Method for improving quality of waste concrete recycled aggregate by using sodium carbonate solution

A technology of waste concrete and recycled aggregate, which is applied in the direction of solid waste management, sustainable waste treatment, and climate sustainability. Effects of cost reduction, solution to processing difficulties, and improvement of apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

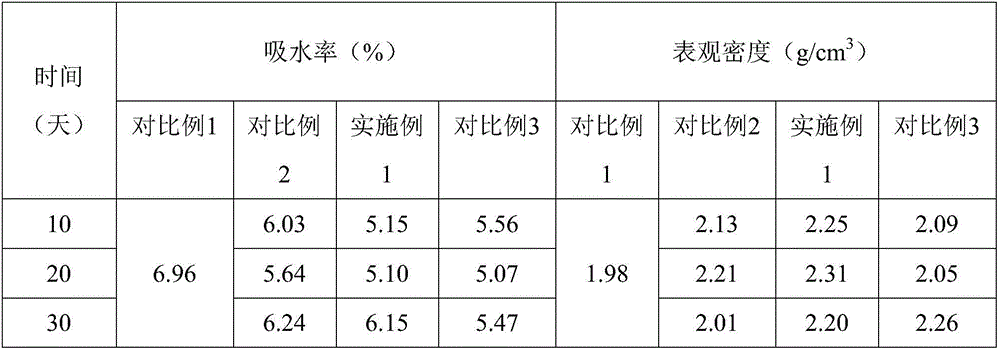

[0021] Example 1 Utilize the mass concentration of 6% sodium carbonate solution to repair waste concrete recycled aggregate

[0022] The waste concrete recycled aggregate was soaked in 6% sodium carbonate solution for 10, 20 and 30 days, and then the water absorption and apparent density of the waste concrete recycled aggregate were tested according to the relevant standards.

Embodiment 2

[0024] A kind of method utilizing sodium carbonate solution to improve the quality of waste concrete regenerated aggregate comprises the following steps:

[0025] Using Na with a mass concentration of 4% 2 CO 3 The aqueous solution soaks the recycled aggregate of waste concrete, and the soaking repair time is 25 days.

[0026] After testing, using 4% Na 2 CO 3 After immersing waste concrete recycled aggregates in aqueous solution, compared with recycled aggregates that were not treated with sodium carbonate solution, the water absorption rate was significantly reduced and the apparent density was significantly increased.

Embodiment 3

[0028] A kind of method utilizing sodium carbonate solution to improve the quality of waste concrete regenerated aggregate comprises the following steps:

[0029] Using Na with a mass concentration of 8% 2 CO 3 The aqueous solution soaks the recycled aggregate of waste concrete, and the soaking repair time is 15 days.

[0030] After testing, using 8% Na 2 CO 3 After immersing waste concrete recycled aggregates in aqueous solution, compared with recycled aggregates that were not treated with sodium carbonate solution, the water absorption rate was significantly reduced and the apparent density was significantly increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com