Black disperse dye composition

A technology of disperse dyes and compositions, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of color change, poor color rendering performance, unsatisfactory color fullness and fastness, etc.

Active Publication Date: 2010-07-07

SHANGYU JINGUAN CHEM IND +2

View PDF11 Cites 45 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among disperse dyes, dark disperse dyes are the most widely used and used in the largest amount, especially blue and black dyes. However, if the above-mentioned varieties are composed of single-color components, they are often not as good in color fullness and fastness. Satisfactory, in this regard, the industry has introduced a variety of black disperse dyes that are compounded and blended. For the famous brand garment fabrics that are strict in all aspects, the dyes are required to have good heat migration resistance and color rendering performance, and the dark disperse dyes currently on the market , due to poor thermal migration resistance, the wet fastness after heat treatment will drop by 1-2 grades, especially the washing fastness and rubbing fastness will drop significantly. Therefore, for fabrics with high dyeing performance requirements, conventional disperse dyes and blindly choosing alternative products often cannot effectively solve the problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

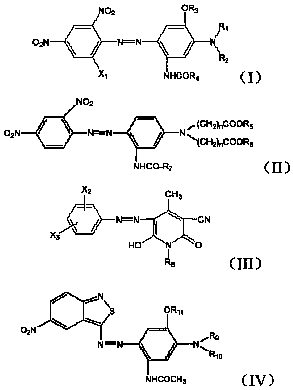

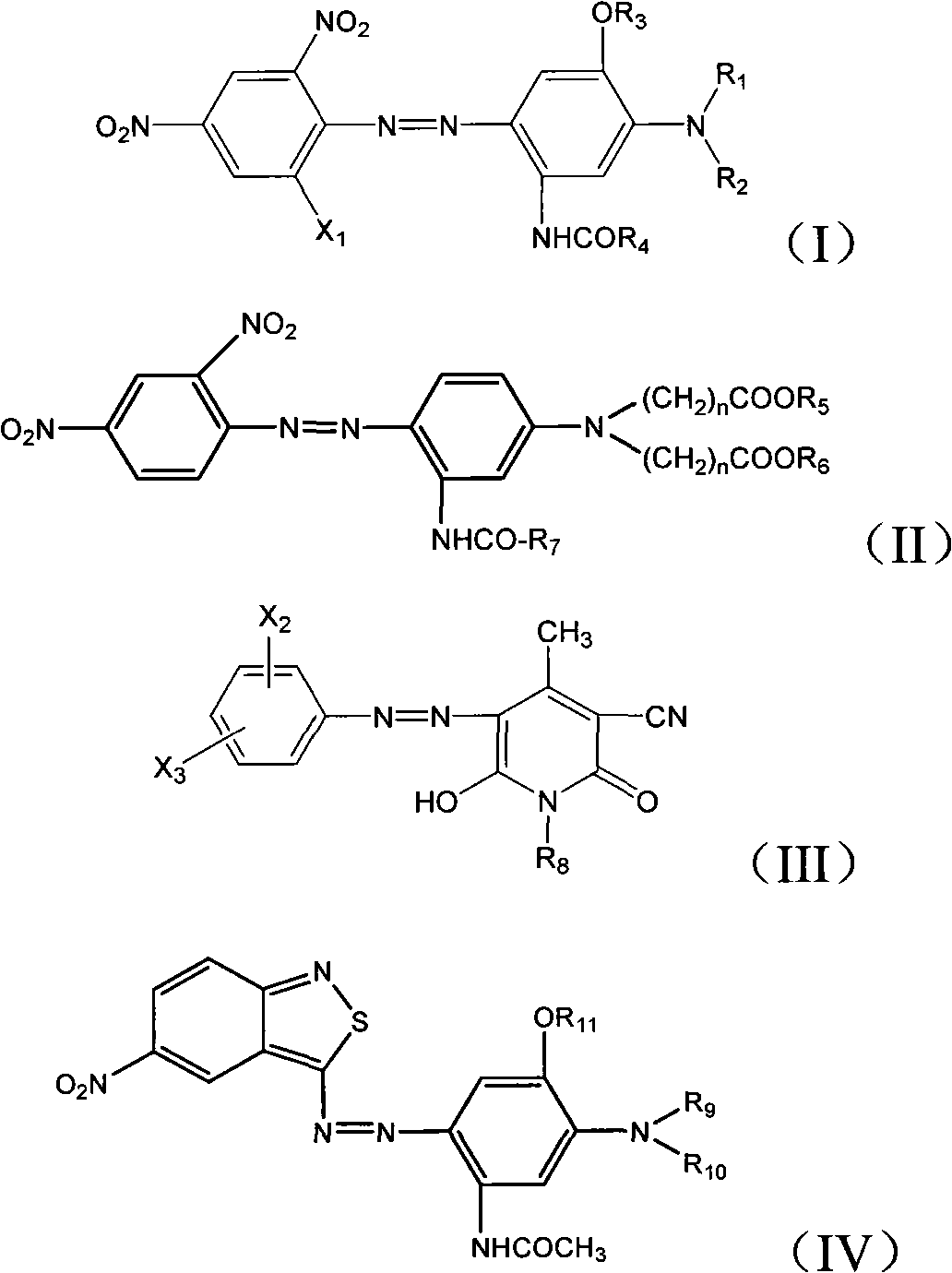

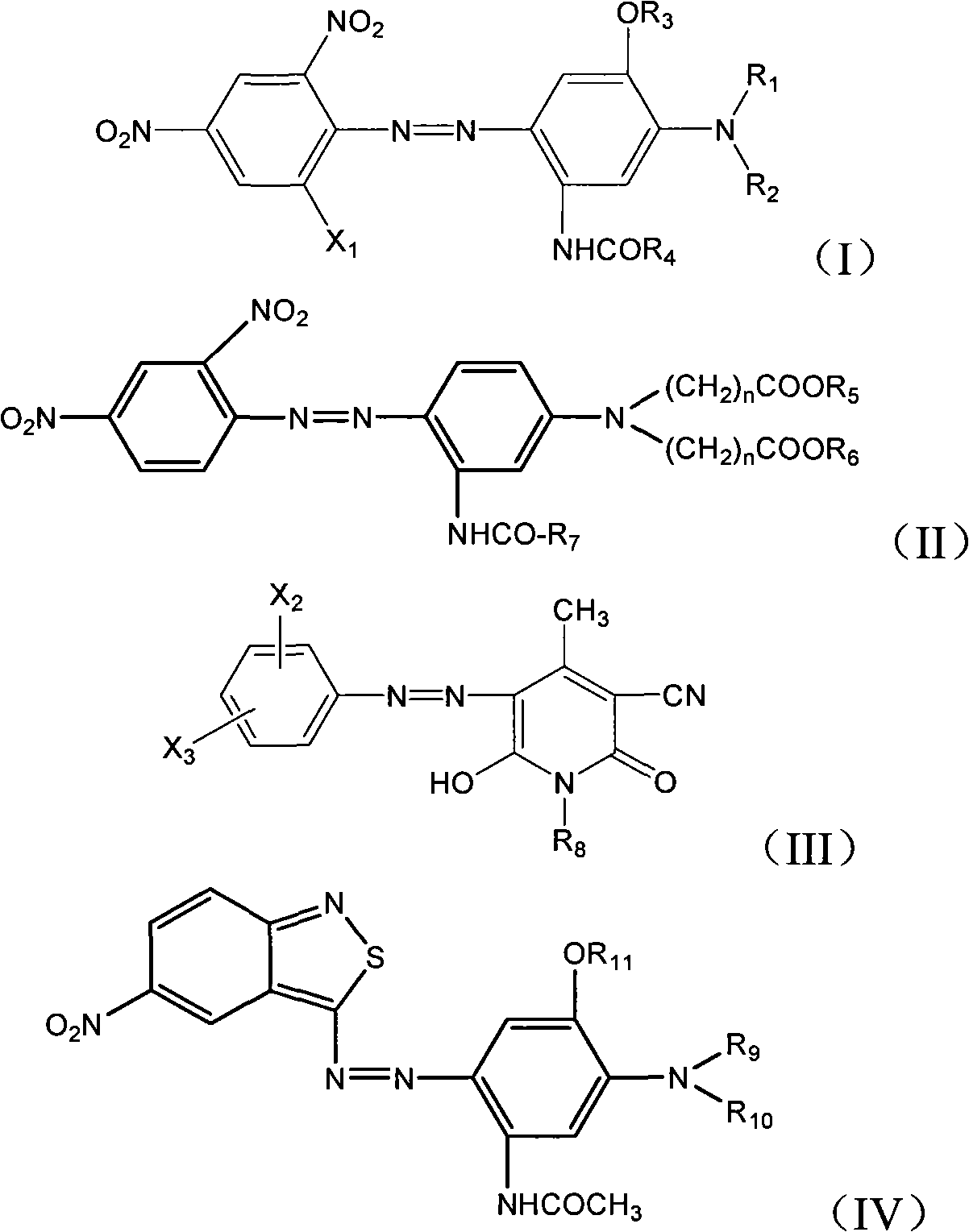

The invention provides a black disperse dye composition, which mainly comprises: one or more blue components A of which the structure is shown as a formula (I), one or more red components B of which the structure is shown as a formula (II), one or more yellow components C of which the structure is shown as a formula (III) and one or more green components D of which the structure is shown as a formula (IV). Based on the components A, components B, components C and components D, the mass fraction of the components A is 35-85%, the mass fraction of the components B is 1-25%, the mass fraction of the components C is 5-45% and the mass fraction of the components D is 1-35%. When the hydrophobic fiber material is dyed by using the dye prepared from the black disperse dye composition, black fabric with excellent color fastness especially excellent washing fastness after heat treatment can be obtained by adjusting the proportion of different components.

Description

(1) Technical field The invention relates to a black disperse dye composition, in particular to a high fastness black disperse dye composition suitable for dyeing and printing hydrophobic fiber materials. (2) Background technology Among disperse dyes, dark disperse dyes are the most widely used and used in the largest amount, especially blue and black dyes. However, if the above-mentioned varieties are composed of single-color components, they are often not as good in color fullness and fastness. Satisfactory, in this regard, the industry has introduced a variety of black disperse dyes that are compounded and blended. For the famous brand garment fabrics that are strict in all aspects, the dyes are required to have good heat migration resistance and color rendering performance, and the dark disperse dyes currently on the market , due to poor thermal migration resistance, the wet fastness after heat treatment will drop by 1-2 grades, especially the washing fastness and rubbin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09B67/22D06P1/18D06P1/19D06P3/54

CPCD06P3/54D06P1/18C09B67/0051

Inventor 欧其高怀庆钟玉霞姜兴中张海斌胡顺勇

Owner SHANGYU JINGUAN CHEM IND

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com