Method for reinforcing recycled aggregate concrete by changing stirring technology

A technology of recycled aggregate and mixing process, which is applied in the field of building materials, can solve the problems affecting the durability and strength of recycled concrete, and achieve the effect of improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for changing the mixing process to strengthen recycled aggregate concrete is carried out according to the following steps:

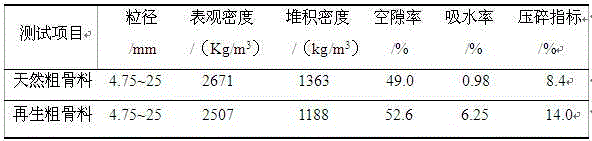

[0032] (1) The solid waste is crushed with a jaw crusher, and then screened to form recycled coarse aggregate that meets the requirements of continuous gradation of 4.75~25mm;

[0033] (2) Mix cement and 50% water, stir for 30s, add recycled coarse aggregate, stir for 30s, then add natural coarse and fine aggregates and stir for 30s, finally add 50% water and stir for 30s, the various materials used in the whole process are Cement 327Kg / m 3 , water 180 Kg / m 3 , coarse aggregate 1208 Kg / m 3 , fine aggregate 651 Kg / m 3 , of which the natural coarse aggregate is 906 Kg / m 3 , recycled coarse aggregate is 302 Kg / m 3 ; The slump of the material is measured to make a test block.

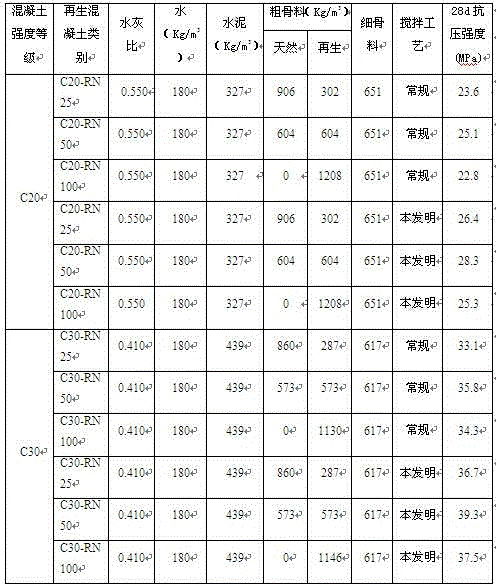

[0034] The performance comparison between the prepared C20-RN25 concrete and the concrete prepared by the conventional mixing method of the same material is show...

Embodiment 2

[0038] A method for changing the mixing process to strengthen recycled aggregate concrete is carried out according to the following steps:

[0039] (1) The solid waste is crushed with a jaw crusher, and then screened to form recycled coarse aggregate that meets the requirements of continuous gradation of 4.75~25mm;

[0040] (2) Mix cement and 50% water, stir for 30s, add recycled coarse aggregate, stir for 30s, then add natural coarse and fine aggregates and stir for 30s, finally add 50% water and stir for 30s, the various materials used in the whole process are cement 327Kg / m 3 , water 180 Kg / m 3 , coarse aggregate 1208 Kg / m 3 , fine aggregate 651 Kg / m 3 , of which the natural coarse aggregate is 604Kg / m 3 , recycled coarse aggregate is 604 Kg / m 3 ; The slump of the material is measured to make a test block.

[0041] The performance comparison between the prepared C20-RN50 concrete and the concrete prepared by the conventional mixing method of the same material is show...

Embodiment 3

[0043] A method for changing the mixing process to strengthen recycled aggregate concrete is carried out according to the following steps:

[0044] (1) The solid waste is crushed with a jaw crusher, and then screened to form recycled coarse aggregate that meets the requirements of continuous gradation of 4.75~25mm;

[0045](2) Mix cement and 50% water, stir for 30s, add recycled coarse aggregate, stir for 30s, then add natural coarse and fine aggregates and stir for 30s, finally add 50% water and stir for 30s, the various materials used in the whole process are cement 327Kg / m 3 , water 180 Kg / m 3 , coarse aggregate 1208 Kg / m 3 , fine aggregate 651 Kg / m 3 , of which the natural coarse aggregate is 0Kg / m 3 , recycled coarse aggregate is 1208 Kg / m 3 ; The slump of the material is measured to make a test block.

[0046] The performance comparison between the prepared C20-RN100 concrete and the concrete prepared by the conventional mixing method of the same material is shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com