General method for preparing spherical porous metal oxide

A technology of porous metals and general methods, applied in chemical instruments and methods, preparation of oxides/hydroxides, chemical/physical processes, etc., can solve the problem of reducing the specific surface area of materials, affecting the specific properties of active components, porous metal oxides There are few reports on the preparation of large spheres, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

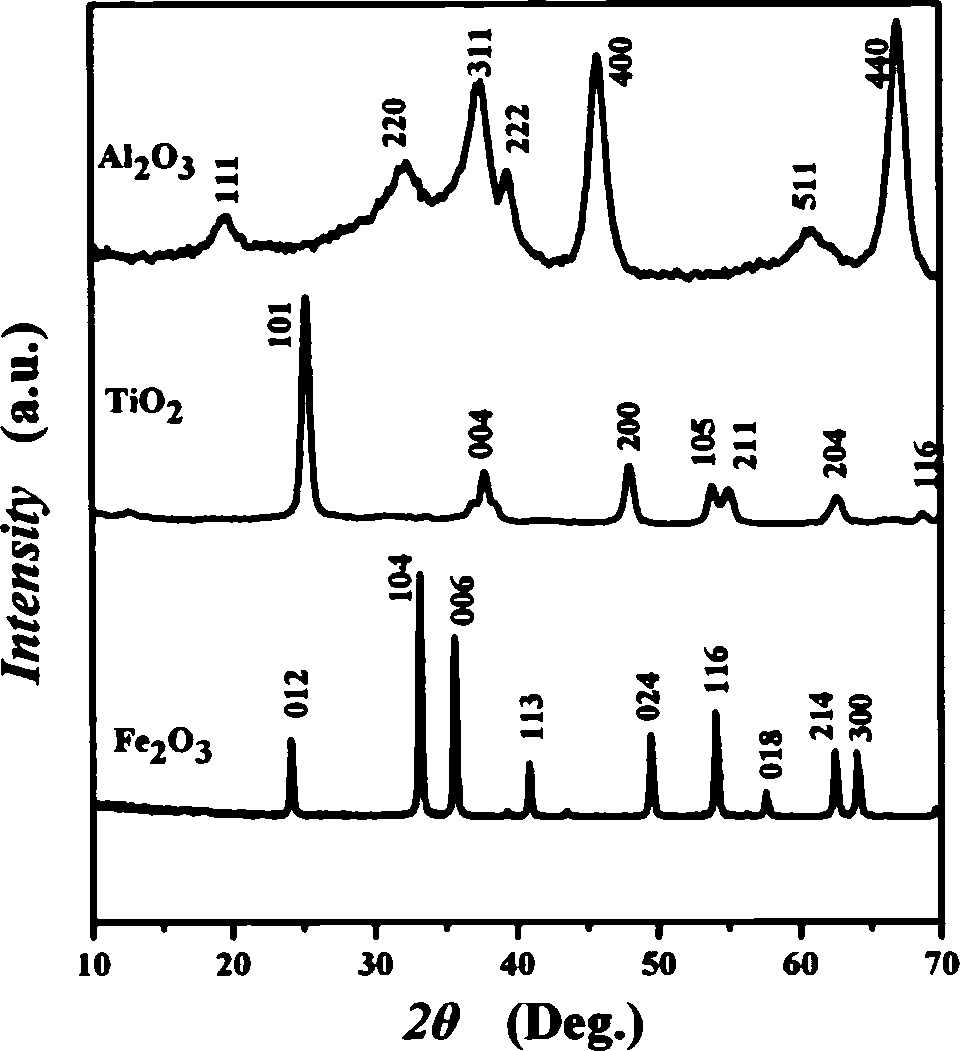

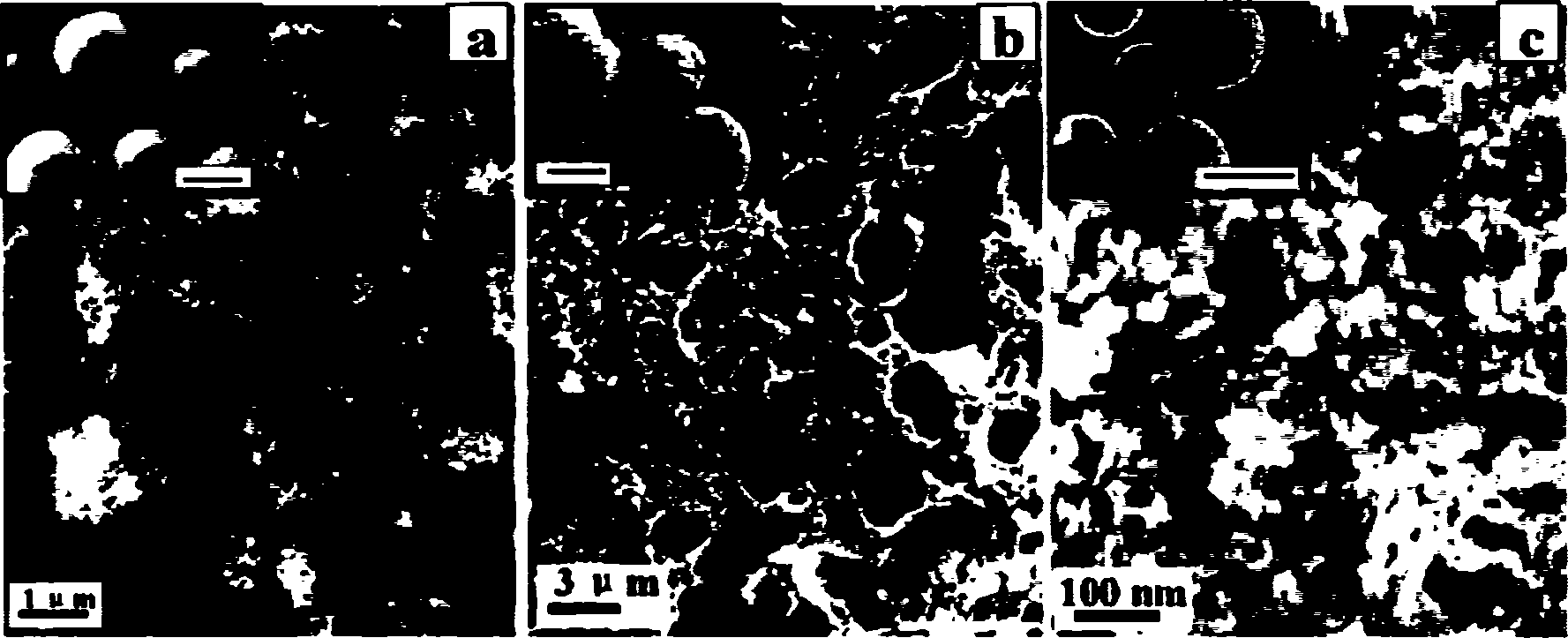

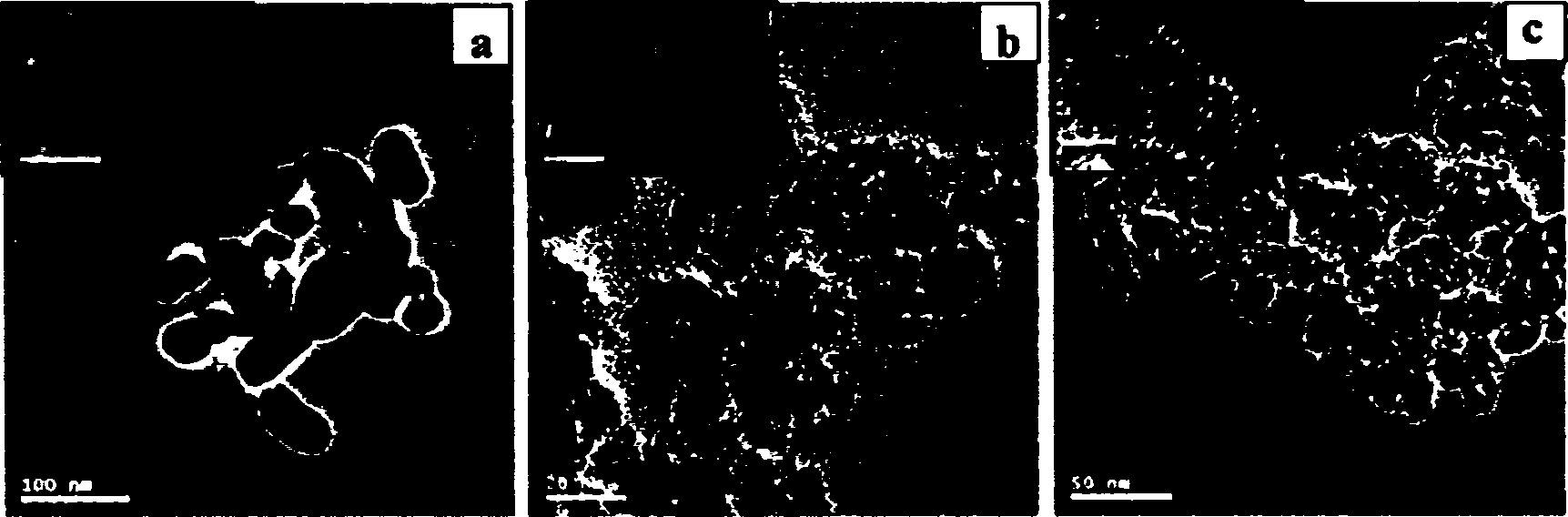

[0027] Add 10g of commercially available cation exchange resin D072 with a particle size of 500~700μm and 60mL of 10% ferrous chloride solution into the container, stir at room temperature for 8 hours to allow the resin to fully ion exchange, then filter and wash with distilled water until the filtrate is in the middle Sex; Add excess lye to the resin, stir at room temperature for 8 hours, filter, and wash with distilled water until the filtrate is neutral to obtain a resin-iron hydroxide composite. Place the composite in a 120℃ oven to dry for 2 hours, then transfer it to a muffle furnace, heat it up to 400℃ at a heating rate of 5~10℃ / min, keep it for 1 hour, continue to raise it to 550℃, keep it for 6 hours, turn off the power , Take it out after cooling to room temperature, and get porous metal iron oxide spheres with a diameter of 300~450μm and a specific surface area of 20.5m 2 / g, the pore volume is 0.26cm 3 / g, pore size distribution is 0.1~1.5μm and 2~16nm, apparent dens...

Embodiment 2

[0029] Add 10 g of a commercially available cation exchange resin D072 with a particle size of 500-700 μm and 70 mL of 10% aluminum nitrate solution to the container, stir at room temperature for 8 hours to fully ion exchange the resin, then filter, and wash with distilled water until the filtrate is neutral; Add excess lye to the resin, stir for 8 hours at room temperature, and filter to obtain a resin-aluminum hydroxide composite. Place the composite in an oven at 120°C to dry for 2 hours, then transfer it to a muffle furnace, heat it up to 800°C at a heating rate of 5-10°C / min, keep it warm for 6 hours, turn off the power supply, and take it out after cooling to room temperature. Large porous metal alumina ball with a diameter of 220~380μm and a specific surface area of 92.7m 2 / g, the pore volume is 0.23cm 3 / g, pore size distribution is 2~200nm, apparent density is 2.08g / cm 3, It is composed of 6-20nm pure γ-type alumina crystals.

Embodiment 3

[0031] Add 10g of a commercially available cation exchange resin D072 with a particle size of 500-700μm and 50mL of 10% titanium sulfate solution to the container, stir at room temperature for 8 hours to allow the resin to fully ion exchange, then filter and wash with distilled water until the filtrate is neutral; Add excess lye to the resin, stir at room temperature for 8 hours, filter, and wash with distilled water until the filtrate is neutral to obtain a resin-titanium hydroxide composite. Place the composite in an oven at 120°C to dry for 2 hours, then transfer it to a muffle furnace, heat it up to 600°C at a heating rate of 5-10°C / min, keep it warm for 6 hours, turn off the power supply, and take it out after cooling to room temperature. Large porous metal iron oxide sphere with a diameter of 350~500μm and a specific surface area of 173.5m 2 / g, the pore volume is 0.77cm 3 / g, the pore size distribution is 0.2~3.0μm and 2~20nm, the apparent density is 0.98g / cm 3 , Compose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com