Recycled concrete with high slump loss resistance and preparation method thereof

A recycled concrete and slump-retaining technology, applied in the field of building materials, can solve the problems of high porosity, high water absorption, and reduced workability, and achieve the effects of improving dispersion performance, increasing slump, and reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

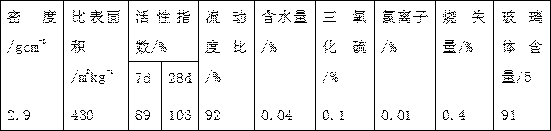

Image

Examples

Embodiment 1

[0033] A method for preparing recycled concrete with high slump retention, comprising the steps of:

[0034] S1: Stir 180 parts by weight of cement, 380 parts of modified recycled coarse aggregate, 400 parts of crushed stone, 680 parts of natural sand, 90 parts of fly ash, and 65 parts of mineral powder, and mix evenly;

[0035] The treatment method of modified recycled coarse aggregate is to place the crushed coarse aggregate in a water glass solution with a concentration of 3%, soak for 4 hours, and then add the recycled coarse aggregate to a solution of 8% polyvinyl alcohol with a concentration of Continue soaking in the mixed emulsion of 4% silane emulsion for 8h, the weight ratio of polyvinyl alcohol solution and silane emulsion is 1.0;

[0036] S2: Add 4.2 parts by weight of polycarboxylate superplasticizer and 3.5 parts of slump-retaining enhancer to 156 parts of water, and mix evenly; the slump-retaining enhancer is a mixture of BTC-2 and BTC500, BTC-2 and BTC500 The ...

Embodiment 2

[0039]A method for preparing recycled concrete with high slump retention, comprising the steps of:

[0040] S1: Stir 200 parts by weight of cement, 440 parts of modified recycled coarse aggregate, 450 parts of crushed stone, 750 parts of natural sand, 110 parts of fly ash, and 81 parts of mineral powder, and mix evenly;

[0041] The treatment method of modified recycled coarse aggregate is to place the crushed coarse aggregate in a water glass solution with a concentration of 5%, soak for 7 hours, and then add the recycled coarse aggregate to a 10% polyvinyl alcohol solution with a concentration of Continue soaking in the mixed solution of 7% silane emulsion for 10h, wherein the weight ratio of polyvinyl alcohol solution to silane emulsion is 1.3;

[0042] S2: Add 5.0 parts by weight of polycarboxylate superplasticizer and 5.0 parts of slump-retaining enhancer to 170 parts of water, and mix evenly; The weight ratio is 1:1

[0043] S3: Add the mixed liquid in step S2 to step ...

Embodiment 3

[0045] A method for preparing recycled concrete with high slump retention, comprising the steps of:

[0046] S1: Stir 220 parts by weight of cement, 490 parts of modified recycled coarse aggregate, 500 parts of crushed stone, 820 parts of natural sand, 130 parts of fly ash, and 98 parts of mineral powder, and mix evenly;

[0047] The treatment method of modified recycled coarse aggregate is to place the crushed coarse aggregate in a water glass solution with a concentration of 7%, soak for 9 hours, and then add the recycled coarse aggregate to a 12% polyvinyl alcohol solution with a concentration of The mixed solution of 10% silane emulsion continued to soak for 12h, wherein the weight ratio of polyvinyl alcohol solution to silane emulsion was 1.5;

[0048] S2: Add 5.8 parts by weight of polycarboxylate superplasticizer and 6.4 parts of slump-retaining enhancer to 185 parts of water, and mix evenly; The weight ratio is 1:1

[0049] S3: Add the mixed liquid in step S2 to step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com