Resource recycling process and system for high-temperature plasma of chlorine-containing waste

A plasma and resource recovery technology, applied in the field of plasma resource recovery process and system, can solve the problems of increased waste treatment cost, large amount of fly ash, large consumption of deacidification agent, etc., to achieve resource recovery and utilization, heat High recovery efficiency and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

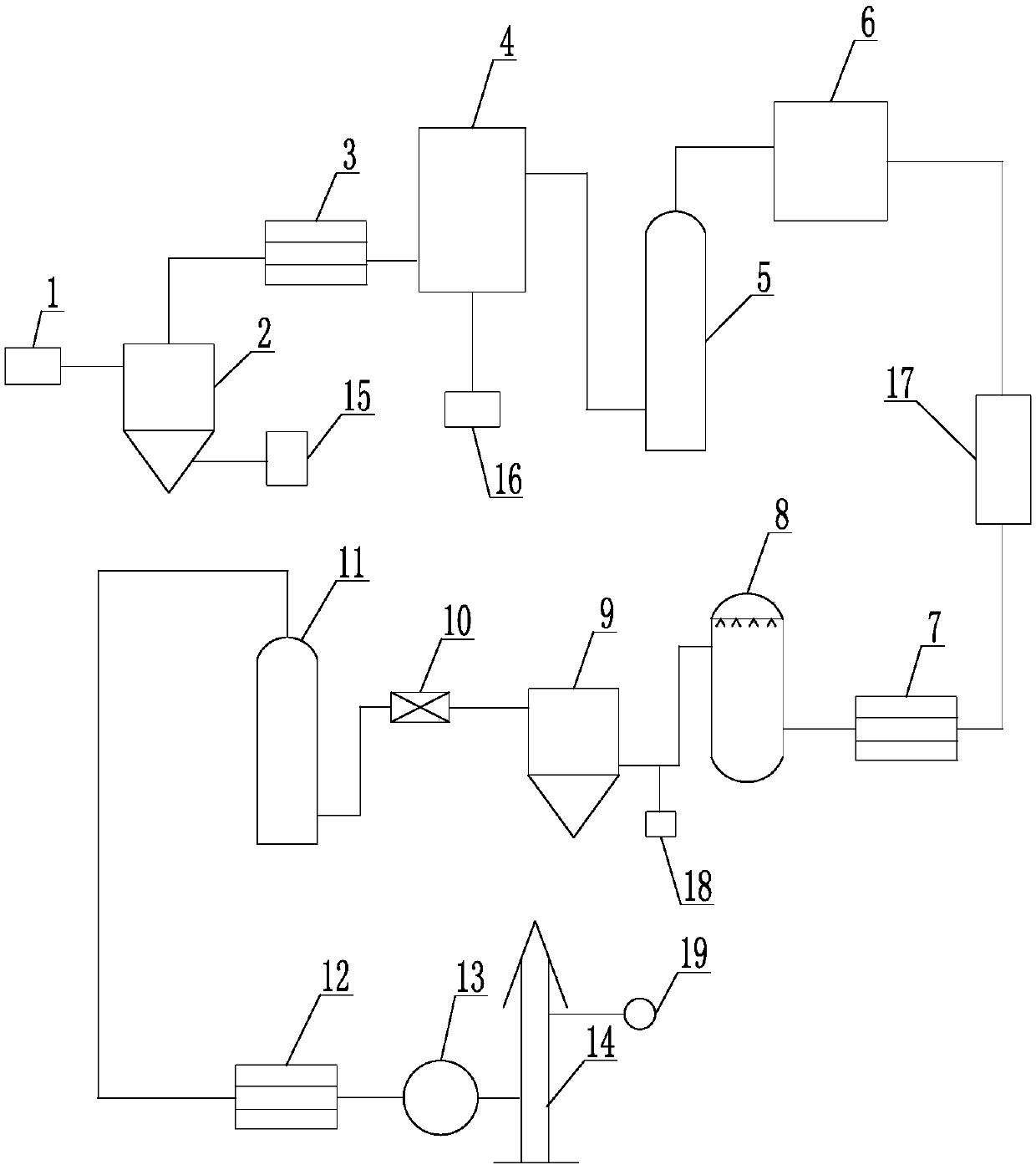

[0063] Such as figure 1 As shown, the system used in the high-temperature plasma recycling process of chlorine-containing wastes includes a sequentially connected feed system 1, plasma gasification furnace 2, primary waste heat exchanger 3, acid absorption system 4, alkali washing Tower 5, secondary combustion chamber 6, secondary waste heat exchanger 7, quench cooler 8, bag filter 9, flue heater 10, SCR catalytic tower 11, heat exchanger 12, induced draft fan 13 and chimney 14.

[0064] The slag outlet of the plasma gasification furnace 2 is also connected with a cooling device 15 .

[0065] The acid absorption system 4 is a circulating water absorption system, and the acid absorption system 4 is also connected with an acid filtering device 16 .

[0066] The rear flue of the second combustion chamber 6 is provided with an SNCR denitrification device 17 .

[0067] Activated carbon and sodium bicarbonate injection device 18 are arranged on the pipeline between quench cooler 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com