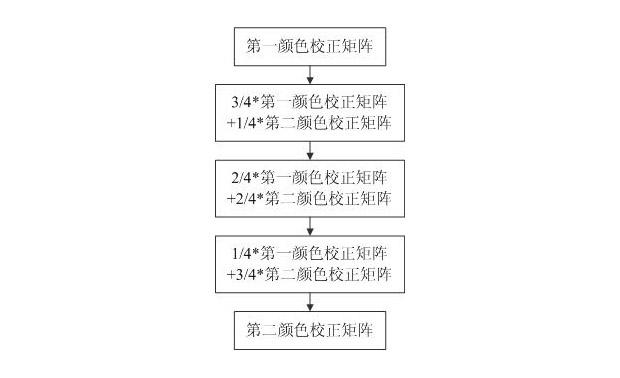

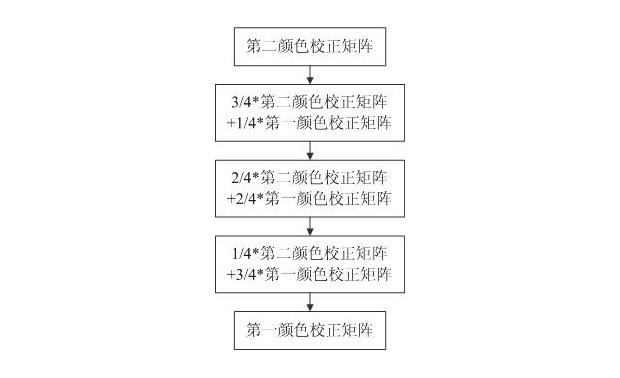

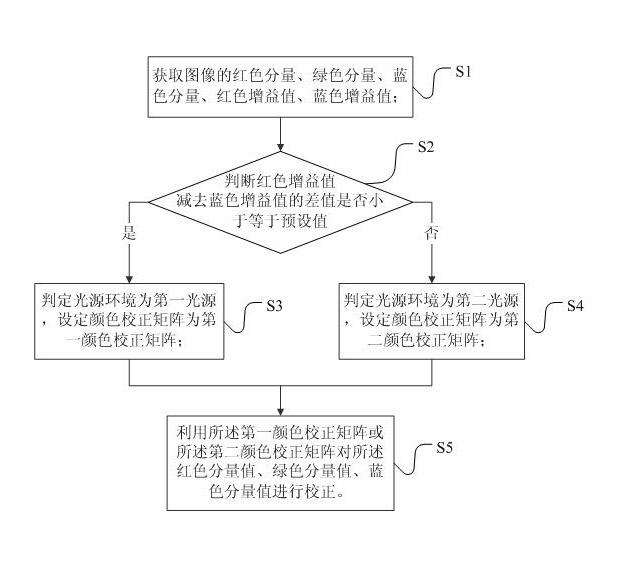

Color correction method

ActiveCN102572206AMeet the requirements of color correctionColor signal processing circuitsColor correctionComputer science

The invention discloses a color correction method, which comprises the following steps of: S1, obtaining the red component value, the green component value, the blue component value, the red gain value and the blue gain value of an image under a certain light source environment; S2, judging whether the red gain value and the blue gain value satisfy the condition that the red gain value is less than or equal to a first preset value and the blue gain value is more than or equal to a second preset value; if not, skipping to S4; S3, judging the light source environment as a first light source, setting a color correction matrix as a first color correction matrix, and skipping to S5; S4, judging the light source environment as a second light source, and setting the color correction matrix as a second color correction matrix; and S5, correcting the red component value, the green component value and the blue component value by the first color correction matrix or the second color correction matrix. With the color correction method, an image is corrected by setting different color correction matrixes according to different light source types so as to solve the technical problem that the traditional color correction method adopts the correction matrix with the single color.

Owner:BYD SEMICON CO LTD

Liquid crystal display

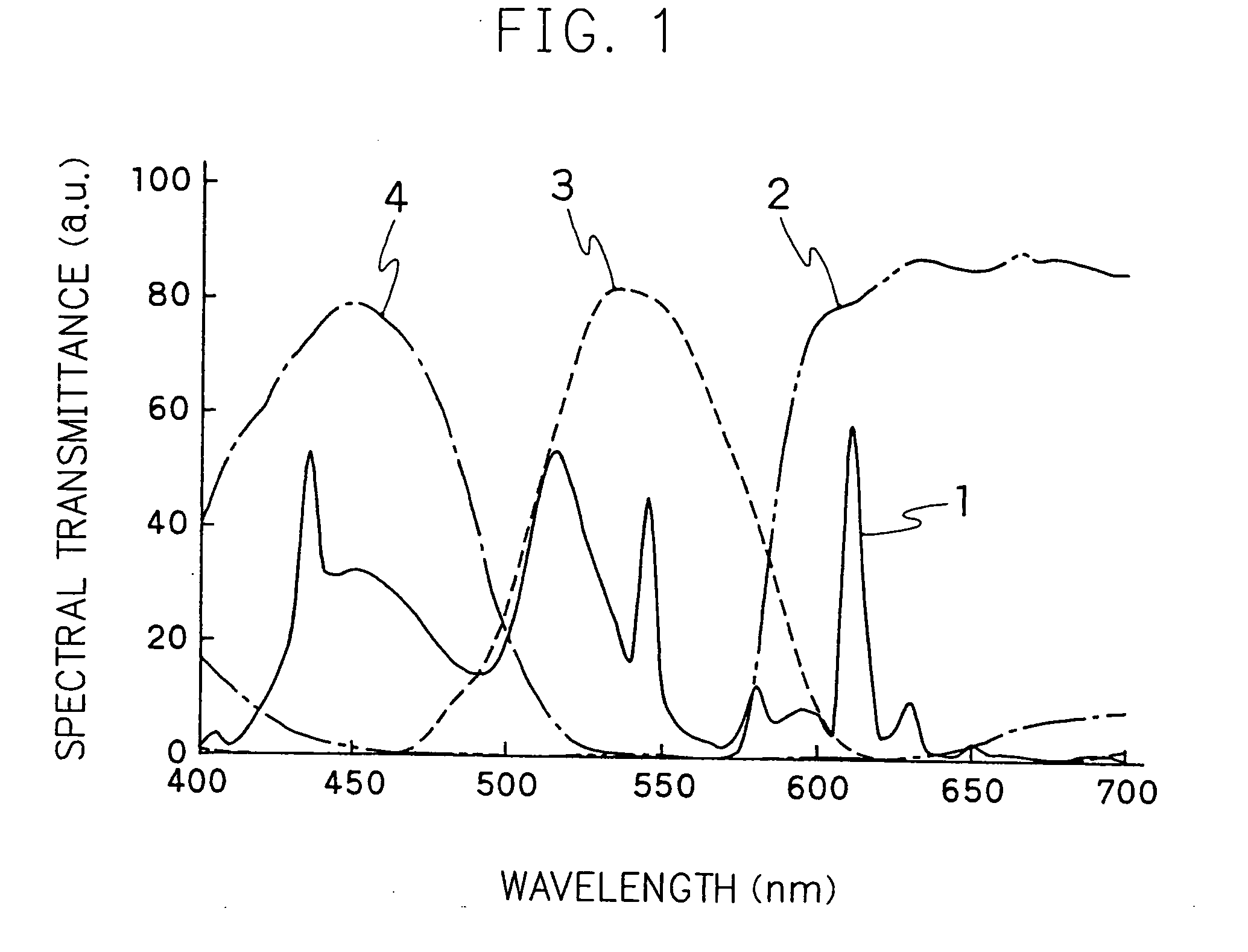

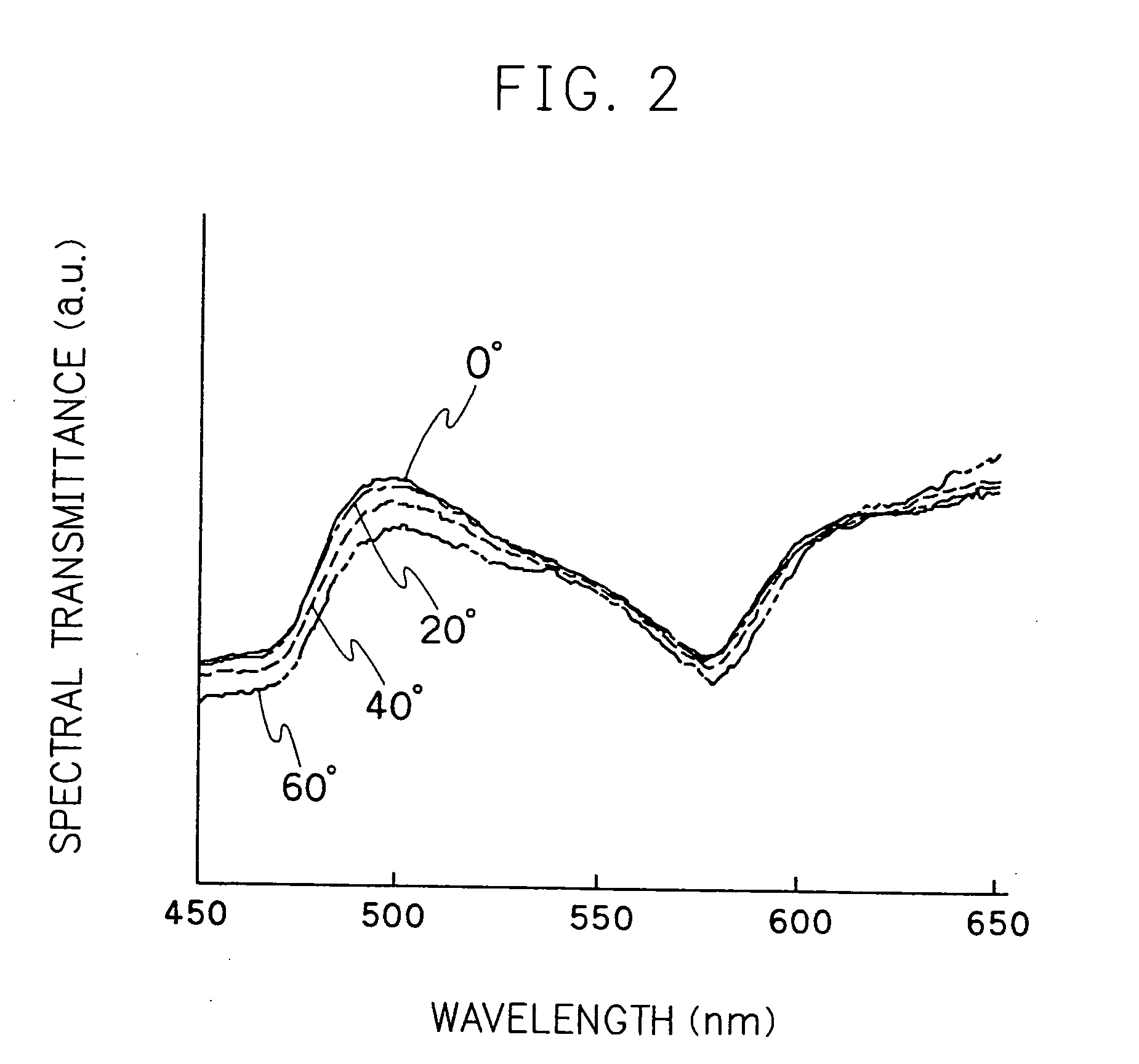

A primary object of the present invention is to provide a liquid crystal display device being capable of displaying an image with large color reappearance area and a genuine hue and chroma, while controlling a displacement of white chromaticity caused by changes of viewing angles. The device includes: a light source; a back light controlling a luminous intensity distribution from the light source; and a liquid crystal display panel controlling a transmission rate of light from the back light. The maximum intensity of a light emitting spectrum of the back light is in a range of 510 nm to 530 nm in a wavelength range of 500 nm to 550 nm, wherein the liquid crystal panel includes a red color filter transmitting red components, a green color filter transmitting green components and a blue color filter transmitting blue components, and a transmit spectrum of the green color filter includes a half value of a maximum transmitting rate of 500 nm to 590 nm in a wavelength range. The change of the transmit spectrum between viewing angle of 0° and 60° is within 20% from front direction in a wavelength range of 500 nm to 600 nm.

Owner:MITSUBISHI ELECTRIC CORP

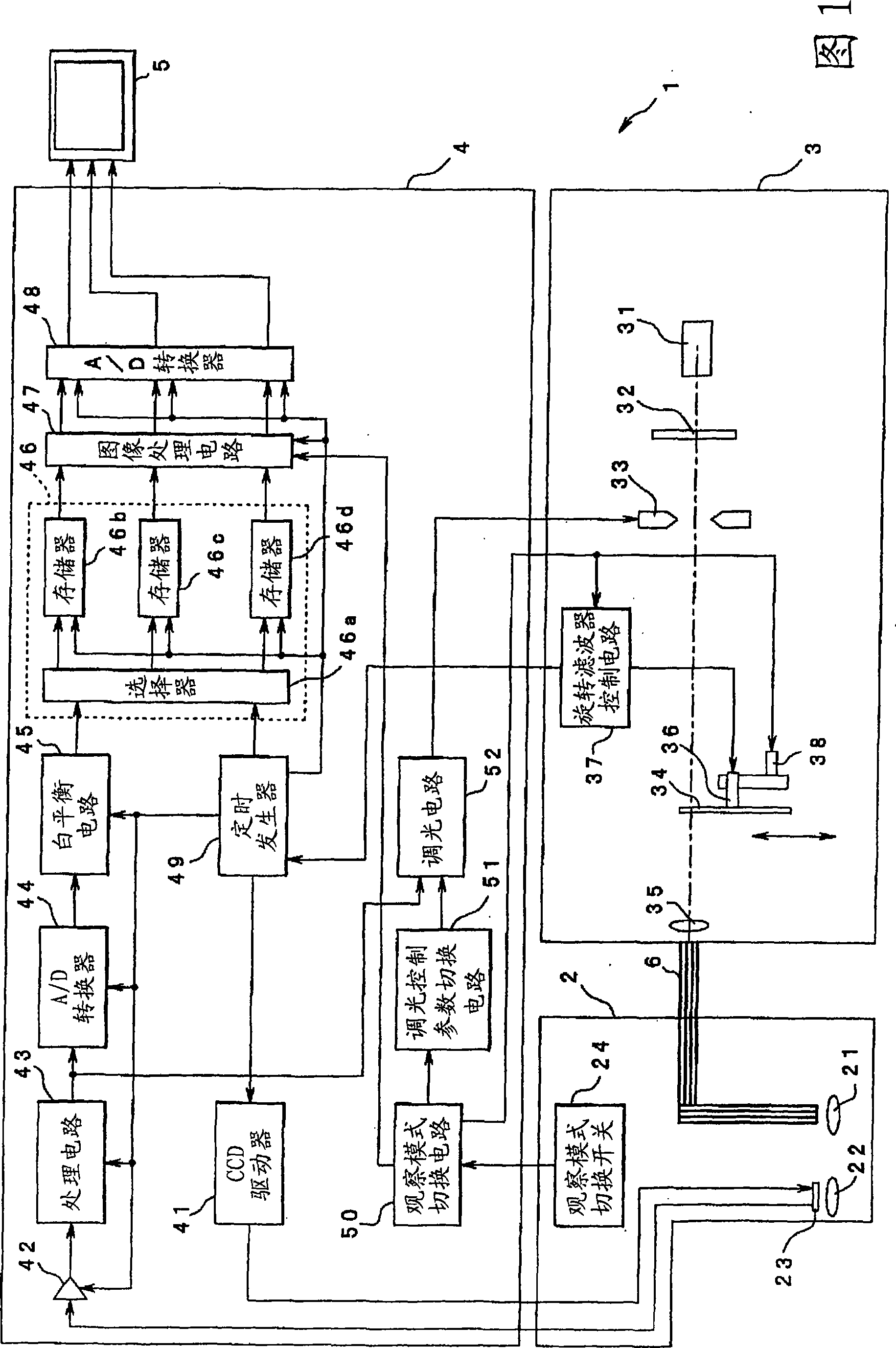

Endoscope device

An endoscope device is comprised of an illuminating means for projecting first narrow band light with a wavelength band of a blue region and second narrow band light with a wavelength band of a green region to an object in a living body, a photographing means for photographing a first object image in the case that the object is illuminated by the first narrow band light and a second object image in the case that the object is illuminated by the second narrow band light, a memory means for storing the first object image as green and blue components and the second object image as red and blue components, a hue converting means for carrying out prescribed color conversion processing for the red, green and blue components so as to make an image of a prescribed object an image of a prescribed first color other than red.

Owner:OLYMPUS CORP

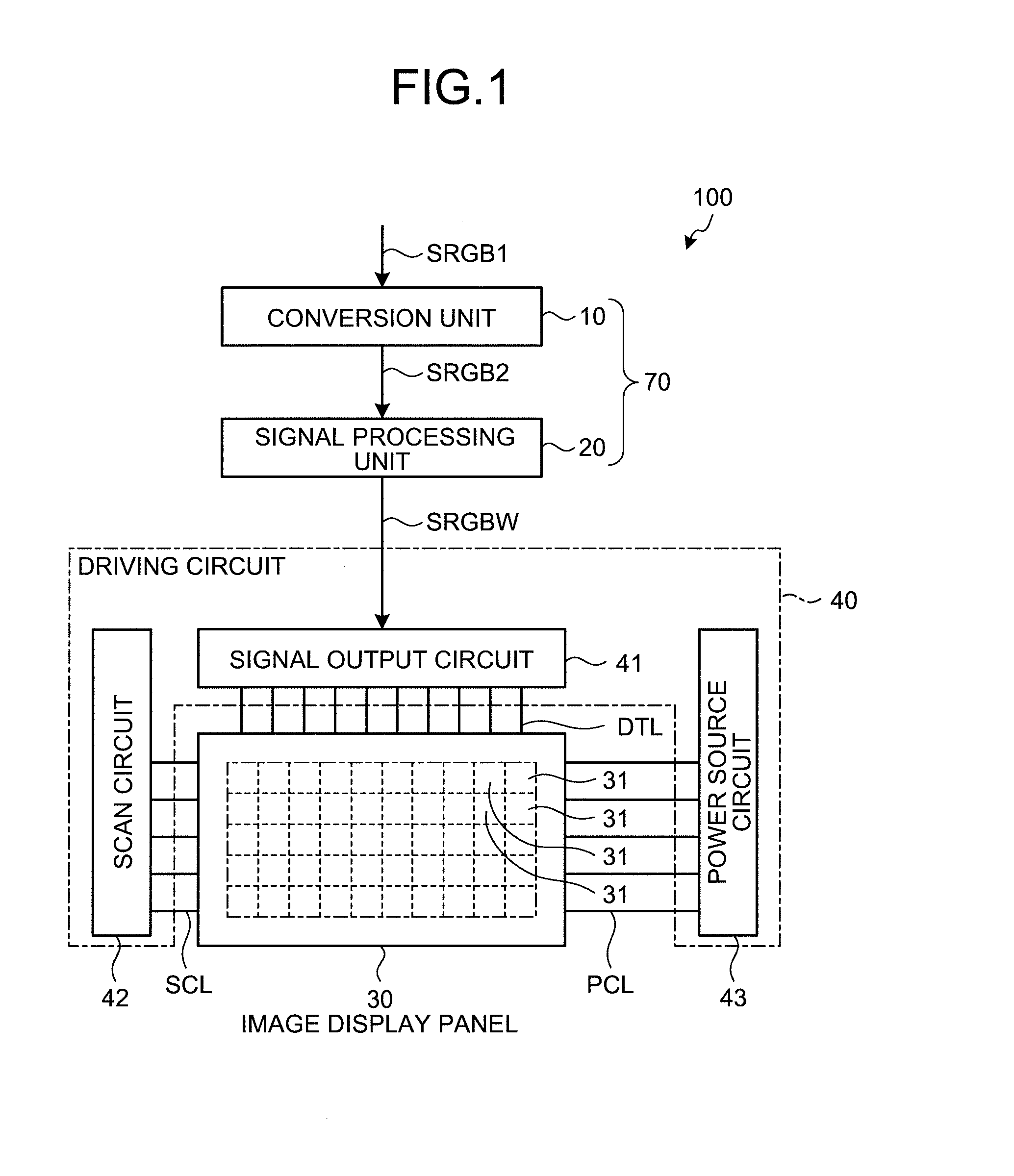

Image processing device, display device, electronic device and method for processing an image

ActiveUS20150109356A1Reduce power consumptionDecrease in luminanceCathode-ray tube indicatorsInput/output processes for data processingImaging processingAttenuation ratio

An image processing device comprising: a conversion unit to receive a first input signal including first color information, a first color being reproduced at pixels on the basis of the first color information, the first input signal including first color information obtained from an input image signal corresponding to a red component, a green component and a blue component, to specify saturation of the first color, and configured to obtain luminance attenuation ratio on the basis of a relationship previously stored between saturation and luminance attenuation ratio, and the saturation of the first color, and to output a second input signal including second color information whose luminance is decreased from the first color information on the basis of the luminance attenuation ratio corresponding to the first color information; and a signal processing unit configured to output an output signal for driving the pixels on the basis of the second input signal.

Owner:JAPAN DISPLAY INC

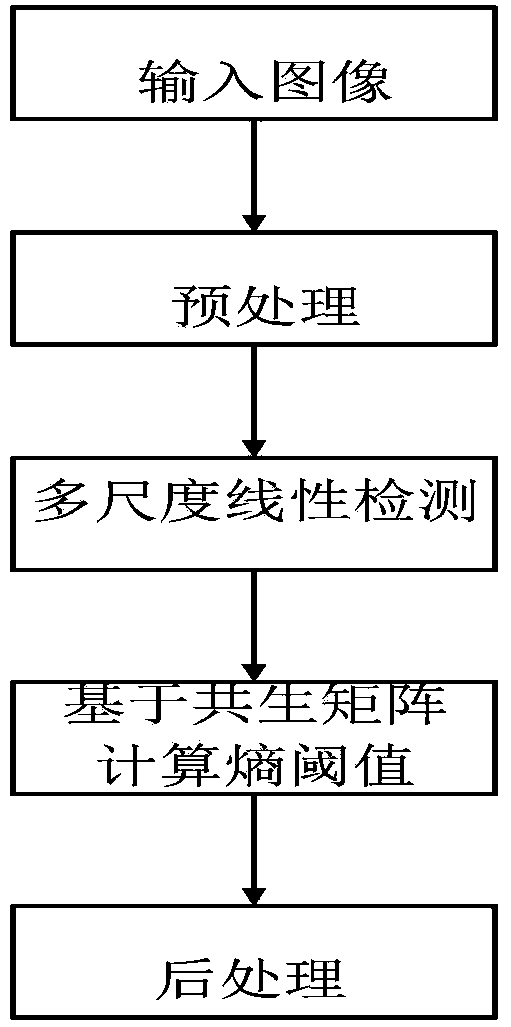

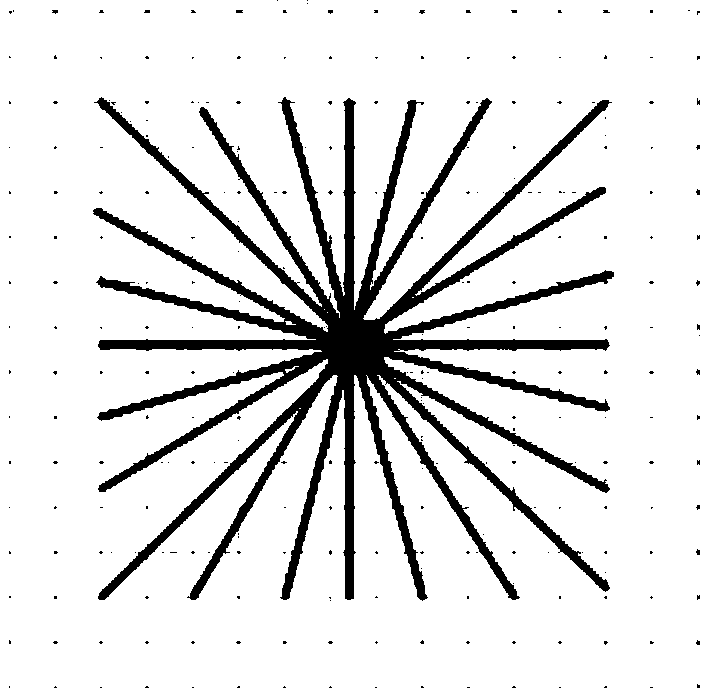

Novel retina eye fundus image segmenting method

The invention provides a novel retina eye fundus image segmenting method. The method is characterized in that the best entropy threshold value is calculated by combining multi-scale linear detection and using the gray-level-gradient co-occurrence matrix of an image. Firstly, green components, containing rich blood vessel outline information, in the retina eye fundus image are extracted, and shadow correcting, noise reducing, CLAHE and other preprocessing are performed on the green components; secondly, multi-scale and multi-direction linear detection is performed on blood vessels of the retina eye fundus image according to morphological structure characteristics of the blood vessels, and image responses of different scales are fused to obtain the characteristics of the blood vessels; finally the best entropy threshold value of the image is calculated on the basis of the gray-level-gradient co-occurrence matrix of the image, and segmentation is performed. The method is high in segmenting accuracy, capable of extracting more fine blood vessels, high in calculating speed, very good in robustness and suitable for segmentation of the normal or lesion retina eye fundus image.

Owner:CHONGQING UNIV

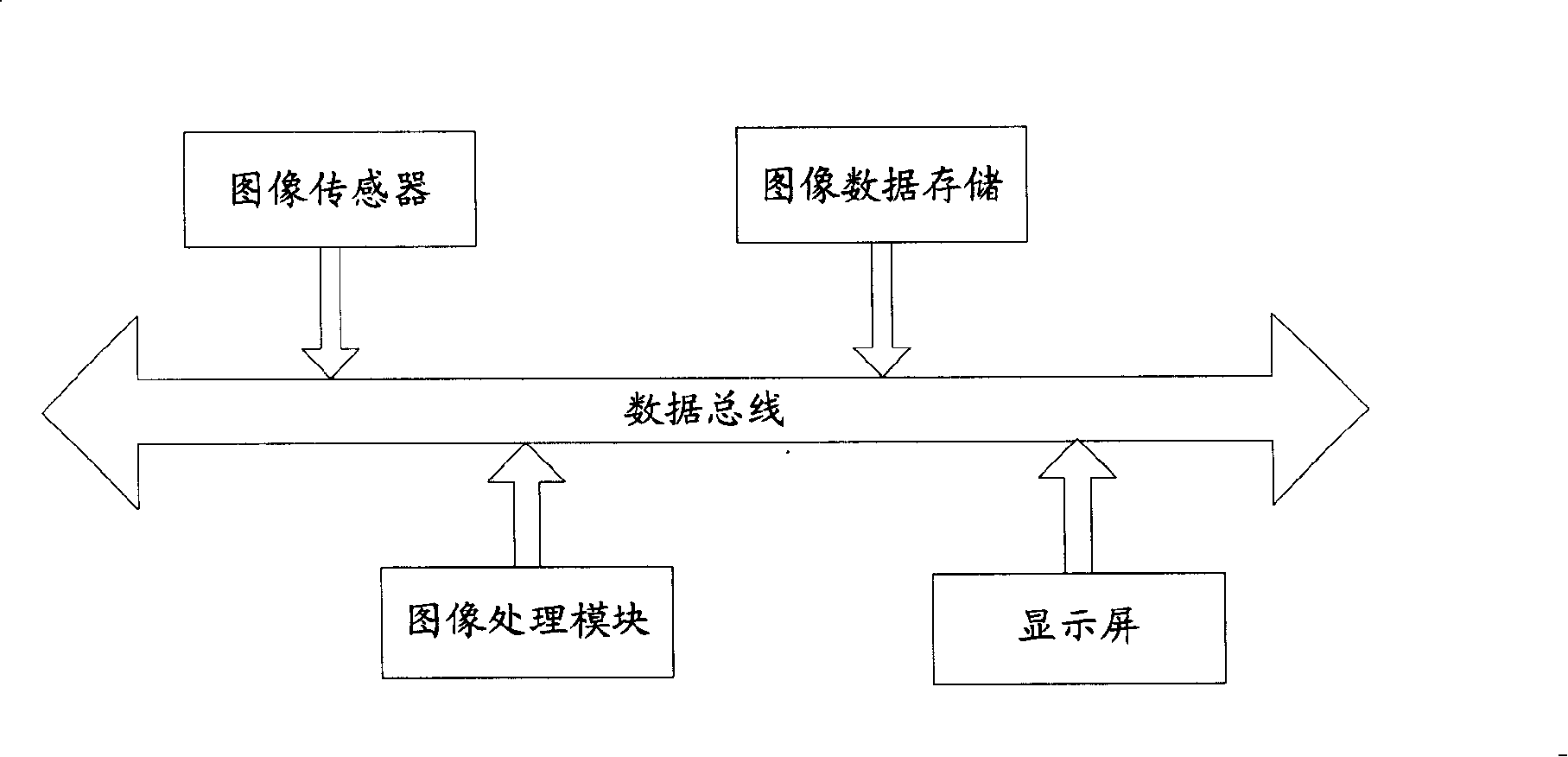

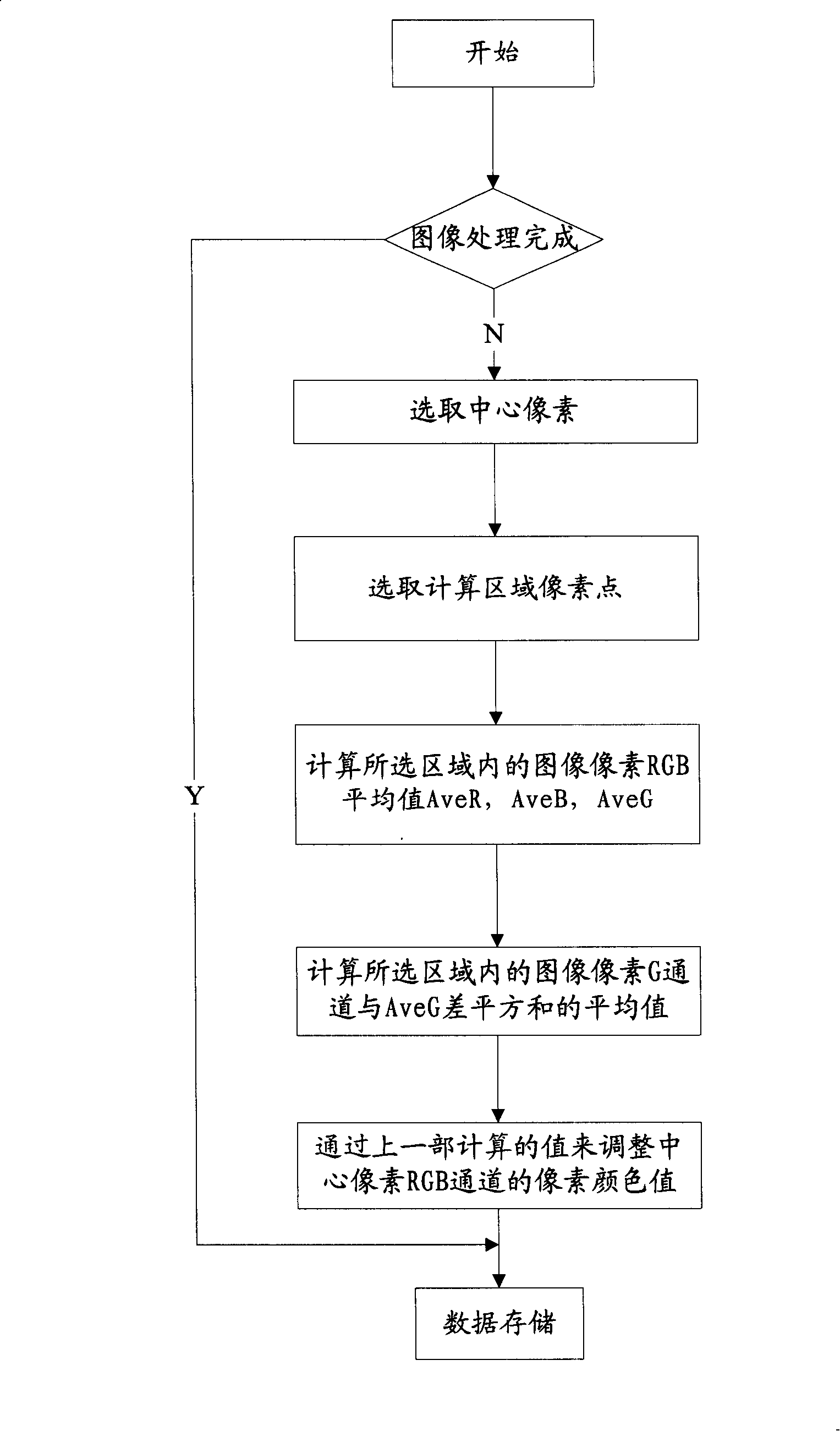

Noise estimation based partial image filtering method

ActiveCN101212563AQuality assuranceEffective estimateTelevision system detailsColor signal processing circuitsPattern recognitionMean square

The invention discloses a method for filtering a partial image based on a noise estimation, which comprises the following the steps: (1) selecting a pixel as a central pixel in the image; (2) selecting a pixel area with a size of M*N in the center of the selected central pixel; (3) obtaining averages R, G, B of a red component (R), a green component (G) and a blue component (B) of all pixel in the selected area; (4) obtaining a sum of squares between the G and the different of G component of all pixel in the selected area, and obtaining a corresponding mean square deviation SE; (5) according to the R, G, B, and the mean square deviation SE, adjusting a corresponding pixel color value and obtaining the filtered corresponding color component; (6) carrying out an iterative processing to the whole image according to the method and then obtaining a filtered image as well as storing the image data. The invention can effectively estimate a noise signal in the image and maintains a sharpening effect in the image edge details and has an effective application in a real-time system.

Owner:ANYKA (GUANGZHOU) MICROELECTRONICS TECH CO LTD

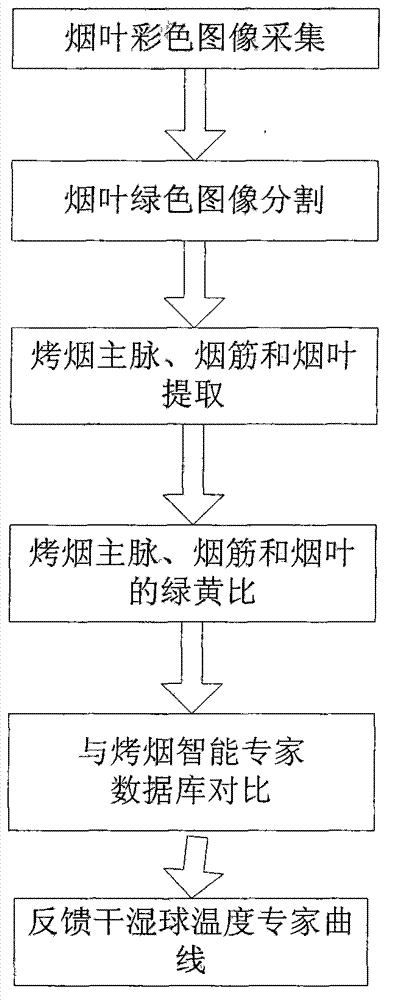

Densification tobacco flue-cure dry-wet bulb temperature automatic control technique based on tobacco image processing

The invention provides a densification tobacco flue-cure dry-wet bulb temperature automatic control technique based on tobacco image processing. The technique includes: building an intelligent expert database of the green-yellow ratio of the tobacco, the tobacco stem and the main vein parts of tobacco flue-cure and the dry-wet bulb temperature curve; using a color video camera to collect the color images of tobacco in a standard flue-cure room in real time; performing binarization on the green component images of the color tobacco images, extracting the tobacco, the tobacco stem and the main vein parts and the like, and calculating the green-yellow ratio of corresponding parts; performing Bayesian crosscheck on the green-yellow ratio of the tobacco, the tobacco stem and the main vein parts and the like and the corresponding features in the intelligent expert database, and estimating current tobacco flue-cure state in real time; feeding the current tobacco flue-cure state to a dry-wet bulb temperature automatic control system of the flue-cure room, calling corresponding dry-wet bulb temperature expert curves to automatically control dry-wet bulb temperature. The technique has the advantages that the constantly changed tobacco flue-cure image features during tobacco flue-cure are utilized to monitor densification tobacco flue-cure quality online in real time, tobacco flue-cure dry-wet bulb temperature is controlled automatically, quality of flue-cured tobacco can be increased effectively, and labor cost of tobacco flue-cure workers can be reduced.

Owner:CHONGQING UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com