Composite antifreezing agent and antifreezing pumping agent

A technology of antifreeze and pumping agent, applied in the field of concrete plus pumping agent, can solve the problem of not being fully suitable for preparing antifreezing pumping agent, etc., achieve good antifreeze effect, improve later strength, and prevent concrete freeze damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The compound antifreeze agent of the embodiment 1 of the present invention is the mixture that salt component and organic solvent component are mixed; Wherein, described salt component is the mixture of calcium nitrate, calcium formate and sodium thiosulfate, and described The organic solvent component is an alcohol with 1 to 3 carbon atoms. The organic solvent component adopts one kind of alcohol, or the mixture of two kinds of alcohols. A mixture of two alcohols is preferred, eg a mixture of methanol and ethylene glycol.

[0041] The mixture of calcium nitrate, calcium formate and sodium thiosulfate, and organic solvent can be applied to the liquid antifreeze pumping agent based on polycarboxylate superplasticizer.

[0042] As a preferred embodiment, the compound antifreeze is, in parts by weight, a mixture of 3 to 6.5 parts of salt components and 1 to 3 parts of organic solvent components; wherein, in the salt components, calcium nitrate 1.5 to 3 parts, 0.5 to 1 pa...

Embodiment 2

[0049] The antifreeze pumping agent of embodiment 2 of the present invention is to comprise the mixture of polycarboxylate water reducer, air-entraining agent, retarder and water, and the compound antifreeze described in the above-mentioned embodiment 1; Wherein, with antifreeze pumping Based on the total mass of the antifreeze agent, the mass percentage of the composite antifreeze agent is 6% to 10%.

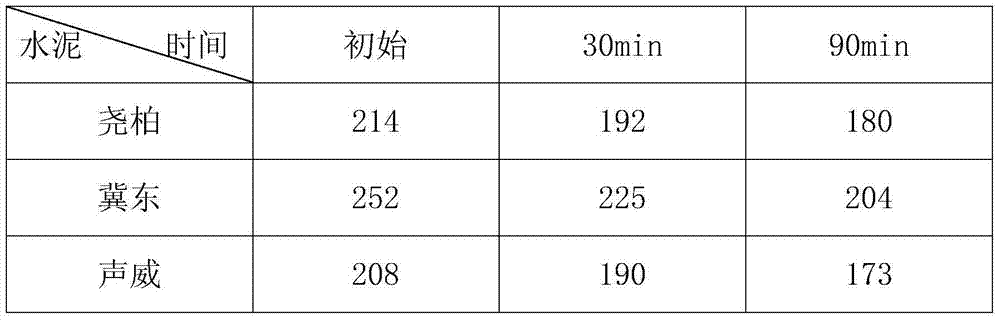

[0050] The antifreeze effect of the antifreeze pumping agent of the present invention can be achieved by adopting the proportion of the existing pumping agent based on polycarboxylate superplasticizer for other components, and the adaptability to cement is good.

[0051] Specifically, embodiment 2 of the present invention provides the prescription of preferred antifreeze pumping agent, as follows:

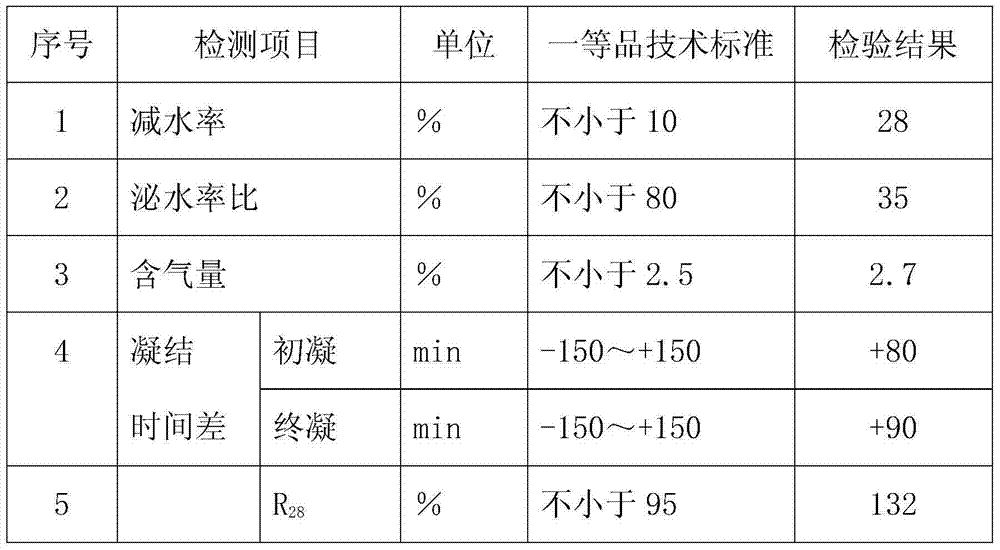

[0052] Antifreeze pumping agent, by mass percentage, includes 15% to 20% polycarboxylate superplasticizer, 0.08% to 0.15% air-entraining agent, 0.5% to 1.0% retarder, 6% to 10% The...

Embodiment 3

[0055] This embodiment 3 is based on the antifreeze pumping agent in embodiment 2, and optimizes the selection of the polycarboxylate water reducer therein. The polycarboxylate water reducer is a composite polycarboxylate water reducer that is a mixture of high water reducing type polycarboxylate water reducer, high slump retention type polycarboxylate water reducer and early strength type polycarboxylate water reducer; control The solid content of the composite polycarboxylate water reducer is 35%-45%. Specifically, the mixing mass ratio of the high water-reducing polycarboxylate water-reducer, the high-slump-holding polycarboxylate water-reducer and the early-strength polycarboxylate water-reducer is 7:3:1 in sequence. Three kinds of water-reducing agents with different properties were mixed and stirred in proportion to prepare a composite polycarboxylate water-reducer solution with a solid content of 40% and a high water-reducing rate, good slump retention effect, and remar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com