Polycarboxylate water reducing agent with high water reducing rate and low slump loss as well as preparation method thereof

A polycarboxylic acid-based, slump-preserving technology, applied in the field of cement dispersants, can solve the problems of unsuitability for industrial scale production, unsatisfactory product performance, complex monomer composition, etc. The effect of short cycle and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. The composition and ratio of the monomers used are as follows:

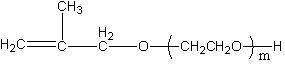

[0035] 1) Monomer A: methallyl polyoxyethylene ether (TPEG), its structural formula is as follows

[0036]

[0037] In the structural formula, m=30, monomer A accounts for 58% of the total monomer weight;

[0038] 2) Monomer B: maleic anhydride, accounting for 14% of the total monomer weight;

[0039] 3) Monomer C: citrate methacrylate, accounting for 18% of the total weight of the monomer, and its structural formula is as follows:

[0040]

[0041] 4) Monomer D: methyl acrylate, accounting for 10% of the total weight of the monomer;

[0042] Two, the preparation process is as follows:

[0043] 1) Add monomer A, monomer B and monomer C into the reaction kettle according to the ratio, and then add deionized water to prepare an aqueous solution, and control the solubility of the monomer mixed aqueous solution at 20%;

[0044] 2) Purge the reactor with nitrogen gas while stirring ...

Embodiment 2

[0047] 1. The composition and ratio of the monomers used are as follows:

[0048] 1) Monomer A: methallyl polyoxyethylene ether (TPEG), its structural formula is as follows

[0049]

[0050] In the structural formula, m=40, monomer A accounts for 75% of the total monomer weight;

[0051] 2) Monomer B: maleic anhydride, accounting for 10% of the total weight of the monomer;

[0052] 3) Monomer C: citrate methacrylate, accounting for 5% of the total weight of the monomer, its structural formula is as follows:

[0053]

[0054] 4) Monomer D: methyl acrylate, accounting for 15% of the total weight of the monomer;

[0055] Two, the preparation process is as follows:

[0056] 1) Add monomer A, monomer B and monomer C into the reaction kettle according to the proportion, then add deionized water to prepare an aqueous solution, and control the solubility of the monomer mixed aqueous solution at 40%;

[0057] 2) Purge the reactor with nitrogen while stirring t...

Embodiment 3

[0060] 1. The composition and ratio of the monomers used are as follows:

[0061] 1) Monomer A: methallyl polyoxyethylene ether (TPEG), its structural formula is as follows

[0062]

[0063] In the structural formula, m=60, monomer A accounts for 92% of the total monomer weight;

[0064] 2) Monomer B: maleic anhydride, accounting for 3% of the total monomer weight;

[0065] 3) Monomer C: citrate methacrylate, accounting for 2% of the total weight of the monomer, its structural formula is as follows:

[0066]

[0067] 4) Monomer D: methyl acrylate, accounting for 3% of the total weight of the monomer;

[0068] Two, the preparation process is as follows:

[0069] 1) Add monomer A, monomer B and monomer C into the reaction kettle according to the proportion, then add deionized water to make an aqueous solution, and control the solubility of the monomer mixed aqueous solution at 40%;

[0070] 2) Purge the reactor with nitrogen gas while stirring and raising...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com