Graphene oxide concrete

A graphene and concrete technology, applied in the field of concrete, can solve the problems of cement matrix strength loss, poor dispersion of graphene oxide, etc., and achieve the effect of reducing pores, uniform and dense gel, and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

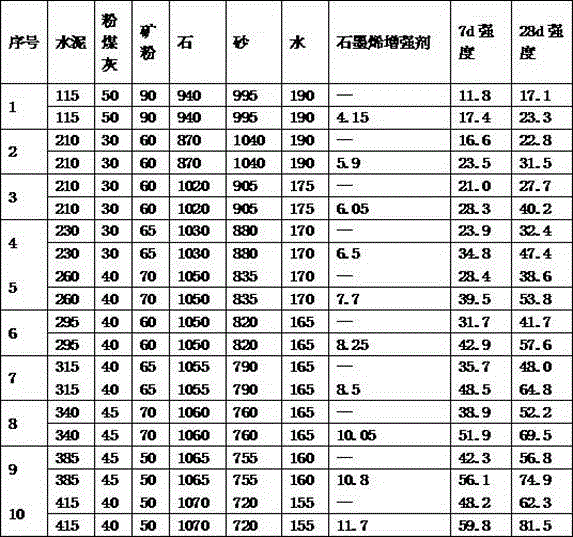

Examples

Embodiment 1

[0029] Graphene reinforcement for graphene oxide concrete:

[0030] (1) Take 10% water-reducing component, 12% slump-preserving component, 3.2% sodium gluconate, 8% graphene oxide, 0.4% stabilizer polyvinylpyrrolidone, and 66% deionized water;

[0031] Wherein, the water-reducing component includes: 30% methyl alkenyl polyoxyethylene ether, 3% acrylic acid, 67% deionized water by weight percentage;

[0032] Wherein, the slump-preserving component includes by weight percentage: 25% allyl polyoxyethylene ether, 10% maleic anhydride, 1% acrylic acid, 5% ethylene glycol diacrylate, 59% deionized water;

[0033] (2) Add the water-reducing component and the slump-preserving component into deionized water, stir well and set aside;

[0034] (3) Add sodium gluconate, stir and mix, then add sodium hydroxide to adjust the pH value to 7.0, then add graphene oxide that has been ultrasonically treated at 20KHz for 3 hours, stir and mix, and finally slowly add stabilizer polyvinylpyrrolidon...

Embodiment 2

[0036] Graphene reinforcement for graphene oxide concrete:

[0037] (1) Take 14% water-reducing component, 18% slump-preserving component, 3.6% sodium gluconate, 12% graphene oxide, 0.6% stabilizer polyvinylpyrrolidone, and 51% deionized water;

[0038] Wherein, the water-reducing component includes: 35% methyl alkenyl polyoxyethylene ether, 4% acrylic acid, 61% deionized water by weight percentage;

[0039] Wherein, the slump-preserving component includes by weight percentage: 30% allyl polyoxyethylene ether, 15% maleic anhydride, 3% acrylic acid, 8% ethylene glycol diacrylate, 44% deionized water;

[0040] (2) Add the water-reducing component and the slump-preserving component into deionized water, stir well and set aside;

[0041] (3) Add sodium gluconate, stir and mix, then add sodium hydroxide to adjust the pH value to 7.0, then add graphene oxide that has been ultrasonically treated at 20KHz for 3 hours, stir and mix, and finally slowly add stabilizer polyvinylpyrrolido...

Embodiment 3

[0043] Graphene reinforcement for graphene oxide concrete:

[0044] (1) Take 12% water-reducing component, 16% slump-preserving component, 3.4% sodium gluconate, 10% graphene oxide, 0.5% stabilizer polyvinylpyrrolidone, and 58.1% deionized water;

[0045] Wherein, the water-reducing component includes by weight percentage: 33% methyl vinyl polyoxyethylene ether, 3.5% acrylic acid, 63.5% deionized water;

[0046] Among them, the slump-preserving component includes: 27% allyl polyoxyethylene ether, 12% maleic anhydride, 2% acrylic acid, 6% ethylene glycol diacrylate, 53% deionized water in terms of weight percentage;

[0047] (2) Add the water-reducing component and the slump-preserving component into deionized water, stir well and set aside;

[0048](3) Add sodium gluconate, stir and mix, then add sodium hydroxide to adjust the pH value to 7.0, then add graphene oxide that has been ultrasonically treated at 20KHz for 3 hours, stir and mix, and finally slowly add stabilizer pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com