Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

229 results about "Attenuation ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The attenuation-to-crosstalk ratio is calculated to ensure that signal transmissions are stronger at the receiver side than interference caused by crosstalk. Attenuation and crosstalk is minimized for acceptable signal transmissions. Attenuation is based on the type and length of cable being used.

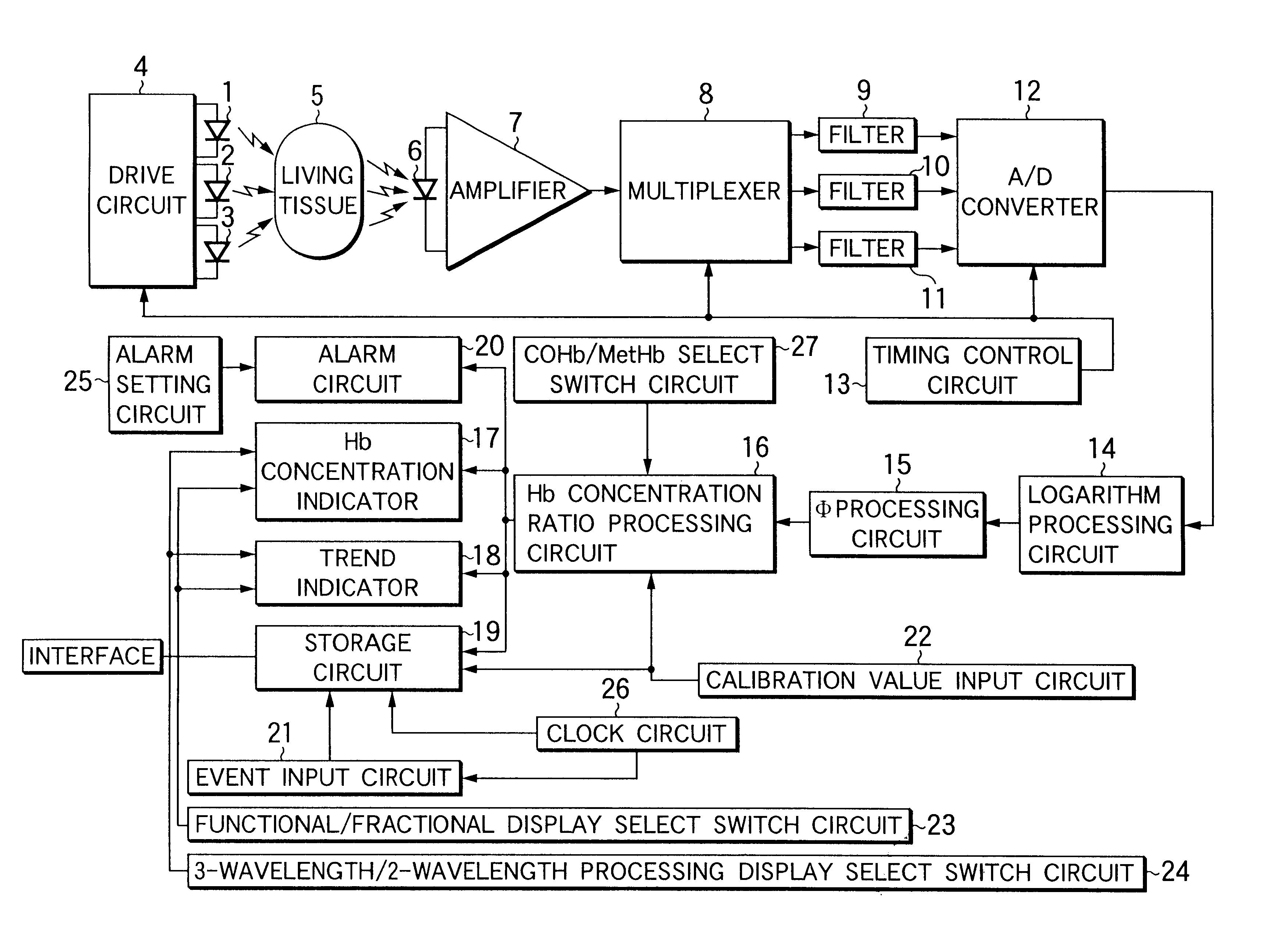

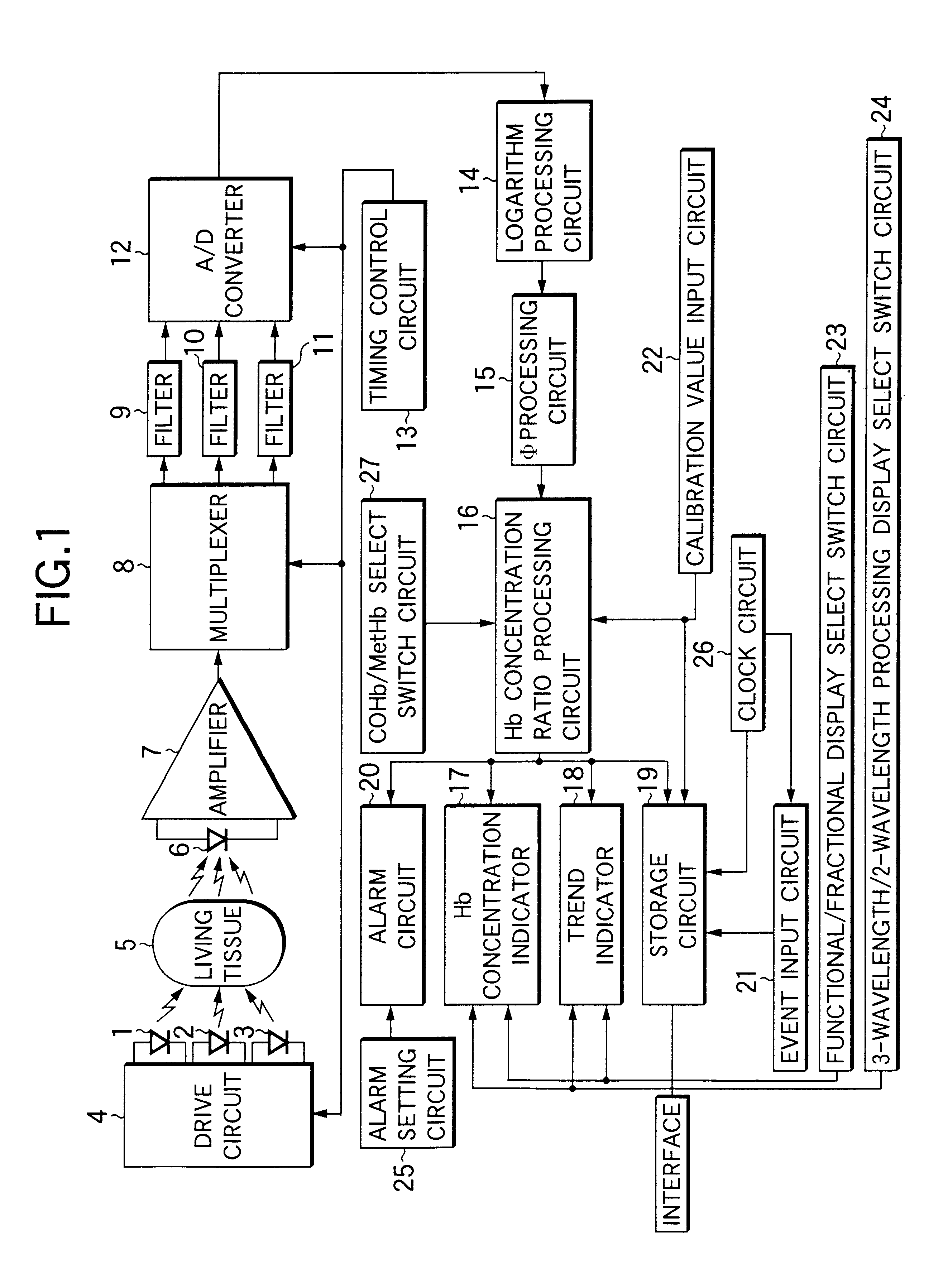

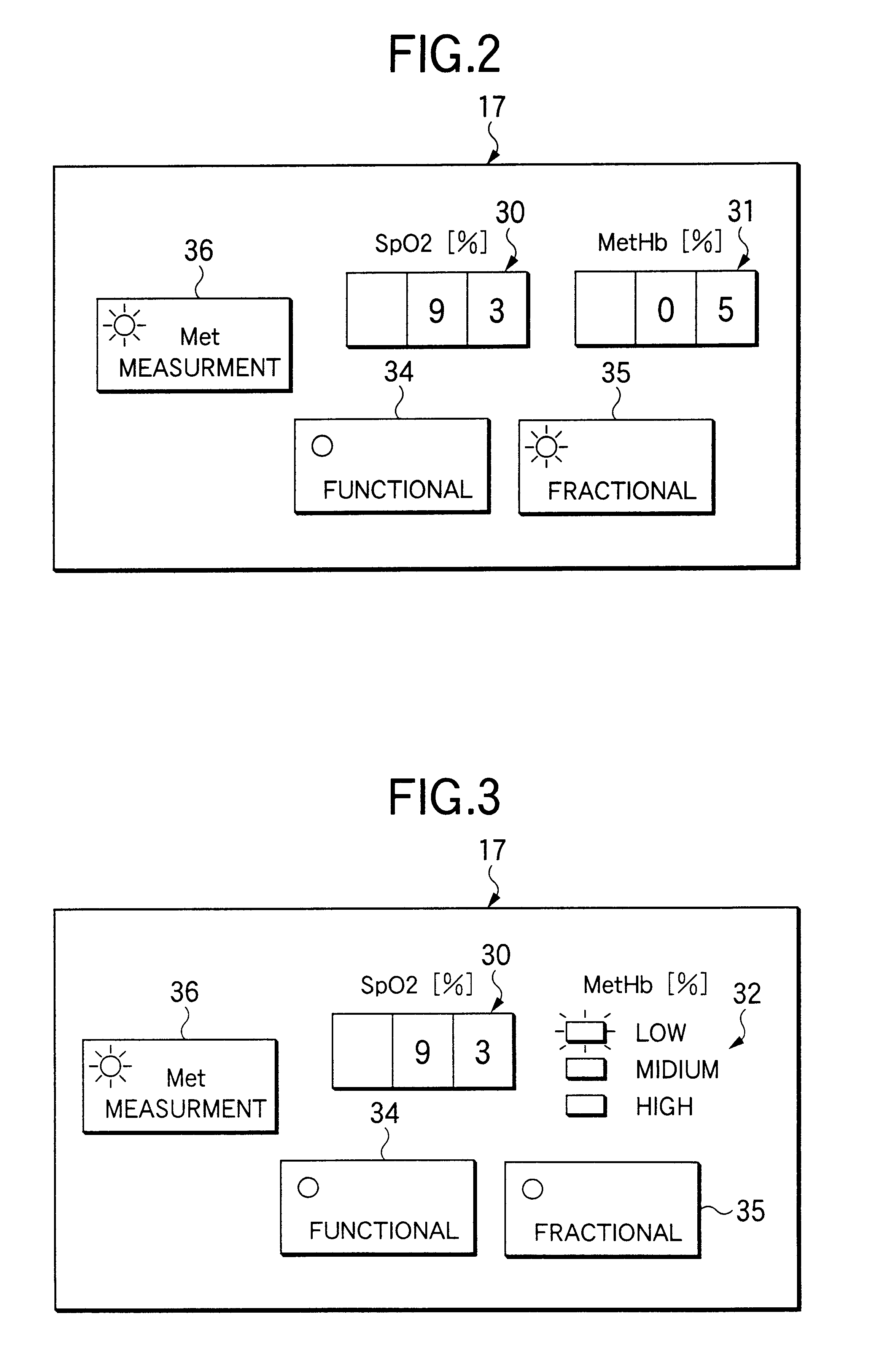

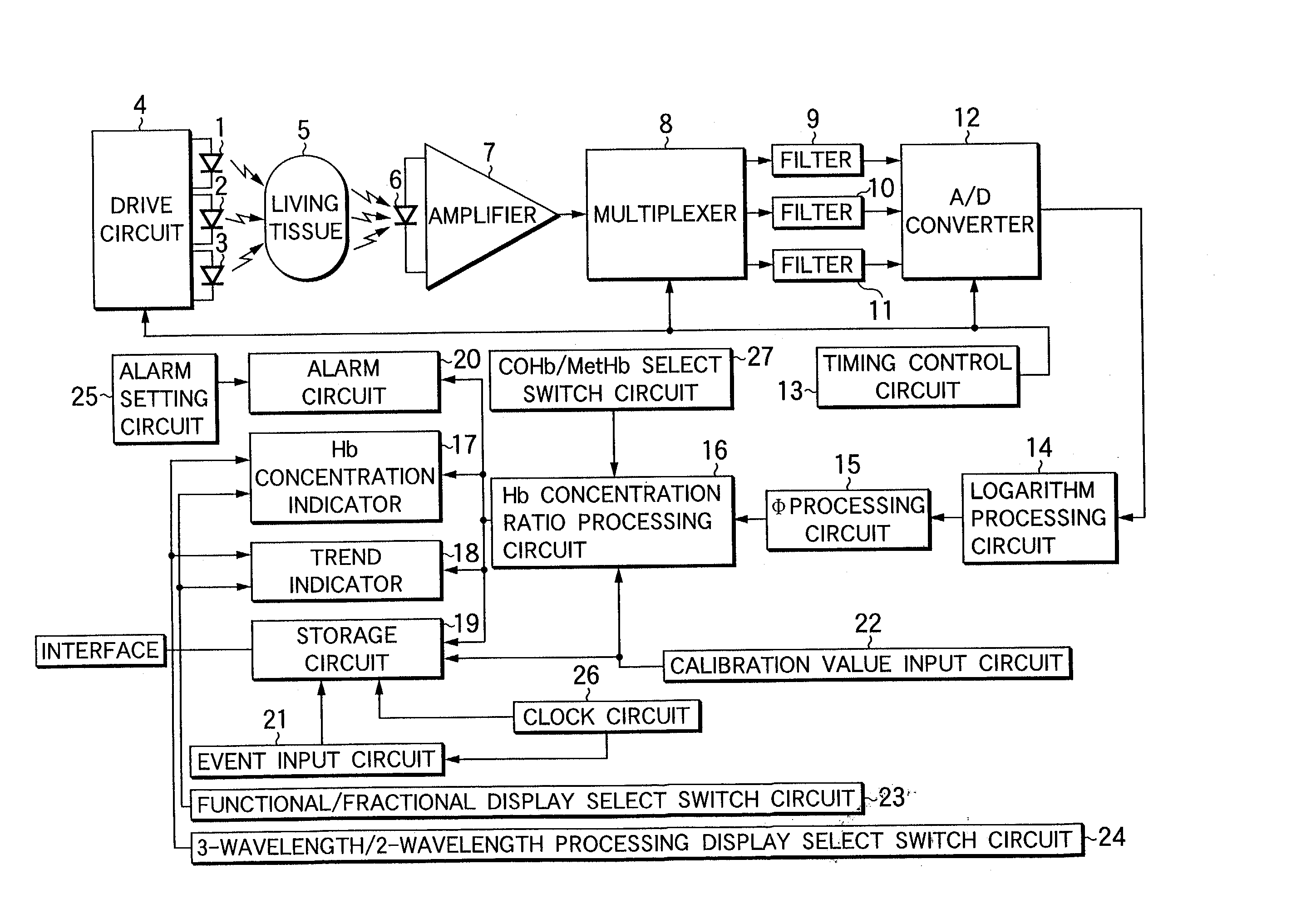

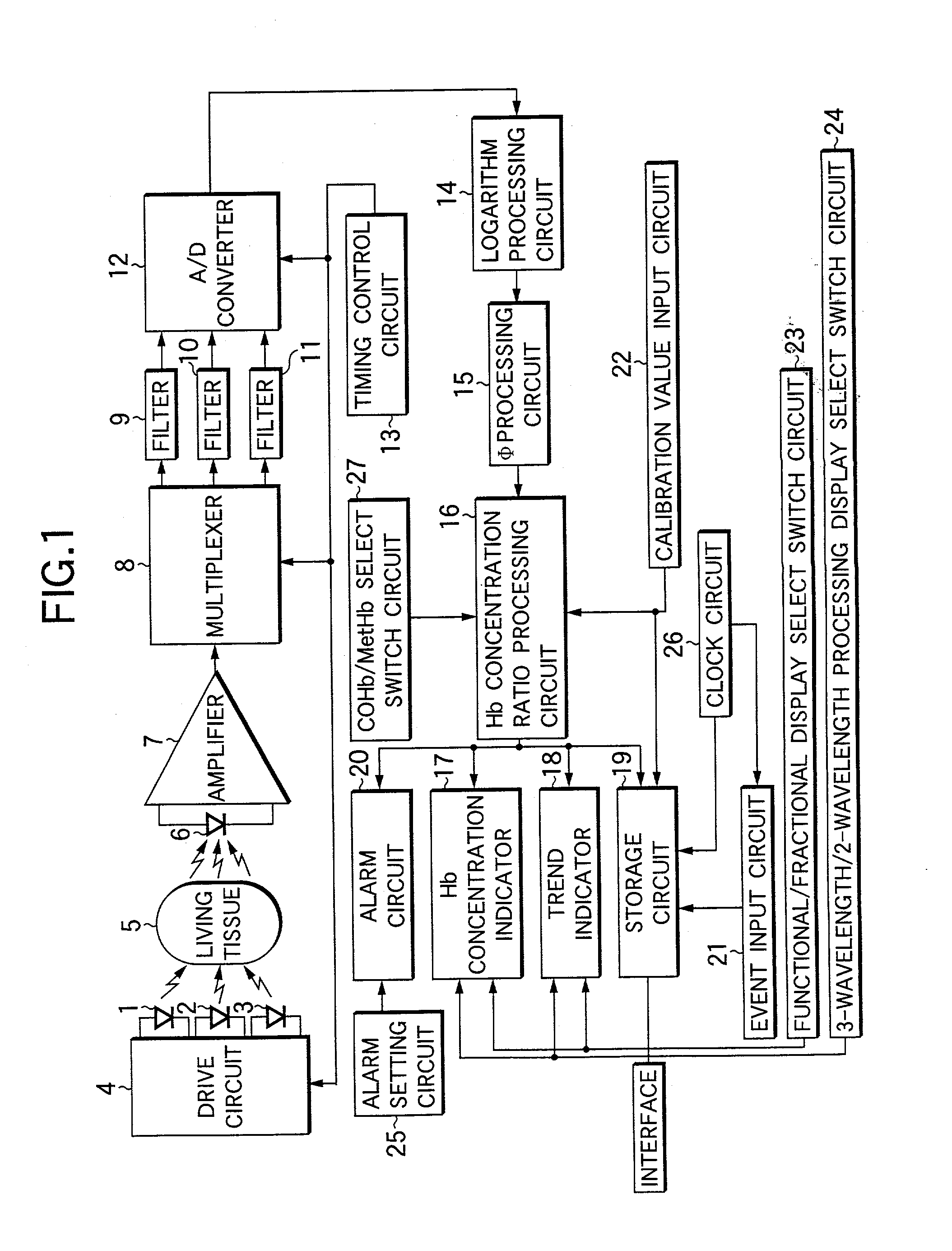

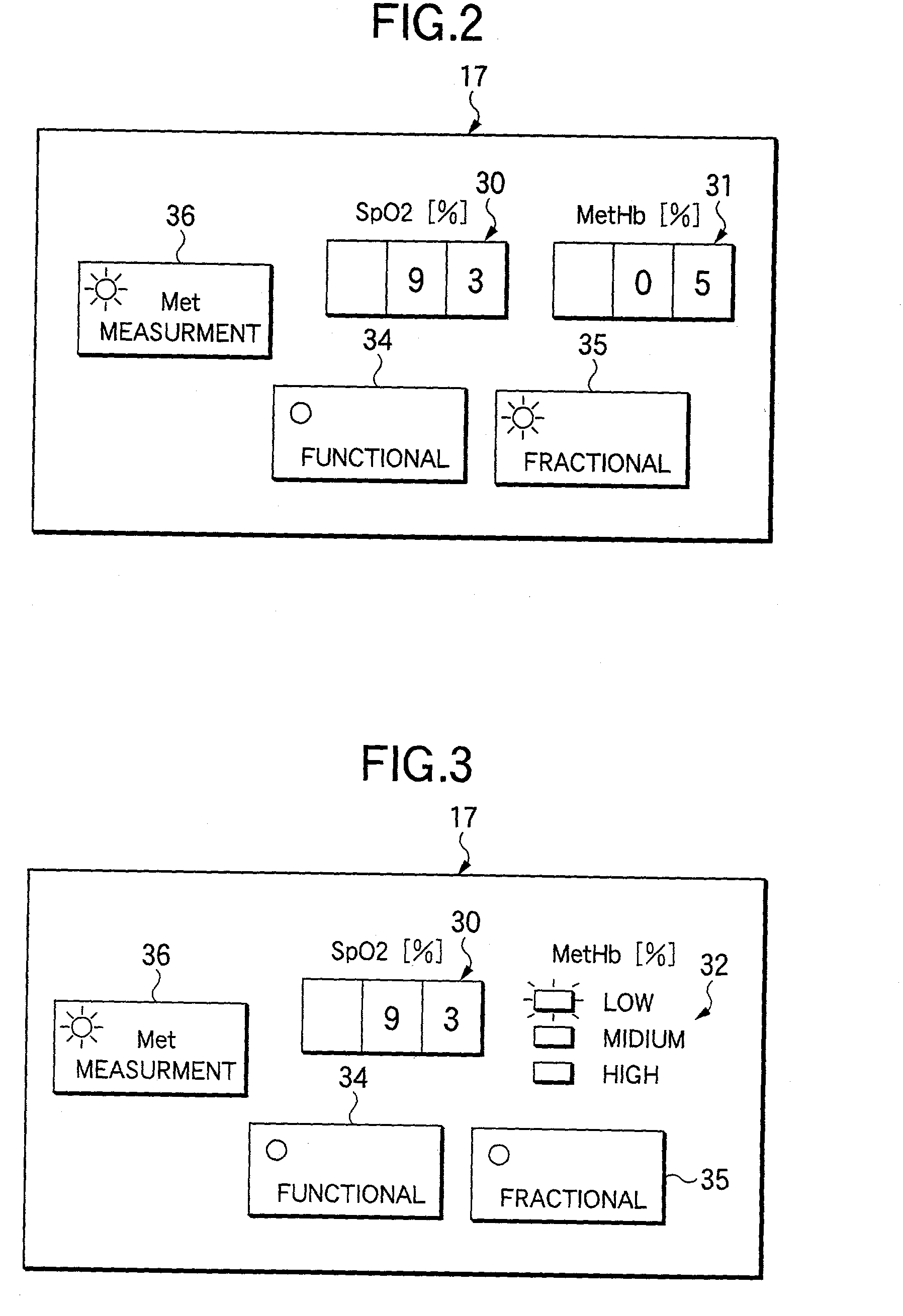

Apparatus for determining concentrations of hemoglobins

InactiveUS6622095B2Easily discriminatedAccurate measurementDiagnostic recording/measuringSensorsUltrasound attenuationConcentration ratio

An apparatus for determining concentrations of hemoglobins includes a light source for emitting lights of at least three different wavelengths, a first wavelength in a near-infrared region, a second wavelength in a red region, and a third wavelength in a red orange region, light receiving device for receiving light emitted by the light source, transmitted through a living tissue or reflected by the living tissue, attenuation ratio processing device for processing attenuation ratios between the wavelengths in accordance with variations of received-light output signals in each of the wavelengths output from the light receiving device, the variations are caused by a pulsation of blood and concentration ratio processing device for processing concentration ratios of at least oxyhemoglobin and methemoglobin based on the output signals from the attenuation ratio processing device.

Owner:NIHON KOHDEN CORP

Apparatus for determining concentrations of hemoglobins

InactiveUS20020111748A1Easily discriminatedImprove signal-to-noise ratioDiagnostic recording/measuringSensorsUltrasound attenuationConcentration ratio

An apparatus for determining concentrations of hemoglobins includes a light source for emitting lights of at least three different wavelengths, a first wavelength in a near-infrared region, a second wavelength in a red region, and a third wavelength in a red orange region, light receiving device for receiving light emitted by the light source, transmitted through a living tissue or reflected by the living tissue, attenuation ratio processing device for processing attenuation ratios between the wavelengths in accordance with variations of received-light output signals in each of the wavelengths output from the light receiving device, the variations are caused by a pulsation of blood and concentration ratio processing device for processing concentration ratios of at least oxyhemoglobin and methemoglobin based on the output signals from the attenuation ratio processing device.

Owner:NIHON KOHDEN CORP

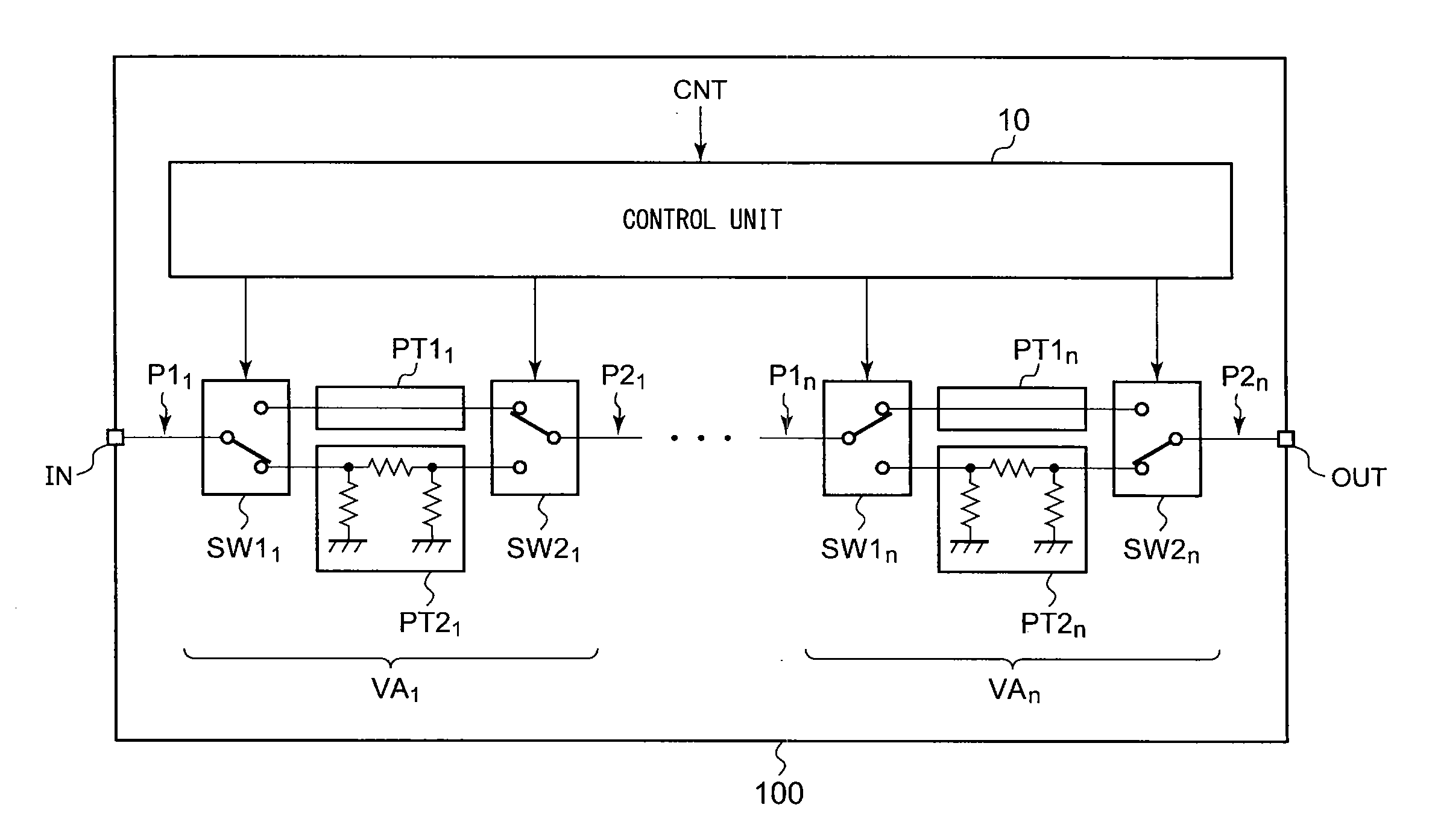

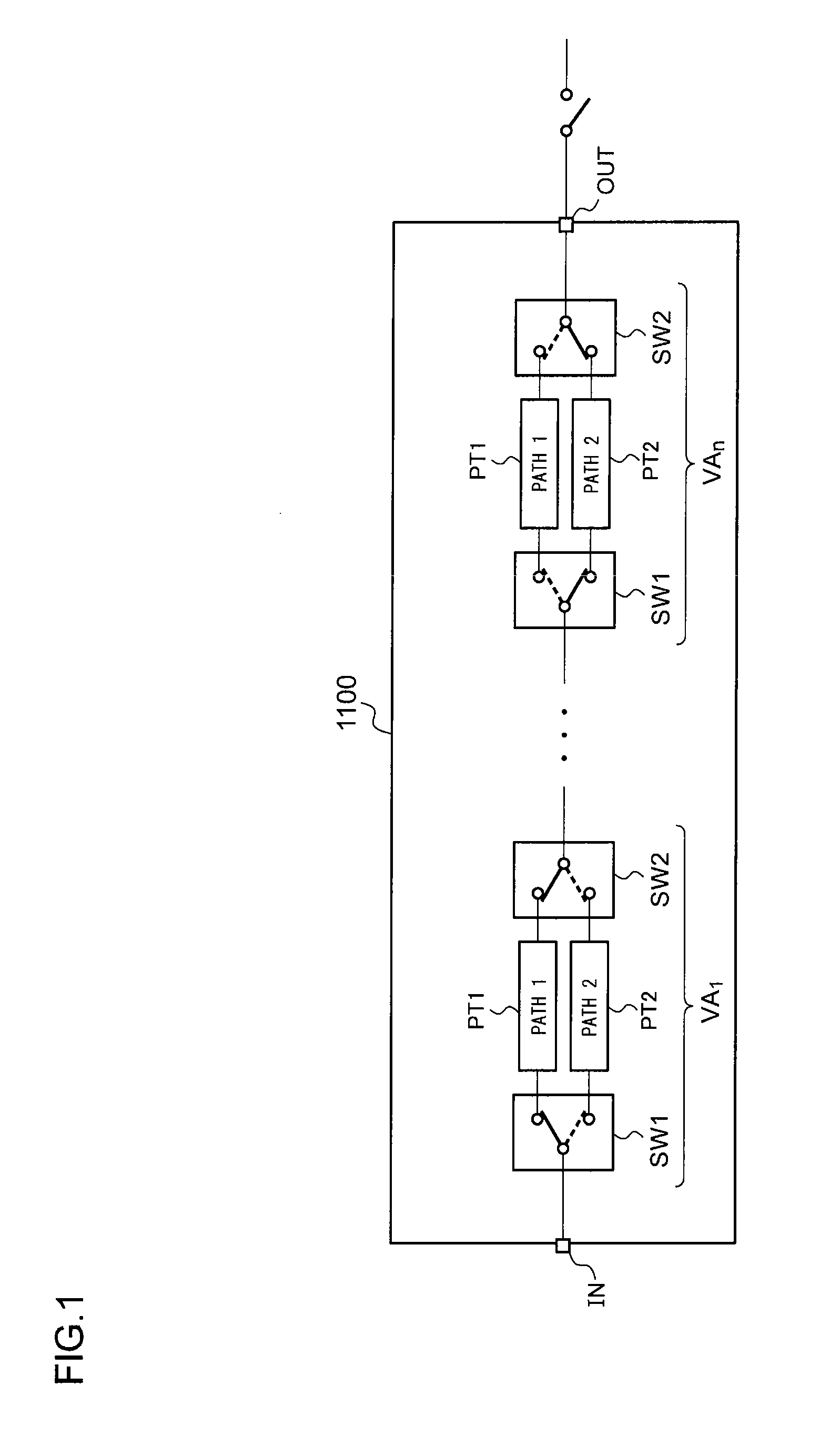

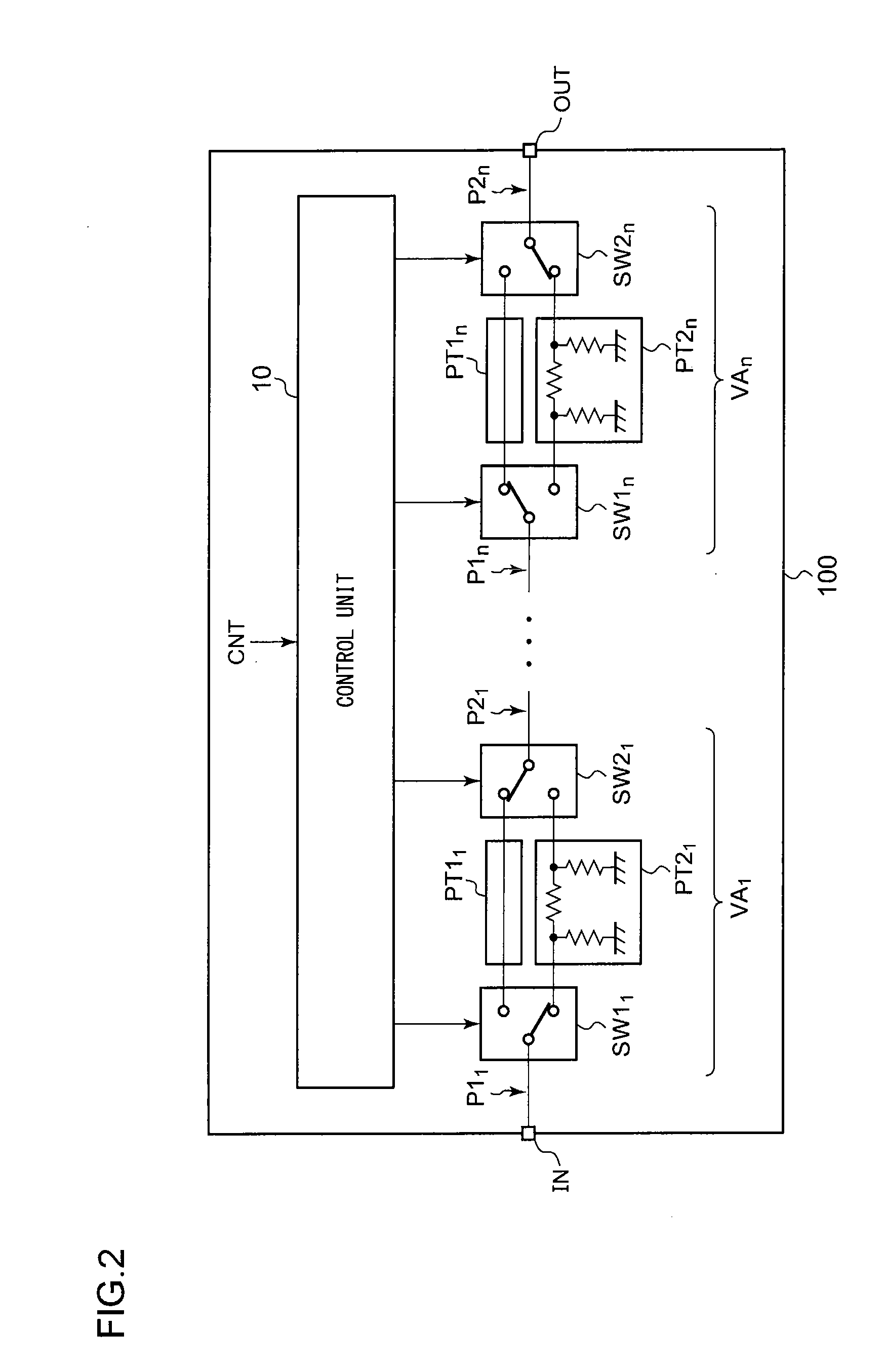

Step attenuator apparatus

InactiveUS20110316645A1Reduce signal reflectionImprove isolationCoupling devicesUltrasound attenuationControl signal

A step attenuator apparatus is provided, having an attenuation ratio which is switchable according to a control signal. Multiple variable attenuators are connected in series. Each variable attenuator includes a first terminal, a second terminal, multiple paths having different attenuation ratios, a first switch that can be connected to one end of a desired path selected from among the multiple paths, and a second switch that can be connected to the other end of a desired path selected from among the multiple paths. When a control signal is an instruction to set the step attenuator apparatus to a disconnected state, a control unit connects the first switch of the first-stage variable attenuator to one of the multiple paths, and connects the second switch of the first-stage variable attenuator to a different one of the multiple paths.

Owner:ADVANTEST CORP

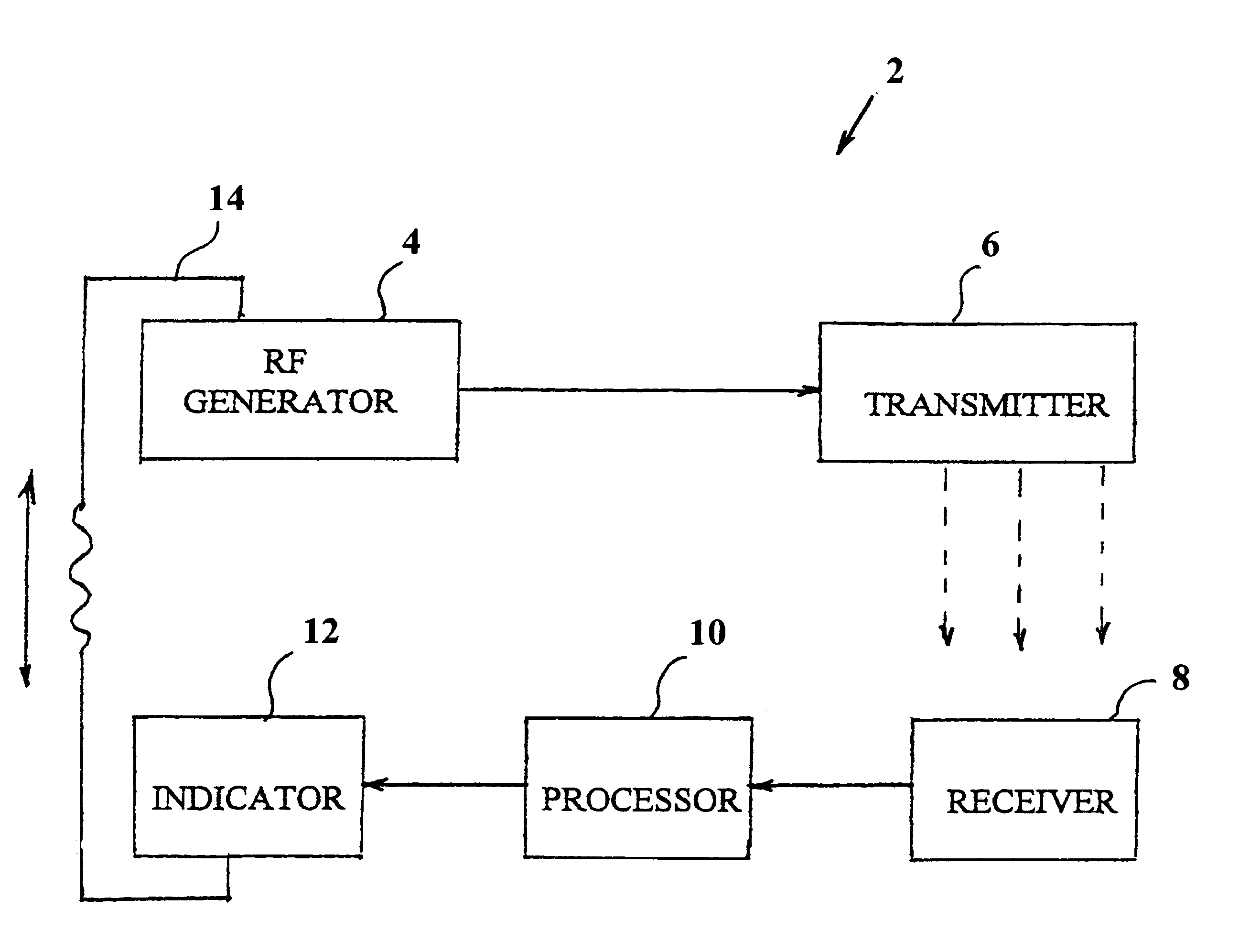

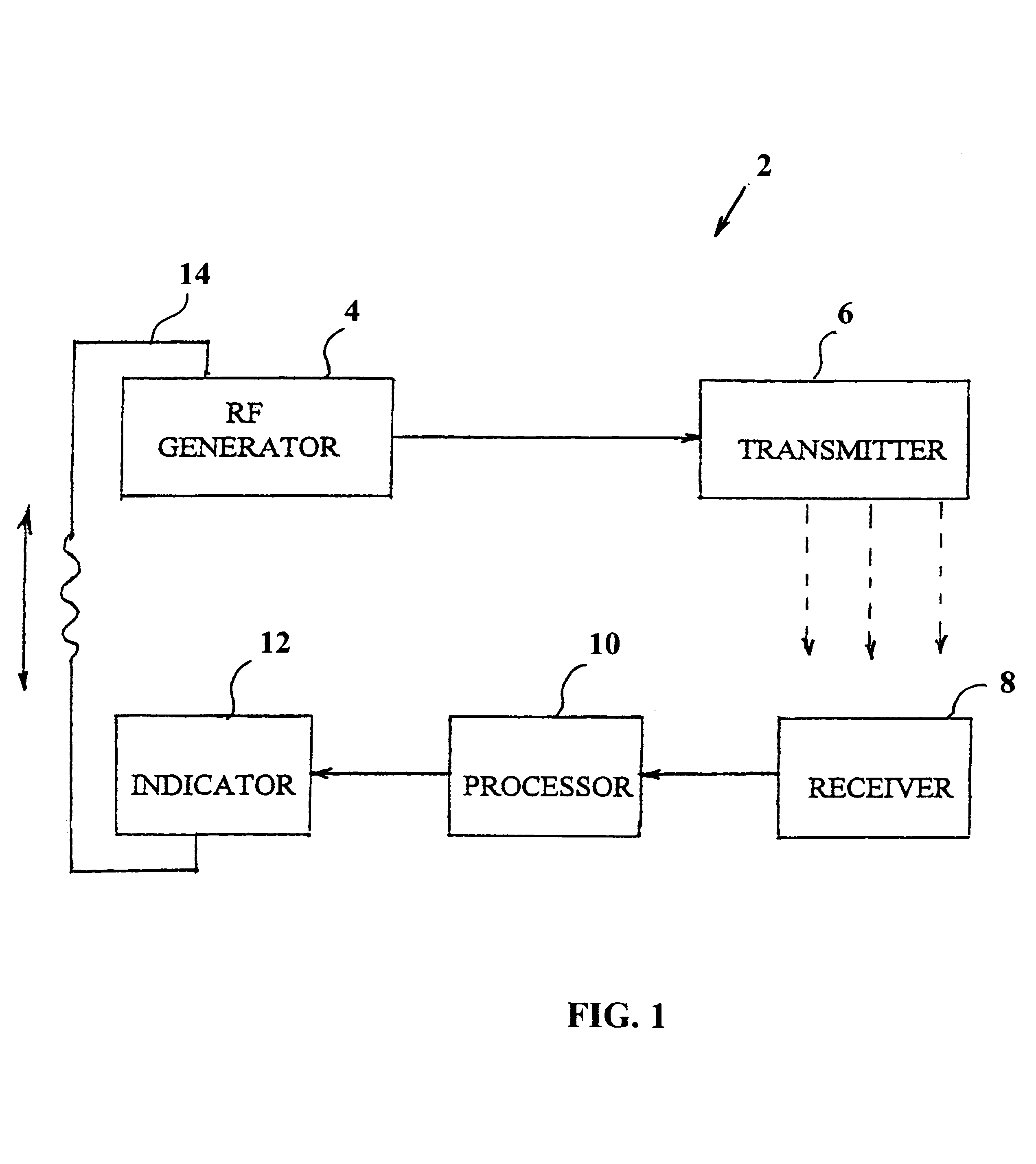

System and method for detecting the state of hydration of a living specimen

The invention provides a system (2) for non-invasive detection of the state of hydration in a living specimen, the system including an RF generator / transmitter (416) for emitting RF radiation signals and for transmitting the radiation signals through a tissue of a living specimen; an RF receiver (8) for receiving RF signals transmitted through the tissue, and for feeding the signals to a processor (10) for comparison of relative attenuation of RF frequencies passing through the tissue with a reference attenuation ratio signal, and an indicator unit (12) for providing an output signal representative of the water content level of the tissue. A method for non-invasive detection of the state of hydration in a living specimen is also described and claimed.

Owner:EYAL BICKELS ELAZAR +1

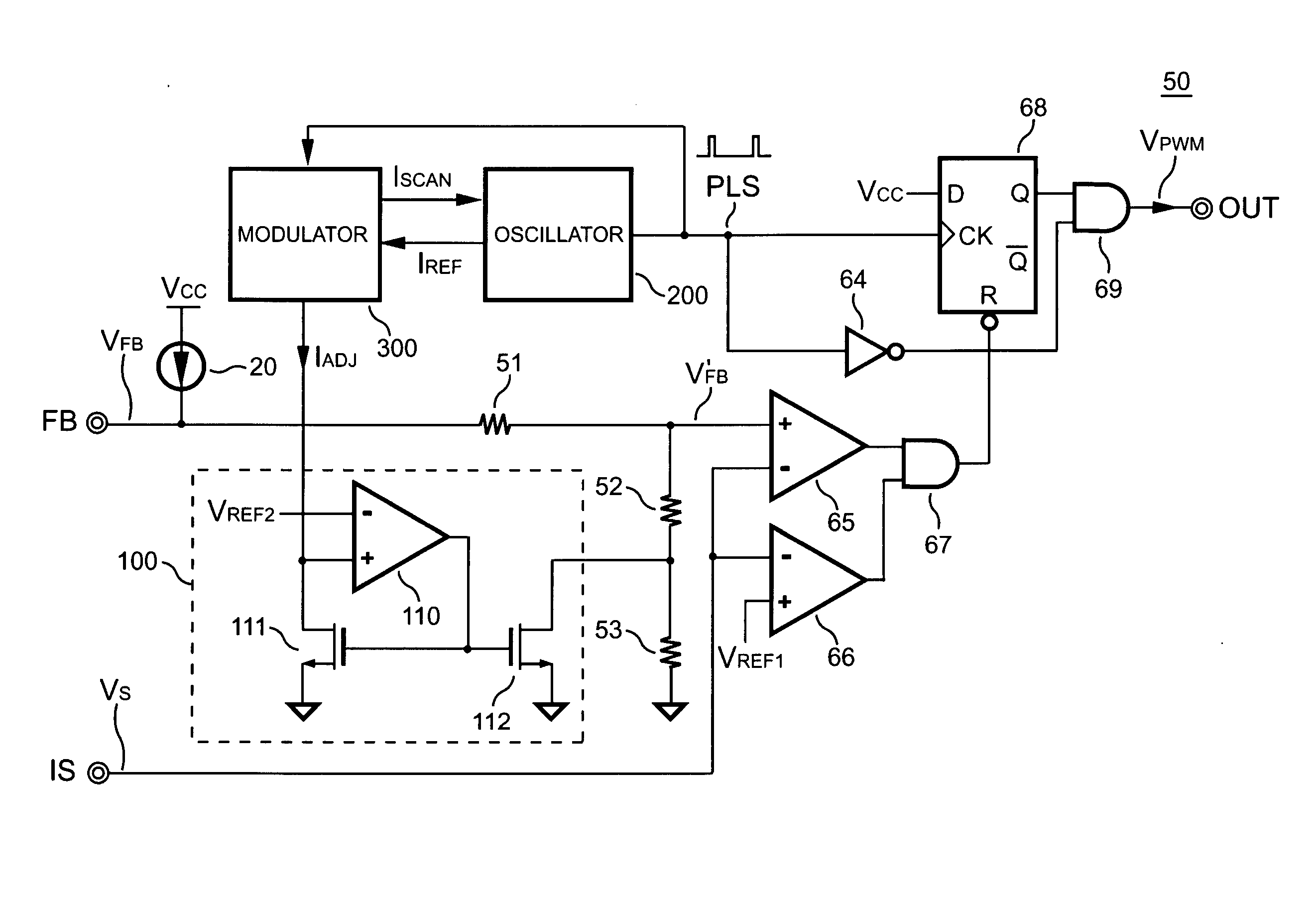

PWM controller having frequency jitter for power supplies

ActiveUS7026851B2Undesired ripple signal can be eliminatedLower impedanceDc-dc conversionElectric pulse generatorUltrasound attenuationAttenuation ratio

Owner:SEMICON COMPONENTS IND LLC

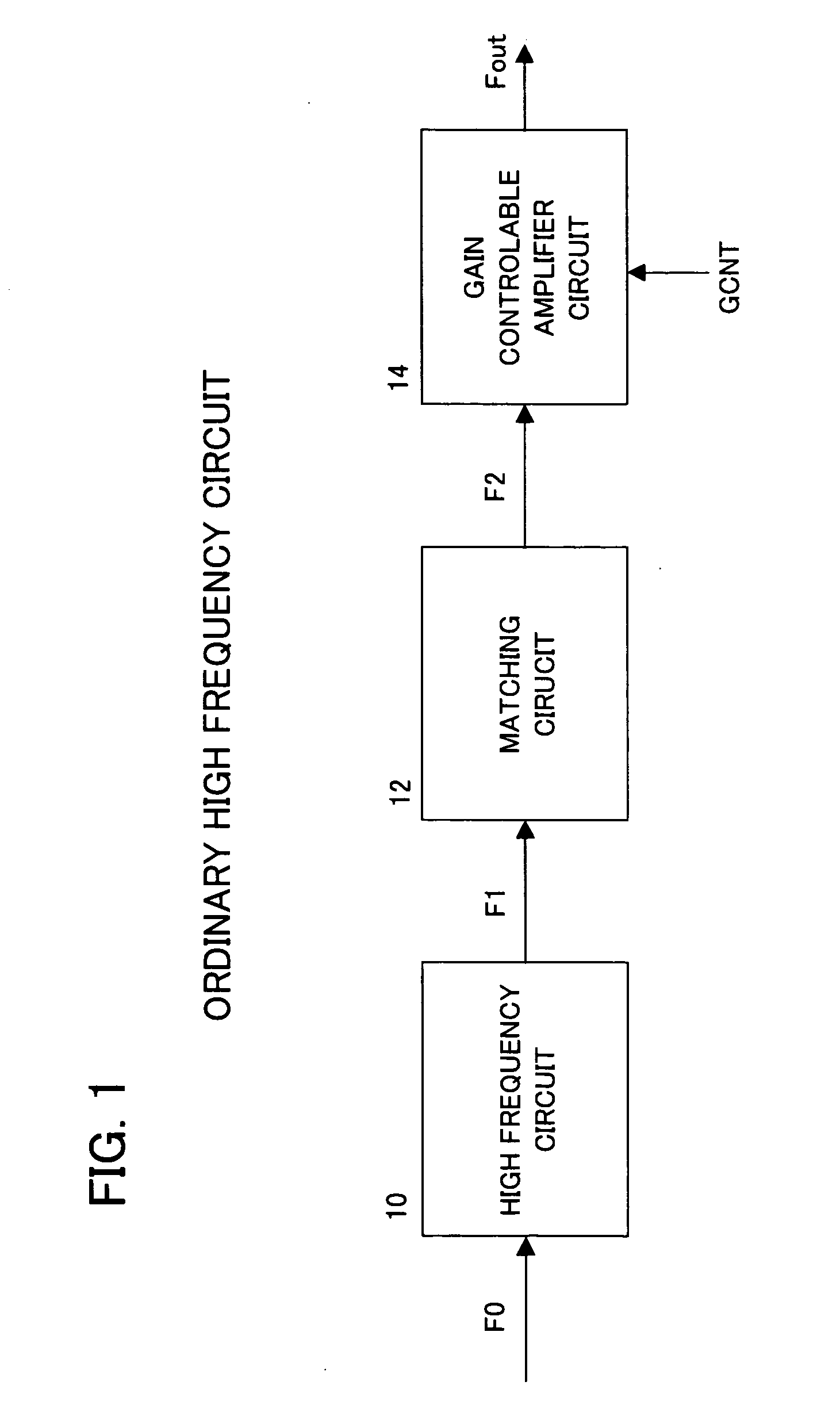

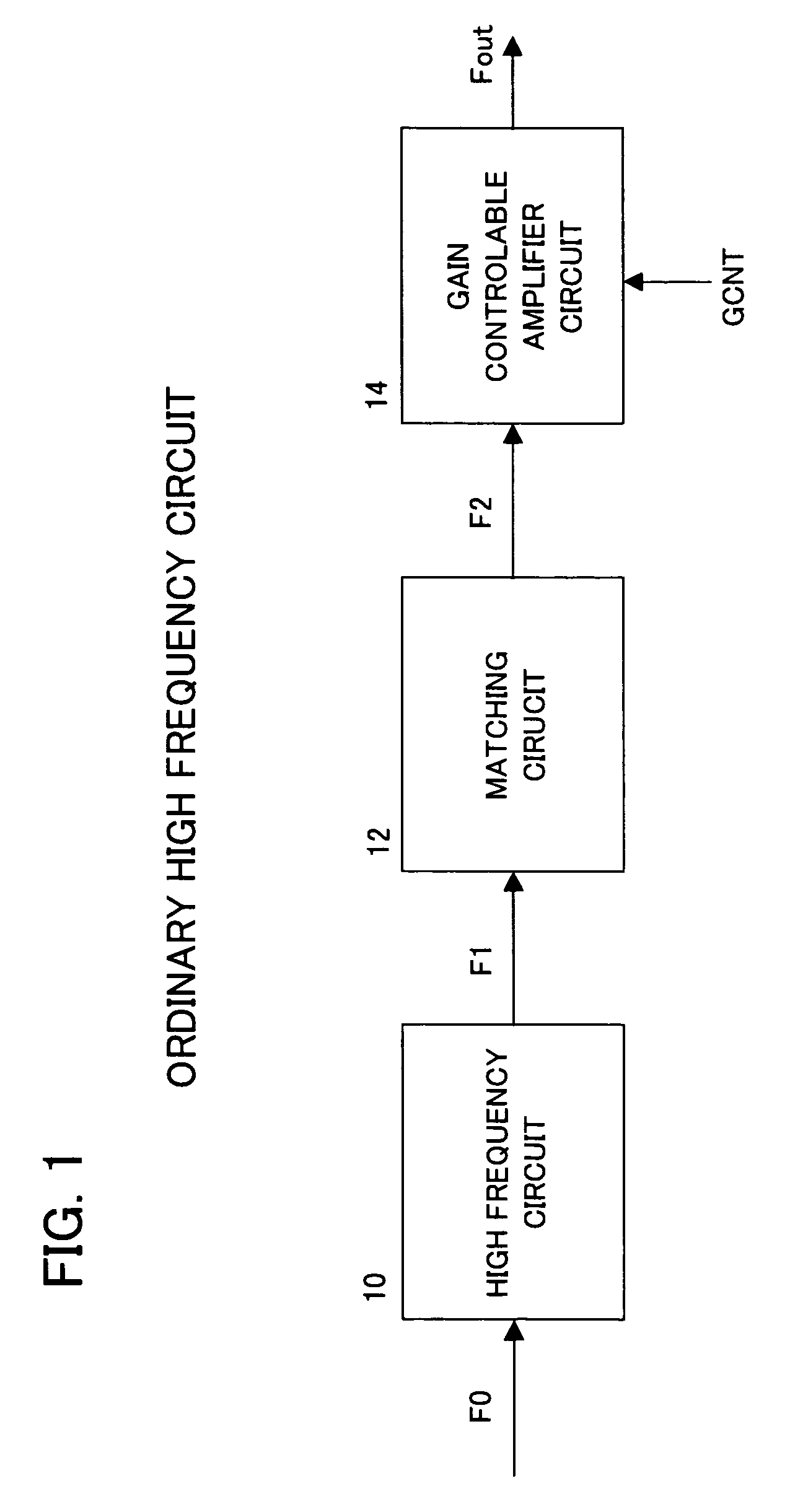

High frequency amplifier circuit permitting variable gain control

InactiveUS20050118971A1Reduce noise figureAmplifier modifications to reduce non-linear distortionPower managementCapacitanceUltrasound attenuation

The present invention is an amplifier circuit that permits variable gain control, comprising an input terminal to which a high frequency input signal is supplied; an amplifier transistor to the gate of which the high frequency input signal supplied to the input terminal is supplied and which generates an amplified signal at the drain side; and a variable attenuator provided in a signal transmission line between the input terminal and the gate of the amplifier transistor, in which a plurality of attenuation units in which an attenuation capacitor and a switch transistor are serially connected are provided in parallel between the signal transmission line and a power supply, and the attenuation ratio of which is variably controlled by controlling the conduction of the switch transistor.

Owner:FUJITSU LTD

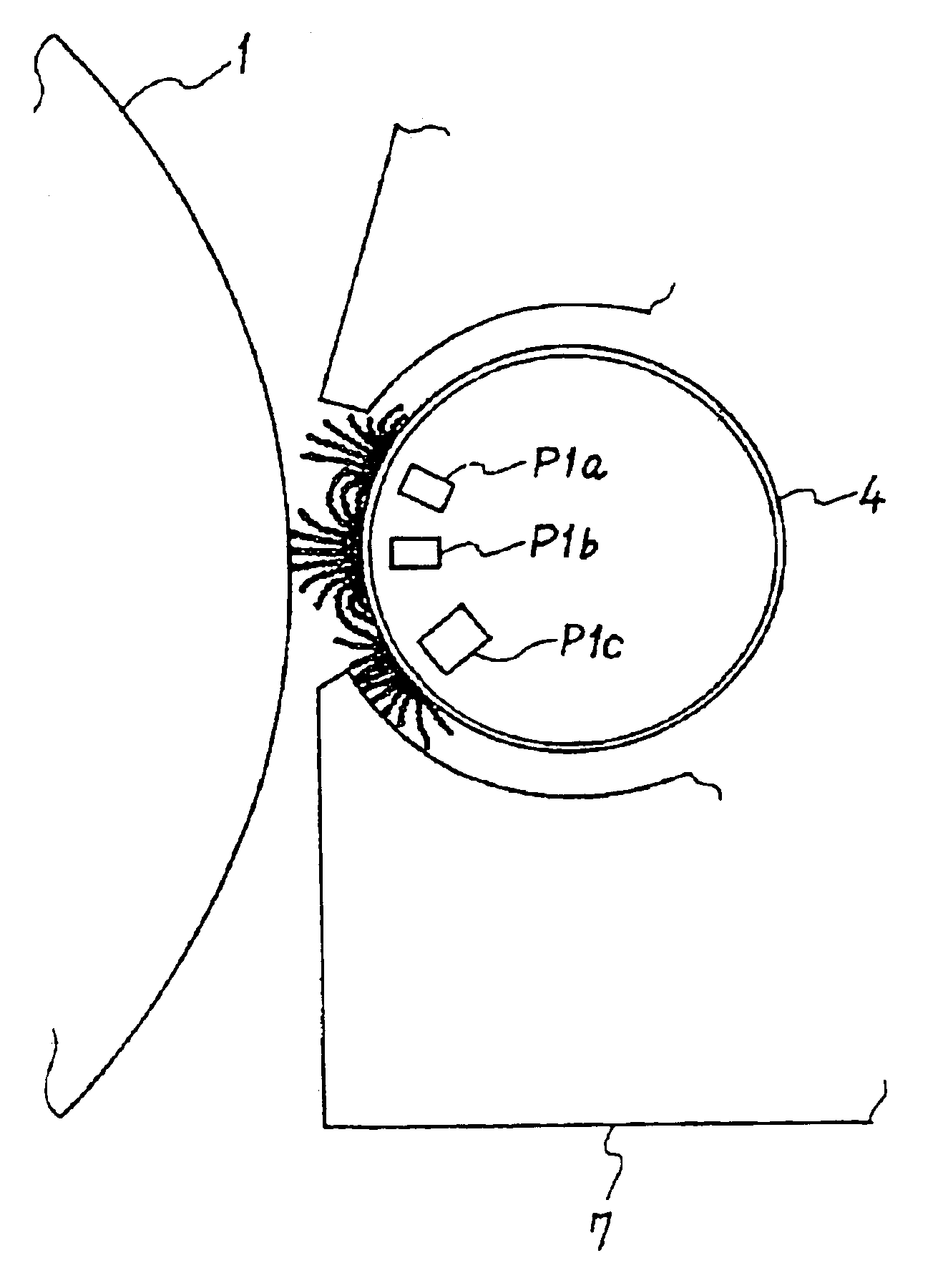

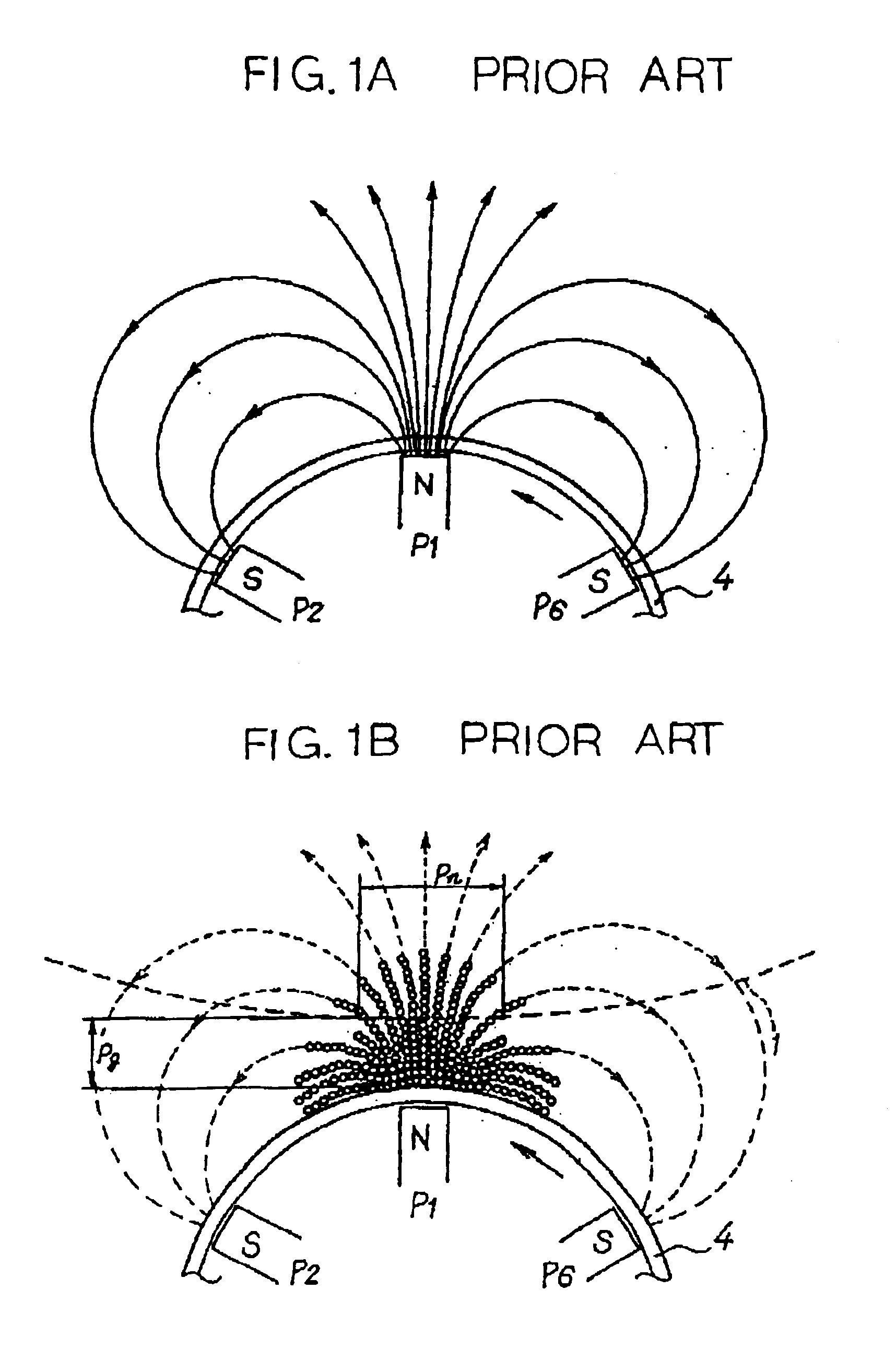

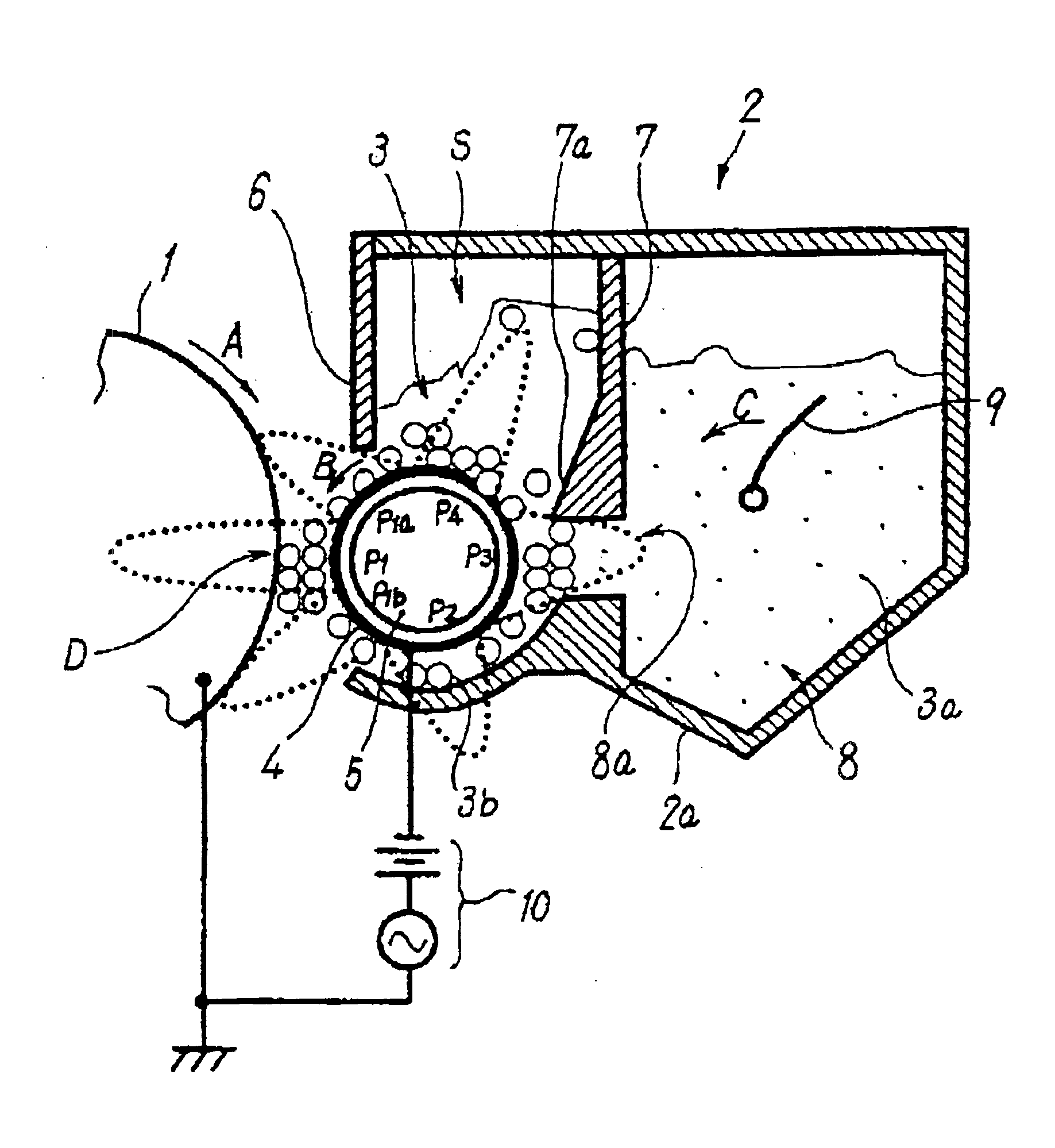

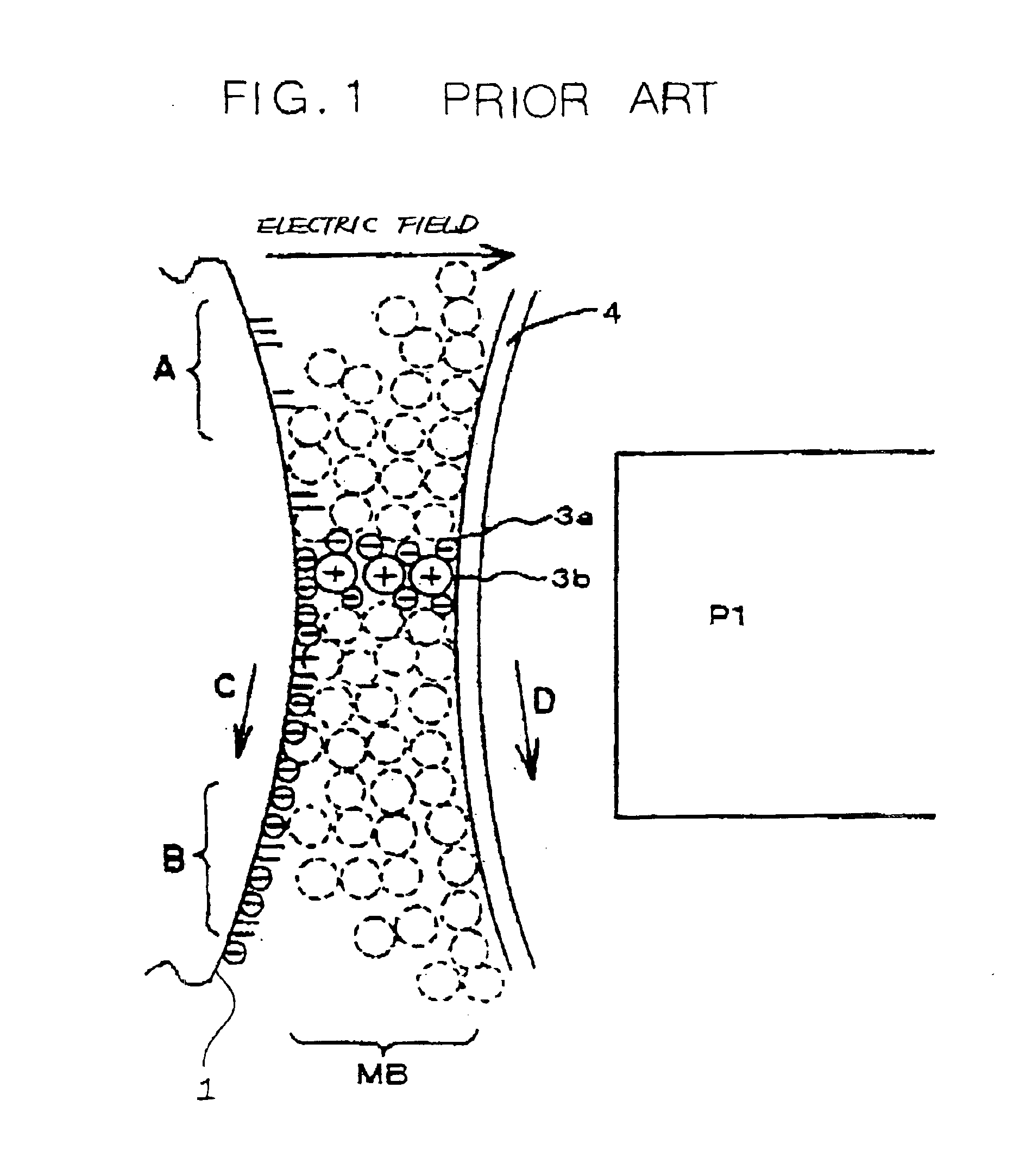

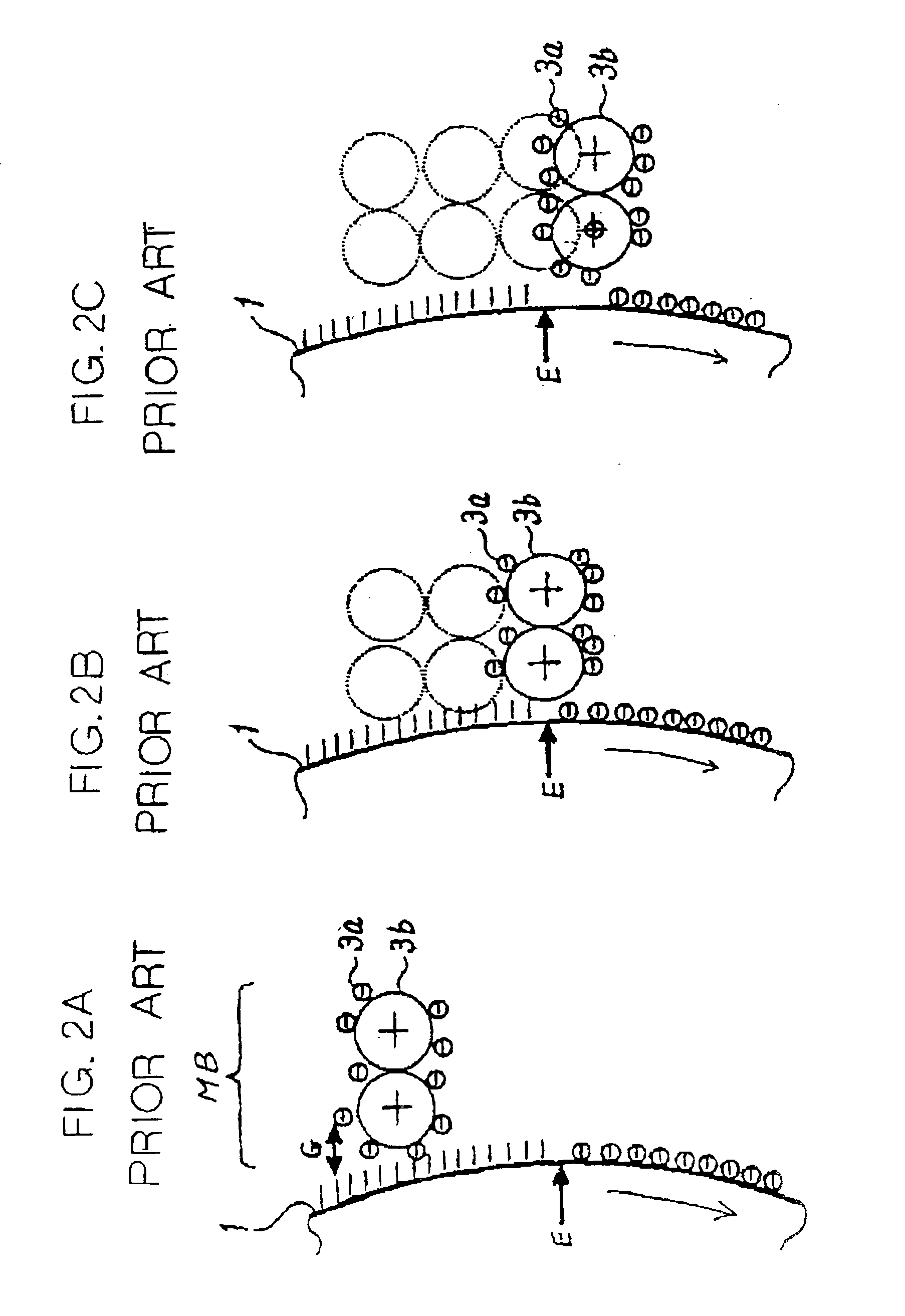

Developing device having a developer forming a magnet brush

InactiveUS6898406B2Good reproducibilityImage degradationElectrographic process apparatusDevelopersMagnetic fluxAttenuation ratio

In a developing device having a developing zone where an image carrier and a developer carrier face each other, the developer carrier carrying a developer thereon moves at a linear velocity of 150 mm / sec or above, but below 500 mm / sec. The amount of the developer conveyed to the developing zone by the developer carrier is between 65 mg / cm2 and 95 mg / cm2. A magnetic flux generated on the developer carrier in the developing zone by a magnetic pole has a flux density having an attenuation ratio of 40% in the direction normal to the developer carrier. The flux density in the direction normal to the developer carrier, as measured on the surface of the developer carrier, is between 100 mT and 200 mT. Magnetic grains, which constitute the developer together with toner grains, have a saturation magnetization value of 40×10−7×4 πWb·m / kg or above, but below 50×10−7×4 πWb·m / kg.

Owner:RICOH KK

Developing device using a two-ingredient type developer and image forming apparatus including the same

InactiveUS6873814B2Faithfully reproducedReducing toner scatteringElectrographic process apparatusDevelopersImage resolutionUltrahigh resolution

A developing device including a developer containing magnetic toner grains and includes a main pole for development disposed in a sleeve. Flux density generated by the magnetic pole in a direction normal to the surface of the sleeve outside of the surface has an attenuation ratio of 50% or above. The toner grains have a weight mean grain size of 6.0 μm to 8.0 μm while the toner grains having grain sizes of 5 μm and below occupy 40% to 80% of the entire developer. The toner grains have magnetization strength of 10 emu / g to 25 emu / g in a magnetic field of 5 kOe or magnetization strength of 7 emu / g to 20 emu / g in a magnetic field of 1 kOe. The toner grains reduce toner scattering and image defects despite that they are magnetic, thereby implementing ultrahigh resolution.

Owner:RICOH KK

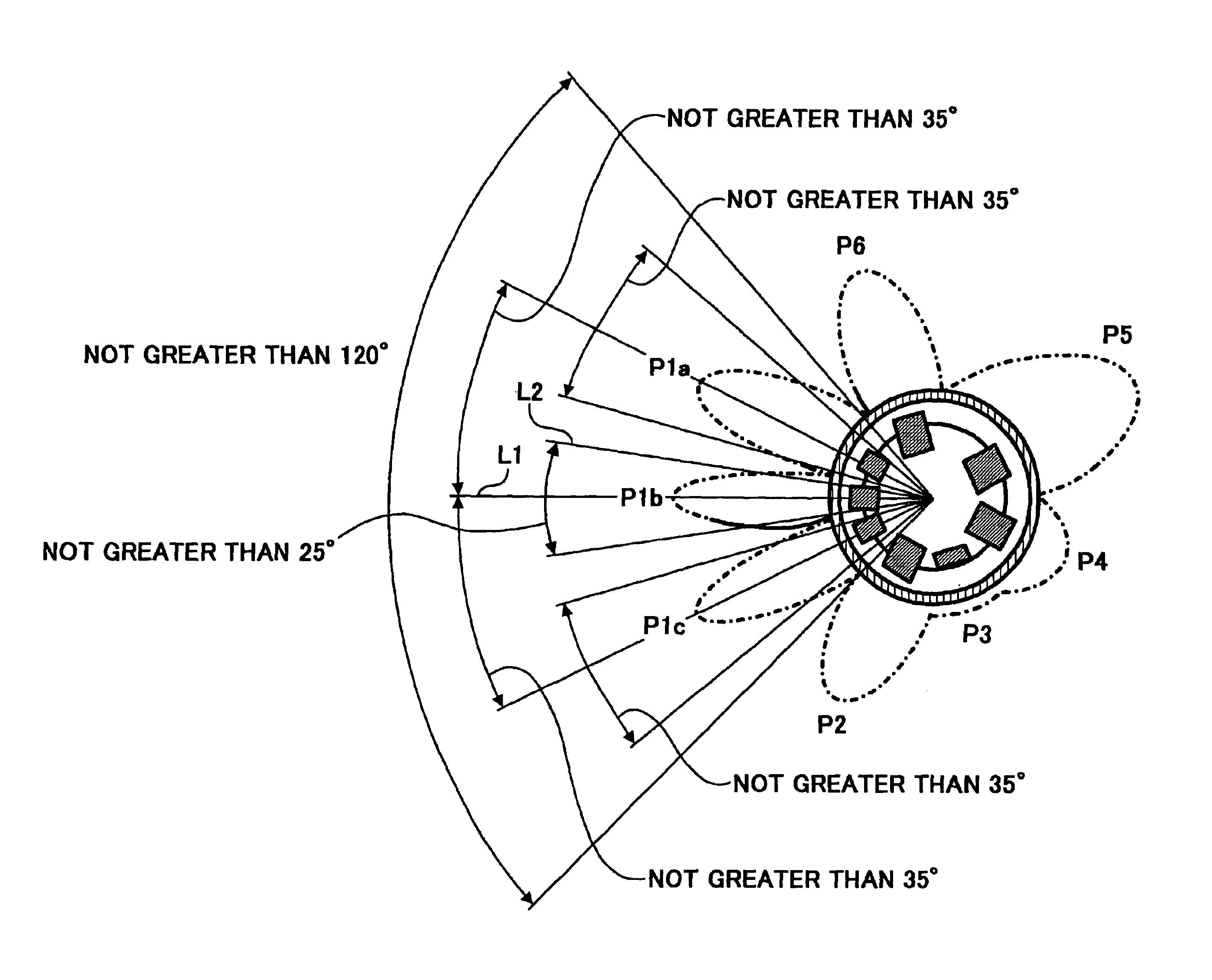

Image forming method and apparatus

A method for developing an electrostatic latent image, including forming a magnet brush of a developer including a toner and a carrier on a developing sleeve including a main magnet and auxiliary magnets; and developing the electrostatic latent image with the magnet brush to form a toner image at a rubbing region, wherein the magnetic flux density in a normal line direction, half width, and attenuation ratio of the main magnet and the angle between the main magnet and auxiliary magnets are specified, and the magnetic sleeve has specific grooves thereon, and wherein the toner has a volume average particle diameter of from 4.0 to 7.0 μm, and includes fine particles having a circle equivalent diameter not greater than 2 μm in an amount not greater than 20% by number.

Owner:RICOH KK

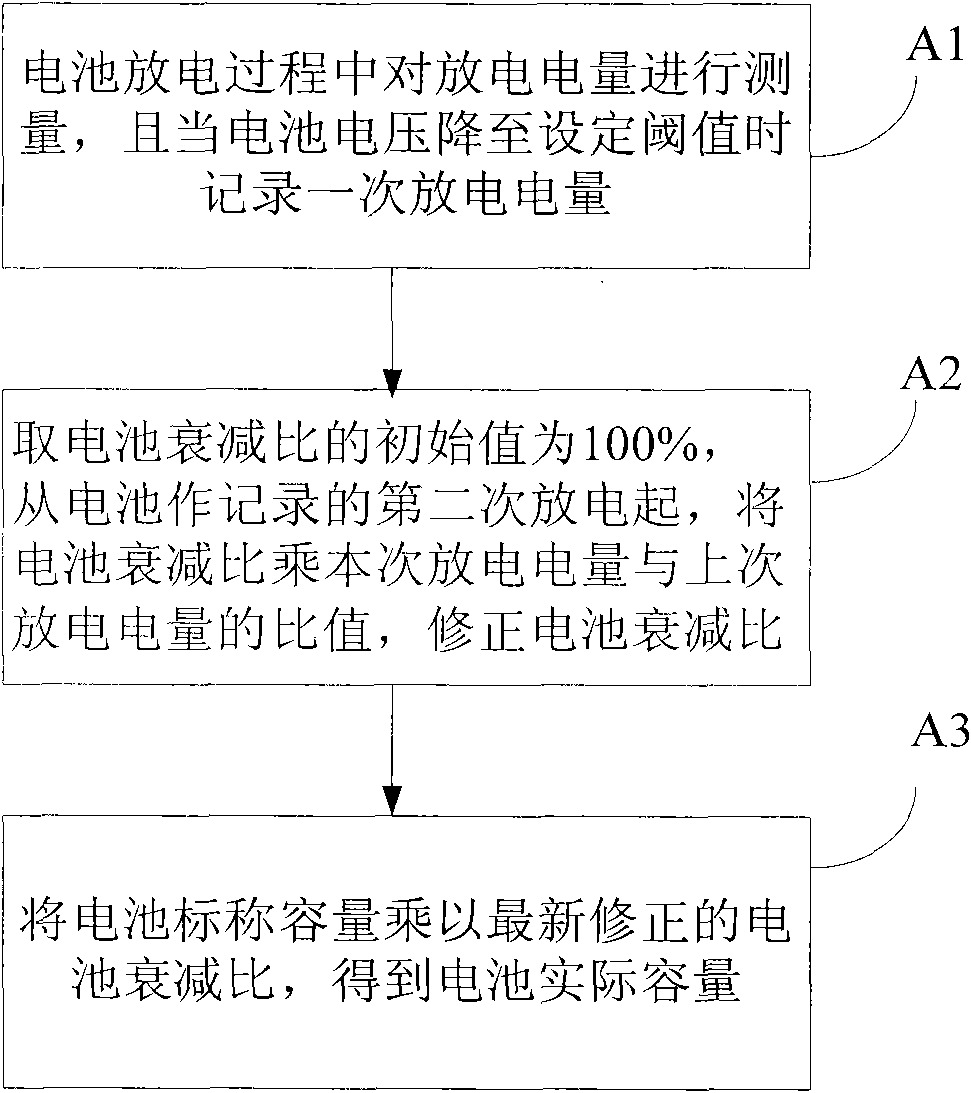

Methods for detecting actual capacity, residual capacity, standby time and health condition of battery

ActiveCN102073016AIn line with the real situationInsufficient improvementCurrent/voltage measurementElectrical testingElectricityState of health

The invention discloses a method for detecting the actual capacity of a battery, which comprises the following steps: (A1) measuring discharge quantity in the battery discharge process, and recording the discharge quantity when the battery voltage is reduced to a set threshold; (A2) setting the initial value of battery attenuation ratio as 100%, and multiplying the battery attenuation ratio by the ratio of the discharge quality this time to the discharge quantity last time after discharge from the recorded second discharge, thus obtaining the corrected battery attenuation ratio; and (A3) multiplying the nominal capacity of the battery by the newly corrected battery attenuation ratio, thus obtaining the actual capacity of the battery. The invention also discloses methods for detecting the residual capacity, the residual standby time and the health condition of a battery based on the method for detecting the actual capacity of a battery. By using the methods disclosed by the invention, the service condition and health state of the battery can be accurately obtained.

Owner:VERTIV CORP

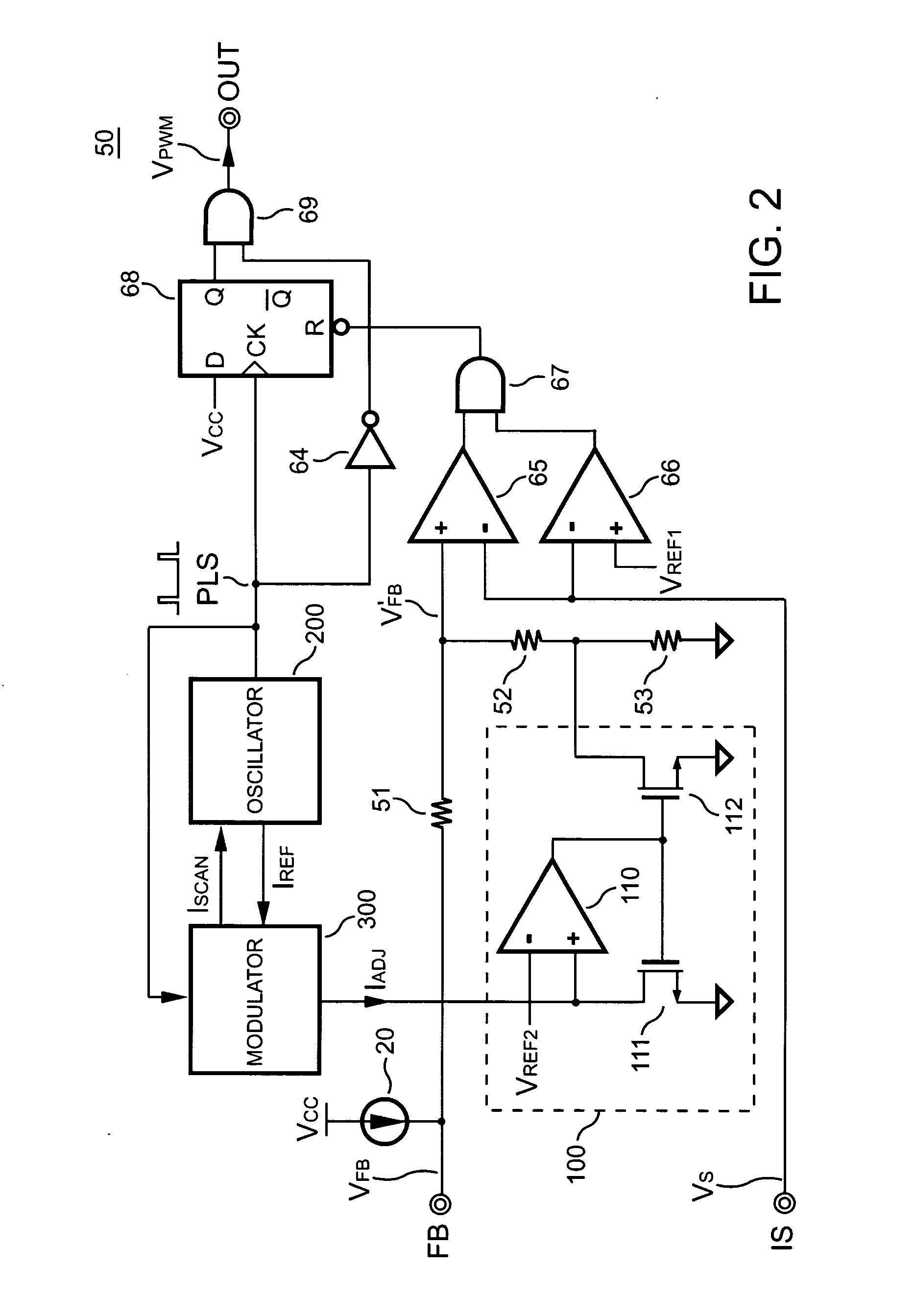

PWM controller having frequency jitter for power supplies

ActiveUS20050253636A1Undesired ripple signal can be eliminatedLower impedanceDc-dc conversionElectric pulse generatorUltrasound attenuationSwitching signal

A PWM controller having frequency jitter includes a modulator for generating a first jitter current and a second jitter current. An oscillator generates a pulse signal for producing a switching frequency in response to the modulation of the first jitter current. An attenuator is connected in a voltage feedback loop for attenuating a feedback signal to an attenuated feedback signal, in which the attenuated feedback signal is utilized to control an on-time of a switching signal. A variable-resistance circuit is connected with the attenuator for programming an attenuation rate of the attenuator in response to the modulation of the second jitter current. The switching frequency increases whenever the first jitter current increases. Meanwhile, the impedance of the attenuator will decreases and the attenuation rate will increase whenever the second jitter current increase. The on-time of the switching signal is thus immediately reduced, which compensates the decrease of the switching period and keeps the output power as a constant.

Owner:SEMICON COMPONENTS IND LLC

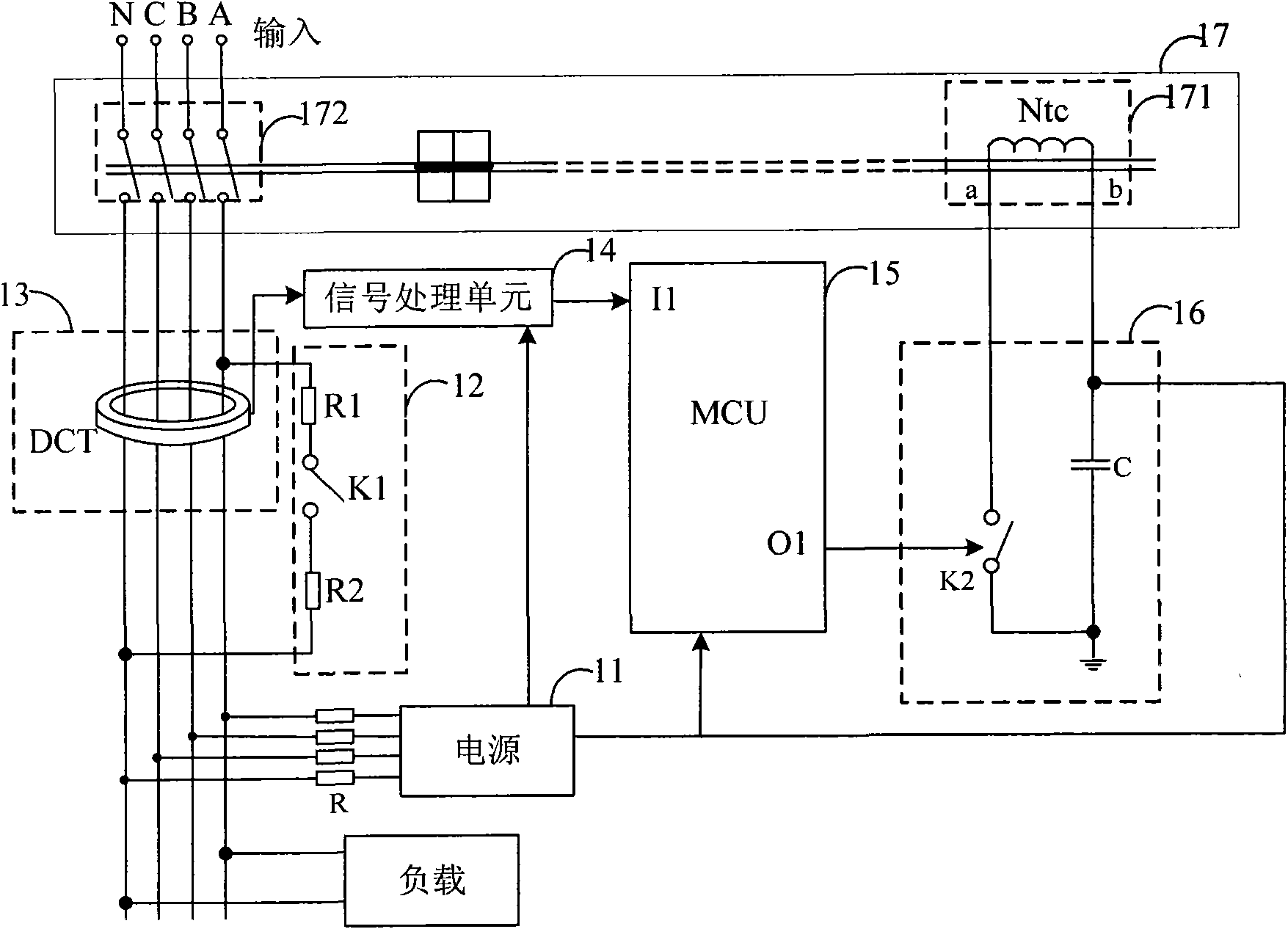

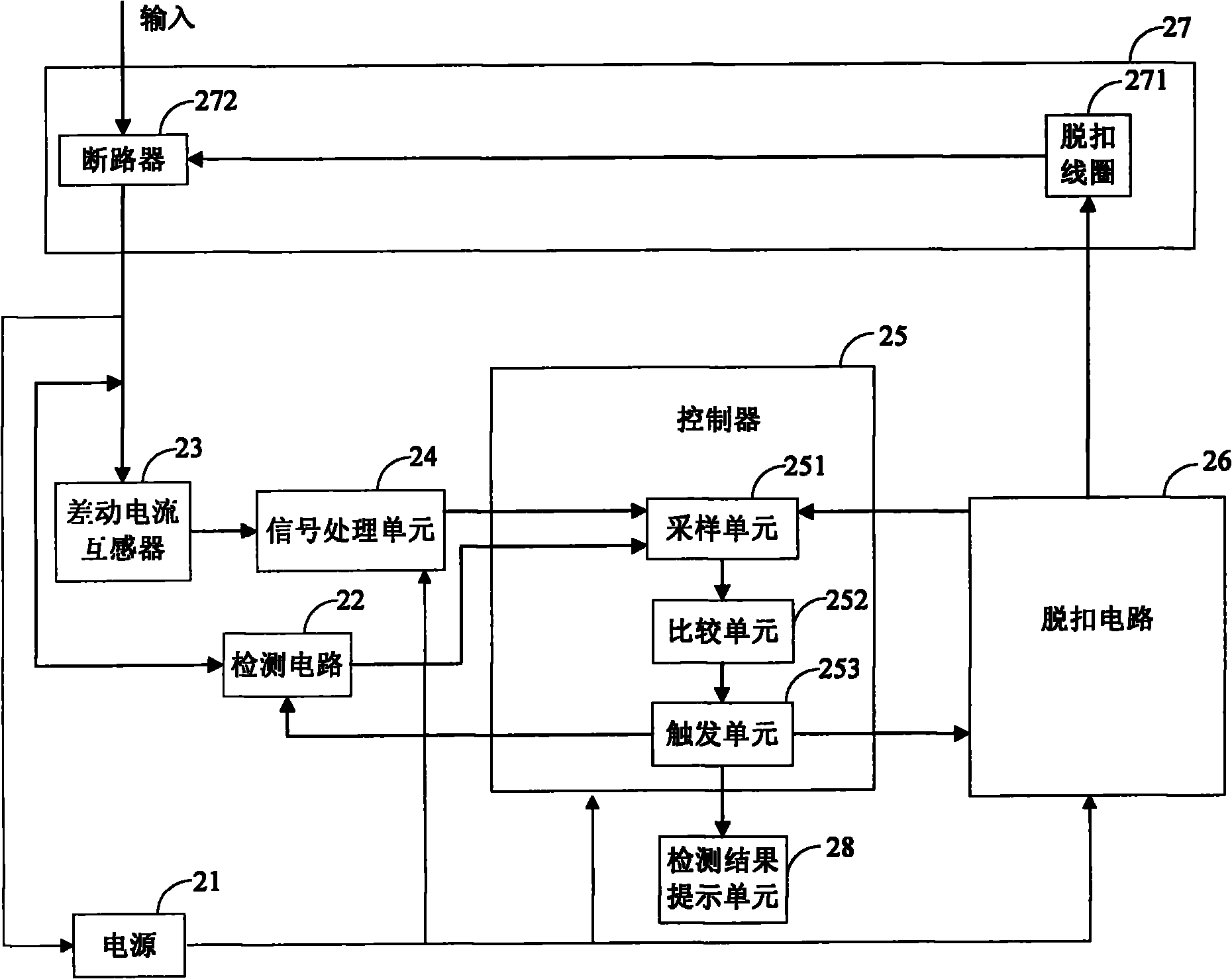

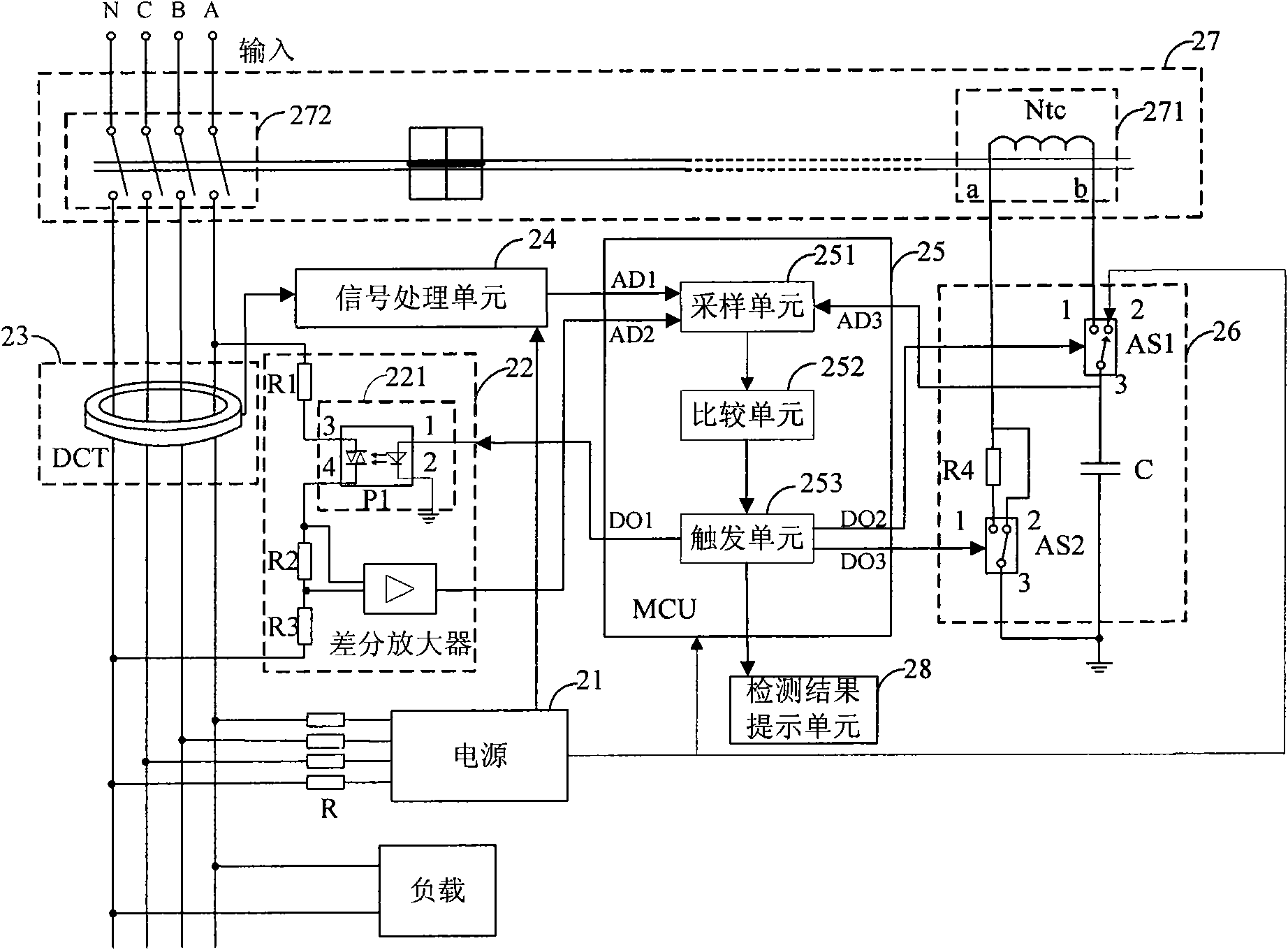

RCD (Residual Current Device) detection device and detection method

The invention discloses an RCD (Residual Current Device) detection device. A detection circuit in the detection device can generate a simulation drain current on the basis of a first control signal output by a controller, and the processed simulation drain current is output to the controller, a differential current transformer can output a drain current obtained in the detection to a signal processing unit which can process and output the drain current to the controller, a trip circuit can generate a simulation voltage based on a second control signal output by the controller and can output the simulation voltage to the controller and a tripping device, and the controller can determine whether the differential current transformer and / or the signal processing unit has faults or not according to the comparison results of the simulation drain current and the drain current, and determine whether the trip circuit and / or the tripping device has faults or not according to the comparison results of the attenuation ratio of the simulation voltage with a preset attenuation ratio, cue signals denoting the detection results can be output to a detection result cue unit, and the detection result cue unit can output the detection results according to the obtained cue signals. The invention further discloses an RCD detection method. By adopting the RCD detection device and the detection method provided by the invention, an RCD (Residual Current Device) can be detected in the case of the connection of a circuit breaker with a power grid.

Owner:SIEMENS AG

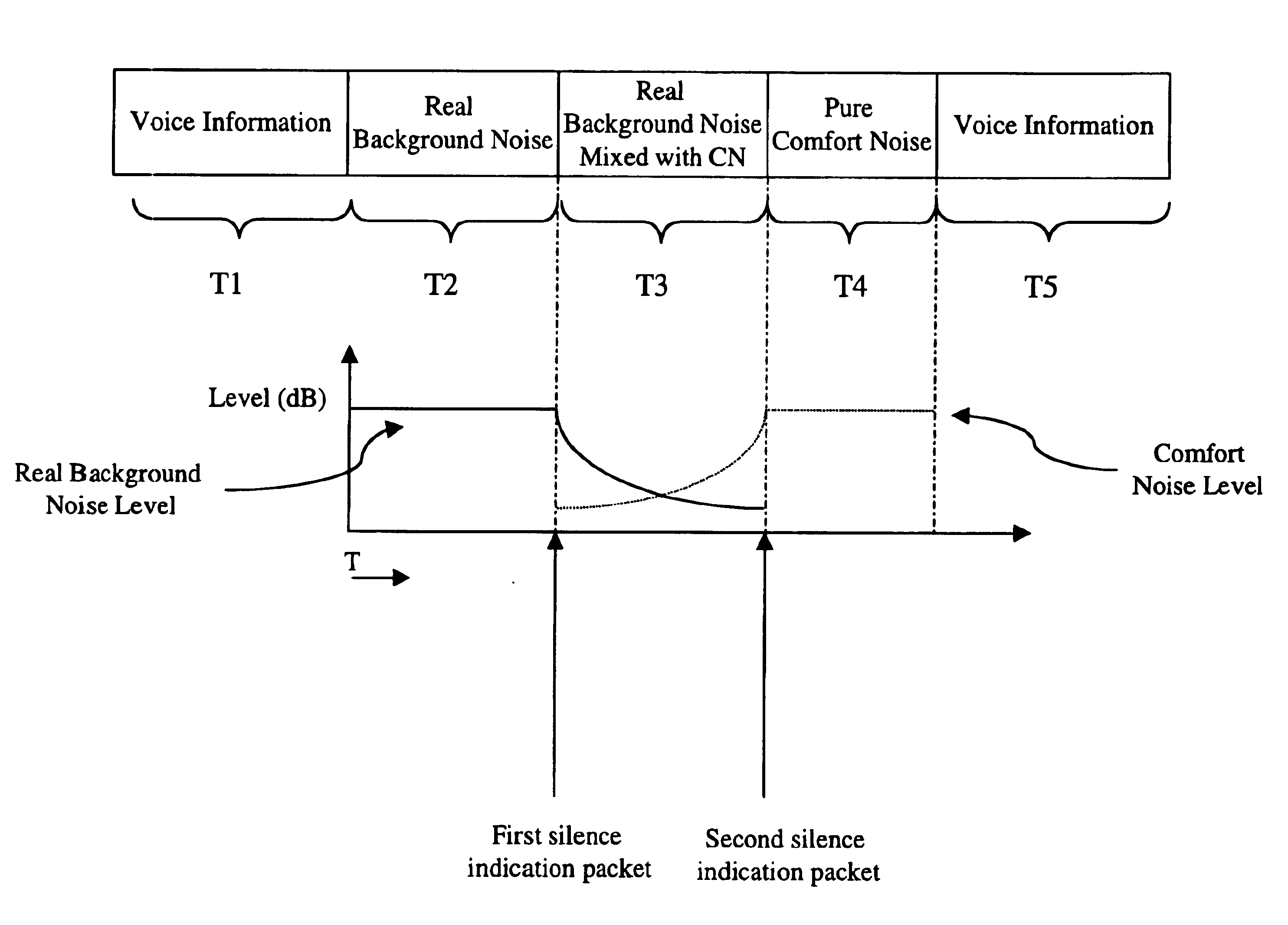

Method and apparatus for transitioning comfort noise in an IP-based telephony system

InactiveUS6873604B1Eliminating and minimizing transitionSatisfies needMultiplex system selection arrangementsSpecial service provision for substationUltrasound attenuationComfort noise

A method is disclosed, where the RX unit of an IP telephone waits for a first silence indication packet to be received. When the first silence indication packet is received, the RX begins attenuating incoming packets. The rate of attenuation may occur at a rate responsive to an indication provided by the TX unit. The RX unit also mixes comfort noise with the attenuated incoming packets. The RX unit the waits for a second silence indication packet to be received. When the second silence indication is received the RX unit mixes in comfort noise at a level responsive to an indication provided by the TX unit. The RX units then waits for voice packets to be received from the TX unit. When normal voice activity resumes, the RX unit stops the generation of comfort noise and begins playing voice packets again.

Owner:CISCO TECH INC

Variable attenuation network

InactiveUS20050174157A1Multiple-port networksPulse automatic controlUltrasound attenuationImage resolution

A variable attenuation network of an input voltage on an input node produces an attenuated voltage on an output node of the network, and includes a voltage divider with multiple-taps that are selectable for producing the attenuated voltage from a voltage applied on the terminals of the voltage divider. The attenuation network produces an output voltage with an attenuation ratio that is determined with at least twice the resolution of the voltage divider, because it includes at least one resistor that may be shorted by a low impedance by-pass line controlled by a switch and alternatively connected between the selected intermediate tap or any one of the two terminals of the voltage divider and the output node of the variable attenuation network, the input node of the attenuation network or a common ground node, respectively. By using more than one shortable resistor, multiple levels of resolution may be obtained.

Owner:STMICROELECTRONICS SRL

Composite of graphene and conducting polymer and preparation method of composite

InactiveCN103963403AEasy to makeReduce square resistanceSynthetic resin layered productsGlass/slag layered productsConductive polymerAttenuation ratio

The invention discloses a composite of graphene and a conducting polymer. The composite comprises a base body; a graphene layer and a conducting polymer layer are arranged in sequence on the surface of the base body, or the conducting polymer layer and the graphene layer are arranged in sequence on the surface of he base body. A preparation method of the composite comprises the following steps: transferring the graphene onto the surface of the base body first, then coating the graphene with the conducting polymer; or coating the surface of the base body with the conducting polymer first, then transferring the graphene onto the conducting polymer; baking to obtain the composite of the graphene and the conducting polymer. According to the invention, the composite is simple in preparation process and can lower sheet resistance obviously after the graphene is transferred; the stability is excellent, that is, even though the composite is placed for a long time, attenuation of the sheet resistance of the graphene is extremely small, and the sheet resistance attenuation ratio of the composite placed for 30 days is less than 10%.

Owner:WUXI GRAPHENE FILM

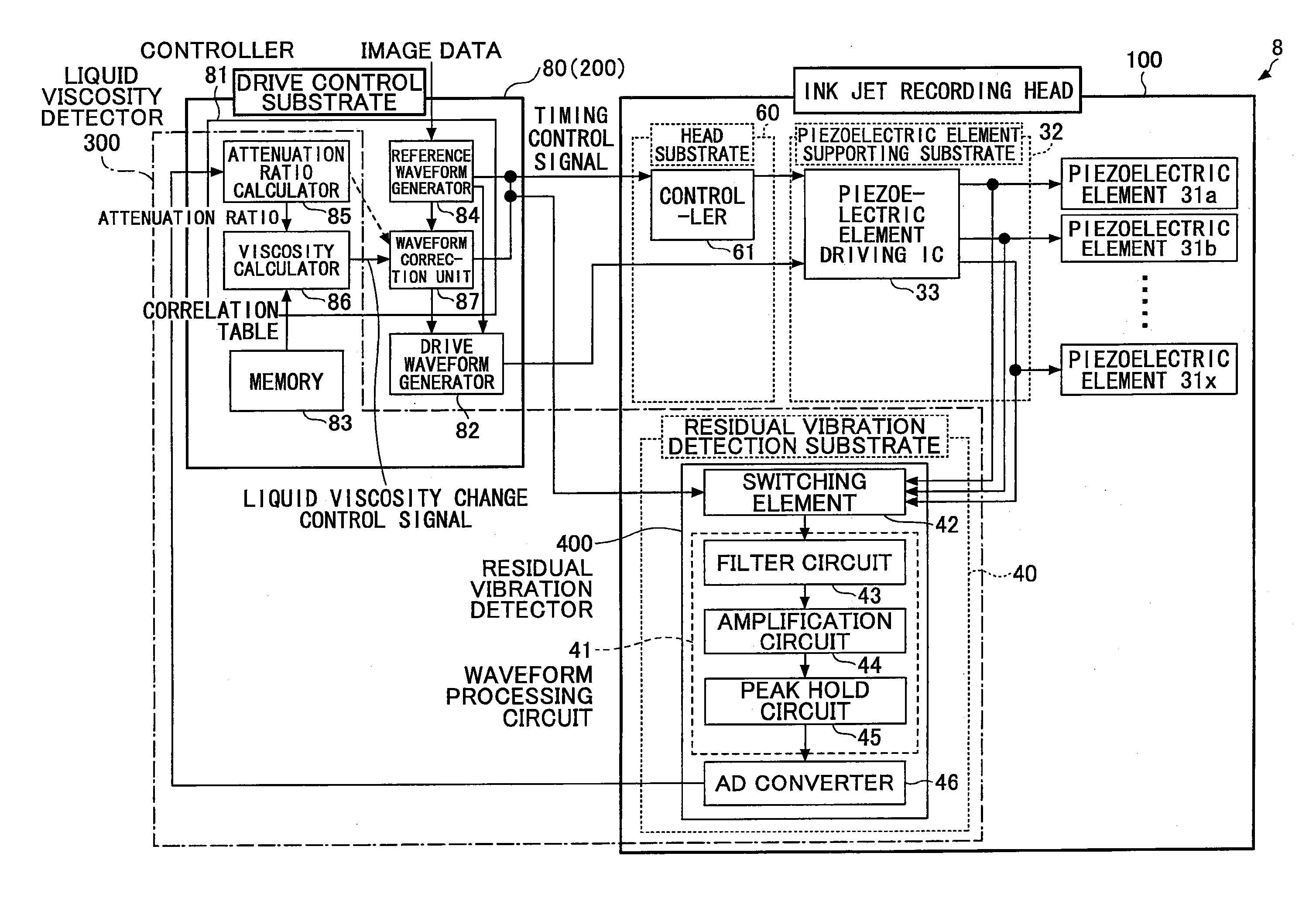

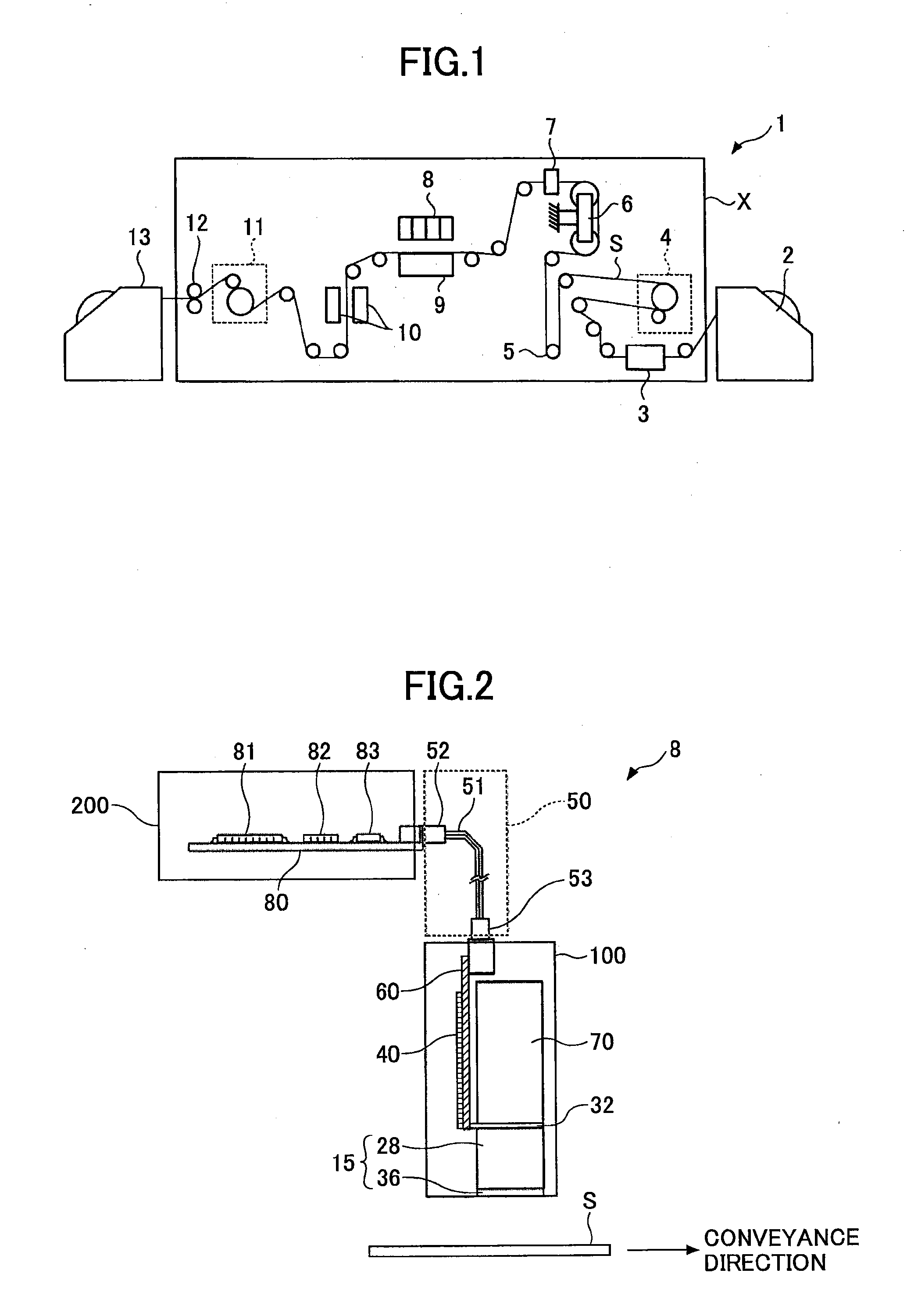

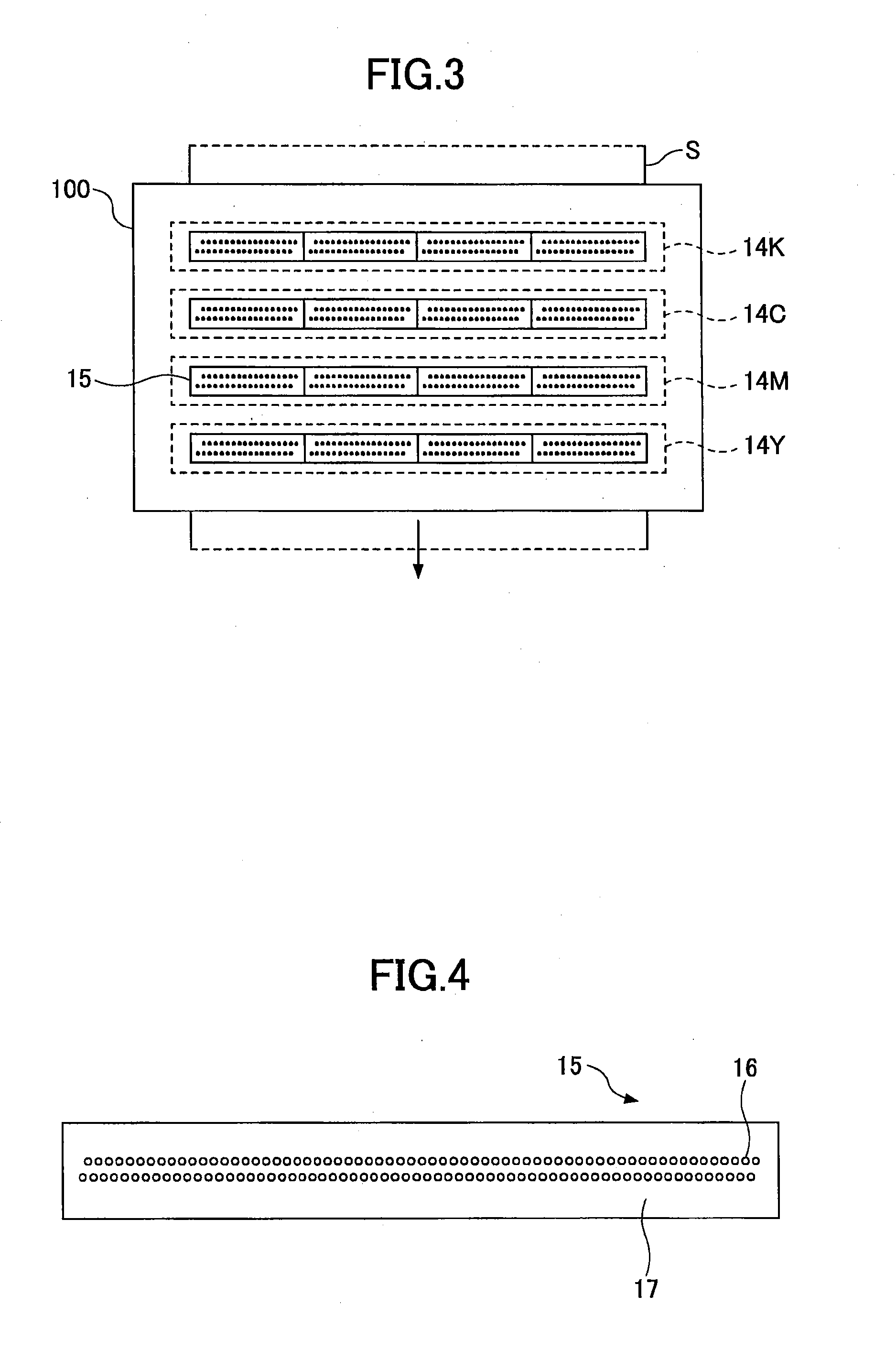

Liquid viscosity detecting method for liquid droplet ejecting device, control method for liquid droplet ejecting device, and liquid droplet ejecting device

A liquid viscosity detecting method is performed in a liquid droplet ejecting device that includes a piezoelectric type droplet ejecting head to which a drive waveform is applied to pressurize a liquid chamber to eject a liquid droplet, a drive waveform generator to apply the drive waveform to the droplet ejecting head, and a residual vibration detector. The method includes detecting, by the residual vibration detector, amplitude values of multiple cycles of a residual vibration waveform occurring within the liquid chamber after the drive waveform is applied; calculating an attenuation ratio based on the amplitude values; and calculating a liquid viscosity in the liquid chamber based on the attenuation ratio.

Owner:RICOH KK

Fruit ripeness ultrasonic non-destructive detection method and system based on comparison method

InactiveCN102095797AImprove accuracyCause physical damageMaterial analysis using sonic/ultrasonic/infrasonic wavesCharacter and pattern recognitionNon destructiveInformation processing

The invention provides a fruit ripeness ultrasonic non-destructive detection method and system based on a comparison method. The method comprises the following steps of: conducting training and learning on fruit, dividing grades for fruit ripeness through training and learning results, and establishing fruit ripeness models and optimum measurement frequency of target fruit; really measuring the target fruit, and acquiring two characteristic values of the target fruit, i.e. attenuation ratio and transmission speed; and comparing the target fruit with the fruit models obtained from training and learning to obtain ripeness degree. The system comprises a fruit detection module, an acoustic range measurement module, an information processing module and a control and display module, wherein the control and display module is connected with the information processing module and the acoustic range measurement module, the information processing module is connected with the fruit detection module, and meanwhile, the fruit detection module is connected with the acoustic range measurement module. The method and the system, which are provided by the invention, can realize non-destructive detection, do not require manual judgment and have the advantages of being simple to realize, easy to operate and wide in application range.

Owner:SOUTH CHINA UNIV OF TECH

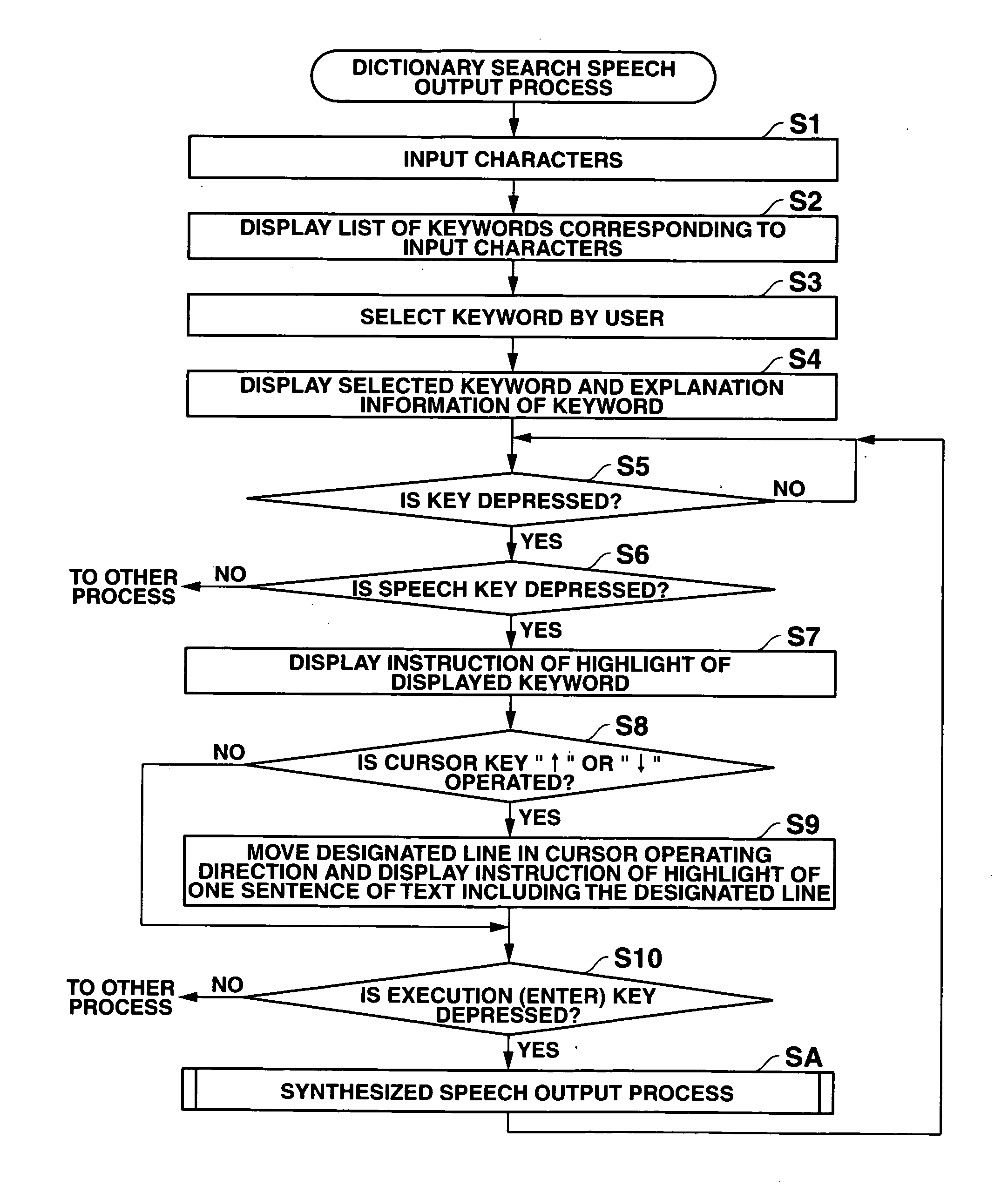

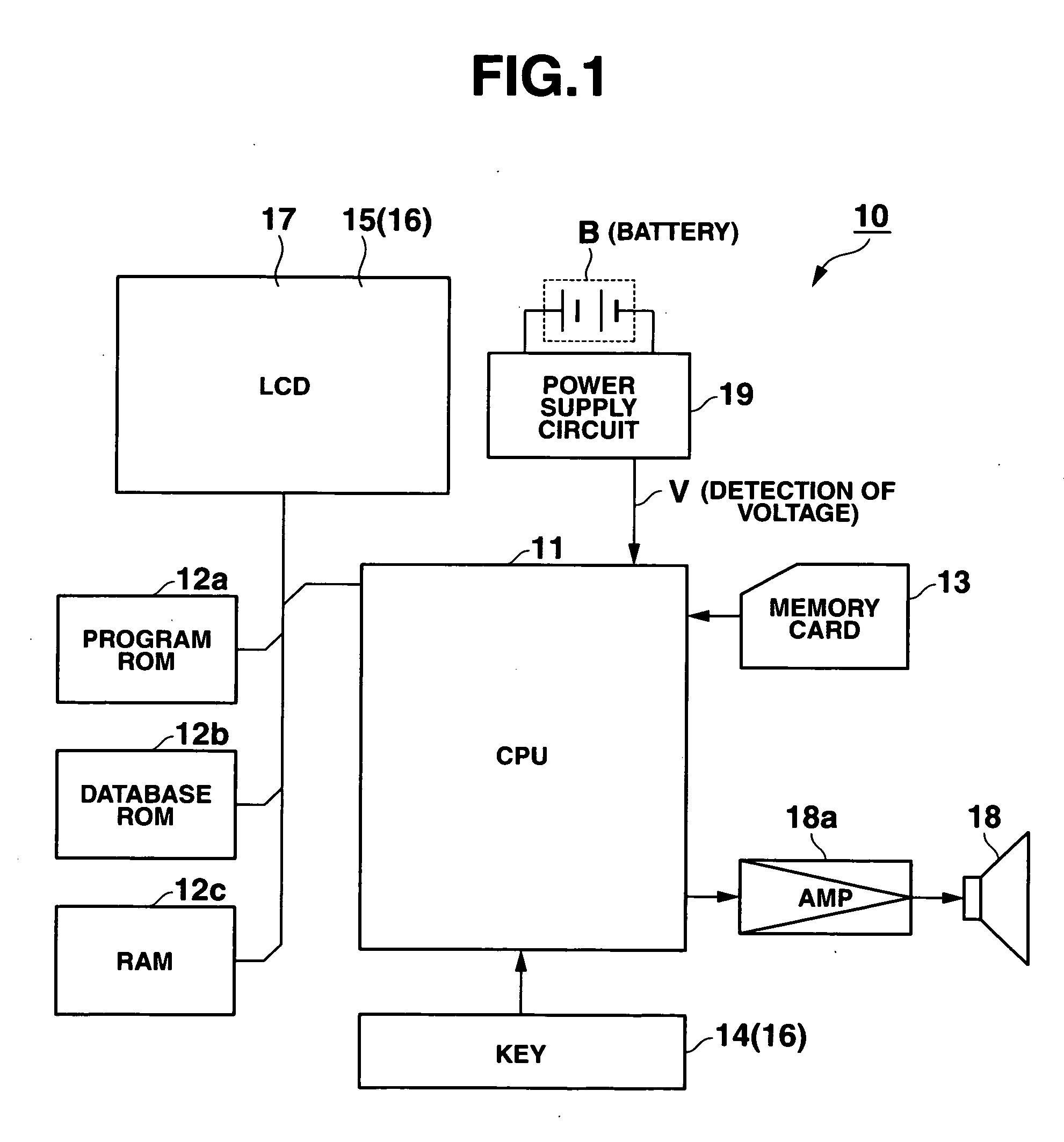

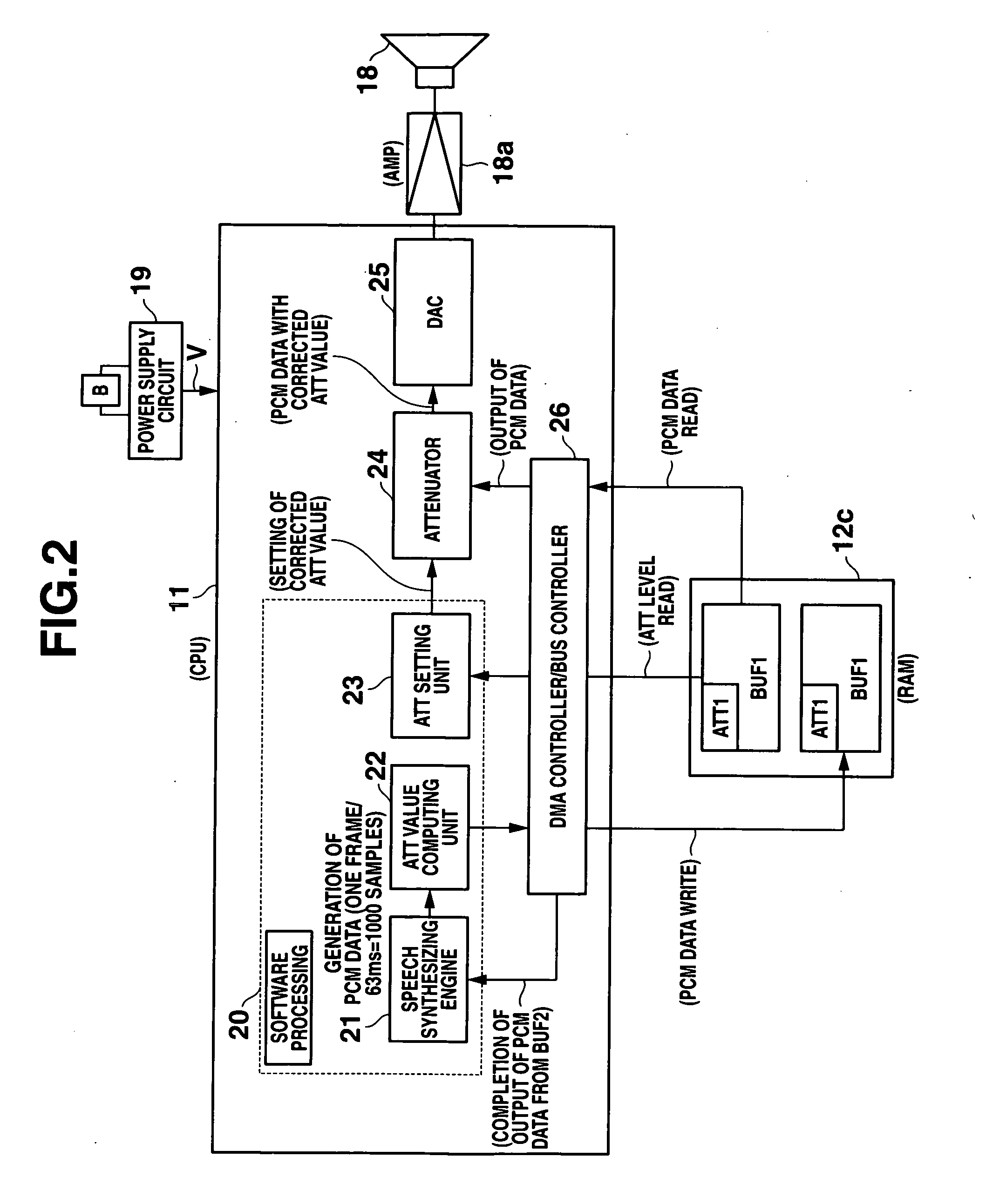

Speech output control device and recording medium recorded with speech output control programs

ActiveUS20060247920A1Easy to hearSupply voltage controlSpeech analysisUltrasound attenuationElectricity

While the amplification factor of an external amplifier is increased to raise the minimum volume level, synthesized speech of text data is generated as PCM data. When the PCM data is output for each frame (63 ms), the voltage of a battery power supply is detected and different ATT values (attenuation ratios) are set in accordance with threshold values (Level 1˜4) corresponding to the detected voltage. The lower the power supply voltage, the larger the attenuation ratios. The PCM data is attenuated by such an attenuation ratio to reduce a load to the battery power supply. Even though the battery power supply is exhausted to some extent, no power-down due to an instantaneous increase in power load occurs, with the result that a high-level part of a series of speech data items is output at an adequate volume level that makes a low-level part thereof easy to hear.

Owner:CASIO COMPUTER CO LTD

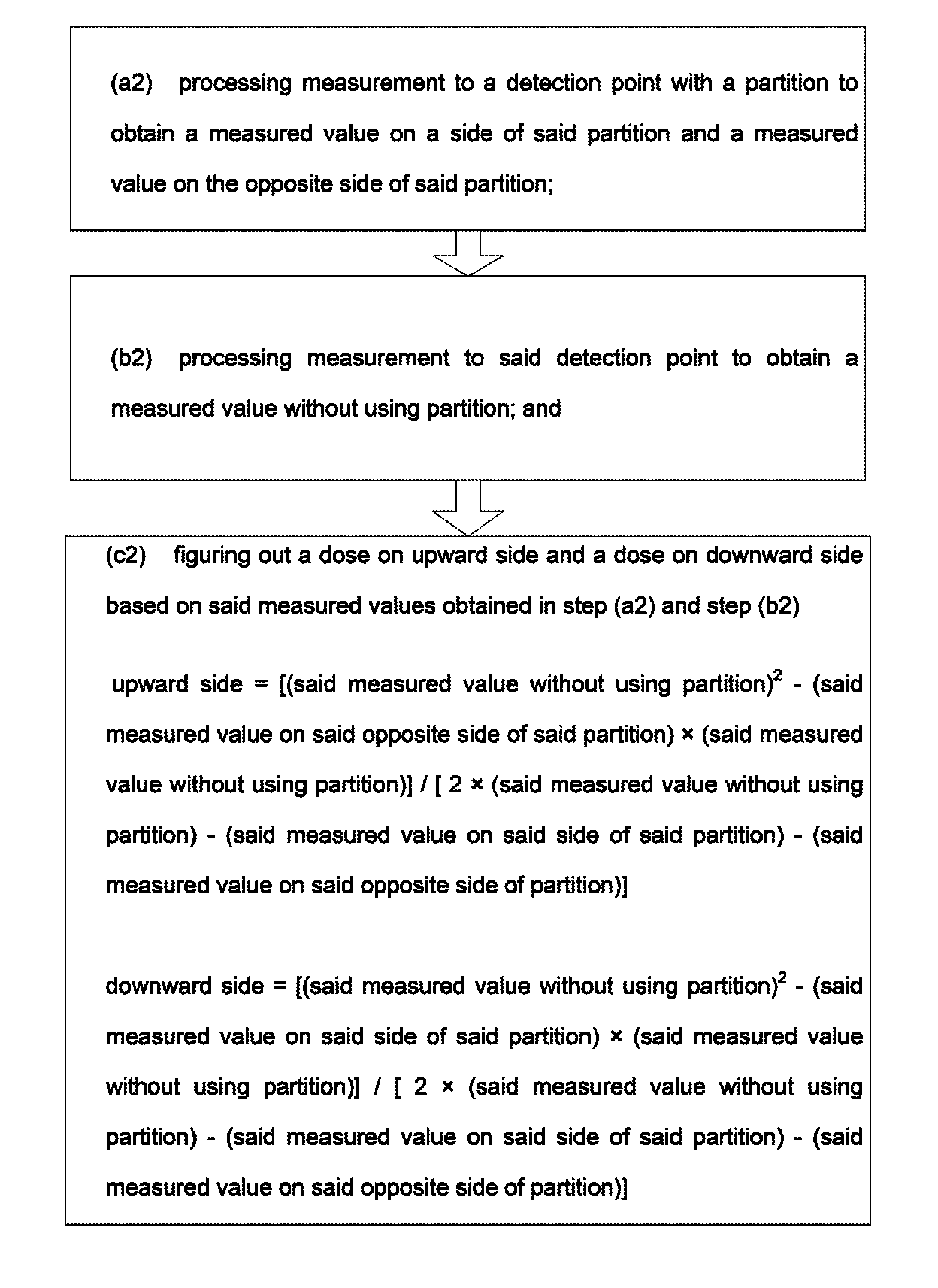

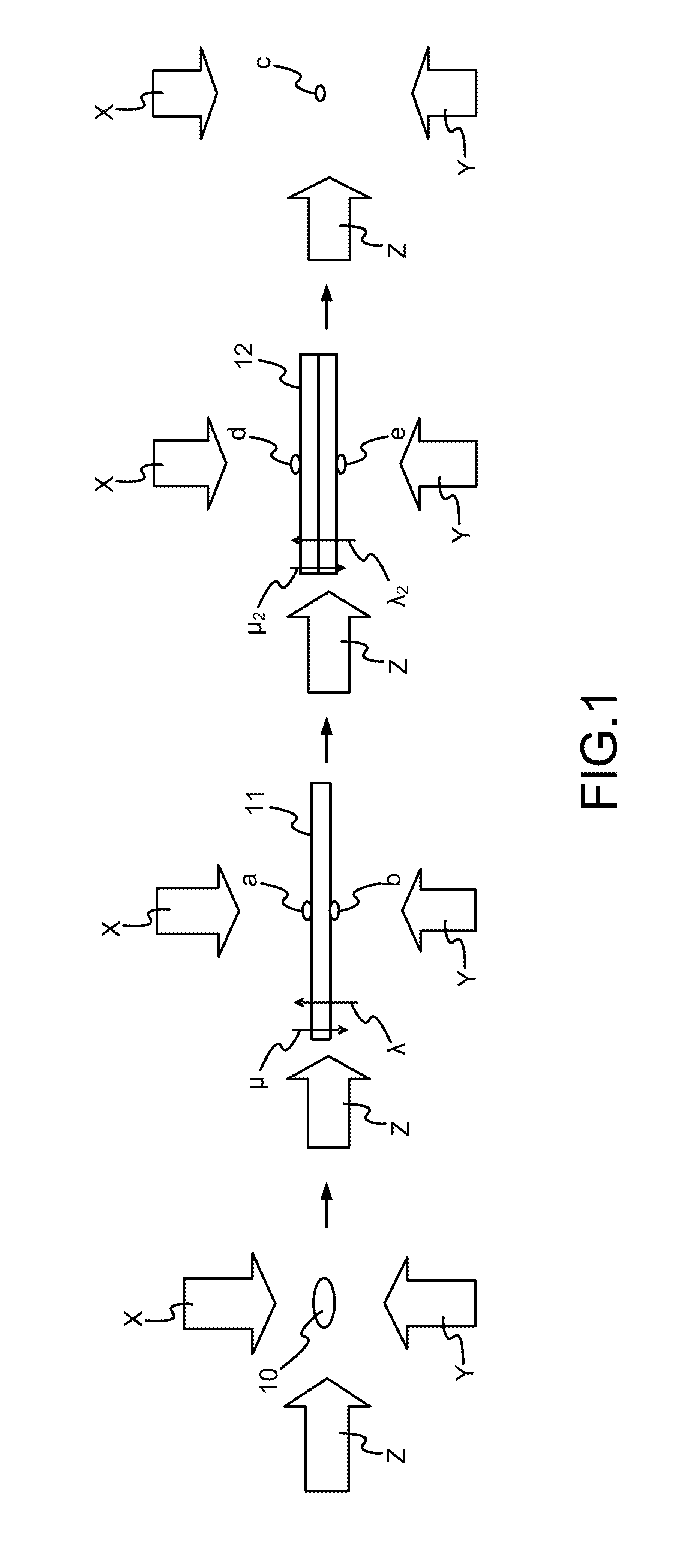

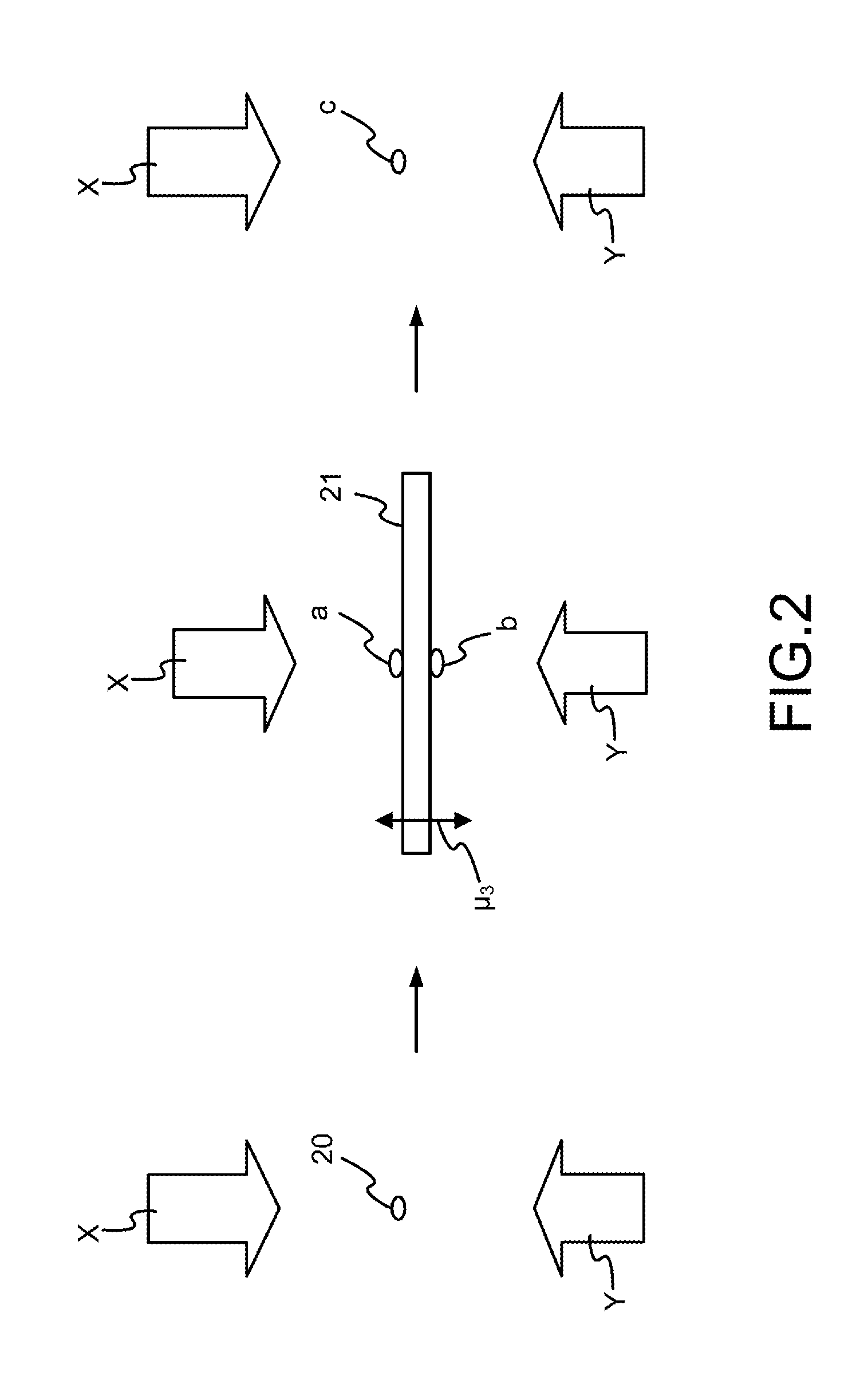

Method of measuring radiation doses on different directions

The present disclosure measures radiation doses on different directions. A partition is used, which has a certain attenuation ratio. With the partition, radiation doses on different directions can be determined without knowing the thickness or material of the partition.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Gallium doped solar silicon wafer and production process thereof

InactiveCN101805923AUniform horizontalUniform longitudinal resistivityPolycrystalline material growthFinal product manufactureAttenuation ratioSingle crystal

The invention relates to a gallium doped solar silicon wafer which is characterized by comprising the following raw materials by weight: 50-80kg of protogenesis polycrystalline silicon and 0.5-2g of 7N high purity gallium. The invention has the advantages that: firstly, a gallium doped solar silicon single crystal rod produced in the invention has uniform transfers and longitudinal resistivity, and the resistance range can be controlled to be 1-4 ohm cm; secondly, the unevenness of central resistance of the head and the tail of the silicon single crystal rod is less than 25 percent; thirdly, the photoinduced attenuation ratio of the monocrystalline silicon piece is generally less than 1 percent; and fourthly, the average photoelectric conversion efficiency is more than 17.4 percent.

Owner:ZHEJIANG XINNENG PHOTOVOLTAIC TECH CO LTD

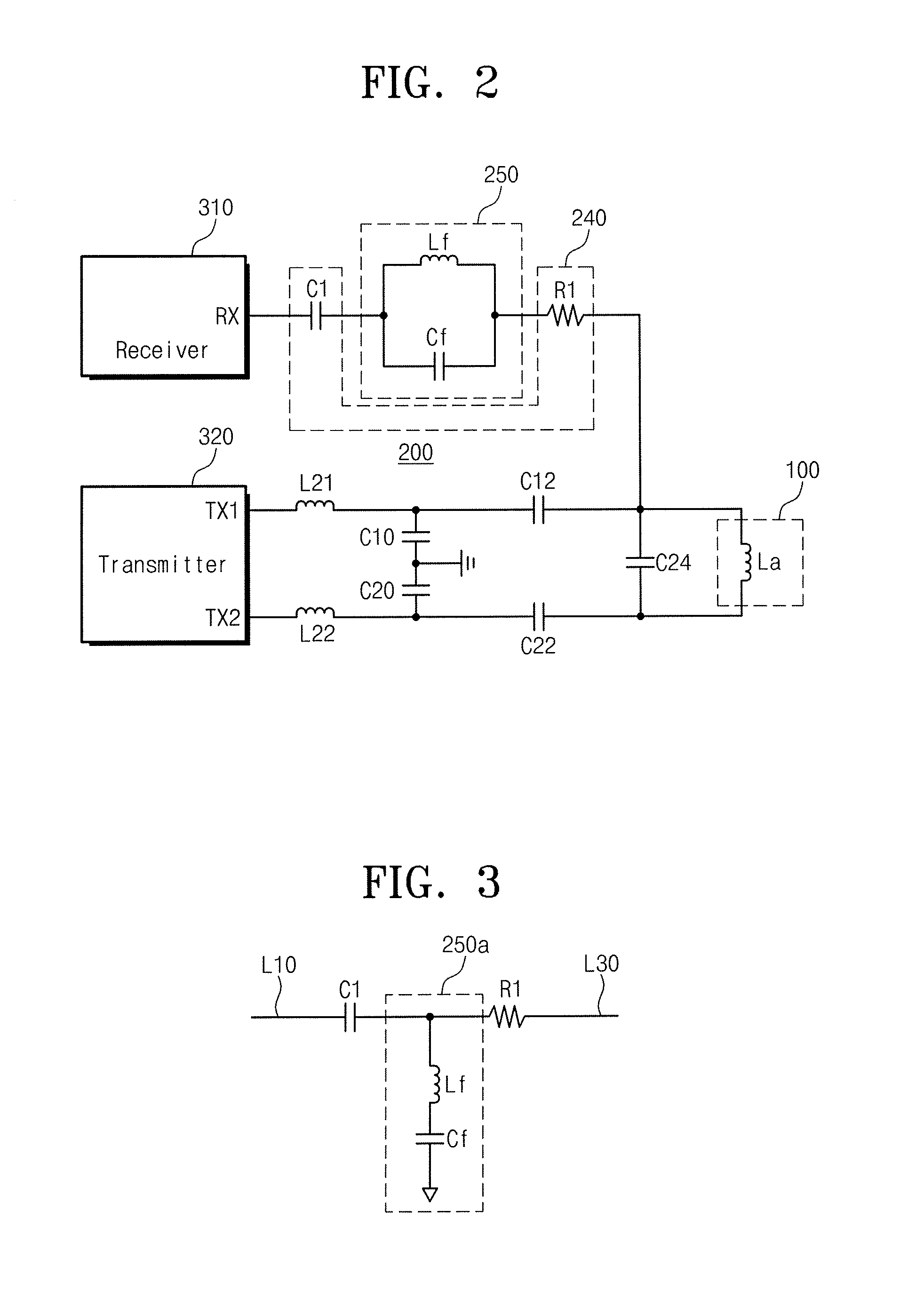

Data transceiver device and receiving method for near field communication

A data transceiver device for near field communication is provided which includes a matching and filtering circuit connected between an antenna and a transceiver and configured to conduct filtering and impedance matching for a reception signal and a transmission signal. The matching and filtering circuit includes a variable attenuator of which the impedance varies with a frequency so that an attenuation ratio of the reception data is smaller than that of the reception carrier signal.

Owner:SAMSUNG ELECTRONICS CO LTD

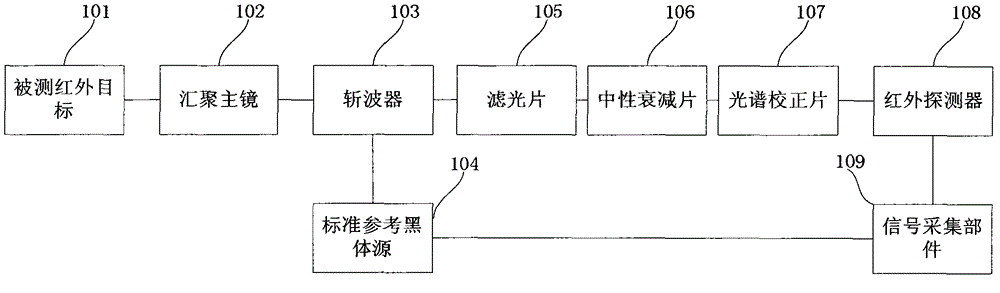

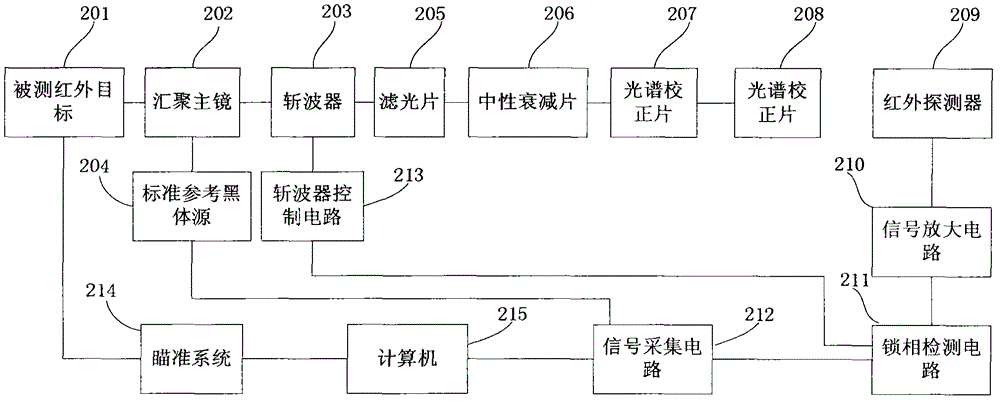

External field type infrared radiometer

The invention relates to the technical field of optical tests, in particular to an external field type infrared radiometer. According to the infrared radiometer, a main convergence mirror is connected with a wave chopper; the wave chopper is connected with a standard reference black body source and light filters; the light filters are connected with neutral attenuation pieces; the neutral attenuation pieces are connected with optical spectrum correcting pieces; the optical spectrum correcting pieces are connected with an infrared detector; a signal acquisition part is connected with the infrared detector and the wave chopper respectively. Through the embodiment, a corresponding optical spectrum curve of a whole system in a measurement waveband can be enabled to be a flat curve through the optical spectrum correcting piece, the linearity and the measurement accuracy of the whole system are improved, and the influence of a radiation spectrum of a tested object on a measurement structure is avoided; the neutral light filters with different attenuation ratios are adopted and the dynamic range of equipment is expanded. Therefore, the equipment has a plurality of ranges and strong and weak radiation targets can be measured.

Owner:BEIJING ZHENXING METROLOGY & TEST INST

High frequency amplifier circuit permitting variable gain control

InactiveUS7257382B2Reduce noise figureAmplifier modifications to reduce non-linear distortionPower managementUltrasound attenuationAudio power amplifier

The present invention is an amplifier circuit that permits variable gain control, comprising an input terminal to which a high frequency input signal is supplied; an amplifier transistor to the gate of which the high frequency input signal supplied to the input terminal is supplied and which generates an amplified signal at the drain side; and a variable attenuator provided in a signal transmission line between the input terminal and the gate of the amplifier transistor, in which a plurality of attenuation units in which an attenuation capacitor and a switch transistor are serially connected are provided in parallel between the signal transmission line and a power supply, and the attenuation ratio of which is variably controlled by controlling the conduction of the switch transistor.

Owner:FUJITSU LTD

Spring manufacturing process

The invention relates to a spring manufacturing process. The spring manufacturing process comprises the following steps of: reeling a spring, namely reeling a steel wire according to a rotating direction, a preset height, an outer diameter and the number of turns, and tightly compressing the two ends of the spring; tempering, namely putting the spring into a tempering furnace for stress relief tempering; grinding end surfaces, namely grinding the two end surfaces of the spring flatly, wherein the grinding angle is more than 300 degrees; performing shot-blasting for three times, wherein a first-time shot-blasting diameter is greater than a second-time shot-blasting diameter, and the second-time shot-blasting diameter is greater than a third-time shot-blasting diameter; performing creep deformation tempering, compressing the spring to ensure that a positioning length is reached, fixing on a fixture, putting the fixture with the spring into the tempering furnace, preserving the heat, and performing water cooling immediately to reach room temperature after a discharging process; washing; demagnetizing; and performing rust-proof treatment. By the spring manufacturing process, the spring has long service life and is low in thermal attenuation ratio under high stress; and the technical problems of short service life and high thermal attenuation ratios of springs under the high stress existing in the prior art are solved.

Owner:HANGZHOU FUCHUN SPRING

Image processing apparatus, image processing method, and storage medium of image processing program

InactiveUS7277557B2Prevent degradationCharacter and pattern recognitionSecret communicationPattern recognitionImaging processing

A pattern generating section forms two patterns based on a pattern size, an embedding strength, and a pattern attenuation ratio. When corresponding pixels in two patterns are added to each other, all of elements become zero. When all of pixels in each of patterns are added to each other, the added pixels become zero. Each of patterns has two edges, which include discontinuous pixel values and pass through a center portion of each of patterns in difference directions from each other. Absolute values of pixel values of the patterns are the largest at a center thereof. The absolute values of pixel values of the patterns decrease as being away from the center thereof. A pattern selecting section selects one of the two patterns in response to additional information. A pattern superimposing section superimposes the additional information on the image data to embed it into the image data.

Owner:FUJIFILM BUSINESS INNOVATION CORP

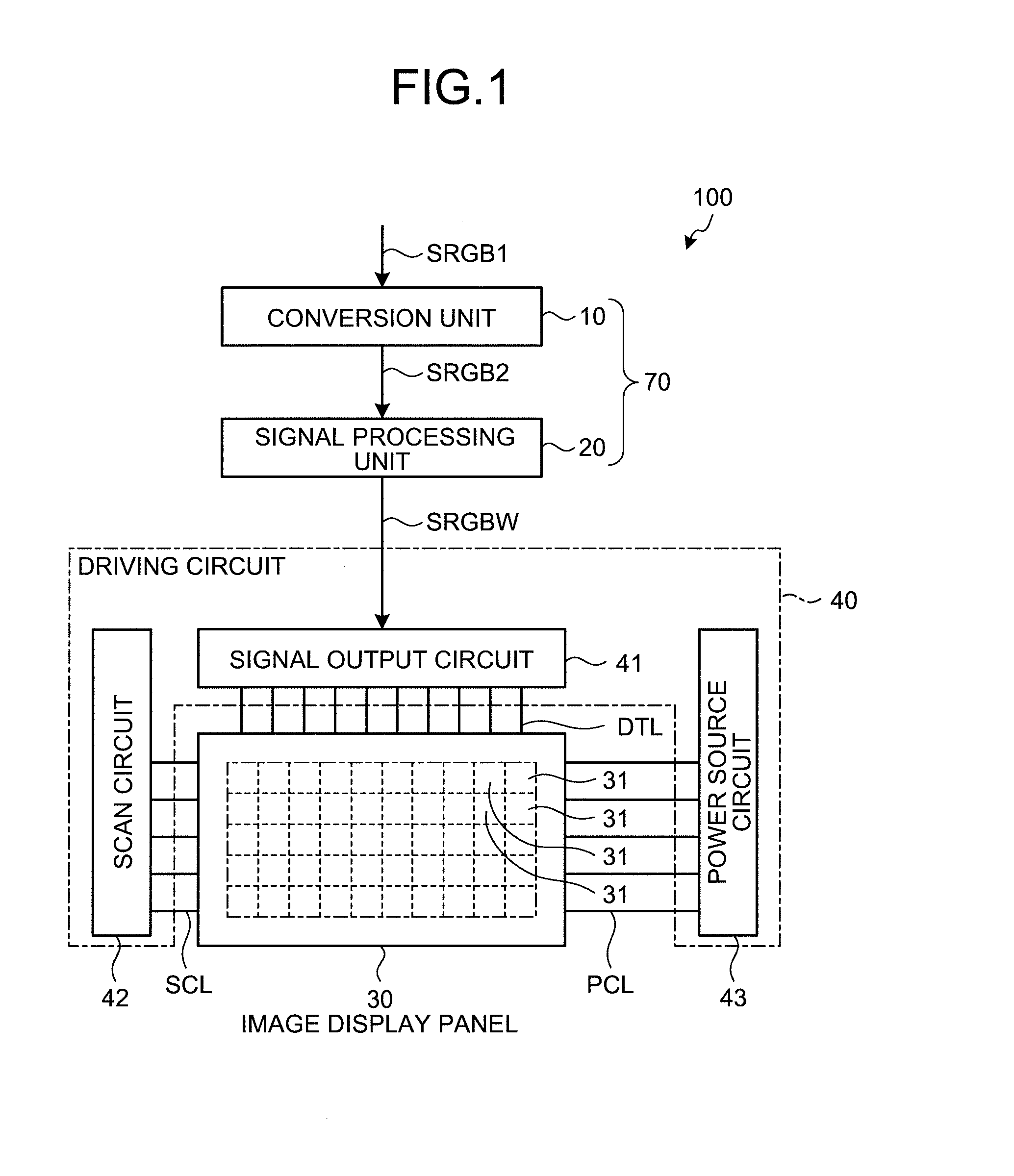

Image processing device, display device, electronic device and method for processing an image

ActiveUS20150109356A1Reduce power consumptionDecrease in luminanceCathode-ray tube indicatorsInput/output processes for data processingImaging processingAttenuation ratio

An image processing device comprising: a conversion unit to receive a first input signal including first color information, a first color being reproduced at pixels on the basis of the first color information, the first input signal including first color information obtained from an input image signal corresponding to a red component, a green component and a blue component, to specify saturation of the first color, and configured to obtain luminance attenuation ratio on the basis of a relationship previously stored between saturation and luminance attenuation ratio, and the saturation of the first color, and to output a second input signal including second color information whose luminance is decreased from the first color information on the basis of the luminance attenuation ratio corresponding to the first color information; and a signal processing unit configured to output an output signal for driving the pixels on the basis of the second input signal.

Owner:JAPAN DISPLAY INC

Signal-to-interference ratio estimation

ActiveUS20060092905A1Reduced signal powerAmplitude-modulated carrier systemsTransmission monitoringChannel powerAttenuation ratio

In a method of estimating a signal-to-interference ratio (SIR), a first average channel power per slot of a first channel that is under a fading environment is estimated. A second average channel power per slot of a second channel that is under a fading environment substantially the same as the first channel is estimated, wherein the first and second channels are multiplexed. A second signal power attenuation ratio of the second channel is calculated using the second average power per slot of the second channel. A third average power per slot of the first channel is calculated using the first average power per slot of the first channel and a reciprocal of the second signal power attenuation ratio of the second channel.

Owner:SAMSUNG ELECTRONICS CO LTD

Developing device and an image forming apparatus including the same

ActiveUS7027761B2Enhanced magnetic forceReduce manufacturing costPermanent magnetsElectrographic process apparatusImage formationAttenuation ratio

A developer carrier for an SLIC developing system includes a developing sleeve and a magnetic roll having a plurality of magnetic poles. A narrow development nip is formed by narrowing the width of a development pole forming a magnet brush and by narrowing a developer rising region in a developing region where a flux density attenuation ratio of the development pole is 40% or more. A half-value width of the flux density of the development pole is 22° or less and the flux density variation rate is 4.0 mT / Deg or more in a circumferential direction in a part where the flux density in at least half of that of a downstream side of a developer carrying direction from a peak magnetic force position of the development pole is 90% or less.

Owner:RICOH KK

Display unit brightness correcting method

ActiveCN102376292AImprove compatibilityEasy to implementCathode-ray tube indicatorsAttenuation ratioControl software

The invention provides a display unit brightness correcting method. According to the invention, the method comprises the following steps of: (S1) outputting an all white test chart and observing the all white test chart; (S2) adjusting edge brightness attenuation ratio and central point offset positions of red, green and blue colors; (S3) generating an observing image according to the adjusted edge attenuation ratio of the red, green and blue colors and central point offset of the red, green and blue colors; (S4) comparing whether the effect of an observation chart generated by PC control software is consistent with the effect displayed by the display unit or not; and if so, executing the step 5; and if not so, continuing to execute the step 2; (S5) figuring out the compensation factor ofeach pixel point; and (S6) compensating the value of each pixel point of an input signal according to the compensation factor. According to the invention, the defects of high cost in correcting and debugging the brightness of the display unit, inconvenience for engineer to carry the instrument, difficulties in operation and difference between the debugging effect and human naked eye observation effect in the prior art are overcome.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

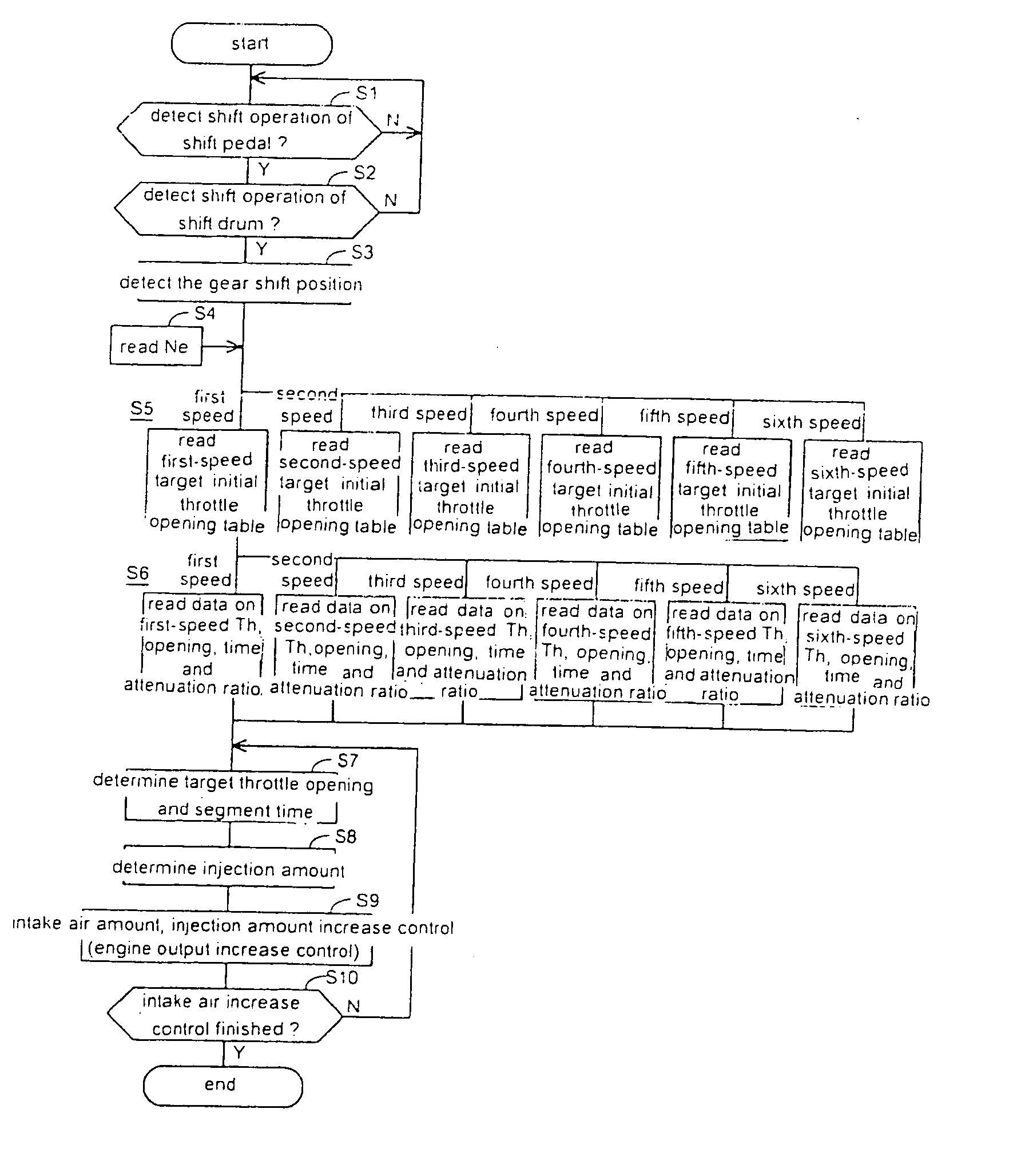

Transmission control device of motorcycle

ActiveUS20060068975A1Smooth transmissionSmooth changeElectrical controlInternal combustion piston enginesStart timeAttenuation ratio

A transmission control device for a vehicle for smoothly performing a transmission manipulation without a clutch manipulation. The transmission control device includes a control unit which determines a shift operation starting time based on a detection signal of a shift operation detector, and controls an intake air amount to an engine corresponding to a gear shift position which is detected by a gear shift position detection means whereby an output of the engine is changed smoothly. For example, the control unit obtains a target initial throttle opening corresponding to the gear shift position from a target initial throttle opening table, obtains data on throttle opening, time and an attenuation ratio corresponding to the gear shift position from a throttle opening, time and attenuation ratio table, and determines the opening time and the target throttle opening. Next, the control unit determines an injection amount and executes a control to increase the intake air amount and the injection quantity.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com